1. Introduction

As the most abundant renewable and sustainable resource, wood has been used for construction, furniture, and fuels for thousands of years. Although it is an old material, modern research has endowed wood with a range of new forms and applications. Wood can be processed into densified wood with a particularly high mechanical performance [

1], into transparent wood for energy-efficient buildings [

2], into thick electrodes for high-energy-density supercapacitor design [

3], etc.

Wood is a kind of natural material with a porous hierarchical structure that has good potential to be optimized for functional porous materials. In the latest research, various concepts of novel bio-based porous materials have been proposed by researchers [

4]. Wood-foamed composites that retain the aligned cellulose structure and compression strength, but with an excellent ability to adsorb or release specific volatiles, are well developed [

5]. Wood sponge with a spring-like lamellar structure is prepared as an effective oil absorbent [

6,

7]. “Insulwood” is a new wood-based material that has high sound absorption and low thermal conductivity [

8]. Inspired by the swallow’s nest, a lightweight and high-strength thermal insulation material was proposed by using bamboo scraps, methylcellulose, and vinyl acetate/ethylene. The density of the composite was 0.42 g/cm

3, but with high compressive strength and low thermal conductivity [

9]. Another environmentally friendly building insulation material using delignified waste poplar wood chips in combination with carboxymethylcellulose sodium salt was proposed in a two-step process. The wood-waste-based foam suppressed thermal transport while possessing high mechanical performance [

10]. These new functional materials are based on natural wood through the removal of lignin, while the framework of the wood structure remains intact. The delignification process normally requires boiling of wood in a dilute solution of sodium hydroxide (e.g., 5 wt.% NaOH). As one of the three main components of wood, lignin particles can also be used as a reinforcement element in phenolic foams or tanninfuranic foams [

11,

12]. Wood byproducts, such as tannins and lignosulfonate, were used to prepare new biobased foams, with a bulk density of 0.11–0.19 g/cm

3 [

13,

14].

The first attempts to develop foamed lightweight insulation materials from wooden components could be dated from the 1940s. A Swedish sulfite pulp factory used chemically treated wood constituents as the starting materials, and then mixed them with binders and foaming agents. Highly porous fiberboards were produced from residues of the sulphite pulp production and alkaline waste liquor using the Ornell–Rosenlund process. The so-called Kramfors boards were successfully produced, with a bulk density of 0.06–0.08 g/cm

3, as lightweight insulating boards. However, the production had ceased by 1951 as they were unable to compete with petrochemical-based products. In 1944, Wilhelm Klauditz invented a kind of wood foam without any additional glue. A process involving deforming and hydrating grinding of fibers was developed to give the strength of lightweight solid foam. Fibers in the wood were flattered in the treatment process to achieve mechanical strength through contact surfaces. In 2007, Müller et al. continued the research to combine wood and grain to develop foamed porous-shaped materials [

15]. Wheat or grain was mixed with wooden flour and yeast to generate foaming gas. A plate-shaped porous material was obtained after the drying of the dough [

16]. The effect of press temperature on the adhesive bond strength was studied, and the proper curing temperature was found to be 105 °C [

17]. A complex fermentation process was employed to foam the mixture of fine wood residues and wheat flour. The resulting porous element had a low density of 0.34 g/cm

3 [

18]. Although it had excellent mechanical performance, this foamed material still had drawbacks due to the use of food products and the competing land use for food and non-food plants.

Concerning environmental and ecological issues, a novel method of turning wood into porous materials was developed by the Fraunhofer Institute for Wood Research Wilhelm Klauditz Institut (WKI) in Braunschweig, Germany. “Wood foam” was given as the name of the new product with the feature of a porous, open-cell structure, a low bulk density, and highly insulating properties. It consists of 100 percent renewable resources, and is climate friendly and recyclable. For this invention, the researchers won the Greentec Award 2015 for wood foam in the category of Construction and Living. The comminuted lignocellulosic fibrous materials were processed at temperatures between 120 °C and 180 °C and a pressure between 2 bar and 8 bar to yield a fiber suspension. This step was of vital importance to activate and release binders from the plant itself [

19].

