Abstract

The building sector is facing the challenge of transitioning to a more industrialized construction approach and is thus promoting the development of new materials that enable the production of lighter prefabricated products with enhanced thermal performance. This study conducts the physicochemical and mechanical characterization of a new plaster material intended for application in the building sector. The plaster material developed contains potassium polyacrylate and perlite in its composition and has been reinforced with wood, glass and polypropylene fibers to improve its physical and mechanical properties. The results demonstrate that the combined incorporation of potassium polyacrylate and expanded perlite leads to a decrease in density and thermal conductivity by 10.5% and 47%, respectively, compared to traditional plasters. In addition, the incorporation of reinforcement fibers in the plaster matrix, particularly glass fiber, improves the mechanical strength of the new material. The plaster composite developed for this research offers lightweight characteristics and improves the energy efficiency of the construction systems into which it can be integrated and is designed for use in prefabricated panels and plates especially. This progress represents a step towards more efficient industrialized construction.

1. Introduction

Gypsum composites have been widely used since ancient times and have a long tradition in Mediterranean construction [1]. They continue to be extensively utilized today, including in interior finishes, building cladding and interior partitions. The popularity of gypsum composites can be attributed to their abundance, low calcination temperature, favorable physical properties, ease of use and cost-effectiveness [2].

Among the most relevant physical properties of plaster-based materials are their ability to set rapidly, which occurs through an exothermic reaction upon contact with water; their strong adhesion to ceramic surfaces; and their good thermal and acoustic performances [3]. On the other hand, plaster has a higher purity and fineness of grind compared to gypsum, resulting in greater mechanical strength, excellent fire resistance and a great capacity for hygrothermal regulation, making it ideal for use as an interior cladding material [4]. Overall, construction-related activities are responsible for about 36% of global CO2 emissions, making them a key player in the fight against climate change [5]. In the specific case of the European Union, it is estimated that around 40% of total energy consumption is attributed to heating and cooling buildings each year [6]. For this reason, numerous researchers are working on the design of new building solutions to enable the transformation of the existing building stock into a network of nearly zero energy buildings (NZEB) [7]. To this end, it is vitally important to develop new, more sustainable materials that make it possible to reduce the energy demand of buildings while maintaining their habitability and thermal comfort [8].

Another significant challenge in the construction industry is to lighten the weight of prefabricated systems. This aims to reduce on-site construction time, minimize permanent loads on buildings and reduce CO2 emissions associated with material transportation [9]. For this reason, the development of new gypsum composite materials that are lighter and facilitate the execution of suspended ceiling plates and prefabricated panels is essential to move towards more industrialized building systems [10].

Extensive research has been conducted on the incorporation of additions in gypsum composite materials to improve some of their properties. Many studies focus on a reduction in the material’s own weight [11] or the improvement of its thermal properties [12,13]. For instance, W. Luan et al. successfully decreased the density of gypsum composites by incorporating pregelatinized starch, phosphates, dispersant compounds and synthetic fibers for the design of prefabricated panels [11]. Other researchers have aimed to develop new plasters with higher mechanical strength while reducing their thermal conductivity. To this end, M. A. Pedreño-Rojas et al. developed gypsum composites with wood waste for industrialized false ceilings panels [14]. Similarly, Vidales-Barriguete et al. incorporated plastic waste from electrical cables into plaster materials, resulting in reduced density, improved water resistance and enhanced thermal resistivity [15]. Therefore, in line with these investigations, which are committed to the design of new lightweight construction materials with high technical performance, this work has developed a new plaster-based material with additions of perlite, potassium polyacrylate and fibers. This material has been registered at the Spanish Patent and Trademark Office (OEPM) under number ES 2 841 130 B2 [16].

There are several existing studies on construction binders that incorporate superabsorbent polymers [17] or setting retarders in their composition [18]. However, there is a wide variety of polymers that have not yet been studied in detail to improve the properties of these materials. This is the case of the hydrogel known as potassium polyacrylate [19]. Thompson et al. studied the impact of incorporating particles of this superabsorbent polymer in gypsum composites, observing an increase in porosity, leading to decreased thermal conductivity, albeit with a decrease in mechanical properties [20].

A similar effect in increasing thermal resistance is achieved with the incorporation of light fillers from waste polyurethane foam in the design of precast plates and panels [21]. Additionally, the industrial polyurethane foam waste present in the new gypsum composite material is reincorporated following circular economy criteria and contributing to energy savings. Another approach, as demonstrated Álvarez Dorado et al. [4], involves incorporating a mixture of polyvinyl acetate, sodium bicarbonate and a boric acid dissolution to traditional plasters, resulting in reduced thermal conductivity, a 30% density decrease and expanded application possibilities for new prefabricated products. These investigations have led to the incorporation of the polymer potassium polyacrylate in plaster composite materials with the aim of improving their thermal resistance and reducing their density by generating a network of internal micropores.

On the other hand, one of the additions that has been most successfully used in the mixing process of these construction binders is perlite, a glassy volcanic rock capable of increasing its volume between 15 and 20 times its original volume when subjected to high temperatures [22]. It is a material commonly used in construction applications that require greater lightness and good acoustic and thermal properties [23]. This can also be seen in the research carried out by Zagorodnyuk et al., where they demonstrated the excellent technical performance of lightened plaster materials with perlite additions reaching thermal conductivity values between 0.118 and 0.059 W/mK [24]. Taking these properties into account, other researchers have designed new materials with high thermal insulation capacity, using gypsum composites with added perlite to produce fire-resistant interior cladding [25].

Finally, with the intention of improving the mechanical properties of gypsum composites, several investigations have been carried out in recent years to study the effect of incorporating reinforcing fibers into the matrix [26]. In their literature review, Jia et al. observed that, although both synthetic and natural fibers may hinder the workability of gypsum composites, they improve their mechanical properties and durability [27]. In addition, natural fibers with a high pore and moisture content can enhance the fire resistance of a material. There are studies that show that the incorporation of polypropylene fibers improves the flexural strength and thermal insulation of the material in most cases. An example of this is the research by Gencel et al. [28,29] or Flores Medina et al. [30] who observed that the incorporation of polypropylene fibers into gypsum composites produces an increase in the flexural strength and durability of the material. Glass fiber is also a good solution for converting brittle materials into pseudo-ductile ones, as Martias et al. found in their composite material of gypsum, vermiculite and glass fiber [31].

Some researchers focus on combining the improved technical performance of materials with sustainable development. Di Bella et al. compared lime-based plasters reinforced with polypropylene fibers to those reinforced with natural sisal and knal fibers [32]. In their study, they concluded that the improvement in the mechanical strength of the hardened material provided by both fibers was similar. On the other hand, Iucolano et al. [33] evaluated the behavior of gypsum composites with biologically treated hemp fibers. This study shows that the good adhesion between binder and fiber improves the flexural strength of the plaster materials without affecting the workability of the mixtures, making these materials an optimal solution for the interior cladding of the walls and ceilings of buildings. All these studies motivated the incorporation of both synthetic and natural fibers to improve the physical-mechanical properties of the material developed in this research.

The main objective of this research is to characterize a new material based on plaster with the addition of perlite and potassium polyacrylate and reinforcement through polypropylene, glass and wood fibers, with the aim of improving the chemical and physical-mechanical properties of traditional plaster, increasing its thermal resistivity and reducing its density. To this end, an extensive experimental campaign is being carried out in two distinct phases. Initially, a mechanical characterization was carried out using two water/plaster ratios, along with the addition of two quantities of potassium polyacrylate and three quantities of perlite, in order to determine the optimum composition for this new material. A comprehensive characterization (chemical, physical and mechanical) of the best performing dosage was then carried out, analyzing the impact of the incorporation of reinforcement fibers in its matrix to be applied in the manufacture of prefabricated construction products. This research shows the benefits of a new plaster material developed, and the steps taken to obtain its optimum composition are described in detail, so that it can be used by other researchers for the development of new plaster construction elements for prefabricated elements.

2. Materials and Methods

This section presents the materials used in the elaboration of the different gypsum composites used in this research, as well as the experimental program developed.

2.1. Materials

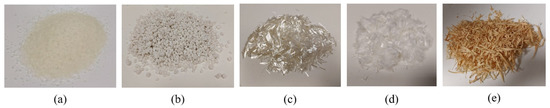

The materials used for the development of this study are plaster, water, potassium polyacrylate, perlite and three types of reinforcement fibers: glass, polypropylene and wood. Figure 1 shows the different additions used.

Figure 1.

Additions used for the elaboration of plaster materials: (a) potassium polyacrylate, (b) expanded perlite, (c) glass fiber, (d) polypropylene fiber and (e) wood fiber.

2.1.1. Binder

The binder used in this study was Iberyola E-35 construction plaster from the commercial brand PLACO Saint-Gobain (Madrid, Spain), as it is a material that is widely used both to produce prefabricated elements and for wall cladding [34]. Plaster is obtained from natural gypsum stone, its chemical formula is CaSO4·2H2O and it is commonly known as gypsum dihydrate (DH). The use of DH in construction follows the following basic reaction scheme:

Gypsum dihyrate (DH) molecules are dehydrated following an endothermic process during kiln firing according to reaction (1), at temperatures close to 105 °C [35], depending on the experimental heating conditions [36]. This predominantly obtains gypsum hemihydrate (HH), CaSO4·1/2H2O, the major component of building plasters, which can have two forms: α and β.

Subsequently, the mixing water added during the laying of the material causes a rehydration of the HH that generates new DH, which is sometimes called rehydrate in order to differentiate it from natural DH. In turn, at around 200 °C, the dehydration of the HH takes place, giving rise to soluble anhydrite (CaSO4) [37]. Finally, the phase change from soluble to insoluble anhydrite takes place, an exothermic transformation without a loss of mass, which, depending on the form of HH, occurs at different temperatures, around 200 °C in HH-α, with greater compactness and resistance (200 °C), or 350 °C in HH-β, with greater solubility and less stability.

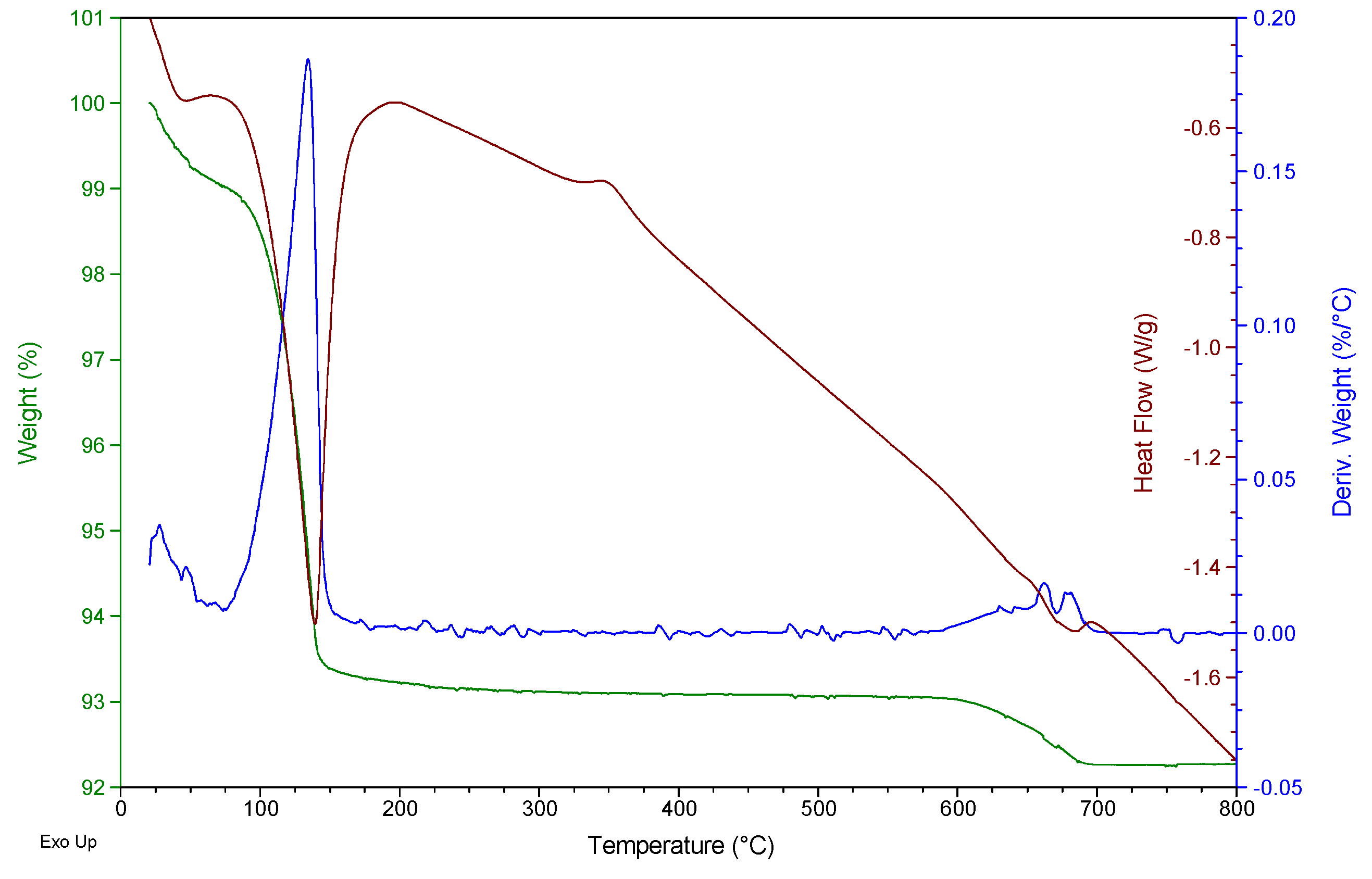

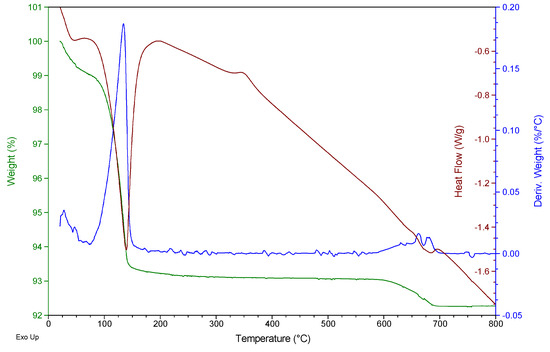

This reaction scheme becomes evident if a thermogravimetric analysis (TGA) is carried out. For this reason, Figure 2 shows the TGA (see equipment and conditions in Section 2.2) conducted for the plaster used as raw material in this research, where the mass losses associated with the different thermal events are shown. Three curves can be observed: the mass loss that occurs as the temperature increases (green), the derivative of this mass loss (blue) and the heat flow associated with this mass loss (maroon), which follow the exothermic event criterion if the peak trends upwards.

