Pythagorean Fuzzy AHP Based Dynamic Subcontractor Management Framework

Abstract

1. Introduction

2. Literature Review

2.1. Subcontractor Evaluation and Selection Processes

2.2. Subcontractor Performance Appraisal On-Site

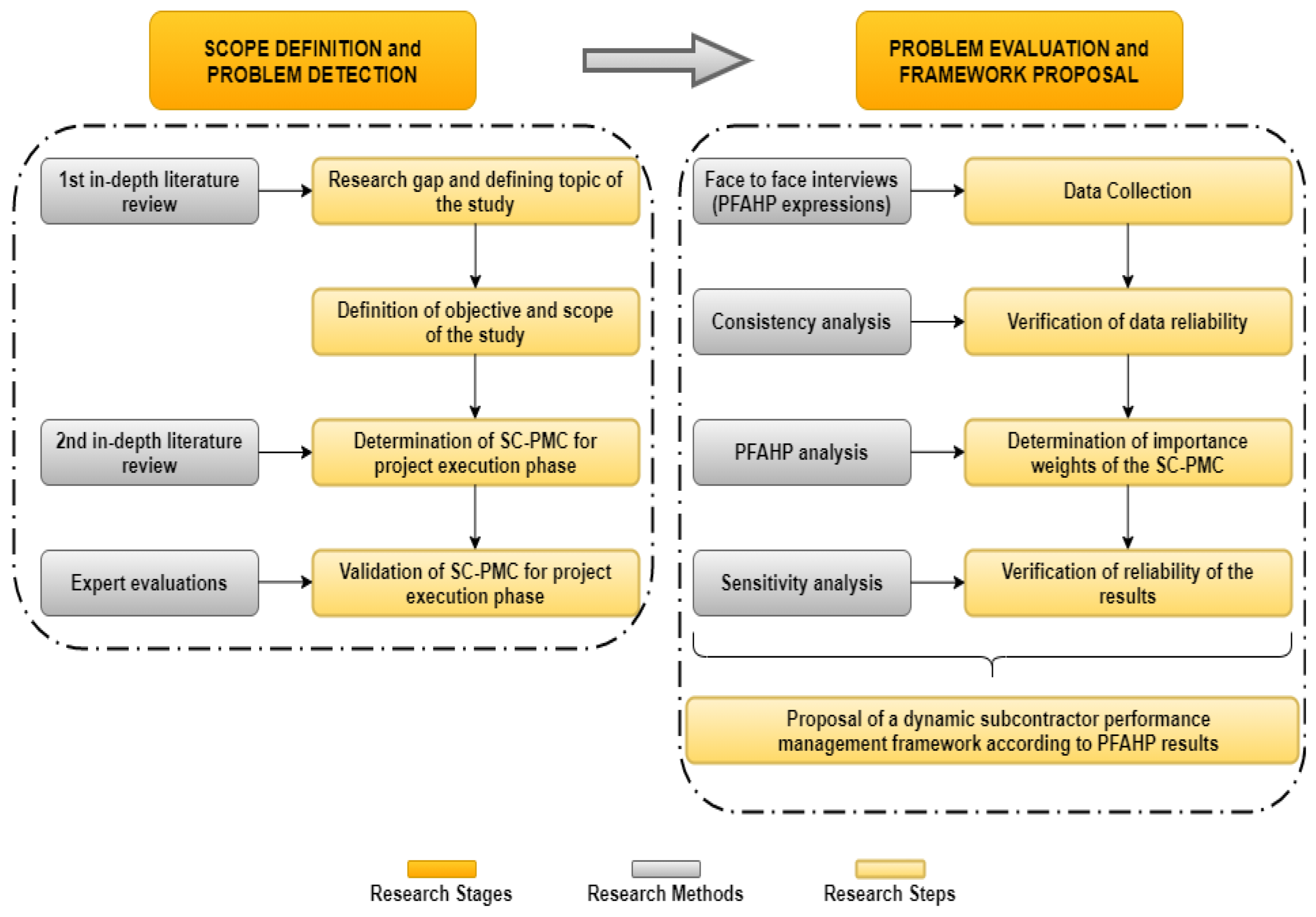

3. Research Methodology

4. Subcontractor Performance Measurement Criteria (SC-PMC) for Project Execution Phase

- Time (C1): In the literature, this criterion has been identified under the names of timely completion of works, on-time delivery, process progress monitoring, and progress control. Shiau et al. [41] established ‘progress control’, ‘work quality’, ‘cooperativeness’, ‘safety management’ and ‘material management’ criteria for SC selection criteria. Ng [24] conducted a study with the criteria of, ‘completion of job within the time’ and ‘adherence to program’ sub-criteria. Hanák and Nekardová [40] created the SC selection criteria, and it is seen that these criteria are also important for performance measurement. The criterion related to time is ‘meeting the delivery deadlines’ and ‘speed in remedying claim of defects’.

- Cost (C2): Some criteria have been found in the literature regarding cost for SCs. Eom et al. [42] proposed four groups for a SC management framework (financial, service, process and improvement) in their study. In the finance element, there are “profitability, growth, activeness, and stability” sub-titles are observed. Arslan et al. [43] also examined the PMC under the headings of cost, quality, time, and adequacy. It has created ‘timely payment to laborers and ‘completion of job within the budget’ sub-criteria within the subject of cost. El-Mashaleh [44] mentioned the importance of cost control by making timely payments with the criterion of ‘prompt payment to labor’. Hanák and Nekardová [40] included ‘meeting the planned price’ criterion related to cost dimension in their studies.

- Quality (C3): Another meaning of successful completion of construction projects is to reach the quality standards specified in the contracts and specifications, together with the desired time and costs of the product. For this reason, the performance of the SCs involved in the production of the products in the projects, in compliance with the quality standards, is important. Pallikkonda et al. [45] presented a SC preliminary evaluation framework for SC ratings with eight main titles: time, cost, quality, technical capability, management capability, health and safety, experience and reputation and adequacy. In the study, the criterion of ‘quality assurance programs’ was mentioned in the quality group. In the studies of Arslan et al. [43] under the main heading of quality, ‘quality of production’, ‘quality of materials used’, ‘job safety’ and ‘number of qualified personal’ criteria are seen. Jasim [46] outlines criteria as ‘performance timelines’, ‘work quality’, ‘budget management’, ‘resource availability’ and ‘communication problems’ in his study to classify and diagnose the causes of poor-quality management in construction projects.

- Resource Adequacy (C4): The researchers have gathered some important criteria here by opening the title of ‘adequacy’. These were determined as ‘adequacy of labor resources’, ‘adequacy of material resources’, ‘compliance with company image’ and ‘compliance with other employees on-site’. Hwang and Lim [47] identified four main categories of critical success factors for project success: project characteristics, contractual arrangements, project participants and interactive processes. The factors that concern SCs were as follows: capability, SC key personal, competency of SC proposed team, SC team turnover rate, SC top management support, SC track record and SC level of service.

