Economic Evaluation of Small Public Office Buildings with Class 1 of Zero Energy Building (ZEB) in Korea by Reflecting Life Cycle Assessment (LCA)

Abstract

1. Introduction

1.1. Background and Purpose

1.2. Procedures and Methods

- (1)

- Prior research review: Prior research on ZEB and LCA conducted mainly in Korea was investigated, and the differences between existing research methods and those used in this study were analyzed.

- (2)

- Selection of analysis targets: Two small non-residential buildings that have achieved ZEB design and construction certification in Korea, specifically public office buildings that have completed both design and construction, were selected as analysis targets.

- (3)

- Comparison of application technologies: The major ZEB application technologies for the two cases and representative cases were selected, and the application technologies for buildings before and after the ZEB application were compared and analyzed.

- (4)

- Energy evaluation and additional construction cost analysis: Energy analysis was conducted using ECO-2, a domestic ZEB certification evaluation program, and additional construction costs were analyzed.

- (5)

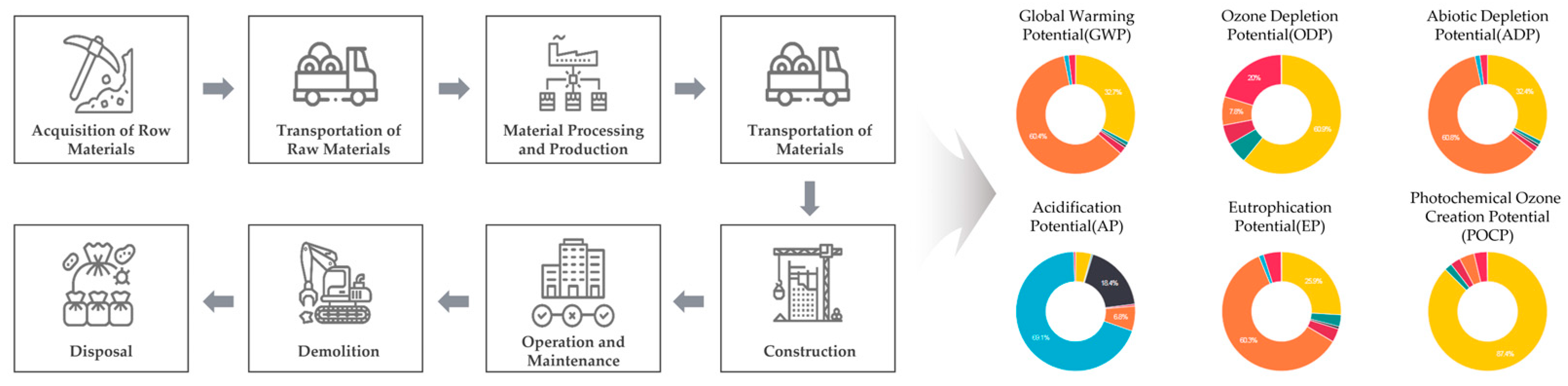

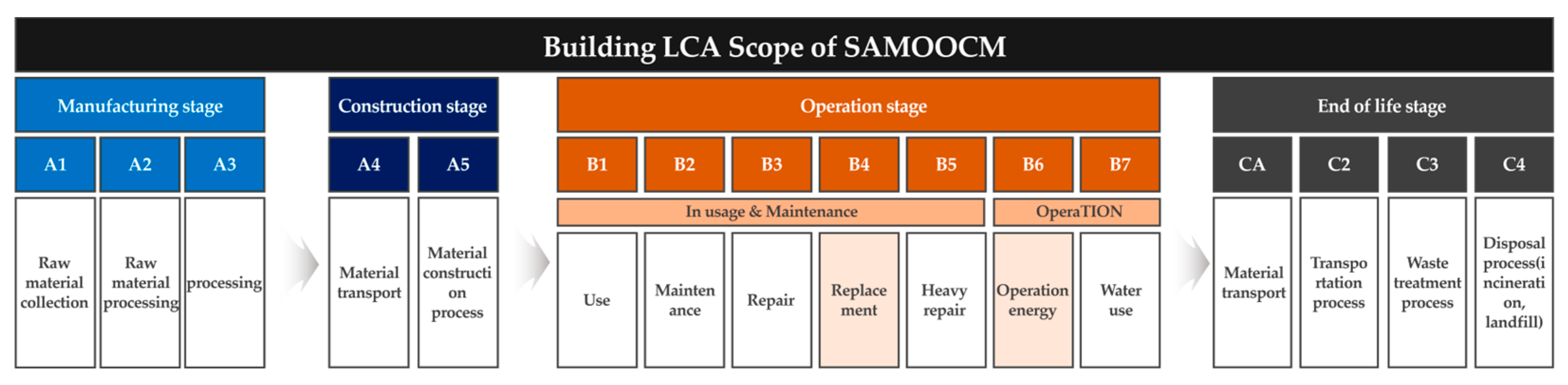

- LCA analysis: In addition to economic feasibility, an LCA based on ISO 14000s and ISO 21931-1 was conducted to evaluate the environmental impact of improvements.

- (6)

- Based on the results of (4) and (5), the NPV was analyzed considering the annual energy savings and environmental impact reduction costs of buildings that achieved ZEB certification compared to general buildings.

- (7)

- Based on the analysis results, the current status of the ZEB certification for small buildings and future improvement directions are presented from an economic evaluation perspective.

2. Literature Review

2.1. Consideration of Previous Studies Related to ZEB

2.2. Consideration of Previous Studies Related to LCA

3. Selection and Analysis of ZEB Certification Targets

3.1. Selection and Analysis Target

3.2. Overview of Analysis Program and ZEB Certification

3.3. Target Project Analysis

3.3.1. ZEB Application Technology for Target Buildings

3.3.2. Comparison and Analysis of Baseline and ZEB Models of Target Buildings

3.3.3. Comparison and Analysis for LCA of Baseline and ZEB Models of Target Buildings

4. Economic Evaluation Reflecting ZEB and LCA

5. Discussion

6. Conclusions

6.1. Main Findings

6.2. Theoretical and Practical Implications

6.3. Limitations and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Land, Infrastructure and Transport. New Leap of Green Building Policy: Implementation of the “2nd Green Building Basic Plan (20~24)”. 2020. Available online: http://www.molit.go.kr/USR/NEWS/m_71/dtl.jsp?id=95083381 (accessed on 10 November 2022).

