Abstract

The potential of Industry 4.0 digitization practices to improve sustainability and enhance overall project performance has garnered significant attention in the construction industry. Nonetheless, there is a necessity for empirical investigations that delve into the particular factors and constructs that contribute to this achievement. This research aims to address the existing gap in the literature by examining the favorable consequences of Industry 4.0 digitalization techniques in the context of sustainable construction management. The research utilized a mixed-methods methodology, integrating exploratory factor analysis (EFA) and structural equation modeling (SEM), to examine survey data obtained from the construction sector in China. The survey questionnaire comprised constructs that pertained to sustainability, technology, design, functional aspects, resource management, and managerial efficiency. The concept of sustainability has been identified as the most significant factor in shaping sustainable construction practices. The findings presented herein contribute to the theoretical comprehension of the determinants that impact the execution of Industry 4.0 digitalization methodologies within the construction sector. The interrelated constructs that have been identified provide valuable insights for practitioners and policymakers seeking to utilize Industry 4.0 practices to achieve sustainability, enhance technology adoption, optimize design processes, streamline functional aspects, improve resource utilization, and increase managerial efficiency. Implementing these strategies can enhance project success and ensure long-term sustainability in the construction industry. This research adds to the expanding pool of information regarding the factors that lead to success in Industry 4.0 digitization practices within sustainable construction management.

1. Introduction

Industry 4.0, often known as the fourth industrial revolution, has emerged due to swift technological progress. The current epoch is distinguished by the assimilation of digital technologies across diverse domains, including the construction industry. The construction sector is pivotal to worldwide economic progress [1,2]. However, it encounters significant obstacles, particularly concerning sustainability. In response to these challenges, the sector is progressively embracing digitalization methodologies consistent with the principles of Industry 4.0 [3].

The digitalization practices of Industry 4.0 encompass a diverse array of technologies, including but not limited to the Internet of Things (IoT), artificial intelligence (AI), big data analytics, robotics, and cloud computing. Implementing these technological advancements facilitates the acquisition, examination, and application of extensive data sets, ultimately augmenting the efficacy of operations, output, and strategic choices within construction administration [4]. Furthermore, they can enhance sustainability by optimizing resource utilization, reducing waste, and enhancing the environmental performance of construction projects [5,6].

The concept of sustainable construction management entails a comprehensive strategy that endeavors to mitigate the adverse effects of construction operations on the natural surroundings, human society, and the financial system while simultaneously optimizing the favorable consequences [7,8]. The concept comprises a range of factors, such as sustainable building design, optimization of energy consumption, effective waste disposal, ethical procurement of resources, and social accountability. The integration of digitalization techniques associated with Industry 4.0 has the potential to significantly contribute to the achievement of sustainable construction management goals.

The aim of this study was to evaluate the effectiveness of Industry 4.0 digitalization tactics in the realm of sustainable construction administration [9,10]. Through an analysis of the determinants that influence the efficacy of these methodologies, the present study endeavors to pinpoint the fundamental constituents that can engender enhanced sustainability results within the realm of construction. Comprehending these success factors holds significance for various industry stakeholders, such as construction firms, policymakers, and researchers, as it enables them to devise efficacious strategies and frameworks for integrating and accepting digital technologies in construction ventures [10,11].

The study outcomes provide significant perspectives on the determinants of Industry 4.0 digitalization strategies to promote sustainable construction management. The findings augment the current corpus of literature by pinpointing factors that lead to success and avenues for utilizing digital technologies to attain sustainability objectives within the construction sector. The primary objective of the study was to facilitate the shift towards a construction industry that is both sustainable and technologically advanced, thereby promoting favorable ecological, societal, and financial outcomes. The study stands out from prior literature due to its distinct emphasis on success factors, its particular focus on the Chinese construction industry, and its thorough assessment of sustainability implications. The aforementioned original contributions present a compelling argument for the novelty of the research, addressing a significant knowledge gap and providing valuable perspectives for the successful implementation of Industry 4.0 in sustainable construction management within China.

2. Related Work

There has been a notable surge in interest in incorporating Industry 4.0 digitalization practices within the construction industry in recent years. This is primarily due to the potential benefits that such practices can offer, including enhancing sustainability and improving construction management [12,13]. However, further academic literature is required to identify the specific factors that contribute to the success of evaluating Industry 4.0 digitalization approaches for sustainable construction management. The aforementioned gap holds significant relevance to China’s construction sector, as there is a requirement for additional assessment and comprehension regarding the productive advancement of Industry 4.0 [14,15].

Numerous scholarly investigations have examined the uptake and execution of digital technologies within the construction sector. The majority of research in this area has concentrated on the advantages and obstacles related to digitalization, with limited attention paid to the specific determinants of triumph that facilitate the enduring progress of Industry 4.0 methodologies in construction management [16,17]. As a result, there need to be more all-encompassing studies that delve into the particular factors essential for attaining favorable results in sustainable construction management [18,19].

The evaluation of success factors for Industry 4.0 digitalization practices is uniquely situated within the Chinese construction industry context [20,21]. Rapid urbanization and infrastructure development in China have resulted in a surge in the need for sustainable construction practices [22]. The government has acknowledged the significance of digitalization within the construction industry and has implemented several measures to encourage the integration of digital technologies. Nonetheless, more scholarly research is needed regarding the efficacious execution and assessment of Industry 4.0 methodologies within the Chinese construction sector [23].

An area of deficiency that has been identified pertains to the necessity of scrutinizing the principal motivators and facilitators of Industry 4.0 implementation within the construction sector of China. Prior research has identified key factors crucial to driving successful digitalization efforts, including organizational culture, leadership support, and technological readiness [24]. Nevertheless, as mentioned earlier, these factors could exhibit distinct manifestations within the Chinese milieu, owing to the distinctive attributes and predicaments of the domestic construction sector [15,20]. Hence, additional investigation is imperative to examine the factors that propel and facilitate the productive establishment and execution of Industry 4.0 digitalization methodologies in China [25,26].

Furthermore, there needs to be more scholarly inquiry concerning the consequences and effects of Industry 4.0 digitization techniques within the construction sector of China. Although certain investigations have explored the advantages of digital technologies, a thorough evaluation of the sustainability implications arising from incorporating Industry 4.0 practices in the construction management domain is required [27,28]. The assessment ought to encompass a range of sustainability facets, such as environmental, social, and economic dimensions, to comprehensively comprehend digitalization’s effects in the Chinese setting [29,30].

It is imperative to address the identified gap in the literature to ensure the effective implementation of Industry 4.0 practices within the Chinese construction sector [31,32]. Through a comprehensive comprehension of the particular success factors and a thorough evaluation of the consequences of digitalization endeavors, policymakers, construction companies, and other relevant stakeholders can make informed decisions and formulate efficacious strategies to harness digital technologies for sustainable construction management [33,34]. The present study aims to address the existing void in the scholarly literature by furnishing customized insights and recommendations specific to the Chinese milieu. The ultimate objective is to foster sustainable development in the nation’s construction sector [35,36].

This study offers several distinctive and innovative contributions that differentiate it from the current literature, in addition to addressing the identified research gap. Prior studies have explored the benefits and obstacles associated with the implementation of digitalization in the construction industry. However, scant consideration has been given to the particular factors that contribute to successful outcomes when assessing Industry 4.0 digitalization strategies for the purpose of promoting sustainable construction management. The study considers the distinctive context of the construction industry in China. The rapid urbanization and infrastructure development in China have resulted in an urgent requirement for sustainable construction practices. In response, the government has demonstrated a robust dedication to advancing digitalization within the industry. Nonetheless, a dearth of all-encompassing studies exists regarding the proficient implementation and assessment of Industry 4.0 methodologies, particularly within the Chinese milieu. The present research endeavors to bridge this lacuna by furnishing tailored perspectives and suggestions that are particular to the Chinese context, augmenting the current pool of knowledge.

