Analysis of Thermal Resistance of Developed Energy-Saving External Enclosing Structures with Air Gaps and Horizontal Channels

Abstract

1. Introduction

2. Materials and Methods

- The enclosure is painted in light color, and the coefficient of absorption of solar radiation by the material of the outer surface is 0.5.

- The height of the building is 18 m.

- To calculate the air parameters in the ventilated air gap, the parameters of “Granitogres” hinged facade with ceramic granite facade tiles 600 × 600 × 10 mm were used. The width of the supply slot is 10 mm. The sum of the coefficients of local resistance in this case is 5.4 [39].

- -

- ambient temperature—absolute minimum (−30.3 °C); average internal temperature was 20 °C;

- -

- ambient temperature—absolute maximum (44.2 °C); average internal temperature was 28 °C;

- -

- ambient temperature—the average temperature of the coldest five-day period with a probability of 0.92 (−14.3 °C); average internal temperature was 20 °C;

- -

- ambient temperature—the average temperature in April (13.5 °C); the average internal temperature was 20 °C.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | Thickness [mm] |

| λ | Thermal conductivity coefficient [W/(m⋅°C)] |

| s | Heat absorption (within a period of 24 h) [W] |

| μ | Vapor permeability [mg/(m·h·Pa)] |

| ANSYS | Universal software system for finite element analysis |

| R | Heat transfer resistance of multilayer enclosing structure [°C·m2/W] |

| αint | Heat transfer coefficient on the inner surface of the enclosing structure [W/(m2·°C)] |

| δ | Thickness of the i-th layer [m] |

| λi | Coefficient of thermal conductivity of the material of the i-th layer [W/(m·°C)] |

| αext | Heat transfer coefficient on the outer surface of the enclosing structure [W/(m2·°C)] |

References

- Kurt, H. The usage of air gap in the composite wall for energy saving and air pollution. Env. Prog. Sus. Eng. 2010, 30, 450–458. [Google Scholar] [CrossRef]

- Demirbas, A. Energy balance, energy sources, energy policy, future developments and energy investments in Turkey. Eng. Conv. Manag. 2001, 42, 1239–1258. [Google Scholar] [CrossRef]

- Bolatturk, A. Determination of optimum insulation thickness for building walls with respect to various fuels and climate zones in Turkey. Ap. Ther. Eng. 2006, 26, 1301–1309. [Google Scholar] [CrossRef]

- Hasan, A. Optimizing insulation thickness for buildings using life cycle cost. Ap. Eng. 1999, 63, 115–124. Available online: https://ideas.repec.org/a/eee/appene/v63y1999i2p115-124.html (accessed on 27 December 2022). [CrossRef]

- DOE: 2011 Building Energy Data Book. Energy Efficiency and Renewable Energy; USA, Maryland, Department of Energy: 2011. Available online: https://ieer.org/wp/wp-content/uploads/2012/03/DOE-2011-Buildings-Energy-DataBook-BEDB.pdf (accessed on 25 December 2022).

- Kudabayev, R.; Suleimenov, U.; Ristavletov, R.; Kasimov, I.; Kambarov, M.; Zhangabay, N.; Abshenov, K. Modeling the Thermal Regime of a Room in a Building with a Thermal Energy Storage Envelope. Math. Model. Eng. Prob. 2022, 9, 351–358. [Google Scholar] [CrossRef]

- Kudabayev, R.; Mizamov, N.; Zhangabay, N.; Suleimenov, U.; Kostikov, A.; Vorontsova, A.; Buganova, S.; Umbitaliyev, A.; Kalshabekova, E.; Aldiyarov, Z. Construction of a model for an enclosing structure with a heat-accumulating material with phase transition taking into account the process of solar energy accumulation. East.-Eur. J. Enterp. Technol. 2022, 6, 26–37. [Google Scholar] [CrossRef]

- Malhotra, M. An Analysis of Maximum Residential Energy-Efficiency in Hot and Humid Climates. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2005. Available online: https://www.semanticscholar.org/paper/An-Analysis-of-Maximum-Residential-Energy-in-Hot-Malhotra-Haberl/1c10d5c7f13324ee41cefadf1765b6d25b0b4e10 (accessed on 25 December 2022).

- Borodin, K.; Zhangabay, N.Z. Mechanical characteristics, as well as physical-and-chemical properties of the slag-filled concretes, and investigation of the predictive power of the metaheuristic approach. Curved Layer. Struct. 2019, 6, 236–244. [Google Scholar] [CrossRef]

- Soudian, S.; Berardi, U. Experimental performance evaluation of a climate-responsive ventilated building façade. J. Build. Eng. 2022, 61, 105233. [Google Scholar] [CrossRef]

- Dombaycı, O.A. The environmental impact of optimum insulation thickness for external walls of buildings. Build Env. 2007, 42, 3855–3859. [Google Scholar] [CrossRef]

- Kaynaklı, O. A study on residential heating energy requirement and optimum insulation thickness. Ren. Eng. 2008, 33, 1164–1172. [Google Scholar] [CrossRef]

- Ucar, A.; Balo, F. Effect of fuel type on the optimum thickness of selected insulation materials for the four different climatic regions of Turkey. Ap. Eng. 2009, 86, 730–736. [Google Scholar] [CrossRef]

- Soylemez, M.S.; Unsal, M. Optimum insulation thickness for refrigeration applications. Eng. Conv. Manag. 1999, 40, 13–21. [Google Scholar] [CrossRef]

- Horn, R.; Burr, M.; Fröhlich, D.; Gschwander, S.; Held, M.; Lindner, J.P.; Munz, G.; Nienborg, B.; Schossig, P. Life cycle assessment of innovative materials for thermal energy storage in buildings. Procedia CIRP 2018, 69, 206–211. [Google Scholar] [CrossRef]

- Comaklı, K.; Yuksel, B. Environmental impact of thermal insulation thickness in building. Ap. Ther. Eng. 2004, 24, 933–940. [Google Scholar] [CrossRef]

- Dombaycı, O.A.; Golcu, M.; Pancar, Y. Optimization of insulation thickness for external walls using different energy-sources. App. Eng. 2006, 83, 921–928. [Google Scholar] [CrossRef]

- Mohsen, M.S.; Akash, B.A. Some prospect of energy savings in buildings. Eng. Conv. Manag. 2001, 42, 1307–1315. Available online: https://aurak.ac.ae/publications/Some-prospects-of-energy-savings-in-buildings.pdf (accessed on 27 December 2022). [CrossRef]

- Zhangabay, N.; Abshenov, K.; Bakhbergen, S.; Zhakash, A.; Moldagaliyev, A. Evaluating the Effectiveness of Energy-Saving Retrofit Strategies for Residential Buildings. Int. Rev. Civ. Eng. 2022, 13, 118–126. [Google Scholar] [CrossRef]

- Al-Sallal, K.A. Comparison between polystyrene and fiberglass roof insulation in warm and cold climates. Ren. Eng. 2003, 28, 603–611. [Google Scholar] [CrossRef]

- CLEAR: Cavities and Air Space. Comfortable Low Energy Architecture. 2016. Available online: http://new-learn.info/packages/clear/thermal/buildings/building_fabric/elements/cavities_andair_spaces.html (accessed on 25 December 2022).

- CIT: Resistance of Air Layers and Surface Layers. Intelligent Energy Europe. Cork Institute of Technology. 2016. Available online: http://tea.ie/wpcontent/uploads/2011/09/Module-3.2-Resistance-of-air-layers-and-surface-layers.pdf (accessed on 5 March 2016).

- Pacific Northwest National Laboratory (PNNL). Oak Ridge National Laboratory: Building Technologies Program, Building America Best Practices Series, Vol. 17. In Energy Renovations: Insulation a Guide for Contractors to Share with Homeowners. PNNL-20972 May 2012.; 2012. Available online: https://www.pnnl.gov/main/publications/external/technical_reports/PNNL-20972.pdf (accessed on 25 December 2022).

- Mavromatidis, L.E.; Bykalyuk, A.; El Mankibi, M.; Michel, P.; Santamouris, M. Numerical estimation of air gaps’ influence on the insulating performance of multilayer thermal insulation. Build. Env. 2012, 49, 227–237. [Google Scholar] [CrossRef]

- Sadrzadehrafiei, S.; Mat, K.; Sopian, S.; Lim, C.H. Determining the cost saving and emission reduction of optimum insulation thickness and air gap for building walls. Aust. J. Basic Appl. Sci. 2011, 5, 2287–2294. Available online: file:///C:/Users/Admin/Downloads/Determining_the_Cost_Saving_and_Emission_Reduction.pdf (accessed on 28 December 2022).

