Investigation of Mineral Admixtures on Mechanical Properties of Alkali-Activated Recycled Concrete Powders Cement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Methods

3. Results

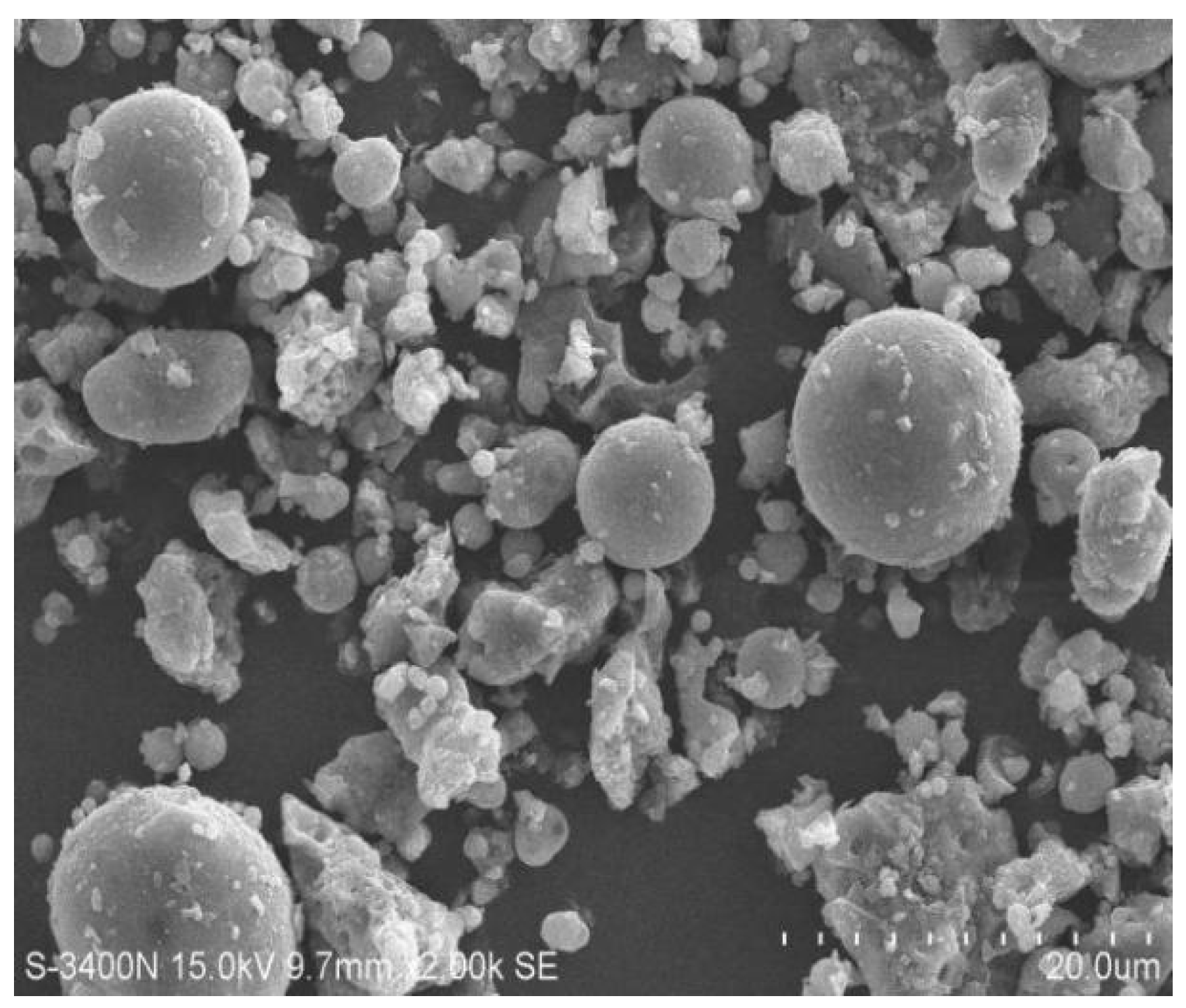

3.1. Fly Ash

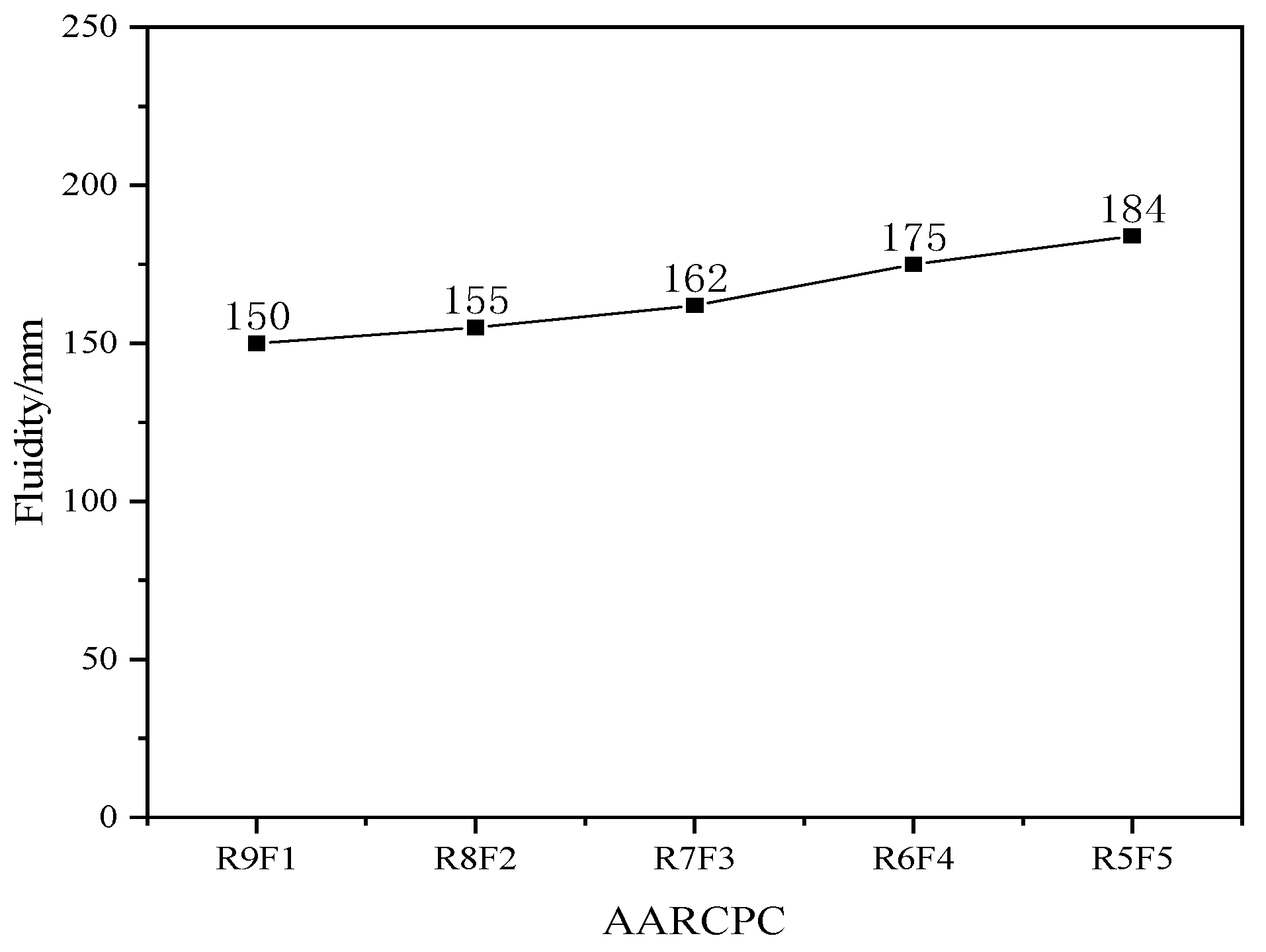

