Quantitative and Qualitative Analysis of Applying Building Information Modeling (BIM) for Infrastructure Design Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Implications of BIM

2.2. Research Framework

2.2.1. Quantitative Measurements

2.2.2. Qualitative Measurements

3. Results

3.1. Quantitative Measures Results

3.2. Qualitative Measures Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Raja Mohd Noor, R.N.H.; Che Ibrahim, C.K.I.; Belayutham, S. The nexus of key attributes influencing the social collaboration among BIM actors: A review of construction literature. Int. J. Constr. Manag. 2021, 1–11. [Google Scholar] [CrossRef]

- Jo, J.; Choi, Y.W.; Lee, J.W.; Kim, H.Y. Using Survey information of BIM-applied Project—Construction Industry Specialist Interview. J. KIBIM 2020, 10, 33–42. [Google Scholar]

- Mesároš, P.; Smetanková, J.; Mandičák, T. The fifth dimension of BIM–implementation survey. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012003. [Google Scholar]

- Malik, Q.; Nasir, A.R.; Muhammad, R.; Thaheem, M.J.; Ullah, F.; Khan, K.I.A.; Hassan, M.U. BIMp-Chart—A Global Decision Support System for Measuring BIM Implementation Level in Construction Organizations. Sustainability 2021, 13, 9270. [Google Scholar] [CrossRef]

- Ahuja, R.; Sawhney, A.; Jain, M.; Arif, M.; Rakshit, S. Factors influencing BIM adoption in emerging markets–the case of India. Int. J. Constr. Manag. 2020, 20, 65–76. [Google Scholar] [CrossRef]

- Hong, Y.; Hammad, A.W.; Akbarnezhad, A. Impact of organization size and project type on BIM adoption in the Chinese construction market. Constr. Manag. Econ. 2019, 37, 675–691. [Google Scholar] [CrossRef]

- Enshassi, A.A.; Hamra, L.A.A.; Alkilani, S. Studying the Benefits of Building Information Modeling (BIM) in Architecture, Engineering and Construction (AEC) Industry in the Gaza Strip. Jordan J. Civ. Eng. 2018, 12, 87–98. [Google Scholar]

- Kim, J.-U.; Hadadi, O.; Kim, H.; Kim, J. Development of A BIM-Based Maintenance Decision-Making Framework for the Optimization between Energy Efficiency and Investment Costs. Sustainability 2018, 10, 2480. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.; Costin, A.M.; Karimi, R.; Shirowzhan, S.; Abbasian, E.; Li, J. BIM and Digital Tools for State-of-the-Art Construction Cost Management. Buildings 2022, 12, 396. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Wright, G.; Cheng, J.C.; Li, X.; Liu, R. A state-of-the-art review on the integration of Building Information Modeling (BIM) and Geographic Information System (GIS). ISPRS Int. J. Geo-Inf. 2017, 6, 53. [Google Scholar] [CrossRef]

- Pishdad-Bozorgi, P. Future smart facilities: State-of-the-art BIM-enabled facility management. J. Constr. Eng. Manag. 2017, 143, 02517006. [Google Scholar] [CrossRef]

- Sacks, R.; Bloch, T.; Katz, M.; Yosef, R. Automating design review with artificial intelligence and BIM: State of the art and research framework. In Proceedings of the ASCE International Conference on Computing in Civil Engineering 2019, Atlanta, GA, USA, 17–19 June 2019; pp. 353–360. [Google Scholar]

- Chang, Y.-T.; Hsieh, S.-H. A review of Building Information Modeling research for green building design through building performance analysis. J. Inf. Technol. Constr. 2020, 25, 1–40. [Google Scholar] [CrossRef]

- Xia, H.; Liu, Z.; Maria, E.; Liu, X.; Lin, C. Study on City Digital Twin Technologies for Sustainable Smart City Design: A Review and Bibliometric Analysis of Geographic Information System and Building Information Modeling Integration. Sustain. Cities Soc. 2022, 84, 104009. [Google Scholar] [CrossRef]

- Teng, Y.; Xu, J.; Pan, W.; Zhang, Y. A systematic review of the integration of building information modeling into life cycle assessment. Build. Environ. 2022, 221, 109260. [Google Scholar] [CrossRef]

