Carbon Fibre-Reinforced Polymer (CFRP) Composites in Civil Engineering Application—A Comprehensive Review

Abstract

1. Introduction

1.1. Material Properties of CFRP Composites

1.2. CFRP Engineering Applications and Future Development in the Construction Industry

- Construction firms increasingly use CFRP composites for structural reinforcement. They are widely used to strengthen and repair concrete bridges, columns, and beams. CFRP composites increase the durability of concrete structures by increasing load-carrying capacity, flexural and tensile strength, and durability;

- Advanced retrofitting and rehabilitation techniques will advance CFRP construction. CFRP composites improve infrastructure performance and durability. Damaged structures can meet modern design requirements and withstand higher loads by externally bonding CFRP laminates or wraps to concrete elements;

- CFRP composites make lightweight construction possible. Their high strength-to-weight ratio makes lightweight structures structurally sound. CFRP composites reduce dead loads on foundations and supporting systems, improving efficiency and sustainability. High-rise buildings and long-span bridges benefit from weight reduction;

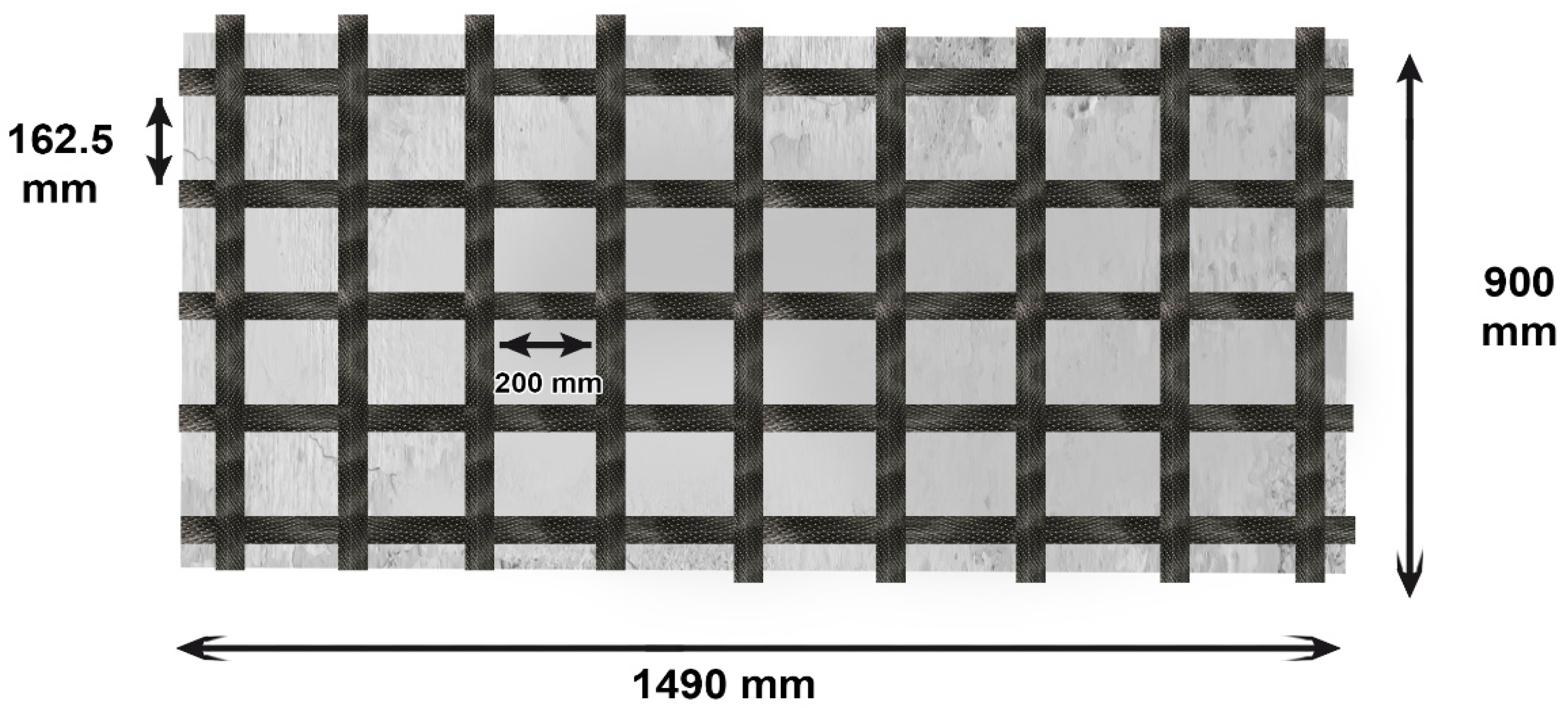

- Future advancements in CFRP in construction will involve investigating novel structural systems. Using CFRP cables, grids, and fabrics, novel structural configurations are created that optimise load distribution, increase structural stiffness, and improve overall performance. These innovative systems offer design flexibility, allowing for the construction of distinctive, visually striking structures with enhanced strength, durability, and sustainability;

- CFRP construction’s future is sustainable. CFRP composites reduce material and energy consumption and prolong the structure’s lifespan, promoting sustainability. CFRP composites are lightweight, reducing transportation costs and carbon emissions. CFRP technology will help achieve sustainable construction goals and build resilient infrastructure as it advances.

1.3. Overview of CFRP Composites in Civil Engineering

1.4. Advantages and Limitations of CFRP Composites in Civil Engineering

2. Types of FRP Composites Used in Civil Engineering

- Glass fibre-reinforced polymer (GFRP);

- Basalt fibre-reinforced polymer (BFRP);

- Aramid fibre-reinforced polymer (AFRP);

- Carbon fibre-reinforced polymer (CFRP).

