The Properties of Sodium-Hypochlorite-Activated Crumb Rubber and the Influence of Aging on the Rheological Properties of Activated Asphalt Rubber

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

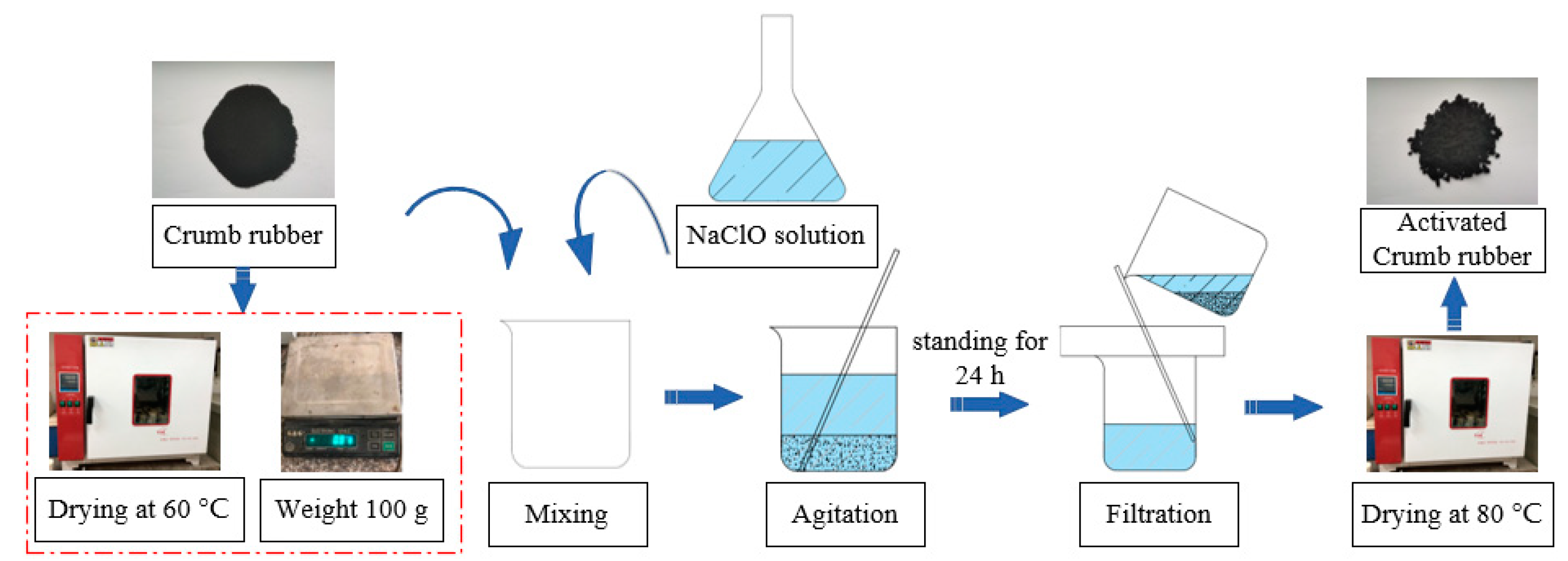

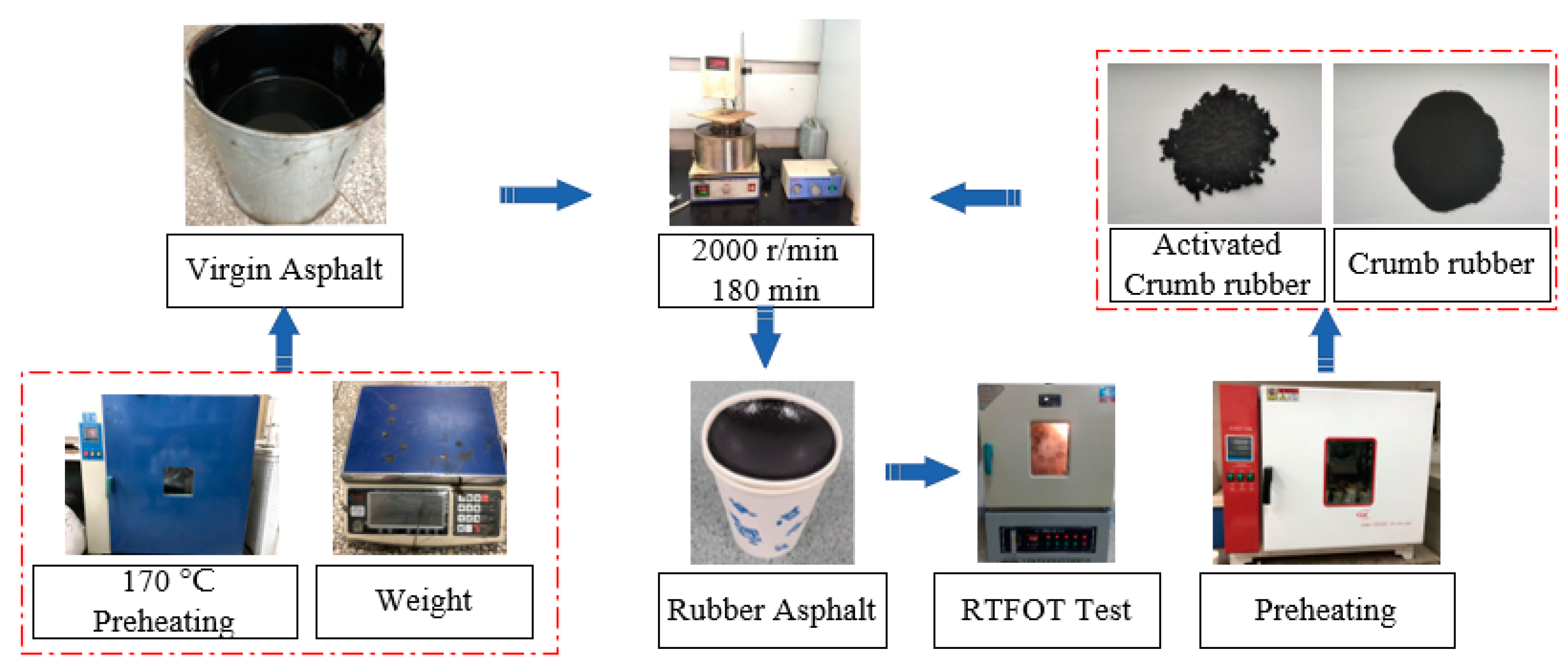

