Circular, Local, Open: A Recipe for Sustainable Building Construction

Abstract

1. Introduction

2. Tracing Sustainable Approaches to Building Construction

2.1. Circularity

2.2. Localisation

2.3. Openness

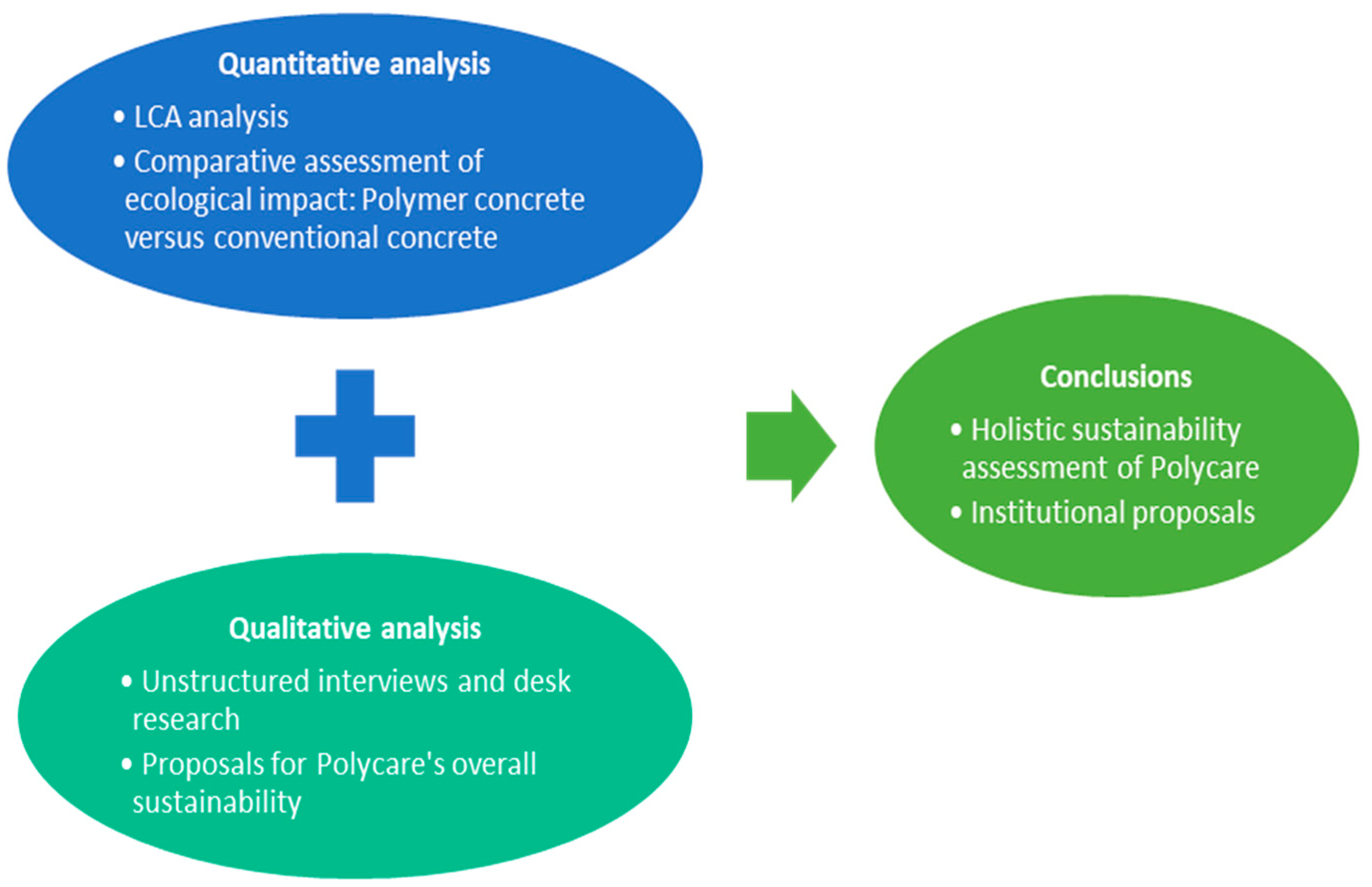

3. Materials and Methods

- -

- Objective and Scope Definition: This initial phase involves defining the objective and scope of the study, which includes determining the system boundary and the level of detail. These elements are contingent on the subject and the intended application of the study. Additionally, the functional unit and spatial and temporal limits of the system are established. The functional unit, as defined by DIN EN ISO 14040 [123], is the quantified benefit of a product system utilised as a comparison unit/reference basis;

- -

- Life-Cycle Inventory (LCI) Preparation: This phase involves quantifying the input and output flows (energy and mass flows) throughout the entire life cycle;

- -

- Impact Assessment: This phase entails quantifying the potential effects of the material and energy flows on the environment in the impact categories defined at the beginning;

- -

- Evaluation: This final phase involves interpreting the results, making conclusions and decisions, or deriving recommendations for further action.