Finally, although certain investigations have examined the advantages of digital technologies in the construction industry, a comprehensive assessment of the sustainability ramifications of integrating Industry 4.0 methodologies into construction management is necessary, particularly within the context of China. The objective of this research is to conduct a comprehensive evaluation of the impacts of digitalization on the Chinese construction industry across environmental, social, and economic dimensions. The findings of this study are expected to offer significant contributions to the advancement of sustainable development.

In summary, the current body of literature exhibits a deficiency in thoroughly analyzing the determinants of successful Industry 4.0 digitalization strategies in the context of sustainable construction management [32,37,38]. The gap holds significant relevance in the context of the construction industry in China, necessitating a thorough assessment and comprehension to facilitate efficacious digitalization endeavors. The resolution of this disparity will make a valuable contribution to the existing pool of knowledge. It furnishes valuable insights and suggestions that can steer the uptake and execution of digital technologies in China’s construction industry. This, in turn, will promote sustainable development and enhance construction management practices.

3. Methodology

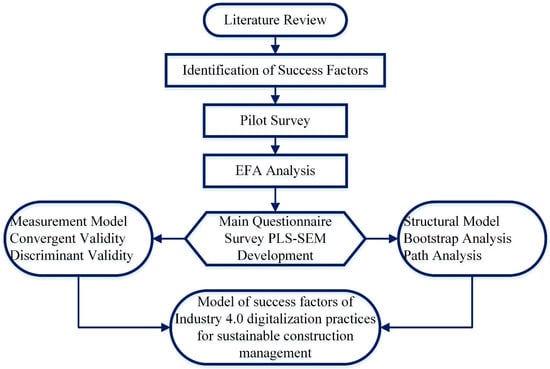

The research employed a mixed-methods study design, as indicated in Figure 1, to thoroughly examine the factors contributing to the success of Industry 4.0 digitization practices in sustainable construction management. The study employed a research methodology that involved a series of consecutive stages. Initially, a comprehensive literature review was undertaken to identify the extant literature and theoretical frameworks about Industry 4.0 digitization practices and their potential determinants of success in the construction sector [39,40]. The present literature review has established a fundamental understanding of the existing knowledge and served as a preliminary framework for subsequent inquiry. Subsequently, the viewpoints of 12 construction engineering practitioners in China were solicited to obtain expert opinions. The selection of these experts was based on their demonstrated proficiency and extensive background in the fields of construction management and Industry 4.0 technologies. The researchers conducted structured interviews and discussions to gather the participants’ insights and opinions. This was done to identify success factors that may have yet to be noticed in the existing literature. A preliminary survey was executed to scrutinize and authenticate the preliminary discoveries [41,42]. The preliminary survey encompassed a limited cohort of construction experts who were requested to furnish their perspectives and evaluations regarding the designated determinants of accomplishment. The pilot survey data underwent exploratory factor analysis (EFA) to evaluate the underlying factor structure and establish the survey instrument’s reliability and validity.

Figure 1.

Flowchart of research method.

After the pilot survey, a primary questionnaire was administered to a more extensive cohort of construction experts in China. The refinement of the survey instrument was informed by the outcomes of the pilot survey and encompassed the incorporation of items that pertained to the identified success factors. The principal data collection tool was utilized to elicit insights and perspectives from the respondents regarding the efficacy determinants linked to Industry 4.0 digitalization initiatives within the framework of sustainable construction administration [43,44]. SEM analysis was performed to examine the data obtained from the primary survey. SEM was utilized to analyze the correlations among the identified success factors and their influence on the outcomes of sustainable construction management [45,46]. The utilization of SEM facilitated the acquisition of valuable insights about the magnitude and significance of the relationships under examination, in addition to the overall adequacy of the model. The SEM framework ultimately underwent a conclusive validation procedure [47,48]. The evaluation process encompassed an examination of the model’s dependability, accuracy, and comprehensive appropriateness by applying various statistical indices and assessments. The ultimate verification process was conducted to ascertain the resilience and precision of the Industry 4.0 digitization success factors model in sustainable construction management.

The study utilized a mixed-methods approach, incorporating techniques such as literature reviews, expert opinions, pilot surveys, main questionnaire surveys, SEM analysis, and final validation to ascertain and authenticate the success factors of Industry 4.0 digitization practices for sustainable construction management in the Chinese setting. The research findings were obtained through a comprehensive and rigorous methodology.

3.1. Identification of Success Factors

A thorough analysis of scholarly literature and expert perspectives was conducted to identify the key success factors for implementing Industry 4.0 digitization practices in sustainable construction management [49,50]. The literature review comprised scholarly articles from reputable platforms, including MDPI, ScienceDirect, Web of Science, and Google Scholar. The study yielded significant findings regarding the current understanding and theoretical models of the digitization of Industry 4.0 in construction management. In addition, the study solicited the viewpoints of 12 proficient practitioners in the domain of construction engineering [51,52]. The valuable insights of experts were identified through structured interviews and discussions, which aided in determining the most critical success factors. The study identified a set of 36 success factors through a comprehensive review of the literature and consultation with experts (Table 1). These factors served as the foundation for subsequent analysis and examination in the later stages of the research.

Table 1.

Success Factors of Industry 4.0.

3.2. Data Collection

The study employed a two-stage data collection process consisting of a pilot and a main questionnaire survey. The aim was to elicit insights and perspectives on the success factors of Industry 4.0 digitization practices for sustainable construction management. Random sampling was employed in both surveys to obtain representative samples from the Chinese construction industry. The preliminary survey encompassed inquiries into the 36 success factors that were identified. The questionnaire is presented in Appendix A section. The study utilized a five-point Likert scale, encompassing a range of responses from strongly disagree to strongly agree. A survey was conducted among 111 respondents who were employed in China’s construction industry and had expertise in sustainable construction management. The primary objective of the pilot survey was to assess the transparency and pertinence of the survey inquiries while also detecting any probable impediments in the data interpretation procedure. The analyses of the pilot survey have revealed specific challenges and areas that require improvement. The challenges mentioned above were integrated into the primary questionnaire design. The primary survey comprised inquiries that tackled the success factors identified alongside the challenges revealed from the pilot survey. The primary questionnaire survey involved 265 participants from the Chinese construction industry who shared similar characteristics with the pilot survey sample. The data collection process was designed to guarantee the incorporation of a wide range of viewpoints from individuals possessing expertise and familiarity in China’s sustainable construction management field. Employing random sampling methods is intended to mitigate bias and enhance the applicability of the results [7,33,41]. The data that was gathered has furnished significant insights for subsequent analysis and scrutiny of the factors that contribute to the success of Industry 4.0 digitization practices in the domain of sustainable construction management in China.

3.3. Demographics

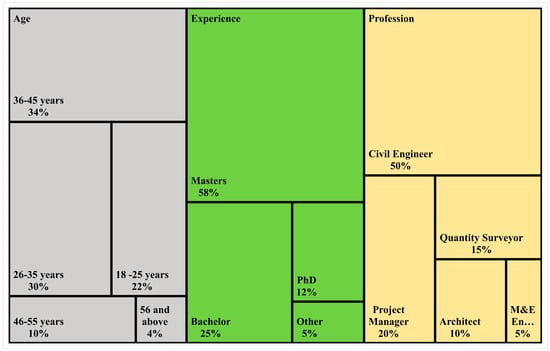

Figure 2 presents the demographic characteristics of the study participants. The age distribution data reveals that a significant proportion of the participants belonged to the age bracket of 26–45 years, constituting 34.0% and 30.0% of the total sample, respectively. The sample consisted of individuals belonging to two age groups, namely 18–25 years and 56 years and above, constituting 22.0% and 4.0% of the participants, respectively. The participants demonstrated a considerable level of educational achievement concerning their experience. The sample population primarily comprised individuals with a master’s degree, constituting 58.0% of the participants. This was followed by individuals with bachelor’s degrees, accounting for 25.0% of the sample. The sample consisted of 12.0% of participants with a Ph.D. degree, whereas 5.0% reported their educational qualification as “Other.” None of the participants reported having a high school education. With respect to occupation, the most sizable cohort of respondents comprised civil engineers, accounting for 50.0% of the population. The study revealed that project managers constituted 20.0% of the sample, whereas architects and quantity surveyors accounted for 10.0% and 15.0% of the participants, respectively. The study revealed that 5.0% of the participants were M&E engineers. The study benefits from including participants with a wide range of ages, educational backgrounds, and professional affiliations, enhancing its representativeness and providing a diverse array of perspectives [52,59]. The educational background of the sample population reveals a significant proportion of individuals possessing a minimum of a master’s degree, which suggests a considerable degree of proficiency and erudition in the construction management domain. The demographic characteristics facilitate a thorough investigation of the determinants of success in Industry 4.0 digitization initiatives within sustainable construction management.