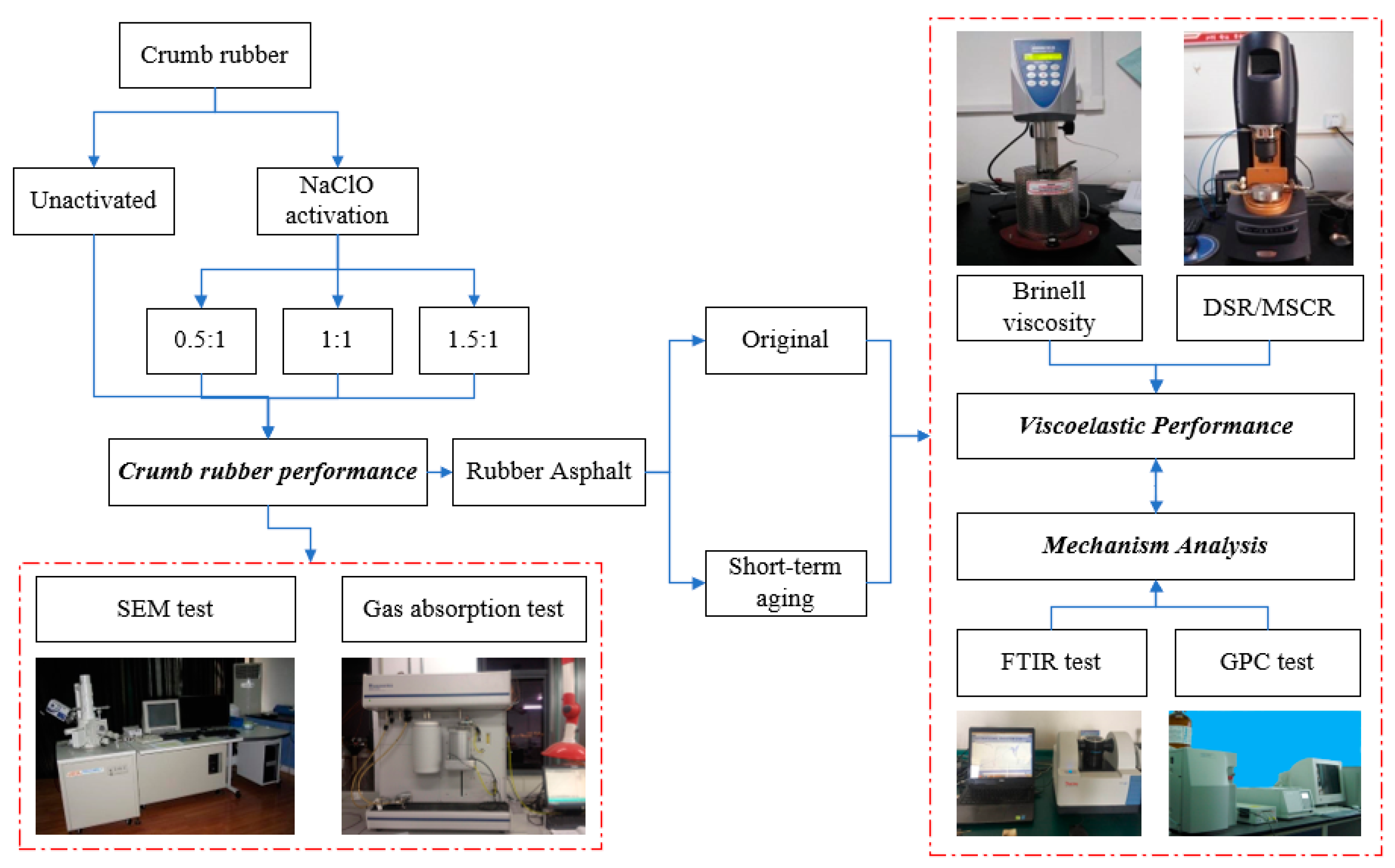

2.2. Sample Preparation

2.3. Test Method

3. Results

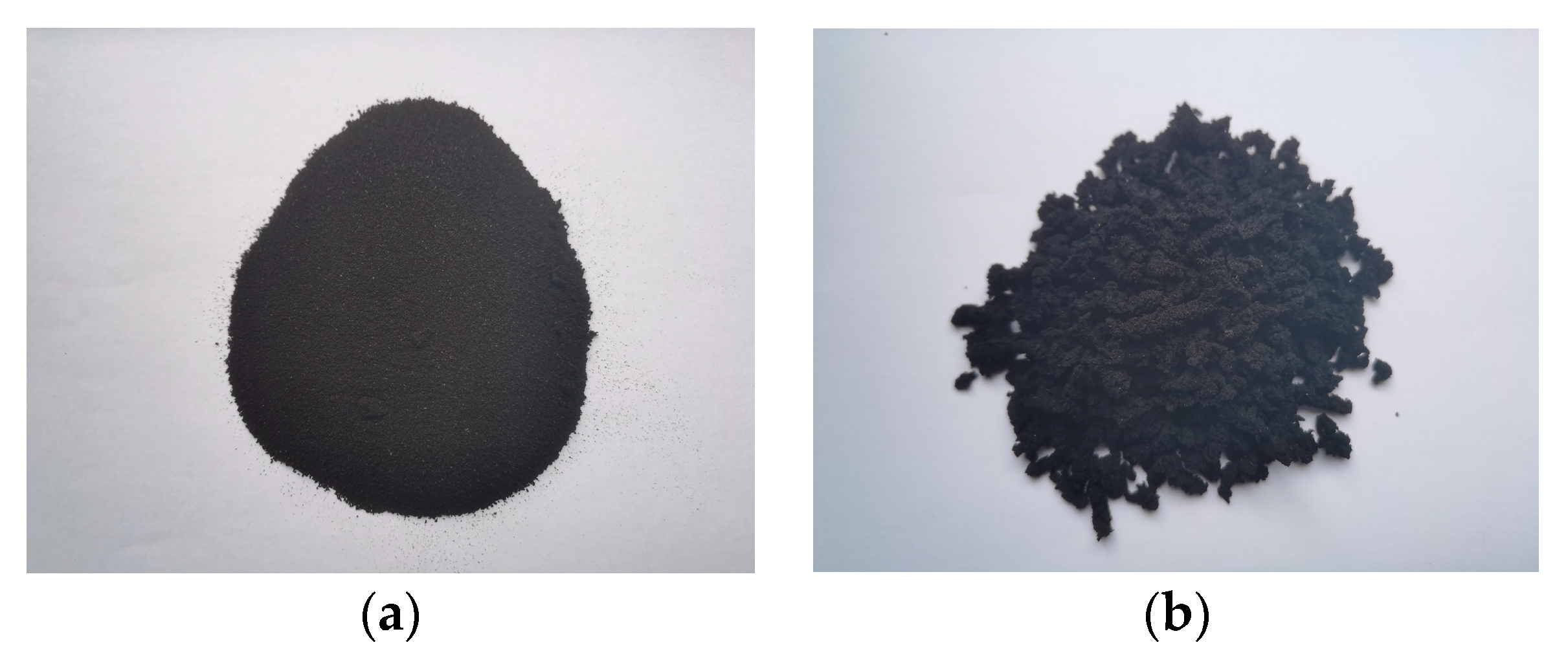

3.1. Characteristics of Activated Crumb Rubber

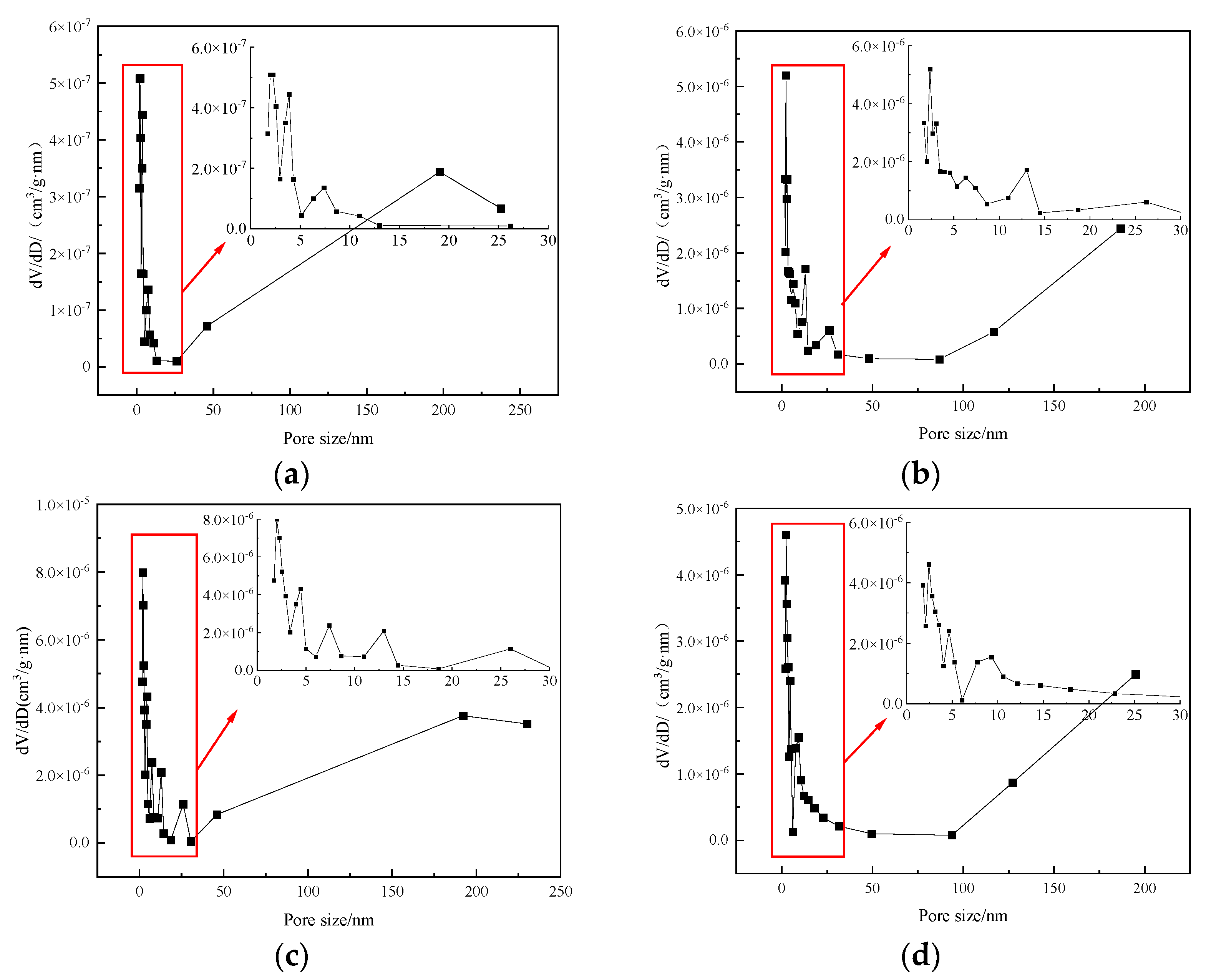

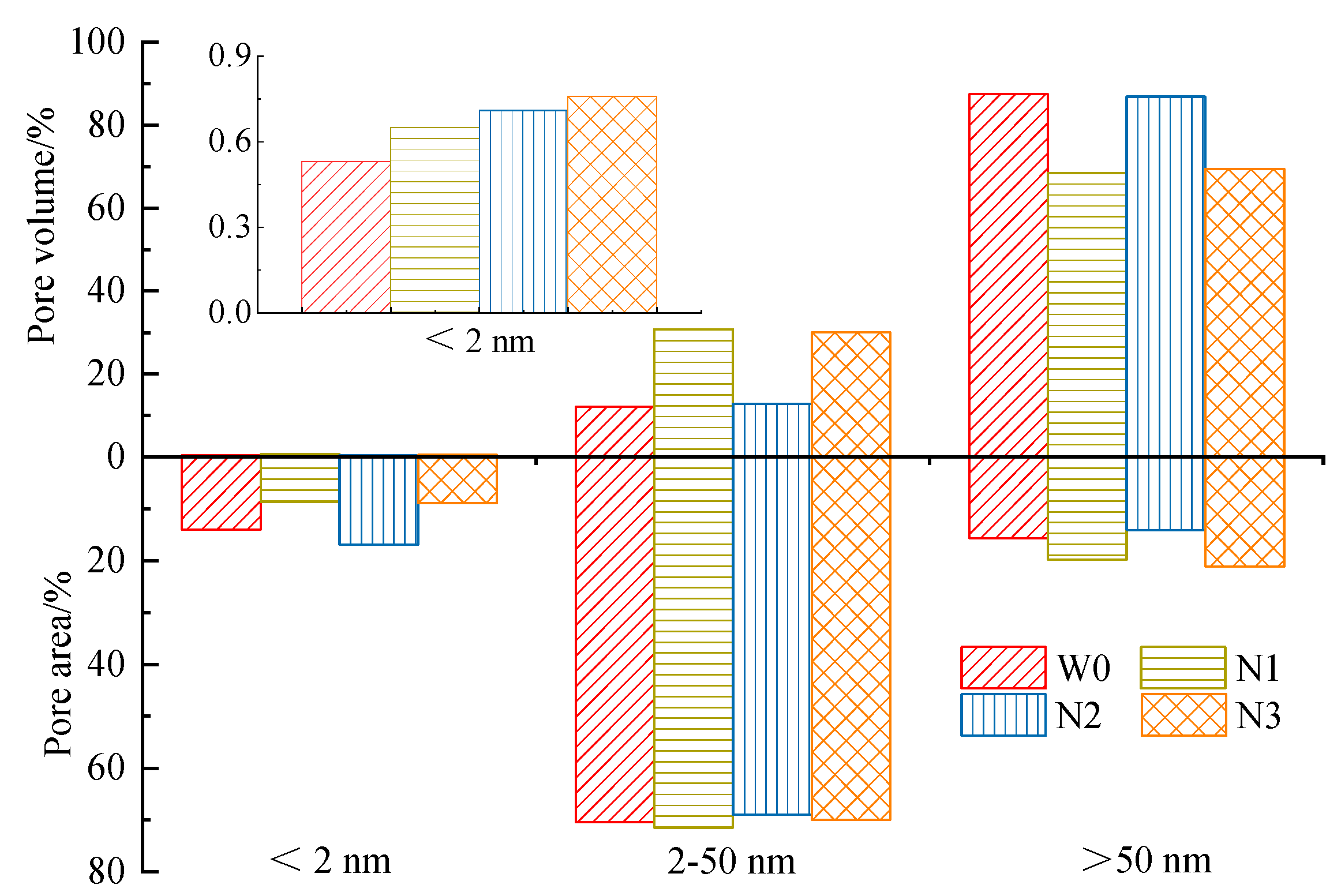

