1. Introduction

Construction represents 9% of the EU’s GDP and 13% worldwide. The industry employs 7% of the global workforce [

1,

2]. In Portugal, the construction sector was 9.9% of the workforce and 5.9% of the country’s GDP in 2008, but due to the economic crisis, its workforce share decreased to 6% in 2013, and its contribution to GDP fell to 3.5% in 2016. As of 2018, it employed 6.1% of the workforce and contributed 3.6% to the country’s GDP. In 2021, the construction sector comprised 5% of Portugal’s total GVA [

3,

4]. Although the economic relevance of the construction sector is well known, there have been several dimensions where the sector has not delivered substantial improvements, unlike other economic sectors.

These dimensions include the overall cost of projects, the level of productivity, the level of innovation, the duration of project completion, compliance with established deadlines, the number of defects and unconformities, the extent of rework required, the degree of customer satisfaction, and the troubling record of health and safety within the industry [

5].

Most of these challenges are related to well-known problems in the construction sector, particularly the low level of industrialization and a suboptimal project organization and management model.

In the last few decades, different approaches have been followed, such as Total Quality Management (TQM), partnership relations, Business Process Reengineering (BPR), supply chain management, and Lean, to name a few. Although Lean has attracted some attention [

5], a generalized adoption has been minimal.

The main objective of this research is to conduct an extensive examination of the factors hindering the successful adoption and implementation of Lean methodology within the construction sector in Portugal. The focus of this research is to identify the key barriers preventing the widespread acceptance of Lean methodology and to delve deeper into the interconnected nature of these barriers, exploring how they are related to each other and their effect on implementing Lean methodology. This will contribute to understanding why Lean is not gaining traction among construction stakeholders, and will help identify improvement areas replicable in similar markets, particularly in the European Union (EU) where there is an “open-market” model.

Through an in-depth analysis of the barriers, this research aims to gain a comprehensive understanding of what obstacles prevent the implementation of Lean in construction. This research also aims to suggest mitigation measures to overcome these identified challenges and promote the use of Lean methodology in the construction industry in Portugal.

This paper is organized as follows: after this introduction,

Section 2 presents the literature review;

Section 3 describes the methodology;

Section 4 presents the results, followed by the main findings and discussion of the mitigation measures in

Section 5; and

Section 6 concludes.

4. Results

To calculate Spearman’s correlation coefficient, a ranking was created where the barriers were listed according to the evaluation of each group. The results are displayed in

Table 4. As stated, results between 0.4 and 0.7 are considered moderate correlations, and anything above 0.7 is a strong correlation. Analysing the results, the clients and contractors have a weak connection; however, the coefficient is close to 0.4. The other combinations between groups have moderate correlations. The consultant’s group is the one with the higher correlation with the global results, which can be explained by the fact that 58% of the respondents were consultants.

The results obtained from the survey are displayed in

Table 5. These results were considered valid by applying several tests, including the calculation of the Cronbach Alpha and by conducting a Levene test, an ANOVA test and, when necessary, a Welch test.

As stated before, the ANOVA method was used to study the differences between the respondent groups. To successfully use ANOVA, it is necessary to meet certain conditions. First, the sample must be collected independently, meaning that the inclusion or exclusion of other members should not influence each sample member. Second, the population from which the sample is drawn must have a normal distribution. A Levene test was performed to ensure that the third condition, homogeneity of variance, was met. The null hypothesis for this test is that the data’s variance, or spread, is equal among all the groups of respondents. The alternative hypothesis is that the variance is not equal among all groups. The p-value, a statistical significance measure, is used to determine whether to accept or reject the null hypothesis. If the p-value is below 0.05, it is considered statistically significant, and the null hypothesis is rejected.

In this case, the Levene test showed that out of the list of barriers considered, the barriers of management’s resistance to change (B17), the lack of understanding of customer needs (B19), and the lack of “design-build” procurement models (B26) had p-values below 0.05. This indicates that the variance for these barriers was not equal to that of the other barriers. Therefore, the homogeneity of variance was not met for this particular barrier. The authors performed the Levene test for the other barriers. When the Levene test had a p-value below 0.05, a Welch test was conducted instead of the ANOVA.