2.1. Carbon Fibre-Reinforced Polymer (CFRP) Composites

2.1.1. Application of CFRP to Buildings’ Structural Elements

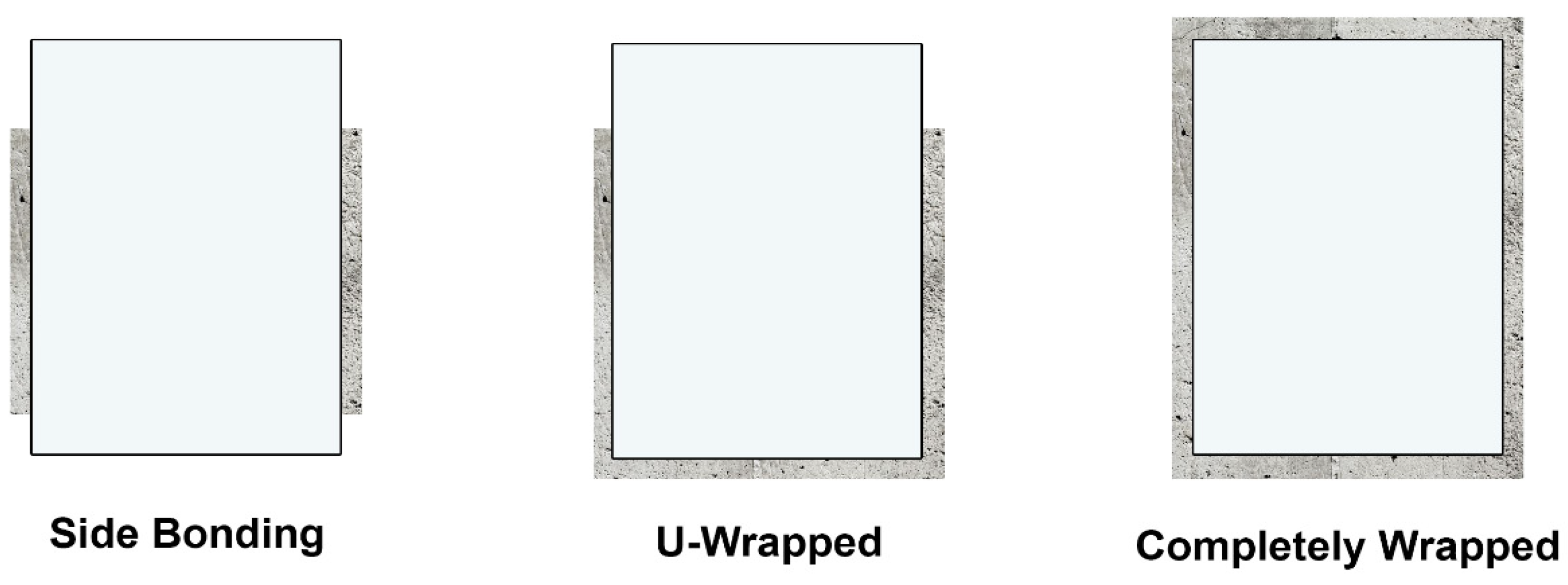

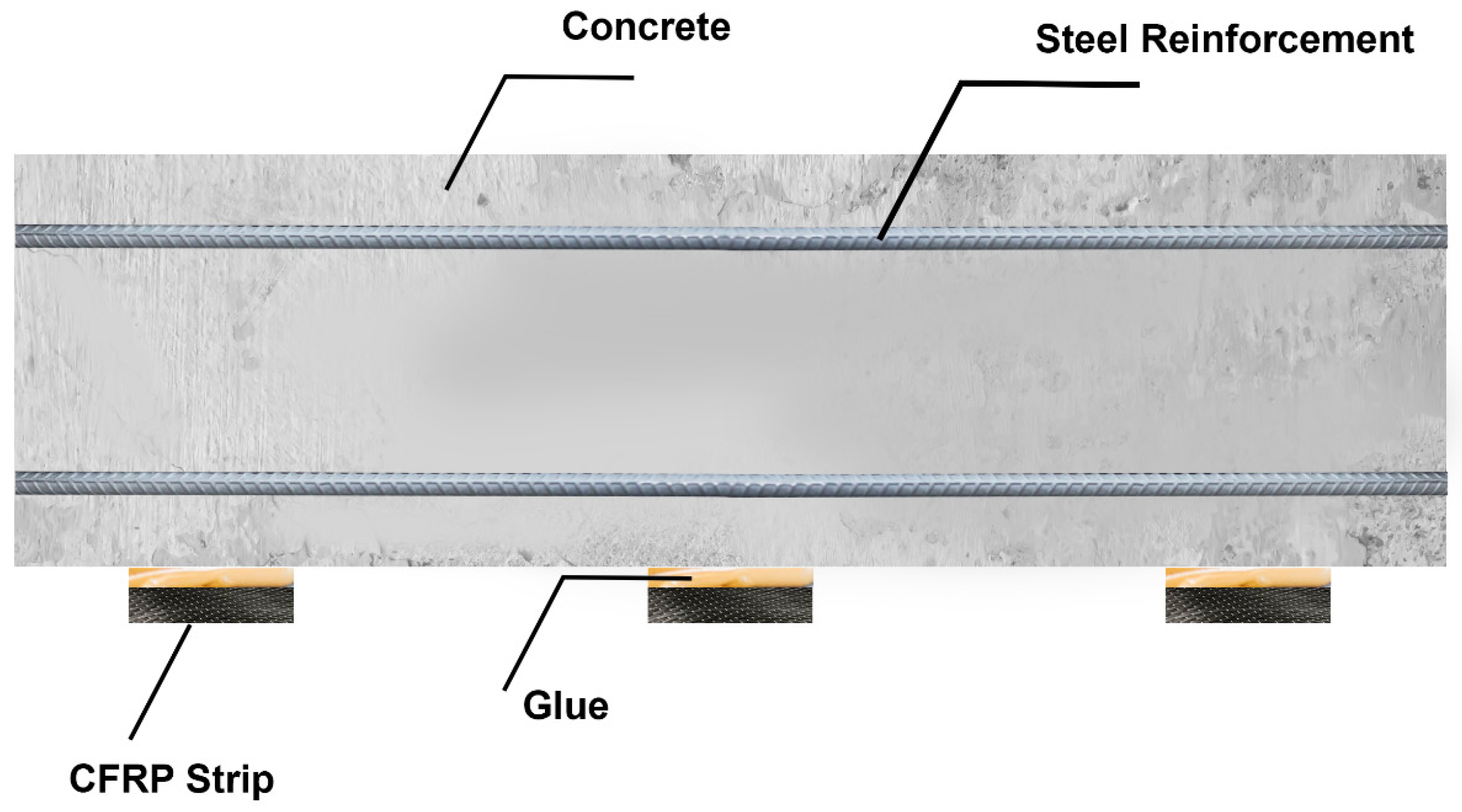

Beams

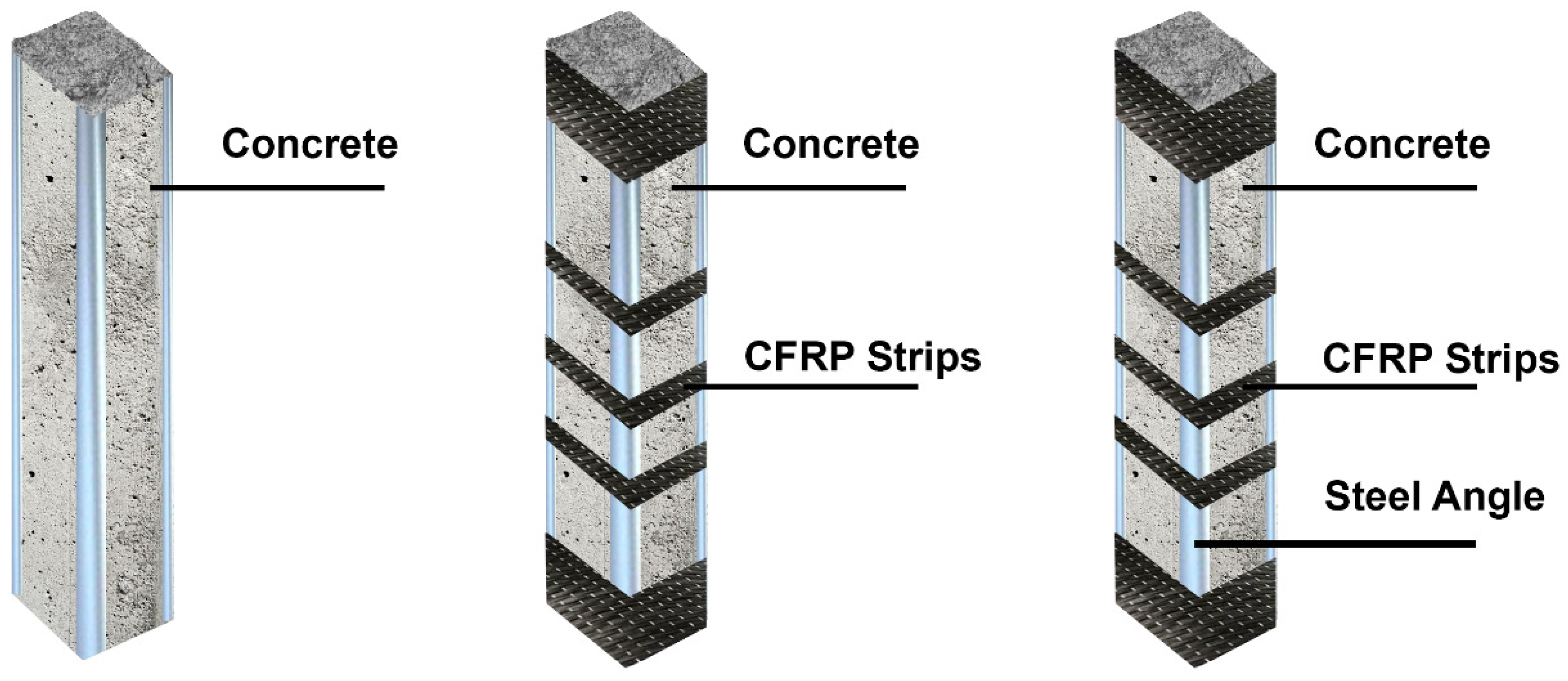

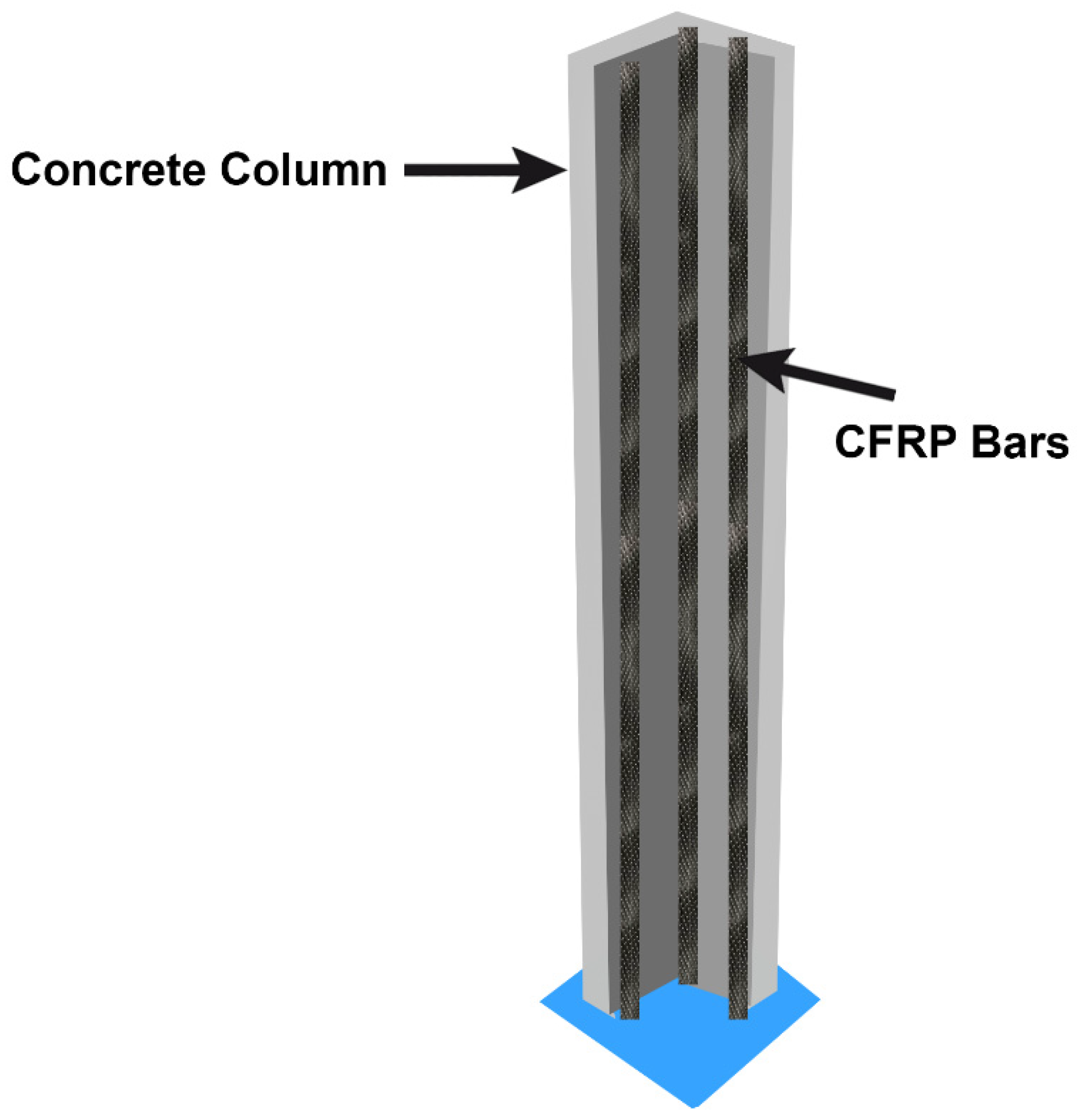

Columns

Slab

Shear Wall

3. Characteristics and Properties of CFRP Composites

3.1. Durabilityh of CFRP

3.1.1. Corrosion Resistance

3.1.2. Fatigue Resistance

3.1.3. The Incorporation of CFRP in Temperature Factors

4. Emerging Materials in CFRP Composites

4.1. Nanostructured Carbon Fibres

4.2. Hybrid Fiber Reinforcement

4.3. Self-Sensing CFRP

4.4. High-Modulus Carbon Fibres

5. Promoting Sustainability through Enhanced Structural Durability and Longevity

6. Disadvantages of CFRP Composites

- Their relatively low transverse shear resistance is one of the disadvantages of CFRP composites. It is well known that CFRP materials have a lower shear strength in the transverse direction than their high tensile strength in the longitudinal direction. This restriction must be considered during structural design to ensure adequate reinforcement and load distribution;

- CFRP composites are fire-prone. CFRP is strong at ambient temperatures but degrades at high temperatures. CFRP’s organic resin matrix degrades easily in fires. Fireproofing CFRP structures requires coatings or encapsulation;

- CFRP composites cannot redistribute loads such as steel or concrete. CFRP fails suddenly without warning or plastic deformation when it reaches its load capacity. This behaviour may require structural redundancy or progressive collapse prevention strategies;

- CFRP costs more than steel and concrete. Carbon fibre production and resin impregnation increase costs. In cost-effective construction projects, this cost factor can affect CFRP adoption;

- UV radiation can degrade CFRP composite resin matrices, reducing their mechanical properties. Over time, sunlight and outdoor conditions can discolour, delaminate, and reduce performance. For CFRP structures to last, UV protection measures such as coatings or UV-resistant additives must be taken.

7. Current Trends and Future Outlook for CFRP Composites in Civil Engineering

- Increasingly, CFRP composites are used in seismic retrofitting initiatives for existing buildings to improve earthquake resistance. This trend is anticipated to continue as more buildings are identified as vulnerable to seismic hazards;

- Developing new manufacturing techniques for CFRP composites is anticipated to increase production efficiency and reduce costs. This could increase the use of CFRP composites in the construction industry;

- Integration of CFRP composites with other building systems, such as Building Information Modelling (BIM) and other digital technologies, is on the rise. This can assist in optimising the design and construction process, decreasing waste, and enhancing project outcomes;