- Alhefnawi, M.A.M.; Abdu-Allah Al-Qahtany, M. Thermal Insulation Efficiency of Unventilated Air-Gapped Facades in Hot Climate. Arab. J. Sc. Eng. 2016, 42, 1155–1160. [Google Scholar] [CrossRef]

- Abdullah, H.K.; Faraj, S.H. Experimental study for the effect of air gap in building walls on heat gain reduction. Mat. Today Proc. 2021, 61, 1043–1051. [Google Scholar] [CrossRef]

- Hamed, H.; David, W. Evaluation and use of airspaces for thermal resistance in buildings. J. Phys. Conf. Ser. 2021, 2069, 012098. [Google Scholar] [CrossRef]

- Ismaiel, M.; Chen, Y.; Cruz-Noguez, C.; Hagel, M. Thermal resistance of masonry walls: A literature review on influence factors, evaluation, and improvement. J. Build Phys. 2021, 4, 528–567. [Google Scholar] [CrossRef]

- Kvande, T.; Bakken, N.; Bergheim, E.; Thue, J.V. Durability of ETICS with Rendering in Norway—Experimental and Field Investigations. Buildings 2018, 8, 93. [Google Scholar] [CrossRef]

- Gullbrekken, L.; Kvande, T.; Jelle, B.P.; Time, B. Norwegian Pitched Roof Defects. Buildings 2016, 6, 24. [Google Scholar] [CrossRef]

- Asphaug, S.K.; Time, B.; Kvande, T. Moisture Accumulation in Building Façades Exposed to Accelerated Artificial Climatic Ageing—A Complementary Analysis to NT Build 495. Buildings 2021, 11, 568. [Google Scholar] [CrossRef]

- Bunkholt, N.S.; Säwén, T.; Stockhaus, M.; Kvande, T.; Gullbrekken, L.; Wahlgren, P.; Lohne, J. Experimental Study of Thermal Buoyancy in the Cavity of Ventilated Roofs. Buildings 2020, 10, 8. [Google Scholar] [CrossRef]

- Gullbrekken, L.; Uvsløkk, S.; Geving, S.; Kvande, T. Local Loss Coefficients inside Air Cavity of Ventilated Pitched Roofs. J. Build. Phys. 2018, 42, 197–219. [Google Scholar] [CrossRef]

- Ingebretsen, A.B.; Andenæs, E.; Kvande, T. Microclimate of Air Cavities in Ventilated Roof and Façade Systems in Nordic Climates. Buildings 2022, 12, 683. [Google Scholar] [CrossRef]

- Code of Rules of the Republic of Kazakhstan 2.04-107-2013 Building Heat Engineering: State Standards in the Field of Ar-chitecture, Urban Planning and Construction. Code of Rules of the Republic of Kazakhstan.—JSC “KazNIISA”, LLP “Astana Stroy-Consulting”, 2013. Approved and Enacted on 1 July 2015. 80p. Available online: https://online.zakon.kz/m/document/?doc_id=37599018 (accessed on 28 December 2022).

- Isachenko, V.P.; Osipova, V.A.; Sukomel, A.S. Heat transfer. In Textbook for Universities, 3rd ed.; Reprint. and Additional—Moscow.: “Energy”; 1975. Volume 488. Available online: https://djvu.online/file/V5R73pysiRdmX (accessed on 2 January 2023).

- Code of Rules of the Republic of Kazakhstan 2.04-01-2017 Building Climatology: State Standards in the Field of Architecture, Urban Planning and Construction. Code of Rules of the Republic of Kazakhstan.—JSC “KazNIISA”, LLP “Astana Stroy-Consulting”, 2017. Approved and Enacted on 20 December 2017. 43p. Available online: https://online.zakon.kz/m/document/?doc_id=37599018 (accessed on 28 December 2022).

- Nikolatev, S.; Granik, U. Recommendations for the Design of Hinged Facade Systems with a Ventilated Air Gap for New Construction and Reconstruction of Buildings; Moskomarchitectura: Moscow, Russia, 2002; p. 159. Available online: https://files.stroyinf.ru/Data1/9/9931/ (accessed on 28 December 2022).

- ANSYS Learning—Thermal Convection in Heat Transfer. Available online: https://courses.ansys.com/index.php/courses/thermal-convection-in-heat-transfer/ (accessed on 28 December 2022).

- Malyarenko, V.A. Technical Thermophysics of Enclosing Structures of Buildings and Structures/ V.A. Malyarenko. Textbook; KHNAGH: Kharkiv, Ukraine, 2001; p. 280. Available online: https://www.studmed.ru/malyarenko-va-redko-af-i-drtehnicheskaya-teplofizika-ograzhdayuschih-konstrukciy-zdaniy-i-sooruzheniy_c9492939c3e.html (accessed on 2 January 2023).

- Umnyakova, N.P. Thermal protection of closed air gaps with reflecting thermal insulation. Zhilishchnoe Stroit. 2014, 2, 16–20. Available online: https://cyberleninka.ru/article/n/teplozaschita-zamknutyh-vozdushnyh-prosloek-s-otrazhatelnoyteploizolyatsiey (accessed on 28 December 2022).

- Gagarin, V.G. About some thermotechnical mistakes made when designing ventilated facades. ABOK 2005, 2, 52–60. Available online: https://www.abok.ru/for_spec/articles.php?nid=2785 (accessed on 28 December 2022).

