Abstract

Energy consumption for building cooling is directly related to incident solar radiation. Therefore, solutions of high reflectivity, while keeping color comfort, are being actively researched. Here, finite-difference time-domain (FDTD) simulations were used to investigate the influence of nanoparticle and core–shell additives on coating reflection and color. Different TiO and CuO nanoparticle mixings were tested, with relative concentrations varying from 0 to 20% of each on acrylic. The same compounds were used to define core–shells with a varied inner radius (0–30 nm) for both TiO and CuO as the core and shell. The numerical simulations demonstrate that mixing CuO with TiO enables dark colors while maintaining the overall reflectance. The reflectance results for the core–shell structure are comparable with those of the nanoparticles when CuO is the core, while a more pronounced color change is originated when CuO is the shell.

1. Introduction

Energy saving is one of the most critical issues of the present due to the depletion of natural resources, increasing energy prices and global warming [1]. In particular, building energy consumption is becoming comparable to that of the industry and transportation sectors due to the increasing demand for refrigeration in warm climates [2]. Nearly 75% of European buildings are energy nonefficient, resulting in huge energy losses [3,4]. Improving the performance of existing buildings and adopting smart constructive solutions and materials when developing or renovating residential houses is an interesting strategy for mitigating such energy consumption. With most of building overheating coming from solar radiation, the development of thermal insulation systems [5,6,7] and reflective materials [8,9,10,11] are key steps to effectively reduce energy consumption. In particular, the incorporation of materials with tuned and enhanced optical properties in envelope systems (roofs, pavements or façades) to improve energy performance is being actively pushed by the scientific community [12,13,14,15]. The application of reflective materials, which reflect a large portion of the solar radiation [16], on those surfaces can be a decisive feature since invisible near-infrared (NIR) radiation is responsible for about half of the solar energy [4]. Most of the reflective surfaces of buildings rely on whitish coatings [17] that, however, result in disadvantages regarding aesthetics, high glare that leads to discomfort [18] and surface contamination that reduces reflectance [19]. Therefore, color-tuned reflective coatings are highly desirable and in dire need [20].

Among reflective nanomaterials, titanium dioxide (TiO) is the most used white pigment for enhanced-reflectivity paints [21]. Several studies have already explored the role of TiO in such paints and their applicability in buildings. As is widely known, TiO presents high spectral reflectance and, therefore, a good thermal performance [22]. Wang et al. added TiO with different crystalline structures to high-density polyethylene (HDPE) to produce a reflective material. The authors found that rutile TiO largely enhanced the total reflectance from 28.8% to 51.1% [23]. Gao et al. prepared different-shaped rutile TiO-coated mica-titania pigments, which exhibited an effective light stabilization in the paint compared to the pristine TiO pigment with NIR solar reflectance as high as 97% [24]. Thus, controlling the size and morphology can be a useful method to improve the solar reflectivity in pigments. On the other hand, copper oxide (CuO), a common black metal oxide, exhibits excellent near infrared (NIR) properties. You et al. experimentally evaluated three coatings for asphalts with different types of CuO nanoparticle shapes (22.6% concentration) on a black substrate and studied their optical performance [25]. The authors highlighted that CuO nanoparticles enhance the reflectance and can substantially reduce the asphalt surface temperature by 7 to 13 C. Baneshi et al. tested black CuO powder in a conventional black base coat to not excessively change the visual aesthetic [26]. Despite the poor thermal performance, the inclusion of CuO enhanced the total solar reflectance to around 30%, a large improvement considering that conventional black paints typically present total reflectances lower than 20%.

The optical properties of these functional materials depend on the particle size, structure and composition. For instance, the interaction of light with nanosized CuO results in dark tones in the visible range, while TiO particles appear white. Knowing the high NIR of the latter, a mixing of both enables the development of dark exterior building surfaces able to reflect solar radiance. Therefore, there is an emerging trend in using these two nanomaterials to act as pigments in coatings to both improve the NIR reflectivity and simultaneously enable dark tones [27]. To overcome the limits mentioned, one appealing strategy is to formulate mixed-particle or core–shell structured coatings, a simple-to-implement and cost-effective method [24]. The synthesis techniques to obtain core–shells include condensation from vapor, synthesis by chemical reaction and solid-state processes such as milling. This preparation usually involves two steps, which are the synthesis of the core followed by the coating of the core with a shell material [28]. In fact, the high reflectance of dark gray composite pigments with TiO/CuO core–shell structures was already experimentally shown [29]. Furthermore, You et al. experimentally evaluated the optical and thermal performance of blending coatings with TiO nanoparticles and CuO micro and nanoparticles [27]. They confirmed that the type of CuO particles influences the surface temperature of these blending coatings.