3.1.1. Fluidity

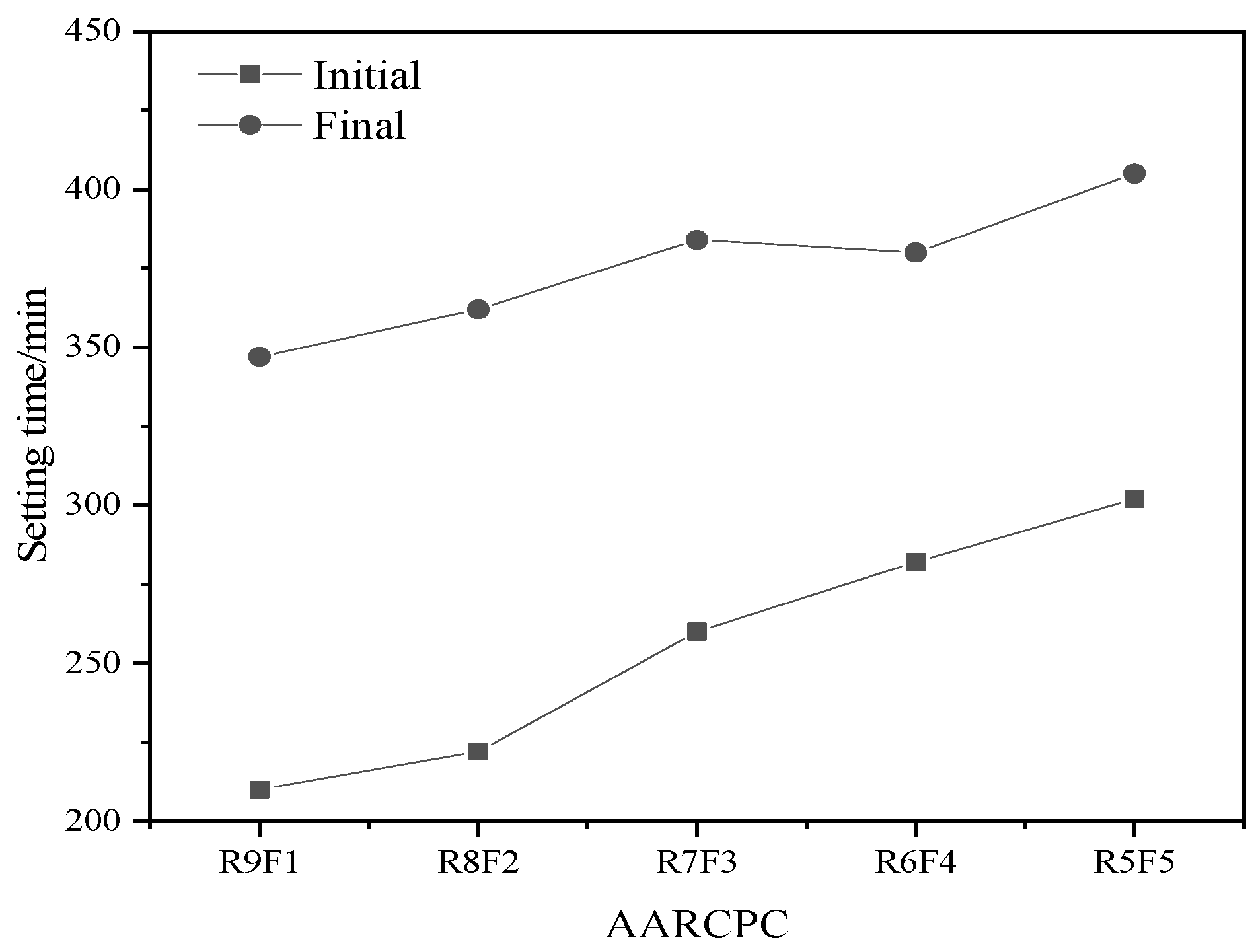

3.1.2. Setting Time

