Research on Construction Workers’ Safety Risk Sharing in Tunneling Projects Based on a Two-Mode Network: A Case Study of the Shangwu Tunnel

Abstract

:1. Introduction

2. Literature Review

2.1. Construction Workers and Safety Risk Analysis in Railway Tunnelling Project

2.2. Risk Sharing of Tunneling Projects

2.3. Research Gap

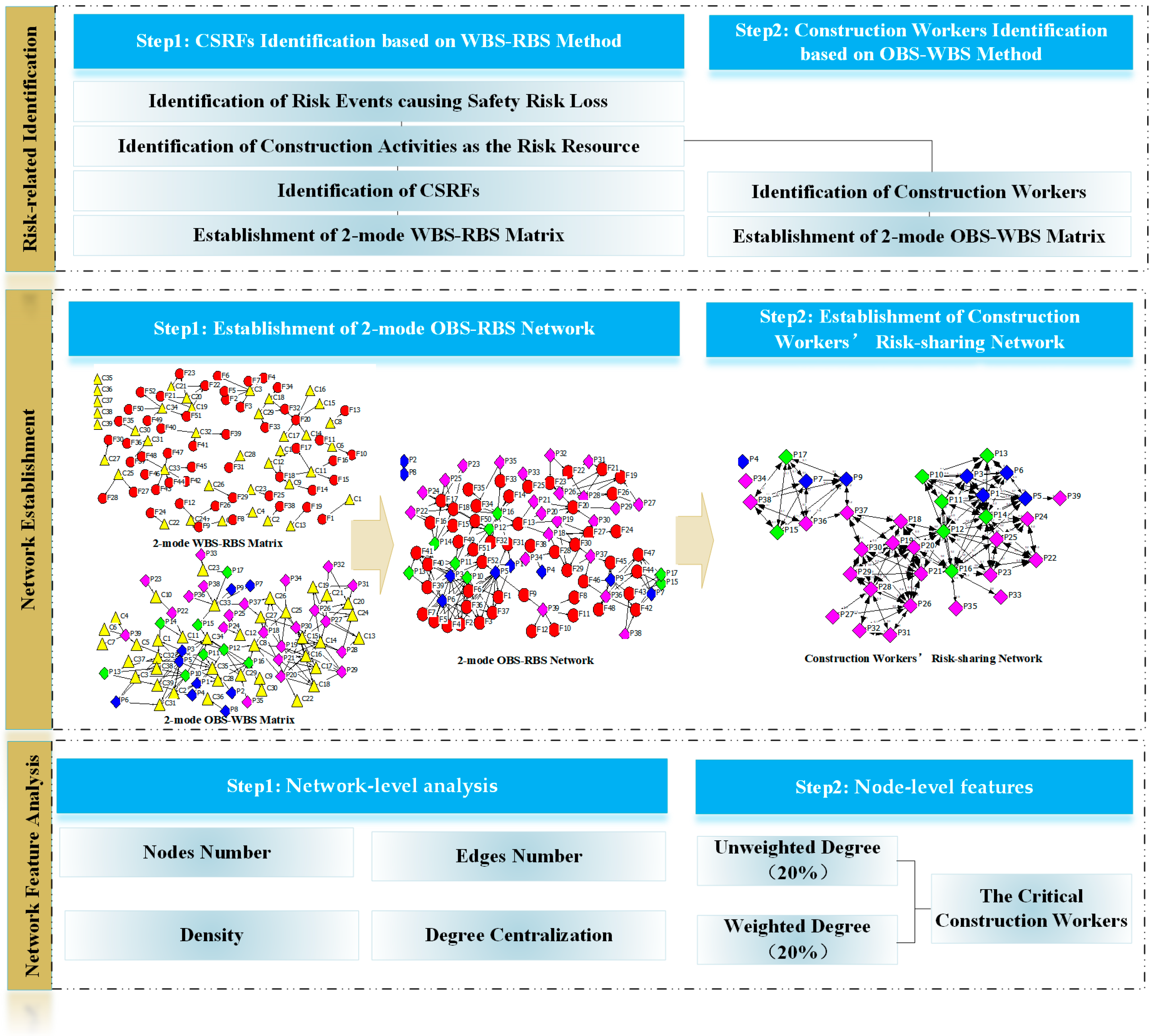

3. Research Design

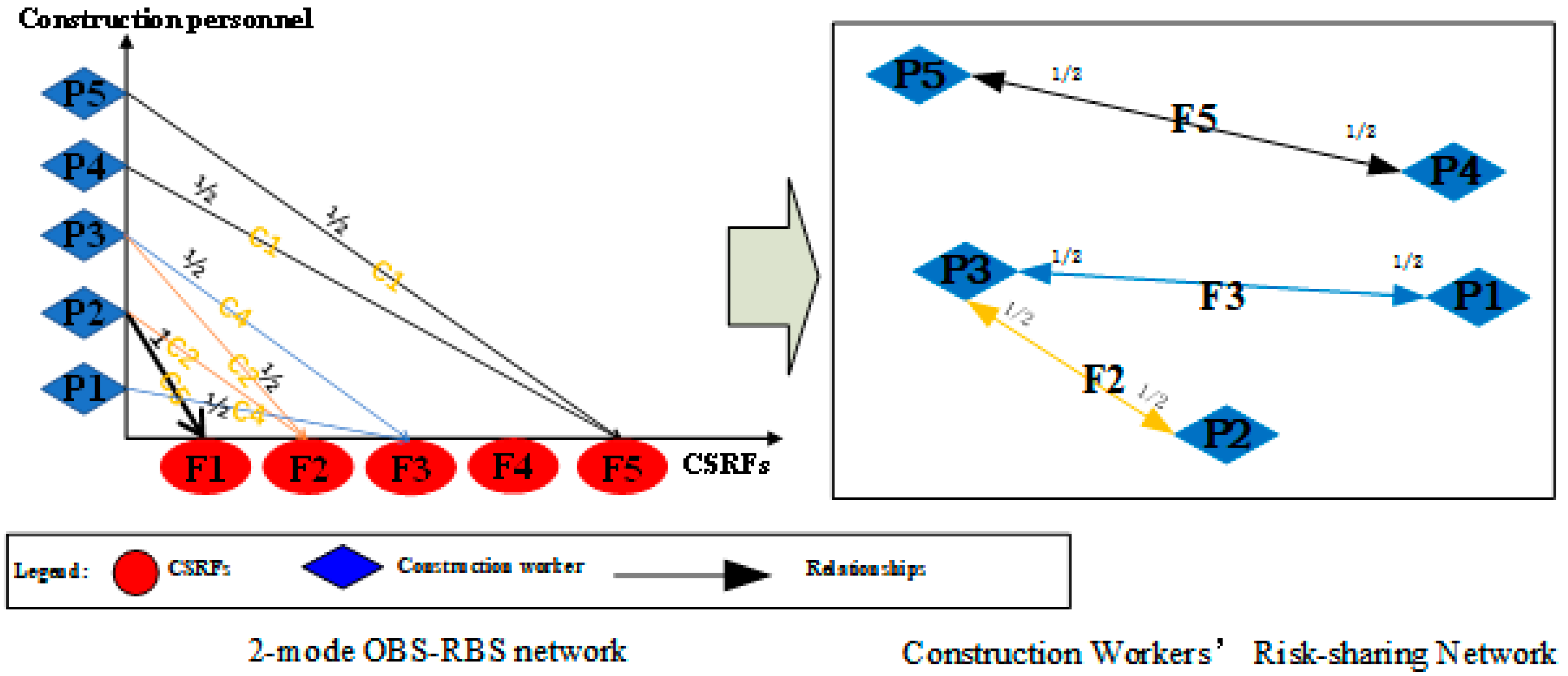

3.1. Research Method: Two-Mode Network