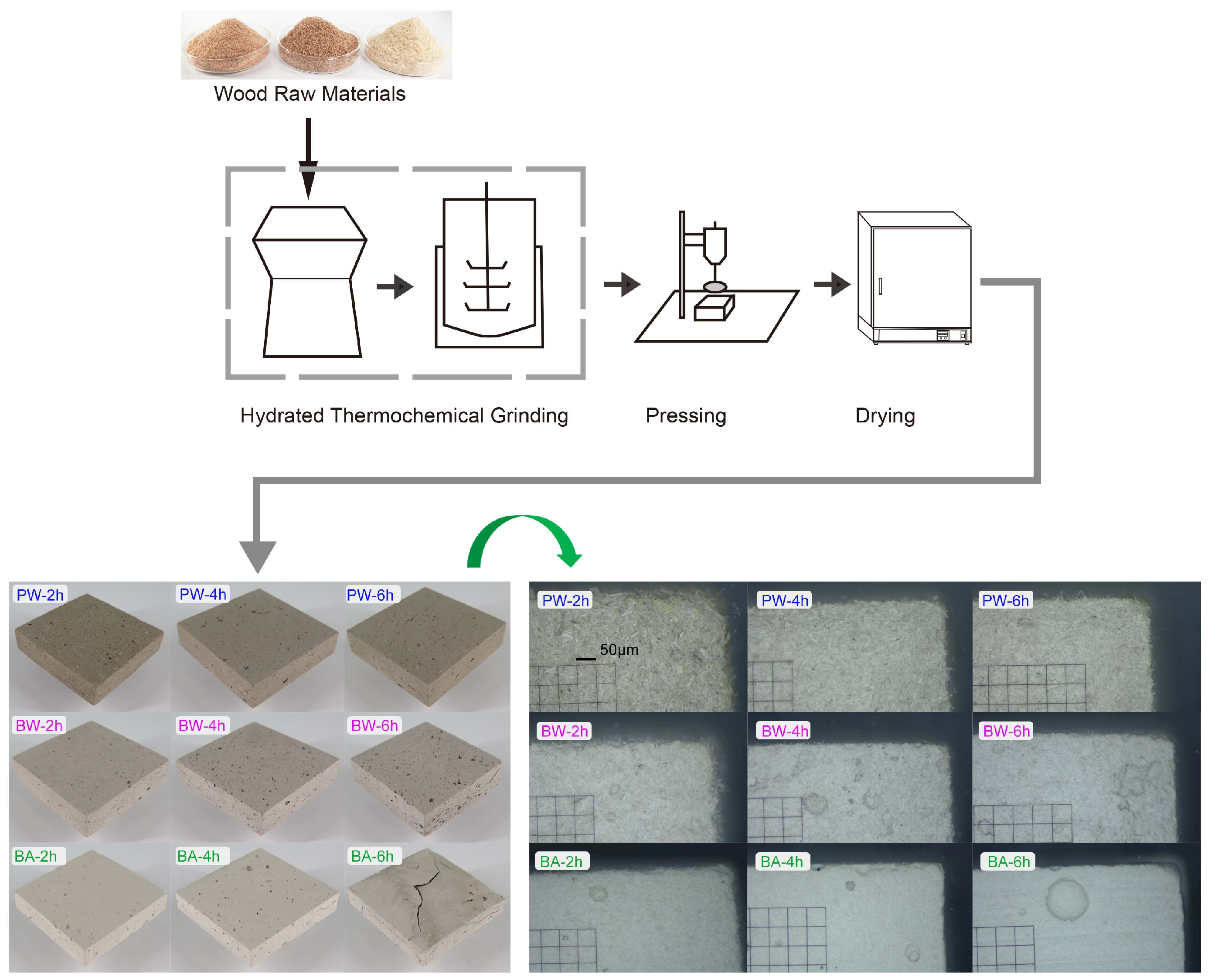

In this study, we used a hydrated thermochemical grinding (HTG) process for the treatment of biomass to obtain auto-adhesive suspensions. Softwood, hardwood, and bamboo were selected as the raw materials and compared. During the mechanical disintegration process, wood and bamboo’s own binders were released due to the crushing and rubbing of cell walls. The grinding process provided a mild temperature and pressure, but a suspension of high viscosity could be obtained. The process was easier to control with reduced production costs. The woody porous molding samples were prepared and analyzed with a focus on the porosity property.

2. Materials and Methods

2.1. Materials

The raw lignocellulosic materials used in this study were pine wood (PW) representing softwood, beech wood (BW) representing hardwood, and bamboo (BA) representing herbaceous plant. They were ground and sieved into 30 mesh particles. The wood particles were oven-dried at 80 °C for 24 h to remove water and then stored at ambient temperature to reach a moisture balance. Deionized water was used as the solvent for the grinding and refining process.

2.2. Preparation of Wood Porous Materials

To achieve a wood porous molding material of high surface quality and mechanical performance, a fabrication and deforming process along with the release of the wood’s own bindings was developed based on our procedure. A total of 40 g of wood powder was mixed with 200 mL of deionized water and placed into a 500 mL stainless-steel griding reactor (3SP2, Nanda Instrument, Nanjing, China). The grinding time was set as 2 h, 4 h, and 6 h. The resulting viscous suspension was transferred into a high-pressure reactor (Model 4547, Parr Instrument, Moline, IL, USA). Temperature and pressure were set at 120 °C and 0.4 MPa. The reaction time was set as 30 min with a rotating speed of 600 rpm. Afterwards, a high-viscosity suspension was collected and 1% G204 antifungal agent was added to avoid it from going moldy. The suspension was foamed physically using an intensive mixer. A stainless-steel mold with the size of 7 cm × 7 cm × 5 cm was used for the formation. Water was removed by using a pressing machine with a pressure of 0.08 MPa. The mold was removed after that, and the porous slab was put in the oven and dried at 80 °C for 24 h to remove water. The surface of the porous sample was removed using a belt sander and used for analysis and characterization.