Figure 2.

Thermogravimetric analysis of reference plaster E-35.

Figure 2 shows, first of all, that the reference plaster presents a first loss of mass of about 1% below 75 °C due to surface humidity. Then, a mass loss of 5.78% is observed between 75–200 °C, linked to an endothermic event indicated by the heat flow curve, resulting from the dehydration of the hemihydrate, giving rise to soluble anhydrite, with a maximum decomposition rate temperature of 134.6 °C. An exothermic process, with no associated mass loss, is observed at a temperature of 350 °C, due to the change from soluble to insoluble anhydrite [37]. Finally, an endothermic mass loss of 0.8% can be observed between 550 and 750 °C, due to the decomposition of the calcium carbonate CaCO3 present in the plaster.

Lastly, Table 1 summarizes the main characteristics of the E-35 plaster used in this research, which were provided by the manufacturer.

Table 1.

Characteristics of Iberyola E-35 type plaster [36].

2.1.2. Water

The mixing water does not contain any element that affects the physico-mechanical properties of the plaster composites produced. Drinking water from the Canal de Isabel II in the Community of Madrid has been used, which has previously been used in another research [39]. This water has its origins in granitic soil with low salt content [40], and its main characteristics and components are shown in Table 2 [41].

Table 2.

Main characteristics of the water used.

2.1.3. Potassium Polyacrylate

Potassium polyacrylate, (C3H3KO2)n, is a white, odorless, super absorbent polymer [42]. This material, supplied by the company Alquera Ciencia S.L. (Cadiz, Spain), stands out for its capacity to absorb up to 300 times its weight in water. This property is used to reduce the density of the hardened plaster material, since, when it is placed in a stove (40 ± 2 °C) at the age of seven days for a period of 24 h, this free water is released in the form of steam, generating a network of pores inside the material. In addition, this polymer reduces setting times by accelerating the hardening of the material in fresh state and decreasing the thermal conductivity of the plaster once it has dried [43].

2.1.4. Perlite

Expanded perlite is a glassy volcanic rock with rounded particles, containing oxides of silicon, SiO2; aluminum, Al2O3; iron, Fe2O3; titanium, TiO2; calcium, CaO; magnesium, MgO; sodium, Na2O; and potassium, K2O. This compound, in addition to not reacting chemically with the plaster mixture and standing out for its low cost, has low toxicity and thermal conductivity [44].

Expanded perlite can be incorporated into the mixing process of plaster, either crushed or uncrushed, although it is true that in order to facilitate the homogeneous mixing of the components, the grain diameter must be less than or equal to 4 mm [22]. It is used as a lightening filler to reduce the weight of the plaster composites due to its low density (30–150 kg/m3). This raw material was supplied by the company Semillas Batlle S.A. (Talavera de la Reina, Spain).

2.1.5. Fibers

In this study, different types of reinforcement fibers were used, one of natural origin (wood fiber) and two of synthetic origin (glass fiber and polypropylene fiber). The glass fiber used is alkali-resistant and is mainly composed of silicon dioxide (62%), aluminum oxide (13%), calcium oxide (12%) and magnesium oxide (10%) [45]. Polypropylene fiber is characterized by being rot-proof and inert to attack by alkalis, acids in general and fungi and bacteria. Both types of synthetic fibers were supplied by the company SIKA. The natural wood fiber was obtained from sawdust from Scots pine wood and manually cut to a length of 12 mm. It is characterized by its low density and high resistance.

The most relevant properties of the fibers used are shown in Table 3. It can be observed that wood fiber had the lowest density compared to the synthetic fibers, as well as high mechanical resistance comparatively. On the other hand, polypropylene fiber is the most elastic reinforcement material, as it has a much higher elongation to fracture than the other fibers used.

Table 3.

Mechanical properties of the fibers used [46].

2.2. Experimental Program

An extensive experimental campaign consisting of chemical, physical and mechanical characterization tests has been carried out in this study.

Throughout the experiment, the standard UNE-EN 13279-2:2014 construction plasters and gypsum-based binders for construction were used. In the second part of the process, testing methods were used to prepare the mixes [2]. Thus, the plaster was mixed with the perlite and potassium polyacrylate and added to water over 30 s. The mixture was then left to settle for 60 s. After 60 s, it was stirred by hand for 30 s using a figure-of-eight motion. The mixture was left to settle for a further 30 s and was then stirred again by hand for a further 30 s.

First, a first experimental phase was carried out for the preparation and characterization of test specimens using two water/plaster ratios by weight (0.7 and 0.8) to analyze the influence of the additions used in the new material developed in this research. The behavior of the hardened plaster material was evaluated using two different proportions of potassium polyacrylate and three different proportions of perlite for each of the two water/plaster ratios mentioned, where the following properties were determined:

- Bulk density by weight of 4 × 4 × 16 cm plaster test specimens.

- Determination of the mechanical resistance to bending and compression using an IBERTEST servo-hydraulic testing machine and WinTest software, following the recommendations of the UNE-EN 13279-2:2014 standard [2].

Thus, in this first phase, the optimum plaster–sodium polyacrylate–perlite ratio is determined, which allows the best technical performance to be obtained, combining good mechanical capacity and reduced density. Subsequently, in a second phase, a complete characterization of this selected dosage is carried out, incorporating the three types of reinforcement fiber used in the matrix of the developed material. The following experimental campaign was then conducted:

Chemical characterization:

- X-ray diffraction (XRD) using Siemens D5000 equipment. This test was carried out with a sample of previously ground and sieved (0.0125 mm mesh light sieve) material of approximately 50 mg and with a Cu-kα graphite monochromator, obtaining diffractograms for a range of 5° ≤ 2θ ≤ 100° every 0.04° and 4 s per step. The crystalline phases were identified using the International Center for Diffraction Data Powder Diffraction Files database (ICDD PDF).

- Thermogravimetric analysis (TGA) using a TA Instruments SD Q600, together with Universal Analysis 2000 software. This test was performed on a sample of previously ground and sieved (0.0125 mm mesh size sieve) material of approximately 50 mg, raising the sample temperature from approximately 20 °C to 900 °C with increments of 10 °C/min, under an air flow rate of 100 cm3/min.

Physical characterization:

- The determination of the setting time of the plaster mass in the fresh state using a Vicat needle and surface hardness of the 4 × 4 × 16 cm specimens using a shore C hardness tester, according to UNE-EN 13279-2:2014 [2].

- Height reached by the water after the capillary absorption test for the 4 × 4 × 16 cm samples according to UNE-EN 459-2:2011 [47].

- The determination of the coefficient of thermal conductivity via the thermal box method, using four thermocouple sensors and Measure software for specimens of dimensions 24 × 24 × 2 cm, according to UNE-EN 12859:2012 [48].

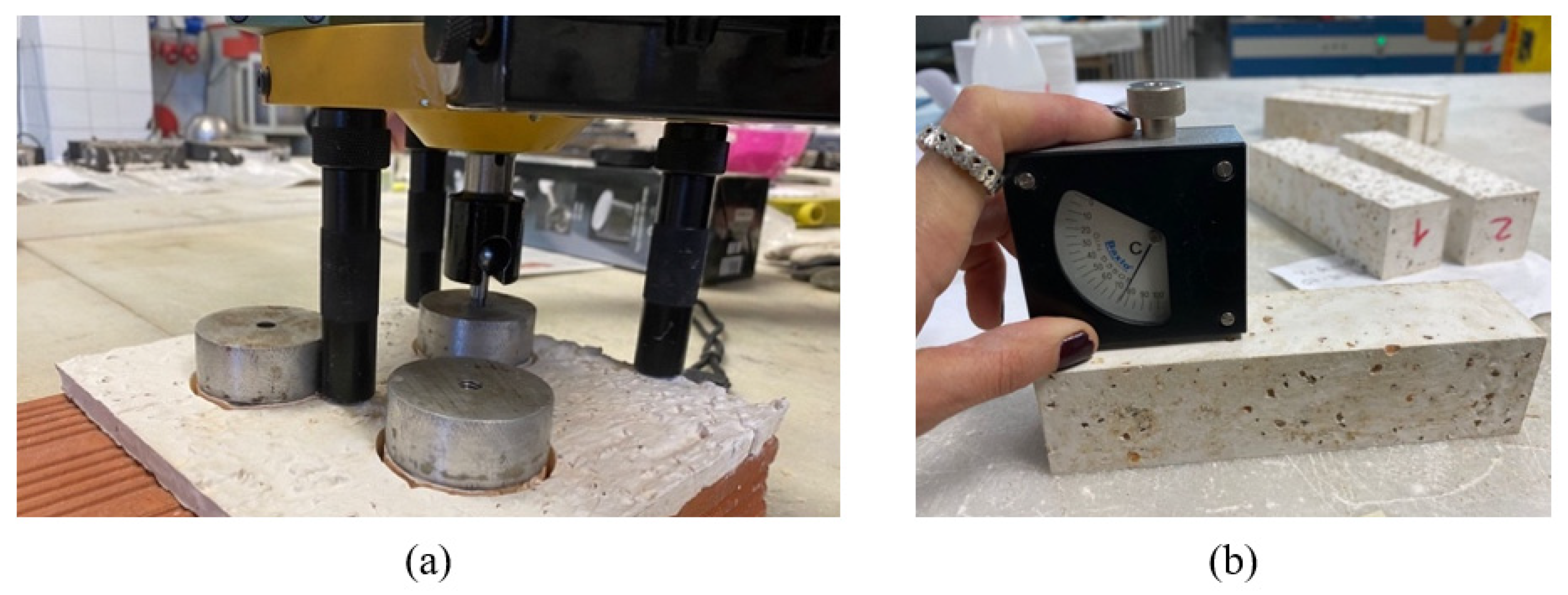

- Adhesion test on ceramic surfaces using a ceramic brick board previously moistened with water and then metal discs of 50 cm diameter glued with epoxy resin and a detachment testing machine, according to UNE-EN 13279-2:2014 [2].

Mechanical characterization:

- The determination of mechanical flexural and compressive strengths using an IBERTEST servo-hydraulic testing machine and WinTest software, following the recommendations of the UNE-EN 13279-2:2014 standard [2].

- The determination of the viability of the above compounds to produce suspended ceiling panels. Samples of dimensions 1.5 × 30 × 40 cm were prepared and tested with the help of a bending machine model Proeti. S.A., following the recommendations of the UNE-EN 13279-2:2014 standard [2].

Structural Characterization [49]:

- Scanning electron microscopy (SEM) using a high-resolution microscope model Nova Nano SEM230 (FEG-SEM) with a resolution of 132 eV. All fragments analyzed were obtained, guaranteeing an unmodified surface texture. The samples were coated with a thin layer of gold using a Cressington 108 metallizer in order to ensure good conductivity to the electron beam generated by the equipment.

It should be noted that all the specimens produced in this research were carried out following the UNE-EN 13279-2:2014 standard, under temperature conditions of 23 ± 2 °C and relative humidity close to 60% for six days, and were then placed in a stove at 40 ± 2 °C for 24 h prior to testing.

3. Results

This section presents the most relevant results obtained for the characterization of the new plaster material developed in this research, with a first phase of preliminary experiments to determine the optimum composition in terms of plaster/water ratio and quantity of potassium polyacrylate and perlite; and a second phase in which different fiber-reinforced dosages are prepared and tested at the previously determined optimum amount. It should be noted that all the samples prepared for each dosage come from the same mix in order to obtain comparable and uniform results.

3.1. First Experimental Phase. Determination of the Water/Plaster Ratio and Proportion of Potassium Polyacrylate and Perlite

To determine the optimum amount of perlite and potassium polyacrylate to design a plaster material with high technical performance, this section includes preliminary tests to obtain the density, flexural strength and compressive strength using different amounts of each addition. In all these preliminary calculations, the following nomenclature is used: EA/E-PaK-P, where E indicates that E-35 plaster has been used, A/E (0.7 or 0.8) indicates the water/plaster ratio by mass used, and PaK refers to the mass of potassium polyacrylate and P refers to the quantity of perlite added. The dosages studied in this preliminary characterization are listed in Table 4.

Table 4.

Dosages of the test specimens of the first experimental phase and their proportions in grams.