4. Case Study: Polycare Construction System

4.1. Materials

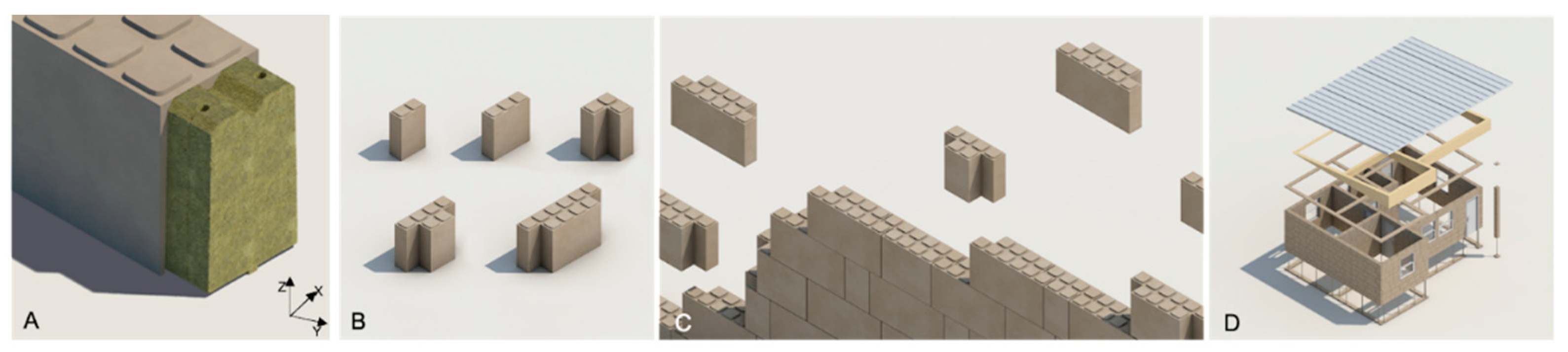

4.2. Design

4.3. Manufacturing and Assembly

4.4. Future Improvements

5. Results and Discussion

5.1. LCA Results

5.2. Discussing the Sustainability Potential of Polycare

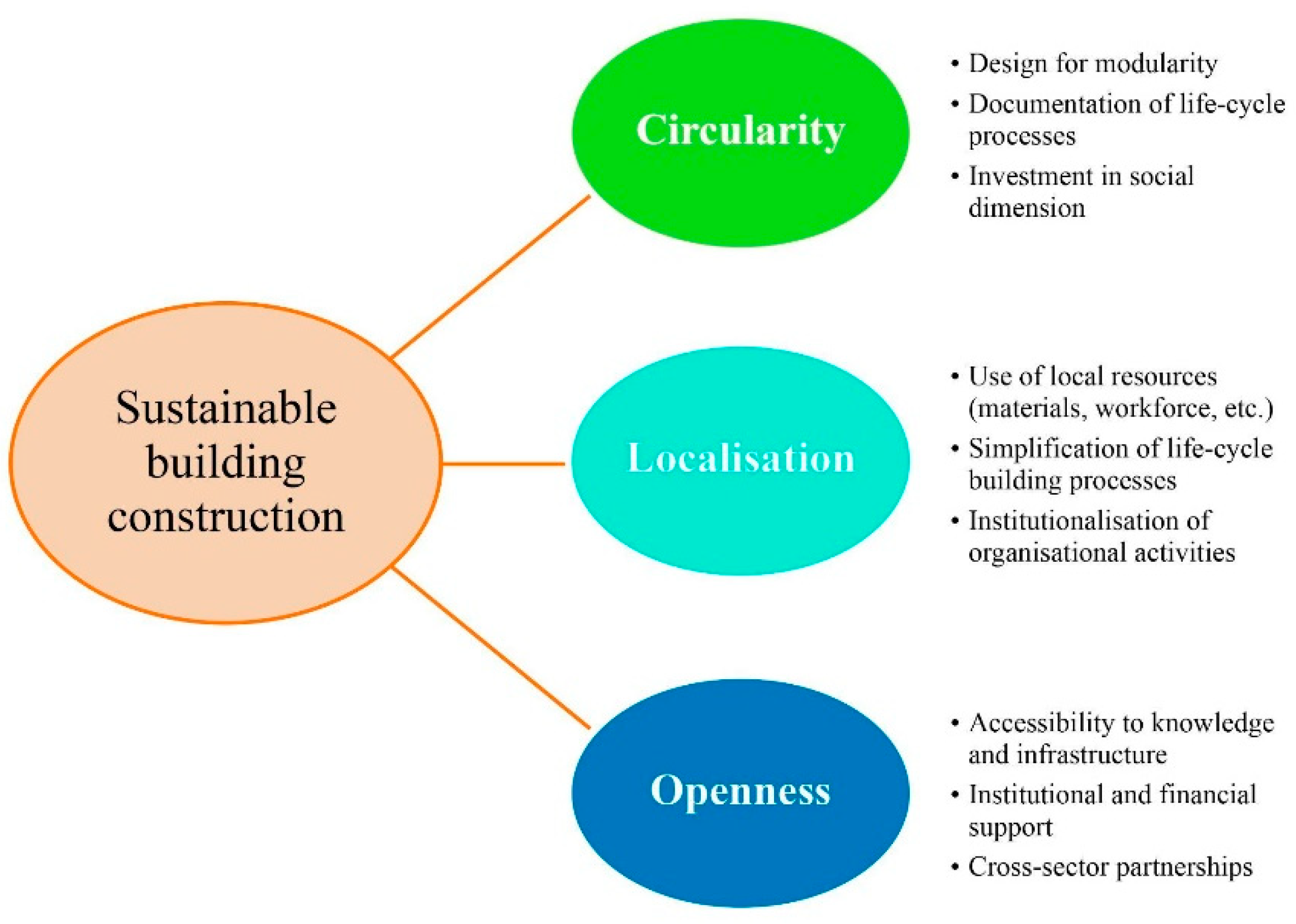

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Global Alliance for Buildings and Construction, International Energy Agency and the United Nations Environment Programme. 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. 2019. Available online: www.globalabc.org (accessed on 29 December 2022).