3.2. Model Design

3.2.1. Model Framework

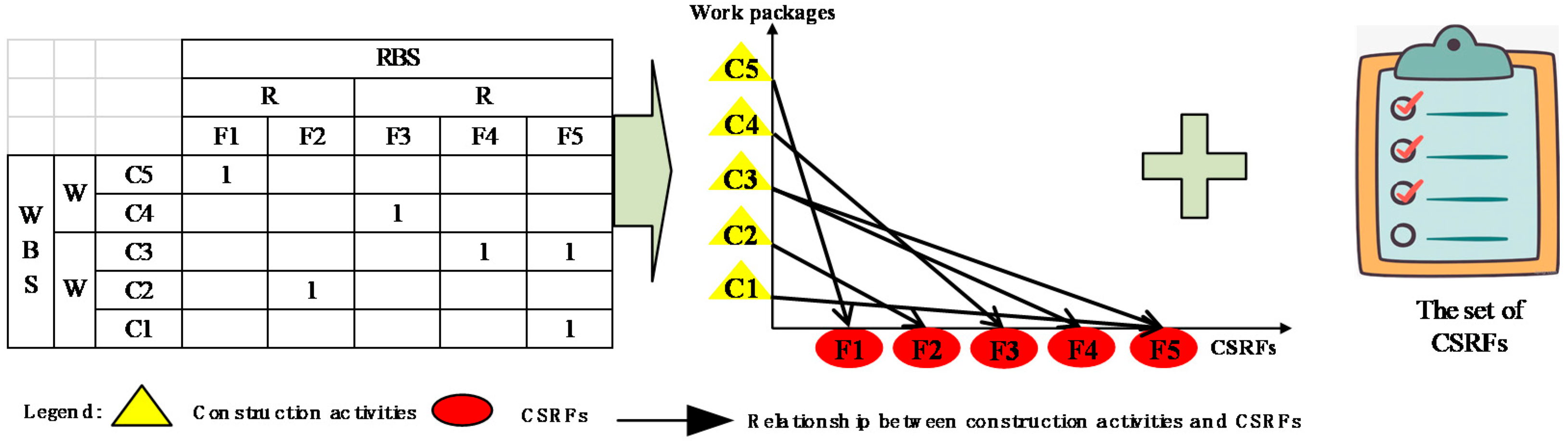

3.2.2. Risk-Related Identification

- (1)

- Risk event identification: The resulting set of risk events was obtained after case analysis, experts’ interviews, etc., where .

- (2)

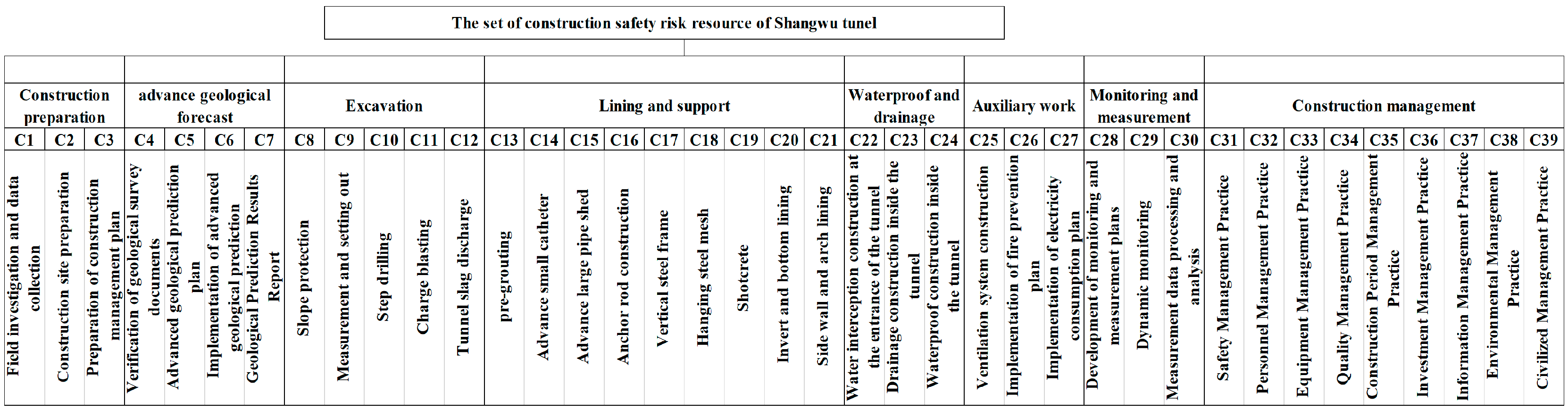

- Risk resource identification: The WBS tool was used to decompose the construction activities into work packages, where .

- (3)