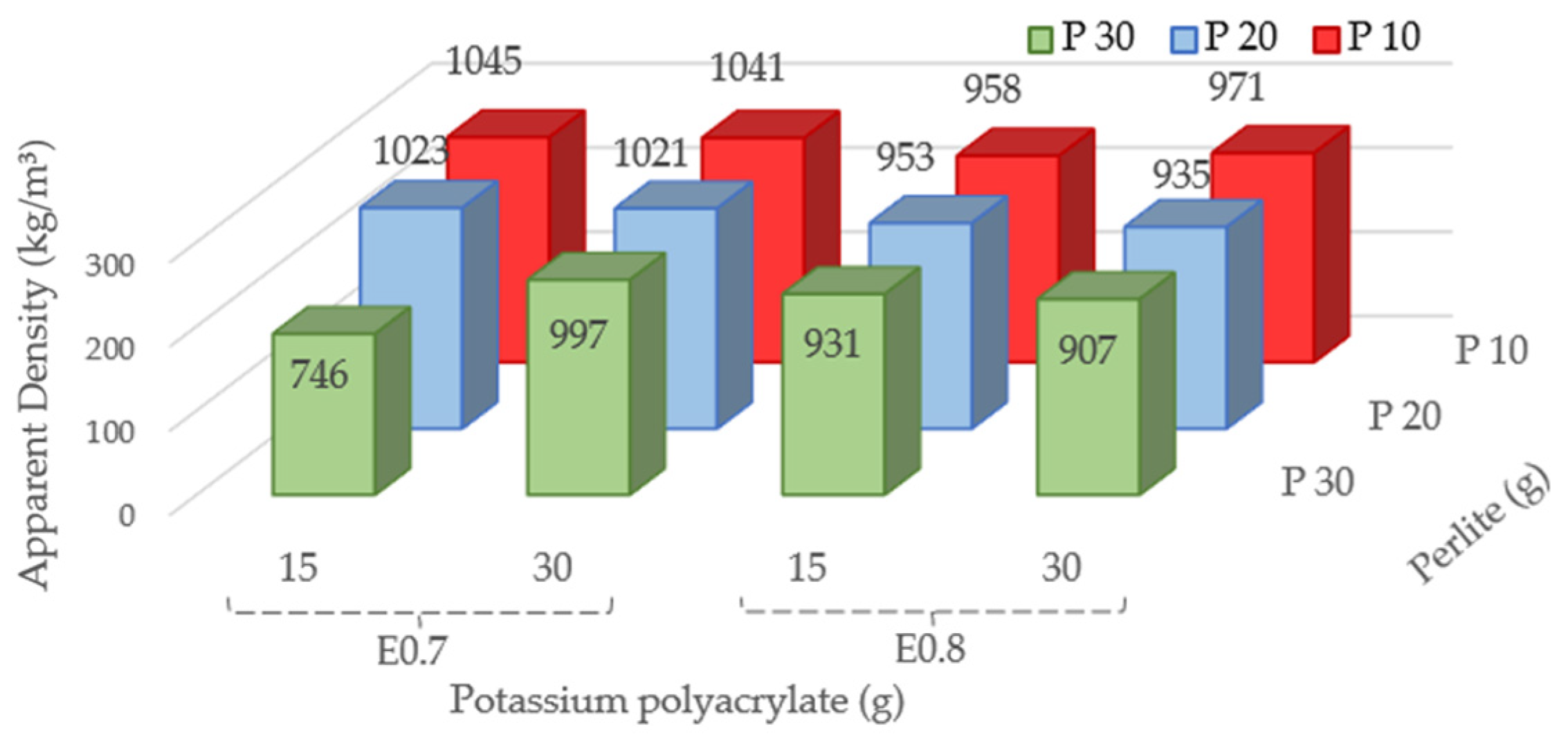

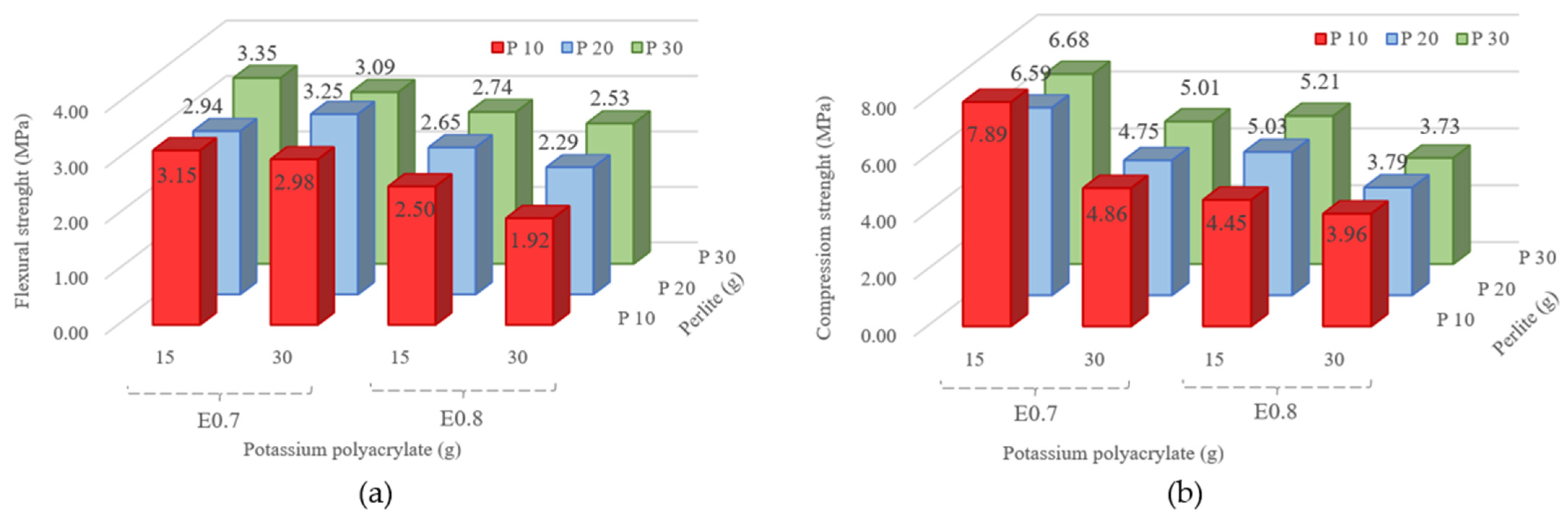

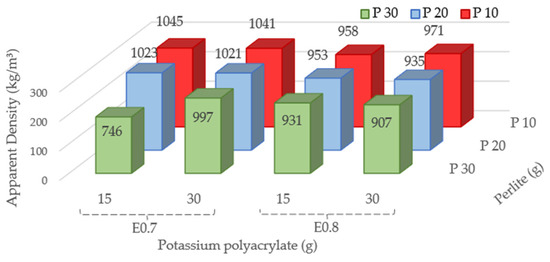

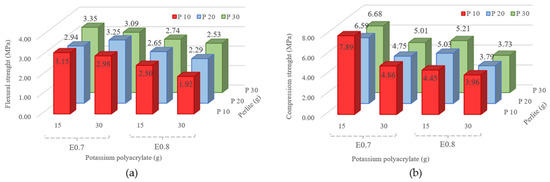

It can be seen in Table 4 that, in all cases, a reference mix has been prepared without additions for each water/plaster ratio used. The pre-characterization tests for the reference plasters without additions are shown in Table 5. On the other hand, the results for the density and mechanical strengths for the different lightened plaster materials are shown in Figure 3 and Figure 4.

Table 5.

Results of reference specimens without additions in their mix.

Figure 3.

Apparent density of the samples studied in the first experimental phase.

Figure 4.

Flexural (a) and compressive (b) strength studied in the first experimental phase.

It can be seen, in the combined analysis of Table 5 and Figure 3, that, in general, the mixes with a water/plaster ratio of 0.7 by weight have higher bulk densities than their counterparts with a ratio of 0.8. However, the best results were obtained for the 0.7 water/plaster mix incorporating 15 g of potassium polyacrylate and 30 g of perlite, reducing the density by about 28.5% with respect to the reference plaster. Nevertheless, in all cases it can be observed that the combined action of the addition of potassium polyacrylate and perlite reduces the density of the plaster composites [20,23].

On the other hand, Figure 4a,b show how in all cases the mixes with a water/plaster ratio of 0.7 by weight had higher flexural and compressive mechanical strengths than the mixes with a ratio of 0.8. In this sense, and in agreement with other studies, a lower water/binder ratio by weight results in a higher flexural and compressive strength of the hardened plaster material [50]. Considering the amount of potassium polyacrylate present in the mixture, Figure 4 shows how the increase in the amount of this addition has an inverse effect on the improvement of the flexural and compressive strength of the material [19]. It should be noted that the incorporation of expanded perlite in the quantities used in this research has a positive effect on the improvement of the flexural strength of the new plaster material developed [12]. However, in general terms and because of the lower density of the plasters produced, the mechanical compressive strength is reduced with the incorporation of these lightening additions [23].

For all these reasons, analyzing the results of density, flexural and compressive strength of the different dosages previously studied, the most appropriate ratio was the one corresponding to the dosage E35-0,7-15-30. This is a material that exceeds the minimum value of flexural and compressive strength required by the UNE-EN 13279-2 standard for plaster materials of 1 MPa and 2 MPa, respectively. At the same time, its low density of 746 kg/m3 favors its application on site and could reduce the execution times of prefabricated products made with this new composite.

3.2. Second Experimental Phase. Characterization Tests of the New Fiber-Reinforced Plaster Material

This section contains the results derived from the characterization of the new fiber-reinforced plaster material designed in this research. Table 6 shows both the nomenclature and the quantities used in each dosage, as well as the setting times of each of the mixes determined by the Vicat needle method, as established in the UNE 13279-2:2014 standard [46]. The proportion of fibers included in each mix corresponds to 1% by weight of plaster for synthetic fibers and 3% by weight of plaster for natural fibers [51].

Table 6.

Final dosage studied.

It is observed that the mixes corresponding to the lightened plaster materials have a slightly lower setting time than that of the reference sample [10]. This is due to the effect caused by the incorporation of potassium polyacrylate in the mixture, which partially acts as a setting accelerator. It should be noted that, in the mixes with the incorporation of reinforcement fibers, these were previously dispersed in the dry plaster before the incorporation of the mixing water to guarantee a homogeneous distribution of the fibers throughout the plaster composite matrix.

3.2.1. Chemical Characterization

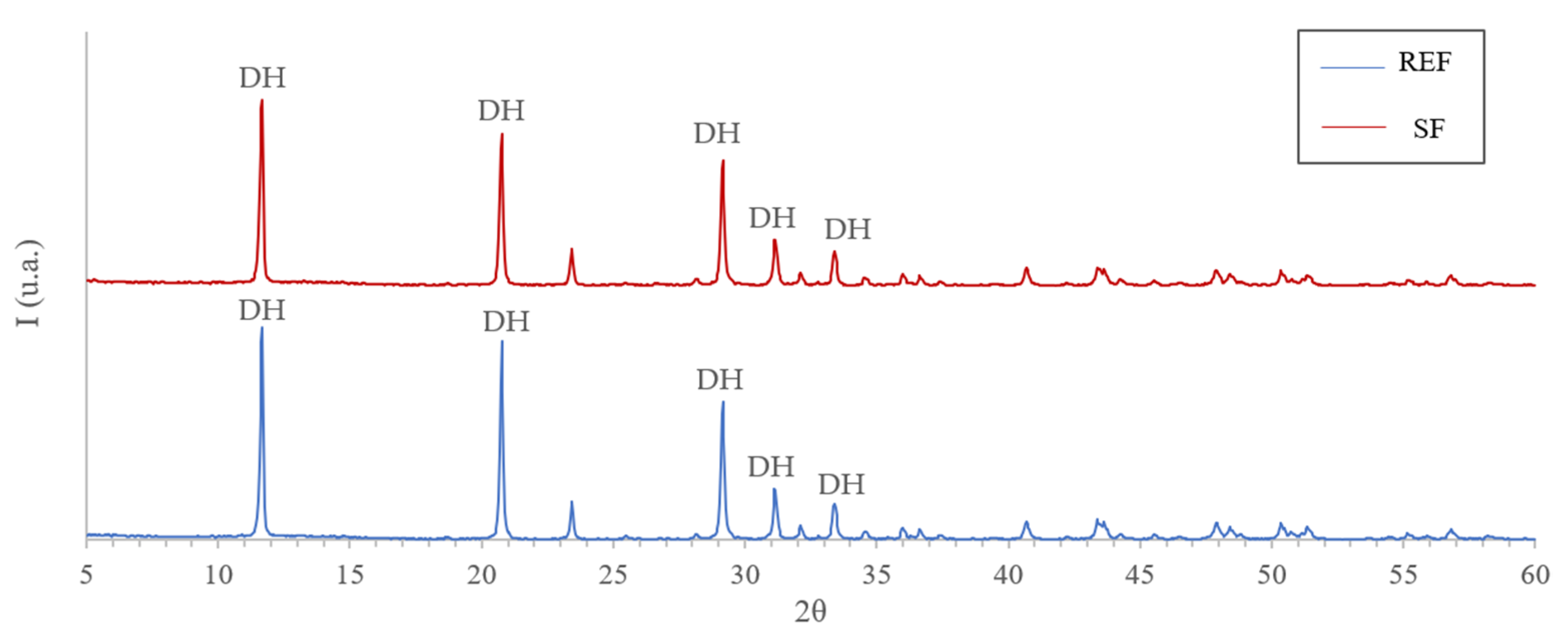

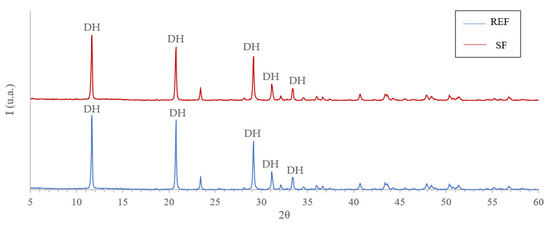

The chemical characterization tests carried out in this phase of the research were X-ray diffraction and thermogravimetric analysis. Figure 5 shows the diffractogram obtained for the reference plaster samples without additives (REF) and the lightened plaster sample without fibers developed in this research (SF).

Figure 5.

X-ray diffractogram of the reference sample compared to the plaster material lightened with potassium polyacrylate and perlite, where DH refers to calcium sulphate dihydrate.

The results obtained show that both the reference sample and the lightened sample present a similar diffractogram with an identical location of the peaks, corresponding to the gypsum dihydrate (DH) and located at 2θ angle values of 11.65°, 20.74°, 23.42°, 29.15°, 31.08° and 33.37°, according to the ICDD PDF database [37].