- Compatibility and Communication (C5): The communication and compliance abilities of the SCs, with whom the MCs are in constant communication, also affect the performances in other categories for the projects. Mbachu [27] prepared a conceptual evaluation framework for evaluating the performance of SCs during the construction phase and has determined different PMC. Among these criteria, there is also the good communication network criterion. Afshar et al. [22] examined the evaluation criteria in two main groups (technical and behavioral) in a multiple decision-making method model that performed for SC pre-evaluation. The behavioral ones as SC’s personality, respect to ethics, creativity, self-control, suitable teamwork, respect for others, honesty, work obligation, having discipline and orderliness, SC personal manner of communication and SC flexibility in interaction with the MC. It is always possible for changes to occur in the projects during the implementation phase of construction projects. How SCs will respond to this has also become an important question. Based on this, Hanak and Nekardova [40] mentioned the ‘ability to flexibility respond to changes in the project’ criterion in their work.

- OHS—Environmental Protection (C6): OHS and Environmental Protection issues are among the most important issues in construction projects, which are frequently encountered in addition to time, cost, and quality dimensions. Ng and Tang [28] obtain more qualified results for measurement by including the topics of ‘health and safety’, ‘environmental protection’, ‘organization’, ‘general obligations’, ‘industry awareness’ and ‘attendance to emergency’. In the SC evaluation study conducted within the framework of lean construction principles, Maturana et al. [26] determined the criteria of ‘quality’, ‘schedule fulfillment’, ‘safety’ and ‘cleanliness’ developed lean principles in these matters. Cheng et al. [38] gathered the SC performance assessment factors under the following headings in their studies. ‘Duration control abilities’, ‘material wastage’, ‘collaboration with other SCs’, ‘safe working environment’, ‘clean working environment’ and ‘financial condition’. Ng and Skitmore [30] considered criteria ‘workmanship’, ‘progress’, ‘safety’, ‘communication’ and ‘environment’ for SC evaluation. Cheng and Wu [39] listed the SC evaluation criteria in the concept of OHS and Environment as follows: Material wastage, safety and protection, tool usage habit, and workspace cleanliness.

- Leadership (C7): For holistic success in projects, it has become a necessity to examine and evaluate other characteristics of SCs apart from the above-mentioned criteria. Social structures, life views and personal characteristics of the parties can also have an impact in works where efforts are made for a common purpose. Akinshipe et al. [48] revealed that innovative thinking style, problem-solving skills, reliability, emotional maturity and control, and trust from project stakeholders are vital features required for the successful completion of projects. Ferdig [49] defines leaders as follows: Leaders are those who inspire and illuminate a common vision, help build consensus, create direction and create incentives among participants in the beliefs and actions needed by an organization. A more advanced concept, ‘Transformational leadership’, is a type of leadership that focuses on collaborators and the development of subordinates. Transformational leaders encourage the development of groups and organizations while raising followers’ desire for success and self-development [50]. Zavari and Afhsar [51] evaluating the effect of the transformational leadership style of construction site managers on the success of construction projects, showed that the transformational leadership of a site manager is directly related to project success.