Table 6 shows the mean of each barrier and the results from the ANOVA and Welch tests. Using the global mean, the barriers with a higher mean were critical barriers and were therefore used in the ISM and MICMAC study. Since there is not a big difference between the means of each barrier, in order to define the critical barriers, the top fifteen barriers with a higher mean were considered critical barriers as Ma et al. [

24], Olorunniwo and Li [

28], and Wu at al. [

29] state that to properly conduct an ISM study the maximum number of variables should be fifteen. The critical barriers are B1, B3, B4, B5, B6, B10, B11, B14, B15, B16, B17, B18, B20, B21, and B23.

Using the global mean, the barriers with a higher mean were critical barriers and were therefore used in the ISM and MICMAC study. Since there was not a big difference between the means of each barrier, in order to define the critical barriers, the top fifteen barriers with a higher mean were considered critical barriers. Ma et al. [

24], Olorunniwo and Li [

28], and Wu at al. [

29] state that to properly conduct an ISM study, the maximum number of variables is 15. The critical barriers are as follows: not recognizing financial advantage (CB1), lack of organizational communication (CB2), lack of communication and transparency between stakeholders (CB3), unsuitable organizational structure (CB4), employees’ aversion to change and fear of new procedures (CB5), inadequate delivery performance and material delivery delays (CB6), lack of prefabrication and the limited usage of off-site construction techniques (CB7), lack of identification and control of waste in the project and in the company (CB8), lack of support and commitment from top management (CB9), lack of adequate lean awareness and understanding (CB10), management’s resistance to change (CB11), lack of planning for quality (CB12), absence of long-term planning (CB13), lack of performance measurement systems (CB14), and excessive bureaucracy and inflexible licensing and approvals (CB15).

The relations between barriers were defined during a meeting with two industry specialists, creating the SSIM (

Table 7) and, following stage III of the methodology, the IRM (

Table 8), FRM (

Table 9), and the Level partitioning (

Table 10).