2.3. Characterization of Wood Porous Materials

The elemental analysis of carbon, hydrogen, and nitrogen contained in the wood porous samples was performed using model Vario UNICUBE from Elementar, Hanau, Germany. The element Fe was analyzed using iCAP PRO ICP-OES from Thermo Fisher Scientific. The ash content was determined using the method from the analysis of forestry biomass GB/T 36057-2018 [

20].

The crystalline structure was determined via X-ray diffraction (Rigku SmartLab, Tokyo, Japan) with Cu Kα radiation (wavelength λ = 0.154 nm). The scanning range was set at 2θ = 5°–40°, the scanning step at 0.02°, the scanning speed at 4°/min, the tube voltage at 40 kV, and the tube current at 30 mA.

The infrared spectra of the samples were recorded via FTIR (IS 5, Thermo Fisher Scientific, Waltham, MA, USA) using the KBr pressed-pellet technique. The sample powder was mixed with KBr in a weight ratio of 1:100 and pressed into transparent pellets. The FTIR spectrometer recorded one spectrum every 30 s with the wavenumber ranging from 400 to 4000 cm−1. The resolution of the spectrometer was 2 cm−1.

The color and shape of 9 samples were analyzed using a C-cell color instrument (Perkin Elmer, Waltham, MA, USA) according to the method AACCi 10-18.01. The samples were directly put in the cell, and photos were taken and analyzed using the C-Cell software (C-Cell BAKING QUALITY ANALYSER, version 3.4.5). Mechanical performance was tested using a texture analyzer (SMS-TA Plus-C, Stable Micro Systems, Godalming, UK). Young’s modulus, hardness, compactness, and uniformity were tested using a cylindrical probe with the mode of compression. The pre-test speed and test speed were set at 1.0 mm/s, while the post-test speed was set at 10.0 mm/s. The target mode was 5 mm distance with a trigger force of 10 g. The data acquisition rate was 200 pps. The three-point bending force was tested using a three-point bend rig with the mode of compression. The pre-test speed and test speed were set at 0.5 mm/s, while post-test speed was set at 1.0 mm/s. All tests were performed in triplicate, and the average values were taken for analysis.

3. Results and Discussion

3.1. Fabrication and Characterization of Wood Porous Molding Materials

The influences of different raw materials and hydrated grinding time on the property of the wood porous samples were studied. Temperature and pressure play an important role in this hydrated grinding and refining process. Pinewood, beech wood, and bamboo were compared in this study. The results of the elemental analysis of raw materials and porous materials are shown in

Table 1. Despite the grinding and refining process, all samples had a carbon content of ca. 46%, a hydrogen content of ca. 6%, and an oxygen content of ca. 48%. No significant elemental changes were found for elemental composition as the treatment was performed in a closed vessel that did not form any volatile organic compounds. However, a certain amount of iron, which could not be neglected, was found in the porous samples. Due to the stainless-steel grinding medium, the content of iron in the wood porous samples was 1.8–2.3 g/kg for PW, 1.4–2.3 g/kg for BW, and 2.3–4.0 g/kg for BA. A longer grinding time leads to a higher content of iron. The iron content in the bamboo samples was higher than that in the softwood and hardwood samples due to the short fibers in the bamboo raw materials. The long fibers in the woody materials protected them from the stainless-steel medium during the grinding process. Since the grinding process involves high temperature and pressure, whether iron has a catalytic influence on the biomass decomposition needs to be clarified in future studies.

After the hydrated grinding and refining process, a closely graded suspension with high viscosity was obtained. The water content of the suspension on wet base was in the range of 83.14% to 84.54%. A high water content makes the molding of the suspension difficult unless it contains a certain proportion of long fibers. Thus, failures always happen in the molding formation process with pure suspension. The method to remove such a high amount of water is important as it is related to energy efficiency and sample quality. We used 80 °C for the curing and drying of the samples as higher temperatures could probably lead to the evaporation of water in a short time, which caused the shrinkage of the suspension and the cracking of the final dried samples. Low-temperature drying takes longer time for the removal of water. Thus, a temperature program for the curing and drying of the suspension should be carefully designed.

The density of the wood porous materials was 0.28–0.37 g/cm

3 for pine wood, 0.38–0.45 g/cm

3 for beech wood, and 0.41–0.67 g/cm

3 for bamboo. Density is an indicator of the porosity and mechanical strength of such wood porous materials which is shown in

Table 2. A low bulk density results in a high porosity of materials with an open-cell structure and highly insulating properties. In traditional fiberboard production, medium-density fiberboard with a density of 0.65 g/cm

3 is the main product, accounting for around 85% of the market share. Wood foam developed by Fraunhofer WKI has an extremely low bulk density but excellent sound and thermal adsorption ability. They used 35% hydrogen peroxide and natural protein to foam the watery suspension [

21]. In our process, only mechanical stirring was used for the foaming; thus, the density of the porous samples from different raw materials was in the range of 0.28–0.67 g/cm

3, which is higher than wood foam made by WKI (density of 0.07–0.28 g/cm

3). However, a higher density leads to higher bonding force and mechanical property.