Although reflective nanomaterials are widely explored to determine energy savings on buildings [8,11,30,31], it has not yet been possible to develop a dark-tone pigment with enhanced reflectance. Furthermore, the actual physical properties and their tuning for improved performance are still not clear. Therefore, the goal of this work is the numerical study of particle mixtures able to achieve high reflectances in dark colors, taking advantage of the physical properties of different materials and structures. Here, we present a numerical study using the finite-difference time-domain (FDTD) method, which simulates the propagation of electromagnetic waves in a medium by solving Maxwell’s equations at different points in space. It was used to calculate the optical properties of the coatings with mixed TiO/CuO metal oxide nanoparticles and both TiO@CuO and CuO@TiO core–shells by maximizing the achieved reflectance while preserving or tuning the color.

2. Materials and Methods

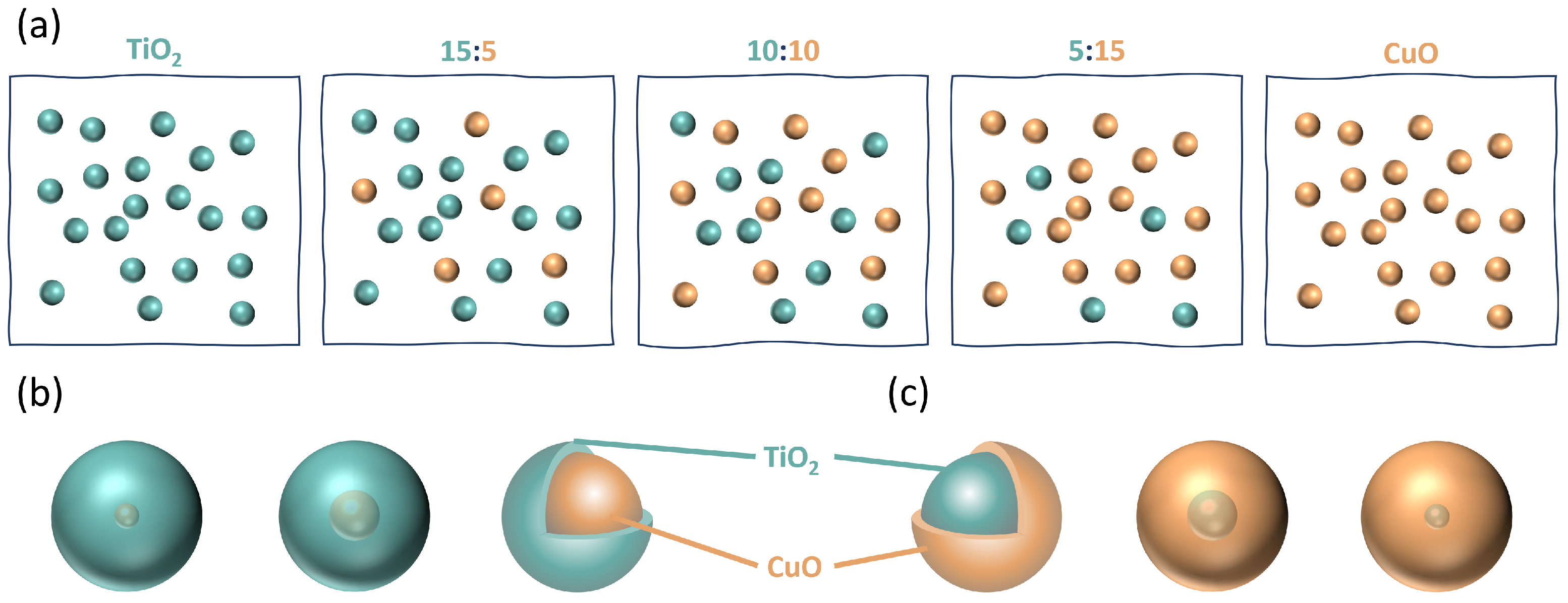

FDTD was implemented by using the Python package Meep [32], which is an open-source software package for electromagnetic simulation, following the methodology described and experimentally validated in Ref. [33]. In short, with a resolution of 50 pixels/m, two models were constructed to represent nanoparticle and core–shell structures randomly embedded in acrylic coatings, as shown in the schematic drawings of Figure 1. The acrylic paint is described by a 40 × 40 m block with a relative dielectric constant of 2.5; the nanoparticles are defined by uniform spheres (Figure 1a) and core–shells by concentric different-size spheres (Figure 1b) of a relative dielectric constant equal to 9 for TiO and 0.8 for CuO. The total particle volume ratio of the nanoparticles and core–shells to acrylic was kept at 20% and the outer diameter at 30 nm. For the nanoparticle mixing, the relative concentration of TiO to CuO was varied from only TiO (20:0) to only CuO (0:20) by increments of 5% (15:5, 10:10 and 5:15). Regarding the core–shells, three core diameters were studied (5, 10 and 20 nm) for both the 30 nm TiO (CuO@TiO) and CuO (TiO@CuO) shells. A Gaussian source from 300 to 2500 nm (solar spectrum) represents the incident light with downward propagation. A perfect matching layer (PML) is used as the vertical boundary condition, and a periodic matching layer is used as the horizontal boundary condition. The RGB (red, green and blue) colors were calculated from the XYZ system obtained by the International Commission on Illumination (CIE) colorimetric system analysis for an input and output illuminant and reference angle of D65 10 and the color difference (E) following metric CIE76 on the CIELAB color space.

Figure 1.

TiO and CuO nanocomposites constituted by 30 nm outer diameter (a) TiO/CuO nanoparticles (variations of 5%), (b) CuO@TiO and (c) TiO@CuO core–shells (5, 10 and 20 nm inner diameters) at fixed total 20% particle volume ratio (not to scale).