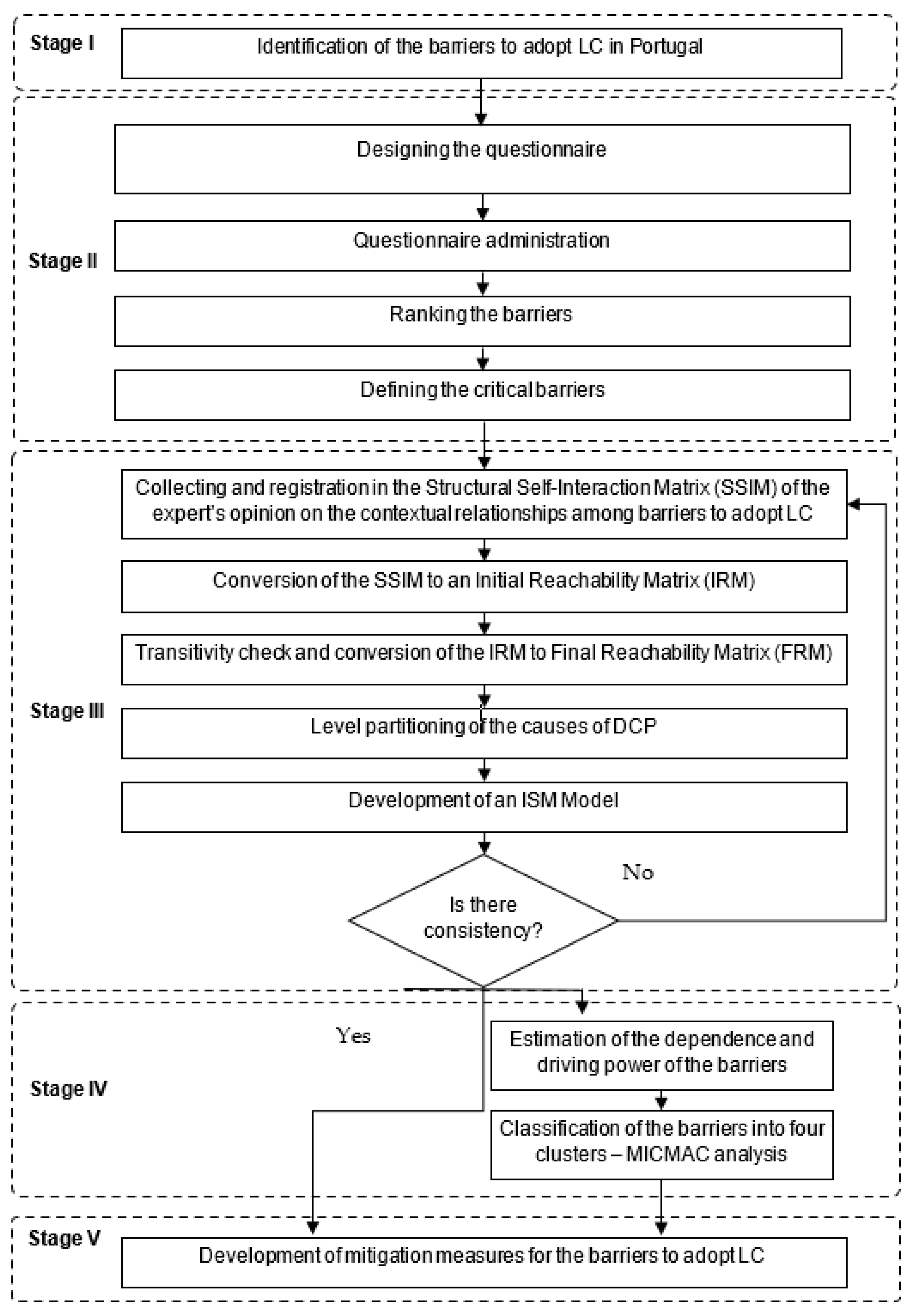

With the IRM defined, an ISM Model with seven levels was established by following the steps described in the methodology (