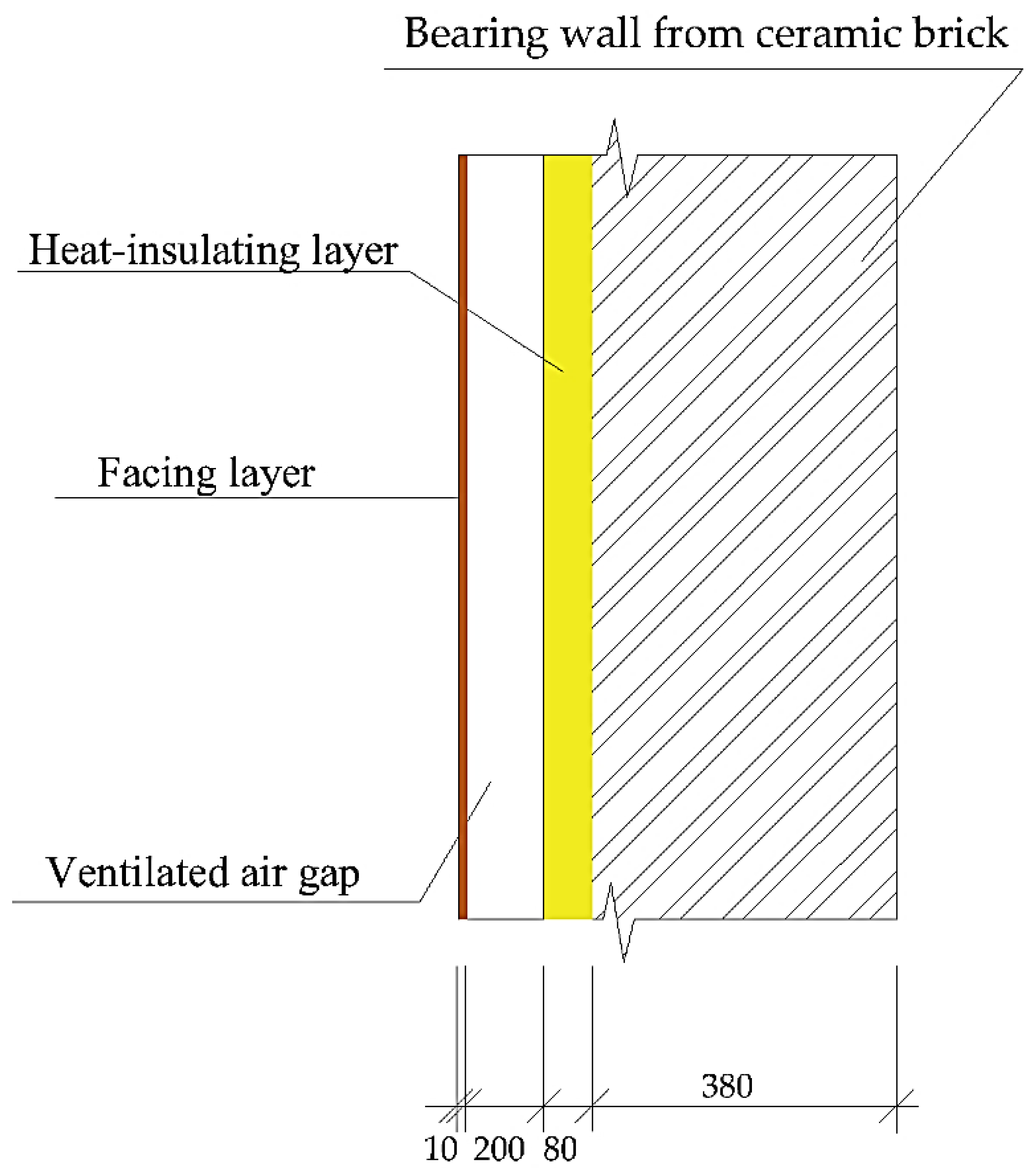

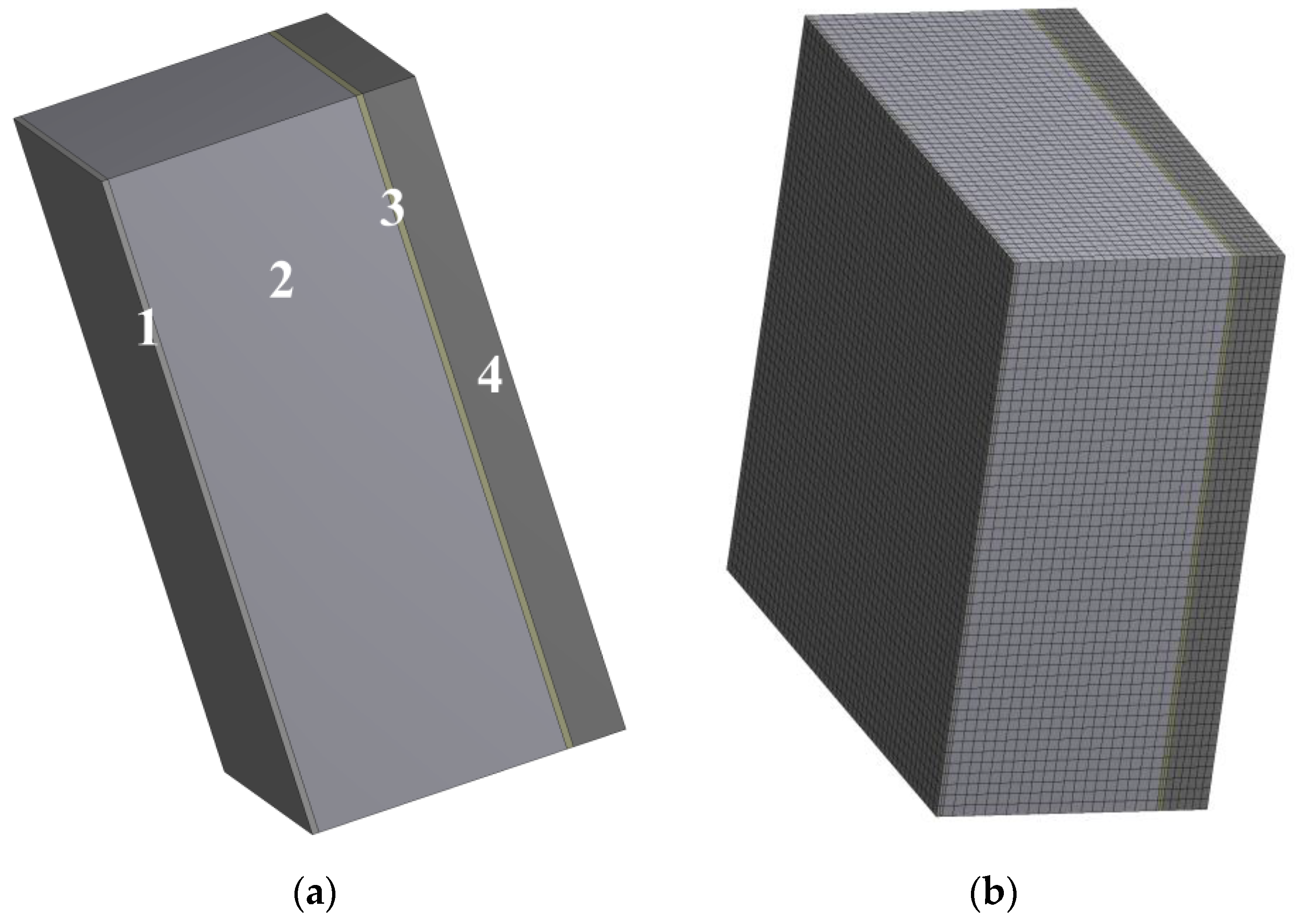

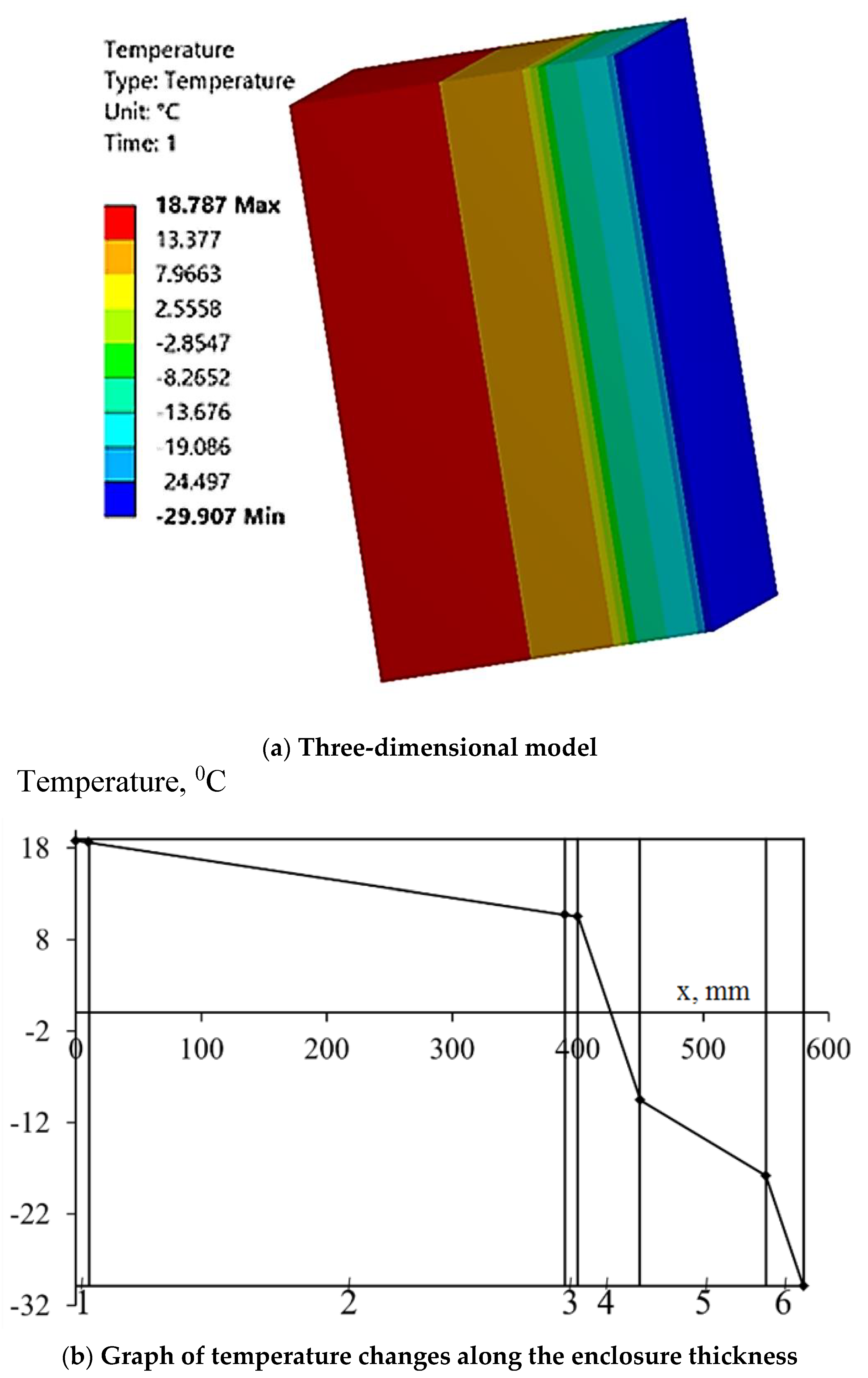

| Layer Number | Description | Thickness, mm | Thermal Conductivity Coefficient, λ, W/(m⋅°C) | Heat Absorption (with a Period of 24 h), s, W | Vapor Permeability, μ, mg/(m·h·Pa) |

|---|---|---|---|---|---|

| 1 | Cement-sand plaster with a density of 1800 kg/m3 | 10 | 0.76 | 9.6 | 0.09 |

| 2 | Ceramic brick laying with a density of 1800 kg/m3 | 380 | 0.58 | 7.91 | 0.14 |

| 3 | Cement-sand plaster with a density of 1800 kg/m3 | 10 | 0.76 | 9.6 | 0.09 |

| 4 | Insulant-extruded polystyrene foam with a density of 25 kg/m3 | 80 | 0.03 | 0.3 | 0.005 |

| 5 | Air gap | 200 | - | - | - |

| 6 | Facing layer from ceramic granite with a density of 2800 kg/m3 | 10 | 3.49 | 25.04 | 0.008 |