- There is potential for using CFRP composites in new applications, including soil reinforcement, bridge construction, and other infrastructure projects. CFRP composites are already used in a variety of concrete structural elements;

- The construction industry is increasingly concerned with sustainability, and CFRP composites are viewed as a more sustainable alternative to conventional building materials. As more building owners and developers prioritise sustainable design and construction, the demand for CFRP composites will increase;

- CFRP is a unique material that demonstrates minimal changes in its mechanical properties under varying temperature conditions, making it suitable for structures exposed to high temperatures or rapid temperature fluctuations. This characteristic enables the use of CFRP in applications including aerospace components, industrial buildings, and high-temperature storage facilities;

- Highly resistant to corrosion, CFRP composites are ideal for marine environments. They do not corrode or deteriorate in saltwater, ensuring long-lasting durability and dependable performance in mooring systems. In addition, they have high fatigue resistance, allowing them to withstand cyclic loading and stress cycles, thereby reducing the risk of material fatigue and extending the service life of mooring systems. This makes CFRP a dependable material for maintaining the stability and safety of marine structures and vessels.

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kiersnowska, A.; Fabianowski, W.; Koda, E. The Influence of the Accelerated Aging Conditions on the Properties of Polyolefin Geogrids Used for Landfill Slope Reinforcement. Polymers 2020, 12, 1874. [Google Scholar] [CrossRef] [PubMed]

- Chalot, A.; Michel, L.; Ferrier, E. Experimental Study of External Bonded CFRP-Concrete Interface under Low Cycle Fatigue Loading. Compos. Part B Eng. 2019, 177, 107255. [Google Scholar] [CrossRef]

- Lee, T.; Jeong, S.; Woo, U.; Choi, H.; Jung, D. Experimental Evaluation of Shape Memory Alloy Retrofitting Effect for Circular Concrete Column Using Ultrasonic Pulse Velocity. Int. J. Concr. Struct. Mater. 2023, 17, 13. [Google Scholar] [CrossRef]

- Cruz, R.; Correia, L.; Cabral-Fonseca, S.; Sena-Cruz, J. Durability of Bond of EBR CFRP Laminates to Concrete under Real-Time Field Exposure and Laboratory Accelerated Ageing. Constr. Build. Mater. 2023, 377, 131047. [Google Scholar] [CrossRef]

- Al-Mawed, L.K.; Hamad, B.S. Experimental and Numerical Assessments of Slab-Column Connections Strengthened Using Bonded Hemp Fiber Fabric Sheets. Int. J. Concr. Struct. Mater. 2023, 17, 8. [Google Scholar] [CrossRef]

- Obaidat, Y.T.; Barham, W.; Obaidat, A.T.; Abuzakham, H. Improving the Shear Capacity of Recycled Aggregate Concrete Beams with NSM-CFRP Strip. Pract. Period. Struct. Des. Constr. 2023, 28, 04023016. [Google Scholar] [CrossRef]

- Yang, J.; Lu, S.; Zeng, J.J.; Wang, J.; Wang, Z. Durability of CFRP-Confined Seawater Sea-Sand Concrete (SSC) Columns under Wet-Dry Cycles in Seawater Environment. Eng. Struct. 2023, 282, 115774. [Google Scholar] [CrossRef]