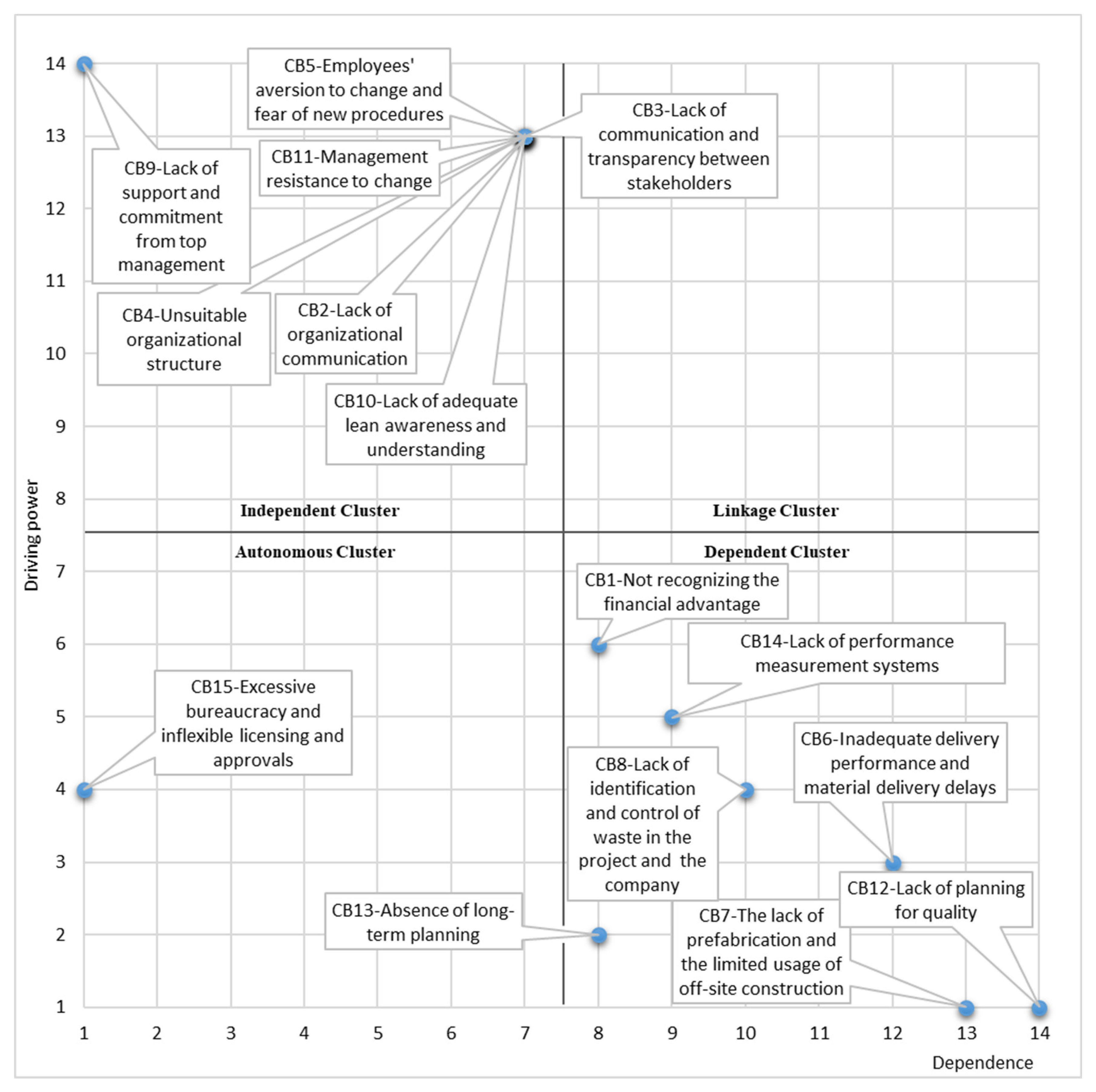

Figure 2). Using the dependence and driving power of the barriers defined in the FRM, the MICMAC analysis split the critical barriers into the clusters explained in the methodology (

Figure 3).

5. Main Findings and Discussion

In this section, the results obtained from the survey were thoroughly analysed, starting with an internal consistency reliability analysis to validate the Likert scale used in the survey. With a Cronbach alpha of 0.8665, the scale was considered valid and the results from the different groups were studied using the Leven, ANOVA, and Welch tests, and the critical barriers were defined using the results.

With the results obtained, it is possible to compare the ranking of the barriers with the studies mentioned in the literature review. In the questionnaire answered by engineers and architects in the Portuguese construction industry, the barrier with the highest ranking was the lack of adequate Lean awareness and understanding (B16). This same barrier was ranked first in the study conducted by Sarhan and Fox [

11] and second in the study conducted by Bayhan et al. [

17]. Albalkhy’s and Sweis’s [

18] study in Jordan also reached the same conclusion, stating that the lack of adequate Lean awareness and understanding was one of the most significant barriers. Cano et al.’s [

14] extensive study of the Colombian construction industry also states that this barrier is critical. However, in the study by Shang and Peng [

13], conducted in China, the barrier was ranked ninth out of twenty two. This ranking is lower than the results obtained in this study and the other studies considered in the literature review. One reason for this difference is the higher level of Lean application across all Chinese industries compared with the industries of the countries where the other studies were conducted.

For the Portuguese construction industry, inadequate delivery performance and material delivery delays (B10) was the second barrier with a higher result, a different result to the studies conducted in Jordan and China. In the Jordan survey conducted by Albalkhy and Sweis [

18], this barrier was one of the barriers with a lower mean score. Regarding the three barriers related to input factors (materials), the inadequate delivery performance and the material delivery delays obtained the lowest scores, compared with this study, where these three barriers were also studied. For the Jordan construction industry, the lack of long-term relationships with suppliers was the barrier related to input factors (labour and materials) with the highest mean, whereas, in the Portuguese survey, this was one of the lowest means across all barriers.