Figure 2.

Demographics.

3.4. Exploratory Factor Analysis (EFA)

The outcomes of the questionnaire utilized in the pilot survey, which focused on the success factors of Industry 4.0 digitization in sustainable construction management, were analyzed through EFA. The objective of the EFA was to ascertain the fundamental factor structure and evaluate the dependability and authenticity of the survey tool. Before conducting the EFA, the Kaiser-Meyer-Olkin (KMO) test and Bartlett’s test of sphericity were administered. The sample’s adequacy was evaluated using the KMO test. In contrast, whether the correlation matrix significantly deviated from an identity matrix was determined using Bartlett’s test [3,39]. Two tests were administered to ascertain the appropriateness of the data for factor analysis. A rotated component matrix with varimax rotation was implemented to scrutinize the factor loadings and ascertain the discrete factor configuration. The Varimax rotation method is utilized to streamline the factor structure through the maximization of the variance of each factor. This methodology facilitated interpreting and categorizing the success factors under their shared variance [6,14].

Furthermore, the internal consistency and reliability of the data were evaluated by measuring Cronbach’s alpha. Cronbach’s alpha was utilized to assess the inter-item reliability, which gauged the degree to which the items within each factor were interrelated and evaluated the identical underlying construct. The EFA yielded valuable insights regarding the underlying factor structure of the success factors of Industry 4.0 digitization in the context of sustainable construction management [14,32]. Using factor loadings and a rotated component matrix facilitated the identification of discrete factors and their correlations with success factors. In addition, Cronbach’s alpha metric was utilized to establish the dependability of the data, validating that the components within each factor were coherent and dependable indicators of the fundamental construct.

3.5. Structure Equation Modelling (SEM)

The SEM analysis was applied to the primary questionnaire survey outcomes gathered from the Chinese construction sector participants. The utilization of SEM analysis facilitated a thorough investigation of the interconnections between the success factors pertaining to the digitization of Industry 4.0 and their influence on the outcomes of sustainable construction management [8,40]. The study collected and analyzed demographic data of the participants, including age, gender, educational background, and years of experience, to enhance comprehension of the sample characteristics and their potential impact on the research variables. Convergent validity was evaluated by scrutinizing the factor loadings, average variance extracted (AVE), and composite reliability (CR). The measures were utilized to assess the degree to which the items comprising each factor exhibited convergence to measure the identical underlying construct. The evaluation of discriminant validity was carried out through an analysis of the inter-factor correlations and a subsequent comparison of these correlations with the square roots of the AVE. The objective of the current investigation was to evaluate the uniqueness of the variables and furnish proof for the discriminative validity of the measuring framework.

The investigators conducted an analysis of the HTMT ratio of correlations to assess the discriminant validity more comprehensively. The use of HTMT ratios facilitated discriminant validity assessment by comparing inter-construct correlations with a predetermined threshold value [2,32,55]. The Fornell and Larcker criterion was utilized to assess the dependability and accuracy of the measurement model. The criterion was utilized to examine the square roots of the Average Variance Extracted (AVE) and the correlations among the latent constructs, thus confirming the convergent and discriminant validity. The study employed path analysis as a statistical method to investigate the interrelationships among success factors and their effects on sustainable construction management outcomes. The present study facilitated the detection of considerable direct and indirect impacts, thereby indicating the magnitude and orientation of the associations [50,56]. The assessment of predictive relevance was conducted by examining various model fit indices, including but not limited to goodness-of-fit measures such as chi-square, comparative fit index, Tucker-Lewis index, and root mean square error of approximation [38,54]. The indices have furnished valuable insights into the comprehensive suitability of the SEM model and the efficacy of the success factors in predicting sustainable construction management outcomes. The SEM analysis yielded a holistic comprehension of the interrelationships between the success factors of Industry 4.0 digitization and their influence on sustainable construction management outcomes [19,24]. The rigorous evaluation of demographic characteristics, a convergence of measures, differentiation of constructs, HTMT ratios, adherence to Fornell and Larcker’s criteria, path analysis, and predictive relevance were instrumental in establishing the strength and credibility of the research outcomes.

3.6. Model Validation Survey

To ensure the veracity of the study’s results and evaluate the resilience of the success factor model in the context of industry 4.0 digitization, a validation survey was administered. The survey enlisted the participation of 12 experts from the industry. The selection of these professionals was based on their extensive experience and specialized knowledge in the fields of construction management and the implementation of Industry 4.0 technologies. The validation survey comprised five inquiries specifically crafted to evaluate the pertinence, comprehensiveness, and precision of the identified success factors and their influence on the management of sustainable construction [60,61]. These inquiries aimed to amass proficient viewpoints and discernments concerning the soundness and practical applicability of the industry 4.0 digitization success factors model. Following were the five validation questions.

- To what extent do you agree that identified constructs play a significant role in successfully implementing industry 4.0 digitization practices for sustainable construction management?

- Focusing on the success factors driving the adoption and integration of Industry 4.0 digitization technologies in the construction industry is important.

- The implementation of 4.0 digitization practices in sustainable construction management is deemed sufficient.

- Are there any additional success factors that should be included in the industry 4.0 digitization success factors model?

- How relevant and applicable do you find the industry 4.0 digitization success factors model in the context of the sustainable management of the Chinese construction industry?

The survey conducted for validation purposes yielded significant expert feedback and insights instrumental in the ultimate validation and refinement of the model for success factors in digitization within the industry 4.0 context. Incorporating expert opinions contributed to the practical relevance and applicability of the model to the construction industry, thereby augmenting the validity and credibility of the study’s findings.

4. Results and Analysis

4.1. Exploratory Factor Analysis (EFA)

The KMO measure of sampling adequacy and Bartlett’s test of sphericity results are displayed in Table 2. The KMO measure produced a result of 0.821, signifying considerable sufficiency in the sample. The statement implies that the survey data is appropriate for factor analysis. The statistical procedure known as Bartlett’s test of sphericity was employed to evaluate the hypothesis that the correlation matrix conforms to an identity matrix. The resulting chi-square value was approximately 10,121.211, and the degrees of freedom were 1015. The statistical analysis revealed a p-value of less than 0.001 (sig. = 0.000), which suggests that the correlation matrix significantly deviates from an identity matrix. Thus, the data displays adequate intercorrelations, indicating the appropriateness of the data for factor analysis.

Table 2.

KMO and Bartlett’s test.

The exploratory factor analysis (EFA) yielded a rotated component matrix presented in Table 3. After applying a varimax rotation, the matrix displays the factor loadings of individual success factor items. A rotated component matrix facilitates a more lucid interpretation of the fundamental factor configuration. The matrix displays the success factor items row-wise, while the rotated component loadings are presented in columns 1 through 6, corresponding to the identified components. Each loading denotes the magnitude and orientation of the correlation between a particular success factor item and its corresponding component. Several success factor items exhibit noteworthy high factor loadings. Instances such as S8, S35, S23, and S24 demonstrate significant loadings in Component 1. The results indicate that Component 4 displays noteworthy loadings for items S3, S7, and S26, whereas robust loadings distinguish Component 5 from items S34, S13, and S5. The observed patterns indicate a strong correlation between the success factor items and their corresponding components. Moreover, the analysis yielded the detection and exclusion of variables that exhibited negligible contributions to the fundamental factor configuration, specifically S29, S11, S4, and S36. The rotated component matrix serves as a valuable tool for comprehending and interpreting the factor structure that underlies the success factors of Industry 4.0 digitization in sustainable construction management [36,49].