- Chan, A.P.C.; Owusu, E.K. Corruption forms in the construction industry: Literature review. J. Constr. Eng. Manag. 2017, 143, 04017057. [Google Scholar] [CrossRef]

- Da, S.; Le Billon, P. Sand mining: Stopping the grind of unregulated supply chains. Extr. Ind. Soc. 2022, 10, 101070. [Google Scholar] [CrossRef]

- Peng, Z.; Lu, W.; Webster, C. If invisible carbon waste can be traded, why not visible construction waste? Establishing the construction waste trading ‘missing market’. Resour. Conserv. Recy. 2022, 187, 106607. [Google Scholar] [CrossRef]

- Adabre, M.A.; Chan, A.P.C. Critical success factors (CSFs) for sustainable affordable housing. Build. Environ. 2019, 156, 203–214. [Google Scholar] [CrossRef]

- Ezennia, I.S.; Hoskara, S.O. Assessing the subjective perception of urban households on the criteria representing sustainable housing affordability. Sci. Afr. 2021, 13, e00847. [Google Scholar] [CrossRef]

- Larson, K.; Intille, S.; McLeish, T.J.; Beaudin, J.; Williams, R.E. Open source building-reinventing places of living. BT Technol. J. 2004, 22, 87–200. [Google Scholar] [CrossRef]

- Taltavull de la Paz, P.; Juárez Tárrega, F. Housing affordability. A literature review. Rev. Galega Econ. 2012, 21, 233–256. [Google Scholar]

- OECD. Building for a Better Tomorrow: Policies to Make Housing More Affordable, Employment, Labour and Social Affairs Policy Briefs; OECD: Paris, France, 2021. [Google Scholar]

- Yılmaz, M.; Bakış, A. Sustainability in construction sector. Procedia Soc. 2015, 195, 2253–2262. [Google Scholar] [CrossRef]

- UN-Habitat. Envisaging the Future of Cities, World Cities Report 2022; UN-Habitat: Nairobi, Kenya, 2022. [Google Scholar]

- Adabre, M.A.; Chan, A.P.C.; Darko, A.; Osei-Kyei, R.; Abidoye, R.; Adjei-Kumi, T. Critical barriers to sustainability attainment in affordable housing: International construction professionals’ perspective. J. Clean. Prod. 2020, 253, 119995. [Google Scholar] [CrossRef]

- UN. Transforming Our World: The 2030 Agenda for Sustainable Development (No. A/RES/70/1). 2015. Available online: https://documents-dds-ny.un.org/doc/UNDOC/GEN/N15/291/89/PDF/N1529189.pdf?OpenElement (accessed on 29 December 2022).

- Huberman, N.; Pearlmutter, D. A life-cycle energy analysis of building materials in the Negev desert. Energy Build. 2008, 40, 837–848. [Google Scholar] [CrossRef]

- Simonen, K.; Rodriguez, B.X.; De Wolf, C. Benchmarking the embodied carbon of buildings. Technol. Archit. Des. 2017, 1, 208–218. [Google Scholar] [CrossRef]

- Baker-Brown, D. The re-Use Atlas: A Designer’s Guide towards a Circular Economy; Riba Publishing: London, UK, 2017. [Google Scholar]

- Mesa, L.; Martínez, Y.; Celia de Armas, A.; González, E. Ethanol production from sugarcane straw using different configurations of fermentation and techno-economical evaluation of the best schemes. Ren. Energy 2020, 156, 377–388. [Google Scholar] [CrossRef]

- Paiho, S.; Mäki, E.; Wessberg, N.; Paavola, M.; Tuominen, P.; Antikainen, M.; Heikkilä, J.; Rozado, C.A.; Jung, N. Towards circular cities—Conceptualizing core aspects. Sustain. Cities Soc. 2020, 59, 102143. [Google Scholar] [CrossRef]

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2020, 243, 118482. [Google Scholar] [CrossRef]

- Yang, Y.; Guan, J.; Nwaogu, J.M.; Chan, A.P.C.; Chi, H.; Luk, C.W.H. Attaining higher levels of circularity in construction: Scientometric review and cross-industry exploration. J. Clean. Prod. 2022, 375, 133934. [Google Scholar] [CrossRef]

- Kohtala, C.; Hyysalo, S. Anticipated Environmental Sustainability of Personal Fabrication. J. Clean. Prod. 2015, 99, 333–344. [Google Scholar] [CrossRef]

- Omer, M.A.B.; Noguchi, T. A conceptual framework for understanding the contribution of building materials in the achievement of Sustainable Development Goals (SDGs). Sustain. Cities Soc. 2020, 52, 101869. [Google Scholar] [CrossRef]

- Priavolou, C. To BIM or not to BIM? Lessons learned from a Greek vernacular museum building. AIMS Environ. Sc. 2020, 7, 192–207. [Google Scholar] [CrossRef]

- Troullaki, K.; Rozakis, S.; Kostakis, V. Bridging barriers in sustainability research: A review from sustainability science to life cycle sustainability assessment. Ecolog. Econom. 2021, 184, 107007. [Google Scholar] [CrossRef]