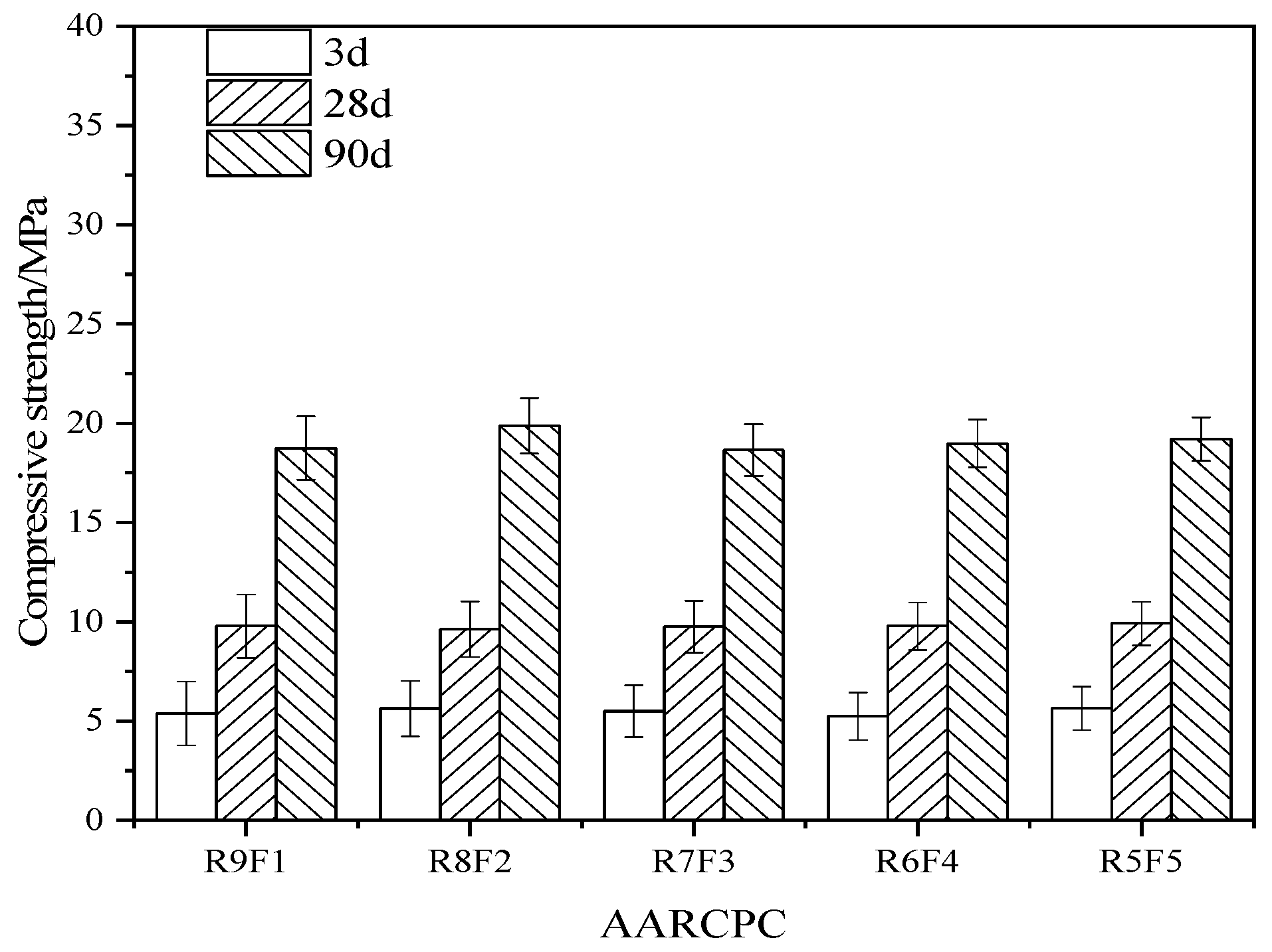

3.1.3. Strength

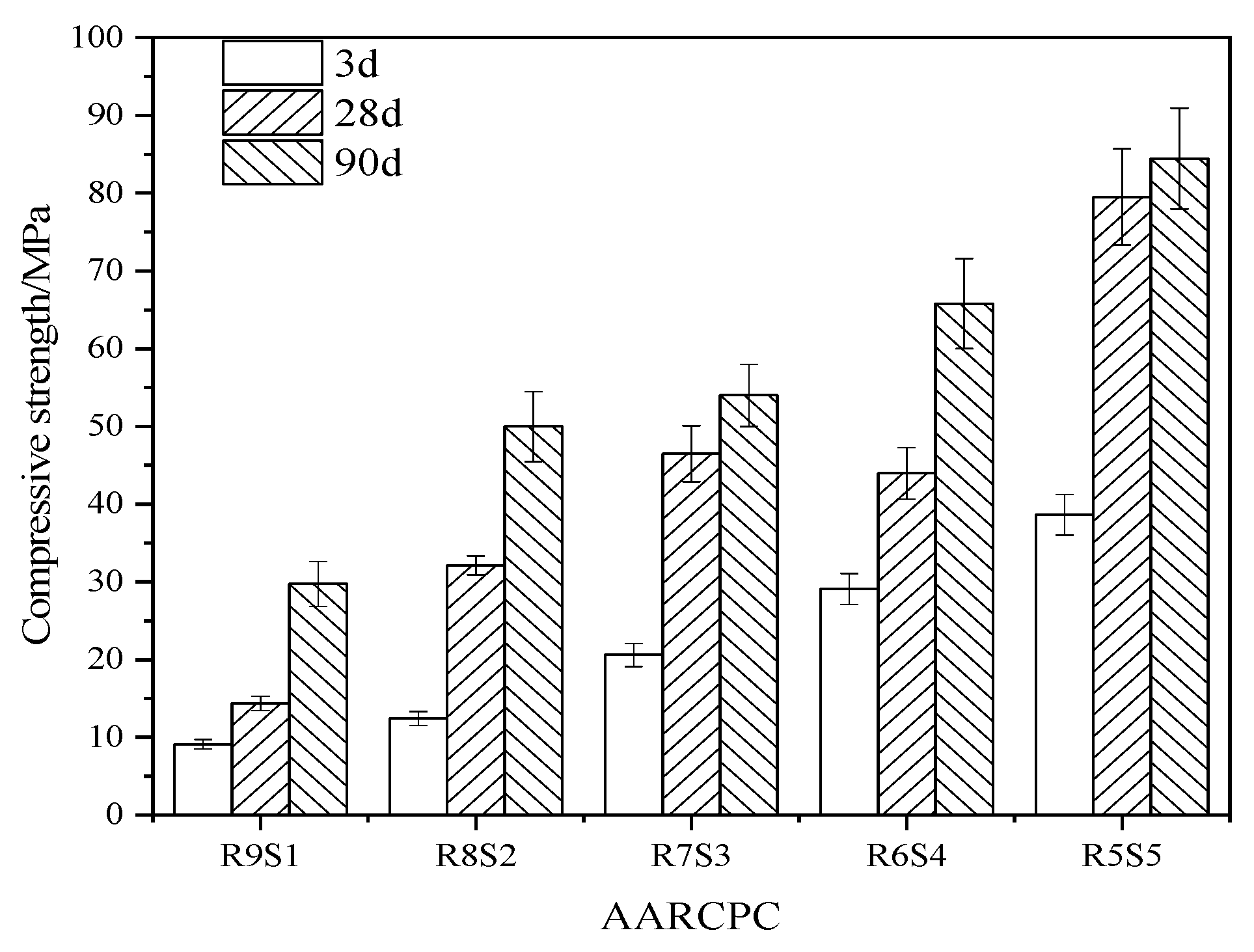

3.2. Slag