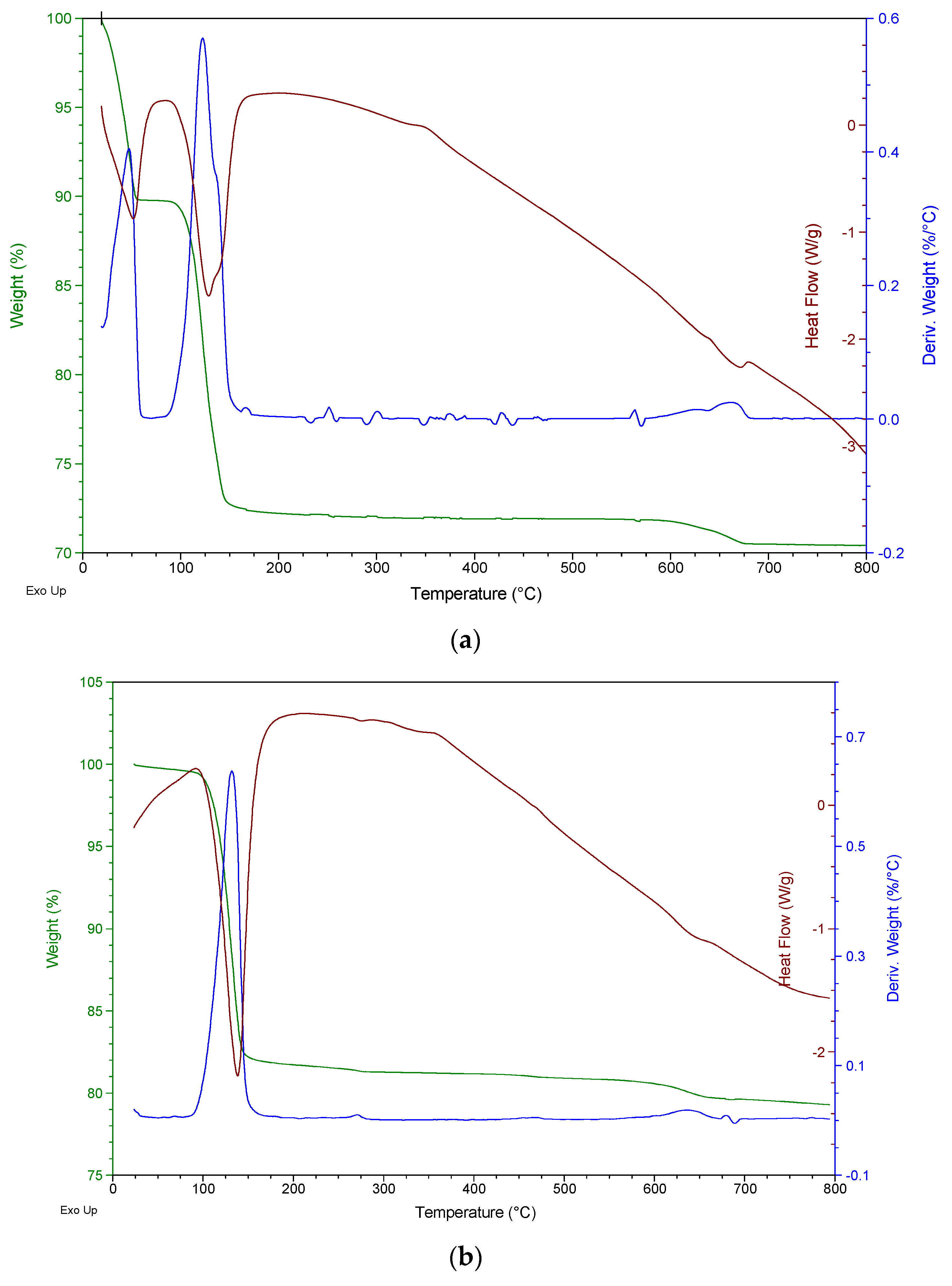

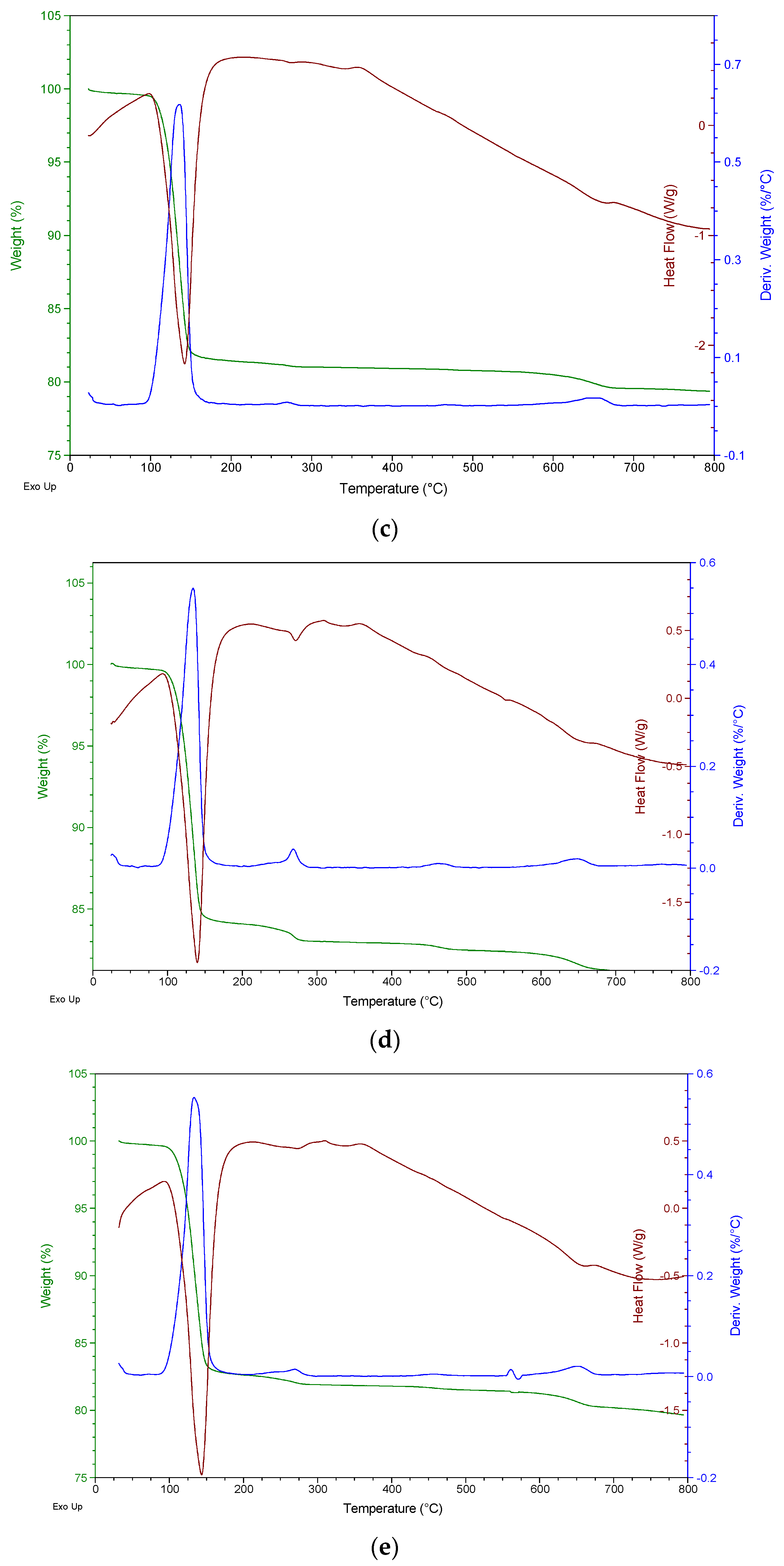

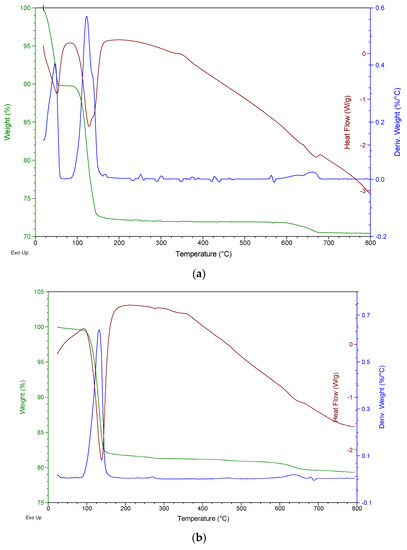

Figure 6 shows the ATG carried out for the different types of plaster analyzed in this section. The same figure shows the mass loss that occurs as the temperature increases (green curve), the derivative of this mass loss versus temperature variation (blue curve) and the heat flow associated with this mass loss (maroon curve) [52].

Figure 6.

(a) Thermogravimetric analysis of sample REF. (b) Thermogravimetric analysis of sample NF. (c) Thermogravimetric analysis of sample GF. (d) Thermogravimetric analysis of sample PF. (e) Thermogravimetric analysis of sample WF.

Figure 6a shows a first mass loss of about 10.2%, which occurs at a temperature below 100 °C, due to the loss of kneading water from the sample (endothermic event). A second mass loss, around 27.6%, is then observed between 100 and 200 °C, corresponding to the sequential dehydration of dihydrate to obtain hemihydrate and of hemihydrate to obtain soluble anhydrite, and this event appears to be a shoulder of the first one in the mass derivative curve with respect to temperature [37]. Then, an exothermic process is observed, without mass loss, corresponding to the transformation of soluble anhydrite to insoluble anhydrite, which shows a maximum at 352.7 °C [45]. Finally, a mass loss of 1.4% can be seen in the range 550–700 °C, reaching the maximum decomposition rate at a temperature of 669.5 °C, due to the endothermic decomposition of the calcium carbonate present in the E35 plaster.

Figure 6b shows thermal events similar to those occurring in the reference sample (REF), although with some differences due to the presence of potassium polyacrylate and perlite. Firstly, endothermic mass loss at temperatures below l00 °C, attributable to the mixing water, barely occurs. Secondly, in the temperature range between 100 and 200 °C, it can be observed that obtaining anhydrite via the decomposition of the hemihydrate is less relevant than in the reference sample, with a total mass loss of about 18.3%. The maximum decomposition rate temperature of the dihydrate is 131.9 °C. Then, in the range between 200 and 300 °C, a mass loss of 0.5% is observed with the maximum mass loss rate at a temperature of 271.2 °C, due to the endothermic oxidative decomposition of the potassium polyacrylate present in the mixture. Next, the exothermic process of transformation from soluble to insoluble anhydrite without associated mass loss is observed between 300 and 400 °C. Finally, an endothermic mass loss of 1.3% can be seen in the range 550–700 °C, with the maximum mass loss rate at a temperature of 638 °C, due to the decomposition of the calcium carbonate in the plaster.

The thermal analysis of the dosage formulation that includes glass fiber (GF) in its mixture presents the same thermal events with mass loss as the one that does not include fibers (NF), that is, those associated with the sequential dehydration of gypsum, the combustion of polyacrylate and the thermal decomposition of carbonate, as well as the phase change of soluble anhydrite to insoluble anhydrite. This is because both glass fiber and perlite are inorganic silicoaluminates and do not undergo thermal decomposition [53]. However, Figure 6d shows all the above thermal events and a mass loss of about 0.5% in the temperature range from 425 to 550 °C, with the rate of maximum loss at a temperature of 464.3 °C. This event is due to the exothermic oxidative decomposition of the polypropylene fiber, which has an organic nature and therefore decomposes with increasing temperature. The thermal analysis of the sample with wood fiber, also of organic nature, shown in Figure 6e, demonstrates the oxidative decomposition of these fibers in the temperature range around 425–550 °C, although in this case, the mass loss is quite small at around 0.3% and the maximum speed of this process is observed in the mass derivative curve with the temperature at 450 °C. It should be noted that the thermal analysis of samples with fibers may not be quantitatively representative of the amount of fibers present in the sample under analysis, since, when grinding and sieving the samples, part of the fibers may have been retained on the sieve.

3.2.2. Physical–Mechanical Characterization

Table 7 shows the results obtained in the physical characterization tests: the bonding strength, surface hardness and bulk density of the samples of the second experimental phase.

Table 7.

Results of the physical characterization of the samples of the second experimental phase.

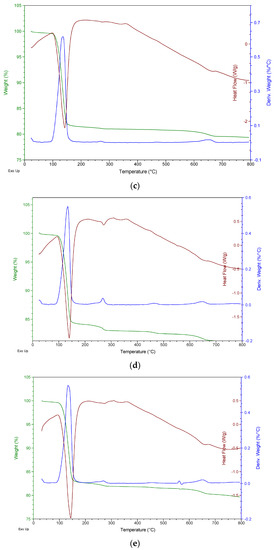

Firstly, it can be seen in Table 7 that there is a decrease in the bonding strength of the plaster on ceramic surfaces in the new material developed. The lightened plaster composites show a lower adhesion than the reference sample. In turn, this adhesion is reduced with the incorporation of reinforcement fibers [54]. The samples with wood fiber additions displayed the worst results for this property. These lower bond strengths show that the best application of this material is in the design of new lightweight prefabricated products for building construction (Figure 7a).

Figure 7.

(a) Bonding strength on ceramic surfaces; (b) shore C surface hardness.

On the other hand, the highest surface hardness was obtained in the lightened plaster composites designed in this research (Figure 7b). It can also be observed that the incorporation of reinforcement fibers does not have a relevant effect on this property [55], with the lightened composites having an average surface hardness of 7.3% higher than that of traditional plaster. As far as bulk density is concerned, the lightest sample is the NF, which decreases its density by almost 18% compared to conventional plaster. This is due to the synergic effects of the incorporated additions, namely, on the one hand, the perlite added as a light load and, on the other hand, the porous network generated as a result of the dehydration of potassium polyacrylate after being previously dried in a stove. For their part, the samples with fiber incorporation show a slightly higher density than that observed for the lightened plaster without fibers (NF).