- Manzoor, B.; Othman, I.; Gardezi, S.S.S.; Harirchian, E. Strategies for adopting building information modeling (Bim) in sustainable building projects—A case of Malaysia. Buildings 2021, 11, 249. [Google Scholar] [CrossRef]

- Gupta, S.; Jha, K.N.; Vyas, G. Proposing building information modeling-based theoretical framework for construction and demolition waste management: Strategies and tools. Int. J. Constr. Manag. 2020, 22, 1–11. [Google Scholar] [CrossRef]

- Schiavi, B.; Havard, V.; Beddiar, K.; Baudry, D. BIM data flow architecture with AR/VR technologies: Use cases in architecture, engineering and construction. Autom. Constr. 2022, 134, 104054. [Google Scholar] [CrossRef]

- Kang, K.-Y.; Wang, X.; Wang, J.; Xu, S.; Shou, W.; Sun, Y. Utility of BIM-CFD Integration in the Design and Performance Analysis for Buildings and Infrastructures of Architecture, Engineering and Construction Industry. Buildings 2022, 12, 651. [Google Scholar] [CrossRef]

- do Carmo, C.S.T.; Sotelino, E.D. A framework for architecture and structural engineering collaboration in BIM projects through structural optimization. J. Inf. Technol. Constr. (ITcon) 2022, 27, 223–239. [Google Scholar]

- Banerjee, A.; Nayaka, R.R. A comprehensive overview on BIM-integrated cyber physical system architectures and practices in the architecture, engineering and construction industry. Constr. Innov. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- ISO. Organization and Digitization of Information about Buildings and Civil Engineering Works, Including Building Information Modelling (BIM); BSI: London, UK, 2018. [Google Scholar]

- Edirisinghe, R.; London, K. Comparative analysis of international and national level BIM standardization efforts and BIM adoption. In Proceedings of the 32nd CIB W78 Conference, Eindhoven, The Netherlands, 27–29 October 2015. [Google Scholar]

- Nam, J.; Kim, M.J. Object-oriented Road Field BIM Standard Object Classification System Suggest Development Plan. J. Korea Acad.-Ind. Coop. Soc. 2018, 19, 119–129. [Google Scholar]

- Musa, S.; Marshall-Ponting, A.; Nifa, F.A.A.; Shahron, S.A. Building information modeling (BIM) in Malaysian construction industry: Benefits and future challenges. In AIP Conference Proceedings; AIP Publishing LLC: New York, NY, USA, 2018. [Google Scholar]

- Yang, J.-B.; Chou, H.-Y. Mixed approach to government BIM implementation policy: An empirical study of Taiwan. J. Build. Eng. 2018, 20, 337–343. [Google Scholar] [CrossRef]

- Liao, L.; Zhou, K.; Fan, C.; Ma, Y. Evaluation of Complexity Issues in Building Information Modeling Diffusion Research. Sustainability 2022, 14, 3005. [Google Scholar] [CrossRef]

- Ozturk, G.B. Interoperability in building information modeling for AECO/FM industry. Autom. Constr. 2020, 113, 103122. [Google Scholar] [CrossRef]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Liu, Z. Combining multi-criteria decision making (MCDM) methods with building information modelling (BIM): A review. Autom. Constr. 2021, 121, 103451. [Google Scholar] [CrossRef]

- Lee, S.; Tae, S.; Kim, S.R.T. Green template for life cycle assessment of buildings based on building information modeling: Focus on embodied environmental impact. Sustainability 2015, 7, 16498–16512. [Google Scholar] [CrossRef]

- Doumbouya, L.; Gao, G.; Guan, C. Adoption of the Building Information Modeling (BIM) for Construction Project Effectiveness: The Review of BIM Benefits. Am. J. Civ. Eng. Archit. 2016, 4, 74–79. [Google Scholar]

- Terreno, S.; Anumba, C.J.; Gannon, E.; Dubler, C. The benefits of BIM integration with facilities management: A preliminary case study. Comput. Civ. Eng. 2015, 675–683. [Google Scholar] [CrossRef]