The high-viscosity suspension was formed into solid porous samples after molding and drying. The incrust of the dried porous molding samples was removed for a better observation of the internal structure and pore distribution, as shown in

Figure 1. The coarse fibers of the samples can be observed in the micrograph pictures. The pine wood samples and beech wood samples had a similar appearance, but the bamboo samples showed a smooth surface. The fibers in the pine wood samples were clearly longer and larger than those in the beech wood and bamboo samples. This is due to the fact that shorter bamboo fibers are more fragile, and they were cracked into short pieces during the grinding and refining process. For the bamboo samples at 6 h, the samples were even cracked into several pieces. Mechanical performance originates from the release of the wood’s own bindings and the anchorage of fibers. Uncondensed lignin proves to be an effect adhesive composition [

22]. If the fibers were too fine and short, the samples would undergo shrinking and cracking during the drying process, such as the BA-6h sample. For all three kinds of raw materials, the degree of defibrillation increased with the grinding time. The release of the wood’s own bindings is highly dependent on the grinding time. However, a longer grinding time destroys long fibers and makes the molding preparation difficult. The determination of grinding time requires a balance between defibrillation and wood’s own binding release, which should be adjusted.

3.2. Volume and Porosity Properties of Wood Porous Samples

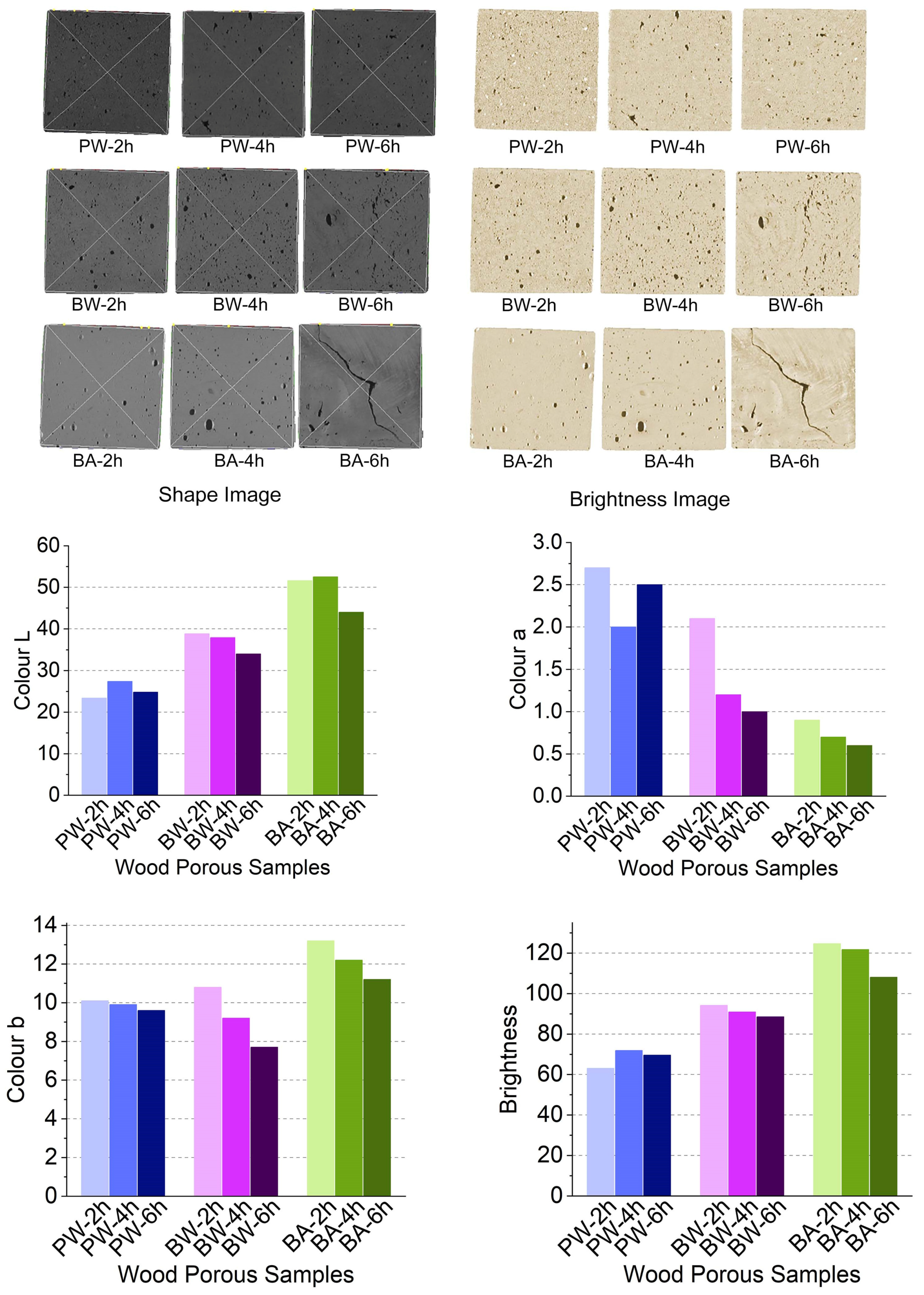

The shape and brightness images of different wood porous materials are shown in

Figure 2. The texture and smoothness of the porous materials are reflected by their brightness and color, which could influence their applications. The color of the samples from the same raw material remained almost the same despite the different grinding times of 2 h to 6 h. For different materials, the samples showed different shapes and brightness, and bamboo had the highest brightness. Color is influenced by wood species, grinding parameters, grinding medium, and drying temperature. High temperatures during grinding and drying could cause oxidation and even carbonization of the fibrous materials. Iron from the stainless-steel grinding mill endowed the samples with a dark color. In this study, the different color of the samples was mainly attributed to the wood species as the production parameters remained the same for all samples. Pine wood as a kind of softwood contains terpenes, waxes, and resins, which could influence the shape and color of the samples. Different types of lignin in softwood, hardwood, and herbaceous plants are also key factors in the formation of the color of porous materials.