As expected from the literature review, the barriers lack of support and commitment from top management (B15), management’s resistance to change (B17), and the lack of communication and transparency between stakeholders (B4) are barriers with a high mean result and are critical barriers to the implementation of the Lean methodology in construction across the world and in Portugal.

The barrier of excessive bureaucracy and inflexible licensing and approvals (B23) also ranked higher than in the studies considered in the literature review. This could result from a higher bureaucracy in Portugal compared with the countries where this barrier was considered, such as China or Jordan.

The absence of long-term planning (B20) was another critical barrier in this survey. The results from the studies in the literature review provide different perspectives regarding this barrier. In the survey conducted in China, the lack of a long-term philosophy was the barrier with the highest mean. The results from the Jordan study are aligned with the ones from the Portuguese study, which consider this barrier as one of the top barriers but not one of the three highest means. In the questionnaire from Bayhan et al. [

17], this barrier was ranked fourteenth with a mean value of 3.67, which is still in the top 15 but is significantly lower than the result from the Portuguese industry, where it is ranked sixth with a mean of 4091.

The lack of prefabrication and the limited usage of off-site construction techniques (B11) is ranked eighth in the Portuguese construction industry survey, a big contrast with the results from the China and Jordan surveys, where the same barrier obtained lower results. In the Chinese construction industry survey by Shang and Peng [

13], the barrier was ranked 20th out of 22 barriers, with a mean value of just 3.22, whereas, in the Jordan survey, the mean was 3.55.

Regarding the unsuitable organizational structure, the survey from the Chinese construction industry showed a different result, with this barrier being only ranked 18th with a mean value of just 3.32. The study from Jordan achieved the same mean as the Chinese study, considering the unsuitable organizational structure one of the barriers with the lowest mean.

Employees’ aversion to change and fear of new procedures (B6) was another critical barrier that had different results across the multiple studies. The barrier achieved a similar result in the study conducted by Bayhan et al. [

17] and was also considered a critical barrier by Cano et al. [

14]. However, Shang and Peng [

13] and Albalkhy and Sweis [

18] also studied the same barrier and it achieved much lower results, with the barrier ranking amongst the lower means.

Regarding the Levene, ANOVA, and Welch analyses, it is possible to state that the three different groups had the same opinion about the barriers’ importance except for the lack of understanding of customer needs (B19), where the clients considered this to be more important than the consultants and the contractors. For the clients, this barrier was ranked third whereas, in the overall ranking, the barrier is ranked twenty-first due to the much lower mean from the consultants’ and contractors’ perspective.

The ISM model established seven different levels, with the lower levels demonstrating barriers that exist as a consequence of the barriers in the higher levels.

In Level VII is the lack of support and commitment from top management (CB9), and in Level VI are the following barriers: a lack of organizational communication (CB2), a lack of communication and transparency between stakeholders (CB3), unsuitable organizational structures (CB4), employees’ aversion to change and fear of new procedures (CB5), a lack of adequate Lean awareness and understanding (CB10), and management’s resistance to change (CB11). These barriers influence the lower levels, with top management’s lack of support and commitment (CB9) being the most important barrier.

The fifth level of the model has just one barrier: not recognizing financial advantage (CB1). The fourth level also has only one barrier, the technical barrier of a lack of performance measurement systems (CB14).

Level III of the ISM model is composed of two barriers, one exogenous barrier, the excessive bureaucracy and inflexible licensing and approvals (CB15), and one barrier related to management, the lack of identification and control of waste in the project and in the company (CB8).

The second level has two barriers, one related to an input factor, inadequate delivery performance and material delivery delays (CB6), and one barrier related to management, the absence of long-term planning (CB13).