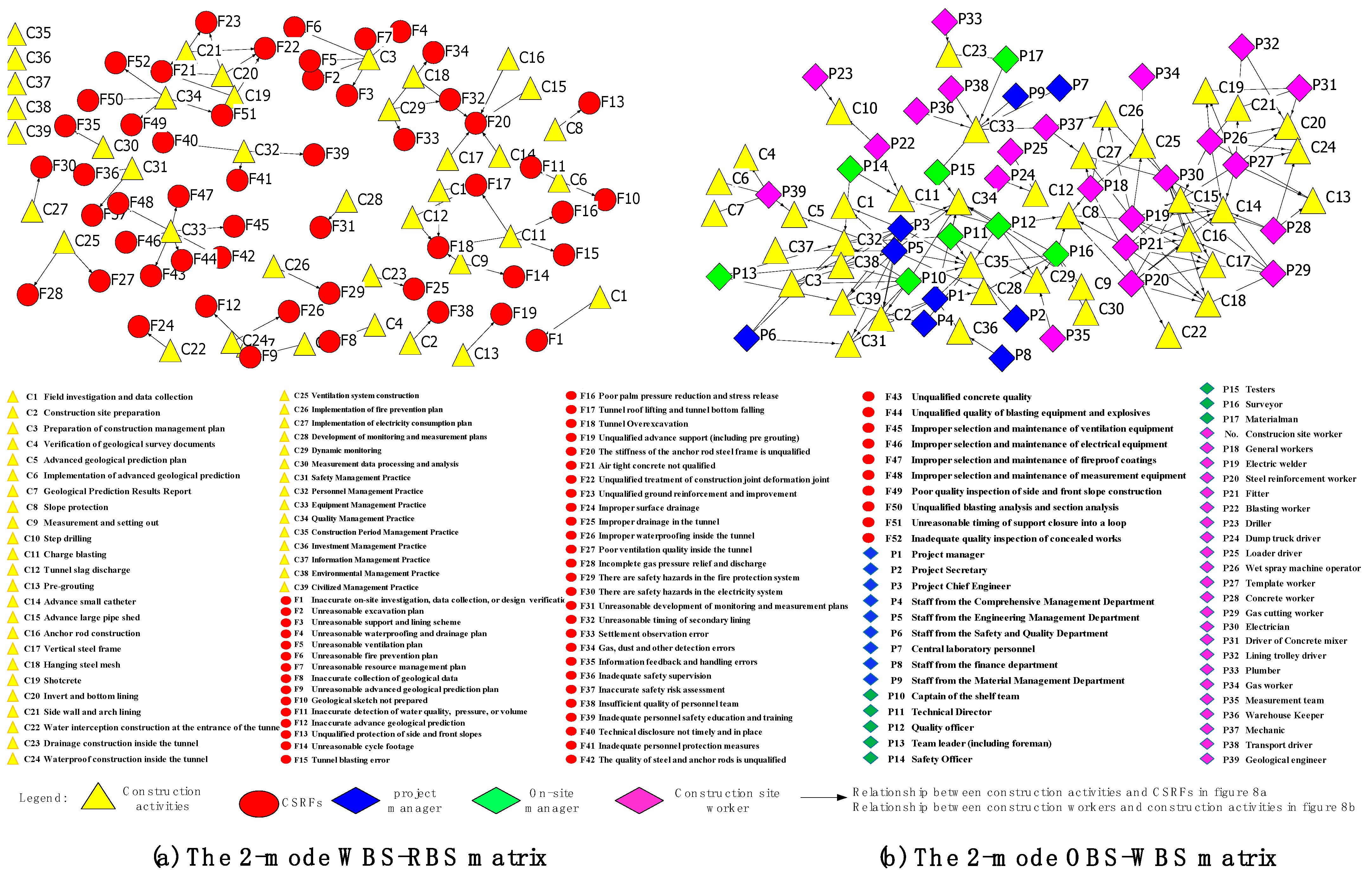

- CSRF identification: The work package in the WBS tree is related to in the RBS tree. Therefore, the CSRFs’ set was established, where . The two-mode WBS-RBS matrix A was established synchronously (See Equation (1)):where C is the nodes set representing work packages, as risk resources; F is the nodes set representing CSRFs; is the edges set representing construction activity C carrying represents the weight of . Let us assume that the weight of defaults to 1 or 0; when , the is sourced from ; when is not sourced form .