3. Results and Discussion

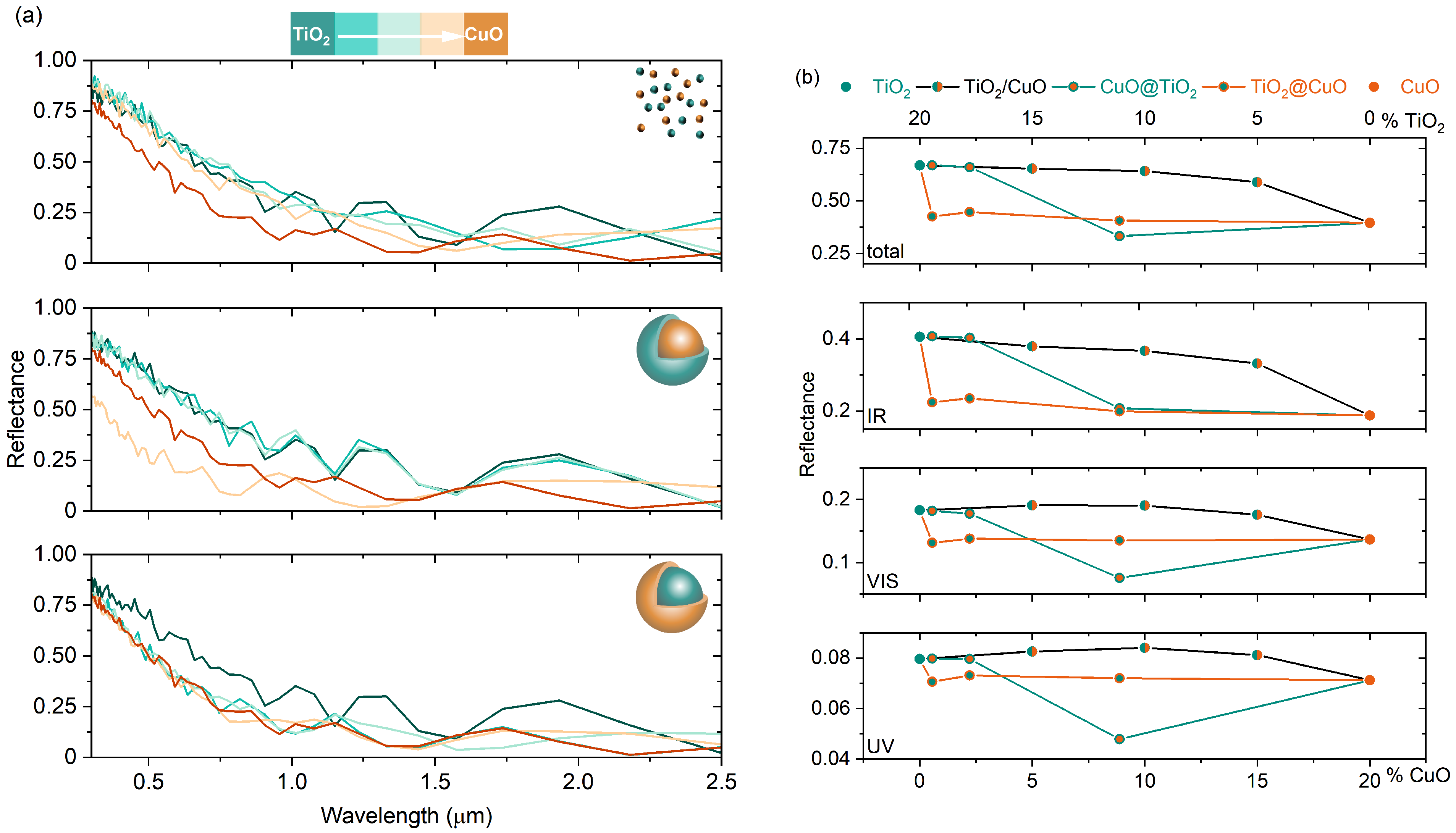

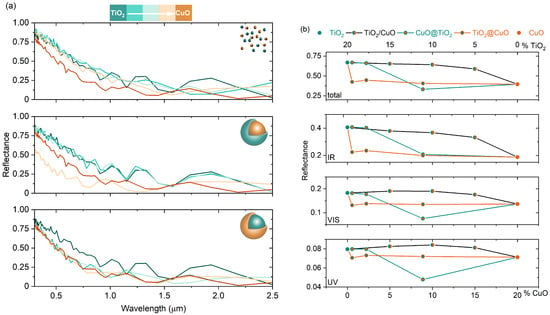

Given that titanium dioxide increases the solar reflectance, one should be able to mix it with other compounds to obtain darker colors while maintaining the high reflectance. Therefore, we performed a study varying the relative concentration of TiO and CuO (TiO/CuO) in an acrylic matrix. Figure 2a shows the reflectance of the TiO/CuO nanoparticles mixing over the solar spectrum wavelengths (300–2500 nm). The reflectance is fairly constant up to 15% TiO in all regions, with a clear decrease for 20% CuO (Figure 2b), translating into a decrease in the total reflectance from 66% to 40%, which is mostly due to a decrease in the IR (40% to 14%) range, with smaller decreases for VIS (4%) and UV (1%).

Figure 2.

(a) Reflectance as a function of TiO and CuO 30 nm diameter nanoparticles incorporation at 20% particle volume fraction (TiO/CuO variations of 5%), TiO and CuO 30 nm diameter core–shells incorporation at 20% particle volume fraction for CuO as core and TiO as shell (CuO@TiO) and TiO@CuO (5, 10 and 20 nm inner diameters). (b) Total reflectance and IR, VIS and UV reflectances as a function of the TiO-CuO/acrylic volume ratio for the configurations shown in (a).

Then, we studied the mixing of these two compounds in core–shell structures (Figure 2a) for both TiO on the outside with different relative diameters (CuO@TiO) and CuO on the outside with the same diameters (TiO@CuO). As shown in Figure 2a, with TiO on the outside, the reflectance for a 20 nm CuO core with a 10 nm TiO shell is lower than for 30 nm CuO nanoparticles. Moreover, up to 10–20 nm, the total reflectance (Figure 2b) stays constant at around 66%, decaying afterward below the single CuO value (33% versus 40%). Once again, this change is more pronounced in the IR (19% decrease) than in the rest of the spectrum (10% for VIS and <1% for UV). Interestingly, a decrease in 50% of the TiO effective outer diameter (from 20 nm to 10 nm) also translates to a 50% total reflectance decrease (from 66% to 33%). For CuO on the outside, all reflectance curves lie below the single TiO nanoparticles and close to the single CuO (Figure 2a). The total reflectance (Figure 2b) is always lower than that of the single TiO case, having an approximately constant value of around 41%. The same tendency is observed for the UV, VIS and NIR ranges.