5. Pythagorean Fuzzy Analytic Hierarchy Process (PFAHP)

5.1. Data Collection

5.2. Data Analysis

5.2.1. Steps of PFAHP

5.2.2. Consistency Analysis

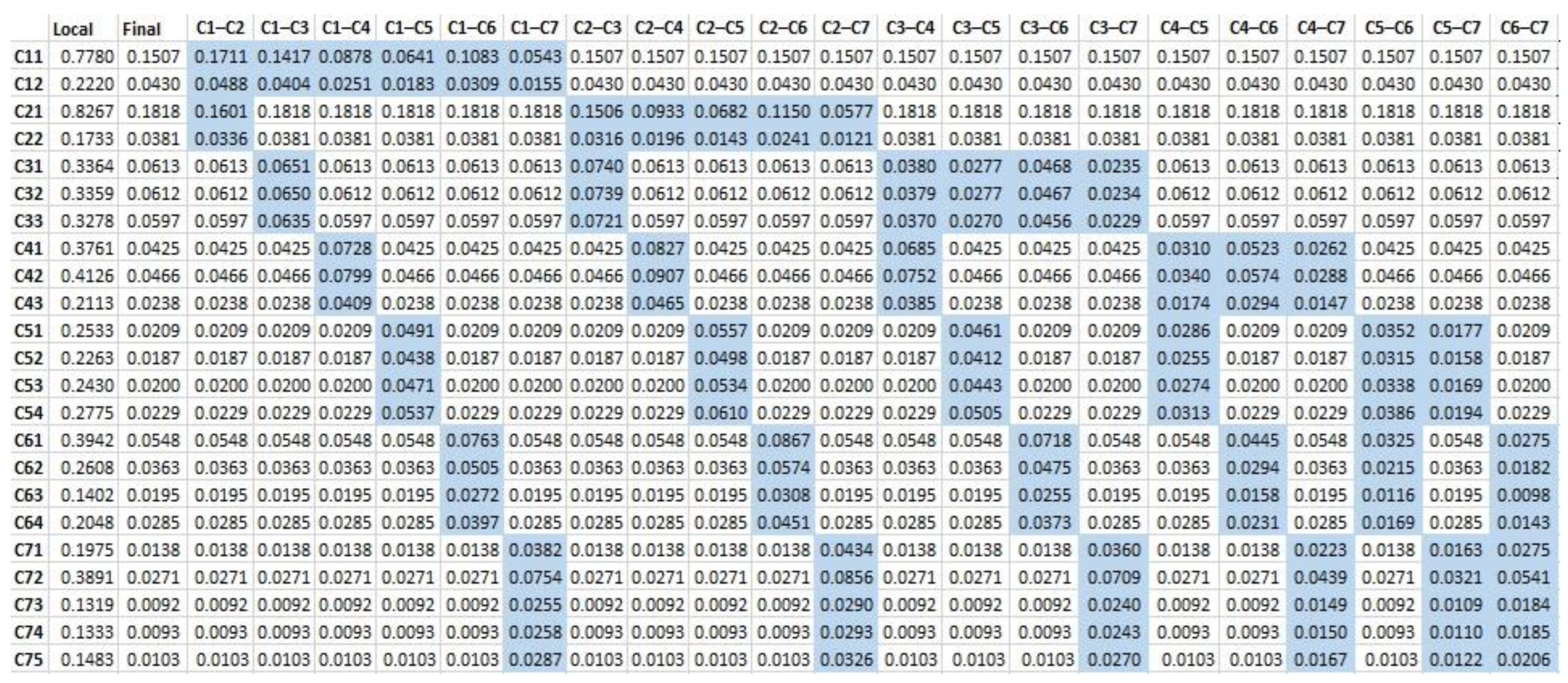

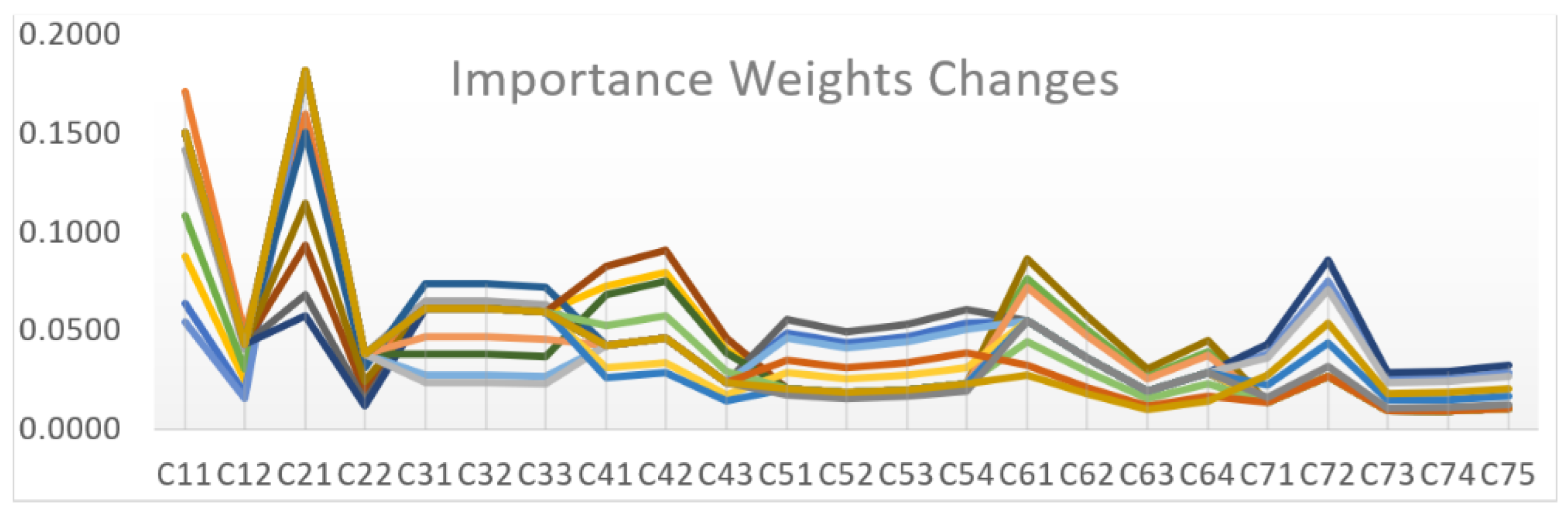

5.2.3. Sensitivity Analysis of the PFAHP Method

5.2.4. PFAHP Analysis Results

5.2.5. Discussion of the PFAHP Analysis Results

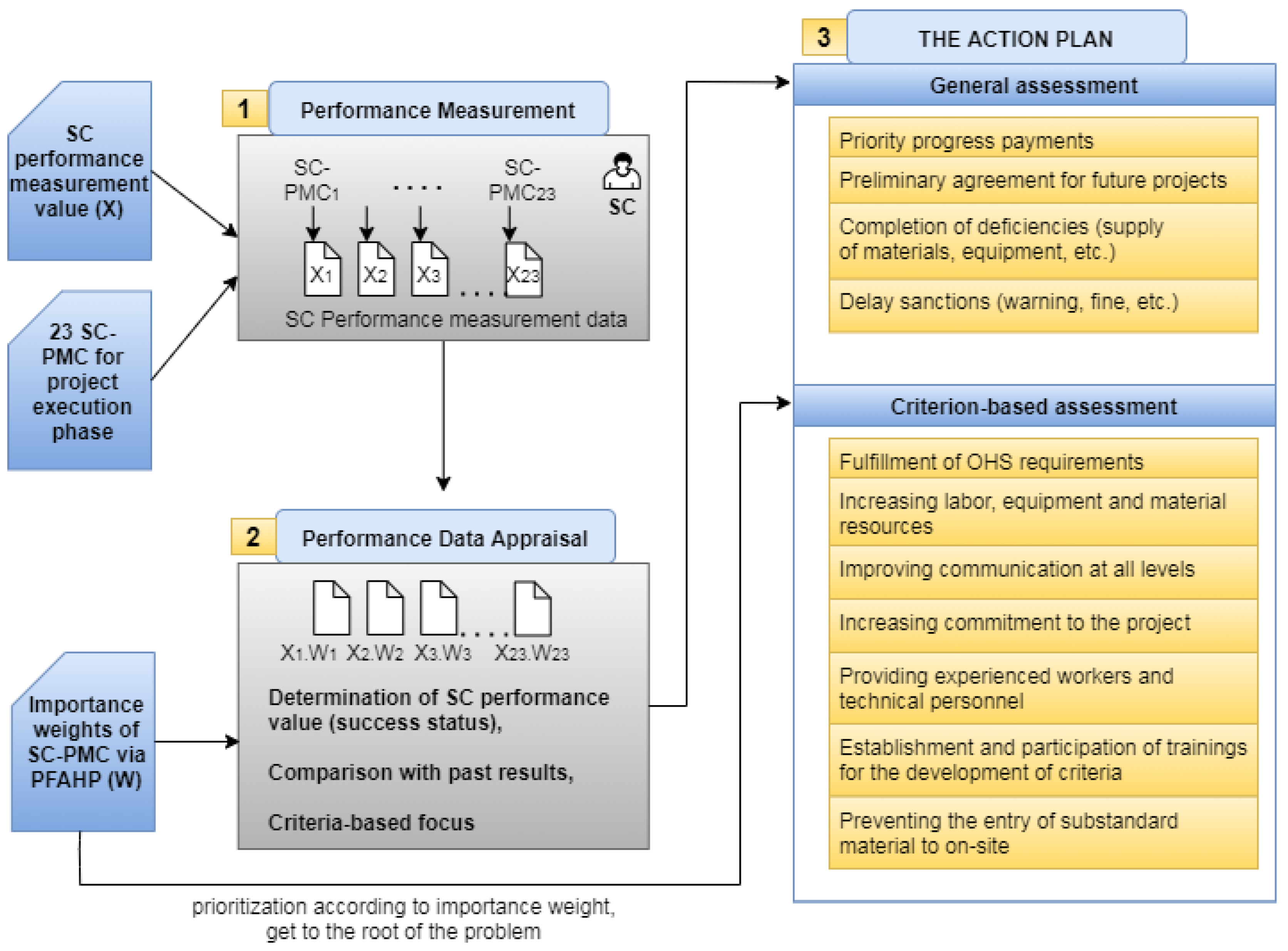

6. A Dynamic Subcontractor Management Framework for Performance Measurement and Evaluation on Project Execution Phase

6.1. Performance Measurement

6.2. Performance Data Appraisal

6.3. The Action Plan

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Artan Ilter, D.; Bakioglu, G. Modeling the relationship between risk and dispute in subcontractor contracts. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2018, 10, 04517022. [Google Scholar] [CrossRef]