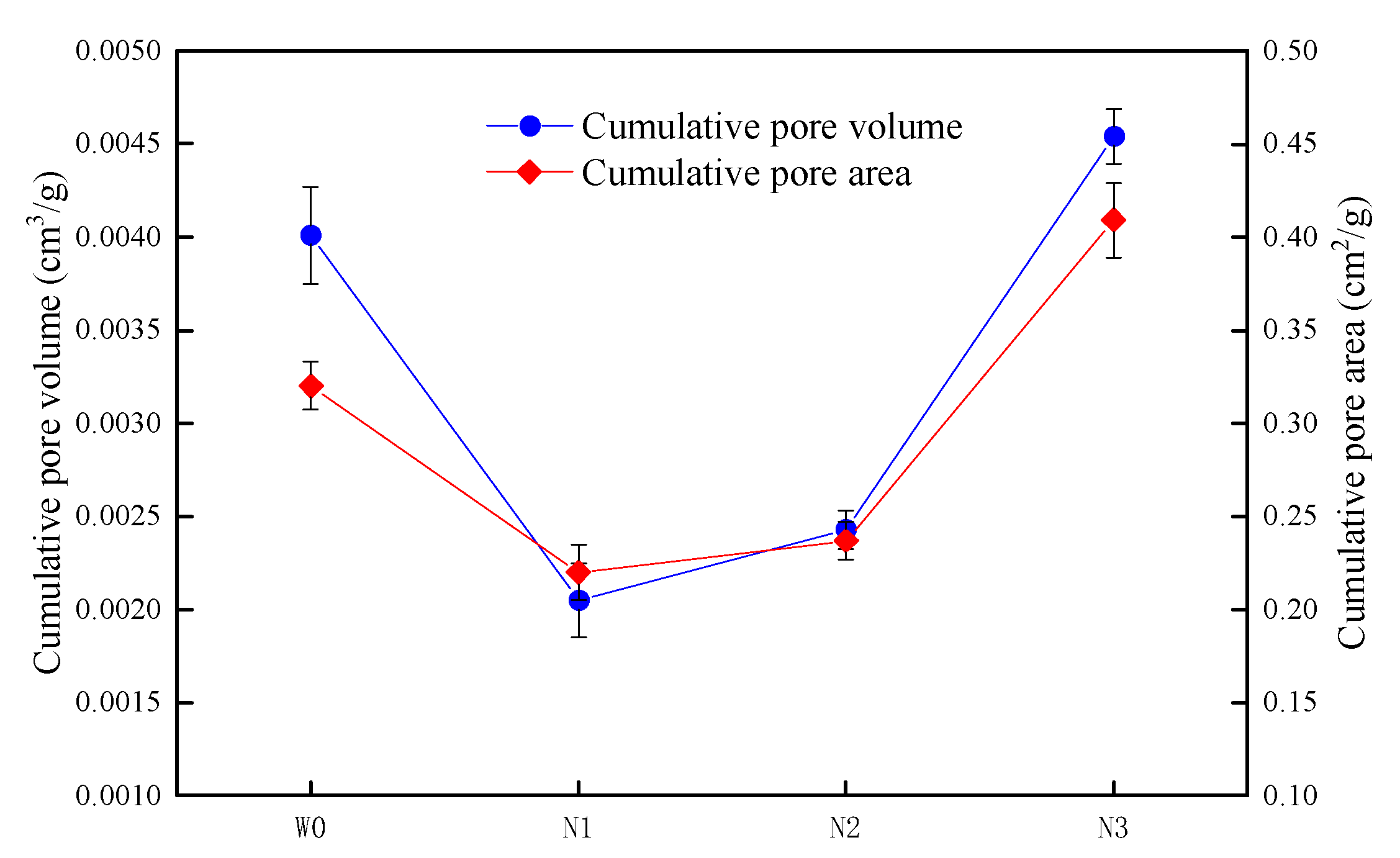

3.1.1. Pore Characteristics

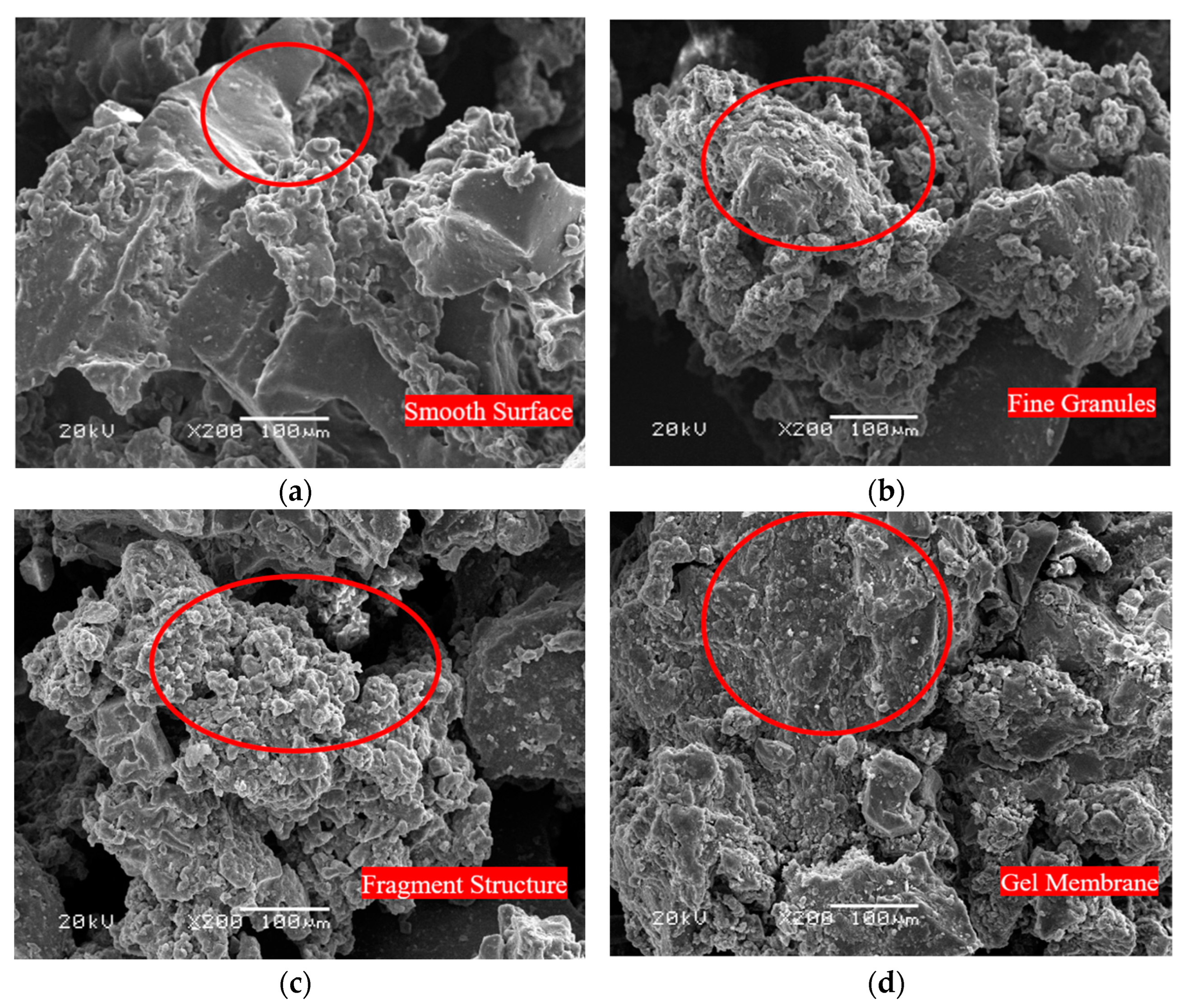

3.1.2. Microstructure

3.2. Rheological Properties of Crumb Rubber Modified Asphalt

3.2.1. Brinell Viscosity Test

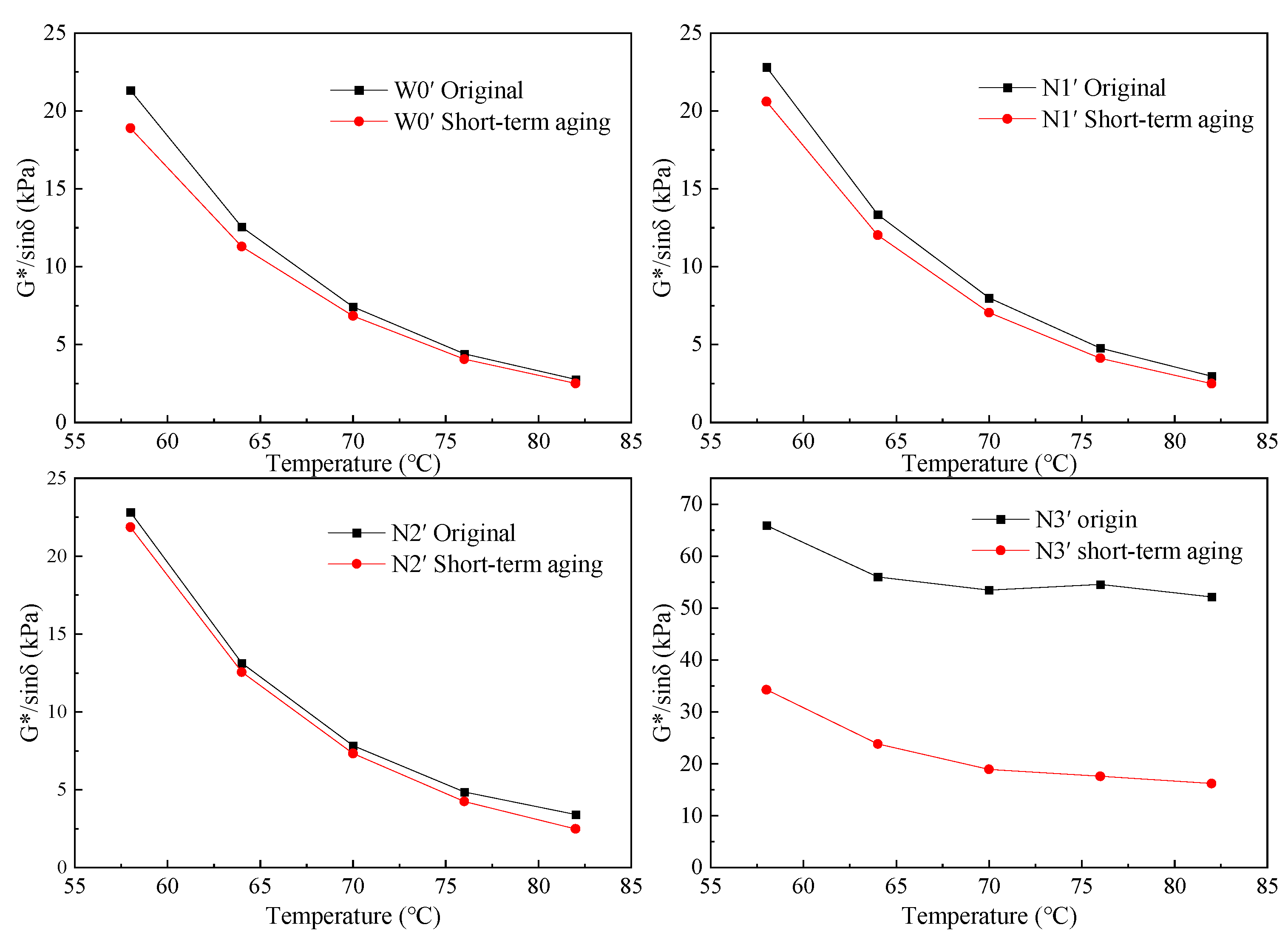