Focusing on the total, IR, VIS and UV reflectance (Figure 2b), when TiO is the shell (CuO@TiO), the behavior of the core–shells is similar to the nanoparticles mixture (TiO/CuO) up to a 10 nm CuO core (2.2% of CuO), decreasing afterwards. This is not the case for CuO on the outside (TiO/CuO), with 20 nm of the TiO core (0.6% of CuO) already considerably decreasing the reflectance to the lowest obtained values, except for the 5 nm TiO core (8.9% of CuO), where it is higher than the CuO@TiO core–shells. This clear difference between a TiO and CuO core may be explained by using Mie theory. The calculations of the extinction cross section, which represent the total power lost by the wave upon incidence on the particle, show that for the TiO@CuO core–shells, independently of the TiO core size, the values are comparable with those of the CuO nanoparticles. This can be understood by the absorption of the radiation at the shell, without a reflectance contribution from the TiO core. The reflectance of the CuO@TiO core–shells are also independent of the size of the CuO core, up to 20 nm in diameter. Below this size, the total reflectance likely arises from contributions from the interface and internal reflections, which results in absorption at the higher core size.

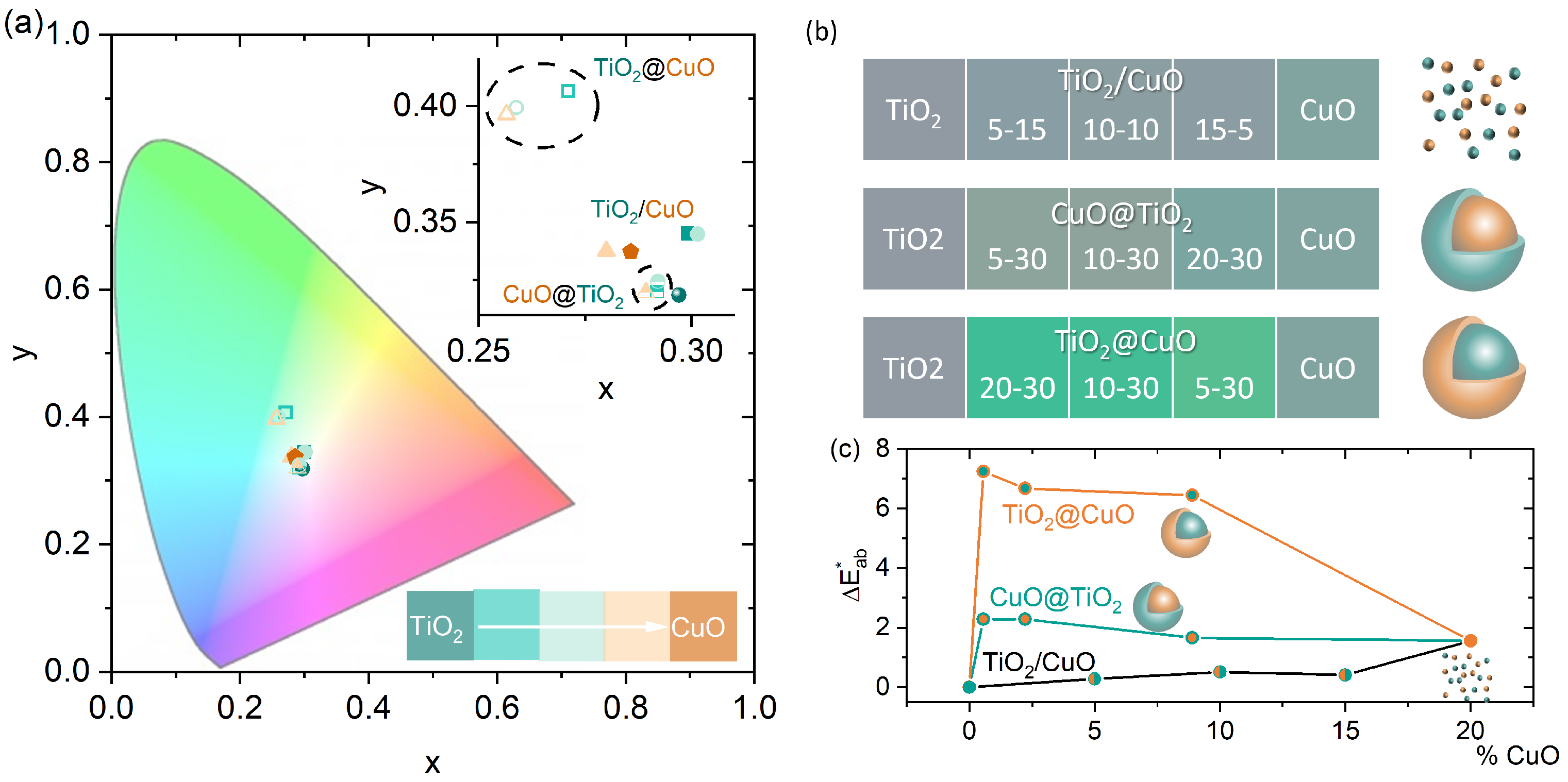

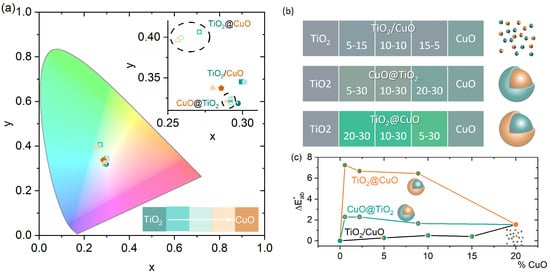

Finally, the CIE colorimetric system was used for color analysis of the coatings (Figure 3a). From the inset, it is observed that core–shells with an inner TiO and outer CuO (TiO@CuO) have the highest variation in the coordinates relative to that of the single TiO and CuO structures, moving toward a greener color. The TiO/CuO mixture and the core–shells with an inner CuO and outer TiO (CuO@TiO) show similar behavior, with the latter being slightly closer to the CuO coordinates. This is clearer from the conversion to the RGB system (Figure 3b). The TiO and CuO nanoparticles (TiO/CuO) mixture shows a grayish color similar to that of the single TiO nanoparticles case, while the core–shells show a variation in the green direction. The change from gray to green is more evident with CuO as the shell (TiO@CuO) for all the tested relative diameters. To quantify the color difference as a function of CuO quantity, Figure 3c shows this metric following CIE76 after the calculation of these colors also on the CIELAB color space. As E≈ 2.3 corresponds to just a noticeable difference, it is evident that the changes in color for TiO/CuO and CuO@TiO are not significant. However, for CuO@TiO, the color difference is high (E≈ 6.4–7.3) and decreases with the increase in the CuO shell thickness

Figure 3.