Table 3.

EFA results of component matrix presenting 6 constructs.

The identified success factors have been classified into six constructs, namely Sustainability, Technology, Design, Functional, Resource, and Managerial, as shown in Table 4. The constructs embody distinct facets of digitization practices in sustainable construction management within the context of Industry 4.0. The following is an analysis of each construct:

Table 4.

Success factors with named constructs.

The concept of sustainability pertains to aspects associated with environmental and social sustainability. The commitment to sustainable practices is evidenced by success factors such as waste reduction through improved material estimation and design optimization (S8), increased use of eco-friendly building materials and techniques (S35), and real-time monitoring of site conditions for worker safety (S23).

The construct of technology emphasizes the utilization of digital tools and innovative techniques in construction management. The elements mentioned earlier are deemed critical success factors, which encompass the real-time monitoring of construction sites to ensure safety (S15), the reduction of energy consumption through the utilization of IoT devices and intelligent building technologies (S16), and the optimization of artificial intelligence and machine learning for predictive maintenance (S9). The aforementioned factors underscore the incorporation of technology in enhancing construction procedures and results.

The construct under consideration pertains to the factors associated with innovative design practices. The success of construction initiatives can be attributed to several factors, such as the enhancement of data precision and quality (S20), the mitigation of environmental impact (S10), and the adoption of prefabricated and modular construction techniques (S14). The aforementioned factors underscore the significance of implementing sustainable design practices, optimizing resource utilization, and embracing innovative construction techniques.

The functional construct pertains to elements associated with the efficiency of operations and quality control. The emphasis on improving functional aspects of construction projects is evidenced by success factors such as enhanced building operation and maintenance (S34), the prevalence of green building certification programs (S13), and the utilization of augmented and virtual reality for design and visualization (S5).

The construct of resources emphasizes aspects of the effective management of resources. The identified success factors comprise the reduction of errors and the minimization of repetitive work (S3), the adoption of sustainable energy sources (S7), and the implementation of digital supply chain management strategies (S26). The aforementioned factors underscore the prioritization of resource optimization, reduction of costs, and implementation of sustainable resource management methodologies.

The managerial construct pertains to elements associated with project management and cooperation. The factors that contribute to success encompass improved project management and construction process efficiency (S28), heightened productivity and accelerated project completion (S32), and improved collaboration and communication among project participants (S22). The aforementioned factors underscore the significance of proficient management methodologies and efficient project implementation.

This study presents a comprehensive framework for understanding the fundamental elements of digitization practices in sustainable construction management within the context of Industry 4.0. The success factors are categorized into six constructs for ease of comprehension. Every construct embodies a unique domain that contributes to the comprehensive achievement of incorporating digital technologies in the construction sector.

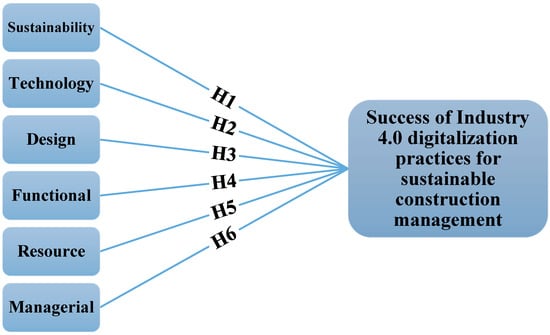

Following the findings from EFA, six research hypotheses, as indicated in the hypothesized framework of Figure 3, were devised as follows.

Figure 3.

Hypothesized framework.

- Hypothesis 1 (H1). Sustainability-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management.

- Hypothesis 2 (H2). Technology-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management.

- Hypothesis 3 (H3). Design-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management.

- Hypothesis 4 (H4). Functional-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management.

- Hypothesis 5 (H5). Resource-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management.

- Hypothesis 6 (H6). Managerial-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management.

4.2. Structure Equation Modeling (SEM)

4.2.1. Measurement Model

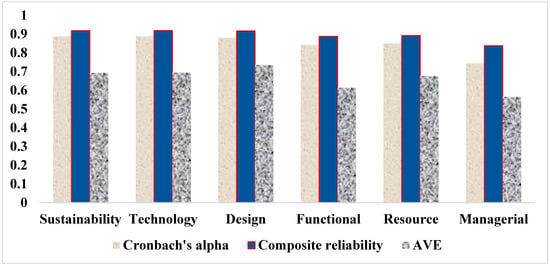

Table 5 displays the statistical indicators of reliability and validity for the model constructs. The statistical indicators of reliability include Cronbach’s alpha, composite reliability, and AVE. The loadings of the construct and the variance inflation factor (VIF) are additionally furnished. The Sustainability construct exhibits strong factor loadings for the success factors S8 (0.860) and S35 (0.863), indicating a significant correlation with the construct.

Table 5.

Model reliability and validity statistics.

The internal consistency of the Sustainability and Technology constructs is deemed good, as evidenced by their respective Cronbach’s alpha values of 0.889. The composite reliability values for both constructs surpass the suggested threshold of 0.70, signifying commendable reliability. The convergence of validity is indicated by the fact that the AVE values for both the Sustainability (0.918) and Technology (0.919) constructs surpass the 0.50 threshold [59,60]. The success factors S20 exhibit a robust loading for the Design construct, suggesting a significant correlation with the construct.

The internal consistency of the Design construct is deemed satisfactory, as indicated by Cronbach’s alpha coefficient of 0.881. The composite reliability value of 0.917 for the Design construct suggests good reliability. The AVE for Design, which is 0.917, surpasses the threshold, signifying convergent validity [49,58]. Within the context of the Functional construct, it can be observed that the success factor denoted as S34 displays a robust loading of 0.785, whereas the remaining factors demonstrate moderate loadings.

The internal consistency of the Functional construct is deemed acceptable, as evidenced by Cronbach’s alpha value of 0.843. The composite reliability value of 0.888 for the Functional construct suggests a good level of reliability [36,49]. Nevertheless, the obtained AVE value of 0.614 is marginally lower than the established threshold, indicating the requirement for additional scrutiny of the convergent validity.

The Resource construct exhibits a robust loading for the success factor S3 (0.906), whereas the remaining factors display moderate loadings. The internal consistency of Resources is deemed acceptable, as evidenced by Cronbach’s alpha value of 0.850. The composite reliability score of resources is 0.892, which suggests a satisfactory level of reliability. The AVE value for the resource (0.676) is below the established threshold, which suggests the necessity for additional evaluation of convergent validity.

Finally, within the Managerial framework, the success factor S28 displays a moderate loading of 0.760, with other factors also demonstrating moderate loadings. The internal consistency of the Managerial construct is deemed acceptable, as evidenced by Cronbach’s alpha value of 0.744 [11,47]. The Managerial composite reliability score of 0.838 suggests a high level of reliability. The AVE value for the Managerial construct (0.565) is below the established threshold, suggesting that additional scrutiny of convergent validity is warranted.

To summarize, most constructs’ statistical reliability measures demonstrate good internal consistency, whereas the composite reliability values indicate good reliability. The comparison of model reliability and validity statistics is indicated in Figure 4. Nevertheless, the AVE values for the Functional, Resource, and Managerial constructs are marginally lower than the established threshold, thereby suggesting the requirement for additional scrutiny of convergent validity [12,22]. The statistical metrics of reliability and validity are essential for assessing the efficacy of the measurement model in capturing the key performance indicators linked to the implementation of Industry 4.0 digitization practices in the realm of sustainable construction management.

Figure 4.

Comparison of model reliability and validity statistics.