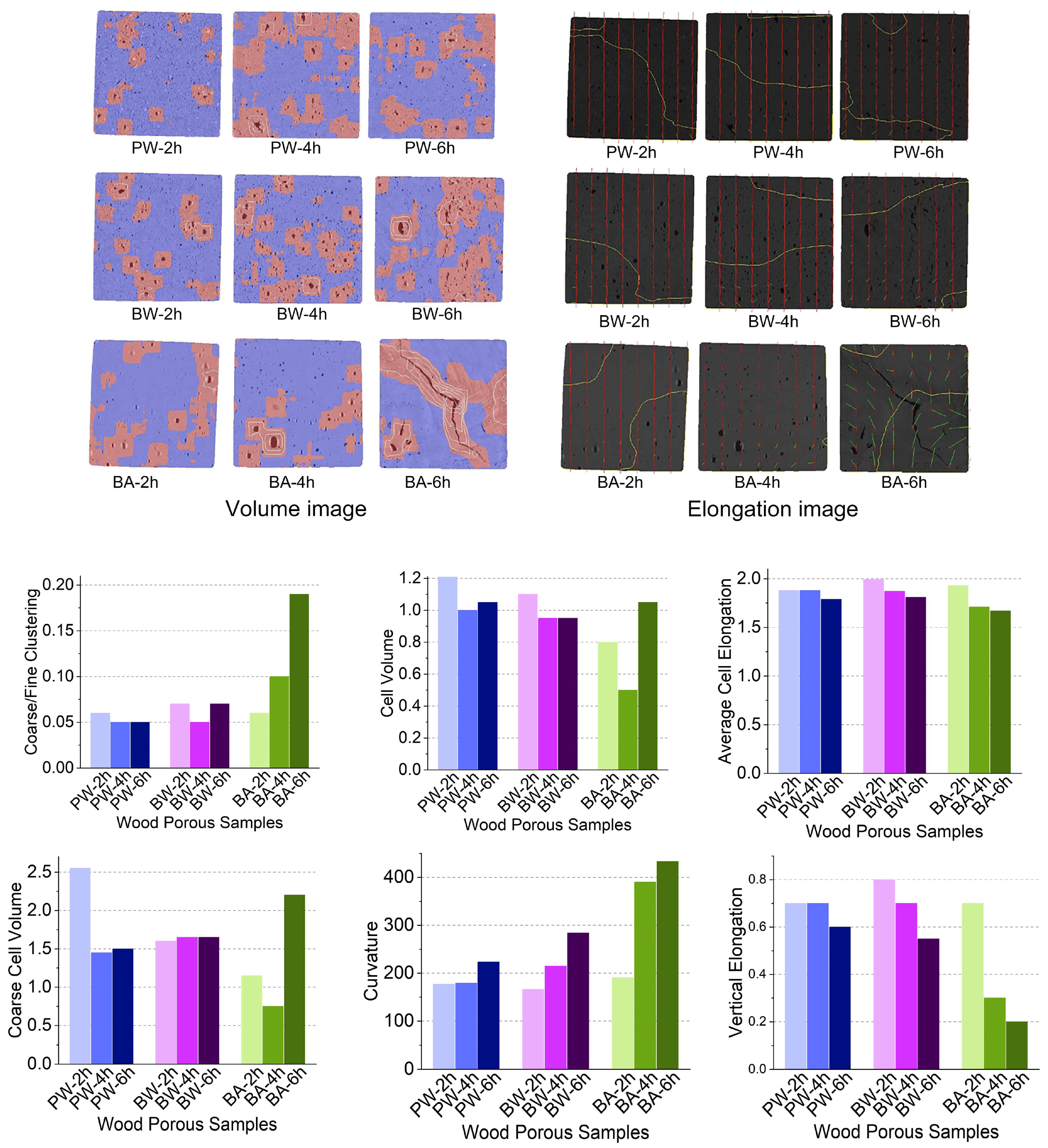

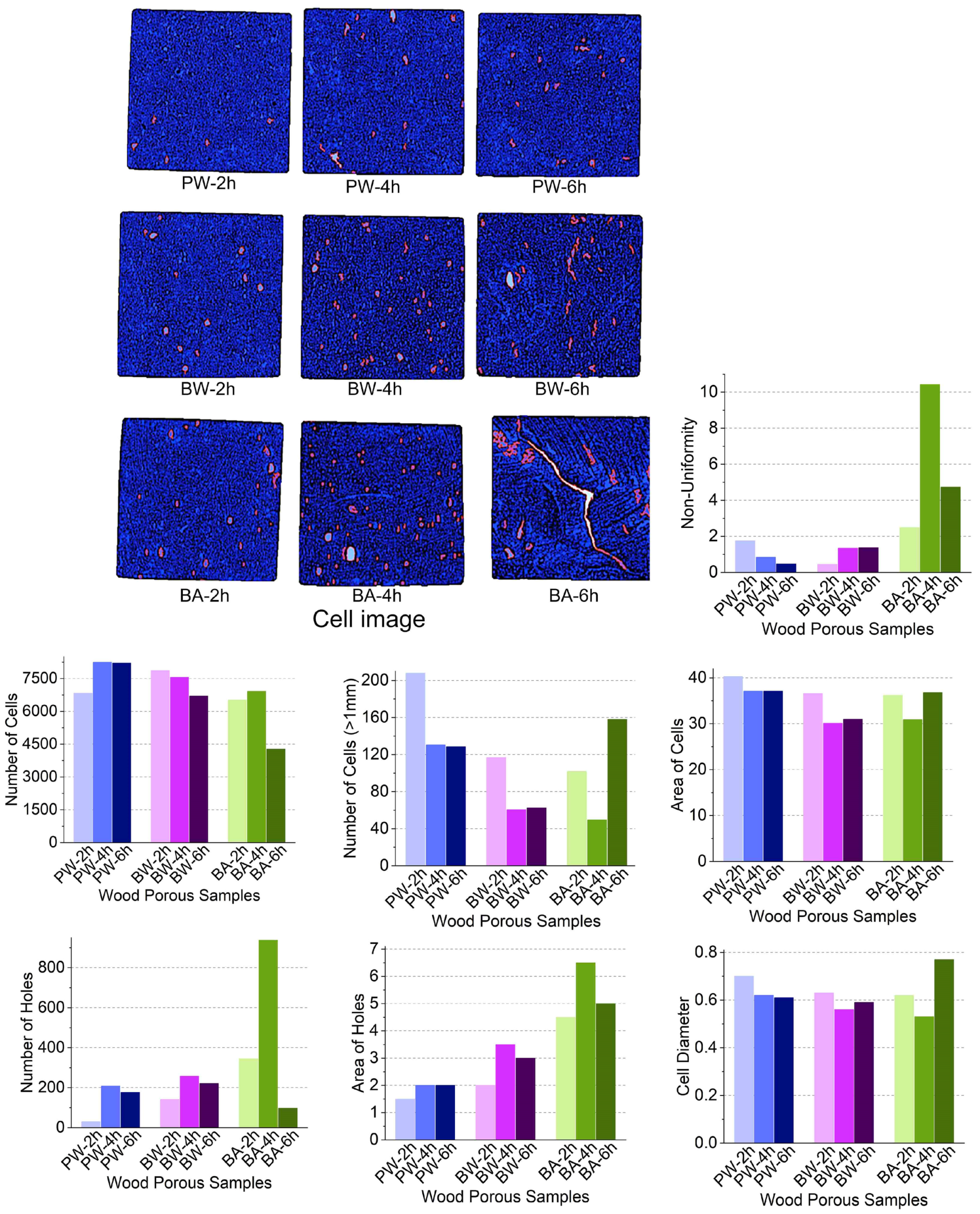

As a kind of porous material, most of the functional properties, such as lightweight, thermal insulation, and sound absorption, are attributed to various pores; thus, the characterization and controlling of pores are of vital importance. In our study, pores were distributed in the samples randomly, which was due to the mechanical foaming and the removal of water. The wood porous materials had an open-pore structure with multiple sizes of cells and holes, as shown in

Figure 3 and

Figure 4.

The cell volume of the samples from pine wood and beech wood was 0.95–1.75, which was higher than that of the samples from bamboo at 0.50–1.05. The number of cells was 6834–8246 (including 128–208 cells > 1 mm) for the PW samples, 6698–7865 (including 60–117 cells > 1 mm) for the BW samples, and 4274–6916 (including 49–158 cells > 1 mm) for the BA samples. No obvious difference in cell diameter was found for the porous samples from different wood species and grinding time. For wood species, a short grinding time of 2 h led to a higher cell number and volume, which could be the reason for the existence of long fibers. The grinding time had a more significant influence on the coarse cell volume of the bamboo samples than the BW samples.