(a) Color coordinates of pigmented coatings for different nanoparticle mixtures (closed symbols) and core–shells (open symbols; the inset shows the x-y plane in more detail). (b) Corresponding RGB color with nanoparticle mixing (top) and core–shells with TiO (middle) and CuO (bottom) as shell for input and output illuminant and reference angle of D65 10. (c) Color difference in relation to single TiO nanoparticles.

Core–shell structures not only improve the physical–chemical characteristics of nanomaterials but also avoid interactions between the inner core and the surroundings. Previous studies [29,34,35] showed that core–shell compositions have higher NIR reflectance than mixed oxide particles due to the improved refractive index. When mixed, it is assumed that the reflective material (in our case, the TiO) will cover a large part of the CuO particle, thus reflecting most of the light and mitigating the CuO visible light absorption. As a result, the mixed material will present a light gray color with enhanced reflectance in the VIS and NIR regions. On the contrary, the distinctive core–shell architecture between the two materials yields an enhanced reflectance with bright colors and gives the possibility for color tuning, considering the particles’ properties [8].

4. Conclusions

When improving coating reflectance by nanoparticle doping, it is important to recognize that particle material, composition, size and concentration must be considered as they influence the interaction with light. With this (previously experimentally validated) method, the optical behavior of different mixings can be predicted for the formulation of new colored coatings. We studied in detail an approach to increase the solar reflectance of coatings while obtaining tuned colors by using a mixture of TiO and CuO nanoparticles as pigments. The proposed system was numerically analyzed with the FDTD method by using Meep. As expected, mixing CuO with TiO decreases the overall reflectance as compared with the single TiO results. However, this decrease only starts to be significant when there is more CuO than TiO (5:15) in the mixing. Furthermore, for CuO as the core, the behavior of the core–shells is comparable to mixing nanoparticles of the two compounds, up to 10 nm in diameter. If CuO is the outer shell (TiO@CuO), the change in color is more pronounced, enabling a larger color-tuning range. In short, starting from the single CuO, the best performance was obtained for the mixture with TiO, without significant color variation (grayish). With CuO as the shell and TiO as the core, the color shows a variation toward green. These results show the influence of compound mixing conditions on color and reflectance, which should be taken into account for the preparation of coating materials.