- Hsieh, T.-Y. Impact of Subcontracting on Site Productivity: Lessons Learned in Taiwan. J. Constr. Eng. Manag. 1998, 124, 91–100. [Google Scholar] [CrossRef]

- Yoke-Lian, L.; Hassim, S.; Muniandy, R.; Teik-Hua, L. Review of subcontracting practice in construction industry. Int. J. Eng. Technol. 2012, 4, 442. [Google Scholar] [CrossRef]

- Sanvido, V.; Grobler, F.; Parfitt, K.; Guvenis, M.; Coyle, M. Critical Success Factors for Construction Projects. J. Constr. Eng. Manag. 1992, 118, 94–111. [Google Scholar] [CrossRef]

- Lew, Y.-L.; Hassim, S.; Muniandy, R.; Hua, L.T. Structural equation modelling for subcontracting practice: Malaysia chapter. Eng. Constr. Arch. Manag. 2018, 25, 835–860. [Google Scholar] [CrossRef]

- Krechowicz, M. Effective Risk Management in Innovative Projects: A Case Study of the Construction of Energy-efficient, Sustainable Building of the Laboratory of Intelligent Building in Cracow. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 062006. [Google Scholar] [CrossRef]

- Vivek, A.; Rao, C.H. Identification and analysing of risk factors affecting cost of construction projects. Mater. Today Proc. 2022, 60, 1696–1701. [Google Scholar] [CrossRef]

- Hartmann, A.; Caerteling, J. Subcontractor procurement in construction: The interplay of price and trust. Supply Chain Manag. Int. J. 2010, 15, 354–362. [Google Scholar] [CrossRef]

- Abbasianjahromi, H.; Rajaie, H.; Shakeri, E. A framework for subcontractor selectıon ın the constructıon ındustry. J. Civ. Eng. Manag. 2013, 19, 158–168. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Huang, C.C. Evaluating Subcontractor Performance Using Evolutionary Gaussian Process Inference Model. Life Sci. J. 2012, 9, 527–532. [Google Scholar]

- Abbasianjahromi, H.; Rajaie, H.; Shakeri, E.; Chokan, F. A New Decision Making Model for Subcontractor Selection and Its Order Allocation. Proj. Manag. J. 2014, 45, 55–66. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Kazaz, A. Fuzzy multı-crıterıa decısıon makıng model for subcontractor selectıon ın ınternatıonal constructıon projects. Technol. Econ. Dev. Econ. 2015, 22, 210–234. [Google Scholar] [CrossRef]

- Shahvand, E.; Sebt, M.H.; Banki, M.T. Developing fuzzy expert system for supplier and subcontractor evaluation in construction industry. Sci. Iran. 2016, 23, 842–855. [Google Scholar] [CrossRef]

- Polat, G. Subcontractor selection using the integration of the AHP and PROMETHEE methods. J. Civ. En-Gineering Manag. 2016, 22, 1042–1054. [Google Scholar] [CrossRef]

- Abbasianjahromi, H.; Sepehri, M.; Abbasi, O. A Decision-Making Framework for Subcontractor Selection in Construction Projects. Eng. Manag. J. 2018, 30, 141–152. [Google Scholar] [CrossRef]

- Shivam, J.; Kashiyani, B. Development of conceptual model for effective selection of subcontractor for building construction project. Int. Res. J. Eng. Technol. 2018, 5, 1413–1417. [Google Scholar]

- Koçak, S.; Kazaz, A.; Ulubeyli, S. Subcontractor selection with additive ratio assessment method. J. Constr. Eng. Manag. Innov. 2018, 1, 18–32. [Google Scholar] [CrossRef]

- Palha, R.; De Almeida, A.T.; Morais, D.C.; Hipel, K.W. Sortıng subcontractors’ actıvıtıes ın constructıon projects wıth a novel addıtıve-veto sortıng approach. J. Civ. Eng. Manag. 2019, 25, 306–321. [Google Scholar] [CrossRef]

- El-Khalek, H.A.; Aziz, R.F.; Morgan, E.S. Identification of construction subcontractor prequalification evaluation criteria and their impact on project success. Alex. Eng. J. 2019, 58, 217–223. [Google Scholar] [CrossRef]

- Nov, P.; Peansupap, V. Using Artificial Neural Network for Selecting Type of Subcontractor Relationships in Construction Project. Eng. J. 2020, 24, 73–88. [Google Scholar] [CrossRef]

- Abdullah, L.; Ong, Z.; Rahim, N. An Intuitionistic Fuzzy Decision-Making for Developing Cause and Effect Criteria of Subcontractors Selection. Int. J. Comput. Intell. Syst. 2021, 14, 991–1002. [Google Scholar] [CrossRef]

- Afshar, M.R.; Shahhosseini, V.; Sebt, M.H. Optimal sub-contractor selection and allocation in a multiple construction project: Project portfolio planning in practice. J. Oper. Res. Soc. 2020, 73, 351–364. [Google Scholar] [CrossRef]

- Karaman, A.E.; Sandal, K. Effect of Sub-Contractor Selection on Construction Project Success in Turkey. Tek. Dergi 2022, 33, 12105–12118. [Google Scholar] [CrossRef]

- Ng, S.T. Using Balanced Scorecard for Subcontractor Performance Appraisal. In Proceedings of the Strategic Integration of Surveying Services, FIG Working Week 2007, Hong Kong, China, 13–17 May 2007; pp. 1–9. [Google Scholar]

- Ko, C.-H.; Cheng, M.-Y.; Wu, T.-K. Evaluating sub-contractors performance using EFNIM. Autom. Constr. 2007, 16, 525–530. [Google Scholar] [CrossRef]

- Maturana, S.; Alarcón, L.F.; Gazmuri, P.; Vrsalovic, M. On-Site Subcontractor Evaluation Method Based on Lean Principles and Partnering Practices. J. Manag. Eng. 2007, 23, 67–74. [Google Scholar] [CrossRef]

- Mbachu, J. Conceptual framework for the assessment of subcontractors’ eligibility and performance in the construction industry. Constr. Manag. Econ. 2008, 26, 471–484. [Google Scholar] [CrossRef]

- Ng, S.T.; Tang, Z. Delineating the predominant criteria for subcontractor appraisal and their latent relationships. Constr. Manag. Econ. 2008, 26, 249–259. [Google Scholar] [CrossRef]

- Ng, T.S.T. A Knowledge-Based System for Construction Subcontractor Appraisal. In Proceedings of the 27th International Conference on Applications of IT in the AEC Industry (CIB W78 2010), Cairo, Egypt, 16–18 November 2010; pp. 1–7. [Google Scholar]