- Tomek, A.; Matějka, P. The impact of BIM on risk management as an argument for its implementation in a construction company. Procedia Eng. 2014, 85, 501–509. [Google Scholar] [CrossRef]

- Lee, J. Environmental Factors of Acceptance Organization Affecting Intention to Accept Bim. Int. J. Manag. 2020, 11, 188–200. [Google Scholar]

- Li, J.; Hou, L.; Wang, X.; Wang, J.; Guo, J.; Zhang, S.; Jiao, Y. A project-based quantification of BIM benefits. Int. J. Adv. Robot. Syst. 2014, 11, 123–131. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

| BIM Use | Firms | Project Type | Total Project Length | Total Project Duration | Total No. of Professional Engineers | No. of Professional BIM Engineers | Project Location |

|---|---|---|---|---|---|---|---|

| BIM | A | Subway Extension | 1.96 km | 60 months | 51 | 15 | Seoul Vicinity |

| B | 5.21 km | 95 months | 78 | 18 | In Seoul | ||

| C | 1.73 km | 60 months | 48 | 12 | Seoul Vicinity | ||

| Non-BIM | D | 2.15 km | 60 months | 60 | N/A | Daejeon Vicinity | |

| E | 4.97 km | 95 months | 85 | In Seoul | |||

| F | 1.81 km | 60 months | 50 | Seoul Vicinity |

| Quantitative Measures | |

| Categories | Areas of Questions |

| Planning Stage | Planned budget for design and planning stage |

| BIM Modeling | Man-hours for creating BIM modeling based on different LODs |

| Error-processing time and labor force required for BIM modeling | |

| Man-hours and the amount of labor required for the design phase | |

| Labor charges for BIM coordination | |

| Man-hours for model checks and quality management | |

| Total working hours to create BIM models | |

| Education and Support | Hours of education for BIM utilization |

| Initial investment for BIM adoption | |

| Types of software and the cost of maintaining it | |

| Relevant Meetings | Additional meetings required when using BIM |

| Meetings required for error and interference checks for BIM models | |

| Qualitative Measures | |

| Categories | Areas of Questions |

| Product LOD | LOD of the final model compared to the initial plan |

| Final LOD of the BIM model | |

| LOD for BIM utilizations | |

| Design Errors and Difficulties | Reasons for errors during BIM modeling during design stage |

| Expected problems during BIM modeling during design stage | |

| Coordination issues | |

| Budget Changes during BIM Application | How to achieve a successful BIM working environment |

| Satisfaction rate from client side | |

| Benefits of using BIM compared to a traditional working environment | |

| Types of BIM experts inside firms | |

| Guidelines | Existence of guidelines for BIM utilization |

| Utilization process for BIM in design stage | |

| Measurement Equations | |

|---|---|

| Categories | Areas of Questions |

| Planning Stage | Planned budget = base cost + (labor charges × man-hours) |

| BIM Modeling (Design of non-BIM) | Drawing and scheduling = labor charges based on LOD × man-hours |

| Design cost = labor charges based on skill level × man-hours | |

| Modeling cost = labor charges based on skill level × man-hours | |

| Model check and quality control = labor charges based on skill level × man-hours | |

| Education and Support (Not applicable to non-BIM) | BIM education = number of education × instructor fees |

| BIM initial cost = software charges + hardware charges + upgrade costs | |

| BIM maintenance cost = (software + hardware maintenance) × number of years | |

| Relevant Meetings | Emergency meetings = number of unexpected meetings × unit price × number of participants |

| Model check meetings = number of unexpected meetings × unit price × number of participants | |

| Item | Code | Descriptions | Firm A | Firm B | Firm C | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Man-Hours (days) | No. of Laborers | Cost Estimates (USD) | Man-Hours (days) | No. of Laborers | Cost Estimates (USD) | Man-Hours (days) | No. of Laborers | Cost Estimates (USD) | |||

| Planning | (a) | Plan management | 3.3 | 1 | 8000 | 5 | 2 | 17,000 | 3.3 | 1 | 15,000 |