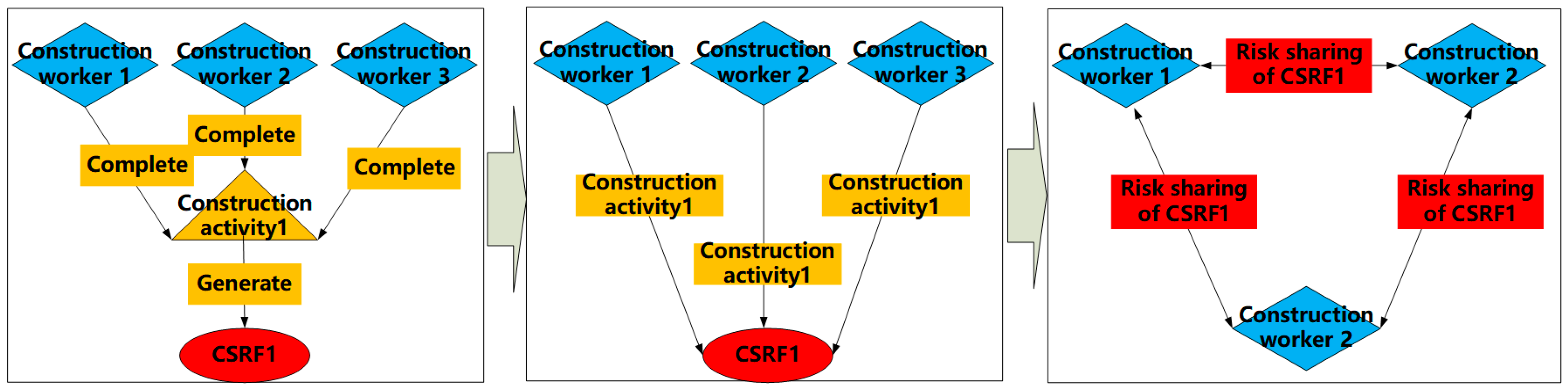

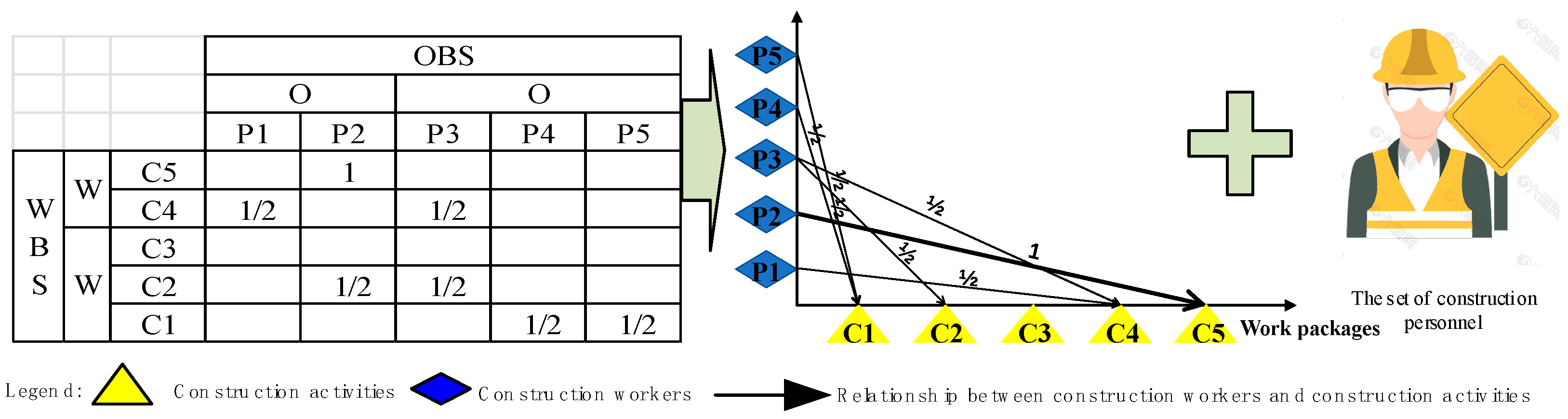

3.2.3. Risk-Sharing Network Establishment

3.2.4. Network Feature Analysis

4. Case Study: Application of the Proposed Risk-Sharing Model to the Shangwu Tunnel Project

4.1. Tunnel Background

4.2. Risk-Related Identification Result

4.2.1. Identification of CSRFs

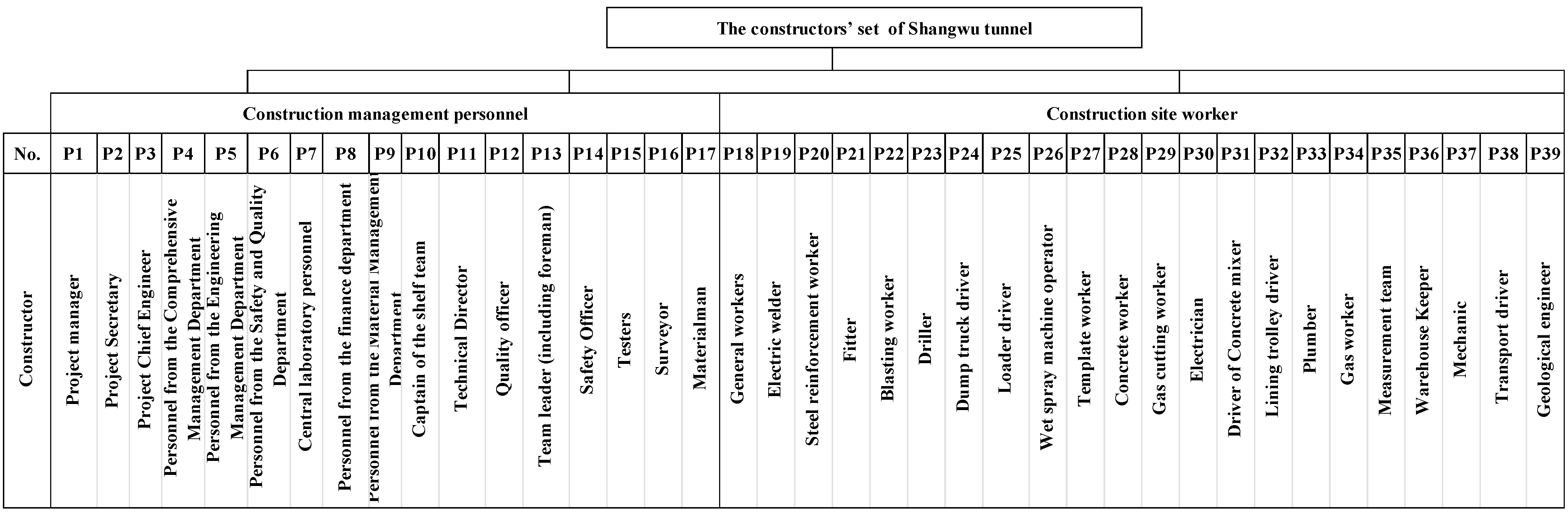

4.2.2. Identification of Construction Workers

4.3. Risk-Sharing Network Result

4.4. Feature Analysis Results

4.4.1. Network-Level Feature

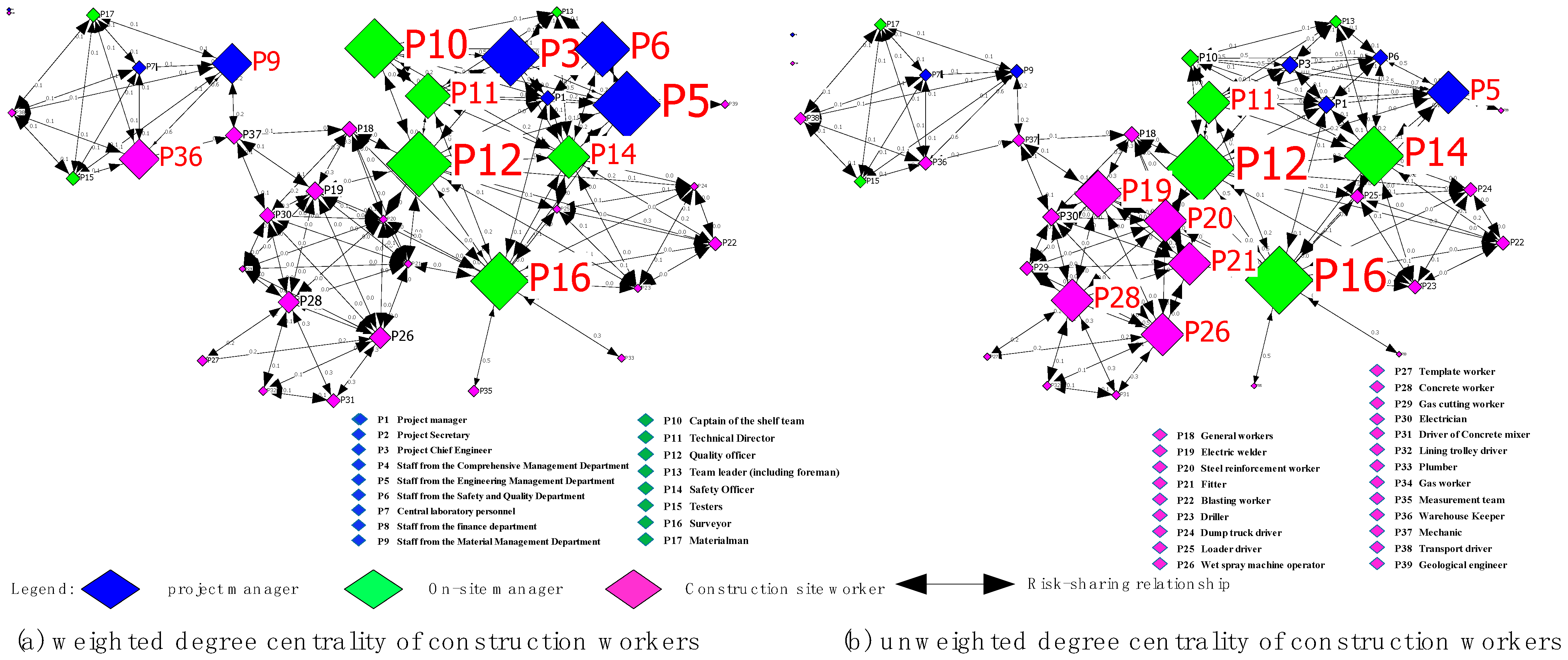

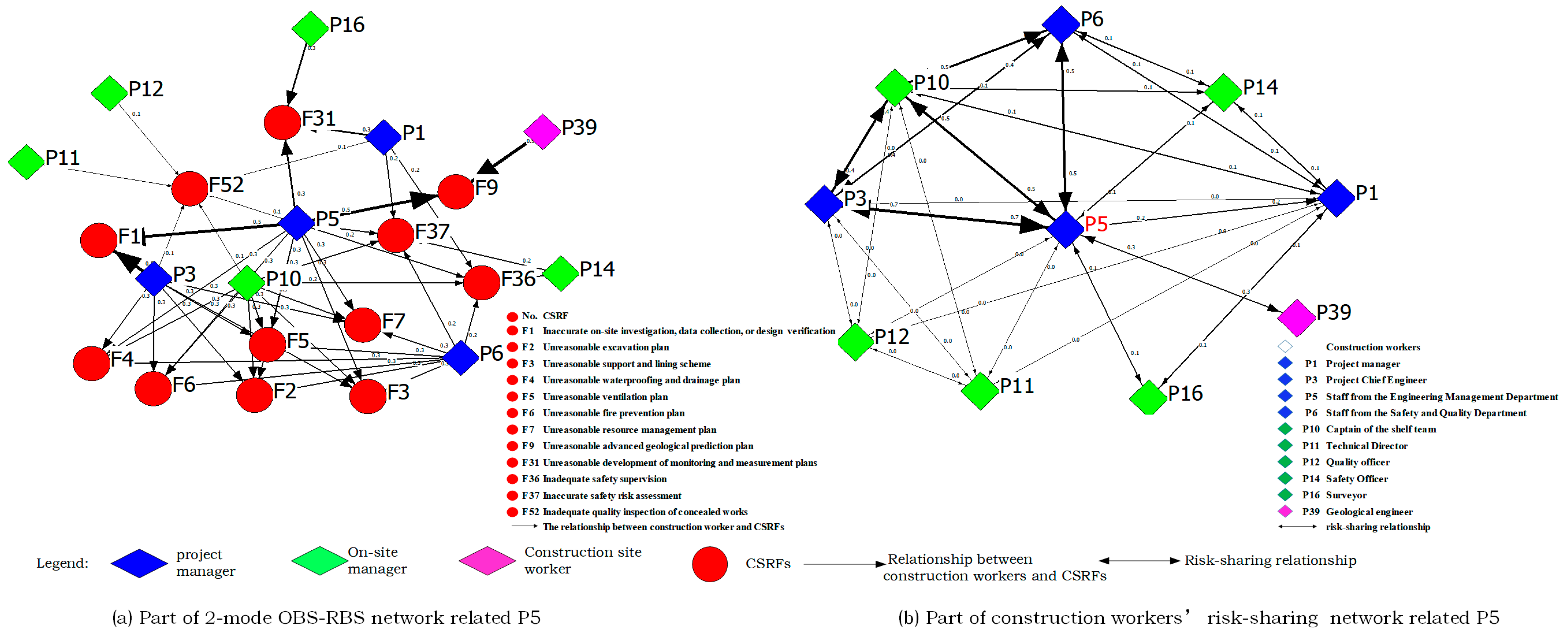

4.4.2. Node-Level Features

5. Discussion on the Model and Results

5.1. Expert Interview for Model Validation

5.2. Risk Mitigation Suggestions Based on Case Study Results

5.3. Further Research on Construction Safety Risk Sharing

- (1)

- In this paper, the measurement of risk-sharing relationships’ strength depends solely on the participation degree of construction workers in a certain activity carrying CSRFs. However, there are more suitable ways to determine the risk-sharing relationships’ weight, including the artificial neural network (ANN). Therefore, this related study can improve the current research on risk management in the future.

- (2)

- This risk-sharing network only explores construction workers’ risk-sharing features. However, construction workers not only have risk-sharing relationships due to work cooperation but also have risk-transmission relationships due to process connection and causal analysis. A typical case is that a driller has a risk-transmission relationship with a blaster during railway tunnel excavation practice. If the driller is not following the drawings when carrying out the drilling operations, the position of the drilling hole may be inaccurate. This will place the blaster in a dangerous situation since unqualified drilling positions may lead to the failure of blasting operations in excavation. Therefore, a risk transmission among construction workers should be developed in future studies.

- (3)

- The related study of construction workers’ risk relationships in risk management is rare. Hence, we consider it valuable to study whether the risk relationships of construction workers are related to their organizational, communicative, or social relationships. For example, if the risk relationships among construction workers are highly related to their organizational relationships, we can modify the organizational structure to reduce the probability of risk transmission. We can also provide quadratic assignment procedure (QAP) analysis in SNA as an effective solution. The QAP analysis explores the relationships between two different relationships [68,69]. Therefore, these related studies will enrich the risk management theory.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Verification of Risk-Sharing Model Questionnaire

Appendix A.1. Verification of Construction Risk Assessment Methodology

- Do you think the set of CSRFs constructed in this tunnel project is reasonable?

- Do you think it is reasonable to identify the risk-sharing relationship of CSRFs based on the work cooperation of construction activities carrying CSRFs?