- Korean Policy Briefing. Joint Agency, “2050 Carbon Neutrality” Promotion Strategy. 2020. Available online: https://www.korea.kr/archive/expDocView.do?docId=39241 (accessed on 10 November 2022).

- Kharn. Seoul City Promotes Early Adoption of ZEB for Private New Buildings. 2022. Available online: http://www.kharn.kr/news/article.html?no=19818 (accessed on 10 November 2022).

- Korea Energy Agency. Zero Energy Building. 2020. Available online: https://zeb.energy.or.kr/BC/BC03/BC03_05_002.do (accessed on 10 November 2022).

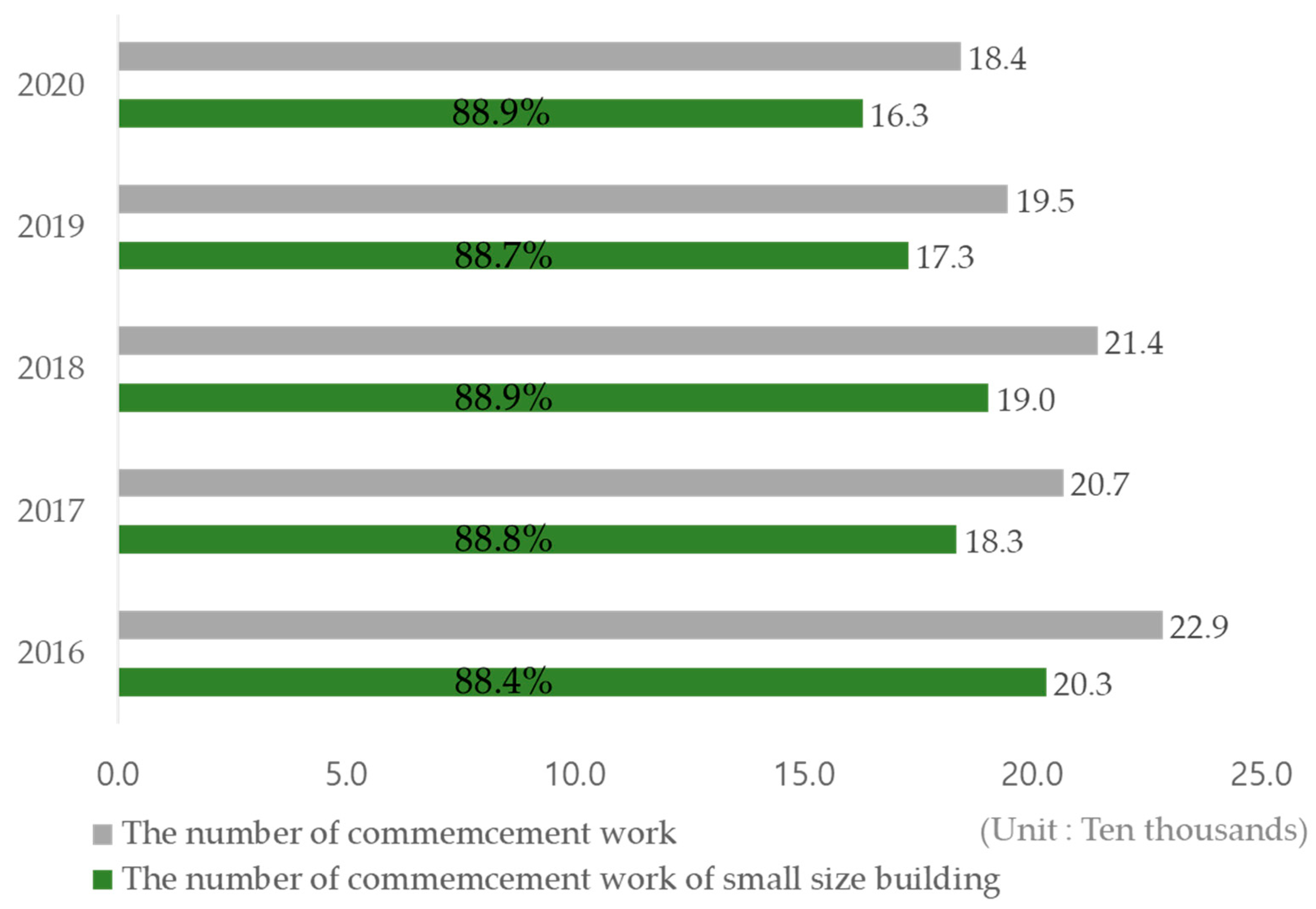

- Ministry of Land, Infrastructure and Transport. MOLIT Statistics System. 2022. Available online: https://stat.molit.go.kr/portal/cate/engStatListPopup.do (accessed on 30 July 2022).

- Presidential Advisory Council on S&T. Early Activation Plan of Zero Energy Building Response to Climate Change. 2014. Available online: https://www.pacst.go.kr/jsp/m/adv/advPostView.jsp?post_id=668&etc_cd1=C0002&cpage=4&board_id=10 (accessed on 30 July 2022).