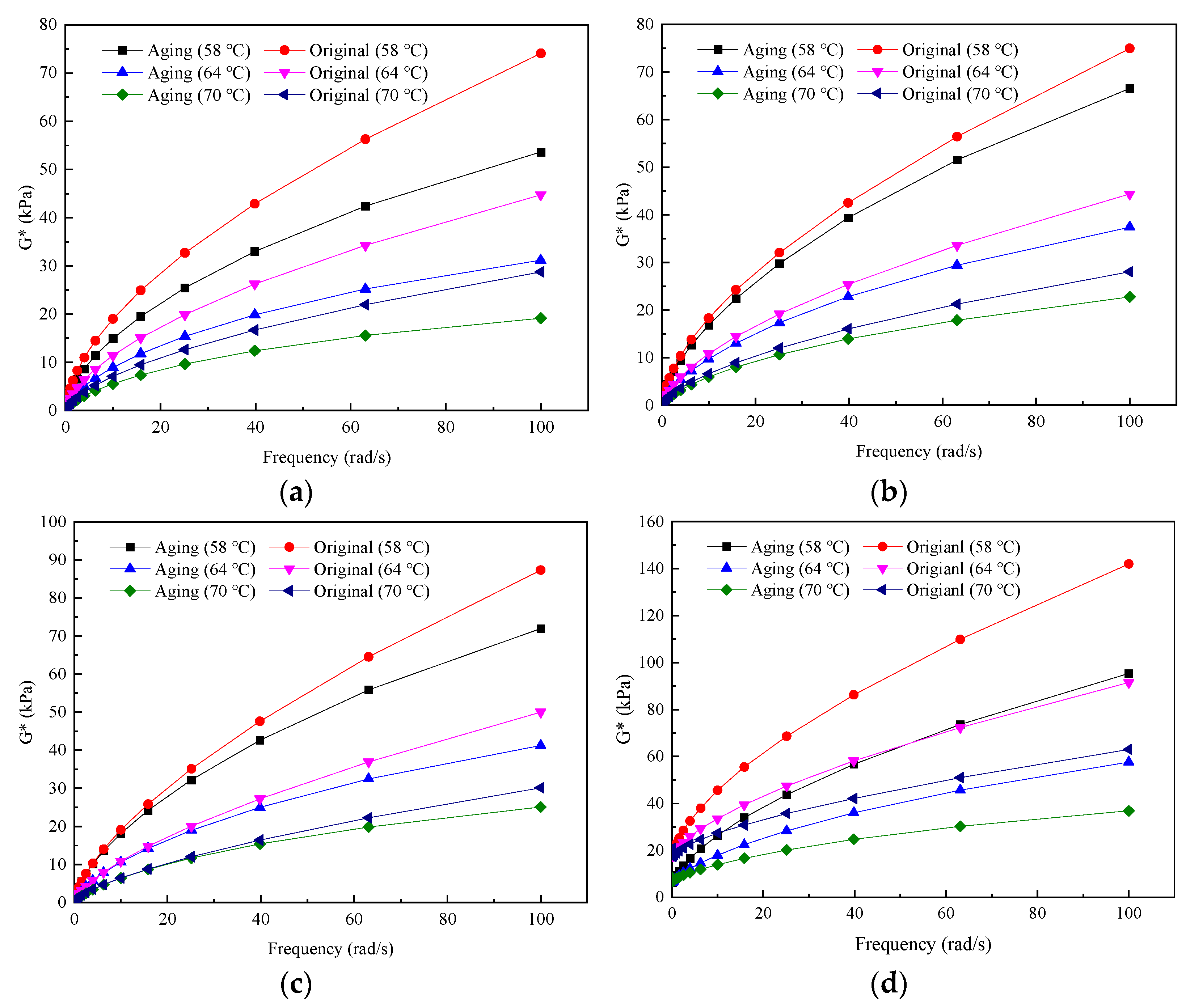

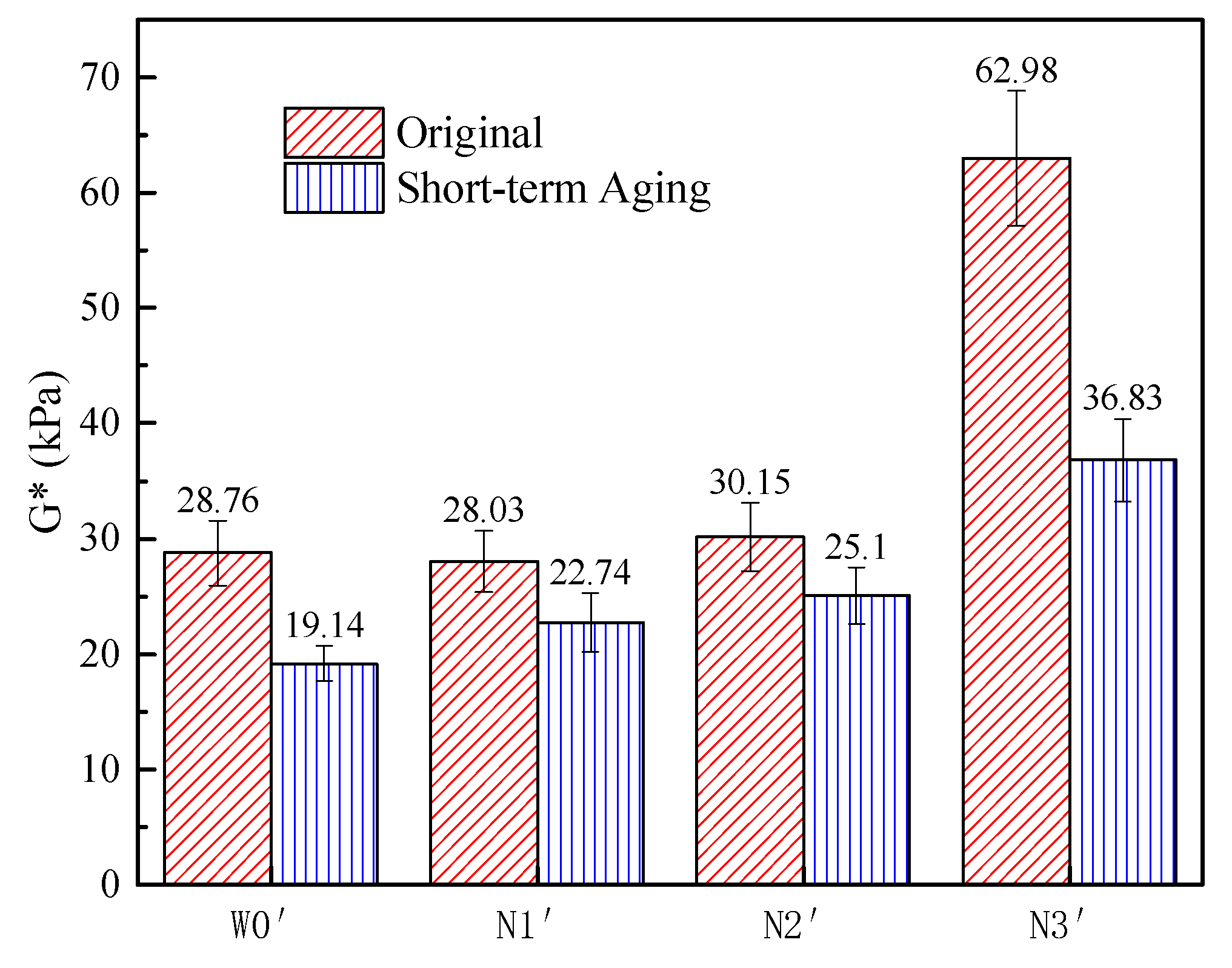

3.2.2. Temperature-Sweep Test

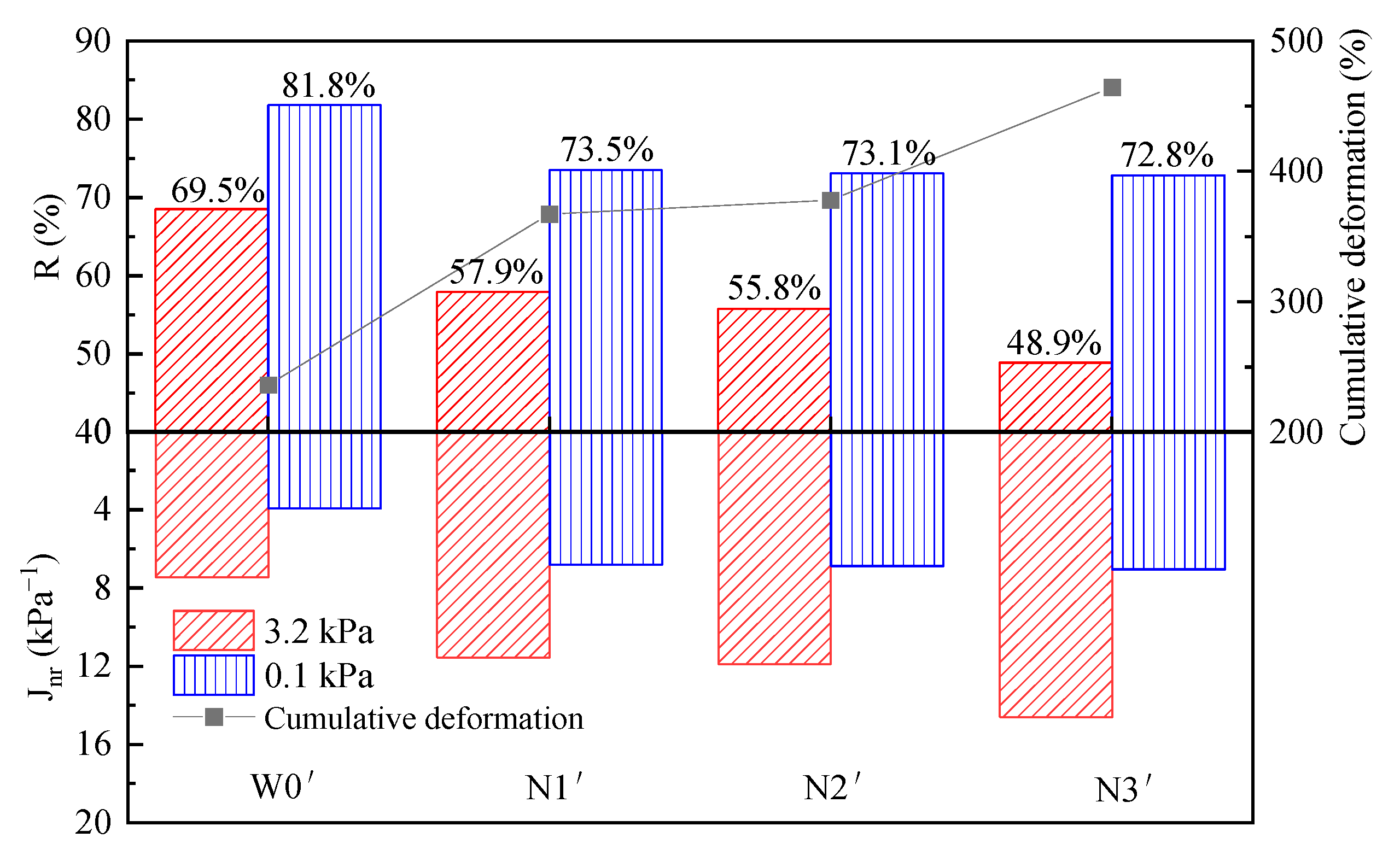

3.2.3. MSCR Test

3.3. Molecular Structure of Activated Asphalt Rubber

3.3.1. FTIR Test

3.3.2. GPC Test

3.3.3. Correlation Analysis

4. Conclusions

- (1)

- The cumulative pore volume and area of the crumb rubber initially reduced and then increased as the degree of engagement increased. The pore volume and area of the crumb rubber were mainly composed of macropores and mesopores, respectively. The fine particles and stacking structures increased with the NaClO concentration, and, finally, a dense gel film was formed. This may have been the reason for the changes in the porosity and the agglomeration of the crumb rubber.