- Li, G.; Li, X.; Fang, C.; Wang, J.; Liu, R. Dynamic Behavior of Concrete-Filled Steel Tube Cantilever Columns Stiffened with Encased Carbon Fiber Reinforced Plastic Profile Subjected to Lateral Impact Load. Int. J. Impact Eng. 2023, 177, 104561. [Google Scholar] [CrossRef]

- Godlewski, T.; Mazur, Ł.; Szlachetka, O.; Witowski, M.; Łukasik, S.; Koda, E. Design of Passive Building Foundations in the Polish Climatic Conditions. Energies 2021, 14, 7855. [Google Scholar] [CrossRef]

- Hadigheh, S.A.; Ke, F.; Fatemi, H. Durability Design Criteria for the Hybrid Carbon Fibre Reinforced Polymer (CFRP)-Reinforced Geopolymer Concrete Bridges. Structures 2022, 35, 325–339. [Google Scholar] [CrossRef]

- Abas Golham, M.; Al-Ahmed, A.H.A. Behavior of GFRP Reinforced Concrete Slabs with Openings Strengthened by CFRP Strips. Results Eng. 2023, 18, 101033. [Google Scholar] [CrossRef]

- Zhou, S.C.; Demartino, C.; Xu, J.J.; Xiao, Y. Effectiveness of CFRP Seismic-Retrofit of Circular RC Bridge Piers under Vehicular Lateral Impact Loading. Eng. Struct. 2021, 243, 112602. [Google Scholar] [CrossRef]

- Ozturk, M.; Sengun, K.; Arslan, G. CFRP Contribution to Load-Carrying Capacity of Retrofitted Geopolymer Concrete Beams. Structures 2023, 48, 1391–1402. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, X.; Huang, Z.; Wu, G.; Sun, S.; Ye, H.; Zhang, Z. A New Approach to Enhancing Interlaminar Strength and Galvanic Corrosion Resistance of CFRP/Mg Laminates. Compos. Part A Appl. Sci. Manuf. 2018, 105, 78–86. [Google Scholar] [CrossRef]

- Shen, J.; Huang, Z.; Song, X.; Lin, H. Cyclic Behavior of Concrete Shear Wall with CFRP Grid-Steel Reinforcement. Compos. Struct. 2022, 297, 115938. [Google Scholar] [CrossRef]

- Yoo, S.W.; Choo, J.F. Behavior of CFRP-Reinforced Concrete Columns at Elevated Temperatures. Constr. Build. Mater. 2022, 358, 129425. [Google Scholar] [CrossRef]

- Guo, X.; Zeng, L.; Zheng, X.; Li, B.; Deng, Z. Flexural Behavior of Damaged Hollow RC Box Girders Repaired with Prestressed CFRP. Materials 2023, 16, 3338. [Google Scholar] [CrossRef]

- Wu, M.; Yuan, F.; Guo, S.; Li, W.; Chen, G.; Zhou, Y.; Huang, Z.; Yang, X. Experimental Investigation of the Shear Behaviour of Concrete Beams with CFRP Strip Stirrups under Static and Fatigue Loading. Structures 2022, 41, 1602–1615. [Google Scholar] [CrossRef]

- Dong, H.; Zhou, Y.; Zhuang, N. Study on Corrosion Characteristics of Concrete-Filled CFRP-Steel Tube Piles under Hygrothermal Environment. Adv. Mater. Sci. Eng. 2020, 2020, 4849038. [Google Scholar] [CrossRef]

- Ananthkumar, M.; Mini, K.M.; Prakash, C.; Sharma, S.V.; Krishnaa, A.C.B. Study on the Efficiency of CFRP and GFRP in Corrosion Resistance of Rebar Embedded in Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012137. [Google Scholar] [CrossRef]

- Seyhan, E.C.; Goksu, C.; Saribas, I.; Ilki, A. Hybrid Use of Externally Embedded FRP Reinforcement for Seismic Retrofitting of Substandard RC Columns. J. Compos. Constr. 2023, 27, 04023022. [Google Scholar] [CrossRef]

- Shakir, Q.M.; Alsaheb, S.D.; Farsangi, E.N. Rehabilitation of Deteriorated Reinforced Self-Consolidating Concrete Brackets and Corbels Using CFRP Composites: Diagnosis and Treatment. J. Build. Pathol. Rehabil. 2023, 8, 16. [Google Scholar] [CrossRef]

- Hanif, M.U.; Seo, S.-Y.; Van Tran, H.; Senghong, K. Monitoring and Characterizing the Debonding in CFRP Retrofitted RC Beams Using Acoustic Emission Technology. Dev. Built Environ. 2023, 14, 100141. [Google Scholar] [CrossRef]

- Moosa, M.K.; Ali, A.Y. Experimental Investigation on The Transform The Simply Supported Girders to Continuous Girder by Using The UHPC Cast in Place Joint. KSCE J. Civ. Eng. 2023, 27, 1697–1707. [Google Scholar] [CrossRef]

- Samy, K.; Fawzy, A.; Founda, M.A. Strengthening of Historic Reinforced Concrete Columns Using Concrete and FRP Jacketing Techniques. Asian J. Civ. Eng. 2022, 24, 885–896. [Google Scholar] [CrossRef]

- Al-Saawani, M.A.; El-Sayed, A.K.; Al-Negheimish, A.I. Inclined FRP U-Wrap Anchorage for Preventing Concrete Cover Separation in FRP Strengthened RC Beams. Arab. J. Sci. Eng. 2022, 48, 4879–4892. [Google Scholar] [CrossRef]

- Tudjono, S.; Prastiwi, Y.A.; Selalatu, D.T. Experimental Study of the Effect of CFRP String on Shear Reinforcement of Reinforced Concrete Beams. In Proceedings of the 6th International Conference On Science And Technology (ICST21): Challenges and Opportunities for Innovation Research on Science Materials, and Technology in the COVID-19 Era, Mataram, Indonesia, 2 November 2021. [Google Scholar]

- Kim, Y.J.; Hassani, A. Stepped Reinforced Concrete Beams Retrofitted with Carbon Fiber-Reinforced Polymer Sheets and Ultra-High-Performance Concrete. Struct. J. 2023, 120, 91–104. [Google Scholar] [CrossRef]

- Murad, Y.Z.; Al-Mahmood, H.; Tarawneh, A.; Aljaafreh, A.J.; AlMashaqbeh, A.; Abdel Hadi, R.; Shabbar, R. Shear Strengthening of RC Beams Using Fabric-Reinforced Cementitious Matrix, Carbon Plates, and 3D-Printed Strips. Sustainability 2023, 15, 4293. [Google Scholar] [CrossRef]

- Guo, R.; Li, C.; Xian, G. Water Absorption and Long-Term Thermal and Mechanical Properties of Carbon/Glass Hybrid Rod for Bridge Cable. Eng. Struct. 2023, 274, 115176. [Google Scholar] [CrossRef]

- Xue, J.; Lavorato, D.; Tarantino, A.M.; Briseghella, B.; Nuti, C. Rebar Replacement in Severely Damaged RC Bridge Column Plastic Hinges: Design Criteria and Experimental Investigation. J. Struct. Eng. 2023, 149, 04023007. [Google Scholar] [CrossRef]

- Saharan, S.; Kaur, G.; Bansal, P.P. Confined Ultrahigh-Performance Fibre-Reinforced Concrete in Retrofitted Beam–Column Joint: Experimental Study. Mag. Concr. Res. 2023, 75, 217–233. [Google Scholar] [CrossRef]

- Saljoughian, A.; Mostofinejad, D.; Raji, A. Retrofit of Concrete Columns with Fibre Strips Using Grooves and Corner Battens. Proc. Inst. Civ. Eng.-Struct. Build. 2023, 176, 203–217. [Google Scholar] [CrossRef]

- Kim, K.-M.; Park, S.-W. Tensile Behavior of Textile Reinforced Concrete Members Reinforced with a Carbon Grid by Different Manufacturing Methods. J. Korea Concr. Inst. 2023, 35, 111–121. [Google Scholar] [CrossRef]

- Xue, X.; Makota, C.; Khalaf, O.I.; Jayabalan, J.; Samui, P.; Abdulsahib, G.M. Machine Learning Approach for Prediction of Lateral Confinement Coefficient of CFRP-Wrapped RC Columns. Symmetry 2023, 15, 545. [Google Scholar] [CrossRef]