- Kim, J. Economic analysis of zero energy building in South Korea-focusing on Cost-Benefit analysis considering social cost. J. Archit. Inst. Korea Struct. Constr. 2020, 36, 147–157. [Google Scholar] [CrossRef]

- Park, S.H.; Jung, Y.H.; Ahn, B.W. Synthetic Envelope Thermal Performance for Satisfying the Building Energy Efficiency Grade (1++) of a Small-scale Building. J. Archit. Inst. Korea 2021, 37, 143–150. [Google Scholar] [CrossRef]

- Kim, J.; Lee, D.; Nam, S. Potential for environmental impact reduction through building LCA (Life Cycle Assessment) of school facilities in material production stage. Build. Environ. 2023, 238, 110329. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Jeon, W.; Nam, S. A Study on the Development of Small-Sized Building Specification for Defect Prevention in Korea. J. Archit. Inst. Korea 2021, 37, 241–252. [Google Scholar] [CrossRef]

- Seong, E.; Oh, S. A Policy Proposal for Quality Improvement and Revitalization of Small Housing Constructions; AURI: Sejong-si, Republic of Korea, 2016; pp. 1–185. [Google Scholar]

- Seo, S.; Song, S.; Kim, J.; Joo, S. A Study on the Assessment and Policy Improvement for Revitalizing the Small Building Market; AURI: Sejong-si, Republic of Korea, 2018; pp. 1–186. [Google Scholar]

- Seoul Metropolitan Government. 2nd Seoul Green Building Formation Plan (‘22~‘26). 2022. Available online: https://news.seoul.go.kr/citybuild/archives/62062 (accessed on 20 June 2022).

- Choe, K. Domestic Zero Energy Building Policies and Trends; Ssangyong Construction Technology: Seoul, Republic of Korea, 2017; Volume 74, pp. 8–15. [Google Scholar]

- Cheng, V. Realizing the Ultimate Goal of Samsung GREEN TOMORROW; Samsung C&T Magazine: Seoul, Republic of Korea, 2009; Volume 61, pp. 40–43. [Google Scholar]

- Jeong, J.; Jo, D.; Yoo, J. Analysis of the Indoor Thermal Environment and Heating Energy Consumption of Zero Carbon Green Home. J. Archit. Inst. Korea Plan. Des. 2015, 31, 151–158. [Google Scholar] [CrossRef]

- Lim, I.; Son, E.; Lee, M. A Study on the Long-term Repair Plan for Additional Energy Saving Elements in Zero Energy Housing Complex. J. Archit. Inst. Korea Plan. Des. 2016, 32, 35–42. [Google Scholar] [CrossRef]

- Lee, M. Will the Mandatory Zero Energy Building Be Possible by 2025; Architecture and Urban Space: Sejong-si, Republic of Korea, 2016; Volume 22, pp. 30–36. [Google Scholar]

- Cho, Y. Analysis of Renewable Energy and Incentive Effects of Zero Energy Buildings; Korea Energy Agency: Ulsan, Republic of Korea, 2017; pp. 2–194. [Google Scholar]

- Lim, I. A Study on Zero Energy Apartment Cost Benefit Analysis. Master’s Thesis, Myongji University, Seoul, Republic of Korea, February 2018. [Google Scholar]

- Kim, M.; Kim, H.; Hong, G. Design Factors and Initial Cost by Zero Energy Building Rating Systems through Case Study. KIEAE J. 2018, 18, 55–60. [Google Scholar] [CrossRef]

- Kim, J.; Bae, M.; Kang, J.; Kwon, H. Improving Design Technique on Energy Efficiency of Existing Small-scale Buildings based on the Green Remodeling Project. J. Korean Soc. Living Environ. Syst. 2021, 28, 547–560. [Google Scholar] [CrossRef]

- Jo, D. Development Trends of Zero Carbon Green Home Application Technology; Ssangyong Construction Technology: Seoul, Republic of Korea, 2010; Volume 57, pp. 11–15. [Google Scholar]

- Kim, K.; Jang, M.; Song, I.; Kim, S. A Study on the Energy Self-sufficiency Rate Based on the Analysis of Building Energy Efficiency Rating System. J. Korean Inst. Archit. Sustain. Environ. Build. Syst. 2017, 11, 331–341. [Google Scholar] [CrossRef]

- Won, D. Case of Eco-Friendly Buildings in Pangyo 2nd Techno Valley Business Support Hub; KIAEBS: Seoul, Republic of Korea, 2018; Volume 12, pp. 54–57. [Google Scholar]

- Jeon, J.; Song, K.; Jeon, I.; Won, J. Analyzing Technical Elements of Zero Energy Building through the Case Study of the Main Certification in Korea. J. Korean Inst. Archit. Sustain. Environ. Build. Syst. 2018, 12, 469–486. [Google Scholar] [CrossRef]

- ISO 21931-1:2010; Sustainability in Building Construction—Framework for Methods of Assessment of the Environmental Performance of Construction Works—Part 1: Buildings. ISO: Geneva, Switzerland, 2010. Available online: https://www.iso.org/standard/45559.html (accessed on 31 December 2022).

- KICT. G-SEED Manual. 2021. Available online: http://gseed.or.kr/greenCommentary.do (accessed on 30 November 2022).

- Park, J.; Jung, H. Introduction of the Building Energy and Greenhouse Gas Information System. In Proceedings of the Korean Society of HVAC Engineers Winter Conference, Seoul, Republic of Korea, 27 November 2015. [Google Scholar]

- Jung, H. Status and Utilization Methods of Building Energy and Greenhouse Gas Information System. J. Build. Environ. Equip. Eng. 2015, 9, 12–19. [Google Scholar]

- Kim, N.; Tae, S.; Chae, C.; Lee, J.; Kim, J. Development of an environmental impact assessment program for eco-friendly building materials by building parts. In Proceedings of the Architectural Institute of Korea Spring Conference, Seoul, Republic of Korea, 24 April 2015. [Google Scholar]

- Kim, N.; Tae, S.; Lee, J.; Kim, J. Case study of the application of environmental performance assessment program for eco-friendly building materials in multi-unit housing. In Proceedings of the Architectural Institute of Korea Spring Conference, Seoul, Republic of Korea, 30 April 2016. [Google Scholar]

- Tae, S. Environmental assessment for promoting green construction materials. J. Korea Inst. Build. Constr. 2015, 15, 20–27. [Google Scholar]

- Roh, S.; Tae, S.; Baek, C.; Shin, S.; Lee, J.; Lee, J.; An, J. The Development of Object-oriented Building Life Cycle CO2 Assessment System (LOCAS). J. Archit. Inst. Korea Struct. Constr. 2012, 28, 101–108. [Google Scholar]