| BIM Modeling | (b) | Drawing and scheduling | 70 | 4 | 14,000 | 60 | 2 | 40,000 | 70 | 4 | 26,500 |

| (c) | Design stage | 30 | 2 * | 94,000 | 60 | 1 * | 168,000 | 30 | 1 * | 70,000 | |

| 30 | 3 ** | 90 | 2 ** | 30 | 2 ** | ||||||

| 30 | 2 *** | 60 | 2 *** | 30 | 2 *** | ||||||

| (d) | Model coordination | 30 | 10 | 50,000 | 90 | 4 | 72,000 | 30 | 7 | 70,000 | |

| (e) | Model checks and quality control | 7 | 2 | 10,000 | 30 | 2 | 12,000 | 1.6 | 2 | 5000 | |

| Education and Support | (f) | BIM education | 0.2 | 5 | 3000 | 0.3 | 2 | 900 | 1.6 | 6 | 2500 |

| (g) | BIM initial investment | N/A | 10,000 | N/A | 68,000 | N/A | 10,000 | ||||

| (h) | Maintenance costs | 20,000/yr | 20,000/yr | 30,000/yr | |||||||

| Relevant Meetings | (i) | Emergency meetings | 0.4 | 2 | 600 | 0.1 | 2 | 600 | 0.1 | 2 | 1200 |

| (j) | Model check meetings | 0.5 | 2 | 1200 | 0.1 | 2 | 1200 | 0.3 | 2 | 4800 | |