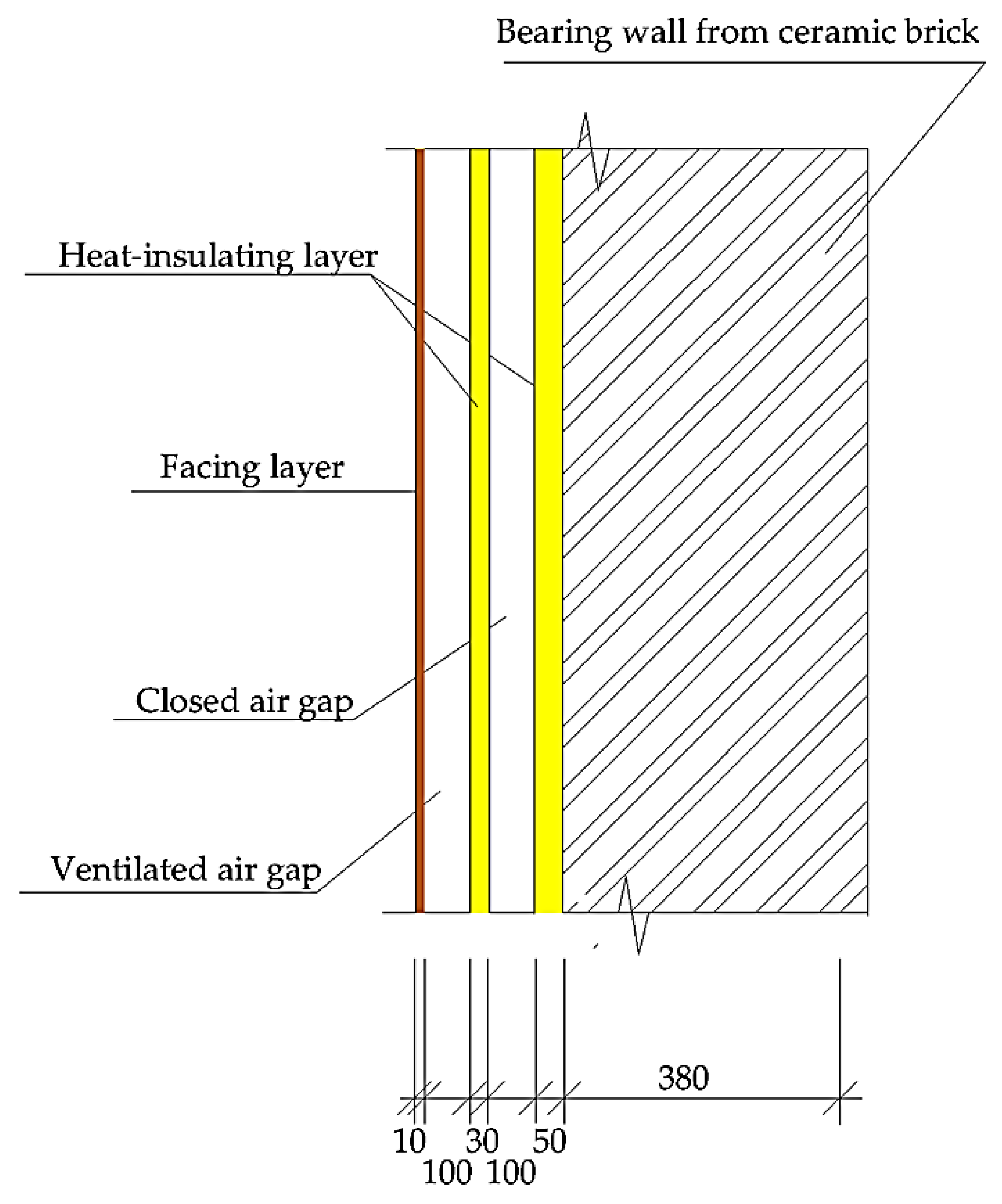

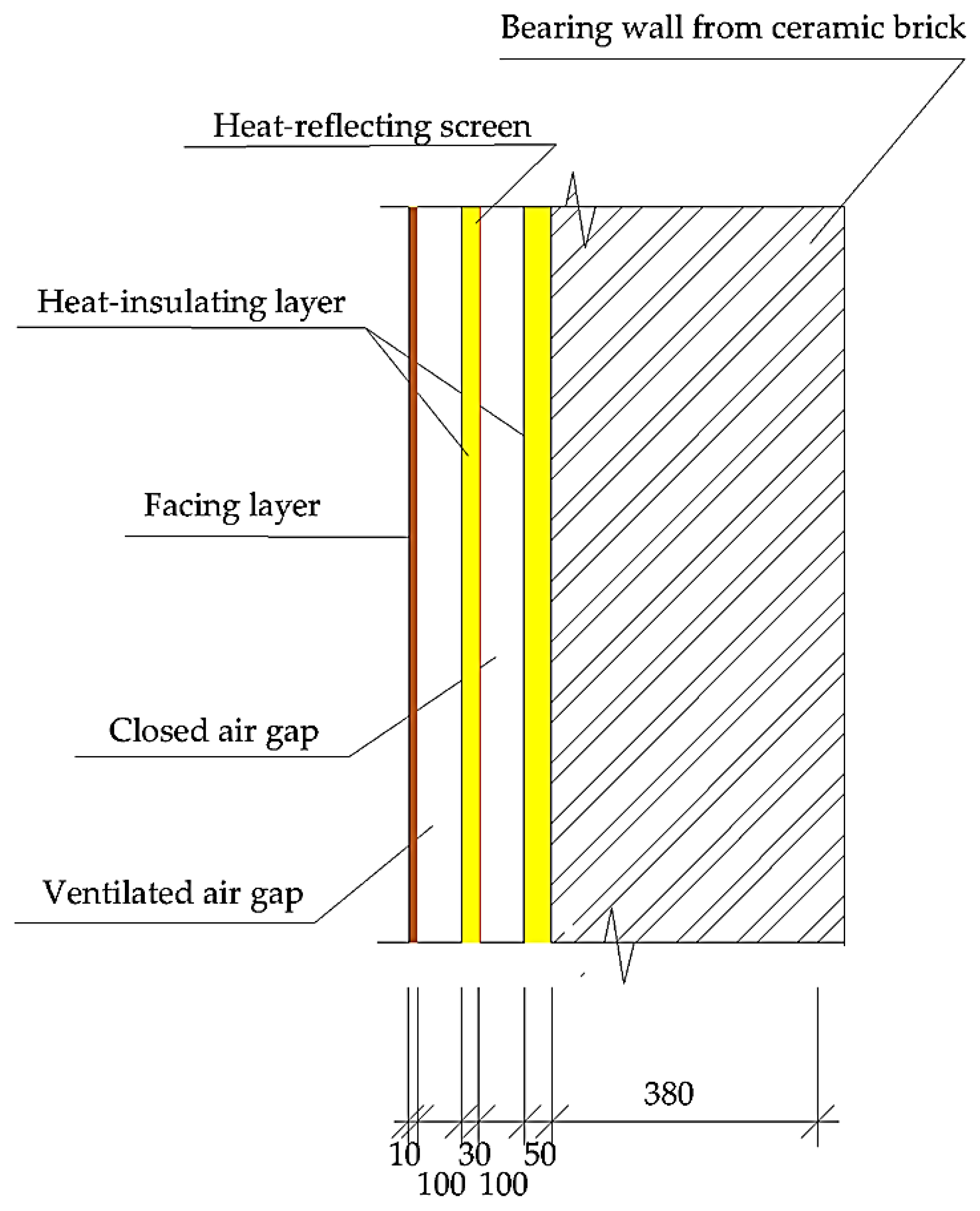

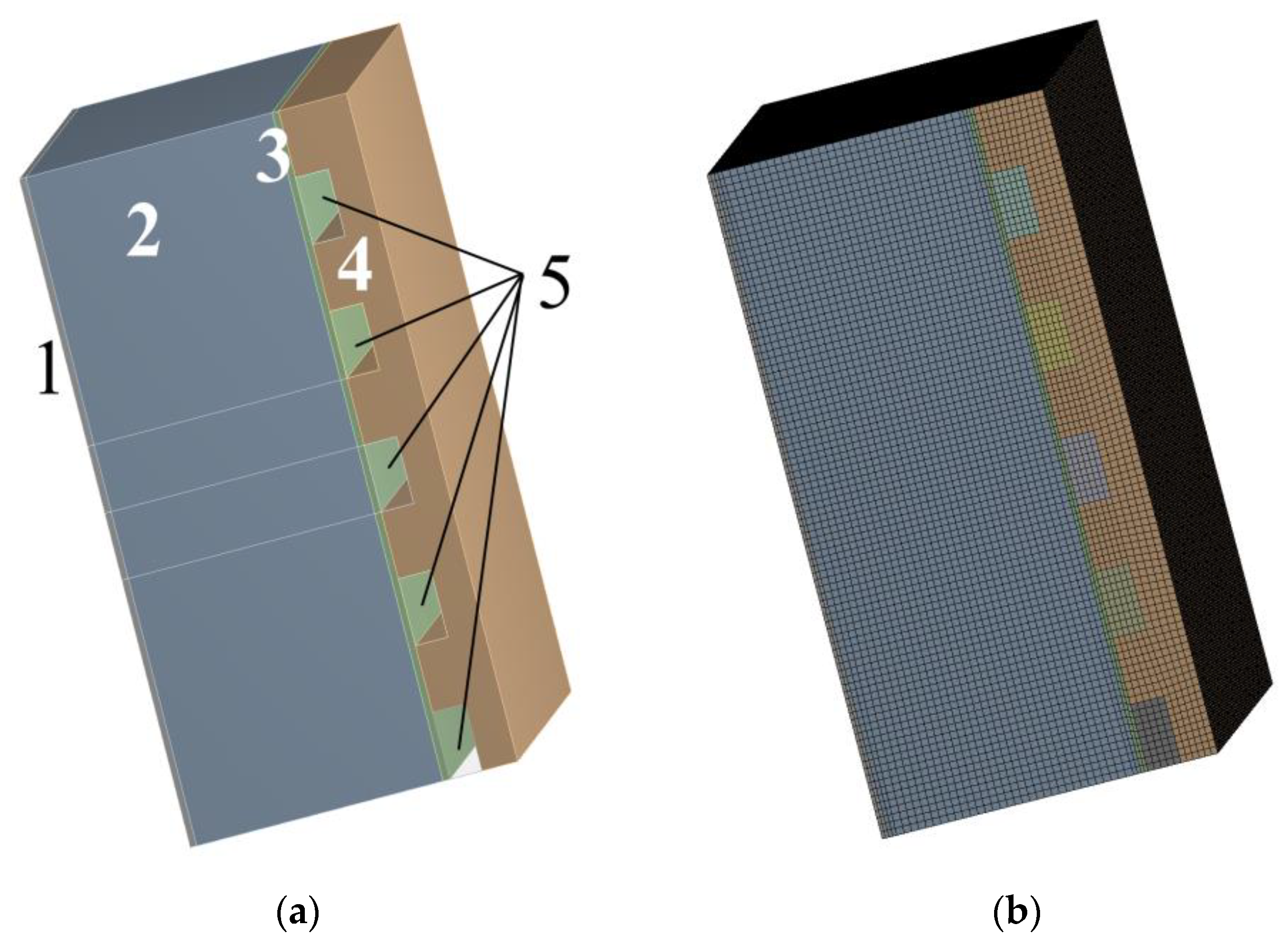

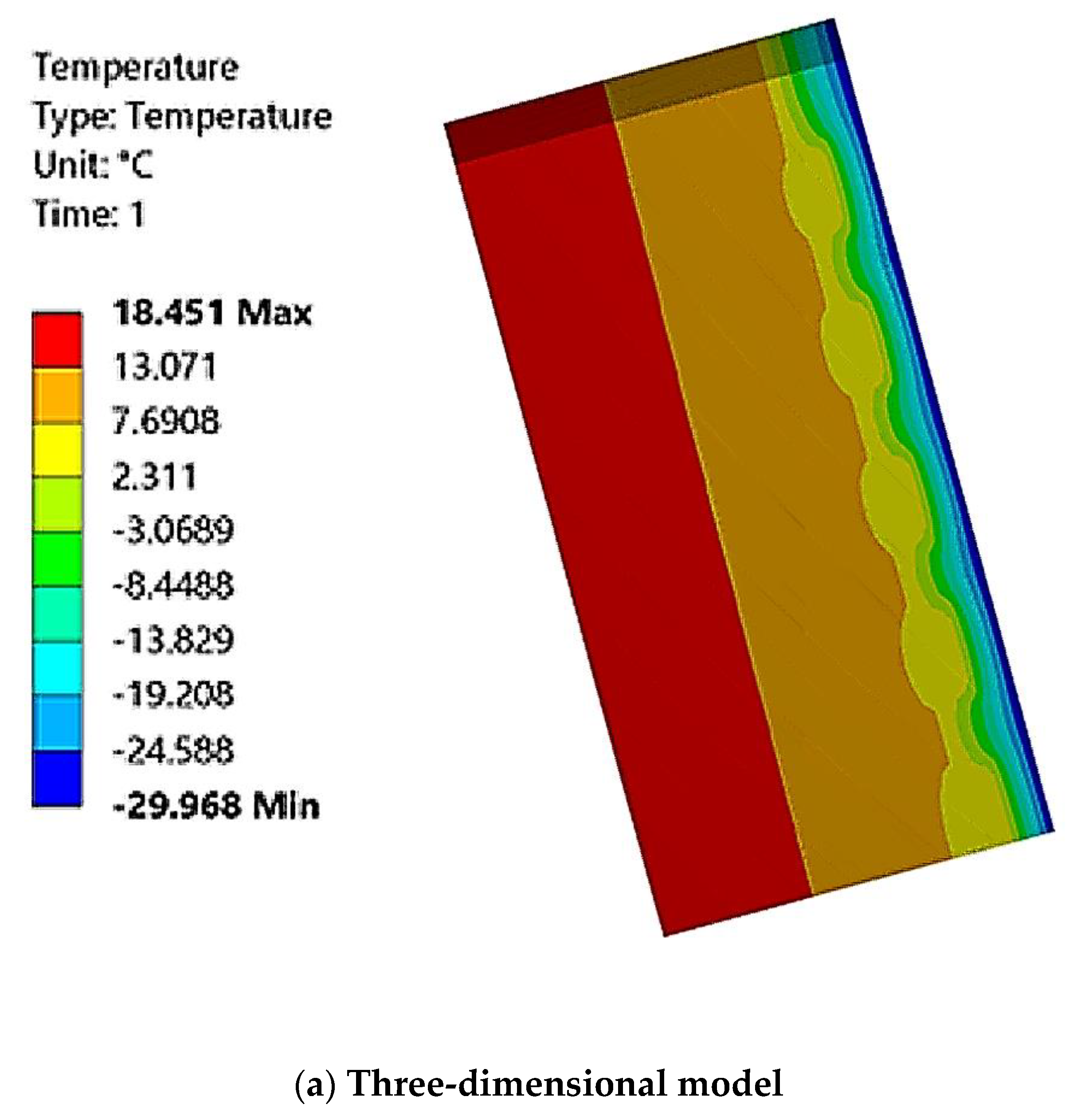

| Layer Number | Description | Thick ness, a mm | Thermal Conductivity Coefficient λ, W/(m⋅°C) | Heat Absorption (with a Period of 24 h), s, W | Vapor Permeability, μ, mg/(m·h·Pa) | Emissivity Factor, [37] | |

|---|---|---|---|---|---|---|---|

| Without Heat-Reflecting Coating | With Heat-Reflecting Coating | ||||||

| 1 | Cement-sand plaster with a density of 1800 kg/m3 | 10 | 0.76 | 9.6 | 0.09 | ||

| 2 | Ceramic brick laying with a density of 1800 kg/m3 | 380 | 0.58 | 7.91 | 0.14 | ||

| 3 | Cement-sand plaster with a density of 1800 kg/m3 | 10 | 0.76 | 9.6 | 0.09 | ||

| 4 | Insulant-extruded polystyrene foam with a density of 25 kg/m3 | 50 | 0.03 | 0.3 | 0.005 | ||

| 5 | Heat-reflecting screen (aluminum foil) | - | - | - | - | 0.9 | 0.039 |

| 6 | Air gap | 100 | - | - | - | ||

| 7 | Heat-reflecting screen (aluminum foil) | - | - | - | - | 0.9 | 0.039 |

| 8 | Insulant-extruded polystyrene foam with a density of 25 kg/m3 | 30 | 0.03 | 0.3 | 0.005 | ||

| 9 | Air gap | 100 | - | - | - | ||

| 10 | Facing layer from ceramic granite with a density of 2800 kg/m3 | 10 | 3.49 | 25.04 | 0.008 | ||