- Keum, W.; Shin, S.; Roh, S.; Tae, S. The Development of Life Cycle CO2 Assessment System Based on Eco-friendly Building Alternative Assessment. J. Archit. Inst. Korea Struct. Constr. 2012, 28, 87–94. [Google Scholar]

- Roh, S.; Tae, S.; Shin, S. Development of Life Cycle Carbon Emissions Assessment System for Building (BEGAS 2.0). In Proceedings of the Architectural Institute of Korea Fall Conference, Seoul, Republic of Korea, 28 October 2014. [Google Scholar]

- Lee, K.; Kim, H.; Kwon, S.; Kim, M. The Program Development for Environmental Quality Level and Evaluation of Carbon Dioxide Emission in Construction Works. LHI J. Land Hous. Urban Aff. 2012, 3, 399–406. [Google Scholar] [CrossRef]

- Hong, T.; Koo, C.; Park, J.; Kim, J. LCCO2 and LCC evaluation system for allocating greenhouse gas emission rights. In Proceedings of the Korean Society of Construction Management Conference, Seoul, Republic of Korea, 9 November 2012. [Google Scholar]

- Lee, S.; Byeon, S.; Park, S.; Cho, K.H. Environmental impact assessment of public facilities based on the environmental load of the entire process using Life Cycle Assessment (LCA). J. Korean Soc. Civ. Eng. 2008, 56, 47–53. [Google Scholar]

- Lee, K.M.; Noh, J.S.; Park, P.J. Determination of weighting factor and its application to the LCA of a Printed Circuit Board (PCB). J. Korean Soc. Life Cycle Assess. 1999, 39–44. [Google Scholar]

- Choi, D.S.; Lee, M.E.; Cho, K.H. Environmental Impact Assessment in Domestic Construction Industry Using Life Cycle Assessment. Korea Inst. Archit. Sustain. Environ. Build. Syst. 2012, 6, 46–55. [Google Scholar]

- Hong, T.; Ji, C.; Jung, K. Environmental Impact Assessment of Buildings based on Life Cycle Assessment (LCA) Methodology. Korean J. Constr. Eng. Manag. 2012, 13, 84–93. [Google Scholar] [CrossRef]

- Jo, K.; Jeon, H.; Choi, D. Integrated Environmental Cost Computation Method in Domestic Construction Industry. J. Korean Soc. Living Environ. Syst. 2012, 19, 605–614. [Google Scholar]

- Kwon, S. Development of an Environmental and Economic Evaluation Model for Construction Projects. Ph.D. Thesis, Chung-Ang University, Seoul, Republic of Korea, February 2008. [Google Scholar]

- Ministry of Government Legislation. Framework Act on the Construction Industry. 2022. Available online: https://www.law.go.kr/LSW//lsInfoP.do?lsiSeq=239989&ancYd=20220203&ancNo=18823&efYd=20220804&nwJoYnInfo=Y&efGubun=Y&chrClsCd=010202&ancYnChk=0#0000 (accessed on 31 August 2022).

- Ministry of Government Legislation. Building Act. 2022. Available online: https://www.law.go.kr/LSW//lsInfoP.do?lsiSeq=245335&ancYd=20221115&ancNo=19045&efYd=20230516&nwJoYnInfo=N&efGubun=Y&chrClsCd=010202&ancYnChk=0#0000 (accessed on 31 August 2022).

- Ministry of Government Legislation. Enforcement Rules of the Building Act. 2022. Available online: https://www.law.go.kr/LSW//lsInfoP.do?lsiSeq=245209&ancYd=20221102&ancNo=01158&efYd=20230503&nwJoYnInfo=N&efGubun=Y&chrClsCd=010202&ancYnChk=0#0000 (accessed on 31 August 2022).

- Korea Energy Agency. Zero Energy Building. 2022. Available online: https://zeb.energy.or.kr/BC/BC03/BC03_06_001.do (accessed on 10 November 2022).

- Ministry of Government Legislation. Energy Saving Design Standards for Buildings. 2022. Available online: https://www.law.go.kr/admRulLsInfoP.do?chrClsCd=010202&admRulSeq=2100000208640 (accessed on 31 August 2022).

- Passive House Institute Korea. Passive House Certification Criteria. 2022. Available online: http://www.phiko.kr/bbs/board.php?bo_table=z5_01&wr_id=1534 (accessed on 31 August 2022).

- Shim, H.S.; Lee, S. A Study on the Increase in Construction Cost for Zero Energy Building. J. Korea Acad.-Ind. Coop. Soc. 2021, 22, 603–613. [Google Scholar] [CrossRef]

- Ministry of Government Legislation. Operation Regulation for Building Energy Efficiency Rating and Zero Energy Building Certification System, Annex 2. 2021. Available online: https://www.law.go.kr/schlPubRulInfoP.do?chrClsCd=010202&schlPubRulSeq=2200000087233 (accessed on 29 May 2022).

- Thibodeau, C.; Bataille, A.; Sié, M. Building rehabilitation life cycle assessment methodology–state of the art. Renew. Sustain. Energy Rev. 2019, 103, 408–422. [Google Scholar] [CrossRef]

- Ministry of Government Legislation. Guidelines for EPD Preparation, Annex 1. 2021. Available online: https://www.law.go.kr/admRulLsInfoP.do?chrClsCd=010202&admRulSeq=2100000199570 (accessed on 30 June 2022).

- Kim, J.Y.; Lee, S.E.; Sohn, J.Y. An assessment of the energy consumption and CO2 emission during the construction stage of apartments. Korea Inst. Build. Constr. 2005, 21, 199–206. [Google Scholar]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Silvestre, J.D.; De Brito, J.; Pinheiro, M.D. Environmental impacts and benefits of the end-of-life of building materials–calculation rules, results and contribution to a “cradle to cradle” life cycle. J. Clean. Prod. 2014, 66, 37–45. [Google Scholar] [CrossRef]

- Lee, J.; Jung, D.; Cho, M.; Kim, Y. Revised General Guidelines for Conducting Preliminary Feasibility Studies on Public Enterprises and Quasi-Governmental Institutions (Second Edition), KDI Public Investment Management Center. 2018; p. 247. Available online: https://www.kdi.re.kr/research/subjects_view.jsp?pub_no=15989 (accessed on 30 June 2022).