The discriminant validity of the constructs was evaluated using the Fornell-Larcker criteria, and the results are displayed in Table 6. The diagonal entries of the table denote the square roots of the mean-variance extracted for each construct, whereas the non-diagonal entries signify the inter-correlations among the constructs. The diagonal elements of the matrix signify the AVE and indicate that each construct exhibits a stronger correlation with its construct than any other construct. This is evident because the diagonal elements are higher than the off-diagonal elements that correspond to other constructs. As an illustration, the AVE pertaining to the Design construct is 0.858, denoting that the Design construct accounts for 85.8% of its variance [16,46]. The AVE values of the Functional, Managerial, Resource, Sustainability, and Technology constructs are reported as 0.784, 0.752, 0.822, 0.832, and 0.834, respectively. The off-diagonal elements denote the interrelationships among the constructs. The findings indicate that the inter-construct correlations are comparatively lower than the AVE values, thereby providing evidence for discriminant validity. As an illustration, the correlation coefficient between the Design and Managerial constructs is 0.174.

Table 6.

Fornell Larker criteria results.

Moreover, the AVE value for design is 0.858, which suggests the presence of discriminant validity [11,22]. To summarize, the outcomes of the Fornell-Larcker criteria validate the distinctiveness of the constructs. The findings suggest that the constructs exhibit a greater correlation with themselves than with other constructs, implying that they are discrete and evaluate diverse facets of sustainable construction management’s industry 4.0 digitization practices. The aforementioned discoveries prove that the constructs encompassed within the model are distinct and augment the comprehensive comprehension of the research subject.

The outcomes of the Hetrotrait-Monotrait (HTMT) ratio are displayed in Table 7. This ratio is employed to evaluate discriminant validity by contrasting the intensity of associations among various constructs with the associations within the same construct. The values presented in the table denote the HTMT ratios. The HTMT ratios are utilized to assess the degree to which the inter-construct correlations are less than the intra-construct correlations. A lower value of the HTMT ratio indicates a higher level of discriminant validity. The table displays the HTMT ratios for the various pairs of constructs. The HTMT ratio of the relationship between Design and Functional constructs is 0.124. The value denotes that the correlation between Design and Functional constructs is equal to 0.124 multiplied by the square root of the Average Variance Extracted (AVE) of the Design construct. Likewise, the HTMT ratios of other pairs of constructs are also furnished. In general, the HTMT ratios presented in Table 7 indicate a comparatively low level, implying that the associations among diverse constructs are less than those within the same construct [12,16]. This finding provides evidence for the distinctiveness of the constructs included in the model. As mentioned earlier, the statement suggests that the constructs are discrete and evaluate diverse facets of industry 4.0 digitization practices concerning sustainable construction management. To summarize, the HTMT statistics offer additional support for the concept of discriminant validity, which suggests that the constructs within the model are distinct and make separate contributions to the comprehension of the research subject.

Table 7.

HTMT statistics.

Table 8 presents the cross-loadings of the variables in the model. Cross-loadings refer to the intercorrelations between individual variables and their respective constructs and their correlations with other constructs. Variable S2 exhibits a robust correlation with the Design construct, as evidenced by its highest loading of 0.897. The construct exhibits slight positive associations with the Managerial (0.188) and resource (0.135) constructs while displaying moderate positive associations with the Sustainability (0.193) and Technology (0.326) constructs. Likewise, diverse variables display distinct levels of correlation with their corresponding constructs and some degree of correlation with other constructs. Variable S15 strongly associates with the Technology construct, as indicated by its highest loading of 0.893.

Table 8.

Cross loadings.

Additionally, it demonstrates moderate positive correlations with the design (0.342), Functional (0.308), Managerial (0.379), and Sustainability (0.35) constructs. The cross-loadings offer valuable insights into the interrelationships among the constructs and variables within the model. The indicators demonstrate the degree to which a given variable contributes to its designated construct and the possibility of its intersection with other constructs. By analyzing cross-loadings, scholars can evaluate the convergent validity of the measurement model [11,47]. The findings in Table 8 indicate that intricate connections exist among the variables and constructs in the model for sustainable construction management success factors in the context of Industry 4.0 digitization.

4.2.2. Structure Path Analysis

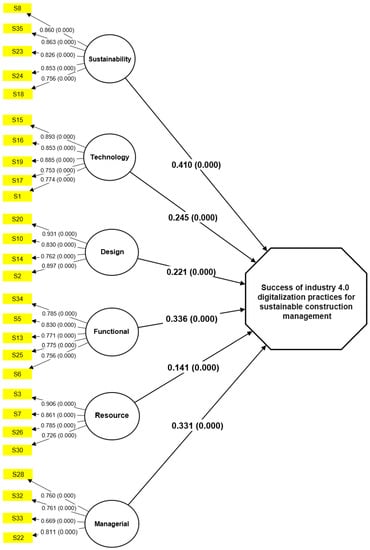

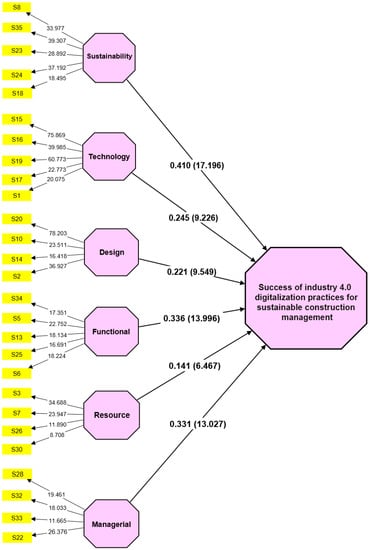

Table 9 presents the results of the path analysis, wherein the interrelationships among various constructs and the efficacy of Industry 4.0 digitalization practices in promoting sustainable construction management are investigated. The β coefficients denote the associations’ magnitude and orientation, whereas the SEs furnish insights into the accuracy of the approximations. Figure 5 displays the path coefficients and their corresponding significance in the model, whereas Figure 6 depicts the model with path coefficients and t-statistic values. The findings indicate noteworthy affirmative associations between every construct and the triumph of industry 4.0 digitalization practices [18,66]. The construct of design exhibits a path coefficient of 0.221 (p < 0.001), signifying a statistically significant influence on the outcome of success. The study findings indicate that the Functional construct exhibits a more robust association with a path coefficient of 0.336 (p < 0.001), while the Managerial construct closely follows with a path coefficient of 0.331 (p < 0.001). The impact of the Resource construct is statistically significant, as evidenced by its path coefficient of 0.141 (p < 0.001). The study reveals a significant correlation between the construct of sustainability and the efficacy of industry 4.0 digitalization practices, as evidenced by a path coefficient of 0.410 (p < 0.001). The statement implies that sustainability factors hold significant importance in ascertaining the efficacy of digitalization practices within the construction sector. In addition, the technology construct exhibits a substantial favorable influence, as evidenced by a path coefficient of 0.245 (p < 0.001). This underscores the significance of technological progress and its incorporation into construction procedures to attain triumph in the digitization of Industry 4.0 [12,22]. The statistical significance of all path coefficients suggests that each construct significantly impacts the success of digitalization practices for sustainable construction management in the context of Industry 4.0. Based on the VIF values, it can be inferred that the analysis is unaffected by multicollinearity since all VIF values are less than 5, indicating a minimal degree of multicollinearity among the predictor variables. The findings of the path analysis validate the importance of several constructs, namely Design, Functional, Managerial, Resource, Sustainability, and Technology, in facilitating the effectiveness of industry 4.0 digitalization practices for sustainable construction management. The aforementioned discoveries offer significant perspectives for professionals in the industry and policymakers to improve their digitalization approaches and encourage sustainability in the construction domain.

Table 9.

Path analysis results.

Figure 5.

Path coefficients and statistical significance of model.

Figure 6.

Model path coefficients and t-stat.