On the first level is a barrier related to management and a barrier related to an input factor. The barrier related to management is the lack of planning for quality (CB12) and the lack of prefabrication, and the limited usage of off-site construction techniques (CB7). These two barriers are the least important of the critical barriers and are the consequence of the barriers on the higher levels.

The MICMAC analysis classified the barriers into four clusters: autonomous, dependent, independent, and linkage.

The independent group consists of the following barriers: a lack of organizational communication (CB2), a lack of communication and transparency between stakeholders (CB3), unsuitable organizational structures (CB4), employees’ aversion to change and fear of new procedures (CB5), a lack of support and commitment from top management (CB9) a lack of adequate Lean awareness and understanding (CB10), and management’s resistance to change (CB11). Of these seven barriers, three are communication barriers, one is a barrier related to an input factor (labour), and the other three are barriers related to management. It is important to notice that of the original three communication barriers, all were considered critical, and all were considered independent barriers and root barriers. These seven barriers are the barriers with a higher driving power and a lower dependence power, meaning that these barriers significantly influence the other barriers and, therefore, are the root causes for the lack of LC in the Portuguese construction industry.

The autonomous group comprises a single barrier: excessive bureaucracy and inflexible licensing and approvals (CB15). This barrier has a driving power of 4 and a dependence power of 1, meaning it has few relations with the other barriers.

The linkage group has no barriers.

The dependent group is composed of all the other critical barriers: not recognizing financial advantage (CB1), inadequate delivery performance and material delivery delays (CB6), the lack of prefabrication and the limited use of off-site construction techniques (CB7), the lack of identification and control of waste in the project and in the company (CB8), the lack of planning for quality (CB12), the absence of long term planning (CB13), and the lack of performance measurement systems (CB14).

As mentioned in the literature review, Khaba and Bhar [

15] conducted a study to develop an ISM model and a MICMAC analysis on the barriers to adopting LC. The results obtained in this research were different. The most significant difference is the resistance to change. In the study by Khaba and Bhar, the resistance to change is on the first level of the ISM model and is the barrier with the highest dependence power. In opposition, in this research, the employees’ aversion to change and fear of new procedures (CB5) and management’s resistance to change (CB11) are on the sixth level of the ISM model and are independent barriers with high driving power over the other barriers. This can be explained by the differences between the Portuguese construction sector in contrast to the construction sector in India. The lack of Lean awareness and understanding (CB10) also obtained a different result, being considered an independent barrier in this research and a linkage barrier in the study conducted by Khaba and Bhar. Not recognizing financial advantage (CB1) and the lack of planning for quality (CB12) were considered linkage barriers in the Khaba and Bhar study [

15], whereas in this research, they were considered dependent barriers. The lack of performance measurement systems (CB14) obtained similar results, being classified as a dependent barrier in both studies. To tackle the critical barriers, a set of 14 mitigation measures was proposed (

Table 11). The first 10 measures tackle the root barriers, on levels VII and VI. Mitigation measures 11 and 12 tackle two dependent barriers on levels V and IV. Finally, the exogenous barrier is tackled by mitigation measures 13 and 14.

6. Conclusions

This research aimed to identify the barriers to implementing LC in the Portuguese construction sector. In the literature review, twenty-seven different barriers were identified and categorized into six groups: financial barriers, communication barriers, barriers related to input factors (labor and materials), barriers related to management, technical barriers, and exogenous barriers. No previous work in Portugal on this matter was found in the literature. Most of the studies focused on developing countries. The barriers were a combination of the most important ones from different studies.

To analyse the barriers, a survey was conducted with responses from 99 workers in the construction industry in Portugal. The results were considered valid and, from the 27 original barriers, 15 were considered critical. This list included the following barriers: a lack of adequate Lean awareness and understanding, inadequate delivery performance and material delivery delays, a lack of support and commitment from top management, excessive bureaucracy and inflexible licensing and approvals, a lack of communication and transparency between stakeholders, the absence of long-term planning, a lack of organizational communication, a lack of prefabrication and the limited usage of off-site construction techniques, management resistance to change, unsuitable organizational structure, a lack of identification and control of waste in the project and in the company, a lack of performance measurement systems, employees’ aversion to change and fear of new procedures, a lack of planning for quality, and not recognizing financial advantage. These results were compared with the articles referred to in the literature review and the results were relatively similar given the fact that it is expected that different countries have different perspectives on the barriers and that most studies were from developing countries that have less in common with Portugal than more developed countries. Since knowing the critical barriers was not enough to successfully propose mitigation measures, another two methods were applied, the ISM approach and the MICMAC analysis, which help understand the relations between the different barriers and which barriers are the root cause of the lack of application of LC in Portugal.