- Ministry of Land, Infrastructure and Transport. Criteria for Adjusting Building Standard Valuation in 2021. 2020. Available online: https://www.mois.go.kr/frt/bbs/type001/commonSelectBoardArticle.do?bbsId=BBSMSTR_000000000012&nttId=81956 (accessed on 10 June 2022).

| Category | Class 5 | Class 4 | Class 3 | Class 2 | Class 1 |

|---|---|---|---|---|---|

| Number of certifications | 1753 | 609 | 205 | 67 | 77 |

| Category | Education | Office | Elderly | Cultural | Etc. |

|---|---|---|---|---|---|

| Number of certifications | 935 | 485 | 210 | 149 | 932 |

| Category | ~1000 m2 | 1000 m2~3000 m2 | 3000 m2~10,000 m2 | 10,000 m2~100,000 m2 | 100,000 m2~ |

|---|---|---|---|---|---|

| Number of Certifications | 81 | 1303 | 944 | 365 | 14 |

| ZEB Mandatory Settlement Requirements (Choe, 2017) [14] | Residential Sector | Non-Residential Sector | ||

|---|---|---|---|---|

| Detached House/Multi-Family Housing | Apartment House/ Multi-Unit Dwelling | Small Buildings | Medium and Large Buildings | |

| Technical aspect | (Vincent, 2009) [15] (Jeong et al., 2015) [16] (Choe, 2017) [14] | (Lim, Son & Lee, 2016) [17] (Lee, 2016) [18] (Jo, 2017) [19] (Choe, 2017) [14] (Lim, 2018) [20] (Kim, Kim, & Hong, 2018) [21] | (Park, Jung, & Ahn, 2021) [8] * (Kim et al., 2021) [22] ** | (Jo, 2010) [23] (Choe, 2017) [14] (Kim et al., 2017) [24] (Won, 2018) [25] (Jeon et al., 2018) [26] (Kim, 2020) [7] |

| Economic aspect | (Choe, 2017) [14] | (Lee, 2016) [18] (Jo, 2017) [19] (Lim, 2018) [20] (Kim, Kim, & Hong, 2018) [21] | - | (Kim, 2020) [7] |

| Authors | Analysis Classification | Analysis Method/ Analysis Program | Weight **/Cost/Economics | |||||

|---|---|---|---|---|---|---|---|---|

| Analysis Target/Results (CO2 or Six Major Environmental Impacts *) | Building Life Cycle | |||||||

| Production | Construction | Operation | Disposal | |||||

| (Park & Jeong, 2015) [29] | Buildings | CO2 | - | - | ○ | - | Conversion of energy consumption | - |

| (Jeong, 2015) [30] | Buildings | CO2 | - | - | ○ | - | Conversion of energy consumption | - |

| (Kim et al., 2015) [31] | Building materials | All | ○ | - | - | - | G-CEAT | - |

| (Kim et al., 2016) [32] | Building materials | All | ○ | - | - | - | G-CEAT | - |

| (Tae, 2015) [33] | Building materials | All | ○ | - | - | - | G-CEAT | - |

| (Roh et al., 2012) [34] | Buildings | CO2 | ○ | ○ | ○ | ○ | LOCAS | - |

| (Keum et al., 2012) [35] | Buildings | CO2 | ○ | ○ | ○ | ○ | Carbon Expert | - |

| (Roh, Tae, & Sin, 2014) [36] | Buildings | CO2 | ○ | ○ | ○ | ○ | BEGAS 2.0 | - |

| (Lee et al., 2012) [37] | Buildings | CO2 | ○ | ○ | ○ | ○ | ECO-DM | - |

| (Hong et al., 2012) [38] | Buildings | CO2 | ○ | ○ | ○ | ○ | PBECAS | ○ |

| (Lee et al., 2008) [39] | Facilities | All | ○ | ○ | ○ | ○ | TOTAL (ver 3.0) | ○ |

| (Lee, Noh, & Park, 1999) [40] | Products | All | ○ | - | - | - | ISO 14000 | ○ |

| (Choi, Lee, & Cho, 2012) [41] | Construction industry | All | - | - | ○ | - | ISO 14000 | ○ |

| (Hong, Ji, & Jeong, 2012) [42] | Buildings | All | - | ○ | - | - | ISO 14000 | ○ |

| (Cho, Chun, & Choi, 2012) [43] | Construction industry | All | - | - | ○ | - | ISO 14000 | ○ |

| (Kwon, 2008) [44] | Facilities | All | ○ | ○ | ○ | ○ | ISO 14000 | ○ |

| Performance for this study | Buildings | All | ○ | ○ | ○ | ○ | Self-development program | ○ |

| Category | Case 1 | Case 2 | ||

|---|---|---|---|---|

| Contents | Bird’s-Eye View | Contents | Bird’s-Eye View | |

| Location | Gwangju Metropolitan City |    | Yangyang County, Gangwon-do |    |

| Purpose | Public office | Public office | ||

| Lot Area | 9557 m2 | 2021 m2 | ||

| Building Area | 324.38 m2 | 319.94 m2 | ||

| Gloss Floor Area | 459.24 m2 | 442.06 m2 | ||

| Scale | 2nd Floor | 2nd Floor | ||

| Structure | Reinforced concrete | Heavy timber structure | ||

| Total Cost | $1,266,013 | $1,650,339 | ||

| ZEB Rating | Class 1 | Class 1 | ||

| Category | Key Contents | |

|---|---|---|

| Standard (1) | ECO-2 evaluation | Primary Energy Requirement (kWh/m2·y) = ∑ Energy consumption by use × Primary energy conversion coefficient |

| Residential: Less than 90 kWh/m2·y | ||

| Non-Residential: Less than 140 kWh/m2·y | ||

| Standard (2) | ECO-2 evaluation | Energy independence rate (%) = Primary energy production per unit area ÷ Primary energy consumption per unit area |