- Dakwale, V.A.; Ralegaonkar, R.V.; Mandavgane, S.A. Improving environmental performance of building through increased energy efficiency: A review. Sustain. Cities Soc. 2011, 1, 211–218. [Google Scholar] [CrossRef]

- Herczeg, M.; McKinnon, D.; Milios, L.; Bakas, I.; Klaassens, E.; Svatikova, K.; Widerberg, O. Resource Efficiency in the Building Sector (No. Final Report to DG Environment); European Commission: Rotterdam, The Netherlands, 2014. [Google Scholar]

- Ingrao, C.; Messineo, A.; Beltramo, R.; Yigitcanlar, T.; Ioppolo, G. How can life cycle thinking support sustainability of buildings? Investigating life cycle assessment applications for energy efficiency and environmental performance. J. Clean. Prod. 2018, 201, 556–569. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Magrini, A.; Lentini, G.; Cuman, S.; Bodrato, A.; Marenco, L. From nearly zero energy buildings (NZEB) to positive energy buildings (PEB): The next challenge-The most recent European trends with some notes on the energy analysis of a forerunner PEB example. Dev. Built Environ. 2020, 3, 100019. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Martínez, M.; Fernández, A.I.; Urge-Vorsatz, D. Affordable construction towards sustainable buildings: Review on embodied energy in building materials. Curr. Opin. Environ. Sustain. 2013, 5, 229–236. [Google Scholar] [CrossRef]

- Ebrahimigharehbaghi, S.; Van der Heijden, H.; Elsinga, M. Sustainable business model of affordable zero energy houses: Upscaling potentials. J. Clean. Prod. 2022, 344, 130956. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Ghufran, M.; Khan, K.I.A.; Ullah, F.; Nasir, A.R.; Al Alahmadi, A.A.; Alzaed, A.N.; Alwetaishi, M. Circular economy in the construction industry: A step towards sustainable development. Buildings 2022, 12, 1004. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Rechberger, H. Improving the recycling potential of buildings through Material Passports (MP): An Austrian case study. J. Clean. Prod. 2019, 217, 787–797. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Kayaçetin, N.C.; Verdoodt, S.; Lefevre, L.; Versele, A. Integrated decision support for embodied impact assessment of circular and bio-based building components. J. Build. Eng. 2023, 63, 105427. [Google Scholar] [CrossRef]

- Ertz, M.; Durif, F.; Arcand, M. A conceptual perspective on collaborative consumption. AMS Rev. 2019, 9, 27–41. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life cycle assessment of a Danish office building designed for disassembly. Build. Res. Inf. 2019, 47, 666–680. [Google Scholar] [CrossRef]

- Allwood, J.M. Squaring the Circular Economy: The role of recycling within a hierarchy of material management strategies. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists; Worrell, E., Reuter, M.A., Eds.; Elsevier: Waltham, MA, USA, 2014; pp. 445–477. [Google Scholar] [CrossRef]

- Henry, M.; Bauwens, T.; Hekkert, M.; Kirchherr, J. A typology of circular start-ups: An Analysis of 128 circular business models. J. Clean. Prod. 2020, 245, 118528. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Andersen, R.; Ravn, A.S.; Ryberg, M.W. Environmental benefits of applying selective demolition to buildings: A case study of the reuse of façade steel cladding. Resour. Conserv. Recycl. 2022, 184, 106430. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Economic analysis of conventional versus selective demolition—A case study. Resour. Conserv. Recycl. 2011, 55, 382–392. [Google Scholar] [CrossRef]

- Kakkos, E.; Heisel, F.; Hebel, D.E.; Hischier, R. Towards urban mining—Estimating the potential environmental benefits by applying an alternative construction practice. A case study from Switzerland. Sustainability 2020, 12, 5041. [Google Scholar] [CrossRef]

- Lausselet, C.; Dahlstrøm, O.A.; Thyholt, M.; Eghbali, A.; Schneider-Marin, P. Methods to account for design for disassembly: Status of the building sector. Buildings 2023, 13, 1012. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Hartmann, T. A framework for BIM-based disassembly models to support reuse of building components. Resour. Conserv. Recycl. 2021, 175, 105825. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Saari, R. A selective disassembly multi-objective optimization approach for adaptive reuse of building components. Resour. Conserv. Recycl. 2020, 154, 104605. [Google Scholar] [CrossRef]

- Ganiyu, S.A.; Oyedele, L.O.; Akinade, O.; Owolabi, H.; Akanbi, L.; Gbadamosi, A. BIM competencies for delivering waste-efficient building projects in a circular economy. Dev. Built Environ. 2020, 4, 100036. [Google Scholar] [CrossRef]

- Llatas, C.; Bizcocho, N.; Soust-Verdaguer, B.; Montes, M.V.; Quiñones, R. An LCA-based model for assessing prevention versus non-prevention of construction waste in buildings. Waste Manag. 2021, 126, 608–622. [Google Scholar] [CrossRef] [PubMed]

- Tokede, O.O.; Rodgers, G.; Waschl, B.; Salter, J.; Ashraf, M. Harmonising life cycle sustainability thinking in material substitution for buildings. Resour. Conserv. Recycl. 2022, 185, 106468. [Google Scholar] [CrossRef]

- Torres-Rivas, A.; Pozo, C.; Palumbo, M.; Ewertowska, A.; Jiménez, L.; Boer, D. Systematic combination of insulation biomaterials to enhance energy and environmental efficiency in buildings. Constr. Build. Mater. 2021, 267, 120973. [Google Scholar] [CrossRef]