- (2)

- Aging causes the viscosity, phase angle, G*/sinδ and complex modulus of asphalt rubber to decrease to varying degrees. The activation can improve the rheological properties of asphalt rubber, and the higher the degree of activation, the more pronounced the effect. The degree of activation has no noticeable effect on the performance of asphalt rubber under low stress. However, it has a significant influence on performance under high stress. In this study, the N3‘ rubber-asphalt sample had the best rheological properties.

- (3)

- Activated asphalt rubber is prone to the formation of oxygen-containing functional groups, a process that is facilitated by ageing under thermal-oxygen conditions. The LMS content of asphalt rubber is inversely proportional to the activation degree of crumb rubber. However, the aging effect has the opposite effect on the LMS content of activated and inactivated asphalt rubber. The LMS content has a good correlation with the rheological properties, and LMS content can be used to predict rheological properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Xiao, M.; Yao, J.T.; Chen, L.Z. Progress in combined modification of rubberized asphalt. IOP Conf. Ser. Earth Environ. Sci. 2021, 634, 012104. [Google Scholar] [CrossRef]

- Ma, T.; Chen, C.L.; Zhang, Y.; Zhang, W.G. Development of Using Crumb rubber in Asphalt Modification: A Review. China J. Highw. Transp. 2021, 34, 1. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Cao, Z.L.; Xu, X.Y.; Xiao, F.P.; Abdel-Wahed, T. Bonding, rheological, and physiochemical characteristics of reclaimed asphalt rejuvenated by crumb rubber modified binder. J. Clean. Prod. 2022, 373, 133896. [Google Scholar] [CrossRef]

- Liang, M.; Ren, S.S.; Sun, C.J.; Zhang, J.Z.; Jiang, H.G.; Yao, Z. Extruded Tire Crumb-Rubber Recycled Polyethylene Melt Blend as Asphalt Composite Additive for Enhancing the Performance of Binder. J. Mater. Civ. Eng. 2020, 32, 04019373. [Google Scholar] [CrossRef]

- Wu, W.J.; Jiang, W.; Xiao, J.J.; Yuan, D.D.; Wang, T.; Xing, C.W. Analysis of thermal susceptibility and rheological properties of asphalt binder modified with microwave activated crumb rubber. J. Clean. Prod. 2022, 377, 134488. [Google Scholar] [CrossRef]

- Ibrahim, I.M.; Fathy, E.S.; El-Shafie, M.; Elnaggar, M.Y. Impact of incorporated gamma irradiated crumb rubber on the short-term aging resistance and rheological properties of asphalt binder. Constr. Build. Mater. 2015, 81, 42–46. [Google Scholar] [CrossRef]

- Zhou, T.; Zhou, J.N.; Li, Q.D.; Li, B. Aging Properties and Mechanism of Microwave-Activated Crumb Rubber Modified Asphalt Binder. Front. Mater. 2020, 7, 603938. [Google Scholar] [CrossRef]

- Yang, X.L.; Shen, A.Q.; Li, B.; Wu, H.S.; Lyu, Z.H.; Wang, H.; Lyu, Z.F. Effect of microwave-activated crumb rubber on reaction mechanism, rheological properties, thermal stability, and released volatiles of asphalt binder. J. Clean. Prod. 2020, 248, 119230. [Google Scholar] [CrossRef]

- Li, B.; Wei, Y.Z.; Wang, Y.; Cui, Y.J. Effect of hydrogen peroxide treated crumb rubber on viscoelasticity of rubber modified asphalt. Acta Mater. Compos. Sin. 2019, 36, 1008–1016. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.H.; Yang, C.C. Pretreatment of Crumb rubber with a Silane Coupling Agent to Improve Asphalt Rubber Performance. Adv. Mater. Sci. Eng. 2021, 2021, 1828145. [Google Scholar] [CrossRef]

- Chen, J.H.; Yan, K.Z.; You, L.Y. Rheological and Spectroscopic Properties of Ethylene Vinyl Acetate–Modified Rubberized Asphalt. J. Mater. Civ. Eng. 2020, 32, 04020142. [Google Scholar] [CrossRef]

- Ren, S.S.; Liu, X.Y.; Lin, P.; Wang, H.P.; Fan, W.Y.; Erkens, S. The continuous swelling-degradation behaviors and chemo-rheological properties of waste crumb rubber modified bitumen considering the effect of rubber size. Constr. Build. Mater. 2021, 307, 124966. [Google Scholar] [CrossRef]

- Wang, S.F.; Cheng, D.X.; Xiao, F.P. Recent developments in the application of chemical approaches to rubberized asphalt. Constr. Build. Mater. 2017, 131, 101–113. [Google Scholar] [CrossRef]

- Yin, L.; Yang, X.L.; Shen, A.Q.; Wu, H.S.; Lyu, Z.F.; Li, B. Mechanical properties and reaction mechanism of microwave-activated crumb rubber-modified asphalt before and after thermal aging. Constr. Build. Mater. 2021, 267, 120773. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Wei, H.; Dai, Y.H. Influence of Different Aging Environments on Rheological Behavior and Structural Properties of Rubber Asphalt. Materials 2020, 13, 3376. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Wu, X.Y.; Wang, S.F.; Ouyang, C.F. Weather aging resistance of different rubber modified asphalts. Constr. Build. Mater. 2016, 106, 443–448. [Google Scholar] [CrossRef]

- Liu, X.H.; Bi, Y.F.; An, Y.N.; Zhou, S.Q.; Li, F. Secondary-Reaction Method to Improve Performance of a Compound Modified Rubber Asphalt after Short-Term Aging. J. Transp. Eng. Part B Pavements 2021, 147, 04021038. [Google Scholar] [CrossRef]

- Chen, R.P.; Zhu, H.Z.; Kong, L.Y.; Xu, Y.L.; Ou, L. Stage-aging characteristics and stages division of crumb rubber modified asphalt binder. Constr. Build. Mater. 2023, 367, 129712. [Google Scholar] [CrossRef]

- JTG F40-2004; Research Institute of Highway Ministry of Transport. Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2004.

- JT/T 798-2011; Research Institute of Highway Ministry of Transport. Asphalt Rubber for Highway Engineering. China Communications Press: Beijing, China, 2011.

- Yang, X.L.; Li, B.; Liu, X.; Zhang, Z.W. Mechanism of Modification of Rubber Asphalt on Process Parameters. J. Build. Mater. 2017, 20, 640–645. [Google Scholar] [CrossRef]

- JTG E20-2011; Research Institute of Highway Ministry of Transport. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- ASTM D5604-96; American Society for Testing and Materials. Standard Test Methods for Precipitated Silica-Surface Area by Single Point B.E.T. Nitrogen Adsorption. US-ASTM: West Conshohocken, PA, USA, 2012.