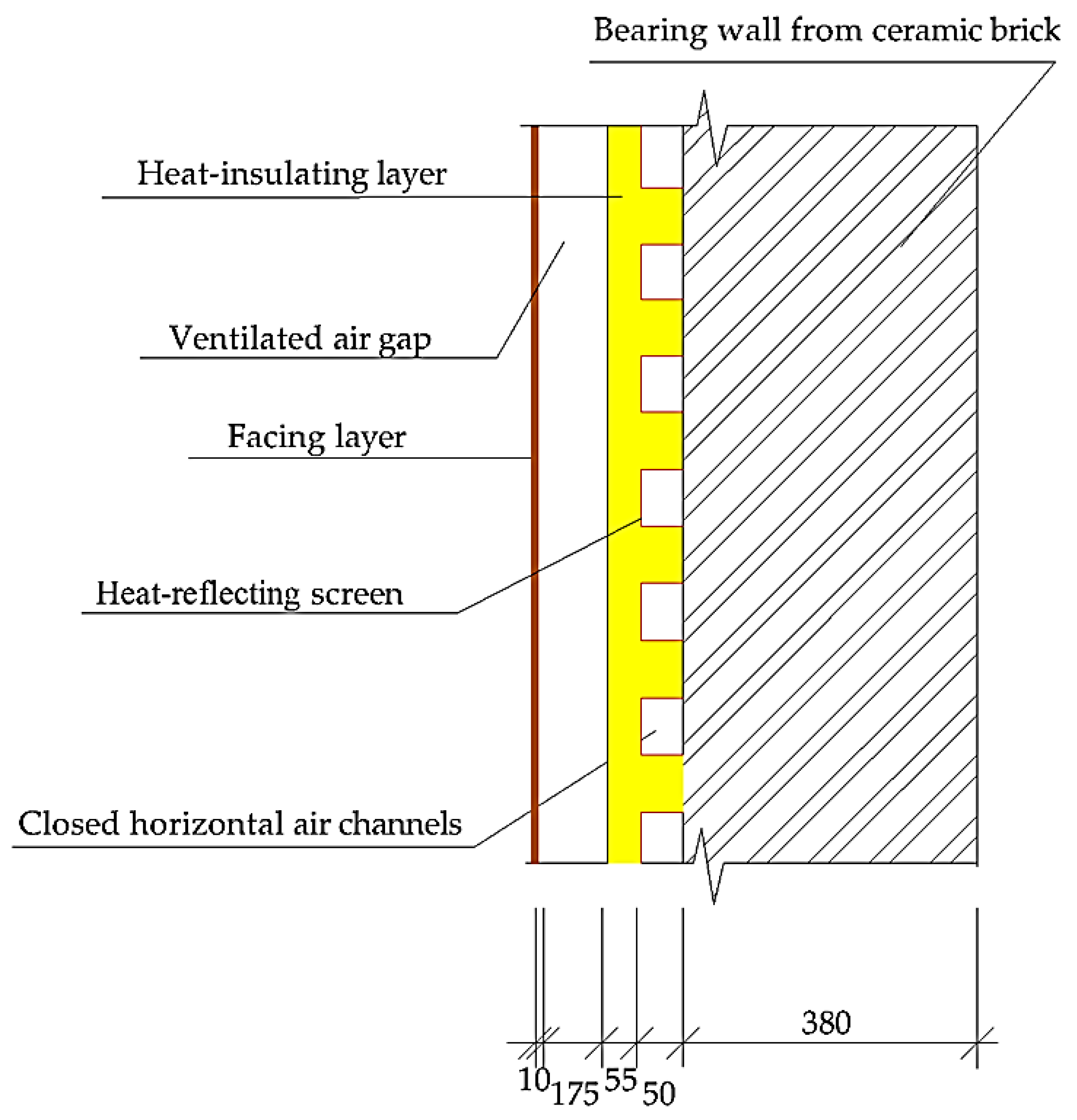

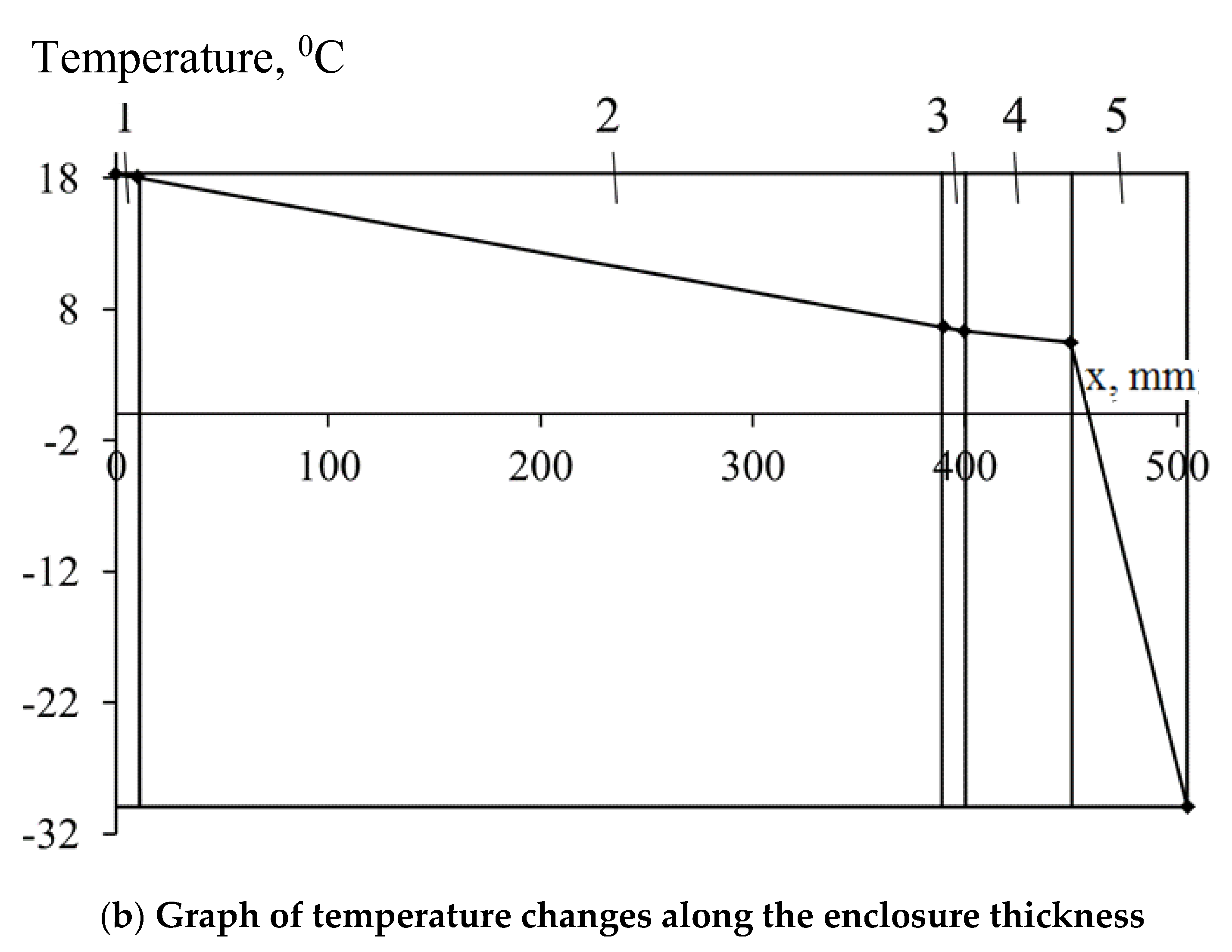

| Layer Number | Description | Thickness, a mm | Width, mm | Thermal Conductivity Coefficien λ, W/(m⋅°C) | Heat Absorption (with a Period of 24 h), s, W | Vapor Permeability, μ, mg/(m·h·Pa) | Emissivity Factor, [37] | |

|---|---|---|---|---|---|---|---|---|

| Without Heat-Reflecting Coating | With Heat-Reflecting Coating | |||||||

| 1 | Cement-sand plaster | 10 | - | 0.76 | 9.6 | 0.09 | - | - |

| 2 | Ceramic brick laying | 380 | - | 0.58 | 7.91 | 0.14 | - | - |

| 3 | Cement-sand plaster | 10 | - | 0.76 | 9.6 | 0.09 | - | - |

| 4 | Insulant with solid extruded polystyrene foam | 105 | - | 0.03 | 0.3 | 0.005 | - | - |

| 5 | Heat-reflecting screen (aluminum foil) | - | - | - | - | - | 0.9 | 0.039 |

| 6 | Insulant with alternating horizontal bars of extruded polystyrene foam/air | 50 | 100 | - | - | - | - | |

| 7 | Air gap | 175 | - | - | - | - | - | - |

| 8 | Facing layer of ceramic granite | 10 | - | 3.49 | 25.04 | 0.008 | - | - |

| № | Criterion | Indicator |

|---|---|---|

| 1 | Building region: | Republic of Kazakhstan, Shymkent |

| 2 | Moist room condition | Normal |

| 3 | Moisture zone | Dry |

| 4 | Operating conditions of enclosing structures | A |

| 5 | Absolute maximum temperature | 44.2 °C |

| 6 | Absolute minimum temperature | −30.3 °C. |

| 7 | Average yearly temperature | 12.6 °C |

| 8 | Average temperature of the coldest five-day period with a probability of 0.92 | −14.3 °C |

| 9 | Average maximum temperature of the warmest month (July) | 33.5 °C |

| 10 | Maximum amplitude of daily fluctuations in outdoor air temperature in July | 14.8 °C |

| 11 | Average monthly outdoor air temperature in July | 26.4 °C |

| 12 | Average monthly temperature of the coldest month (January) | −1.5 °C |

| 13 | Average relative moisture of the coldest month (January) | 73% |

| 14 | Average annual moisture | 57% |

| 15 | Maximum and average values of total solar radiation under clear sky in July for vertical surfaces of western orientation |

|

| 16 | Minimum of average wind speeds in points in July, the frequency of which is 16% or more | 1.3 m/s |

| 17 | Maximum of average speeds in points in January | 6 m/s |

| 18 | Heating season duration | 137 days |

| 19 | Average air temperature in the first month after the heating season (April) | 13.5 °C |

| 20 | Average air moisture in the first month after the heating season (April) | 62% |

| 21 | Internal temperature | in winter 20–22 °C in summer 24–28 °C |

| 22 | Internal moisture | at temperatures up to 24 °C—50–60%, over 24 °C—40–50% |