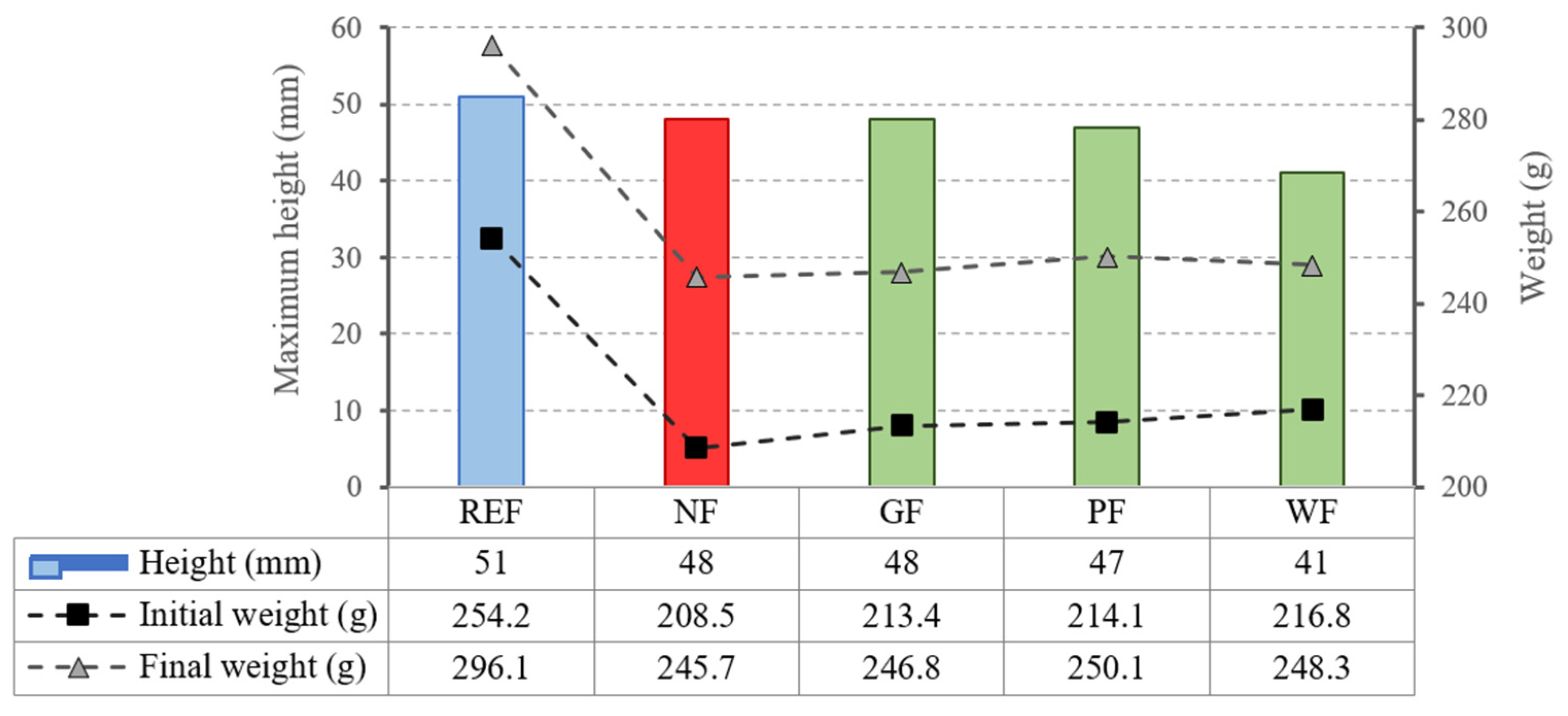

To study the behavior of the new material with respect to water, a capillary absorption test was carried out in a time range of 10 min following the UNE-EN 459-2:2001 standard [44]. The results obtained for this property can be seen in Figure 8.

Figure 8.

Results of the capillary water absorption test.

Figure 8 shows how, after the capillary water absorption test, the final height reached by the capillary meniscus in the lightened plaster samples is lower than that obtained for the reference samples. Furthermore, after the ten-minute test, the lightened plaster composites absorb a lower mass of water, with the sample made with wood fiber (WF) showing the best results for this property. However, in general terms, in all the mixes made with fibers, a lower capillary height and a lower final water absorption were obtained.

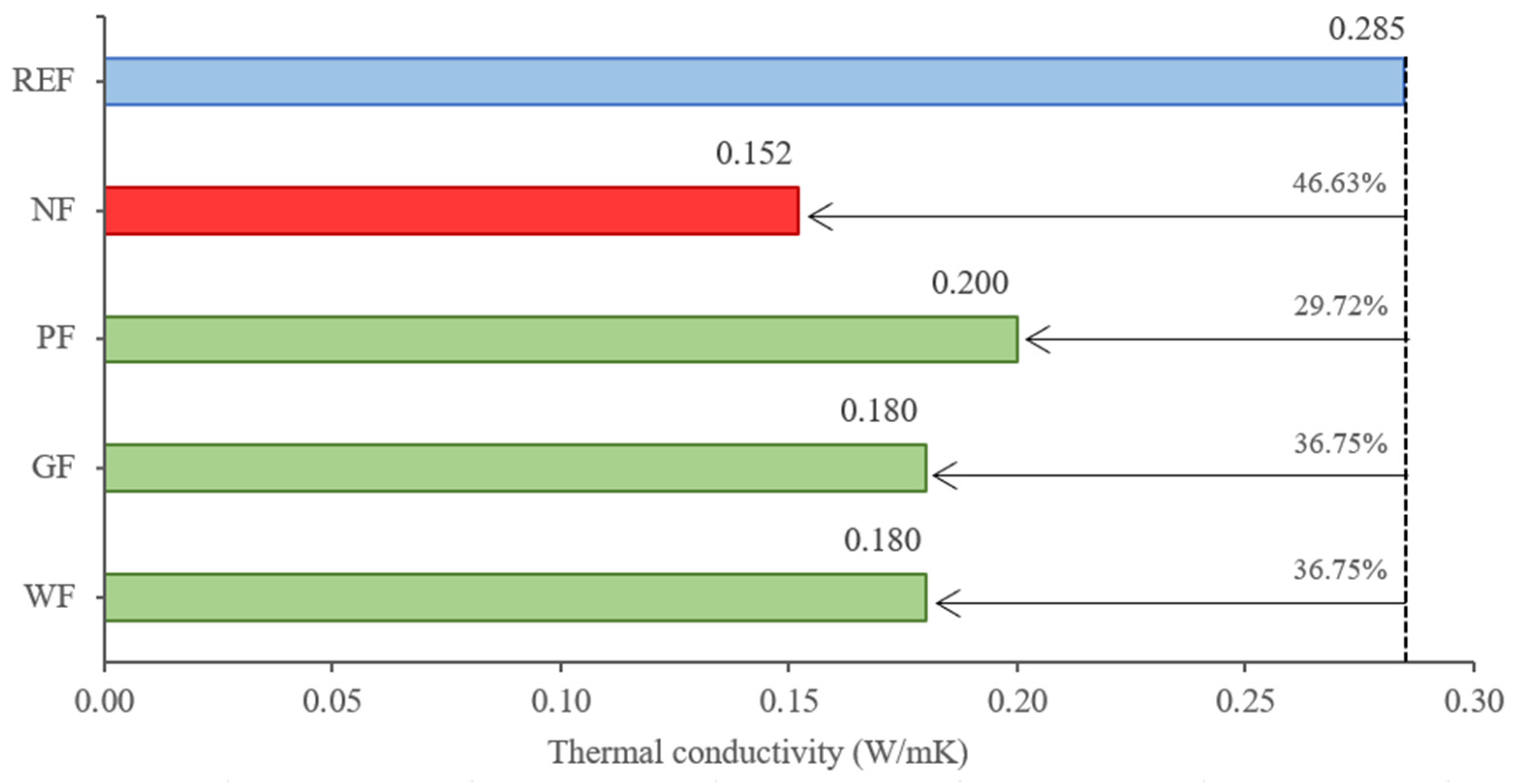

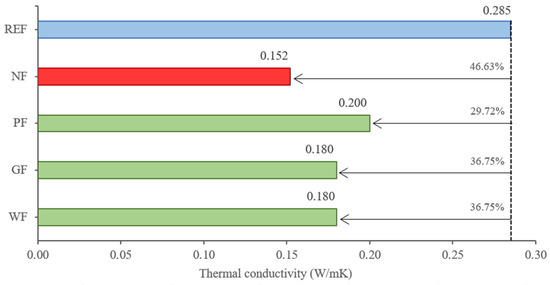

In order to identify the thermal insulation capacity offered by the new material developed, a test was carried out to measure the thermal conductivity, thus obtaining the results shown in Figure 9.

Figure 9.

Thermal conductivity of the dosages studied.

Figure 9 shows that, with the incorporation of the additions of perlite and polymer, the thermal conductivity of the new material (NF) is 46.63% lower than that obtained for the reference specimen (REF), almost half the value of the traditional plaster. The higher porosity and interior air occlusion generated by the combined incorporation of expanded perlite and potassium polyacrylate in the mixture produces a higher thermal resistivity of the new material [20,24]. On the other hand, although the incorporation of fibers in the mixture slightly increases the thermal conductivity of the lightened material, it is still much lower than that obtained by the reference plaster, as it is reduced by 36.75% for the GF and WF samples and by 29.72% for the FP mixture.