- Can you understand the proposed process for building this construction workers’ risk-sharing network?

- Do you think it is reasonable to use graph network analysis to build and analyze this risk-sharing network? What needs to be improved?

Appendix A.2. Verification of Construction Risk Assessment Results

- Do you think the indices of construction risk-sharing features produced for this tunnel project are reasonable?

- Do you think the overall feature analysis of the construction risk-sharing results is reasonable?

References

- Yan, J. Dominant Developing Trends of World Tunnel Engineering Techniques: Safe, Economical, Green and Artistic. Tunn. Constr. 2021, 41, 4. [Google Scholar]

- O’Reilly, M. Mont Cenis—The first trans-Alpine tunnel. Tunn. Tunn. Int. 2002, 34, 24–27. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-0036497181&partnerID=40&md5=4b36358d509436259596c7a0566b4db7 (accessed on 9 August 2023). (In English).

- Patzelt, J.; Thuro, K. Analysis of stress conditions at Deep Seated Tunnel—A Case Study at Brenner Base Tunnel. In Engineering Geology for Society and Territory—Volume 6: Applied Geology for Major Engineering Projects; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 459–463. [Google Scholar]

- Bratschi, O. The railway systems and tender procedure for the Gotthard base tunnel. Eisenbahningenieur 2004, 55, 34–37. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-5444273687&partnerID=40&md5=d8ee0b1df9ea387d0eb373acd0699a4c (accessed on 10 August 2023). (In German).

- Pedersen, S.K.; Brøndum, S. Fehmarnbelt fixed link: The world’s longest road and rail immersed tunnel. Proc. Inst. Civ. Eng. Civ. Eng. 2018, 171, 17–23. [Google Scholar] [CrossRef]

- Fruhwirt, D.; Sturm, P.; Steiner, H.; Borchiellini, R. Development of a methodology for studying tunnel climate in long railway tunnels and for optimizing the design process of cross-passage cooling systems. Tunn. Undergr. Space Technol. 2023, 138, 105194. [Google Scholar] [CrossRef]

- Cai, Q.; Hu, Q.; Ma, G. Improved Hybrid Reasoning Approach to Safety Risk Perception under Uncertainty for Mountain Tunnel Construction. J. Constr. Eng. Manag. 2021, 147, 04021105. [Google Scholar] [CrossRef]

- Raghavan, S. Two Workers Dead in Mishap at Greenko RE Project in AP’s Nandyal District. 2023. Available online: https://timesofindia.indiatimes.com/city/amaravati/two-workers-dead-in-mishap-at-greenko-re-project-in-aps-nandyal-district/articleshow/102022029.cms (accessed on 13 August 2023).

- Chhetri, V. Worker Dies in Tunnel of Sikkim Rail Link. Available online: http://www.telegraphindia.com/west-bengal/worker-dies-in-tunnel-of-sikkim-rail-link/cid/1930431 (accessed on 13 August 2023).

- Emergency Management Department of the People’s Republic of China. 7 Trapped in Tunnel Collapse Accident in Shuangjiang County, Lincang, Yunnan, All Rescued; Emergency Management Department of the People’s Republic of China: Beijing, China, 2023. [Google Scholar]

- Valico, T. Fatal Accident in Italy: Worker’s Death Leads to Strike. Available online: https://www.railfreight.com/specials/2023/02/08/fatal-accident-in-italy-workers-death-leads-to-strike/?gdpr=accept (accessed on 13 August 2023).