| The proportion of renewable energy production among energy consumed by buildings | ||

| Standard (3) | Evaluation of applicability with a checklist | (BEMS) Evaluation of nine items, including data collection and display, information monitoring, and control system interworking |

| A system that measures and manages energy consumption in real-time | (Remote meter reading) Evaluate six categories, including data collection and display, instrument management, and data management | |

| Rating | Energy Independence Rate (%) |

|---|---|

| Class 1 | Energy independence rate above 100% |

| Class 2 | Energy independence rate of 80% or more to less than 100% |

| Class 3 | Energy independence rate of 60% or more to less than 80% |

| Class 4 | Energy independence rate of 40% or more to less than 60% |

| Class 5 | Energy independence rate of 20% or more to less than 40% |

| Category | Application Techniques of ZEB in Case 1 | Application Techniques of ZEB in Case 2 | |

|---|---|---|---|

| Architecture | Wall (U-value) | Glass wool 32 K 180 mm (U-value = 0.190 W/m2·K) | Bead method insulation plate 2 type No. 3 250 mm (U-value = 0.126 W/m2·K) |

| Roof (U-value) | Extrusion method insulation Plate No. 1 180 mm (U-value = 0.150 W/m2·K) | Glass wool 25 K 40 mm + Cellulose 285 mm (U-value = 0.106 W/m2·K) | |

| 1st Floor (U-value) | Extrusion method insulation plate No. 1 150 mm (U-value = 0.167 W/m2·K) | Extrusion method insulation plate No. 1 150 mm (U-value = 0.169 W/m2·K) | |

| Window (U-value) | T47 Low-e triple glass (U-value = 0.786 W/m2·K) | T47 Low-e triple glass (U-value = 0.786 W/m2·K) | |

| Shading | External electric blind (South, west, east) | External electric blind (South, west, east) | |

| Thermal bridge | Apply thermal bridge-blocking frame | Apply thermal bridge-blocking frame | |

| Mechanical facilities | Heating and cooling equipment | EHP (COP, Heating/Cooling = 4.52/3.90) | EHP (COP, Heating/Cooling = 4.204/3.652) |

| Gas boiler (Gas meter) | Gas boiler (Gas meter) | ||

| Hot water | Electric water heater/Gas boiler (Remote meter reading, flowmeter) | Electric water heater (100%, Remote meter reading) | |

| Ventilation | Heat recovery ventilation system (Efficiency, Heating/Cooling = 76%/67%) | Heat recovery ventilation system (Efficiency, Heating/Cooling = 76%/56%) | |

| Electricity facilities | Light density | 5.0 W/m2 | 6.3 W/m2 |

| Power trunk lines | Building energy management system (BEMS) | Remote meter electronic meter | |

| Renewable energy | Photovoltaic 30.1 kWp (Efficiency, 20%) | Photovoltaic 39.6 kWp (Efficiency, 20%) | |

| Energy requirement | −7 kWh/m2·y | −11.1 kWh/m2·y | |

| Energy independence rate | 106.5% | 110.2% | |

| Category | Application Techniques of Base Model in Case 1 | Application Techniques of Base Model in Case 2 | |

|---|---|---|---|

| Architecture | Wall (U-value) | Extrusion method insulation plate 100 mm (U-value = 0.288 W/m2·K) | Bead method insulation plate 2 type No. 3 130 mm (U-value = 0.234 W/m2·K) |

| Roof (U-value) | Extrusion method insulation plate 180 mm (U-value = 0.166 W/m2·K) | Glass wool 25 K 40 mm + Cellulose 185 mm (U-value = 0.149 W/m2·K) | |

| 1st Floor (U-value) | Extrusion method insulation plate 100 mm (U-value = 0.285 W/m2·K) | Extrusion method insulation plate No. 1 90 mm (U-value = 0.266 W/m2·K) | |

| Window (U-value) | T24 Low-e double glass (U-value = 1.800 W/m2·K) | T24 Low-e double glass (U-value = 1.500 W/m2·K) | |

| Shading | - | - | |

| Thermal bridge | - | - | |

| Mechanical facilities | Heating and cooling equipment | EHP (COP, Heating/Cooling = 4.52/3.90) | EHP (COP, Heating/Cooling = 4.204/3.652) |

| Gas boiler (Gas meter) | Gas boiler (Gas meter) | ||

| Hot water | Electric water heater/Gas boiler | Electric water heater (100%) | |

| Ventilation | - | - | |

| Electricity facilities | Light density | 5.0 W/m2 | 6.3 W/m2 |

| Power trunk lines | - | - | |

| Renewable energy | - | - | |

| Energy requirement | 104.6 kWh/m2·y | 110.7 kWh/m2·y | |

| Category | Results of Case 1 | Results of Case 2 | ||||

|---|---|---|---|---|---|---|

| Energy Requirement (kWh/m2·y) = (a) | Used Area (Total Area) (m2) (b) | Annual Energy Use (kWh/m2·y) = (a) × (b) | Energy Requirement (kWh/m2·y) (a) | Used Area (Total Area) (m2) (b) | Annual Energy Use (kWh/m2·y) = (a) × (b) | |

| ZEB model | −5.7 | 459.24 | −2617.67 | |||

| Base model | 104.6 | 459.24 | 48,036.50 | |||

| Savings (kWh/m2·y) | Differences in annual energy use between ZEB and base models | 51,251.18 | Differences in annual energy use between ZEB and base models | 53,842.91 | ||

| Savings rate (%) | 106.69 | 110.03 | ||||

| Savings cost ($) | Apply $0.07 Power Charge (40 years of building life) | 3598 (66,216) | Apply $0.07 Power Charge (40 years of building life) | 3764 (69,273) | ||

| Scope | Unit Process | Number | Description |

|---|---|---|---|

| Manufacturing | Building material production | A1~3 | The process of producing building materials to be injected into buildings by consuming resources and energy necessary for production, such as the collection and processing of raw materials and the manufacture of products |

| Construction stage | Building material transportation | A4 | The process of transporting materials to be injected into a building from the place of purchase and storage to the construction site |