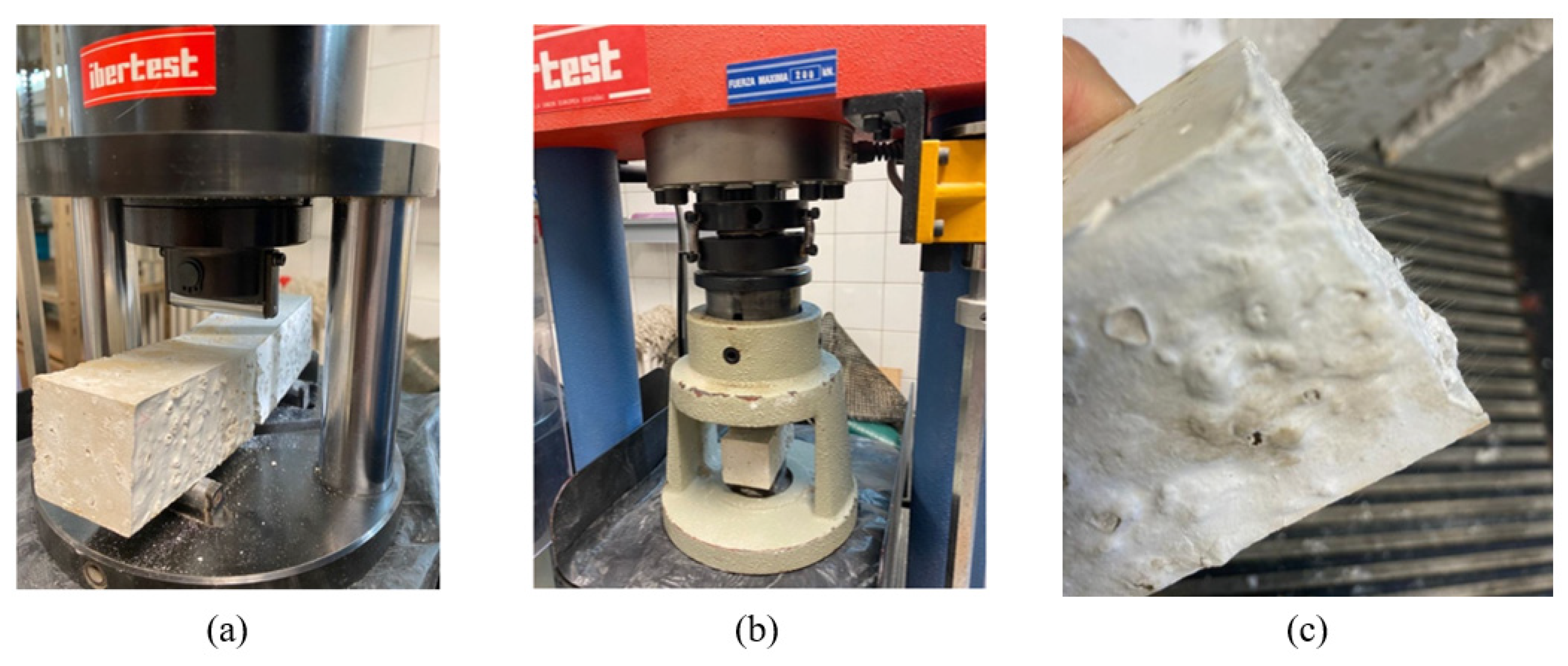

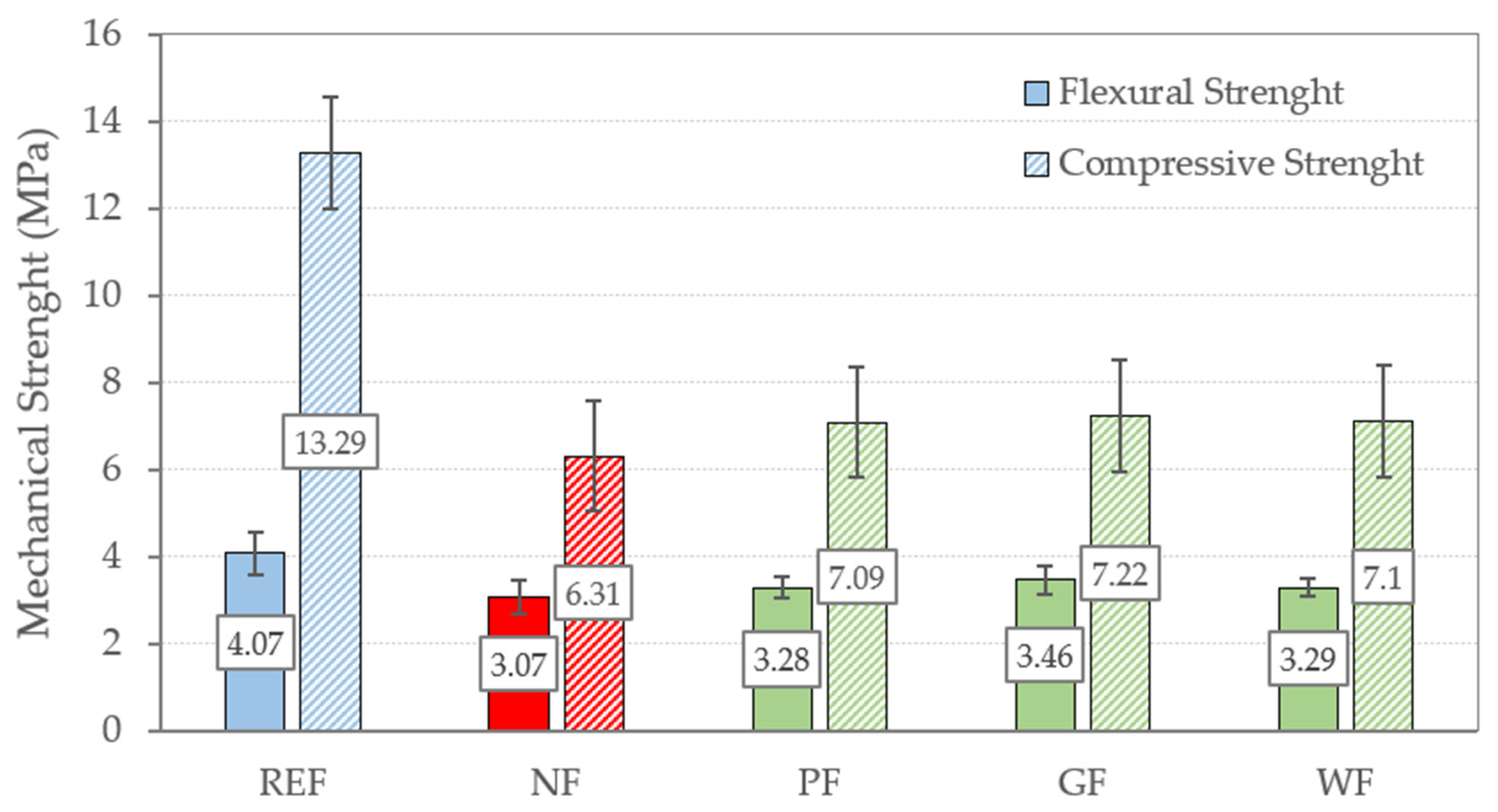

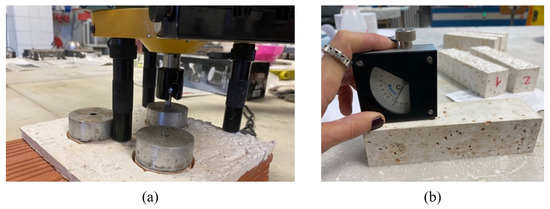

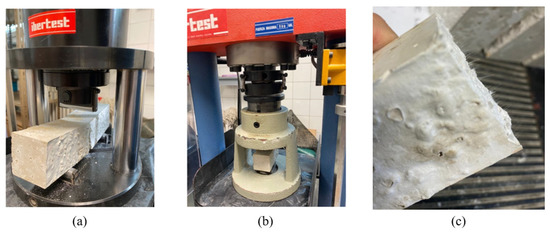

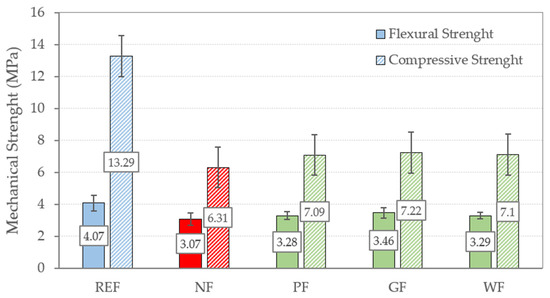

Subsequently, a mechanical characterization was carried out to evaluate the flexural and compressive strength of each of the dosages produced, as shown in Figure 10. The results obtained for these properties are presented in Figure 11.

Figure 10.

Mechanical characterization: (a) flexural strength test; (b) compressive strength test; and (c) semi-sample obtained after the flexural splitting test for specimen GF.

Figure 11.

Mechanical properties of the final dosages tested in 40 × 40 × 160 mm samples. Flexural strength in solid columns and compressive strength in columns with grid pattern.

From the analysis of Figure 11, it can be observed that, although the flexural and compressive strength of the new lightened plaster material is lower than that obtained for traditional plasters, in both cases the minimum strength required by the UNE-EN 31279-2:2014 standard of 1MPa and 2MPa, respectively [43] is exceeded. Regarding the flexural strength shown in Figure 11a, a decrease close to 25% is observed for the lightened plaster material compared to the reference sample. This decrease in flexural strength is less pronounced if reinforcement fibers [56], especially glass fiber, are incorporated, as the ductility of the new construction material developed in this work is significantly improved. As for the compressive strength of the new material, shown in Figure 11, being a less dense and more porous material, the mechanical capacity of the lightened plaster is reduced to approximately half that of traditional plaster. Both the synthetic and natural fibers studied produced an improvement in the compressive strength of the new material of more than 12%.

Table 8 below shows other research carried out using lightened plaster materials that can be used to contextualize the results obtained in this research and presented in Figure 11.

Table 8.

Comparison between the plaster composites produced and the results obtained in other investigations where the addition included in plaster composites with the same binder/water by weight ratio.

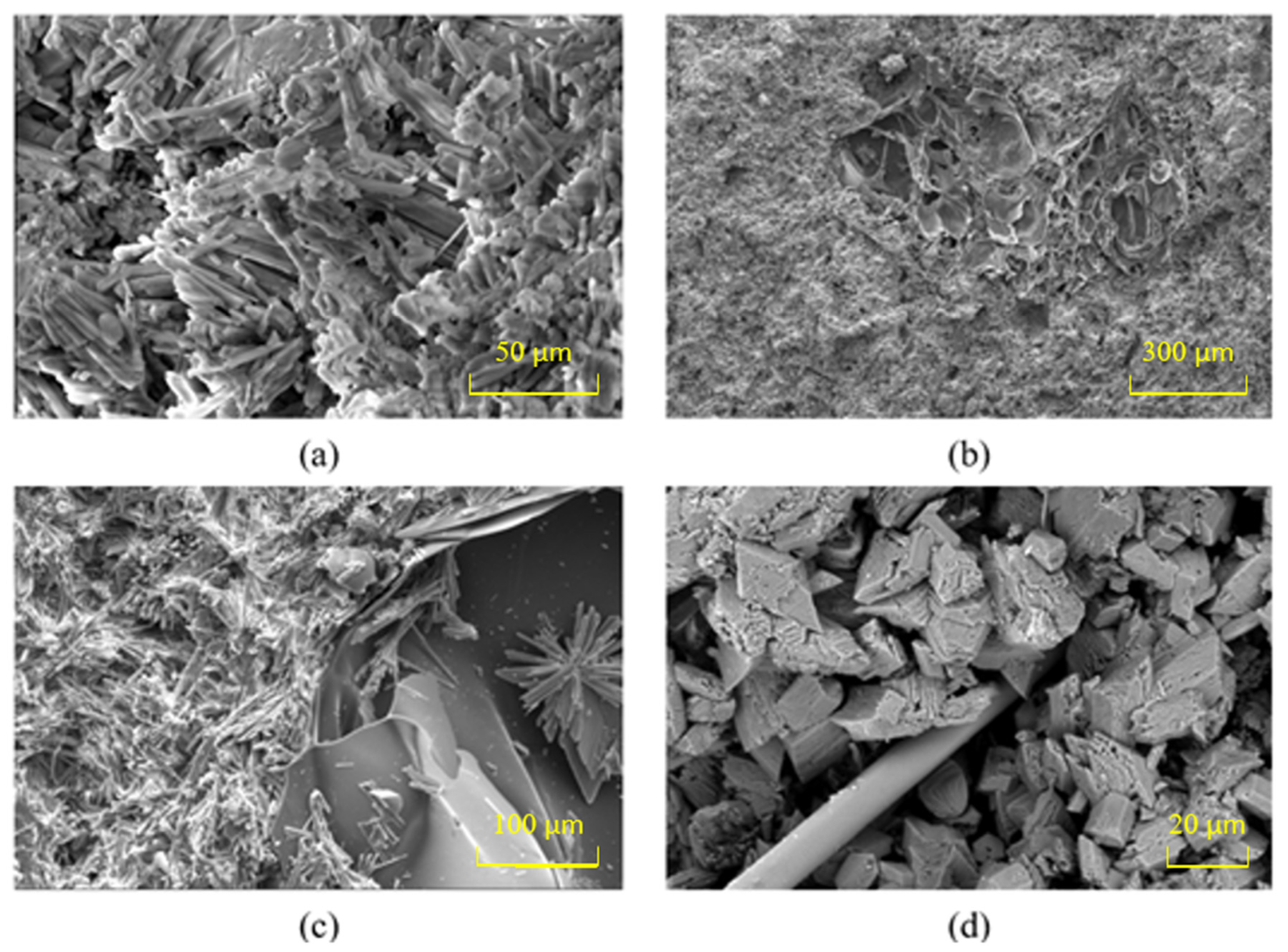

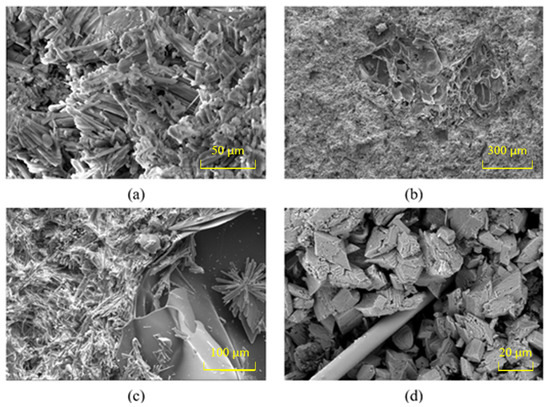

To complement the mechanical results, a series of images were obtained via scanning electron microscopy (SEM). The images taken for different samples are shown in Figure 12.

Figure 12.

Scanning electron microscopy (SEM) of sample with magnifications (a) REF 1000×, (b) WF 100×, (c) 200× and (d) GF 2000×.

Figure 12a shows the interior microstructure of the reference plaster, in which the needle-shaped gypsum dihydrate crystals can be seen. In Figure 12b, the porosity of the new lightened plaster material as a consequence of the dehydration of the potassium polyacrylate after being placed in a stove for 24 h can be seen. Figure 12c shows the perfect bond between the dihydrate crystals and the addition of expanded perlite, and Figure 12d, highlights the interface between the reinforcement fibers and the matrix of the lightened gypsum plaster material. Although the mechanical flexural strengths increase with the incorporation of fibers in the material matrix, the adhesion between these fibers and the plaster composite is not very strong, which caused the fibers to separate via internal sliding after the test when the reinforced plasters broke [58].

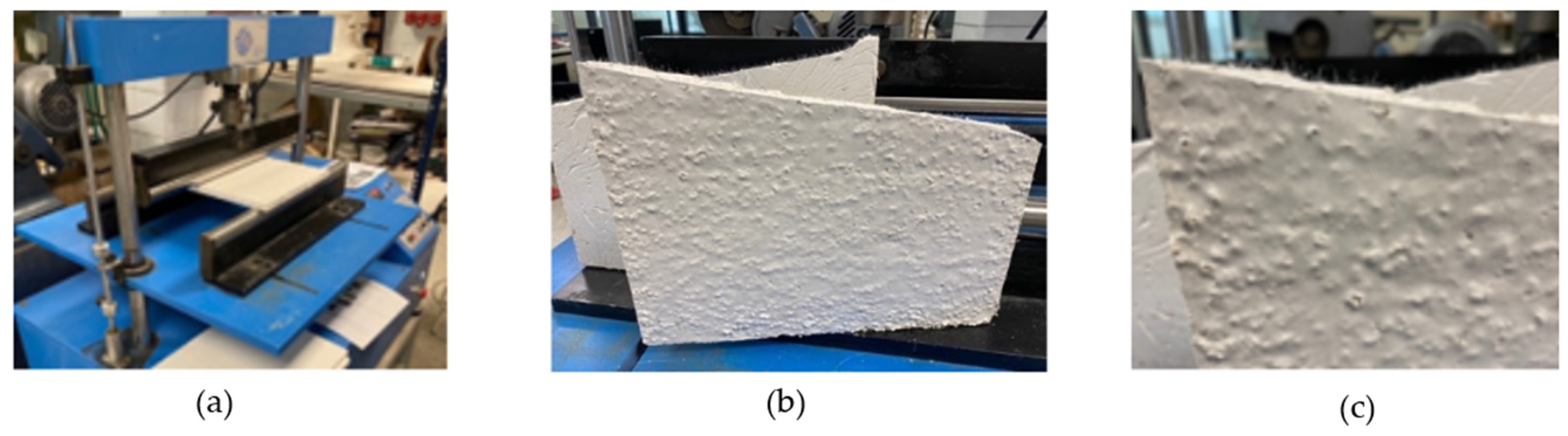

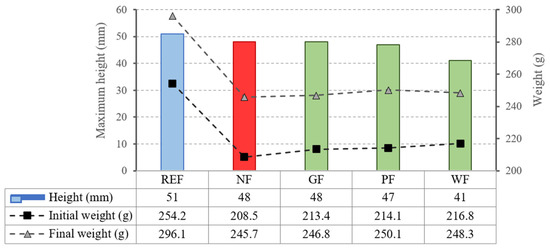

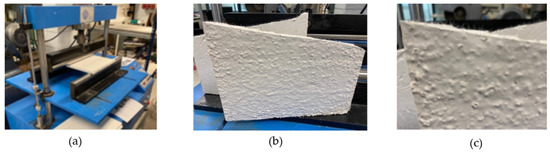

Finally, the suitability of the new plaster material to produce prefabricated products was studied. For this purpose, plates similar to those used in the manufacture of false ceilings were tested using simple bending, as shown in Figure 13, since this is the main way in which these construction elements work. The results obtained in this test are shown in Figure 14.