- Kyrö, R.; Jylhä, T.; Peltokorpi, A. Embodying circularity through usable relocatable modular buildings. Facilities 2019, 37, 75–90. [Google Scholar] [CrossRef]

- Garusinghe, G.D.A.U.; Perera, B.A.K.S.; Weerapperuma, U.S. Integrating circular economy principles in modular construction to enhance sustainability. Sustainability 2023, 15, 11730. [Google Scholar] [CrossRef]

- Mackenbach, S.; Zeller, J.C.; Osebold, R. A Roadmap towards Circularity-Modular Construction as a Tool for Circular Economy in the Built Environment. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 052027. [Google Scholar] [CrossRef]

- van Oorschot, J.A.W.H.; Halman, J.I.M.; Hofman, E. The adoption of green modular innovations in the Dutch housebuilding sector. J. Clean. Prod. 2021, 319, 128524. [Google Scholar] [CrossRef]

- Baldwin, C.Y.; Clark, K.B. Design Rules: The Power of Modularity; MIT Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Kanters, J. Circular building design: An analysis of barriers and drivers for a circular building sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Kostakis, V. How to reap the benefits of the “digital revolution”? Modularity and the commons. Halduskultuur 2019, 20, 4–19. [Google Scholar] [CrossRef]

- Priavolou, C.; Niaros, V. Assessing the openness and conviviality of open source technology: The case of the WikiHouse. Sustainability 2019, 11, 4746. [Google Scholar] [CrossRef]

- Gentile, P.D. Theory of modularity, a hypothesis. Procedia Comput. Sci. 2013, 20, 203–209. [Google Scholar] [CrossRef]

- Andersen, S.C.; Sohn, J.; Oldfield, P.; Birkved, M. Evaluating the environmental impacts of conventional and modular buildings in absolute measures: A case study across different geographical contexts. Build. Environ. 2022, 223, 109509. [Google Scholar] [CrossRef]

- Hammad, A.W.A.; Akbarnezhad, A.; Wu, P.; Wang, X.; Haddad, A. Building information modelling-based framework to contrast conventional and modular construction methods through selected sustainability factors. J. Clean. Prod. 2019, 228, 1264–1281. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Res. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Cheng, B.; Lu, K.; Li, J.; Chen, H.; Luo, X.; Shafique, M. Comprehensive assessment of embodied environmental impacts of buildings using normalized environmental impact factors. J. Clean. Prod. 2022, 334, 130083. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Schmidt, W.; Commeh, M.; Olonade, K.; Schiewer, G.L.; Dodoo-Arhin, D.; Dauda, R.; Fataei, S.; Tawiah, A.T.; Mohamed, F.; Thiedeitz, M.; et al. Sustainable circular value chains: From rural waste to feasible urban construction materials solutions. Develop. Built Environ. 2021, 6, 100047. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle recurrent embodied energy calculation of buildings: A review. J. Clean. Prod. 2019, 209, 731–754. [Google Scholar] [CrossRef]

- Rabello, L.G.; Ribeiro, R.C.; Da, C. Bio-based polyurethane resin: An ecological binder for a novel class of building materials-composites. Mater. Lett. 2022, 311, 131566. [Google Scholar] [CrossRef]

- Revathi, T.; Vanitha, N.; Jeyalakshmi, R.; Sundararaj, B.; Jegan, M.; Rajkumar, P.R.K. Adoption of alkali-activated cement-based binders (geopolymers) from industrial by-products for sustainable construction of utility buildings—A field demonstration. J. Build. Eng. 2022, 52, 104450. [Google Scholar] [CrossRef]

- Tallini, A.; Cedola, L. A review of the properties of recycled and waste materials for energy refurbishment of existing buildings towards the requirements of NZEB. Energy Procedia 2018, 148, 868–875. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Hossain, M.U.; Wang, L.; Yu, I.K.M.; Tsang, D.C.W.; Poon, C.-S. Environmental and technical feasibility study of upcycling wood waste into cement-bonded particleboard. Constr. Build. Mater. 2018, 173, 474–480. [Google Scholar] [CrossRef]

- Munir, Q.; Abdulkareem, M.; Horttanainen, M.; Kärki, T. A comparative cradle-to-gate life cycle assessment of geopolymer concrete produced from industrial side streams in comparison with traditional concrete. Sci. Total Environ. 2023, 865, 161230. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rodríguez-Liñán, C. Eco-efficient acoustic and thermal conditioning using false ceiling plates made from plaster and wood waste. J. Clean. Prod. 2017, 166, 690–705. [Google Scholar] [CrossRef]

- Haq, Z.U.; Sood, H.; Kumar, R. Effect of using plastic waste on mechanical properties of fly ash based geopolymer concrete. Mater. Today Proc. 2022, 69, 147–152. [Google Scholar] [CrossRef]

- Igue, F.D.; Tran Le, A.D.; Bourdot, A.; Promis, G.; Nguyen, S.T.; Douzane, O.; Lahoche, L.; Langlet, T. Impact of temperature on the moisture buffering performance of palm and sunflower concretes. Appl. Sci. 2021, 11, 5420. [Google Scholar] [CrossRef]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable construction materials using Agro-wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Gálvez, F.; Morales-Conde, M.J.; Pedreño-Rojas, M.A. Use of bioceramics enhanced with effective microorganisms as an additive for construction. Study of physical and mechanical properties in cement mortars and gypsum Plasters. Appl. Sci. 2021, 11, 3519. [Google Scholar] [CrossRef]