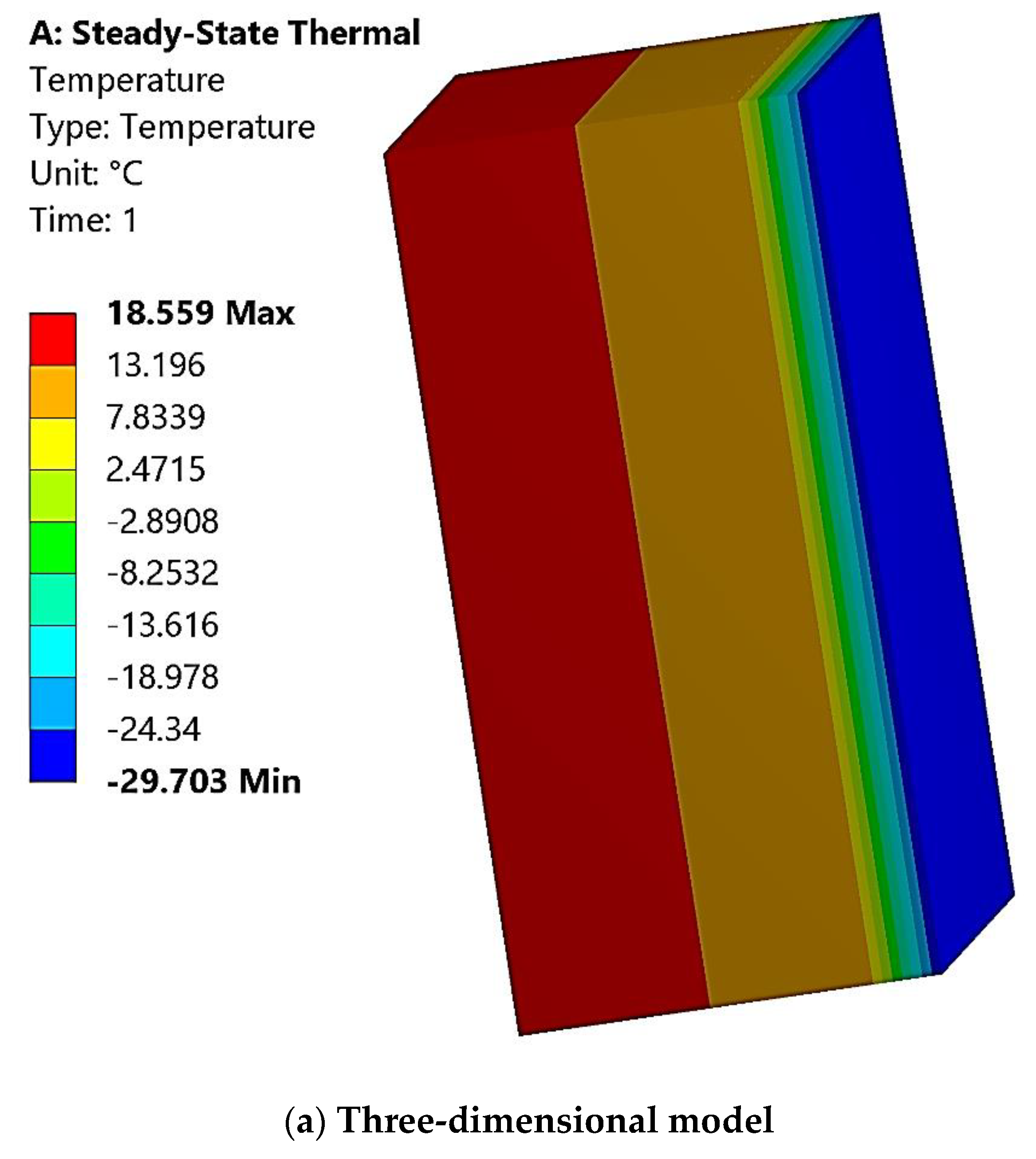

| Parameter | Value, m2·(°C/W) |

|---|---|

| Thermal resistance of the inner wall, minimum temperature | 3.348 |

| Thermal resistance of the inner wall, maximum temperature | 3.348 |

| Thermal resistance of the inner wall, five days | 3.348 |

| Thermal resistance of the inner wall, April | 3.348 |

| Thermal resistance of the enclosure, maximum temperature | 3.462 |

| Thermal resistance of the enclosure, five days | 3.493 |

| Thermal resistance of the enclosure, April | 3.478 |

| Parameter | Value, m2·(°C/W) |

| Thermal resistance of the inner wall, minimum temperature | 3.580 |

| Thermal resistance of the inner wall, maximum temperature | 3.509 |

| Thermal resistance of the inner wall, five days | 3.566 |

| Thermal resistance of the inner wall, April | 3.558 |

| Thermal resistance of the enclosure, maximum temperature | 3.622 |

| Thermal resistance of the enclosure, five days | 3.710 |

| Thermal resistance of the enclosure, April | 3.687 |

| Thermal resistance of the gap, minimum temperature | 0.233 |

| Thermal resistance of the gap, maximum temperature | 0.161 |

| Thermal resistance of the gap, five days | 0.218 |

| Thermal resistance of the gap, April | 0.210 |

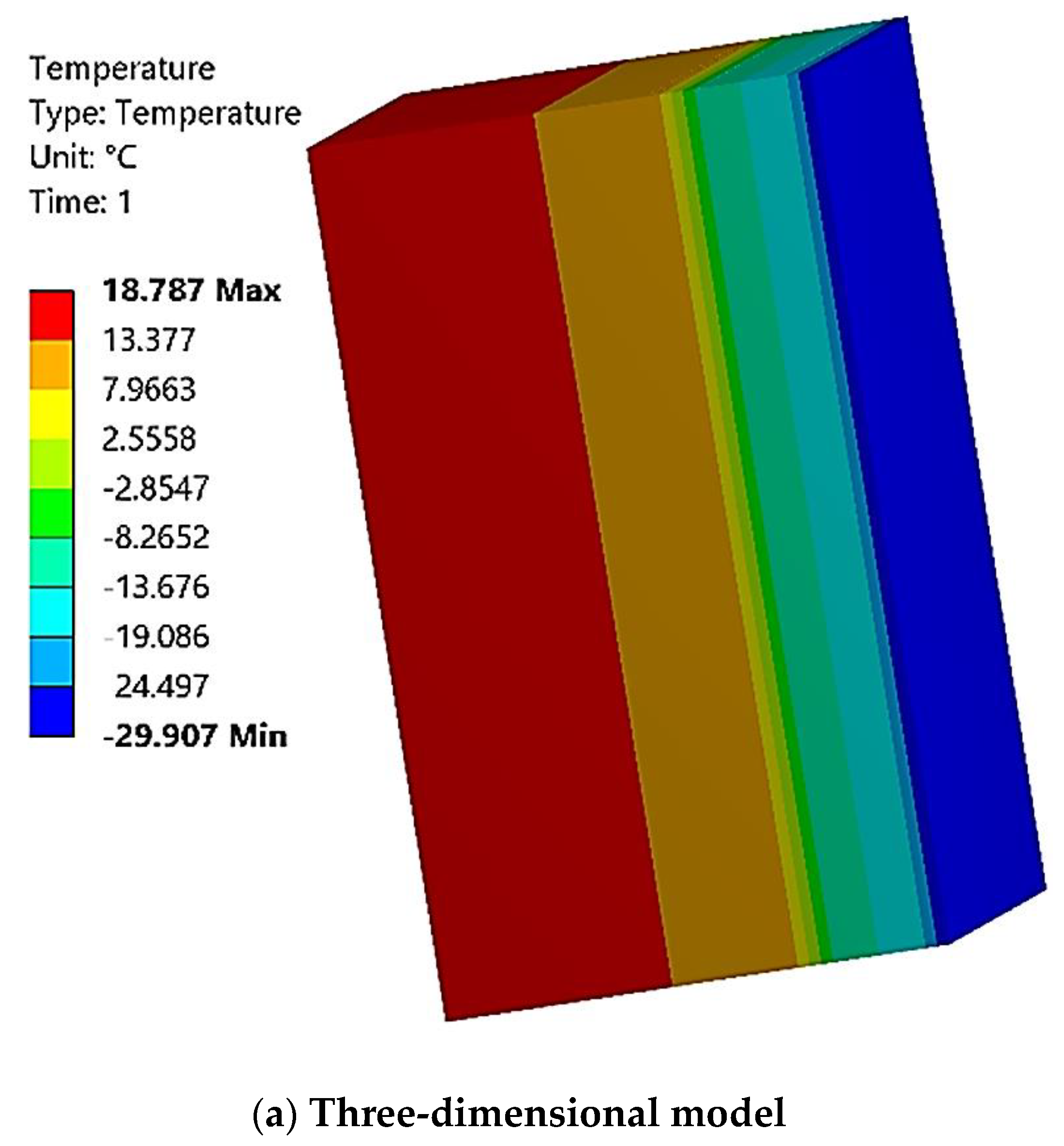

| Parameter | Value, m2·(°C/W) |

|---|---|

| Thermal resistance of the inner wall, minimum temperature | 4.011 |

| Thermal resistance of the inner wall, maximum temperature | 4.119 |

| Thermal resistance of the inner wall, five days | 4.058 |

| Thermal resistance of the inner wall, April | 4.313 |

| Thermal resistance of the enclosure, maximum temperature | 4.233 |

| Thermal resistance of the enclosure, five days | 4.202 |

| Thermal resistance of the enclosure, April | 4.442 |

| Thermal resistance of the gap, minimum temperature | 0.668 |

| Thermal resistance of the gap, maximum temperature | 0.770 |

| Thermal resistance of the gap, five days | 0.710 |

| Thermal resistance of the gap, April | 0.964 |

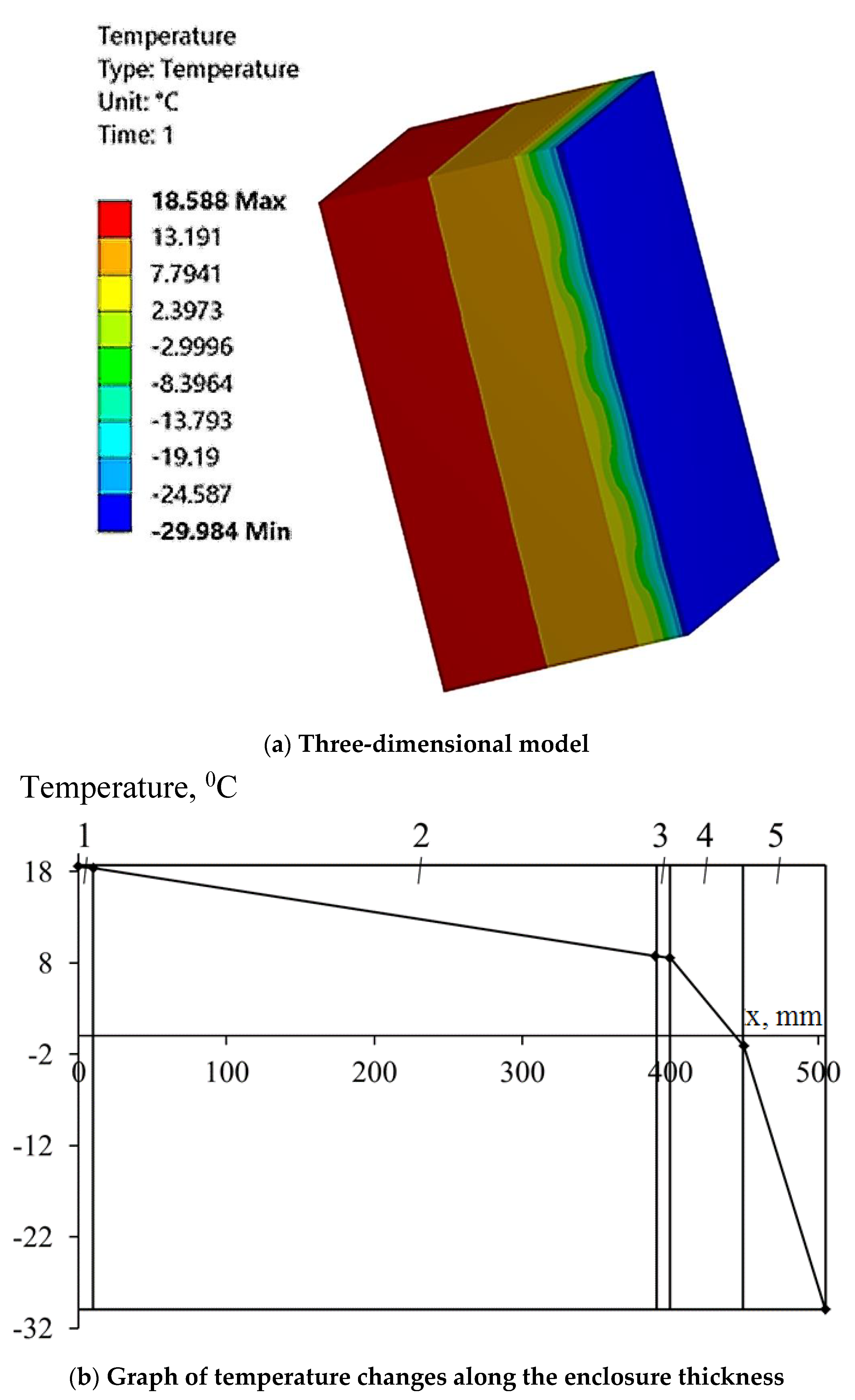

| Parameter | Value, m2·(°C/W) |

|---|---|

| Thermal resistance of the inner wall, minimum temperature | 4.034 |

| Thermal resistance of the inner wall, maximum temperature | 4.192 |

| Thermal resistance of the inner wall, five days | 4.058 |

| Thermal resistance of the inner wall, April | 4.390 |

| Thermal resistance of the inner wall, July | 5.132 |

| Thermal resistance of the enclosure, maximum temperature | 4.305 |

| Thermal resistance of the enclosure, five days | 4.202 |

| Thermal resistance of the enclosure, April | 4.519 |

| Thermal resistance of the gap, minimum temperature | 0.690 |

| Thermal resistance of the gap, maximum temperature | 0.829 |