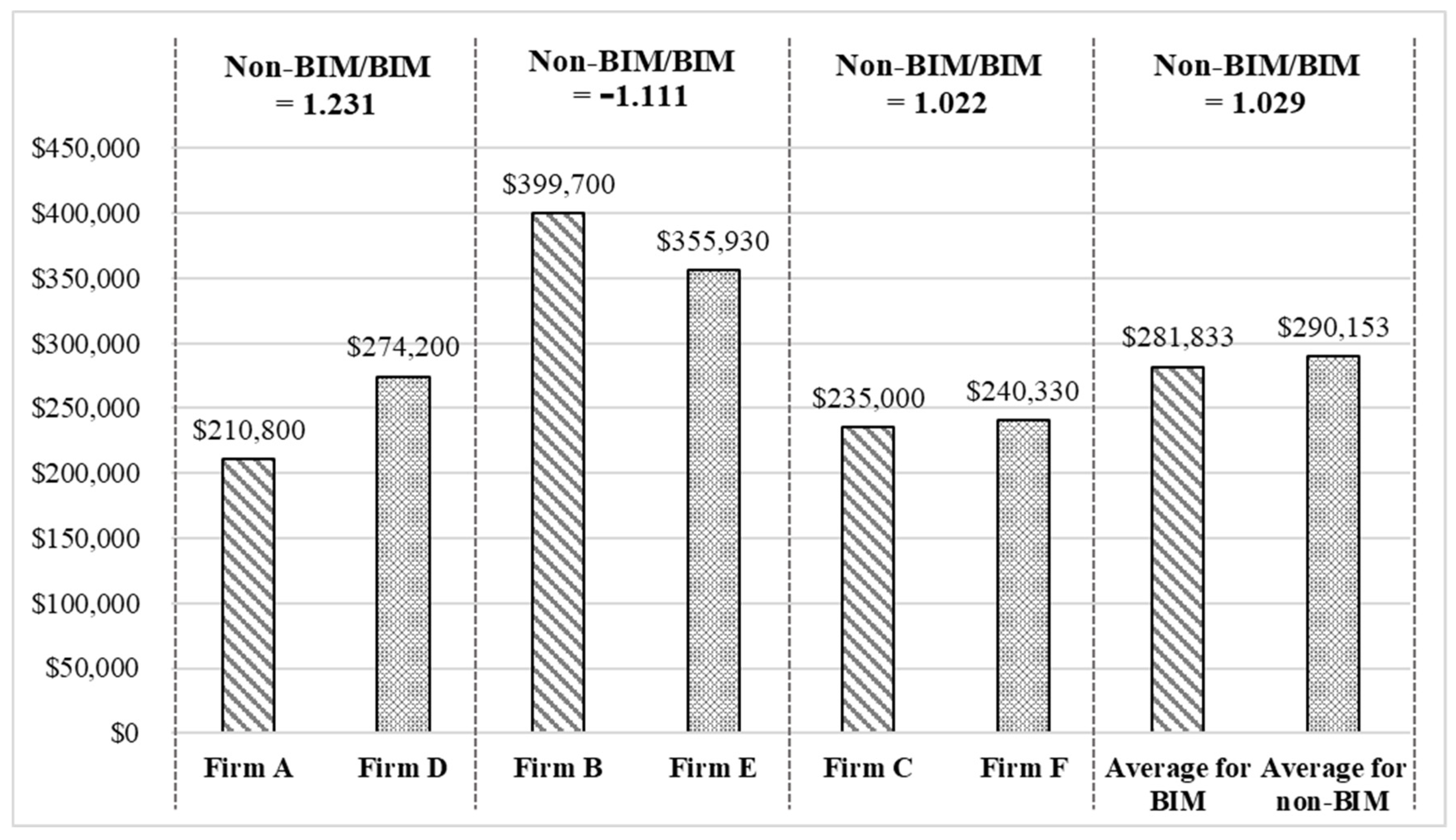

| Total | 201.4 | 33 | 210,800 | 395.5 | 21 | 410,500 | 196.9 | 29 | 235,000 | ||

| Average for three firms | 263.6 days/27.7 men/USD 283,285 | ||||||||||

| Item | Code | Descriptions | Firm D | Firm E | Firm F | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Man-Hours (days) | No. of Laborers | Cost Estimates (USD) | Man-Hours (days) | No. of Laborers | Cost Estimates (USD) | Man-Hours (days) | No. of Laborers | Cost Estimates (USD) | |||

| Planning | (a) | Plan management | 1.0 | 1 * | 11,000 | 2 | 2 * | 11,000 | 4.5 | 2 * | 12,000 |

| Design Drawings | (b) | Drawing and scheduling | 90 | 2 * | 24,000 | 80 | 2 * 1 ** | 28,000 | 60 | 2 ** | 16,000 |

| (c) | Design stage | 100 | 10 * | 159,000 | 300 | 6 * 2 ** | 270,000 | 210 | 7 * 1 ** | 175,000 | |

| (d) | Detail drawing | 40 | 12 * | 63,600 | 100 | 2 ** 1 ** | 35,000 | 60 | 4 * 1 ** | 32,000 | |

| (e) | Drawing checks and quality control | 10 | 10 * | 13,300 | 20 | 5 * | 10,000 | 10 | 3 * | 3000 | |

| Relevant Meetings | (i) | Emergency meetings | 3 | 1 ** 1 *** | 1250 | 2 | 2 ** | 600 | 3 | 1 * 2 ** | 1100 |

| (j) | Drawing check meetings | 3 | 2 * 1 ** 1 *** | 2050 | 3.3 | 1 * 2 ** | 1330 | 2.3 | 2 ** | 1230 | |

| Total | 247 | 41 | 274,200 | 507.3 | 26 | 355,930 | 349.8 | 25 | 240,330 | ||

| Average for three firms | 368.1 days/30.7 men/USD 290,153 | ||||||||||

| Items | Descriptions | Results | |||

|---|---|---|---|---|---|

| Firm A | Firm B | Firm C | Firm D | ||

| Product LODs | BIM utilization rate based on the initial plan |

|

|

|

|

| Planned LOD |

|

|

|

| |

| Final LOD |

|

|

|

| |

| Issues in BIM Designing | Main reasons for BIM errors |

|

|

|

|

| Expected problems with BIM errors |

|

|

|

| |

| Coordination issues |

|

|

|

| |

| Financial Risk in BIM Use | BIM coordinating costs |

|

|

|

|

| Reasons for changes in man-hours |

|

|

|

| |

| Initial investment in BIM implementation |

|

|

|

| |

| Benefits and Advantages of using BIM | Requests for more effective BIM usage |

|

|

|

|

| Satisfaction level of clients |

|

|

|

| |

| Advantages of using BIM |

|

|

|

| |

| Types of BIM experts in firms |

|

|

|

| |

| BIM Guidelines | Guidelines for using BIM |

|

|

|

|

| BIM implementation point |

|

|

|

| |

| (In USD) | Planning Stage | BIM Modeling | Design Drawings | Education and Support | Relevant Meetings | Total | |