Figure 13.

(a–c) Flexural strength test on precast plates.

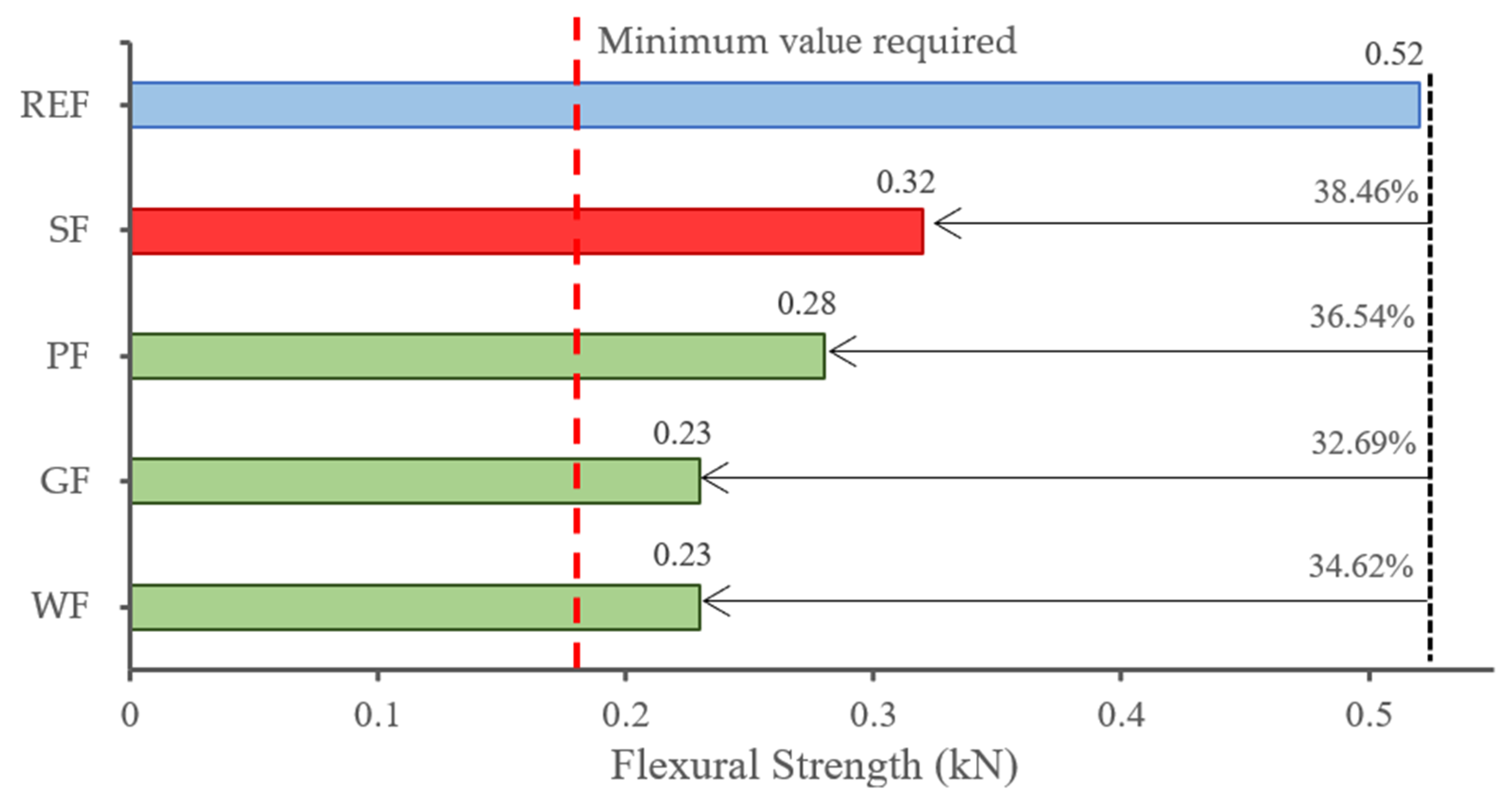

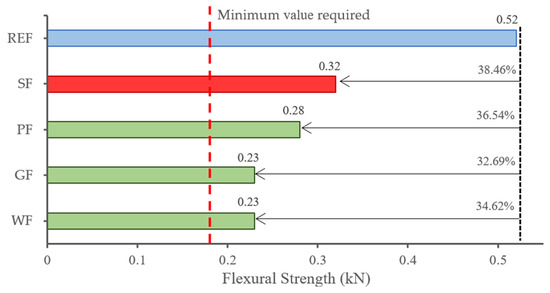

Figure 14.

Flexural strength of precast plates.

The values obtained in Figure 14 correspond only to the plaster material that would make up the precast matrix. They show that, as was the case in the test with standardized RILEM specimens of 4 × 4 × 16 cm, the incorporation of the additions to lighten the weight of the traditional plaster casts results in a decrease in their flexural strength of less than 40%, achieving, once again, values higher than the minimum of 0.18 kN required by the UNE-EN 520:2005+A1:2010 standard. This, with the addition of cardboard on both sides of the plate, would convert the precast into a material with a considerably increased flexural strength.

In this research, the characterization of the new material, specially designed for the manufacture of prefabricated plates and panels for the construction of interior partition walls or false ceilings, has been carried out. The development of this research has led to the granting of patent ES 2 841 130 B2, registered at the Spanish Patent and Trademark Office. However, although good results have been obtained after the characterization of the new plaster composite, it would be advisable to carry out studies using this material with real dimensions of the prefabricated elements to be built and to study its durability in greater depth. In addition, due to the good results obtained for the combination of the synergistic effects of perlite and potassium polyacrylate, it would be interesting in future research to identify the technical feasibility of these compounds for the development of other lightweight construction conglomerate materials with high thermal resistance.

Finally, it is worth highlighting the beneficial effect derived from the inclusion of reinforcement fibers in the matrix of the composites developed for this research. In the tests related to the mechanical properties of the lightened plasters developed in the standardized tests, according to UNE-EN 13279-2, the samples made with fibers (and especially with glass fiber) improved the strength of the hardened composites. In addition, it should be noted that all the samples with fibers showed a ductile fracture and after the flexural test the tested piece did not split into two parts, as can be seen in Figure 10a. In this sense, the fibers studied appear to be suitable reinforcing materials for the use of these plaster composites in the matrix of new lightweight plates and panels.

4. Conclusions

The physicochemical and mechanical characterization of this new lightened plaster composite has been carried out, from which the following conclusions can be drawn:

- Regarding the initial characterization, it can be concluded that the combined action of perlite and potassium polyacrylate in the mixture reduces the density of the plaster composites by up to 28.5%. It can also be observed that a lower water/binder ratio by weight results in a higher flexural and compressive strength of the hardened material. Among all the mixes produced, the E35-0.7-15-30 mix exhibits the best technical performance. Thus, it has been possible to reduce the density and obtain a plaster material that can be competitive in the market for use as a prefabricated product, aligning with other research using gypsum plaster composites for building applications [60].

- Regarding physicochemical characterization, X-ray diffraction reveals a similar crystalline structure for both the mixes with additions and the reference mix. However, thermogravimetric analysis demonstrates that the incorporation of perlite and potassium polyacrylate results in less mass loss of the material at temperatures below 200 °C. At temperatures below 100 °C, the loss of mass associated with mixing water is not appreciable. On the other hand, at temperatures above 200 °C the new material exhibits slightly higher mass loss compared to the reference plaster. Between 200 and 300 °C, there is a loss of mass due to the endothermic oxidative decomposition of potassium polyacrylate. Additionally, between 425 and 550 °C, the exothermic oxidative decomposition of the organic polypropylene and wood fiber leads to a slight further mass loss of the material.

- As for the physical properties of the new material developed, it has been verified that the plaster material lightened with perlite and potassium polyacrylate (NF) has a thermal conductivity coefficient 46.63% lower than traditional plasters (REF). This decrease in thermal conductivity is attributed to a 10.44% reduction in the density of the plaster compound produced compared to the reference plaster E0.7.

- The results obtained for flexural and compressive strength in all the produced dosages for the plaster lightened with fibers surpass the minimum value established by the reference standard (1 MPa in flexural strength and 2 MPa for compressive strength). It should be noted that the incorporation of reinforcement fibers, both synthetic and natural, means an increase in the mechanical capacity of the material produced, leading to an improvement in the flexural strength of the hardened composite. In the case of flexural strength, the incorporation of glass fiber exhibits the best results, decreasing the strength value by 24.6% compared to traditional plaster down to 15%. In compressive strength, this reduction is more notable, as the perlite and the polymer cause the new material to resist 52.52% less than the plaster currently used.

Consequently, it can be inferred that the primary application of this new lightweight plaster composite would be in the production of false ceiling plates and prefabricated panels. It is a lightweight material, which exceeds the breaking load of 0.18 kN established by the UNE-EN 520:2005+A1:2010 standard for the application of plaster composites in false ceiling panels, and it exhibits excellent thermal behavior. With the development of these composite materials, the aim is to move towards an industrialization of the building sector, reducing on-site construction time and facilitating easier installation for construction workers. However, as a future line of work, an economic study should be carried out to show the potential competitive advantages and product differentiation derived from the application of this new material. Additionally, it would be advisable to carry out complementary research to optimize the factors affecting mechanical and physical properties before utilizing this new material.

5. Patents

Based on the results of this research, a new building material has been registered under patent reference ES 2 841 130 B2.

This work demonstrates the development and characterization process of a new plaster composite material for use in building construction. The most relevant tests included in the regulations were carried out, which have allowed the physical, chemical and mechanical characterization of the produced composites. In addition, this paper demonstrated how the experimental process was carried out in two distinct parts, first determining the optimum composition to lighten the matrix of the plaster composite and then choosing the most appropriate reinforcement fiber for use in the building. Thus, it was possible to fully characterize this new building material and explore new avenues of application for industrialized construction.

Author Contributions

Conceptualization, D.F. and P.G.-M.; methodology, D.F. and P.G.-M.; software, P.G.-M., E.A.-S. and A.Z.-B.; validation, P.G.-M., E.A.-S. and A.Z.-B.; formal analysis, P.G.-M., E.A.-S. and D.F.; investigation, P.G.-M., E.A.-S. and D.F.; resources, D.F.; data curation, P.G.-M., E.A.-S. and A.Z.-B.; writing—original draft preparation, P.G.-M. and D.F.; writing—review and editing, E.A.-S. and A.Z.-B.; visualization, P.G.-M.; supervision, E.A.-S.; project administration, D.F.; funding acquisition, D.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not available.

Acknowledgments

The authors would like to thank the laboratory technicians involved in the scanning electron microscopy (SEM) tests for their help in the interpretation of the images.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pinto, N.; Fioriti, C.; Akasaki, J.; Acunha, T.; Okimoto, F. Rendimiento de compuestos de yeso que incorporan partículas de neumáticos de goma. Rev. Ing. Construcción 2020, 35, 216–232. [Google Scholar] [CrossRef]

- Vega, D.F.; Fernandez, C.M.; Sánchez, E.A.; Martínez, P.S. Material de Escayola de Rápido Fraguado y Aligerado Con Polímero de Granza, ES2781675. 19 June 2020. Available online: https://es.espacenet.com/publicationDetails/biblio?CC=ES&NR=2781675A1&KC=A1&FT=D&ND=3&date=20200904&DB=&locale=es_ES (accessed on 24 May 2023).

- Viñas, J.L.G. Nuevas Aplicaciones de Recursos Yesíferos: Desarrollo, Caracterización y Reciclado. Ph.D. Thesis, Universidad Politécnica de Madrid, Escuela Técnica Superior de Ingeniería de Minas, Madrid, Spain, 2005. [Google Scholar]

- Vega, D.F.; Fernandez, C.M.; Dorado, M.Á.; Martínez, P.S.; Material de Escayola Aligerada con Polímeros Para Uso en Placas y Paneles Prefabricados. ES2722598; ES2722598. 2019. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=20190813&DB=&locale=en_EP&CC=ES&NR=2722598A1&KC=A1&ND=5 (accessed on 13 August 2019).

- Santos, P.; Mateus, D. Experimental assessment of thermal break strips performance in load-bearing and non-load-bearing LSF walls. J. Build. Eng. 2020, 32, 101693. [Google Scholar] [CrossRef]

- Directiva 2012/27/UE del Parlamento Europeo y del Consejo. Boletín Oficial del Estado. 2012. Available online: https://www.boe.es/doue/2012/315/L00001-00056.pdf (accessed on 25 October 2012).

- Ohene, E.; Chan, A.P.C.; Darko, A. Review of global research advances towards net-zero emissions buildings. Energy Build. 2022, 266, 112142. [Google Scholar] [CrossRef]

- Rodríguez, Y.J.R. Caracterización Físico-Mecánica del Yeso de Construcción con Adición de Residuos de Poliestireno Extruído y Residuos Cerámicos. Master’s Thesis, Universidad Politénica de Madrid, Escuela Técnica Superior de Edificación de Madrid, Madrid, Spain, 2015. [Google Scholar]

- Duarte, P.C.; Nakao, F.; Ortenzi, A. Integrated product development and lifecycle management in building production—A case study for logistic of mortar distribution in building sites. J. Build. Eng. 2020, 32, 101802. [Google Scholar] [CrossRef]

- Mucha, M.; Mroz, P.; Wrona, D.; Konca, P.; Marszalek, J. Microstructural formation of gypsum by setting in the presence of hydroxypropyl methylcellulose (HPMC). J. Therm. Anal. Calorim. 2020, 147, 1107–1113. [Google Scholar] [CrossRef]

- Luan, W.; Weixin, D.S.; Veeramasuneni, S. Panel de Yeso Resistente al Fuego de Poco Peso y Densidad. ES2699227T3. 2019. Available online: https://worldwide.espacenet.com/patent/search/family/046001717/publication/ES2699227T3?q=ES2699227 (accessed on 8 February 2019).