| Thermal resistance of the gap/air channel, five days | 0.710 |

| Thermal resistance of the gap, April | 1.028 |

| Parameter | Value, m2·(°C/W) |

|---|---|

| Thermal resistance of the inner wall, minimum temperature | 3.048 |

| Thermal resistance of the inner wall, maximum temperature | 3.018 |

| Thermal resistance of the inner wall, five days | 3.047 |

| Thermal resistance of the inner wall, April | 3.054 |

| Thermal resistance of the enclosure, maximum temperature | 3.131 |

| Thermal resistance of the enclosure, five days | 3.192 |

| Thermal resistance of the enclosure, April | 3.183 |

| Thermal resistance of the air channel, minimum temperature | 0.180 |

| Thermal resistance of the air channel, maximum temperature | 0.157 |

| Thermal resistance of the air channel, five days | 0.179 |

| Thermal resistance of the air channel, April | 0.185 |

| Parameter | Value, m2·(°C/W) |

|---|---|

| Thermal resistance of the inner wall, minimum temperature | 3.375 |

| Thermal resistance of the inner wall, maximum temperature | 3.496 |

| Thermal resistance of the inner wall, five days | 3.401 |

| Thermal resistance of the inner wall, April | 3.663 |

| Thermal resistance of the enclosure, maximum temperature | 3.610 |

| Thermal resistance of the enclosure, five days | 3.546 |

| Thermal resistance of the enclosure, April | 3.793 |

| Thermal resistance of the air channel, minimum temperature | 0.475 |

| Thermal resistance of the air channel, maximum temperature | 0.616 |

| Thermal resistance of the air channel, five days | 0.525 |

| Thermal resistance of the air channel, April | 0.769 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhangabay, N.; Baidilla, I.; Tagybayev, A.; Sultan, B. Analysis of Thermal Resistance of Developed Energy-Saving External Enclosing Structures with Air Gaps and Horizontal Channels. Buildings 2023, 13, 356. https://doi.org/10.3390/buildings13020356

Zhangabay N, Baidilla I, Tagybayev A, Sultan B. Analysis of Thermal Resistance of Developed Energy-Saving External Enclosing Structures with Air Gaps and Horizontal Channels. Buildings. 2023; 13(2):356. https://doi.org/10.3390/buildings13020356

Chicago/Turabian StyleZhangabay, Nurlan, Islambek Baidilla, Askhat Tagybayev, and Bakhbergen Sultan. 2023. "Analysis of Thermal Resistance of Developed Energy-Saving External Enclosing Structures with Air Gaps and Horizontal Channels" Buildings 13, no. 2: 356. https://doi.org/10.3390/buildings13020356

APA StyleZhangabay, N., Baidilla, I., Tagybayev, A., & Sultan, B. (2023). Analysis of Thermal Resistance of Developed Energy-Saving External Enclosing Structures with Air Gaps and Horizontal Channels. Buildings, 13(2), 356. https://doi.org/10.3390/buildings13020356