- Sheng, D.D.C.V.; Ramegowda, N.S.; Guna, V.; Reddy, N. Groundnut shell and coir reinforced hybrid bio composites as alternative to gypsum ceiling tiles. J. Build. Eng. 2022, 57, 104892. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Ahmed, S.M.; Hafez, R.D.A. Sugarcane pulp sand and paper grain sand as partial fine aggregate replacement in environment-friendly concrete bricks. Case Stud. Constr. Mater. 2023, 18, e01612. [Google Scholar] [CrossRef]

- Yadav, M.; Agarwal, M. Biobased building materials for sustainable future: An overview. Mater. Today Proc. 2021, 43, 2895–2902. [Google Scholar] [CrossRef]

- Bredenoord, J. Sustainable building materials for low-cost housing and the challenges facing their technological developments: Examples and lessons regarding bamboo, earth-block technologies, Building blocks of recycled materials, and improved concrete panels. J. Arch. Eng. Technol. 2017, 6, 1. [Google Scholar] [CrossRef]

- Morel, J.C.; Mesbah, A.; Oggero, M.; Walker, P. Building houses with local materials: Means to drastically reduce the environmental impact of construction. Build. Environ. 2001, 36, 1119–1126. [Google Scholar] [CrossRef]

- Nasr, M.S.; Ali, I.M.; Hussein, A.M.; Shubbar, A.A.; Kareem, Q.T.; AbdulAmeer, A.T. Utilization of locally produced waste in the production of sustainable mortar. Case Stud. Constr. Mater. 2020, 13, e00464. [Google Scholar] [CrossRef]

- Raut, A.N.; Gomez, C.P. Development of thermally efficient fibre-based eco-friendly brick reusing locally available waste materials. Constr. Build. Mater. 2017, 133, 275–284. [Google Scholar] [CrossRef]

- Sonebi, M.; Abdalqader, A.; Amziane, S.; Dvorkin, L.; Ghorbel, E.; Kenai, S.; Khatib, J.; Lushnikova, N.; Perrot, A. Trends and opportunities of using local sustainable building materials in the Middle East and North Africa region. RILEM Tech. Lett. 2022, 7, 127–138. [Google Scholar] [CrossRef]

- Subekti, S.; Bayuaji, R.; Darmawan, M.S.; Husin, N.A.; Wibowo, B.; Anugraha, B.; Irawan, S.; Dibiantara, D. Review: Potential Strength of Fly Ash-Based Geopolymer Paste with Substitution of Local Waste Materials with High-Temperature Effect. IOP Conf. Ser. Mater. Sci. Eng. 2017, 267, 012001. [Google Scholar] [CrossRef]

- Uddin, M.N.; Wei, H.H.; Chi, H.L.; Ni, M.; Elumalai, P. Building information modeling (BIM) incorporated green building analysis: An application of local construction materials and sustainable practice in the built environment. J. Build. Pathol. Rehabilitation 2021, 6, 13. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Karakhan, A.A.; Simmons, D.R. Development of a Workforce Sustainability Model for Construction (Small Study No. No. 17-8-PS); The Center for Construction Research and Training (CPWR): Silver Spring, MD, USA, 2019. [Google Scholar]

- Child, B.; Cooney, R. Local Commons for Global Benefits: Indigenous and Community-Based Management of Wild Species, Forests, and Drylands; Scientific and Technical Advisory Panel to the Global Environment Facility: Washington, DC, USA, 2019. [Google Scholar]

- Keohane, R.; Ostrom, E. (Eds.) Local Commons and Global Interdependence: Heterogeneity and Cooperation in Two Domains; SAGE Publications Ltd.: London, UK, 1995. [Google Scholar]

- Bredenoord, J. Sustainable Housing and Building Materials for Low-Income Households. J. Archit. Eng. Technol. 2016, 5, 1000158. [Google Scholar] [CrossRef]

- Reddy, B.V.V. Sustainable building technologies. Curr. Sci. 2004, 87, 899–907. Available online: https://www.jstor.org/stable/24109393 (accessed on 30 July 2023).

- Mihai, F.-C. Construction and demolition waste in Romania: The route from illegal dumping to building materials. Sustainability 2019, 11, 3179. [Google Scholar] [CrossRef]

- Priavolou, C.; Tsiouris, N.; Niaros, V.; Kostakis, V. Towards sustainable construction practices: How to reinvigorate vernacular buildings in the digital era? Buildings 2021, 11, 297. [Google Scholar] [CrossRef]

- Balka, K.; Raasch, C.; Herstatt, C. The effect of selective openness on value creation in user innovation communities: Selective openness and value creation by users. J. Prod. Innov. Manag. 2014, 31, 392–407. [Google Scholar] [CrossRef]

- von Hippel, E. Comment on ‘Is open innovation a field of study or a communication barrier to theory development? Technovation 2010, 30, 555. [Google Scholar] [CrossRef]

- Bollier, D. Viral Spiral-How the Commoners Built a Digital Republic of Their Own; New Press: London, UK; New York, NY, USA, 2008. [Google Scholar]

- Priavolou, C. The emergence of open construction systems: A sustainable paradigm in the construction sector? J. Futures Stud. 2018, 23, 67–84. [Google Scholar] [CrossRef]