- He, Y.P.; Yang, S.J. Application of BET Specific Surface Area Method in Material Research. Adv. Fine Petrochem. 2018, 19, 52–56. [Google Scholar] [CrossRef]

- Li, L.L.; Huang, X.M.; Zhu, D.Y.; Han, D.; Dong, M.S. Application of generalized Kelvin model in asphalt pavement. J. Southeast Univ. (Nat. Sci. Ed.) 2016, 46, 413–418. [Google Scholar] [CrossRef]

- Li, X.Y.; Ping, L.; Wang, H.N.; Zhang, C.; You, Z.P. Performance test of rubber asphalt based on domestic and abroad test methods. J. Traffic Transp. Eng. 2015, 15, 10–17. [Google Scholar] [CrossRef]

- Li, B.; Wang, J.; Cao, G.; Wang, C.H.; Yang, X.L. Influence Mechanism of Crumb rubber Characteristics on High-temperature Performance for Rubber Modified Asphalt Binder. J. Basic. Sci. Eng. 2017, 25, 347–355. [Google Scholar] [CrossRef]

- Amir, A.; Ziari, H.; Saadatjoo, S.A.; Hashemifar, N.S.; Goli, A. Rutting resistance, fatigue properties and temperature susceptibility of nano clay modified asphalt rubber binder. Constr. Build. Mater. 2021, 267, 120946. [Google Scholar] [CrossRef]

- Xiao, F.P.; Zong, Q.D.; Wang, J.G.; Chen, J.; Liu, J. Storage stability characterization and improvement of SBS and Crumb rubber composite modified asphalt. Road Mater. Pavement Des. 2022, 23, 509–526. [Google Scholar] [CrossRef]

- Li, M.C.; Xing, C.W.; Liu, L.P.; Huang, W.Q.; Meng, Y.F. Gel permeation chromatography-based method for assessing the properties of binders in reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2022, 316, 126005. [Google Scholar] [CrossRef]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar] [CrossRef]

- Shang, L.N.; Wang, S.F.; Zhang, Y.; Zhang, Y.X. Pyrolyzed wax from recycled cross-linked polyethylene as warm mix asphalt (WMA) additive for SBS modified asphalt. Constr. Build. Mater. 2010, 25, 886–891. [Google Scholar] [CrossRef]

- Tang, N.P.; Huang, W.D. High Temperature Performance Evaluation and Grading of SBS Modified Asphalt Based on Multiple Stress Creep Recovery Test. J. Build. Mater. 2016, 19, 665–671. [Google Scholar] [CrossRef]

- Asib, A.S.M.; Rahman, R.; Romero, P.; Hoepfner, M.P.; Mamun, A. Physicochemical characterization of short and long-term aged asphalt mixtures for low-temperature performance. Constr. Build. Mater. 2022, 319, 126038. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.N.; Yu, J.M.; Xu, W. Study on Multi-scale Characteristics of Matrix Asphalt before and after Aging. J. Build. Mater. 2018, 21, 420–425. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S.J.; Amirkhanian, S.N.; Jeong, K.D. Quantification of Oxidative Aging of Polymer-Modified Asphalt Mixes Made with Warm Mix Technologies. J. Mater. Civ. Eng. 2013, 25, 1–8. [Google Scholar] [CrossRef]

- Xiang, Y.; Fan, H.J.; Liu, Z.H. Structural characteristics of silane-modified ground tyre rubber and high-temperature creep property of asphalt rubber. Constr. Build. Mater. 2020, 236, 117600. [Google Scholar] [CrossRef]

| Performance | Unit | Test Result | Specification Limits |

|---|---|---|---|

| Penetration (100 g, 5 s, 25 °C) | 0.1 mm | 86.8 | 80–100 |

| Softening point | °C | 45.5 | ≥42 |

| Ductility (15 °C, 5 cm/min) | cm | >100 | ≥100 |

| 60 °C dynamic viscosity | Pa·s | 145 | ≥140 |

| RTFOT 163 °C, 85 min | |||

| Mass loss | % | −0.06 | ≤±0.8 |

| Penetration ratio | % | 68 | ≥54 |

| Ductility (10 °C) | cm | 8.8 | ≥6 |

| Test Properties | Indicators | Result |

|---|---|---|

| Bulk density/(kg/m3) | 260–460 | 303.2 |

| Moisture content/% | <1 | 0.0 |

| Metal content/% | <0.03 | 0.007 |

| Fiber content/% | <1 | 0.062 |

| Ash content/% | ≤8 | 7.1 |

| Acetone extract/% | ≤22 | 7.0 |

| Carbon-black content/% | ≥28 | 31 |

| Rubber hydrocarbon content/% | ≥42 | 50 |

| Activation Methods | Inactivated | NaClO Solution Activation | ||

|---|---|---|---|---|

| Crumb-rubber sample | W0 | N1 | N2 | N3 |

| Asphalt-rubber sample | W0′ | N1′ | N2′ | N3′ |

| Mass ratio | 0:1 | 0.5:1 | 1:1 | 1.5:1 |

| Test Properties | Peak Area | CI | SI | |||

|---|---|---|---|---|---|---|

| C=O | S=O | 600 cm−1–2000 cm−1 | ||||

| W0′ | Original | 0 | 1.728 | 115.684 | 0.0000 | 0.0149 |

| Short-term aging | 0.469 | 3.226 | 74.382 | 0.0063 | 0.0434 | |

| N1′ | Original | 0 | 1.394 | 125.557 | 0.0000 | 0.0111 |

| Short-term aging | 0.556 | 2.293 | 77.164 | 0.0072 | 0.0297 | |

| N2′ | Original | 0 | 1.511 | 152.094 | 0.0000 | 0.0099 |

| Short-term aging | 0.585 | 3.361 | 93.992 | 0.0062 | 0.0358 | |

| N3′ | Original | 0 | 1.135 | 87.848 | 0.0000 | 0.0129 |

| Short-term aging | 0.731 | 3.66 | 99.771 | 0.0073 | 0.0367 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Li, D.; Li, B.; Wang, Y.; Wei, Y.; Wang, B.; Zhang, B. The Properties of Sodium-Hypochlorite-Activated Crumb Rubber and the Influence of Aging on the Rheological Properties of Activated Asphalt Rubber. Buildings 2023, 13, 712. https://doi.org/10.3390/buildings13030712

Zhang P, Li D, Li B, Wang Y, Wei Y, Wang B, Zhang B. The Properties of Sodium-Hypochlorite-Activated Crumb Rubber and the Influence of Aging on the Rheological Properties of Activated Asphalt Rubber. Buildings. 2023; 13(3):712. https://doi.org/10.3390/buildings13030712

Chicago/Turabian StyleZhang, Peng, Dongna Li, Bo Li, Yongning Wang, Yongzheng Wei, Binghui Wang, and Binlin Zhang. 2023. "The Properties of Sodium-Hypochlorite-Activated Crumb Rubber and the Influence of Aging on the Rheological Properties of Activated Asphalt Rubber" Buildings 13, no. 3: 712. https://doi.org/10.3390/buildings13030712

APA StyleZhang, P., Li, D., Li, B., Wang, Y., Wei, Y., Wang, B., & Zhang, B. (2023). The Properties of Sodium-Hypochlorite-Activated Crumb Rubber and the Influence of Aging on the Rheological Properties of Activated Asphalt Rubber. Buildings, 13(3), 712. https://doi.org/10.3390/buildings13030712