Author Contributions

Conceptualization, C.D. and J.V.; methodology, C.D.; software, C.D.; validation, C.D. and R.C.V.; formal analysis, C.D.; investigation, C.D.; resources, J.V.; data curation, C.D.; writing—original draft preparation, C.D.; writing—review and editing, C.D., R.C.V. and J.V.; visualization, C.D.; supervision, J.V.; project administration, J.V.; funding acquisition, J.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by FCT and IFIMUP through projects UIDB/04968/2020 and UIDP/04968/2020 and by Project Circular2B—37_CALL#2—Circular Construction in Energy-Efficient Modular Buildings financing under the Environment, Climate Change and Low Carbon Economy Program within the scope of the European Economic Area Financial Mechanism EEA Grants 2014–2021. R. C. Veloso would like to acknowledge the support of FCT—Fundação para a Ciência e a Tecnologia—for the funding of the Doctoral Grant SFRH/BD/148785/2019.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| FDTD | Finite-difference time-domain |

| IR | Infrared |

| VIS | Visible |

| UV | Ultraviolet |

| CIE | International Commission on Illumination |

References

- Buonomano, A.; Barone, G.; Forzano, C. Latest advancements and challenges of technologies and methods for accelerating the sustainable energy transition. Energy Rep. 2023, 9, 3343–3355. [Google Scholar] [CrossRef]

- Duan, H.; Chen, S.; Song, J. Characterizing regional building energy consumption under joint climatic and socioeconomic impacts. Energy 2022, 245, 123290. [Google Scholar] [CrossRef]

- Cozza, E.; Alloisio, M.; Comite, A.; Tanna, G.D.; Vicini, S. NIR-reflecting properties of new paints for energy-efficient buildings. Sol. Energy 2015, 116, 108–116. [Google Scholar] [CrossRef]

- Doulos, L.; Santamouris, M.; Livada, I. Passive cooling of outdoor urban spaces. The role of materials. Sol. Energy 2004, 77, 231–249. [Google Scholar] [CrossRef]

- Kamel, E.; Memari, A. Residential Building Envelope Energy Retrofit Methods, Simulation Tools, and Example Projects: A Review of the Literature. Buildings 2022, 12, 954. [Google Scholar] [CrossRef]

- Papadopoulos, A. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Veloso, R.C.; Souza, A.; Maia, J.; Ramos, N.M.M.; Ventura, J. Nanomaterials with high solar reflectance as an emerging path towards energy-efficient envelope systems: A review. J. Mater. Sci. 2021, 56, 19791–19839. [Google Scholar] [CrossRef]

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy 2011, 85, 3085–3102. [Google Scholar] [CrossRef]

- Rawat, M.; Singh, R. Impact of light-colored paint materials on discomfort in a building for hot-dry climate. Mater. Today Proc. 2022, 52, 998–1005. [Google Scholar] [CrossRef]

- Santamouris, M.; Yun, G.Y. Recent development and research priorities on cool and super cool materials to mitigate urban heat island. Renew. Energy 2020, 161, 792–807. [Google Scholar] [CrossRef]

- Rosati, A.; Fedel, M.; Rossi, S. NIR reflective pigments for cool roof applications: A comprehensive review. J. Clean. Prod. 2021, 313, 127826. [Google Scholar] [CrossRef]

- Bretz, S.; Akbari, H.; Rosenfeld, A. Practical issues for using solar-reflective materials to mitigate urban heat islands. Atmos. Environ. 1998, 32, 95–101. [Google Scholar] [CrossRef]

- Xie, N.; Li, H.; Abdelhady, A.; Harvey, J. Laboratorial investigation on optical and thermal properties of cool pavement nano-coatings for urban heat island mitigation. Build. Environ. 2019, 147, 231–240. [Google Scholar] [CrossRef]

- Mourou, C.; Zamorano, M.; Ruiz, D.P.; Martín-Morales, M. Cool Surface Strategies with an Emphasis on the Materials Dimension: A Review. Appl. Sci. 2022, 12, 1893. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, W.; Shi, Y.; Song, J.; Qu, J.; Qin, J.; Zhang, T.; Li, Y.; Zhang, H.; Zhang, R. Optical properties across the solar spectrum and indoor thermal performance of cool white coatings for building energy efficiency. Energy Build. 2013, 63, 49–58. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.; Overvig, A.C.; Jia, M.; Sun, K.; Shi, N.N.; Zhou, H.; Xiao, X.; Yu, N.; Yang, Y. Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling. Science 2018, 362, 315–319. [Google Scholar] [CrossRef]

- Taha, H.; Sailor, D.; Akbari, H. High-Albedo Materials for Reducing Building Cooling Energy Use; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 1992. [CrossRef]

- Levinson, R.; Berdahl, P.; Akbari, H. Solar spectral optical properties of pigments—Part II: Survey of common colorants. Sol. Energy Mater. Sol. Cells 2005, 89, 351–389. [Google Scholar] [CrossRef]