The outcomes of the predictive relevance analysis for the model are displayed in Table 10. The SSO, representing the sum of squares for the outcome, has been computed to be 14,980.000, whereas the SSE, which denotes the sum of squares for the error, has been determined to be 12,964.915. The model’s predictive significance, as denoted by Q2, is established through the computation of the ratio of SSO to SSE subtracted from 1. The Q2 value of 0.135 suggests that the model exhibits a predictive relevance of 13.5%. The aforementioned statement implies that the model exhibits a moderate predictive capability in elucidating the efficacy of industry 4.0 digitalization practices for sustainable construction management [16,22].

Table 10.

Prediction relativity of model.

4.2.3. Model Validation

The validation outcomes derived from the feedback of a sample of 12 participants are displayed in Table 11. Participants were instructed to assess their level of agreement or perception on a five-point scale to the five questions of the success factors identified and the applicability of the industry 4.0 digitization success factors model within the framework of sustainable construction management. The mean values represent the arithmetic average of the ratings provided by the participants. According to the findings presented in question 1, the mean score of 4.42 indicates a consensus among the respondents regarding the importance of the identified constructs in facilitating the successful implementation of industry 4.0 digitization practices for sustainable construction management [34,48]. The results indicate that Question 2 obtained a mean score of 3.8, suggesting that the participants acknowledged the significance of prioritizing the identified success factors. However, there were certain discrepancies in their perceptions.

Table 11.

Validation results.

Regarding question 3, the computed average score of 4.0 suggests that the respondents held the view that the success factors associated with the adoption of industry 4.0 digitalization practices were generally acceptable [18,37]. The data indicates that Question 4 garnered an average score of 4.2, indicating that the participants believed that additional success factors might exist that ought to be incorporated into the industry 4.0 digitization success factors model. The industry 4.0 digitization success factors model was assessed in question 5, and the respondents assigned a high rating to its relevance and applicability, as evidenced by a mean score of 4.8. In general, the feedback provided by the participants suggests a favorable outlook toward the success factors identified and the model for industry 4.0 digitization success factors [9,11]. Nevertheless, certain discrepancies were observed in their evaluations, underscoring the necessity for additional investigation and enhancement of the framework to encompass a holistic comprehension of the determinants that impact the productive execution of industry 4.0 digitalization methodologies within sustainable construction administration.

5. Discussion

Sustainability constructs include S8, S35, S23, S24, and S18. The hypothesis, “H1: Sustainability-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management”, is fully validated. The study has identified that the integration of sustainability constructs such as enhanced material estimation and design optimization, augmented utilization of eco-friendly materials and techniques, real-time monitoring of site conditions, environmental factor monitoring, and improved risk management has a favorable impact on the efficacy of Industry 4.0 digitalization practices for sustainable construction management. The aforementioned discovery corroborates the supposition that achieving sustainability-related achievements results from implementing Industry 4.0 digitalization methodologies. This study’s distinctive feature lies in its emphasis on the contribution of Industry 4.0 technologies toward fostering sustainability within the construction sector. Prior research has acknowledged the significance of sustainability within the realm of construction. However, the amalgamation of Industry 4.0 digitalization methodologies to attain sustainability objectives is a relatively new concept [12,47]. This research contributes to the existing academic discourse by highlighting the significance of incorporating Industry 4.0 technologies in the context of sustainable construction management. The research showcases the capacity of contemporaneous monitoring, optimization of design, and management of risks to attain sustainability goals.

The technology construct includes S15, S16, S19, S1, and S17. The hypothesis, “H2: Technology-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management”, is fully validated. The present investigation incorporates a technology construct that comprises diverse components, including but not limited to real-time monitoring, energy efficiency, project visibility, data analytics, and resource management. These elements collectively contribute to the triumph of Industry 4.0 digitalization practices for sustainable construction management. As mentioned earlier, the hypothesis’s validation elucidates the affirmative correlation between triumph in technology and the assimilation of Industry 4.0 methodologies. The aforementioned discoveries expand on prior investigations by underscoring the significance of distinct technological components in attaining sustainability objectives within the construction sector [16,22]. Prior research has recognized the significance of technology in construction management. However, this study offers distinctive perspectives by establishing a direct correlation between triumphs related to technology and the execution of Industry 4.0 digitalization methodologies. The utilization of Industry 4.0 technologies, which include real-time monitoring, energy reduction, enhanced project visibility, data analytics, and resource management, has the potential to facilitate sustainable construction management.

The design construct includes S20, S10, S14, and S2. The hypothesis, “H3: Design-related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management”, is fully validated. This study emphasizes the significance of Industry 4.0 digitalization practices in attaining design-related triumph for sustainable construction management. The hypothesis that has been validated suggests that there exists a positive correlation between the success of design-related activities and the adoption of Industry 4.0 technologies. The study adds to the extant literature by focusing on the influence of design-related variables on the efficacy of Industry 4.0 digitalization initiatives within the construction sector. Prior research has recognized the importance of design in sustainable construction. However, this study offers a distinct viewpoint by establishing a direct correlation between achieving design-related objectives and implementing Industry 4.0 technologies [9,46]. Industry 4.0 practices, such as data precision, environmental impact reduction, prefabrication and modular construction techniques, and additive manufacturing, can improve design outcomes and facilitate sustainable construction management.

The functional construct includes S34, S13, S5, S6, and S25. The hypothesis, “H4: Functionally related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management”, is fully validated. The study emphasizes the functional construct and its favorable implications for sustainable construction management and Industry 4.0 digitalization practices. The hypothesis that has been validated suggests that the adoption of Industry 4.0 technologies has a positive impact on functional-related success. The study adds to the extant body of literature by investigating the effects of Industry 4.0 digitalization practices on the functional aspects of the construction sector. Prior research has acknowledged the significance of functional considerations in sustainable construction. However, this investigation provides a distinctive viewpoint by establishing a direct correlation between success in functional-related aspects and implementing Industry 4.0 technologies. Implementing Industry 4.0 practices in construction management has demonstrated the potential for improved functional outcomes and sustainable practices [11,22]. This is evidenced by the increased emphasis on enhanced building operation and maintenance, the proliferation of green building certification programs, the adoption of augmented and virtual reality for design and visualization, the use of digital instruments and automation for quality control, and the implementation of predictive maintenance for reduced maintenance costs.

Resource constructs include S3, S7, and S26. The hypothesis, “H5: Resource related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management”, is fully validated. This study investigates the effects of Industry 4.0 digitalization practices on resource-related aspects of sustainable construction management through the lens of the resource construct. The aim is to identify the potential positive outcomes of such practices. The hypothesis that has been validated asserts that the adoption of Industry 4.0 technologies has a positive impact on the success of resources. The aforementioned discovery adds to the current pool of knowledge by underscoring the significance of Industry 4.0 methodologies in enhancing the efficiency of resource allocation and administration within the construction sector. Prior research has recognized the significance of effective resource management in achieving sustainable construction. However, this study presents a distinctive viewpoint by directly correlating successful resource utilization and adopting Industry 4.0 digitalization techniques. Using Industry 4.0 technologies in construction projects can optimize resource efficiency and enhance sustainability [2,63]. This is demonstrated through implementing digital supply chain management for cost reduction, using renewable energy sources, and emphasizing reducing mistakes and redoing labor. Incorporating Industry 4.0 practices can aid in attaining sustainable construction management objectives by addressing pertinent resource-related factors.

The managerial construct includes S28, S32, S22, and S33. The hypothesis, “H6: Managerial related success is the positive outcome of Industry 4.0 digitalization practices for sustainable construction management”, is fully validated. This study explores the managerial construct and its correlation with positive outcomes from implementing Industry 4.0 digitalization practices in sustainable construction management. The hypothesis that has been validated affirms that the adoption of Industry 4.0 technologies has a positive impact on the success of managerial activities. The study adds to the extant body of literature by underscoring the importance of Industry 4.0 practices in augmenting project management efficacy, output, cooperation, and supply chain management in the construction sector. Prior research has acknowledged the significance of professional project management and cooperation in accomplishing triumphant construction projects. However, this study presents an exceptional viewpoint by establishing a direct correlation between these managerial aspects and the execution of Industry 4.0 digitalization methodologies [24,38]. The utilization of Industry 4.0 technologies has the potential to optimize managerial processes and improve sustainable construction management through a focus on project management and construction process efficiency, increased productivity, enhanced collaboration, and augmented supply chain management. By considering managerial-related factors, implementing Industry 4.0 practices can enhance project outcomes and promote sustainability objectives within the construction sector.