- Ng, S.T.; Skitmore, M. Developıng a framework for subcontractor appraısal usıng a balanced scorecard. J. Civ. Eng. Manag. 2014, 20, 149–158. [Google Scholar] [CrossRef]

- Yang, C.-C.; Su, I.-M.; Wang, C.; Chang, C.-H.; Bien, Y.-H. Evaluation of Interior Staff and Subcontractor Performance. J. Stat. Manag. Syst. 2015, 18, 561–572. [Google Scholar] [CrossRef]

- Chamara, H.W.L.; Waidyasekara, K.G.A.S.; Mallawaarachchi, H. Evaluating Subcontractor Performance in Construction Industry. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 11–13 December 2015; Volume 5, pp. 137–147. [Google Scholar]

- Tan, Y.; Xue, B.; Cheung, Y.T. Relationships between Main Contractors and Subcontractors and Their Impacts on Main Contractor Competitiveness: An Empirical Study in Hong Kong. J. Constr. Eng. Manag. 2017, 143, 05017007. [Google Scholar] [CrossRef]

- Tesha, D.N.G.A.K.; Luvara, V.G. Main Contractors’ Strategies in Managing Construction Quality of Subcontracted Works in Tanzania. Int. Res. J. Eng. Technol. 2017, 4, 1. [Google Scholar]

- Poovitha, R.; Ambika, D.; Lavanya, B. A review on performance management and appraisal in construction industry towards project performance. Int. Res. J. Eng. Technol. 2018, 5, 1012–1015. [Google Scholar]

- Gankhuyag, B.S.; Tsai, P.F.J. Use Analytic Hierarchy Process for Subcontractor Evaluation in Construction Industry: A Case Study. 2016. Available online: https://hdl.handle.net/11296/632v23 (accessed on 27 April 2023).

- Wang, J.-Q.; Peng, J.-J.; Zhang, H.-Y.; Liu, T.; Chen, X.-H. An Uncertain Linguistic Multi-criteria Group Decision-Making Method Based on a Cloud Model. Group Decis. Negot. 2015, 24, 171–192. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Tsai, H.-C.; Sudjono, E. Evaluating subcontractor performance using evolutionary fuzzy hybrid neural network. Int. J. Proj. Manag. 2011, 29, 349–356. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Wu, Y.-W. Improved constructıon subcontractor evaluatıon performance usıng esım. Appl. Artif. Intell. 2012, 26, 261–273. [Google Scholar] [CrossRef]

- Hanák, T.; Nekardová, I. Selecting and Evaluating Suppliers in the Czech Construction Sector. Period. Polytech. Soc. Manag. Sci. 2020, 28, 155–161. [Google Scholar] [CrossRef]

- Shiau, Y.; Tsai, T.; Wang, W.; Huang, M. Use Questionnaire and AHP Techniques to Develop Subcontractor Selection System. In Proceedings of the 2002 19th ISARC, Washington, WA, USA, 23–27 September 2002; pp. 35–40, ISSN 2413-5844. [Google Scholar] [CrossRef]

- Eom, C.S.; Yun, S.H.; Paek, J.H. Subcontractor Evaluation and Management Framework for Strategic Partnering. J. Constr. Eng. Manag. 2008, 134, 842–851. [Google Scholar] [CrossRef]

- Arslan, G.; Kivrak, S.; Birgonul, M.T.; Dikmen, I. Improving sub-contractor selection process in construction projects: Web-based sub-contractor evaluation system (WEBSES). Autom. Constr. 2008, 17, 480–488. [Google Scholar] [CrossRef]

- El-Mashaleh, M.S. A construction subcontractor selection model. Jordan J. Civ. Eng. 2009, 3, 375–383. [Google Scholar]

- Pallikkonda, K.D.; Siriwardana, C.S.A.; Karunarathna, D.M.T.G.N.M. Developing a Sub-Contractor Pre-Assessment Framework for Sri Lankan Building Construction Industry. In Proceedings of the Structural Engineering and Construction Engineering 2, ICSESM2019-34, Kandy, Sri Lanka; 2019; Volume 1, p. 15. [Google Scholar]

- Jasim, N.A. Evaluation of Contractors Performance in Iraqi Construction Projects Using Multiple Criteria Complex Proportional Assessment Method (COPRAS). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1076, 012106. [Google Scholar] [CrossRef]

- Hwang, B.-G.; Lim, E.-S.J. Critical success factors for key project players and objectives: Case study of Singapore. J. Constr. Eng. Manag. 2013, 139, 204–215. [Google Scholar] [CrossRef]

- Akinshipe, O.; Aigbavboa, C.; Fatai, O.; Thwala, D. Core Competencies Required for Construction Project Success: The Project Management Angle. Human Factors in Architecture, Sustainable Urban Planning and Infra-Structure. In Proceedings of the AHFE 2022 International Conference, New York, NY, USA, 24–28 July 2022; Maciejko, A., Ed.; Volume 58, pp. 323–329. [Google Scholar]

- Ferdig, M.A. Sustainability Leadership: Co-creating a Sustainable Future. J. Chang. Manag. 2007, 7, 25–35. [Google Scholar] [CrossRef]

- Bass, B.M.; Avolio, B.J. Developing Transformational Leadership: 1992 and Beyond. J. Eur. Ind. Train. 1990, 14, 21–27. [Google Scholar] [CrossRef]

- Zavari, M.; Afshar, M.R. The role of site manager transformational leadership in the construction project success. Int. J. Build. Pathol. Adapt. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Dulewicz, V.; Higgs, M. Leadershıp at the top: The need for emotıonal ıntellıgence ın organızatıons. Int. J. Organ. Anal. 2003, 11, 193–210. [Google Scholar] [CrossRef]

- Wideman, R.M. First Principles of Project Management; AEW Services: Vancouver, BC, Canada, 2000. [Google Scholar]

- Mahfouz, S.A.; Awang, Z.; Muda, H. The impact of transformational leadership on employee commitment in the construction industry. Int. J. Innov. Creat. Change 2019, 7, 151–167. [Google Scholar]

- Limsila, K.; Ogunlana, S.O. Performance and leadership outcome correlates of leadership styles and subordinate commitment. Eng. Constr. Arch. Manag. 2008, 15, 164–184. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, J.; Darko, A. How Does Transformational Leadership Promote Innovation in Construction? The Mediating Role of Innovation Climate and the Multilevel Moderation Role of Project Requirements. Sustainability 2018, 10, 1506. [Google Scholar] [CrossRef]

- Yildiz, A.; Ayyildiz, E.; Gümüş, A.T.; Özkan, C. Ülkelerin yaşam kalitelerine göre değerlendirilmesi için hibrit pisagor bulanık AHP-TOPSIS metodolojisi: Avrupa Birliği örneği. (Pythagorean Fuzzy AHP-Topsis Methodology for the Evaluation of Countries According To Life Quality: European Unıon Case). Avrupa Bilim ve Teknol. Derg. 2019, 17, 1383–1391. [Google Scholar]