- Sproul, J.; Wan, M.P.; Mandel, B.H.; Rosenfeld, A.H. Economic comparison of white, green, and black flat roofs in the United States. Energy Build. 2014, 71, 20–27. [Google Scholar] [CrossRef]

- Löf, D.; Hamieau, G.; Zalich, M.; Ducher, P.; Kynde, S.; Midtgaard, S.R.; Parasida, C.F.; Arleth, L.; Jensen, G.V. Dispersion state of TiO2 pigment particles studied by ultra-small-angle X-ray scattering revealing dependence on dispersant but limited change during drying of paint coating. Prog. Org. Coat. 2020, 142, 105590. [Google Scholar] [CrossRef]

- Gao, Q.; Wu, X.; Fan, Y. Solar spectral optical properties of rutile TiO2 coated mica-titania pigments. Dyes Pigment. 2014, 109, 90–95. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J. Effect of titanium dioxide (TiO2) on largely improving solar reflectance and cooling property of high density polyethylene (HDPE) by influencing its crystallization behavior. J. Alloys Compd. 2014, 617, 163–169. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, S.; Sun, Y.; Zhou, C.; Bu, Y.; Chai, J. A novel model of mixed-particle coating for accurate performance quantifications at varying composition percentages. Int. J. Heat Mass Transf. 2022, 191, 122833. [Google Scholar] [CrossRef]

- You, Z.; Zhang, M.; Wang, J.; Pei, W. A black near-infrared reflective coating based on nano-technology. Energy Build. 2019, 205, 109523. [Google Scholar] [CrossRef]

- Baneshi, M.; Gonome, H.; Maruyama, S. Cool black roof impacts into the cooling and heating load demand of a residential building in various climates. Sol. Energy Mater. Sol. Cells 2016, 152, 21–33. [Google Scholar] [CrossRef]

- You, Z.; Zhang, M.; Wang, J.; Pei, W.; Li, G. Experimental study of optical and cooling performances of CuO and TiO2 near-infrared reflective blending coatings. Sol. Energy 2021, 225, 19–32. [Google Scholar] [CrossRef]

- Chaudhuri, R.G.; Paria, S. Core/Shell Nanoparticles: Classes, Properties, Synthesis Mechanisms, Characterization, and Applications. Chem. Rev. 2012, 112, 2373–2433. [Google Scholar] [CrossRef]

- Yao, B.; Geng, S.; Wang, J.; Wang, L. Synthesis, Characterization, and Optical Properties of Near-Infrared Reflecting Composite Inorganic Pigments Composed of TiO2/CuO Core–Shell Particles. Aust. J. Chem. 2018, 71, 373. [Google Scholar] [CrossRef]

- Hernández-Pérez, I.; Álvarez, G.; Xamán, J.; Zavala-Guillén, I.; Arce, J.; Simá, E. Thermal performance of reflective materials applied to exterior building components—A review. Energy Build. 2014, 80, 81–105. [Google Scholar] [CrossRef]

- Hernández-Pérez, I.; Xamán, J.; Macías-Melo, E.; Aguilar-Castro, K.; Zavala-Guillén, I.; Hernández-López, I.; Simá, E. Experimental thermal evaluation of building roofs with conventional and reflective coatings. Energy Build. 2018, 158, 569–579. [Google Scholar] [CrossRef]

- Oskooi, A.F.; Roundy, D.; Ibanescu, M.; Bermel, P.; Joannopoulos, J.D.; Johnson, S.G. Meep: A flexible free-software package for electromagnetic simulations by the FDTD method. Comput. Phys. Commun. 2010, 181, 687–702. [Google Scholar] [CrossRef]

- Dias, C.; Veloso, R.; Maia, J.; Ramos, N.; Ventura, J. Oversight of radiative properties of coatings pigmented with TiO2 nanoparticles. Energy Build. 2022, 271, 112296. [Google Scholar] [CrossRef]

- He, W.; Sun, H.; Zhou, Y.; Lu, K.; Xue, K.; Miao, X. Customized binary and multi-level HfO2-x-based memristors tuned by oxidation conditions. Sci. Rep. 2017, 7, 10070. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Wang, F.; Liu, H.; Li, J.; Niu, L. Synthesis and coloration of highly dispersed NiTiO3@TiO2 yellow pigments with core-shell structure. J. Eur. Ceram. Soc. 2017, 37, 2965–2972. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).