5.1. Empirical and Theoretical Contributions

The present study presents novel contributions to the field of sustainable construction management and the adoption of Industry 4.0 digitalization strategies, both in practical and theoretical terms. The study presents empirical evidence supporting the beneficial effects of Industry 4.0 digitalization practices on various constructs associated with sustainable construction management from an empirical perspective. Through statistical analysis and hypothesis validation, the study affirms that various factors such as design, functionality, management, resources, sustainability, and the success of Industry 4.0 digitalization practices are significantly influenced by the impact of technology. The aforementioned empirical findings enhance comprehension of the functions of said constructs in attaining objectives pertaining to sustainable construction management. The research also adds to the theoretical framework in the respective field of study. This study expands upon current theoretical frameworks by establishing a connection between Industry 4.0 digitalization practices and pertinent constructs of sustainable construction management. The integration in question offers a thorough comprehension of how Industry 4.0 technologies can benefit various facets of sustainable construction, including but not limited to design optimization, resource management, managerial efficiency, and technological advancements. The results corroborate the theoretical underpinnings of the research and provide valuable perspectives on the fundamental mechanisms and connections between Industry 4.0 practices and sustainable construction management outcomes.

Additionally, the study’s distinct emphasis on the construction sector within a particular setting, such as the construction industry in China, contributes to the existing literature by offering context-specific perspectives. The aforementioned facilitates scholarly investigators and professionals to comprehend the feasibility and significance of Industry 4.0 methodologies in the enduring administration of construction undertakings in China. The empirical and theoretical contributions of this study serve to augment our understanding of the potential benefits and drawbacks associated with Industry 4.0 digitalization practices in the context of sustainable construction management. The results offer significant perspectives for scholars, professionals, and decision-makers who aim to exploit Industry 4.0 innovations to augment sustainability and efficacy in the construction sector.

5.2. Managerial Suggestions

Based on the findings of the investigation, a number of managerial suggestions can be put forward to optimize the implementation of Industry 4.0 digitalization tactics within the realm of sustainable construction management. Facilitate collaboration and communication among project stakeholders by leveraging digital tools and platforms. The implementation of this approach has the potential to enhance the efficiency of project management, facilitate the exchange of knowledge, and promote coordination among various stakeholders. Promote a culture of innovation by fostering the adoption of innovative digital technologies and practices within the organization. Encourage a cultural shift that prioritizes ongoing education and experimentation with emerging technologies to enhance efficiency, productivity, and sustainability in construction endeavors. To improve supply chain management, it is recommended to utilize digital practices for managing the supply chain. This can aid in optimizing procurement processes, reducing shipping and delivery expenses, and guaranteeing the timely availability of materials. The adoption of this methodology possesses the capability to augment resource effectiveness and foster ecological stability in the milieu of building ventures. It is advisable to give precedence to the well-being of laborers by integrating instantaneous surveillance mechanisms and advancements in construction zones. This measure will help ensure the safety of workers. Implementing wearable devices, IoT sensors, and data analytics can facilitate the identification of potential hazards, enhance safety protocols, and alleviate risks. By implementing managerial recommendations, construction companies can efficiently utilize Industry 4.0 digitalization strategies to attain sustainable objectives in construction management. The optimization of efficiency and productivity in construction projects not only yields benefits for the success of the project but also for environmental sustainability.

6. Conclusions

The study examined the favorable consequences of Industry 4.0 digitalization strategies on sustainable construction management. The investigation substantiated the conjectures by scrutinizing diverse constructs such as sustainability, technology, design, functionality, resource, and managerial aspects. It furnished significant insight into the interconnections among these constructs and the triumph of Industry 4.0 digitalization practices within the milieu of sustainable construction management. The results obtained from this investigation make a valuable contribution to the subject’s practical and conceptual understanding. The study provides empirical evidence that Industry 4.0 digitalization practices positively impact sustainability, technology utilization, design optimization, functional improvements, resource management, and managerial efficiency. There is significant consistency among the prior research and this study, while considering the domain and furnishing additional substantiation of the advantages linked to the adoption of Industry 4.0 methodologies within the construction sector.

The study enhances our comprehension of the distinct factors and constructs that play a role in the triumph of Industry 4.0 digitalization practices within the framework of sustainable construction management from a theoretical perspective. The text underscores the significance of sustainability, technology, design, functionality, resource management, and interrelatedness in attaining favorable results. Recognizing and verifying these concepts plays a crucial role in formulating a comprehensive structure for the effective execution of Industry 4.0 methodologies within the construction sector. Nevertheless, it is imperative to recognize the constraints of this research, which entail the concentration on the construction sector in China and the utilization of self-reported information. Subsequent investigations should tackle the aforementioned constraints and examine the relevance of the results in diverse settings while utilizing unbiased data-gathering techniques.

This study offers significant insights for professionals and decision-makers in the construction sector, emphasizing the significance of incorporating Industry 4.0 digitalization techniques to ensure sustainable construction management. By implementing suitable strategies and prioritizing the identified constructs, organizations can augment their sustainability performance, technological competencies, design efficacy, functional efficiency, resource allocation, and managerial proficiency. This can result in an overall enhancement of project success and long-term sustainability in the construction industry.

It is imperative to acknowledge certain constraints associated with the study. The study is centered on the construction industry in China, which may constrain the extent to which the results can be applied to other settings. The study is subject to potential response bias and limited objectivity due to using self-reported data from a particular sample. Potential avenues for further investigation involve cross-cultural examinations to authenticate the results in varying environments and utilizing a range of data collection techniques to ensure a more exhaustive and impartial analysis. Furthermore, it is recommended that longitudinal studies be carried out to investigate the enduring consequences of incorporating Industry 4.0 practices in sustainable construction management and to evaluate their sustainability implications over an extended period.

Author Contributions

Conceptualization, M.S. and A.H.; methodology, A.H.; software, A.W.; validation, I.I.F.; formal analysis, S.H.A.; investigation, A.S.B.; resources, A.M.A.; data curation, M.S.; writing—original draft preparation, M.S. and A.W.; writing—review and editing, A.H. and I.I.F.; visualization, A.M.A.; supervision, A.H.; project administration, A.H.; funding acquisition, S.H.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Deanship of Scientific Research at King Khalid University (KKU) through the Research Group Program under the grant code RGP2/551/44.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University (KKU) for funding this work through the Research Group Program Under the grant code RGP2/551/44.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

| Survey Questionnaire | ||||||

| Part 1—Demographics | ||||||

| QA: What is your age group? | ||||||

| ||||||

| QB: What is your level of education? | ||||||

| ||||||

| QC: What is your profession? | ||||||

| ||||||

| Part 2—Main Questions | ||||||

| Sr. # | Success Factors | Strongly Disagree (1) | Disagree (2) | Neutral (3) | Agree (4) | Strongly Agree (5) |

| 1 | Enhanced utilization of data analytics in decision-making. | |||||

| 2 | Utilization of 3D printing and other additive manufacturing techniques at a higher rate. | |||||

| 3 | Reduced mistakes and redid labor. | |||||

| 4 | Increase the recycling process in construction. | |||||

| 5 | The utilization of augmented and virtual reality for design and visualization will increase. | |||||

| 6 | Enhanced quality control using digital instruments and automation. | |||||

| 7 | Utilization of more renewable energy sources. | |||||

| 8 | Through improved material estimation and design optimization, waste will be reduced. | |||||

| 9 | Artificial intelligence and machine learning are utilized at a higher rate for predictive maintenance. | |||||

| 10 | Reduce the environmental impact of construction initiatives. | |||||

| 11 | Increased utilization of autonomous vehicles for logistics on construction sites. | |||||