- Wang, Z.; Cai, Z.; Wu, Y. An improved YOLOX approach for low-light and small object detection: PPE on tunnel construction sites. J. Comput. Des. Eng. 2023, 10, 1158–1175. [Google Scholar] [CrossRef]

- Shafique, M.; Rafiq, M. An overview of construction occupational accidents in Hong Kong: A recent trend and future perspectives. Appl. Sci. 2019, 9, 2069. [Google Scholar] [CrossRef]

- Casse, C.; Caroly, S. Analysis of critical incidents in tunnels to improve learning from experience. Saf. Sci. 2019, 116, 222–230. [Google Scholar] [CrossRef]

- Ministry of Construction of the People’s Republic of China. Ministry of Construction of the People’s Republic of China Construction Site Environment and Health Standards; China Architecture & Building Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Liang, Q.; Zhou, Z.; Ye, G.; Shen, L. Unveiling the mechanism of construction workers’ unsafe behaviors from an occupational stress perspective: A qualitative and quantitative examination of a stress–cognition–safety model. Saf. Sci. 2022, 145, 105486. [Google Scholar] [CrossRef]

- Chen, W.T.; Merrett, H.C.; Huang, Y.H.; Bria, T.A.; Lin, Y.H. Exploring the relationship between safety climate and worker safety behavior on building construction sites in Taiwan. Sustainability 2021, 13, 3326. [Google Scholar] [CrossRef]

- Ministry of Construction of the People’s Republic of China. Interim Provisions on Risk Assessment and Management of Railway Tunnel; China Railway Publishing House: Beijing, China, 2007. [Google Scholar]

- Einstein, H.H. Risk and risk analysis in rock engineering. Tunn. Undergr. Space Technol. 1996, 11, 14. [Google Scholar] [CrossRef]

- Einstein, H.H.; Labreche, D.A.; Markow, M.J.; Baecher, G.B. Decision analysis applied to rock tunnel exploration. Eng. Geol. 1978, 12, 14. [Google Scholar] [CrossRef]

- Yao, P.; Yu, Z.; Lv, Y.; Shi, B.; He, Y.; Wang, H.; Liu, D.; Wei, S. Safety level assessment of shield tunneling in water rich sandy pebble strata with large particle size. Sci. Rep. 2023, 13, 3854. [Google Scholar] [CrossRef]

- Sorlini, A.; Maxia, L.; Patrucco, M.; Pira, E. Occupational Safety and Health Improvements through Innovative Technologies in Underground Construction Sites: Main Trends and Some Case Histories. Infrastructures 2023, 8, 104. [Google Scholar] [CrossRef]

- Chen, X.; Guo, C.; Song, J.; Wang, X.; Cheng, J. Occupational health risk assessment based on actual dust exposure in a tunnel construction adopting roadheader in Chongqing, China. Build. Environ. 2019, 165, 106415. [Google Scholar] [CrossRef]

- Aneziris, O.N.; Papazoglou, I.A.; Kallianiotis, D. Occupational risk of tunneling construction. Saf. Sci. 2010, 48, 964–972. [Google Scholar] [CrossRef]

- Albert, A.; Hallowell, M.R.; Kleiner, B.; Chen, A.; Golparvar-Fard, M. Enhancing construction hazard recognition with high-fidelity augmented virtuality. J. Constr. Eng. Manag. 2014, 140, 04014024. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Chan, A.H.S.; Seo, J.; Anwer, S.; Mi, H.Y.; Wu, Z.; Wong, A.Y.L. A science mapping-based review of work-related musculoskeletal disorders among construction workers. J. Saf. Res. 2023, 85, 114–128. [Google Scholar] [CrossRef] [PubMed]

- Terheijden, O.T.; van Gelder, P.H.A.J.M.; Broere, W. Impact of occupational risk prevention measures during process disturbances in TBM tunnelling. Tunn. Undergr. Space Technol. 2022, 127, 104576. [Google Scholar] [CrossRef]

- Spangenberg, S.; Hannerz, H.; Tuchsen, F. Hospitalized injuries among bridge and tunnel construction workers. Constr. Manag. Econ. 2005, 23, 237–240. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, T.; Zhou, W.; Tang, J. Safety risk factors of metro tunnel construction in China: An integrated study with EFA and SEM. Saf. Sci. 2018, 105, 98–113. [Google Scholar] [CrossRef]

- Liu, P.; Wu, W.; Xu, J.; Shang, Y. Statistical analysis of domestic subway accidents based on GRA. J. Eng. Manag. 2023, 37, 53–58. (In Chinese) [Google Scholar]

- Huang, X.; Hu, Z. Statistical analysis and research of subway construction accidents. J. Saf. Sci. Technol. 2022, 18, 218–224. (In Chinese) [Google Scholar]

- Jiang, X.; Wang, J.; Wang, Y. Study on the Coupled Evolution of Collapse Risk in Deep Underground Tunnels from a Catastrophic Perspective. China Saf. Sci. J. 2023, 33, 103–111. (In Chinese) [Google Scholar]

- Zhang, M.; Yu, D.; Wang, T.; Xu, C. Coupling Analysis of Tunnel Construction Safety Risks Based on N-K Model and SD Causality Diagram. Buildings 2023, 13, 1081. [Google Scholar] [CrossRef]

- Zhang, F.; Wu, Z.; Wang, X.; He, Y. Safety risk assessment of railway tunnel construction by drilling and blasting method in complex and dangerous areas. J. Railw. Sci. Eng. 2023, 20, 1891–1901. [Google Scholar] [CrossRef]

- Zack, J.G., Jr. “Risk-Sharing”—Good concept, bad name. Cost Eng. 1996, 38, 26–31. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-0030196945&partnerID=40&md5=18f7e95193c393dc807e93e4182c169f (accessed on 1 August 2023).

- Antill, J.M. Contractual Aspect of Latent Conditions in Tunnelling. 1976, pp. 223–231. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-0017272804&partnerID=40&md5=6820ed5ce84838cbb515493211c7cc5c (accessed on 1 August 2023).

- Pfister, R.E. Contractual Share of Risk (Some Basic Thoughts of Swiss Standards for Underground Work). In Proceedings of the Electric Power Research Institute (Report) EPRI EL, Tokyo, Japan, 29 May–2 June 1978; pp. 357–362. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-0018713263&partnerID=40&md5=b9d0e1dfedd1640c5fe568912fc10a7b (accessed on 13 August 2023).

- Salter, W.A. ITA recommendations on contractual sharing of risks/AITES recommandations sur le partage contractuel des risques. Tunn. Undergr. Space Technol. Inc. Trenchless 1990, 5, 337–341. [Google Scholar] [CrossRef]

- Abdel Salam, M.E. Contractual sharing of risks in underground construction: ITA views. Tunn. Undergr. Space Technol. Inc. Trenchless 1995, 10, 433–437. [Google Scholar] [CrossRef]

- Wang, X.; Wang, T.; Lu, C.; Xue, W. Situation, Problems, and Countermeasures of Urban Utility Tunnel Based on Public-Private Partnership. In Proceedings of the ICCREM 2017: Prefabricated Buildings, Industrialized Construction, and Public-Private Partnerships; Proceedings of the International Conference on Construction and Real Estate Management 2017, Guangzhou, China, 10–12 November 2017; pp. 109–118. [Google Scholar] [CrossRef]

- Guo, K.; Zhang, L.; Wang, T. Concession period optimisation in complex projects under uncertainty: A public–private partnership perspective. Constr. Manag. Econ. 2021, 39, 156–172. [Google Scholar] [CrossRef]

- Song, J.; Jin, L.; Zhao, Y.; Hu, W. Using bargaining-game model to negotiate compensation for the early termination of BOT highway projects. Transp. Res. Part A Policy Pract. 2017, 105, 197–209. [Google Scholar] [CrossRef]

- Yau, K.; Paraskevopoulou, C.; Konstantis, S. Spatial variability of karst and effect on tunnel lining and water inflow. A probabilistic approach. Tunn. Undergr. Space Technol. 2020, 97, 103248. [Google Scholar] [CrossRef]

- Sánchez, L.R. Fair risk allocation in tunneling: A game modelling approach. In Expanding Underground—Knowledge and Passion to Make a Positive Impact on the World; Proceedings of the ITA-AITES World Tunnel Congress, WTC 2023, Athens, Greece, 12–18 May 2023; CRC Press: Boca Raton, FL, USA; pp. 3453–3461. [CrossRef]

- Zhou, X.; Pan, H.; Shen, Y. China’s Underground Comprehensive Utility Tunnel Project of PPP Mode Risk Identification. In Proceedings of the ICCREM 2017: Prefabricated Buildings, Industrialized Construction, and Public-Private Partnerships; Proceedings of the International Conference on Construction and Real Estate Management 2017, Guangzhou, China, 10–12 November 2017; pp. 318–327. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Zhang, H. Social Network Management of Safety Risk in Prefabricated Building Construction Based on Computer Simulation. In Proceedings of the 2021 3rd International Conference on Artificial Intelligence and Advanced Manufacture, Manchester, UK, 23–25 October 2021; pp. 247–253. Available online: https://dl.acm.org/doi/10.1145/3495018.3495060 (accessed on 3 September 2023).