- Ayyildiz, E.; Gumus, A.T. Pythagorean fuzzy AHP based risk assessment methodology for hazardous material transportation: An application in Istanbul. Environ. Sci. Pollut. Res. 2021, 28, 35798–35810. [Google Scholar] [CrossRef]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning. Part II Inf. Sci. 1975, 8, 301–357. [Google Scholar] [CrossRef]

- Atanassov, K.T.; Atanassov, K.T. Intuitionistic Fuzzy Sets; Physica-Verlag: Heidelberg, Germany, 1999; pp. 1–137. [Google Scholar]

- Smarandache, F. A unifying field in logics: Neutrosophic logic. In Philosophy; American Research Press: Rehoboth, DE, USA, 1999; pp. 1–141. [Google Scholar] [CrossRef]

- Torra, V. Hesitant fuzzy sets. Int. J. Intell. Syst. 2010, 25, 529–539. [Google Scholar] [CrossRef]

- Yager, R.R. Pythagorean Fuzzy Subsets. In Proceedings of the 2013 Joint IFSA World Congress and NAFIPS Annual Meeting (IFSA/NAFIPS), Edmonton, AL, Canada, 24–28 June 2013; pp. 57–61. [Google Scholar]

- Ak, M.F.; Gul, M. AHP–TOPSIS integration extended with Pythagorean fuzzy sets for information security risk analysis. Complex Intell. Syst. 2018, 5, 113–126. [Google Scholar] [CrossRef]

- Li, D.; Zeng, W. Distance measure of Pythagorean fuzzy sets. Int. J. Intell. Syst. 2018, 33, 348–361. [Google Scholar] [CrossRef]

- Peng, X.; Yang, Y. Fundamental Properties of Interval-Valued Pythagorean Fuzzy Aggregation Operators. Int. J. Intell. Syst. 2016, 31, 444–487. [Google Scholar] [CrossRef]

- Yucesan, M.; Gul, M. Hospital service quality evaluation: An integrated model based on Pythagorean fuzzy AHP and fuzzy TOPSIS. Soft Comput. 2020, 24, 3237–3255. [Google Scholar] [CrossRef]

- Tepe, S.; Kaya, I. A fuzzy-based risk assessment model for evaluations of hazards with a real-case study. Hum. Ecol. Risk Assess. Int. J. 2020, 26, 512–537. [Google Scholar] [CrossRef]

- Lin, M.; Chen, Y.; Chen, R. Bibliometric analysis on Pythagorean fuzzy sets during 2013–2020. Int. J. Intell. Comput. Cybern. 2021, 14, 104–121. [Google Scholar] [CrossRef]

- Garg, H. A Novel Correlation Coefficients between Pythagorean Fuzzy Sets and Its Applications to Decision-Making Processes. Int. J. Intell. Syst. 2016, 31, 1234–1252. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Z. Extension of TOPSIS to Multiple Criteria Decision Making with Pythagorean Fuzzy Sets. Int. J. Intell. Syst. 2014, 29, 1061–1078. [Google Scholar] [CrossRef]

- Ma, Z.; Xu, Z. Symmetric Pythagorean Fuzzy Weighted Geometric/Averaging Operators and Their Application in Multicriteria Decision-Making Problems. Int. J. Intell. Syst. 2016, 31, 1198–1219. [Google Scholar] [CrossRef]

- Xiao, F.; Ding, W. Divergence measure of Pythagorean fuzzy sets and its application in medical diagnosis. Appl. Soft Comput. 2019, 79, 254–267. [Google Scholar] [CrossRef]

- Karasan, A.; Ilbahar, E.; Kahraman, C. A novel pythagorean fuzzy AHP and its application to landfill site selection problem. Soft Comput. 2018, 23, 10953–10968. [Google Scholar] [CrossRef]

- Song, P.; Li, L.; Huang, D.; Wei, Q.; Chen, X. Loan risk assessment based on Pythagorean fuzzy analytic hierarchy process. J. Phys. Conf. Ser. 2020, 1437, 12101. [Google Scholar] [CrossRef]

- Çalık, A.; Afşar, B. Prioritization of Bank Selection Decision in Pandemic Process Using a Novel Decision-Making Model. In Handbook of Research on Strategies and Interventions to Mitigate COVID-19 Impact on SMEs; India IGI Global: Pune, India, 2021; pp. 477–492. [Google Scholar]

- Deveci, M.; Eriskin, L.; Karatas, M. A Survey on Recent Applications of Pythagorean Fuzzy Sets: A State-of-the-Art Between 2013 and 2020. In Pythagorean Fuzzy Sets: Theory and Applications; Springer: Singapore, 2021; pp. 3–38. [Google Scholar] [CrossRef]

- Sarkar, B.; Biswas, A. Pythagorean fuzzy AHP-TOPSIS integrated approach for transportation management through a new distance measure. Soft Comput. 2021, 25, 4073–4089. [Google Scholar] [CrossRef]

- Boyacı, A.; Şişman, A. Pandemic hospital site selection: A GIS-based MCDM approach employing Pythagorean fuzzy sets. Environ. Sci. Pollut. Res. 2021, 29, 1985–1997. [Google Scholar] [CrossRef]

- Yucesan, M.; Kahraman, G. Risk evaluation and prevention in hydropower plant operations: A model based on Pythagorean fuzzy AHP. Energy Policy 2019, 126, 343–351. [Google Scholar] [CrossRef]

- Mete, S. Assessing occupational risks in pipeline construction using FMEA-based AHP-MOORA integrated approach under Pythagorean fuzzy environment. Hum. Ecol. Risk Assess. Int. J. 2019, 25, 1645–1660. [Google Scholar] [CrossRef]

- Gul, M.; Ak, M.F. A comparative outline for quantifying risk ratings in occupational health and safety risk assessment. J. Clean. Prod. 2018, 196, 653–664. [Google Scholar] [CrossRef]

- Peng, C.; Deng, K.; Tang, L. PFAHP-Based Index Weighting in Operation Quality Evaluation of GSM-R. In Proceedings of the 3rd International Conference on Computer Engineering, Information Science & Application Technology (ICCIA 2019), Chongqing, China, 30–31 May 2019; Atlantis Press: Amsterdam, The Netherlands, 2019; pp. 313–321. [Google Scholar]

- Saaty, T. A scaling method for priorities in hierarchical structures. J. Math. Psychology. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Gupta, V.; Kansal, R. Improvement of construction labor productivity in Chambal Region. Int. J. Res. Eng. Technol. 2014, 3, 34–37. [Google Scholar]

- Lin, J.; Mills, A. Measuring the occupational health and safety performance of construction companies in Australia. Facilities 2001, 19, 131–139. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Improving waste management in construction projects: An Aus-tralian study. Resour. Conserv. Recycl. 2015, 101, 73–83. [Google Scholar] [CrossRef]