| 12 | Using drones and other crewless aircraft for surveillance and surveys will increase. | |||||

| 13 | A rise in the prevalence of green building certification programs. | |||||

| 14 | Utilization of more prefabricated and modular construction techniques. | |||||

| 15 | Real-time monitoring of construction sites increases safety. | |||||

| 16 | Reduced energy consumption via the Internet of Things devices and intelligent building technologies. | |||||

| 17 | Enhanced resource management via digital instruments and automation. | |||||

| 18 | Enhanced risk management through surveillance and analysis in real-time. | |||||

| 19 | Enhanced project visibility and openness. | |||||

| 20 | Increased data precision and quality. | |||||

| 21 | Enhanced site design and logistical planning. | |||||

| 22 | Enhanced collaboration and communication between project participants. | |||||

| 23 | Real-time monitoring of site conditions has increased worker safety. | |||||

| 24 | Monitoring environmental factors in real-time to ensure sustainability. | |||||

| 25 | Reduced maintenance costs through predictive maintenance, which improved sustainability reporting and accountability. | |||||

| 26 | Digital supply chain management decreases shipping and delivery costs. | |||||

| 27 | Increased construction industry adoption of circular economy principles. | |||||

| 28 | Enhanced project management and construction process efficiency. | |||||

| 29 | Use of blockchain technology to increase supply chain security and transparency. | |||||

| 30 | There were fewer project delays and cost overruns. | |||||

| 31 | Using digital waste management systems to reduce construction waste. | |||||

| 32 | Increased productivity and expedited project completion. | |||||

| 33 | Augmentation of supply chain management. | |||||

| 34 | Enhanced building operation and maintenance. | |||||

| 35 | Increased use of eco-friendly building materials and techniques. | |||||

| 36 | Enhanced water management via the Internet of Things sensors and intelligent irrigation systems. | |||||

References

- Zabidin, N.S.; Belayutham, S.; Ibrahim, K.I. A bibliometric and scientometric mapping of Industry 4.0 in construction. J. Inf. Technol. Constr. 2020, 25, 287–307. [Google Scholar] [CrossRef]

- Ahlam, B.Q.A.; Rahim, Z.A. A Review of Risks for Bim Adoption in Malaysia Construction Industries: Multi Case Study. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 012037. [Google Scholar] [CrossRef]

- Sangaran, G.; Selvanayagam, G. A Review of the Current Hotel Industry Situation in Malaysia. J. Tour. Hosp. Culin. Arts 2021, 13, 9–20. [Google Scholar]

- Suferi, N.S.M.; Rahman, M.M. Adopting Industry 4.0 in Construction Industry. Int. J. Integr. Eng. 2021, 13, 27–33. [Google Scholar] [CrossRef]

- Mokhtar, M.A.; Noordin, N. An exploratory study of industry 4.0 in Malaysia: A case study of higher education institution in Malaysia. Indones. J. Electr. Eng. Comput. Sci. 2019, 16, 978–987. [Google Scholar] [CrossRef]

- Karim, M.A.; Abdullah, M.Z.; Deifalla, A.F.; Azab, M.; Waqar, A. An assessment of the processing parameters and application of fibre-reinforced polymers (FRPs) in the petroleum and natural gas industries: A review. Results Eng. 2023, 18, 101091. [Google Scholar] [CrossRef]

- Rodzalan, S.A.; Noor, N.N.M.; Saat, M.M.; Abdullah, N.H.; Singh, H.; Emran, N.M. An Investigation of Present and Future Work Skills in Industry 4.0: Systematic Literature Review. J. Adv. Res. Appl. Sci. Eng. Technol. 2022, 28, 356–371. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Shafiq, N.; Mansoor, M.S. Applications of AI in oil and gas projects towards sustainable development: A systematic literature review. Artif. Intell. Rev. 2023. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Yi, L.Y.; Abdul Azim, A.; Halis, R.; Liat, L.C.; Khoo, A.; Daud, M.M.M.; Senin, A.L.; Ab Latib, H.; Bueno, M.V.; et al. Assessing the awareness and readiness of the Malaysian furniture industry for Industry 4.0. BioResources 2020, 15, 4866–4885. [Google Scholar] [CrossRef]

- Waqar, A.; Khan, M.B.; Shafiq, N.; Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Assessment of Challenges to the Adoption of IOT for the Safety Management of Small Construction Projects in Malaysia: Structural Equation Modeling Approach. Appl. Sci. 2023, 13, 3340. [Google Scholar] [CrossRef]

- Oke, A.; Atofarati, J.; Bello, S. Awareness of 3D Printing for Sustainable Construction in an Emerging Economy. Constr. Econ. Build. 2022, 22, 52–68. [Google Scholar] [CrossRef]

- Perera, S.; Nanayakkara, S.; Rodrigo, M.N.N.; Senaratne, S.; Weinand, R. Blockchain Technology: Is It Hype or Real in the Construction Industry? J. Ind. Inf. Integr. 2020, 17, 100125. [Google Scholar] [CrossRef]

- Waqar, A.; Qureshi, A.H.; Alaloul, W.S. Barriers to Building Information Modeling (BIM) Deployment in Small Construction Projects: Malaysian Construction Industry. Sustainability 2023, 15, 2477. [Google Scholar] [CrossRef]

- Khan, M.B.; Waqar, A.; Bheel, N.; Shafiq, N.; Sor, N.H.; Radu, D.; Benjeddou, O. Optimization of Fresh and Mechanical Characteristics of Carbon Fiber-Reinforced Concrete Composites Using Response Surface Technique. Buildings 2023, 13, 852. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; González-Lezcano, R.A. Challenges to the Implementation of BIM for the Risk Management of Oil and Gas Construction Projects: Structural Equation Modeling Approach. Sustainability 2023, 15, 8019. [Google Scholar] [CrossRef]

- Piñones, P.; Derpich, I.; Venegas, R. Circular Economy 4.0 Evaluation Model for Urban Road Infrastructure Projects, CIROAD. Sustainability 2023, 15, 3205. [Google Scholar] [CrossRef]

- Schönbeck, P.; Löfsjögård, M.; Ansell, A. Collaboration and knowledge exchange possibilities between industry and construction 4.0 research. Procedia Comput. Sci. 2021, 192, 129–137. [Google Scholar] [CrossRef]

- Nagy, O.; Papp, I.; Szabó, R.Z. Construction 4.0 Organisational Level Challenges and Solutions. Sustainability 2021, 13, 12321. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, D.; Liu, Z.; Osmani, M.; Demian, P. Construction 4.0, Industry 4.0, and Building Information Modeling (BIM) for Sustainable Building Development within the Smart City. Sustainability 2022, 14, 10028. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Shafiq, N.; Altan, H.; Ozarisoy, B. Modeling the Effect of Overcoming the Barriers to Passive Design Implementation on Project Sustainability Building Success: A Structural Equation Modeling Perspective. Sustainability 2023, 15, 8954. [Google Scholar] [CrossRef]

- Waqar, A.; Skrzypkowski, K.; Almujibah, H.; Zagórski, K.; Khan, M.B.; Zagórska, A.; Benjeddou, O. Success of Implementing Cloud Computing for Smart Development in Small Construction Projects. Appl. Sci. 2023, 13, 5713. [Google Scholar] [CrossRef]

- Perrier, N.; Bled, A.; Bourgault, M.; Cousin, N.; Danjou, C.; Pellerin, R.; Roland, T. Construction 4.0: A survey of research trends. J. Inf. Technol. Constr. 2020, 25, 416–437. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Sepasgozar, S.M.E.; Shirowzhan, S.; Niemela, M.; Tripp, A.; Nagabhyrava, S.; Ko, Z.M.K.; Alonso-Marroquin, F. Criteria development for sustainable construction manufacturing in Construction Industry 4.0: Theoretical and Laboratory Investigations. Constr. Innov. 2020, 20, 379–400. [Google Scholar] [CrossRef]