- Chen, W.; Li, Y.; Yu, J. Construction and Evaluation of Safety Risk Network for Urban Comprehensive Pipe Corridor Based on Social Network Analysis. J. Saf. Environ. 2020, 20, 1652–1660. (In Chinese) [Google Scholar]

- Ke, L.; Chen, K.; Hu, N. Risk assessment of blasting safety in open-pit mines based on SNA. China Saf. Sci. J. 2022, 32, 48–56. (In Chinese) [Google Scholar]

- Yuan, J.; Chen, K.; Li, W.; Ji, C.; Wang, Z.; Skibniewski, M.J. Social network analysis for social risks of construction projects in high-density urban areas in China. J. Clean. Prod. 2018, 198, 940–961. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, Y. Toward a Stakeholder Perspective on Safety Risk Factors of Metro Construction: A Social Network Analysis. Complexity 2020, 2020, 8884304. [Google Scholar] [CrossRef]

- Zhang, M.; Shi, R.; Yang, Z. A critical review of vision-based occupational health and safety monitoring of construction site workers. Saf. Sci. 2020, 126, 104658. [Google Scholar] [CrossRef]

- Siami-Irdemoosa, E.; Dindarloo, S.R.; Sharifzadeh, M. Work breakdown structure (WBS) development for underground construction. Autom. Constr. 2015, 58, 85–94. [Google Scholar] [CrossRef]

- Aggrawal, N.; Anand, A. Social Networks: Modelling and Analysis; CRC Press: Boca Raton, FL, USA, 2022; pp. 1–235. Available online: https://www.taylorfrancis.com/books/mono/10.1201/9781003088066/social-networks-niyati-aggrawal-adarsh-anand-mangey-ram (accessed on 3 September 2023).

- Huang, J.; Yang, Y.; Cai, X.; Cai, C. Research on multiple risk network of railway tunnel construction crossingfault fracture zone. J. Railw. Sci. Eng. 2021, 18, 2782–2792. (In Chinese) [Google Scholar] [CrossRef]

- Wang, P.; Wei, Q.; Wang, J.; Zhao, G. Risk Assessment of Railway Tunnel Construction Based on Grey Fuzzy Linguistic Theory. J. Railw. Eng. Soc. 2023, 39, 106–112. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85150681305&partnerID=40&md5=5d4c0e13c59796c3223307e5230046cb (accessed on 13 August 2023).

- Eid, M.A.; Hu, J.W.; Issa, U. Developing a Model for Analyzing Risks Affecting Machinery Tunnel Execution. Buildings 2023, 13, 1757. [Google Scholar] [CrossRef]

- Wang, Q.; Xiong, Z.; Zhu, K.; Guo, P. Construction Safety Risks of Metro Tunnels Constructed by the Mining Method in Wuhan City, China: A Structural Equation Model-Fuzzy Cognitive Map Hybrid Method. Buildings 2023, 13, 1335. [Google Scholar] [CrossRef]

- Zhang, H.; Hao, W.; Gu, W. Construction risk assessment of Lhasa-Linzhi railway tunnel based on data field clustering. J. Railw. Sci. Eng. 2020, 17, 1874–1883. (In Chinese) [Google Scholar] [CrossRef]

- Lei, M.; Lin, D.; Huang, Q.; Shi, C.; Huang, L. Research on the construction risk control technology of shield tunnel underneath an operational railway in sand pebble formation: A case study. Eur. J. Environ. Civ. Eng. 2020, 24, 1558–1572. [Google Scholar] [CrossRef]

- Ministry of Construction of the People’s Republic of China. Environmental and Hygienic Standards for Construction Sites; China Architecture & Building Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Liu, S.; Song, Z.; Zhang, Y.; Guo, D.; Sun, Y.; Zeng, T.; Xie, J. Risk assessment of deep excavation construction based on combined weighting and nonlinear FAHP. Front. Earth Sci. 2023, 11, 1204721. [Google Scholar] [CrossRef]

- You, Q.; Zhang, Z.; Wang, H.; Xu, M. Risk identification of subway tunnel shield construction based on WBS-RBS method. Int. J. Crit. Infrastruct. 2023, 19, 261–273. [Google Scholar] [CrossRef]

- Derkach, D.W. Construction in an operating environment. In Proceedings of the 1996 40th Annual Meeting of AACE International, Vancouver, BC, Canada, 23–26 June 1996; 1996; pp. PS31–PS33. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-0029699435&partnerID=40&md5=28b718d483f2216d6609889a56de164c (accessed on 13 August 2023).

- Eissa, R.; Eid, M.S.; Elbeltagi, E. Current Applications of Game Theory in Construction Engineering and Management Research: A Social Network Analysis Approach. J. Constr. Eng. Manag. 2021, 147, 0002085. [Google Scholar] [CrossRef]

- Attanasio, O.; Krutikova, S. JEEA-FBBVA LECTURE 2019: Consumption Insurance in Networks with Asymmetric Information: Evidence from Tanzania. J. Eur. Econ. Assoc. 2020, 18, 1589–1618. [Google Scholar] [CrossRef]

- Tsai, M.K.; Yang, J.B.; Lin, C.Y. Synchronization-based model for improving on-site data collection performance. Autom. Constr. 2007, 16, 323–335. [Google Scholar] [CrossRef]

- Shin, W.S. Development of work supporting system for design-for-safety of construction project. J. Archit. Inst. Korea 2020, 36, 203–213. [Google Scholar] [CrossRef]