- Famakin, I.; Abisuga, A. Effect of path-goal leadership styles on the commitment of employees on construction projects. Int. J. Constr. Manag. 2016, 16, 67–76. [Google Scholar] [CrossRef]

- Ofori, G.; Toor, S.U.R. Leadership and Construction Industry Development in Developing Countries. J. Constr. Dev. Ctries. 2012, 17, 1–21. [Google Scholar]

- Rehman, M.A.; Ishak, M.S.B. Investigating the Relationship Between Active Leadership and Construction Risk Management Among Contractors in Kingdom of Saudi Arabia. J. Surv. Constr. Prop. 2022, 13, 34–51. [Google Scholar]

- Meng, X. The effect of relationship management on project performance in construction. Int. J. Proj. Manag. 2012, 30, 188–198. [Google Scholar] [CrossRef]

| SC-PMC | Definitions | ||

|---|---|---|---|

| Time (C1) | C11 | Ability to adhere to the project schedule | Compliance with the determined work schedule |

| C12 | Speed in remedying defects and problems | The speed of faulty or forgotten production in rectifying the defect or deficiency upon warning. | |

| Cost (C2) | C21 | Ability to adhere to the project budget | Staying within the budget limits agreed in the contract. |

| C22 | Timely payment to its workers | Payment performance to workers in each progress payment period. | |

| Quality (C3) | C31 | The quality of the material used | Material usage status in accordance with the standards specified in the contract and general specifications. |

| C32 | The quality of workmanship | The quality of the construction workmanship done during the application. | |

| C33 | The quality of the resulting final product | Compliance status of the finished production with the project and specifications. | |

| Resource Adequacy (C4) | C41 | Technical competence of the employees | The experience, knowledge and competence of the technical personnel employed by the SCs. |

| C42 | Adequate labor resource availability | Number of workers, availability of machinery, equipment, and vehicles. | |

| C43 | Adequate material resource availability | Whether the material to be used in the production is available at a sufficient level. | |

| Compatibility –Communication (C5) | C51 | Compliance with other SCs and employees on-site | Working situation in coordination with other SCs and employees on-site and not causing delay. |

| C52 | Communication and compliance with the MC | The use of coordinated work execution skills and information exchange in the execution of the project with the MC | |

| C53 | SC’s own team harmony | Compatibility and coordination within the SC’s own team. | |

| C54 | Ability to adopt and respond to changes in the project | When a change is requested in the productions in the projects, the reactions and analysis skills. | |

| OHS—Environmental Protection (C6) | C61 | Attitude towards OHS requirements | The state of adopting and complying with the OHS rules requested by the MC. |

| C62 | Environmental awareness capability (waste management, etc.) | The ability to re-evaluate the wastes generated as a result of its work or to dispose of the wastes with environmental protection awareness. | |

| C63 | Ability to provide a clean and tidy work environment | A clean and orderly working situation that will not disturb other employees in the working environment and prevent them from doing their jobs. | |

| C64 | Attitude towards material waste | The situation of avoiding unnecessary use and wastage in the use of materials, the ability to use the energy (fuel electricity, etc.) consumed by the vehicles they use efficiently. | |

| Leadership (C7) | C71 | Transformational leadership | Showing leadership that focuses on collaborators and the development of subordinates. |

| C72 | Commitment | Commitment to the project, the effort it contributed to the solution of the problems with the MC, its contribution to the overall project, apart from his own work part, the ability to make sacrifices. | |

| C73 | Critical analysis and judgment | Ability to accurately identify the advantages and disadvantages of situations, make sound judgments and make decisions based on factual information. | |

| C74 | Vision and imagination | The ability to be creative and innovative and to set solid priorities for future work. | |

| C75 | Strategic perspective | Ability to make short- and long-term assessments and anticipate opportunities and threats. |

| SC-PMC | Researchers | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Criteria | Sub-Criteria | Shiau et al. (2003) [41] | Ng, S.T. (2007) [24] | Ng and Tang (2008) [28] | Eom et al. (2008) [42] | Arslan et al. (2008) [43] | Mbachu, J. (2008) [27] | El-Mashaleh (2009) [44] | Maturana et al. (2009) [26] | Hartmann & Caerteling (2010) [8] | Cheng et al. (2011) [38] | Cheng and Wu (2012) [39] | Ng and Skitmore (2014) [30] | Chamara et al. (2015) [32] | Pallikkonda et al. (2019) [45] | Hanák and Nekardová(2020) [40] | Jasim (2021) [46] | Afshar et al. (2020) [22] | Dulewicz and Higgs (2003) [52] | Wideman (2000) [53] | Mahfouz et al. (2019) [54] | Ferdig (2007) [49] | Limsila and Ogunlaga (2008) [55] | Zhang et al. (2018) [56] | Zavari and Afshar (2021) [51] | Frequency | |

| Time C1 | C11 | Ability to adhere to the project schedule | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 15/24 | |||||||||

| C12 | Speed in remedying defects and problems | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 6/24 | |||||||||||||||||||

| Cost C2 | C21 | Ability to adhere to the project budget | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 9/24 | |||||||||||||||

| C22 | Timely payment to its workers | ✔ | ✔ | ✔ | 3/24 | ||||||||||||||||||||||

| Quality C3 | C31 | The quality of the material used | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 9/24 | |||||||||||||||

| C32 | The quality of workmanship | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 12/24 | |||||||||||||

| C33 | The quality of the resulting final product | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 11/24 | ||||||||||||||

| Resource Adequacy C4 | C41 | Technical competence of the employees | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 8/24 | ||||||||||||||||

| C42 | Adequate labor resource availability | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 6/24 | |||||||||||||||||||

| C43 | Adequate material resource availability | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 7/24 | ||||||||||||||||||

| Compatibility and Communication C5 | C51 | Compliance with other SCs and employees on-site | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 11/24 | |||||||||||||

| C52 | Communication and compliance with the MC | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 12/24 | |||||||||||||

| C53 | SC’s own team harmony | ✔ | ✔ | ✔ | ✔ | 4/24 | |||||||||||||||||||||

| C54 | Ability to adopt and respond to changes in the project | ✔ | ✔ | ✔ | ✔ | ✔ | 5/24 | ||||||||||||||||||||

| Occupational Health & Safety -Environmental Protection C6 | C61 | Attitude towards OHS requirements | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 11/24 | |||||||||||||

| C62 | Environmental awareness capability (waste management, etc.) | ✔ | ✔ | ✔ | ✔ | ✔ | 5/24 | ||||||||||||||||||||

| C63 | Ability to provide a clean and tidy work environment | ✔ | ✔ | ✔ | ✔ | 4/24 | |||||||||||||||||||||

| C64 | Attitude towards material waste | ✔ | ✔ | ✔ | ✔ | ✔ | 5/24 | ||||||||||||||||||||