- Khan, A.-R.; Nasir, R.; Fareed, S. Simulation of Reinforced Concrete Columns Strengthened with CFRP Wraps. Int. J. Civ. Eng. 2023, 21, 299–313. [Google Scholar] [CrossRef]

- Yin, X.; Huang, Z.; Liu, Y. Damage Features Extraction of Prestressed Near-Surface Mounted CFRP Beams Based on Tunable Q-Factor Wavelet Transform and Improved Variational Modal Decomposition. Structures 2022, 45, 1949–1961. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, Y.; Duan, L.; Huo, Y.; Liu, H. Dynamic Behavior of CFRP Strengthen RC Beams Based on Digital Image Correlation Technology. Eng. Fract. Mech. 2022, 271, 108597. [Google Scholar] [CrossRef]

- Zhu, M.; Li, X.; Deng, J.; Peng, S. Electrochemical Impedance Based Interfacial Monitoring for Concrete Beams Strengthened with CFRP Subjected to Wetting–Drying Cycling and Sustained Loading. Constr. Build. Mater. 2023, 366, 130238. [Google Scholar] [CrossRef]

- Qiang, X.; Chen, L.; Jiang, X. Experimental and Theoretical Study on Flexural Behavior of Steel–Concrete Composite Beams Strengthened by CFRP Plates with Unbonded Retrofit Systems. Compos. Struct. 2023, 309, 116763. [Google Scholar] [CrossRef]

- Yu, X.Y.; Jiang, C.; Zhang, W.P. Failure Mode-Based Calculation Method for Bending Bearing Capacities of Corroded RC Beams Strengthened with CFRP Sheets. Eng. Struct. 2022, 271, 114946. [Google Scholar] [CrossRef]

- Wang, Z.; Xian, G.; Yue, Q. Finite Element Modeling of Debonding Failure in CFRP-Strengthened Steel Beam Using a Ductile Adhesive. Compos. Struct. 2023, 311, 116818. [Google Scholar] [CrossRef]

- Guo, D.; Gao, W.Y.; Liu, Y.L.; Dai, J.G. Intermediate Crack-Induced Debonding in CFRP-Retrofitted Notched Steel Beams at Different Service Temperatures: Experimental Test and Finite Element Modeling. Compos. Struct. 2023, 304, 116388. [Google Scholar] [CrossRef]

- Liu, X.; Yu, W.; Huang, Y.; Yang, G.; You, W.; Gao, L.; Song, J. Long-Term Behaviour of Recycled Aggregate Concrete Beams Prestressed with Carbon Fibre-Reinforced Polymer (CFRP) Tendons. Case Stud. Constr. Mater. 2023, 18, e01785. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, J.; Li, D.; Du, X. Meso-Scale Analysis of Shear Performance and Size Effect of CFRP Sheets Strengthened RC Beams. Structures 2022, 45, 1630–1645. [Google Scholar] [CrossRef]

- Huang, Z.; Deng, W.; Li, R.; Chen, J.; Sui, L.; Zhou, Y.; Zhao, D.; Yang, L.; Ye, J. Multi-Impact Performance of Prestressed CFRP-Strengthened RC Beams Using H-Typed End Anchors. Mar. Struct. 2022, 85, 103264. [Google Scholar] [CrossRef]

- Lam, C.C.; Zhang, Y.; Gu, J.; Cai, J. Reinforcing Strategies of CFRP Plate for Coped Steel Beams against Local Buckling. Eng. Struct. 2023, 275, 115227. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, J.; Du, W.; Tong, C.; Zhu, Z.; Jing, Y. Residual Load-Carrying Performance of CFRP Strengthened RC Beam after Drop Hammer Impact. Int. J. Impact Eng. 2023, 175, 104547. [Google Scholar] [CrossRef]

- Hasan, M.A.; Akiyama, M.; Kojima, K.; Izumi, N. Shear Behaviour of Reinforced Concrete Beams Repaired Using a Hybrid Scheme with Stainless Steel Rebars and CFRP Sheets. Constr. Build. Mater. 2023, 363, 129817. [Google Scholar] [CrossRef]

- Alabdulhady, M.Y.; Ojaimi, M.F.; Chkheiwer, A.H. The Efficiency of CFRP Strengthening and Repair System on the Flexural Behavior of RC Beams Constructed with Different Concrete Compressive Strength. Results Eng. 2022, 16, 100763. [Google Scholar] [CrossRef]

- Gemi, L.; Aksoylu, C.; Yazman, Ş.; Özkılıç, Y.O.; Arslan, M.H. Experimental Investigation of Shear Capacity and Damage Analysis of Thinned End Prefabricated Concrete Purlins Strengthened by CFRP Composite. Compos. Struct. 2019, 229, 111399. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Yazman, Ş.; Aksoylu, C.; Arslan, M.H.; Gemi, L. Numerical Investigation of the Parameters Influencing the Behavior of Dapped End Prefabricated Concrete Purlins with and without CFRP Strengthening. Constr. Build. Mater. 2021, 275, 122173. [Google Scholar] [CrossRef]

- Aksoylu, C.; Yazman, Ş.; Özkılıç, Y.O.; Gemi, L.; Arslan, M.H. Experimental Analysis of Reinforced Concrete Shear Deficient Beams with Circular Web Openings Strengthened by CFRP Composite. Compos. Struct. 2020, 249, 112561. [Google Scholar] [CrossRef]

- Gemi, L.; Madenci, E.; Özkılıç, Y.O. Experimental, Analytical and Numerical Investigation of Pultruded GFRP Composite Beams Infilled with Hybrid FRP Reinforced Concrete. Eng. Struct. 2021, 244, 112790. [Google Scholar] [CrossRef]

- Arslan, M.H.; Yazman, Ş.; Hamad, A.A.; Aksoylu, C.; Özkılıç, Y.O.; Gemi, L. Shear Strengthening of Reinforced Concrete T-Beams with Anchored and Non-Anchored CFRP Fabrics. Structures 2022, 39, 527–542. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; Yazman, Ş.; Gemi, L.; Arslan, M.H. Behavior of CFRP-Strengthened RC Beams with Circular Web Openings in Shear Zones: Numerical Study. Structures 2022, 41, 1369–1389. [Google Scholar] [CrossRef]

- Gemi, L.; Madenci, E.; Özkılıç, Y.O.; Yazman, Ş.; Safonov, A. Effect of Fiber Wrapping on Bending Behavior of Reinforced Concrete Filled Pultruded GFRP Composite Hybrid Beams. Polymers 2022, 14, 3740. [Google Scholar] [CrossRef]

- Gemi, L.; Alsdudi, M.; Aksoylu, C.; Yazman, Ş.; Özkılıç, Y.O. Optimum Amount of CFRP for Strengthening Shear Deficient Reinforced Concrete Beams. Steel Compos. Struct. 2022, 43, 735–757. [Google Scholar] [CrossRef]

- Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Safonov, A. The Effects of Eccentric Web Openings on the Compressive Performance of Pultruded GFRP Boxes Wrapped with GFRP and CFRP Sheets. Polymers 2022, 14, 4567. [Google Scholar] [CrossRef] [PubMed]

- Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Asyraf, M.R.M.; Syamsir, A.; Supian, A.B.M.; Mamaev, N. Buckling Analysis of CNT-Reinforced Polymer Composite Beam Using Experimental and Analytical Methods. Materials 2023, 16, 614. [Google Scholar] [CrossRef] [PubMed]

- Aksoylu, C.; Özkılıç, Y.O.; Madenci, E.; Safonov, A. Compressive Behavior of Pultruded GFRP Boxes with Concentric Openings Strengthened by Different Composite Wrappings. Polymers 2022, 14, 4095. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Gemi, L.; Madenci, E.; Aksoylu, C.; Kalkan, İ. Effect of the GFRP Wrapping on the Shear and Bending Behavior of RC Beams with GFRP Encasement. Steel Compos. Struct. 2022, 45, 193–204. [Google Scholar] [CrossRef]

- Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Asyraf, M.R.M.; Syamsir, A.; Supian, A.B.M.; Elizaveta, B. Experimental and Analytical Investigation of Flexural Behavior of Carbon Nanotube Reinforced Textile Based Composites. Materials 2023, 16, 2222. [Google Scholar] [CrossRef]