- Patterson, M.S.; Goodson, P. Using social network analysis to better understand compulsive exercise behavior among a sample of sorority members. J. Phys. Act. Health 2017, 14, 360–367. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhuang, X.; Lu, Y.; Wang, J. Spatial linkage of volatility spillovers and its explanation across G20 stock markets: A network framework. Int. Rev. Financ. Anal. 2020, 71, 101454. [Google Scholar] [CrossRef]

| No. | CSRF | |||

|---|---|---|---|---|

| Set of CSRFs in the Shangwu tunnel | Construction preparation | Inaccurate on-site investigation, data collection, or design verification [18,54] | ||

| Unreasonable excavation plan [54,55] | ||||

| Unreasonable lining support plan [54,55] | ||||

| Unreasonable waterproofing plan [54,55] | ||||

| Unreasonable ventilation plan [54,55] | ||||

| Unreasonable fire prevention plan [54,55] | ||||

| Unreasonable resource management plan [54,55] | ||||

| Advance Geological Forecast | Inaccurate collection of geological data [33,54,56,57] | |||

| Unreasonable advanced geological prediction plan [33,54,57] | ||||

| Unqualified geological sketch [33,54,57] | ||||

| Inaccurate detection of water quality, pressure, or volume [33,54,57] | ||||

| Inaccurate advance geological prediction [33,54,57] | ||||

| Excavation | Unqualified protection of side and front slopes [33,54,57] | |||

| Unreasonable cycle footage [33,54,57] | ||||

| Errors in blasting [33,54,57,58] | ||||

| Poor palm pressure reduction or stress release [33,54,57,59] | ||||

| Unqualified roof lifting or tunnel bottom falling [33,54,57] | ||||

| Over excavation [33,54,57] | ||||

| Lining and support | Unqualified advanced support (including pre grouting) [33,54,57,58] | |||

| Unqualified stiffness of the anchor rod steel frame [33,54,57,58] | ||||

| Unqualified air-tight concrete [33,54,57,58] | ||||

| Unqualified construction or deformation joint [33,54,57,58] | ||||

| Unqualified ground reinforcement or improvement [33,54,57,58,59] | ||||

| Waterproof and drainage | Improper surface drainage [33,54,57,58] | |||

| Improper drainage in the tunnel [33,54,57,58] | ||||

| Improper waterproofing inside the tunnel [33,54,57,58] | ||||

| Auxiliary work | Ventilation shaft | Poor ventilation quality inside the tunnel [54,57] | ||

| Incomplete gas pressure relief and discharge [54,57] | ||||

| fire prevention | Safety hazards in the fire protection system [57] | |||

| Safety hazards in the electrical system [56,57] | ||||

| Monitoring and measurement | Unreasonable monitoring and measurement plans [54] | |||

| Unreasonable timing of secondary lining [54] | ||||

| Error in settlement observation [54,56] | ||||

| Gas, dust, and other detection errors [54] | ||||

| Information feedback and handling errors [54,56] | ||||

| Construction management | Construction safety | Inadequate safety supervision [54,58] | ||

| Inaccurate safety risk assessment [54,58] | ||||

| Construction personnel | Insufficient quality of personnel team [54,58] | |||

| Inadequate personnel safety education and training [54,58] | ||||

| Technical disclosure not timely or in place [54] | ||||

| Inadequate personnel protection measures [54] | ||||

| Construction equipment | Unqualified steel and anchor rods’ quality [54,55,59] | |||

| Unqualified concrete quality [54,55,59] | ||||

| Unqualified blasting equipment and explosives [54,55,58,59] | ||||

| Improper ventilation equipment [55,58,59] | ||||

| Improper electrical equipment [55] | ||||

| Improper fireproof coatings [54,55] | ||||

| Improper measurement equipment [55] | ||||

| Construction quality | Poor inspection of side and front slope construction {Ministry of Railways, 2007 #3} | |||

| Unqualified blasting analysis and section analysis [54] | ||||

| Unreasonable timing of support closure into a loop [54,59] | ||||

| Inadequate quality inspection of concealed works [56] | ||||

| Construction Worker | Rank | Rank | |||||

| OBS tree for the Shangwu tunnel | construction manager | project manager | Project manager | 17 | 0.68 | 11 | 8 |

| Project secretary | 37 | 37 | |||||

| Project chief engineer | 4 | 1.93 | 12 | 8 | |||

| Staff from the Comprehensive Management Department | 36 | 0.00 | 36 | 0 | |||

| Staff from the Engineering Management Department | 1 | 2.31 | 5 | 9 | |||

| Staff from the Safety and Quality Department | 6 | 1.86 | 15 | 7 | |||

| Central laboratory personnel | 20 | 0.60 | 24 | 5 | |||

| Staff from the finance department | 37 | 37 | |||||

| Staff from the Material Management Department | 9 | 1.29 | 17 | 6 | |||

| on-site manager | Captain of the shelf team | 3 | 2.00 | 13 | 8 | ||

| Technical director | 7 | 1.50 | 6 | 9 | |||

| Quality officer | 2 | 2.21 | 1 | 15 | |||

| Team leader (including foreman) | 25 | 0.42 | 25 | 5 | |||

| Safety officer | 8 | 1.38 | 3 | 13 | |||

| Testers | 21 | 0.60 | 26 | 5 | |||

| Surveyor | 5 | 1.93 | 2 | 15 | |||

| Materialman | 22 | 0.60 | 27 | 5 | |||

| construction site worker | General workers | 16 | 0.74 | 16 | 7 | ||

| Electric welder | 13 | 0.88 | 4 | 10 | |||

| Steel reinforcement worker | 27 | 0.29 | 7 | 9 | |||

| Fitter | 28 | 0.29 | 8 | 9 | |||

| Blasting worker | 18 | 0.65 | 18 | 6 | |||

| Driller | 29 | 0.28 | 19 | 6 | |||

| Dump truck driver | 30 | 0.28 | 20 | 6 | |||

| Loader driver | 31 | 0.28 | 21 | 6 | |||

| Wet spray machine operator | 11 | 1.10 | 9 | 9 | |||

| Template worker | 24 | 0.44 | 32 | 2 | |||

| Concrete worker | 12 | 1.10 | 10 | 9 | |||

| Gas cutting worker | 35 | 0.15 | 22 | 6 | |||

| Electrician | 15 | 0.74 | 14 | 8 | |||

| Driver of concrete mixer | 19 | 0.61 | 30 | 3 | |||

| Lining trolley driver | 26 | 0.33 | 31 | 3 | |||

| Plumber | 33 | 0.25 | 33 | 1 | |||

| Gas worker | 37 | 0.00 | 37 | 0 | |||

| Measurement team | 23 | 0.50 | 34 | 1 | |||

| Warehouse keeper | 10 | 1.29 | 23 | 6 | |||

| Mechanic | 14 | 0.82 | 28 | 5 | |||

| Transport driver | 32 | 0.28 | 29 | 5 | |||

| Geological engineer | 34 | 0.25 | 35 | 1 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, X.; Huang, J.; Peng, C. Research on Construction Workers’ Safety Risk Sharing in Tunneling Projects Based on a Two-Mode Network: A Case Study of the Shangwu Tunnel. Buildings 2023, 13, 2689. https://doi.org/10.3390/buildings13112689

Cai X, Huang J, Peng C. Research on Construction Workers’ Safety Risk Sharing in Tunneling Projects Based on a Two-Mode Network: A Case Study of the Shangwu Tunnel. Buildings. 2023; 13(11):2689. https://doi.org/10.3390/buildings13112689

Chicago/Turabian StyleCai, Xi, Jianling Huang, and Chunyan Peng. 2023. "Research on Construction Workers’ Safety Risk Sharing in Tunneling Projects Based on a Two-Mode Network: A Case Study of the Shangwu Tunnel" Buildings 13, no. 11: 2689. https://doi.org/10.3390/buildings13112689

APA StyleCai, X., Huang, J., & Peng, C. (2023). Research on Construction Workers’ Safety Risk Sharing in Tunneling Projects Based on a Two-Mode Network: A Case Study of the Shangwu Tunnel. Buildings, 13(11), 2689. https://doi.org/10.3390/buildings13112689