|---|---|---|---|---|---|---|---|

| BIM Projects | Firm A | 8000 | 168,000 | N/A | 33,000 | 1800 | 210,800 |

| Firm B | 17,000 | 292,000 | N/A | 88,900 | 1800 | 399,700 | |

| Firm C | 15,000 | 171,500 | N/A | 42,500 | 6000 | 235,000 | |

| Average | 13,333 | 210,500 | N/A | 54,800 | 3200 | 281,833 | |

| Non-BIM Projects | Firm D | 11,000 | N/A | 259,900 | N/A | 3300 | 274,200 |

| Firm E | 11,000 | N/A | 343,000 | N/A | 1930 | 355,930 | |

| Firm F | 12,000 | N/A | 226,000 | N/A | 2330 | 240,330 | |

| Average | 11,333 | N/A | 276,300 | N/A | 2520 | 290,153 | |

| Planning Stage | BIM Modeling | Design Drawings | Education and Support | Relevant Meetings | Total | |||

|---|---|---|---|---|---|---|---|---|

| BIM Projects | Firm A | Man-hours | 3.3 | 197 | N/A | 0.2 | 0.9 | 201.4 |

| Laborers | 1 | 23 | N/A | 5 | 4 | 33 | ||

| Firm B | Man-hours | 5 | 390 | N/A | 0.3 | 0.2 | 395.5 | |

| Laborers | 2 | 13 | N/A | 2 | 4 | 21 | ||

| Firm C | Man-hours | 3.3 | 191.6 | N/A | 1.6 | 0.4 | 196.9 | |

| Laborers | 1 | 18 | N/A | 6 | 4 | 29 | ||

| Average | Man-hours | 3.9 | 259.5 | N/A | 0.7 | 0.5 | 264.6 | |

| Laborers | 1.3 | 18 | N/A | 4.3 | 3 | 27.7 | ||

| Non-BIM Projects | Firm D | Man-hours | 1 | N/A | 240 | N/A | 6 | 247 |

| Laborers | 1 | N/A | 34 | N/A | 6 | 41 | ||

| Firm E | Man-hours | 2 | N/A | 500 | N/A | 5.3 | 507.3 | |

| Laborers | 2 | N/A | 19 | N/A | 5 | 26 | ||

| Firm F | Man-hours | 4.5 | N/A | 340 | N/A | 5.3 | 349.8 | |

| Laborers | 2 | N/A | 18 | N/A | 5 | 25 | ||

| Average | Man-hours | 2.5 | N/A | 360 | N/A | 5.5 | 368.1 | |

| Laborers | 1.7 | N/A | 23.7 | N/A | 5.3 | 30.7 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, M.-H.; Jung, J.-H.; Kim, H.-Y. Quantitative and Qualitative Analysis of Applying Building Information Modeling (BIM) for Infrastructure Design Process. Buildings 2022, 12, 1476. https://doi.org/10.3390/buildings12091476

Shin M-H, Jung J-H, Kim H-Y. Quantitative and Qualitative Analysis of Applying Building Information Modeling (BIM) for Infrastructure Design Process. Buildings. 2022; 12(9):1476. https://doi.org/10.3390/buildings12091476

Chicago/Turabian StyleShin, Min-Ho, Ji-Hyun Jung, and Hwan-Yong Kim. 2022. "Quantitative and Qualitative Analysis of Applying Building Information Modeling (BIM) for Infrastructure Design Process" Buildings 12, no. 9: 1476. https://doi.org/10.3390/buildings12091476

APA StyleShin, M.-H., Jung, J.-H., & Kim, H.-Y. (2022). Quantitative and Qualitative Analysis of Applying Building Information Modeling (BIM) for Infrastructure Design Process. Buildings, 12(9), 1476. https://doi.org/10.3390/buildings12091476