- Solaimani, S.; Sedighi, M. Toward a holistic view on lean sustainable construction: A literature review. J. Clean. Prod. 2020, 248, 119213. [Google Scholar] [CrossRef]

- Kostakis, V.; Latoufis, K.; Liarokapis, M.; Bauwens, M. The convergence of digital commons with local manufacturing from a degrowth perspective: Two illustrative cases. J. Clean. Prod. 2018, 197, 1684–1693. [Google Scholar] [CrossRef]

- Lizarralde, I.; Tyl, B. A framework for the integration of the conviviality concept in the design process. J. Clean. Prod. 2018, 197, 1766–1777. [Google Scholar] [CrossRef]

- Shuman, M. Local Dollars, Local Sense: How to Shift Your Money from Wall Street to Main Street and Achieve Real Prosperity; Chelsea Green Pub: White River Junction, VT, USA, 2012. [Google Scholar]

- IEA. Buildings; IEA: Paris, France, 2022. [Google Scholar]

- Goyal, S.; Ott, D.; Liebscher, J.; Höfling, D.; Müller, A.; Dautz, J.; Gutzeit, H.O.; Schmidt, D.; Reuss, R. Sustainability analysis of fish feed derived from aquatic plant and insect. Sustainability 2021, 13, 7371. [Google Scholar] [CrossRef]

- Gardner, T.A.; Benzie, M.; Börner, J.; Dawkins, E.; Fick, S.; Garrett, R.; Godar, J.; Grimard, A.; Lake, S.; Larsen, R.K.; et al. Transparency and sustainability in global commodity supply chains. World Dev. 2019, 121, 163–177. [Google Scholar] [CrossRef]

- Baldwin, C.; von Hippel, E. Modeling a paradigm shift: From producer innovation to user and open collaborative innovation. Organ. Sci. 2011, 22, 1399–1417. [Google Scholar] [CrossRef]

- Maxwell, E. Open standards, open source, and open innovation: Harnessing the benefits of openness. Innov. Technol. Gov. Glob. 2006, 1, 119–176. [Google Scholar] [CrossRef]

- van Abel, B.; Evers, L.; Klaassen, R.; Troxler, P. Open Design Now: Why Design Cannot Remain Exclusive, 1st ed.; BIS: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Maier, A.M.; Eckert, C.M.; Clarkson, P.J. Factors influencing communication in collaborative design. J. Engin. Des. 2021, 32, 671–702. [Google Scholar] [CrossRef]

- Rahmawati, Y.; Utomo, C.; Anwar, N.; Nurcahyo, C.B.; Negoro, N.P. Theoretical framework of collaborative design issues. J. Teknol. 2014, 70. [Google Scholar] [CrossRef][Green Version]

- Astarini, S.D.; Utomo, C.; Rohman, M.A. Integration factors of design participants in performance-based building design of commercial property. Designs 2022, 6, 111. [Google Scholar] [CrossRef]

- Azari, R.; Kim, Y.-W. Integration evaluation framework for integrated design teams of green buildings: Development and validation. J. Manag. Eng. 2016, 32, 04015053. [Google Scholar] [CrossRef]

- Thomson, C.C.; Jakubowski, M. Toward an Open Source Civilization: (Innovations Case Narrative: Open Source Ecology). Innovations: Technology, Governance. Globaliz 2012, 7, 53–70. [Google Scholar] [CrossRef]

- Bloom, P.N.; Chatterji, A.K. Scaling social entrepreneurial impact. Calif. Manag. Rev. 2009, 51, 114–133. [Google Scholar] [CrossRef]

- Kralisch, D.; Ott, D. Environmental analyses and life cycle assessment studies. In Contemporary Catalysis: Science, Technology, and Applications; Kamer, P.C.J., Vogt, D., Thybaut, J., Eds.; The Royal Society of Chemistry: London, UK, 2017. [Google Scholar]

- Kralisch, D.; Ott, D.; Lapkin, A.A.; Yaseneva, P.; De Soete, W.; Jones, M.; Minkov, N.; Finkbeiner, M. The need for innovation management and decision guidance in sustainable process design. J. Clean. Prod. 2018, 172, 2374–2388. [Google Scholar] [CrossRef]

- Ott, D.; Kralisch, D.; Denčić, I.; Hessel, V.; Laribi, Y.; Perrichon, P.D.; Berguerand, C.; Kiwi-Minsker, L.; Loeb, P. Life cycle analysis within pharmaceutical process optimization and intensification: Case study of active pharmaceutical ingredient production. Chem. Sus. Chem. 2014, 7, 3521–3533. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 22 September 2022).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 22 September 2022).