| Leadership C7 | C71 | Transformational leadership | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 7/24 | |||||||||||||||||

| C72 | Commitment | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | 12/24 | |||||||||||||

| C73 | Critical analysis and judgment | ✔ | 1/24 | ||||||||||||||||||||||||

| C74 | Vision and imagination | ✔ | ✔ | ✔ | ✔ | 4/24 | |||||||||||||||||||||

| C75 | Strategic perspective | ✔ | ✔ | ✔ | 3/24 | ||||||||||||||||||||||

| Linguistic Variables | Interval-Valued Pythagorean Fuzzy Numbers | |||

|---|---|---|---|---|

| Certainly low important (CL) | 0.0 | 0.0 | 0.9 | 1.0 |

| Very low important (VL) | 0.1 | 0.2 | 0.8 | 0.9 |

| Low important (L) | 0.2 | 0.35 | 0.65 | 0.8 |

| Below average important (BA) | 0.35 | 0.45 | 0.55 | 0.65 |

| Exactly equal (EE) | 0.1965 | 0.1965 | 0.1965 | 0.1965 |

| Average important (A) | 0.45 | 0.55 | 0.45 | 0.55 |

| Above average important (AA) | 0.55 | 0.65 | 0.35 | 0.45 |

| High important (H) | 0.65 | 0.8 | 0.2 | 0.35 |

| Very high important (VH) | 0.8 | 0.9 | 0.1 | 0.2 |

| Certainly high important (CH) | 0.9 | 1.0 | 0.0 | 0.0 |

| Main Criteria | C1 | C2 | C3 | C4 | C5 | C6 | C7 | |

|---|---|---|---|---|---|---|---|---|

| Consistency Ratio (CR) | 0.0089 | - | - | 0.0077 | 0.0596 | 0.0254 | 0.0164 | 0.0062 |

| Main Criteria | Weight | Rank | Sub-Criteria | Local Weight | Final Weight | Rank |

|---|---|---|---|---|---|---|

| C1 Time | 0.1937 | 2 | C11 | 0.7780 | 0.1507 | 2 |

| Ability to adhere to the project schedule | ||||||

| C12 | 0.2220 | 0.0430 | 8 | |||

| Speed in remedying defects and problems | ||||||

| C2 Cost | 0.2200 | 1 | C21 | 0.8267 | 0.1818 | 1 |

| Ability to adhere to the project budget | ||||||

| C22 | 0.1733 | 0.0381 | 10 | |||

| Timely payment to its workers | ||||||

| C3 Quality | 0.1822 | 3 | C31 | 0.3364 | 0.0613 | 3 |

| The quality of the material used | ||||||

| C32 | 0.3359 | 0.0612 | 4 | |||

| The quality of workmanship | ||||||

| C33 | 0.3278 | 0.0597 | 5 | |||

| The quality of the resulting final product | ||||||

| C4 Resource Adequacy | 0.1129 | 5 | C41 | 0.3761 | 0.0425 | 9 |

| Technical competence of the employees | ||||||

| C42 | 0.4126 | 0.0466 | 7 | |||

| Adequate labor resource availability | ||||||

| C43 | 0.2113 | 0.0238 | 14 | |||

| Adequate material resource availability | ||||||

| C5 Compatibility-Communication | 0.0824 | 6 | C51 | 0.2533 | 0.0209 | 16 |

| Compliance with other SCs and employees on-site | ||||||

| C52 | 0.2263 | 0.0187 | 19 | |||

| Communication and compliance with the MC | ||||||

| C53 | 0.2430 | 0.0200 | 17 | |||

| SC’s own team harmony | ||||||

| C54 | 0.2775 | 0.0229 | 15 | |||

| Ability to adopt and respond to changes in the project | ||||||

| C6 OHS-Environmental Protection | 0.1391 | 4 | C61 | 0.3942 | 0.0548 | 6 |

| Attitude towards OHS requirements | ||||||

| C62 | 0.2608 | 0.0363 | 11 | |||

| Environmental awareness capability (waste management) | ||||||

| C63 | 0.1402 | 0.0195 | 18 | |||

| Ability to provide a clean and tidy work environment | ||||||

| C64 | 0.2048 | 0.0285 | 12 | |||

| Attitude towards material waste | ||||||

| C7 Leadership | 0.0698 | 7 | C71 | 0.1975 | 0.0138 | 20 |

| Transformational leadership | ||||||

| C72 | 0.3891 | 0.0271 | 13 | |||

| Commitment | ||||||

| C73 | 0.1319 | 0.0092 | 23 | |||

| Critical analysis and judgment | ||||||

| C74 | 0.1333 | 0.0093 | 22 | |||

| Vision and imagination | ||||||

| C75 | 0.1483 | 0.0103 | 21 | |||

| Strategic perspective | ||||||

| Sub-Criteria | Targeted Outputs |

|---|---|

| C21 Ability to adhere to the project budget | Anticipating budget overruns and taking action |

| C11 Ability to adhere to the project schedule | Preventing the project from exceeding the deadline by foreseeing possible delays |

| C31 The quality of the material used | Producing in accordance with quality standards by preventing all defects previously that may occur in the final product |

| C32 The quality of workmanship | |

| C33 The quality of the resulting final product | |

| C61 Attitude towards OHS requirements | Reducing occupational accidents and diseases by providing stricter follow-up of OHS rules |

| C42 Adequate labor resource availability | Preventing problems such as manufacturing errors and delays that may be caused by elements such as insufficient workers, equipment and machinery |

| C12 Speed in remedying defects and problems | Avoiding wasted time by taking more responsibility by SCs to quickly fix manufacturing defects |

| C41 Technical competence of the employees | Increasing the ratio of employees with more experience and suitable technical qualifications |

| C22 Timely payment to its workers | Reducing pull out of the work and dissatisfaction by tracking the payments of SCs to their employees |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Başaran, Y.; Aladağ, H.; Işık, Z. Pythagorean Fuzzy AHP Based Dynamic Subcontractor Management Framework. Buildings 2023, 13, 1351. https://doi.org/10.3390/buildings13051351

Başaran Y, Aladağ H, Işık Z. Pythagorean Fuzzy AHP Based Dynamic Subcontractor Management Framework. Buildings. 2023; 13(5):1351. https://doi.org/10.3390/buildings13051351

Chicago/Turabian StyleBaşaran, Yunus, Hande Aladağ, and Zeynep Işık. 2023. "Pythagorean Fuzzy AHP Based Dynamic Subcontractor Management Framework" Buildings 13, no. 5: 1351. https://doi.org/10.3390/buildings13051351

APA StyleBaşaran, Y., Aladağ, H., & Işık, Z. (2023). Pythagorean Fuzzy AHP Based Dynamic Subcontractor Management Framework. Buildings, 13(5), 1351. https://doi.org/10.3390/buildings13051351