The areas of holes were 4.5–6.5 for the BA samples, 1.5–2.0 for the PW samples, and 2.0–3.5 for the BW samples. The bamboo samples had an obvious higher area of holes than the PW and BW samples. The number of holes of BA-4h even reached 938, which was much higher than that of the woody samples (30–257). The non-uniformity was 2.49–10.43 for the bamboo samples, 0.47–1.75 for the PW samples, and 0.95–1.10 for the BW samples. The bamboo samples showed the feature of high non-uniformity. The integrity of bamboo fibers was easily destroyed during grinding, even during a 2 h treatment. The anchorage of fibers occurred to a larger extent in wood species than in bamboo. This explained why the bamboo samples had a higher number and area of holes than the woody porous samples. The average cell elongation of the porous samples decreased slightly with the grinding time. However, an obvious increase in curvature and a decrease in vertical elongation with grinding time were found for the porous samples, especially for those made from bamboo. The rigidity of the bamboo samples was much higher than that of the woody samples. This is probably due to the combined effect of defibration and degradation of cellulose, hemicellulose, and lignin in the raw materials. Note that biomass is a complex material, and the properties of samples may differ when coupled with slight changes in the preparation technique.

3.3. Mechanical Performance of Wood Porous Molding Materials

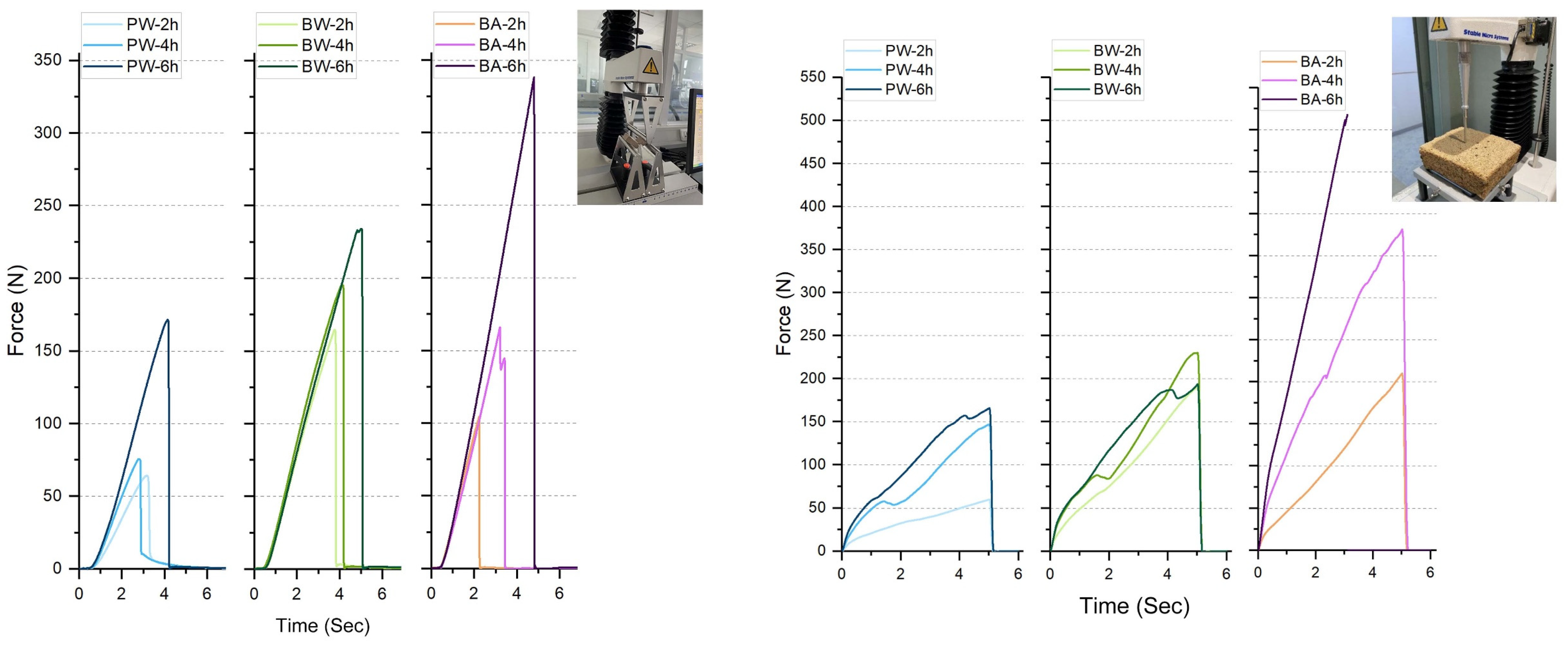

The results of the three-point bending and puncture tests are shown in

Figure 5. The bending strength increased with an increased grinding time for almost all samples. The adhesive components in the biomass were released to a larger extent along with the grinding time. The bending forces of the samples of 6 h were much higher than those of the 2 h and 4 h samples, as a longer grinding time caused the formation of microfibrils and nanofibrils. In our study, hardwood showed higher bending forces than softwood, while bamboo had the highest bending strength. Similar results were obtained for the puncture tests. The puncture strength of the bamboo samples after 6 h of grinding was even outside the measuring range of the analysis equipment.