- Hischier, R.; Hellweg, S.; Capello, C.; Primas, A. Establishing life cycle inventories of chemicals based on differing data availability (9 pp). Int. J. Life Cycle Assess. 2005, 10, 59–67. [Google Scholar] [CrossRef]

- Heijungs, R.; Goedkoop, M.; Struijs, J.; Effting, S.; Sevenster, M.; Huppes, G. Towards a life cycle impact assessment method which comprises category indicators at the midpoint and the endpoint level. In Report of the First Project Phase Design of the New Method; 2003; Available online: https://d1wqtxts1xzle7.cloudfront.net/38733263/recipe_phase1-libre.pdf?1441952852=&response-content-disposition=inline%3B+filename%3DTowards_a_life_cycle_impact_assessment_m.pdf&Expires=1696055705&Signature=NlZHI2Yi7F2YAVpd8l6qdzN9O0wNUHoPr30bRIQ23iOo6gJpjQI1zEm11vnCjsQxjLc21nUHnz6TlAymDmnsbONvioZRByWOBWx1OE4l6Fzl2rSlrUwxVniRGOjM9-ChxdZTH-mDpbW6MWUOMaB-y6MiOv7IjAuOK8KburdaZt~Q3X-UYjQlRvci1o2gIJQ-AaJYlQkrKXb-C-MjbbvU3qxiZvfrZvP-Tl2PhJqql7yq-208zAT4zxIe5ijVVZ5DW1jqB6bD-DEh6yrFq2WO8gm1Bw2EkGsLNKka8zP4l-2temcPeYrIKnSX3oOE42NknkyCjvFF0a~GM~4QNMEMvQ__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (accessed on 7 July 2023).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- van Stijn, A.; Malabi Eberhardt, L.C.; Wouterszoon Jansen, B.; Meijer, A. A Circular Economy Life Cycle Assessment (CE-LCA) model for building components. Resour. Conserv. Recycl. 2021, 174, 105683. [Google Scholar] [CrossRef]

- DIN EN 13501-2:2010-02; Fire Classification of Construction Products and Building Elements—Part 2: Classification Using Data from Fire Resistance Tests, excluding Ventilation Services. DIN: Berlin, Germany, 2010.

- DIN 4102-4:2016-05; Fire Behaviour of Building Materials and Building Components—Part 4: Synopsis and Application of Classified Building Materials, Components and Special Components. DIN: Berlin, Germany, 2016.

- Voglhuber-Slavinsky, A.; Zicari, A.; Smetana, S.; Moller, B.; Dönitz, E.; Vranken, L.; Zdravkovic, M.; Aganovic, K.; Bahrs, E. Setting life cycle assessment (LCA) in a future-oriented context: The combination of qualitative scenarios and LCA in the agri-food sector. Eur. J. Futures Res. 2022, 10, 15. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Di Capua, S.E.; Paolotti, L.; Moretti, E.; Rocchi, L.; Boggia, A. Evaluation of the Environmental Sustainability of Hemp as a Building Material, through Life Cycle Assessment. Environ. Clim. Technol. 2021, 25, 1215–1228. [Google Scholar] [CrossRef]

- Ott, D.; (EurA AG) on behalf of PolyCare Research Technology GmbH & Co. KG, Germany. Ecological Evaluation of the PolyCare MAS Technology and Comparison to Conventional Concrete based on DIN EN ISO 14040 and 14044. 2018; Note: This Report Is an Internal Document Which Contains Confidential Information. Publicly Available Results Can Be Found in the Abstract “Life Cycle Assessment Study of PolyCare MAS Technology”. [Google Scholar]

- Scrucca, F.; Ingrao, C.; Maalouf, C.; Moussa, T.; Polidori, G.; Messineo, A.; Arcidiacono, C.; Asdrubali, F. Energy and carbon footprint assessment of production of hemp hurds for application in buildings. Environ. Imp. Assess. Rev. 2020, 84, 106417. [Google Scholar] [CrossRef]

- Marchesi, M.; Tweed, C. Social innovation for a circular economy in social housing. Sustain. Cities Soc. 2021, 71, 102925. [Google Scholar] [CrossRef]

- Prendeville, S.; Cherim, E.; Bocken, N. Circular cities: Mapping six cities in transition. Environ. Innov. Soc. Transit. 2018, 26, 171–194. [Google Scholar] [CrossRef]

- Avelino, F.; Wittmayer, J.M.; Pel, B.; Weaver, P.; Dumitru, A.; Haxeltine, A.; Kemp, R.; Jørgensen, M.S.; Bauler, T.; Ruijsink, S.; et al. Transformative social innovation and (dis)empowerment. Technol. Forecast. Soc. Chang. 2019, 145, 195–206. [Google Scholar] [CrossRef]

- The Young Foundation. Social Innovation Overview: A Deliverable of the Project: “The Theoretical, Empirical and Policy Foundations for Building Social In-novation in Europe” (TEPSIE) (European Commission–7th Framework Programme); DG Research; European Commission: Brussels, Belgium, 2012. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kouvara, A.; Priavolou, C.; Ott, D.; Scherer, P.; van Zyl-Bulitta, V.H. Circular, Local, Open: A Recipe for Sustainable Building Construction. Buildings 2023, 13, 2493. https://doi.org/10.3390/buildings13102493

Kouvara A, Priavolou C, Ott D, Scherer P, van Zyl-Bulitta VH. Circular, Local, Open: A Recipe for Sustainable Building Construction. Buildings. 2023; 13(10):2493. https://doi.org/10.3390/buildings13102493

Chicago/Turabian StyleKouvara, Asimina, Christina Priavolou, Denise Ott, Philipp Scherer, and Verena Helen van Zyl-Bulitta. 2023. "Circular, Local, Open: A Recipe for Sustainable Building Construction" Buildings 13, no. 10: 2493. https://doi.org/10.3390/buildings13102493

APA StyleKouvara, A., Priavolou, C., Ott, D., Scherer, P., & van Zyl-Bulitta, V. H. (2023). Circular, Local, Open: A Recipe for Sustainable Building Construction. Buildings, 13(10), 2493. https://doi.org/10.3390/buildings13102493