| Building construction | A5 | The construction process of building materials transported to the site using various construction equipment | |

| Operation stage | Building maintenance | B4 | The process of repairing and replacing aging buildings over time to keep them similar to the initial situation (reflecting dismantling and disposal of replacement materials) |

| Building use | B6 | The process of living while keeping the indoor environment comfortable by using various equipment machines while residents occupy the building | |

| Disposal and demolition stage | Demolition of a building | C1 | The process of dismantling a building using construction equipment |

| Transportation of waste materials | C2 | The process of transporting waste materials generated after dismantling to the relevant disposal site according to the treatment method | |

| Disposal and recycling | C4 | The process of reclaiming, incinerating, or recycling waste materials |

| Classification | Unit Process | Number | Global Warming Potential (GWP) | Ozone Depletion Potential (ODP) | Abiotic Depletion Potential (ADP) | Acidification Potential (AP) | Eutrophication Potential (EP) | Photochemical Ozone Creation Potential (POCP) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (tCO2eq) | (tCFC11eq) | (tSbeq) | (tSO2eq) | (tPO43-eq) | (tC2H4eq) | |||||||||

| Base | ZEB | Base | ZEB | Base | ZEB | Base | ZEB | Base | ZEB | Base | ZEB | |||

| Manufacturing | A1~3 | 3.314E+02 | 1.149E+03 | 1.658E-05 | 1.561E-04 | 4.739E+00 | 2.008E+01 | 6.518E-01 | 8.501E+00 | 8.198E-02 | 1.187E+00 | 6.881E-01 | 2.579E+00 | |

| Construction stage | Building materials transportation | A4 | 1.339E+01 | 1.994E+01 | 2.720E-06 | 5.242E-06 | 9.028E-02 | 1.348E-01 | 8.125E-02 | 1.127E-01 | 1.424E-02 | 1.932E-02 | 3.574E-02 | 5.116E-02 |

| Building construction | A5 | 5.225E+00 | 5.225E+00 | 1.883E-09 | 1.883E-09 | 3.405E-02 | 3.405E-02 | 2.005E+00 | 2.005E+00 | 1.759E-03 | 1.759E-03 | 2.601E-04 | 2.601E-04 | |

| Operation stage | Replacement | B4 | 9.613E+02 | 1.974E+01 | 3.387E-04 | 9.805E-07 | 1.023E+01 | 4.584E-01 | 2.621E+00 | 7.164E-02 | 2.601E-01 | 1.001E-02 | 2.226E+00 | 2.560E-02 |

| Operational energy use | B6 | 1.090E+03 | −2.072E+02 | 3.013E-08 | −5.722E-09 | 6.895E+00 | −1.309E+00 | 1.844E+00 | −3.502E-01 | 3.432E-01 | −6.518E-02 | 7.766E-03 | −1.475E-03 | |

| Disposal and demolition stage | Building demolition | C1 | 1.697E+01 | 2.102E+01 | 6.659E-10 | 8.245E-10 | 1.135E-01 | 1.406E-01 | 1.374E+01 | 1.701E+01 | 5.918E-03 | 7.328E-03 | 1.225E-03 | 1.517E-03 |

| Waste transportation | C2 | 2.620E+01 | 3.244E+01 | 9.796E-06 | 1.213E-05 | 1.781E-01 | 2.205E-01 | 1.276E-01 | 1.580E-01 | 2.078E-02 | 2.573E-02 | 6.215E-02 | 7.698E-02 | |

| Landfill/ Incineration | C3 | 2.495E+01 | 2.940E+01 | 4.265E-06 | 5.297E-06 | 1.878E-01 | 2.333E-01 | 6.410E-01 | 7.973E-01 | 4.187E-02 | 4.965E-02 | 4.403E-02 | 5.439E-02 | |

| Total | 2.469E+03 | 1.070E+03 | 3.721E-04 | 1.797E-04 | 2.247E+01 | 1.999E+01 | 2.171E+01 | 2.831E+01 | 7.698E-01 | 1.236E+00 | 3.065E+00 | 2.787E+00 | ||

| Classification | Unit process | Number | Global Warming Potential (GWP) | Ozone Depletion Potential (ODP) | Abiotic Depletion Potential (ADP) | Acidification Potential (AP) | Eutrophication Potential (EP) | Photochemical Ozone Creation Potential (POCP) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (tCO2eq) | (tCFC11eq) | (tSbeq) | (tSO2eq) | (tPO43-eq) | (tC2H4eq) | |||||||||

| Base | ZEB | Base | ZEB | Base | ZEB | Base | ZEB | Base | ZEB | Base | ZEB | |||

| Manufacturing | A1~3 | −6.348E+01 | −5.439E+01 | 5.386E-05 | 5.399E-05 | 9.747E+00 | 9.749E+00 | 3.675E+00 | 3.691E+00 | 6.110E-01 | 6.131E-01 | 1.129E+00 | 1.141E+00 | |

| Construction stage | Building materials transportation | A4 | 1.846E+01 | 1.855E+01 | 5.393E-06 | 5.426E-06 | 1.250E-01 | 1.256E-01 | 1.005E-01 | 1.009E-01 | 1.703E-02 | 1.710E-02 | 4.640E-02 | 4.662E-02 |

| Building construction | A5 | 5.028E+00 | 5.028E+00 | 1.812E-09 | 1.812E-09 | 3.277E-02 | 3.277E-02 | 1.929E+00 | 1.929E+00 | 1.693E-03 | 1.693E-03 | 2.503E-04 | 2.503E-04 | |

| Operation stage | Replacement | B4 | 1.706E+03 | 1.706E+03 | 6.119E-04 | 6.119E-04 | 1.825E+01 | 1.825E+01 | 4.633E+00 | 4.633E+00 | 4.535E-01 | 4.535E-01 | 3.993E+00 | 3.993E+00 |

| Operational energy use | B6 | 1.215E+03 | −1.198E+02 | 3.357E-08 | −3.309E-09 | 7.681E+00 | −7.572E-01 | 2.055E+00 | −2.025E-01 | 3.823E-01 | −3.769E-02 | 8.653E-03 | −8.530E-04 | |