- Patel, T.K.; Salla, S.R.; Vasanwala, A.; Patel, D. Experimental Study on the Stress–Strain Behavior of Partially and Fully Wrapped Axially Loaded Square RC Columns Strengthened with BFRP. In Sustainable Building Materials and Construction; Lecture Notes in Civil Engineering; Kondraivendhan, B., Modhera, C.D., Matsagar, V., Eds.; Springer: Singapore, 2022; pp. 179–186. [Google Scholar]

- Xu, J.; Tan, C.; Aboutaha, R.S. Experimental Investigations of Fire-Damaged RC Columns Retrofitted with CFRP or Steel Jackets. In EASEC16; Lecture Notes in Civil Engineering; Wang, C.M., Dao, V., Kitipornchai, S., Eds.; Springer: Singapore, 2021; pp. 1607–1614. [Google Scholar]

- Tang, H.; Wang, H.; Liu, R.; Zou, X.; Jia, Y. Axial Compression Behavior of CFRP-Confined Square Concrete-Filled Double Skin Tube Stub Columns with Stainless Steel Outer Tube. Ocean Eng. 2022, 266, 112871. [Google Scholar] [CrossRef]

- Li, G.; Sun, X.; Yang, Z.; Fang, C.; Qiu, Z. Buckling Behavior of Slender Square Concrete Filled Steel Tubular Columns Strengthened with CFRP Profile under Combined Compression and Bending. J. Build. Eng. 2022, 53, 104563. [Google Scholar] [CrossRef]

- Tang, H.; Zou, X.; Yue, Z.; Liu, Y. Compressive Behavior of CFRP-Confined Concrete-Filled Double-Skin Stainless-Steel Tube Stub Columns. Ocean Eng. 2023, 271, 113735. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, W.; Zheng, Y.; Liu, X.; Cao, H.; Hui, Y. Dynamic Behavior of RC Columns Confined with CFRP Grid-Reinforced ECC Subjected to Lateral Low-Velocity Impact. Int. J. Impact Eng. 2023, 172, 104402. [Google Scholar] [CrossRef]

- Samy, K.; Fouda, M.A.; Fawzy, A.; Elsayed, T. Enhancing the Effectiveness of Strengthening RC Columns with CFRP Sheets. Case Stud. Constr. Mater. 2022, 17, e01588. [Google Scholar] [CrossRef]

- Cao, X.; Chen, Y.; Wang, H.; Cheng, C.; Zhou, X.; Zhang, H.; Kim, S.E.; Kong, Z. Experimental and Numerical Investigation of 800 MPa HSS Welded T-Section Column Strengthened with CFRP. Thin-Walled Struct. 2023, 184, 110510. [Google Scholar] [CrossRef]

- Tan, C.; Jiang, X.; Qiang, X.; Xu, G. Flexural Strengthening of Full-Scale RC Columns with Adhesively-Bonded Longitudinal CFRP Plates: An Experimental Investigation. J. Build. Eng. 2023, 67, 105969. [Google Scholar] [CrossRef]

- Chen, Z.; Pang, Y.; Xu, R.; Zhou, J.; Xu, W. Mechanical Performance of Ocean Concrete-Filled Circular CFRP-Steel Tube Columns under Axial Compression. J. Constr. Steel Res. 2022, 198, 107514. [Google Scholar] [CrossRef]

- Mohammed, T.A.; Abebe, S. Numerical Investigation on CFRP Strengthening and Reinforcement Bar Detailing of RC Columns to Resist Blast Load. Heliyon 2022, 8, e10059. [Google Scholar] [CrossRef]

- Rodríguez, V.; Guerrero, H.; Alcocer, S.M.; Tapia-Hernández, E. Rehabilitation of Heavily Damaged Beam-Column Connections with CFRP Wrapping and SFRM Casing. Soil Dyn. Earthq. Eng. 2021, 145, 106721. [Google Scholar] [CrossRef]

- Xiong, C.N.; Shao, Y.B.; Tong, L.W.; Dai, K.S.; Luo, Y.X. Static Strength of CFRP-Strengthened Preloaded Circular Concrete-Filled Steel Tube Stub Column Columns—Part II: Theoretical and Numerical Analysis. Thin-Walled Struct. 2023, 184, 110547. [Google Scholar] [CrossRef]

- Afefy, H.M.; Kassem, N.M.; Taher, S.E.-D.F. Retrofitting of Defected Closure Strips for Full-Depth Precast Concrete Deck Slabs Using EB-CFRP Sheets. Pract. Period. Struct. Des. Constr. 2019, 24, 1–12. [Google Scholar] [CrossRef]

- Türer, A.; Mercimek, Ö.; Anıl, Ö.; Erbaş, Y. Experimental and Numerical Investigation of Punching Behavior of Two-Way RC Slab with Different Opening Locations and Sizes Strengthened with CFRP Strip. Structures 2023, 49, 918–942. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, L.; Wang, Y.; Fang, Z. Experimental Study on the Flexural Strengthening of One-Way RC Slabs with End-Buckled and/or Externally Bonded CFRP Sheets. Eng. Struct. 2023, 282, 115832. [Google Scholar] [CrossRef]

- Yazdani, S.; Asadollahi, S.; Shoaei, P.; Dehestani, M. Failure Stages in Post-Tensioned Reinforced Self-Consolidating Concrete Slab Strengthened with CFRP Layers. Eng. Fail. Anal. 2021, 122, 105219. [Google Scholar] [CrossRef]

- Azevedo, A.S.; Firmo, J.P.; Correia, J.R.; Chastre, C.; Biscaia, H.; Franco, N. Fire Behaviour of CFRP-Strengthened RC Slabs Using Different Techniques—EBR, NSM and CREatE. Compos. Part B Eng. 2022, 230, 109471. [Google Scholar] [CrossRef]

- Yang, G.; Fan, Y.; Wang, G.; Cui, X.; Li, Q.; Leng, Z.; Deng, K. Mitigation Effects of Air-Backed RC Slabs Retrofitted with CFRP Subjected to Underwater Contact Explosions. Ocean Eng. 2023, 267, 113261. [Google Scholar] [CrossRef]

- Assad, M.; Hawileh, R.A.; Abdalla, J.A. Modeling the Behavior of CFRP-Strengthened RC Slabs under Fire Exposure. Procedia Struct. Integr. 2022, 42, 1668–1675. [Google Scholar] [CrossRef]

- Bielak, J. On the Role of Dowel Action in Shear Transfer of CFRP Textile-Reinforced Concrete Slabs. Compos. Struct. 2023, 311, 116812. [Google Scholar] [CrossRef]

- Ghayeb, H.H.; Atea, R.S.; Al-Kannoon, M.A.A.; Lee, F.W.; Wong, L.S.; Mo, K.H. Performance of Reinforced Concrete Flat Slab Strengthened with CFRP for Punching Shear. Case Stud. Constr. Mater. 2023, 18, e01801. [Google Scholar] [CrossRef]

- Breveglieri, M.; Czaderski, C. RC Slabs Strengthened with Externally Bonded CFRP Strips under Long-Term Environmental Exposure and Sustained Loading. Part 2: Laboratory Experiments. Compos. Part C Open Access 2021, 6, 100210. [Google Scholar] [CrossRef]

- Alrousan, R.Z.; Alnemrawi, B.R. The Behavior of Alkali-Silica Reaction-Damaged Full-Scale Concrete Bridge Deck Slabs Reinforced with CFRP Bars. Results Eng. 2022, 16, 100651. [Google Scholar] [CrossRef]

- Ebadi-Jamkhaneh, M.; Kontoni, D.-P.N. Numerical Finite Element Investigation of Thin Steel Shear Walls Retrofitted with CFRP Layers under Reversed Cyclic Loading. J. Build. Pathol. Rehabil. 2022, 7, 62. [Google Scholar] [CrossRef]

- Shen, J.; Huang, Z.; Song, X.; Yao, Y. Deformation Performance Analysis of Concrete Shear Wall with CFRP Grids Based on the Modified Uniaxial Shear-Flexural Model. J. Build. Eng. 2022, 54, 104621. [Google Scholar] [CrossRef]

- Sahebjam, A.; Showkati, H. Experimental Study on the Cyclic Behavior of Perforated CFRP Strengthened Steel Shear Walls. Arch. Civ. Mech. Eng. 2016, 16, 365–379. [Google Scholar] [CrossRef]

- El-Kashif, K.F.O.; Adly, A.K.; Abdalla, H.A. Finite Element Modeling of RC Shear Walls Strengthened with CFRP Subjected to Cyclic Loading. Alex. Eng. J. 2019, 58, 189–205. [Google Scholar] [CrossRef]