The ISM model and the MICMAC analysis were studied in a meeting with two industry specialists. The results separated the barriers into different levels and clusters based on their importance. With the ISM model, the relations between the barriers were established. The FRM was used to determine the driving and dependence power of each barrier, with the lack of support and commitment from top management (CB9) being the barrier with the highest driving power and the lack of prefabrication and the limited usage of off-site construction techniques being the barrier with the highest dependence power. The barriers in the independent cluster are considered root causes for the lack of LC application in the Portuguese construction industry and, therefore, are considered the most significant barriers. These barriers are the lack of organizational communication (CB2), the lack of communication and transparency between stakeholders (CB3), unsuitable organizational structures (CB4), employees’ aversion to change and fear of new procedures (CB5), the lack of support and commitment from top management (CB9), the lack of adequate Lean awareness and understanding (CB10), and management’s resistance to change (CB11). Of these seven barriers, three are communication barriers, one is a barrier related to an input factor (labour), and the other three are barriers related to management. It is essential to notice that, of the original three communication barriers, all were considered critical, independent, and root barriers. It is also important to state that the independent barrier related to labour is based on the resistance to change, which has the same correspondence and importance as the management’s resistance to change. This shows that the main barriers are mostly related to the industry’s conservative attitude and lack of innovation, which leads to a fear of new ideas and a higher resistance to change.

An in-depth analysis of the ISM model and the MICMAC analysis was conducted to understand the interrelationships between the barriers to successfully propose mitigation measures. With the understanding from this analysis, fourteen mitigation measures were proposed, with ten tackling independent barriers, two tackling the autonomous barrier, and two tackling dependent barriers.

The objectives proposed in this research were accomplished with the barriers identified in the literature review and the critical barriers selected based on the survey’s result. Using the ISM model and MICMAC analysis, it was possible to study the relations between those barriers to determine the root causes needed to propose mitigation measures successfully.

All the barriers studied in this research were previously mentioned in articles that studied the barriers to applying LC in other countries. This means that some barriers may not be identified since they only apply to the Portuguese case.

One of this study’s limitations is that only 15 barriers were considered for the ISM model and MICMAC analysis. These barriers were selected based on the survey’s results. However, since there was no significant difference in the importance given to each barrier, different results could have easily been obtained with a slightly different response group. From the 99 answers to the survey, only 12 were clients, whereas 57 were consultants, so the perspectives on the problem were not even for the different groups meaning the results could change with a more balanced response group. Another limitation of the survey was the fact that, from the 99 respondents, only 17 had prior experience with Lean methodology. This information is crucial as it indicates that most of the participants were not familiar with the principles and practices of LC, which may have affected their responses to the questions related to the implementation of LC in Portugal. This means the results from the ISM and MICMAC could have been different. There is a possibility that one of the root causes for the lack of LC in Portugal is one of the barriers that was not considered critical.

Regarding the survey, a larger and more balanced sample could be used in future work to achieve more reliable results.

In future works, a focus group with specialists in LC could validate the critical barriers and validate the relations between barriers, as this was a limitation in the research.

This research proposed a list of mitigation measures to tackle the critical barriers to adopting LC in Portugal. With the help of a focus group with industry experts, the measures could be validated, and new measures could be proposed with a proper plan to implement those measures.

Future studies about real application studies should be conducted to better understand the impact of each measure applicated and improve results. The conclusions from these studies should be shared with the construction industry sector.