- Astorqui, J.S.C.; del Rio Merino, M.; Saez, P.V.; Porras-Amores, C. Analysis of the relationship between density and mechanical strength of lightened gypsums: Proposal for a coefficient of lightening. Adv. Mater. Sci. Eng. 2017, 2017, 7092521. [Google Scholar] [CrossRef]

- Jianxin, Y.L.C. Preparation Method of Heat-Insulation Type Plastering Anhydrite. 2019. Available online: https://worldwide.espacenet.com/patent/search/family/065674275/publication/CN109467378A?q=CN109467378A (accessed on 15 March 2019).

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rodríguez-Liñán, C. Eco-efficient acoustic and thermal conditioning using false ceiling plates made from plaster and wood waste. J. Clean. Prod. 2017, 166, 690–705. [Google Scholar] [CrossRef]

- Vidales-Barriguete, A.; Santa-Cruz-Astorqui, J.; Piña-Ramírez, C.; Kosior-Kazberuk, M.; Kalinowska-Wichrowska, K.; Atanes-Sánchez, E. Study of the Mechanical and Physical Behavior of Gypsum Boards with Plastic Cable Waste Aggregates and Their Application to Construction Panels. Materials 2021, 14, 2255. [Google Scholar] [CrossRef]

- Vega, D.F.; Fernández, C.M.; Dorado, M.Á.; Miragaya, P.G. Material de Construcción Aligerado Para la Elaboración de PREFABRICADOS. ES2841130. 2021. Available online: https://es.espacenet.com/publicationDetails/biblio?DB=es.espacenet.com&II=0&ND=3&adjacent=true&locale=es_ES&FT=D&date=20210707&CC=ES&NR=2841130A1&KC=A1 (accessed on 7 July 2021).

- Rahman, M.M.; Jyoti, L.T.Z.; Paul, S.; Al-Ishmam; Hossain, M. A. Mechanical and Thermal Performance of Cement Mortar Incorporating Super Absorbent Polymer (SAP). Civ. Eng. J. Tehran 2020, 6, 2231–2244. [Google Scholar] [CrossRef]

- Kang, S.-H.; Hong, S.-G.; Moon, J. The effect of superabsorbent polymer on various scale of pore structure in ultra-high performance concrete. Constr. Build. Mater. 2018, 172, 29–40. [Google Scholar] [CrossRef]

- James, J.D.; Ludwick, J.M.; Wheeler, M.L.; Oyen, M.L. Compressive failure of hydrogel spheres. J. Mater. Res. 2020, 35, 1227–1235. [Google Scholar] [CrossRef]

- Thompson, B.R.; Horozov, T.S.; Stoyanov, S.D.; Paunov, V.N. Hierarchically porous composites fabricated by hydrogel templating and viscous trapping techniques. Mater. Des. 2018, 137, 384–393. [Google Scholar] [CrossRef]

- González, S.G.; Carpintero, V.C.; Saiz, Á.R.; Saiz, J.G.; Petrement, C.J.; López, J.G. Procedimiento de Obtención de Placas de Yeso Laminado Aligeradas con Residuo de Espuma de Poliuretano, Placa Obtenida y Uso de la Misma. ES2522792; ES2522792; ES2522792. 2014. Available online: https://es.espacenet.com/publicationDetails/biblio?CC=ES&NR=2522792A1&KC=A1&FT=D&ND=7&date=20141118&DB=&locale=es_ES (accessed on 18 November 2014).

- El Mir, A.; Nehme, S.G.; Assaad, J.J. Durability of self-consolidating concrete containing natural waste perlite powders. Heliyon 2020, 6, e03165. [Google Scholar] [CrossRef] [PubMed]

- Vyšvařil, M.; Pavlíková, M.; Záleská, M.; Pivák, A.; Žižlavský, T.; Rovnaníková, P.; Bayer, P.; Pavlík, Z. Non-hydrophobized perlite renders for repair and thermal insulation purposes: Influence of different binders on their properties and durability. Constr. Build. Mater. 2020, 263, 120617. [Google Scholar] [CrossRef]

- Fenoglio, E.; Fantucci, S.; Serra, V.; Carbonaro, C.; Pollo, R. Hygrothermal and environmental performance of a perlite-based insulating plaster for the energy retrofit of buildings. Energy Build. 2018, 179, 26–38. [Google Scholar] [CrossRef]

- Katsushiko, S. Inorganic Lightweight Heat Insulating Material. JP2012036020A. 2012. Available online: https://worldwide.espacenet.com/patent/search/family/045848448/publication/JP2012036020A?q=JP2012036020A (accessed on 23 February 2012).

- del Cura, S.H.; Zaldivar, Ó.L.; Díez, R.V.L.; Olivares, F.H.; Lobo, P.L.M. Yeso Aligerado con Polvo de Caucho Procedente de Neumáticos Fuera de Uso (NFU) y Reforzado con Fibras de Carbono, su Procedimiento de Obtención y Uso. ES2732159 (A1); ES2732159 (B2). 2019. Available online: https://es.espacenet.com/publicationDetails/biblio?CC=ES&NR=2732159A1&KC=A1&FT=D&ND=5&date=20191120&DB=&locale=es_ES (accessed on 20 November 2019).

- Jia, R.; Wang, Q.; Feng, P. A comprehensive overview of fibre-reinforced gypsum-based composites (FRGCs) in the construction field. Compos. Part B Eng. 2021, 205, 108540. [Google Scholar] [CrossRef]

- Gencel, O.; del Coz Diaz, J.J.; Sutcu, M.; Koksal, F.; Rabanal, F.A.; Martinez-Barrera, G.; Brostow, W. Properties of gypsum composites containing vermiculite and polypropylene fibers: Numerical and experimental results. Energy Build. 2014, 70, 135–144. [Google Scholar] [CrossRef]

- Gencel, O.; del Coz Diaz, J.J.; Sutcu, M.; Koksal, F.; Rabanal, F.P.Á.; Martínez-Barrera, G. A novel lightweight gypsum composite with diatomite and polypropylene fibers. Constr. Build. Mater. 2016, 113, 732–740. [Google Scholar] [CrossRef]

- Medina, N.F.; Barbero-Barrera, M.M. Mechanical and physical enhancement of gypsum composites through a synergic work of polypropylene fiber and recycled isostatic graphite filler. Constr. Build. Mater. 2017, 131, 165–177. [Google Scholar] [CrossRef]

- Martias, C.; Joliff, Y.; Favotto, C. Effects of the addition of glass fibers, mica and vermiculite on the mechanical properties of a gypsum-based composite at room temperature and during a fire test. Compos. Part B Eng. 2014, 62, 37–53. [Google Scholar] [CrossRef]

- Di Bella, G.; Fiore, V.; Galtieri, G.; Borsellino, C.; Valenza, A. Effects of natural fibres reinforcement in lime plasters (kenaf and sisal vs. Polypropylene). Constr. Build. Mater. 2014, 58, 159–165. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Aprea, P.; Caputo, D. Thermo-mechanical behaviour of hemp fibers-reinforced gypsum plasters. Constr. Build. Mater. 2018, 185, 256–263. [Google Scholar] [CrossRef]

- De San Antonio González, A.; Del rio Merino, M.; Arrebola, C.V.; Saez, P.V. Procedimiento Para la Obtención de un Material de Construcción a Base de Yeso. ES2515640 (A1). 2014. Available online: https://es.espacenet.com/publicationDetails/biblio?CC=ES&NR=2515640A1&KC=A1&FT=D&ND=3&date=20141029&DB=&locale=es_ES (accessed on 29 October 2014).

- Vega, D.F.; Martínez, P.S.; Fernández, C.M.; Sánchez, E.A. Análisis comparativo de las escayolas reforzadas con fibras para la elaboración de prefabricados. Dyna 2020, 95, 333–338. [Google Scholar] [CrossRef]

- Fleck, W.; Jones, M.; Kuntze, R.; McAdie, H. The differential thermal analysis of natural and synthetic hydrates of calcium sulphate. Can. J. Chem. 2011, 38, 936–943. [Google Scholar] [CrossRef]

- Strydom, C.A.; Potgieter, J.H. Dehydration behaviour of a natural gypsum and a phosphogypsum during milling. Thermochim. Acta 1999, 332, 89–96. [Google Scholar] [CrossRef]

- Código Técnico de la Edificación. Documento Básico, Seguridad en Caso de Incendio. December 2019. Available online: https://www.codigotecnico.org/pdf/Documentos/SI/DBSI.pdf (accessed on 6 May 2023).

- Yedra, E.; Ferrández, D.; Morón, C.; Saiz, P. New test methods to determine water absorption by capillarity. Experimental study in masonry mortars. Constr. Build. Mater. 2022, 319, 125988. [Google Scholar] [CrossRef]

- Control del agua del grifo. El agua del Grifo de Madrid. 2020. Available online: https://madridsalud.es/control-del-agua-del-grifo/ (accessed on 6 May 2023).

- Canal de Isabel II. Informe Anual Sobre la Calidad del Agua en Madrid; Canal de Isabel II: Madrid, Spain, 2012. [Google Scholar]

- Deska, I.; Mrowiec, M.; Ociepa, E.; Lacisz, K. Investigation of the influence of hydrogel amendment on the retention capacities of green roofs. Ecol. Chem. Eng. S 2018, 25, 373–382. [Google Scholar] [CrossRef]

- Alicia de San Antonio González. Caracterización de Compuestos Eco-Eficientes de Yeso Aligerado con Residuo de Poliestireno Extruido (XPS). Ph.D. Thesis, Universidad Politécnica de Madrid, Escuela Técnica Superior de Edificación de Madrid, Madrid, Spain, 2017. [Google Scholar] [CrossRef]

- Kapeluszna, E.; Kotwica, L.; Pichor, W.; Nocun-Wczelik, W. Cement-based composites with waste expanded perlite—Structure, mechanical properties and durability in chloride and sulphate environments. Sustain. Mater. Technol. 2020, 24, e00160. [Google Scholar] [CrossRef]

- Álvarez, M.; Ferrández, D.; Morón, C.; Atanes-Sánchez, E. Characterization of a New Lightened Gypsum-Based Material Reinforced with Fibers. Materials 2021, 14, 1203. [Google Scholar] [CrossRef]

- UNE-EN-ISO 13279-2; Yeso de Construcción y Conglomerantes a Base de Yeso de Construcción, Parte 2: Métodos de Ensayo. AENOR: Madrid, Spain, 2014.

- UNE-EN 459-2:2011; Cales Para la Construcción. Parte 2: Métodos de Ensayo. AENOR: Madrid, Spain, 2011.

- UNE-EN 12859:2012; Paneles de Yeso. Definiciones, Especificaciones y Métodos de Ensayo. AENOR: Madrid, Spain, 2012. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0049169 (accessed on 6 May 2023).

- Agbabiaka, O.G.; Adegun, M.H.; Chan, K.-Y.; Zhang, H.; Shen, X.; Kim, J.-K. BN-PVDF/rGO-PVDF Laminate Nanocomposites for Energy Storage Applications. Nanomaterials 2022, 12, 4492. [Google Scholar] [CrossRef]

- Mercedes del Río Merino. Elaboración y Aplicaciones Constructivas de Paneles Prefabricados de Escayola Aligerada y Reforzada con Fibras de Vidrio E y Otros Aditivos. Ph.D. Thesis, Universidad Politécnica de Madrid, Escuela Técnica Superior de Arquitectura, Madrid, Spain, 1999. [Google Scholar]

- Wu, Y.-F. The structural behavior and design methodology for a new building system consisting of glass fiber reinforced gypsum panels. Constr. Build. Mater. 2009, 23, 2905–2913. [Google Scholar] [CrossRef]

- Vidales, A.; Piña, C.; del Río Merino, M.; Sánchez, E.; Viñas, C. Analysis of the feasibility of the use of CDW as a low-environmental-impact aggregate in conglomerates. Constr. Build. Mater. 2018, 178, 83–91. [Google Scholar] [CrossRef]

- García, A.B.; Yuna, F.G.; Escamilla, A.C. Morteros con Propiedades Mejoradas de Ductilidad por Adición de Fibras de Vidrio, Carbono y Basalto. Ph.D. Thesis, Universidad Politécnica de Madrid, Escuela Técnica Superior de Edificación, Madrid, Spain, 2018. Available online: https://oa.upm.es/cgi/oai2 (accessed on 6 May 2023).

- Piñeiro, S.R. Refuerzo de la Escayola Mediante Fibras de Lana Mineral Procedentes del Reciclaje de RCD. Ph.D. Thesis, Universidad Politénica de Madrid, Escuela Técnica Superior de Edificación de Madrid, Madrid, Spain, 2016. [Google Scholar]

- Romero-Gómez, M.I.; Pedreño-Rojas, M.A.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Characterization of gypsum composites with polypropylene fibers from non-degradable wet wipes. J. Build. Eng. 2021, 34, 101874. [Google Scholar] [CrossRef]

- Romaniega, S.; del Río, M.; Pérez, C. New Plaster Composite with Mineral Wool Fibres from CDW Recycling. Adv. Build. Technol. Constr. Mater. 2015, 2015, 854192. [Google Scholar] [CrossRef]

- Del Río, M.; Hernández-Olivares, F. Lightened plaster: Alternative solutions to cellular solids addition. Mater. Construcción 2003, 54, 65–76. [Google Scholar] [CrossRef]

- Álvarez, M.; Ferrández, D.; Guijarro-Miragaya, P.; Morón, C. Characterization and under Water Action Behaviour of a New Plaster-Based Lightened Composites for Precast. Materials 2023, 16, 872. [Google Scholar] [CrossRef]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Evaluating the potential use of recycled glass fibers for the development of gypsum-based composites. Constr. Build. Mater. 2022, 321, 126320. [Google Scholar] [CrossRef]

- Del Río, M.; Vidales, A.; Piña, C.; Vitiello, V.; Santa Cruz, J.; Castelluccio, R. A review of the research about gypsum mortars with waste aggregates. J. Build. Eng. 2022, 45, 103338. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).