- Altin, S.; Anil, Ö.; Kopraman, Y.; Kara, M.E. Hysteretic Behavior of RC Shear Walls Strengthened with CFRP Strips. Compos. Part B Eng. 2013, 44, 321–329. [Google Scholar] [CrossRef]

- Hatami, F.; Ghamari, A.; Rahai, A. Investigating the Properties of Steel Shear Walls Reinforced with Carbon Fiber Polymers (CFRP). J. Constr. Steel Res. 2012, 70, 36–42. [Google Scholar] [CrossRef]

- Yu, J.G.; Zhu, S.Q.; Feng, X.T. Seismic Behavior of CFRP-Steel Composite Plate Shear Wall with Edge Reinforcement. J. Constr. Steel Res. 2023, 203, 107816. [Google Scholar] [CrossRef]

- Meftah, S.A.; Yeghnem, R.; Tounsi, A.; Adda bedia, E.A. Seismic Behavior of RC Coupled Shear Walls Repaired with CFRP Laminates Having Variable Fibers Spacing. Constr. Build. Mater. 2007, 21, 1661–1671. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, J.; Lin, H.; Song, X.; Yao, Y. Shear Behavior of Concrete Shear Walls with CFRP Grids under Lateral Cyclic Loading. Eng. Struct. 2020, 211, 110422. [Google Scholar] [CrossRef]

- Yu, J.-G.; Zhu, S.-Q. Study on Seismic Behavior of Oblique CFRP Corrugated Plate-Steel Plate Light Weight Sandwich Composite Shear Wall. Structures 2023, 48, 2062–2081. [Google Scholar] [CrossRef]

- Thomas, C.A.; Baskar, K. Testing and Evaluation of Bond Surface Profile Influencing the CFRP Strengthening of Steel Members. J. Test. Eval. 2018, 46, 20170195. [Google Scholar] [CrossRef]

- Zhang, E.Q.; Tang, L.; Bernin, D.; Jansson, H. Effect of the Paste-Anode Interface under Impressed Current Cathodic Protection in Concrete Structures. Mater. Corros. 2018, 69, 1104–1116. [Google Scholar] [CrossRef]

- Karim, M.A.; Bae, J.H.; Kam, D.H.; Kim, C.; Choi, W.H.; Park, Y. Do Assessment of Rivet Coating Corrosion Effect on Strength Degradation of CFRP/Aluminum Self-Piercing Riveted Joints. Surf. Coat. Technol. 2020, 393, 125726. [Google Scholar] [CrossRef]

- Huang, X.; Zhou, Y.; Zheng, X.; Xing, F.; Sui, L.; Hu, B. Bond Performance between Corroded Steel Bars and Concrete in Cathodic Protection System with CFRP as Anode. Compos. Struct. 2023, 309, 116739. [Google Scholar] [CrossRef]

- Shao, W.; Sun, Q.; Xu, X.; Yue, W.; Shi, D. Durability Life Prediction and Horizontal Bearing Characteristics of CFRP Composite Piles in Marine Environments. Constr. Build. Mater. 2023, 367, 130116. [Google Scholar] [CrossRef]

- Ren, X.; Sherif, M.M.; Wei, Y.; Lyu, Y.; Sun, Y.; Ozbulut, O.E. Effect of Corrosion on the Tensile and Fatigue Performance of CFRP Strand Sheet/Steel Double Strap Joints. Eng. Struct. 2022, 260, 114240. [Google Scholar] [CrossRef]

- Wu, C.; Yu, Y.Z.; ho Tam, L.; Orr, J.; He, L. Effect of Glass Fiber Sheet in Adhesive on the Bond and Galvanic Corrosion Behaviours of CFRP-Steel Bonded System. Compos. Struct. 2021, 259, 113218. [Google Scholar] [CrossRef]

- Hu, J.; Wang, S.; Lu, Y.; Li, S. Investigation on Efficiency of Cathodic Protection Applied on Steel in Concrete Cylinder with CFRP Wrap Serving as Anode. Case Stud. Constr. Mater. 2022, 17, e01389. [Google Scholar] [CrossRef]

- Chen, Y.; Li, M.; Su, T.; Yang, X. Mechanical Degradation and Corrosion Characterization of Riveted Joints for CFRP/Al Stacks in Simulated Marine Environments. Eng. Fail. Anal. 2022, 137, 106382. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, H.; Li, Y.; Chen, J.; Zhuang, N. Numerical and Experimental Investigation on the Chloride Ion Resistance of Reinforced Concrete Piles Externally Bonded with CFRP Sheets under Dry-Wet Cycles. Constr. Build. Mater. 2022, 359, 129521. [Google Scholar] [CrossRef]

- Suo, H.; Cheng, H.; Liang, B.; Deng, K.; Luo, B.; Zhang, K.; Chen, H. The Mechanical Degradation Mechanism of CFRP/Al Double-Lap Bolted Joints (with and without Corrosion Protections) after Seawater Ageing. Compos. Struct. 2021, 276, 114561. [Google Scholar] [CrossRef]

- Mohabeddine, A.; Correia, J.; Montenegro, P.A.; De Jesus, A.; Castro, J.M.; Calçada, R.; Berto, F. An Approach for Predicting Fatigue Life of CFRP Retrofitted Metallic Structural Details. Int. J. Fatigue 2022, 154, 106557. [Google Scholar] [CrossRef]

- Doroudi, Y.; Fernando, D.; Hosseini, A.; Ghafoori, E. Behavior of Cracked Steel Plates Strengthened with Adhesively Bonded CFRP Laminates under Fatigue Loading: Experimental and Analytical Study. Compos. Struct. 2021, 266, 113816. [Google Scholar] [CrossRef]

- Gadomski, J.; Pyrzanowski, P. Experimental Investigation of Fatigue Destruction of CFRP Using the Electrical Resistance Change Method. Meas. J. Int. Meas. Confed. 2016, 87, 236–245. [Google Scholar] [CrossRef]

- He, Z.; Luo, Q.; Li, Q.; Zheng, G.; Sun, G. Fatigue Behavior of CFRP/Al Adhesive Joints—Failure Mechanisms Study Using Digital Image Correlation (DIC) Technique. Thin-Walled Struct. 2022, 174, 109075. [Google Scholar] [CrossRef]

- Li, A.; Xu, S.; Wang, Y.; Wu, C.; Nie, B. Fatigue Behavior of Corroded Steel Plates Strengthened with CFRP Plates. Constr. Build. Mater. 2022, 314, 125707. [Google Scholar] [CrossRef]

- Li, J.; Zhu, M.; Deng, J. Flexural Behaviour of Notched Steel Beams Strengthened with a Prestressed CFRP Plate Subjected to Fatigue Damage and Wetting/Drying Cycles. Eng. Struct. 2022, 250, 113430. [Google Scholar] [CrossRef]

- Lesiuk, G.; Katkowski, M.; Duda, M.; Królicka, A.; Correia, J.A.F.O.; De Jesus, A.M.P.; Rabiega, J. Improvement of the Fatigue Crack Growth Resistance in Long Term Operated Steel Strengthened with CFRP Patches. Procedia Struct. Integr. 2017, 5, 912–919. [Google Scholar] [CrossRef]

- Vavouliotis, A.; Paipetis, A.; Kostopoulos, V. On the Fatigue Life Prediction of CFRP Laminates Using the Electrical Resistance Change Method. Compos. Sci. Technol. 2011, 71, 630–642. [Google Scholar] [CrossRef]

- Kotrotsos, A.; Geitona, A.; Kostopoulos, V. On the Mode I and Mode II Fatigue Delamination Growth of CFRPs Modified by Electrospun Bis-Maleimide Resin. Compos. Sci. Technol. 2023, 237, 110000. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Vimalathithan, P.K.; Pugliese, M.; Maiorano, V. Thermomechanical and Morphological Studies of CFRP Tested in Different Environmental Conditions. Materials 2018, 12, 63. [Google Scholar] [CrossRef]

- Al-Tamimi, A.K.; Hawileh, R.A.; Abdalla, J.A.; Rasheed, H.A.; Al-Mahaidi, R. Durability of the Bond between CFRP Plates and Concrete Exposed to Harsh Environments. J. Mater. Civ. Eng. 2015, 27, 04014252. [Google Scholar] [CrossRef]