The mechanical performances of the wood porous samples are shown in

Table 3. In terms of Young’s modulus, compactness, and hardness, beech wood had a better performance than pine wood, while bamboo showed the best performance. For samples with a grinding time shorter than 4 h, a higher density led to higher strength due to the wood’s own bindings and anchorage of fibers. A long grinding time of 6 h caused a decrease in compactness and hardness for the pine wood and beech wood samples. Bamboo fibers are easier to be separated and demolished compared to woody fibers. A longer grinding time of bamboo results in the release of more bindings but less long fibers. BA-6h had an especially high value as, in this treatment, the active components in bamboo were released to a large extent. Although they had better mechanical performance, the porous samples made from bamboo showed significant shrinkage during the drying process. The BA-6h sample even cracked into several pieces. Compared to woody biomass, bamboo has much shorter fibers, which are divided into microfibrils during high-temperature and high-pressure grinding and refining processes. The bending strength of the wood porous materials had a close relationship with density, as shown in

Figure 6. The bending strength of the bamboo samples increased with density for all samples. At high densities, fibers are closer, along with a stronger fiber anchorage. BA-6h showed the highest bending strength due to the much shorter bamboo fibers and the release of the bindings. However, the lack of long fibers also made the BA-6h sample more fragile to be cracked into pieces.

3.4. FTIR and XRD of Wood Porous Molding Materials

The molecular structure and functional groups of the raw cellulosic materials and porous molding materials were characterized by means of FTIR, as shown in

Figure 7. The peak at 3435 cm

−1 represents the stretching vibration of the O-H group, the peak at 1917 cm

−1 represents the asymmetrical stretching vibration of the C-H group, and the peak at 1733 cm

−1 represents the stretching vibration of the C=O group. The increase in these peaks indicated the changes in the molecular structure of the biomass during the grinding and refining process. Under the condition of high temperature and pressure, the cleavage of the glycosidic bond in cellulose and hemicellulose caused the formation of oligosaccharides and monosaccharides. These saccharides were further converted into furfural, which contained free hydroxyl and carbonyl groups. The hydroxyl groups formed hydrogen bonds in the porous molding materials. The peaks at 1615 cm

−1 and 1510 cm

−1 represent the C-C vibration of benzene, indicating the depolymerization of lignin [

23]. The reactions of low-molecular-weight lignin fragments with aldehydes and ketones contributed to the mechanical strength of the porous molding materials.

The XRD patterns of the three raw materials and all porous samples are shown in

Figure 8. The typical planes (101), (10ī), and (002) appear at 14.8°, 16.5°, and 22.5°. They are representative of cellulose Ⅰ structure, which is formed by parallel cellulose molecular chains. The lignocellulosic biomass did not show a significant difference after the grinding and refining treatment. Most of the monoclinic crystal structure of cellulose remained intact during the refining process. This corresponded to the course fibers observed in the molding samples in

Figure 1. These fibers stretch to each other to provide mechanical strength to the molding samples physically. Together with chemical forces, the prepared samples have excellent mechanical performance but still with porous properties.

Limitations of the study: The raw materials of wood and bamboo powder were provided by the wood processing factory without detailed sorting. The collection and storage could cause impurities in the wood and bamboo powder. Another limitation of this study is the insufficient sample size for statistical measurements. The morphology and property of the final wood porous moldings may vary to some extent due to the randomness of the raw materials.

4. Conclusions

In this study, we demonstrated a preparation method for wood porous molding materials. A hydrated thermochemical grinding process followed by high-temperature and high-pressure refining was used to fabricate and activate lignocellulosic biomass. The density of the wood porous materials was in the range of 0.28–0.67 g/cm3, while the bamboo raw material had the highest density. With a treatment time of 2–6 h, the pine wood and beech wood samples showed good consistency in shape and pores. A longer grinding time of 6 h led to the cracking of the bamboo porous samples during the drying process. All samples showed better mechanical performance with grinding time. The pine and beech porous moldings are suitable for lightweight insulation materials, while the bamboo moldings meet the needs of high compactness and hardness. The disintegration of cell walls and the degradation of the main components were observed during the grinding process. The crystal structure of cellulose remained intact during the grinding process. The bonding forces originated from the release of bindings in the biomass and the anchorage of fibers. The wood porous moldings are fully composed of lignocellulose, which is readily recyclable. Forestry residues and sawdust could be used as raw materials for large-scale production. Various shapes are possible by using different molds accordingly. This bio-based “green” material is of great potential in the building industry, with potential applications in ceiling, thermal insulation, and core materials in sandwich panels.