| Disposal and demolition stage | Building demolition | C1 | 1.745E+01 | 1.750E+01 | 6.844E-10 | 6.866E-10 | 1.167E-01 | 1.171E-01 | 1.412E+01 | 1.417E+01 | 6.083E-03 | 6.103E-03 | 1.259E-03 | 1.263E-03 |

| Waste transportation | C2 | 2.699E+01 | 2.708E+01 | 1.009E-05 | 1.013E-05 | 1.835E-01 | 1.841E-01 | 1.315E-01 | 1.319E-01 | 2.141E-02 | 2.148E-02 | 6.403E-02 | 6.425E-02 | |

| Landfill/ Incineration | C3 | 2.458E+01 | 2.466E+01 | 3.926E-06 | 3.941E-06 | 1.775E-01 | 1.782E-01 | 6.385E-01 | 6.409E-01 | 1.769E-01 | 1.770E-01 | 7.244E-02 | 7.259E-02 | |

| Total | 2.950E+03 | 1.625E+03 | 6.852E-04 | 6.854E-04 | 3.631E+01 | 2.788E+01 | 2.728E+01 | 2.509E+01 | 1.670E+00 | 1.252E+00 | 5.315E+00 | 5.318E+00 | ||

| Category | Global Warming Potential (GWP) | Ozone Depletion Potential (ODP) | Abiotic Depletion Potential (ADP) | Acidification Potential (AP) | Eutrophication Potential (EP) | Photochemical Ozone Creation Potential (POCP) |

|---|---|---|---|---|---|---|

| (tCO2eq) | (tCFC11eq) | (tSbeq) | (tSO2eq) | (tPO43-eq) | (tC2H4eq) | |

| ZEB savings | 1.399E+03 | 1.924E-04 | 2.480E+00 | −6.600E+00 | −4.662E-01 | 2.780E-01 |

| ZEB savings rate | −56.66% | −51.71% | −11.04% | 30.40% | 60.56% | −9.07% |

| Impact ratio converted to CO2 | 1.0000E+00 | 1.3762E+05 | 1.7812E+02 | 1.7351E+01 | 5.5662E+01 | 1.2111E+02 |

| Total (19.59$/tCO2) | $34,492 | |||||

| Category | Global Warming Potential (GWP) | Ozone Depletion Potential (ODP) | Abiotic Depletion Potential (ADP) | Acidification Potential (AP) | Eutrophication Potential (EP) | Photochemical Ozone Creation Potential (POCP) |

|---|---|---|---|---|---|---|

| (tCO2eq) | (tCFC11eq) | (tSbeq) | (tSO2eq) | (tPO43-eq) | (tC2H4eq) | |

| ZEB savings | 1.325E+03 | −2.000E-07 | 8.430E+00 | 2.190E+00 | 4.180E-01 | −3.000E-03 |

| ZEB savings rate | −44.92% | 0.03% | −23.22% | −8.03% | −25.03% | 0.06% |

| Impact ratio converted to CO2 | 1.0000E+00 | 1.3762E+05 | 1.7812E+02 | 1.7351E+01 | 5.5662E+01 | 1.2111E+02 |

| Total (19.59$/tCO2) | $56,573 | |||||

| Description of Symbols | Application Criteria | ||

|---|---|---|---|

| Bt | Present value of benefits | Cost of annual energy savings | Cost of annual energy savings($/year) = annual energy savings(kWh/year) × Power unit price($/kWh) |

| Power unit price, $0.7/kWh | |||

| Ct | Present value of cost | Additional construction costs for achieving ZEB certification | |

| r | Interest rate | Social discount rate, 4.5% | (Lee et al., 2018) [58] |

| n | Year of analysis year | Life of reinforced concrete structures, 40 years | (Lee, 2020) [59] |

| R | Cost of environmental impact reduction | Environmental impact cost converted from LCA results | |

| Total Cost [Ct] (Additional Construction Costs for Achieving ZEB Certification) | Total Benefits | |

|---|---|---|

| Cost of Annual Energy Savings [Bt] | Cost of Environmental Impact Reduction [R] | |

| $234,940 | $66,216 (28.2% Reduction) | $34,492 (11.7% Reduction) |

| Sum of total benefits = $100,708 (39.9% Reduction) | ||

| NPV analysis results | −$134,232 (<0) | |

| Total Cost [Ct] (Additional Construction Costs for Achieving ZEB Certification) | Total Benefits | |

|---|---|---|

| Cost of Annual Energy Savings [Bt] | Cost of Environmental Impact Reduction [R] | |

| $224,108 | $69,273 (30.9% Reduction) | $56,573 (11.6% Reduction) |

| Sum of total benefits = $125,846 (42.5% Reduction) | ||

| NPV analysis results | −$98,262 (<0) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Kim, J.; Kim, Y.I. Economic Evaluation of Small Public Office Buildings with Class 1 of Zero Energy Building (ZEB) in Korea by Reflecting Life Cycle Assessment (LCA). Buildings 2023, 13, 1693. https://doi.org/10.3390/buildings13071693

Lee D, Kim J, Kim YI. Economic Evaluation of Small Public Office Buildings with Class 1 of Zero Energy Building (ZEB) in Korea by Reflecting Life Cycle Assessment (LCA). Buildings. 2023; 13(7):1693. https://doi.org/10.3390/buildings13071693

Chicago/Turabian StyleLee, Duhwan, Jaemoon Kim, and Young Il Kim. 2023. "Economic Evaluation of Small Public Office Buildings with Class 1 of Zero Energy Building (ZEB) in Korea by Reflecting Life Cycle Assessment (LCA)" Buildings 13, no. 7: 1693. https://doi.org/10.3390/buildings13071693

APA StyleLee, D., Kim, J., & Kim, Y. I. (2023). Economic Evaluation of Small Public Office Buildings with Class 1 of Zero Energy Building (ZEB) in Korea by Reflecting Life Cycle Assessment (LCA). Buildings, 13(7), 1693. https://doi.org/10.3390/buildings13071693