- Li, Y.; Ma, X.; Li, H.; Zheng, H.; Li, C.; Gao, Y.; Long, J.; Li, Z. Effect of Moisture-Heat Coupling on Mechanical Behavior of Nano-SiO2 Adhesives and CFRP-Steel Lap Joints. Thin-Walled Struct. 2023, 183, 110391. [Google Scholar] [CrossRef]

- Al-Abdwais, A.H.; Al-Mahaidi, R.S. Evaluation of High Temperature Endurance of RC Beams Retrofitted with NSM Technique Using CFRP Composites and Modified Cement-Based Adhesive. Eng. Struct. 2022, 264, 114445. [Google Scholar] [CrossRef]

- Yoo, S.J.; Kim, Y.H.; Yuan, T.F.; Yoon, Y.S. Evaluation of Residual Bond Behavior of CFRP and Steel Bars Embedded in UHPC after Exposure to Elevated Temperature. J. Build. Eng. 2022, 56, 104768. [Google Scholar] [CrossRef]

- Wang, Y.J.; Wu, Z.M.; Liu, H.B.; Zhang, Q.M.; Yang, S.T.; Li, Y.C. Influence of Thermal Effects on Debonding Response of CFRP-to-Concrete/Steel Interfaces under Thermal and Mechanical Loads: An Analytical Solution. Compos. Struct. 2023, 303, 116333. [Google Scholar] [CrossRef]

- Kaiser, I.; Zhang, C.; Tan, K.T. Mechanical Behavior and Failure Mechanisms of CFRP and Titanium Tubular Adhesive Lap Joints at Extreme Temperatures. Compos. Struct. 2022, 290, 115528. [Google Scholar] [CrossRef]

- Peng, K.; Wang, Q.; Shao, Y. Test on Shearing Performance of Concrete Filled Square CFRP-Steel Tube. Ocean Eng. 2023, 274, 114065. [Google Scholar] [CrossRef]

- Jahani, Y.; Baena, M.; Codina, A.; Barris, C.; Torres, L. Time-Dependent Behavior of NSM CFRP-Strengthened RC Beams under Different Service Temperatures. Compos. Struct. 2022, 300, 116106. [Google Scholar] [CrossRef]

- Alkhawaldeh, A.A.; Al-Rousan, R.Z. Upgrading Cyclic Response of Heat-Damaged RC Beam-Column Joints Using CFRP Sheets. Case Stud. Constr. Mater. 2022, 17, e01699. [Google Scholar] [CrossRef]

- Li, Y.; Guo, X.; Yang, J.; Li, M. Preparation of Nano-SiO2/Carbon Fiber-Reinforced Concrete and Its Influence on the Performance of Oil Well Cement. Int. J. Polym. Sci. 2019, 2019, 2783018. [Google Scholar] [CrossRef]

- Jongvivatsakul, P.; Thongchom, C.; Mathuros, A.; Prasertsri, T.; Adamu, M.; Orasutthikul, S.; Lenwari, A.; Charainpanitkul, T. Enhancing Bonding Behavior between Carbon Fiber-Reinforced Polymer Plates and Concrete Using Carbon Nanotube Reinforced Epoxy Composites. Case Stud. Constr. Mater. 2022, 17, e01407. [Google Scholar] [CrossRef]

- Du, Y.; Lu, S.; Xu, J.; Xia, W.; Wang, T.; Wang, Z. Experimental Study of Impact Mechanical and Microstructural Properties of Modified Carbon Fiber Reinforced Concrete. Sci. Rep. 2022, 12, 12928. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Ababneh, A.; Alhassan, M. Hybrid CFRP-Steel for Enhancing the Flexural Behavior of Reinforced Concrete Beams. J. King Saud Univ.-Eng. Sci. 2021, 33, 459–470. [Google Scholar] [CrossRef]

- Abolfazli, M.; Ivan John Reyes, R.; Choong, D.; Bazli, M.; Rajabipour, A.; Pourasiabi, H.; Arashpour, M. Bond Behaviour between CFRP, GFRP, and Hybrid C-GFRP Tubes and Seawater Sea Sand Concrete after Exposure to Elevated Temperatures. Constr. Build. Mater. 2023, 392, 131884. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, S.W. Self-Sensing-Based Deflection Control of Carbon Fibre-Reinforced Polymer (CFRP)-Based Shape Memory Alloy Hybrid Composite Beams. Compos. Struct. 2020, 251, 112544. [Google Scholar] [CrossRef]

- Todoroki, A.; Kurokawa, H.; Mizutani, Y.; Matsuzaki, R.; Yasuoka, T. Self-Sensing Time Domain Reflectometry Method for Damage Monitoring of a CFRP Plate Using a Narrow-Strip Transmission Line. Compos. Part B Eng. 2014, 58, 59–65. [Google Scholar] [CrossRef]

- Shin, P.S.; Baek, Y.M.; Kim, J.H.; Kwon, D.J. The Factor Influencing Self-Sensing Property of Carbon Fiber. Compos. Sci. Technol. 2023, 238, 110017. [Google Scholar] [CrossRef]

- Yoshitake, I.; Hasegawa, H.; Shimose, K. Monotonic and Cyclic Loading Tests of Reinforced Concrete Beam Strengthened with Bond-Improved Carbon Fiber Reinforced Polymer (CFRP) Rods of Ultra-High Modulus. Eng. Struct. 2020, 206, 110175. [Google Scholar] [CrossRef]

- Lamba, N.; Raj, R.; Singh, P. Mechanical Response of Recycled Carbon Fiber Reinforced Polymer Fibers in High-Strength Concrete. Mater. Today Proc. 2023, 78, 603–607. [Google Scholar] [CrossRef]

- Zhang, L.W.; Sojobi, A.O.; Liew, K.M. Sustainable CFRP-Reinforced Recycled Concrete for Cleaner Eco-Friendly Construction. J. Clean. Prod. 2019, 233, 56–75. [Google Scholar] [CrossRef]

- Xiong, C.; Li, Q.; Lan, T.; Li, H.; Long, W.; Xing, F. Sustainable Use of Recycled Carbon Fiber Reinforced Polymer and Crumb Rubber in Concrete: Mechanical Properties and Ecological Evaluation. J. Clean. Prod. 2021, 279, 123624. [Google Scholar] [CrossRef]

- Maxineasa, S.G.; Taranu, N.; Bejan, L.; Isopescu, D.; Banu, O.M. Environmental Impact of Carbon Fibre-Reinforced Polymer Flexural Strengthening Solutions of Reinforced Concrete Beams. Int. J. Life Cycle Assess. 2015, 20, 1343–1358. [Google Scholar] [CrossRef]

- Khorgade, P.; Rettinger, M.; Burghartz, A.; Schlaich, M. A Comparative Cradle-to-Gate Life Cycle Assessment of Carbon Fiber-Reinforced Polymer and Steel-Reinforced Bridges. Struct. Concr. 2022, 24, 1737–1750. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.Y.; Yan, L. Mechanical Performance of CFRP-Confined Sustainable Geopolymeric Recycled Concrete under Axial Compression. Eng. Struct. 2020, 224, 111246. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vijayan, D.S.; Sivasuriyan, A.; Devarajan, P.; Stefańska, A.; Wodzyński, Ł.; Koda, E. Carbon Fibre-Reinforced Polymer (CFRP) Composites in Civil Engineering Application—A Comprehensive Review. Buildings 2023, 13, 1509. https://doi.org/10.3390/buildings13061509

Vijayan DS, Sivasuriyan A, Devarajan P, Stefańska A, Wodzyński Ł, Koda E. Carbon Fibre-Reinforced Polymer (CFRP) Composites in Civil Engineering Application—A Comprehensive Review. Buildings. 2023; 13(6):1509. https://doi.org/10.3390/buildings13061509

Chicago/Turabian StyleVijayan, Dhanasingh Sivalinga, Arvindan Sivasuriyan, Parthiban Devarajan, Anna Stefańska, Łukasz Wodzyński, and Eugeniusz Koda. 2023. "Carbon Fibre-Reinforced Polymer (CFRP) Composites in Civil Engineering Application—A Comprehensive Review" Buildings 13, no. 6: 1509. https://doi.org/10.3390/buildings13061509

APA StyleVijayan, D. S., Sivasuriyan, A., Devarajan, P., Stefańska, A., Wodzyński, Ł., & Koda, E. (2023). Carbon Fibre-Reinforced Polymer (CFRP) Composites in Civil Engineering Application—A Comprehensive Review. Buildings, 13(6), 1509. https://doi.org/10.3390/buildings13061509