3.2.1. Fluidity

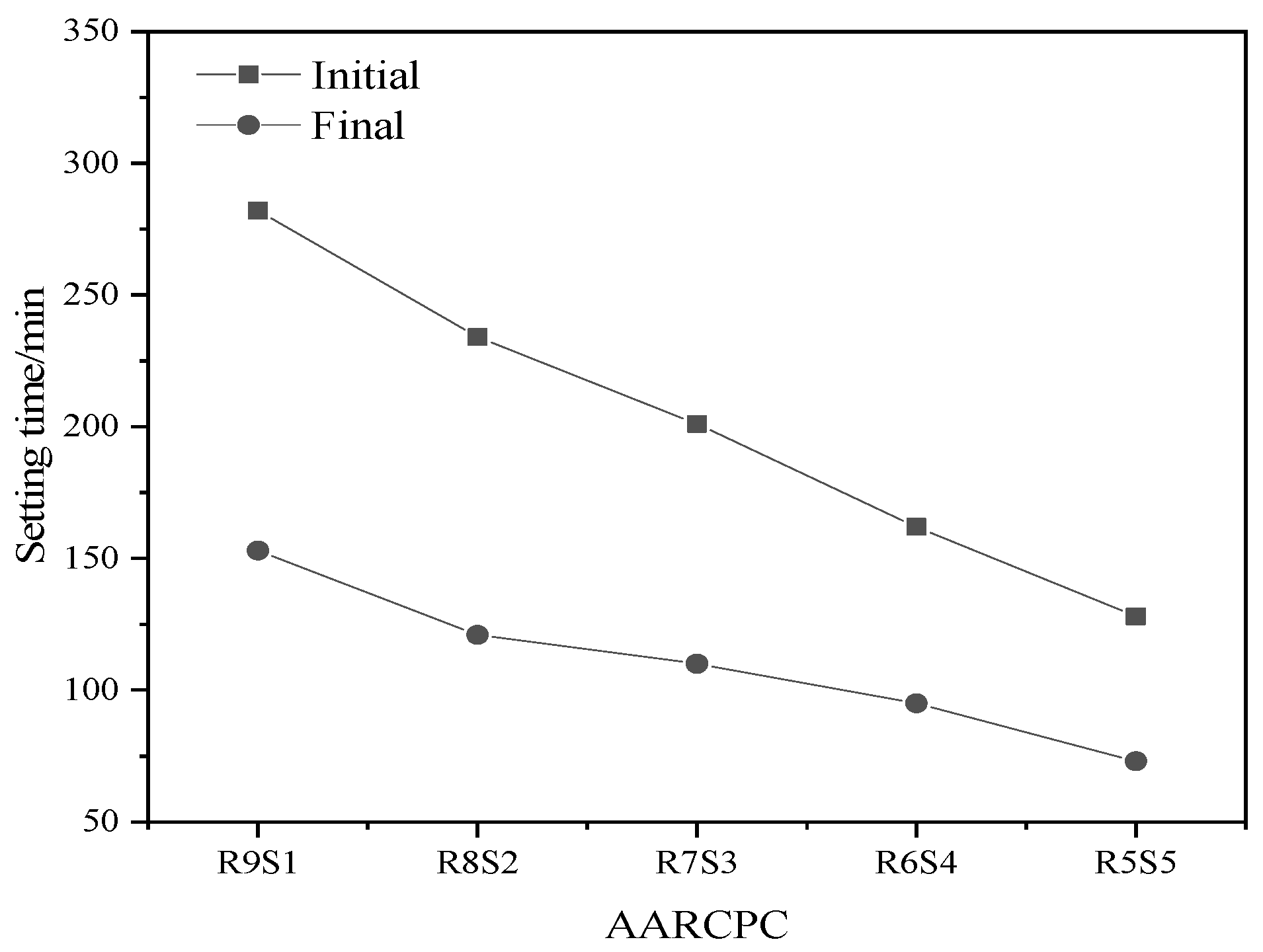

3.2.2. Setting Time

3.2.3. Strength

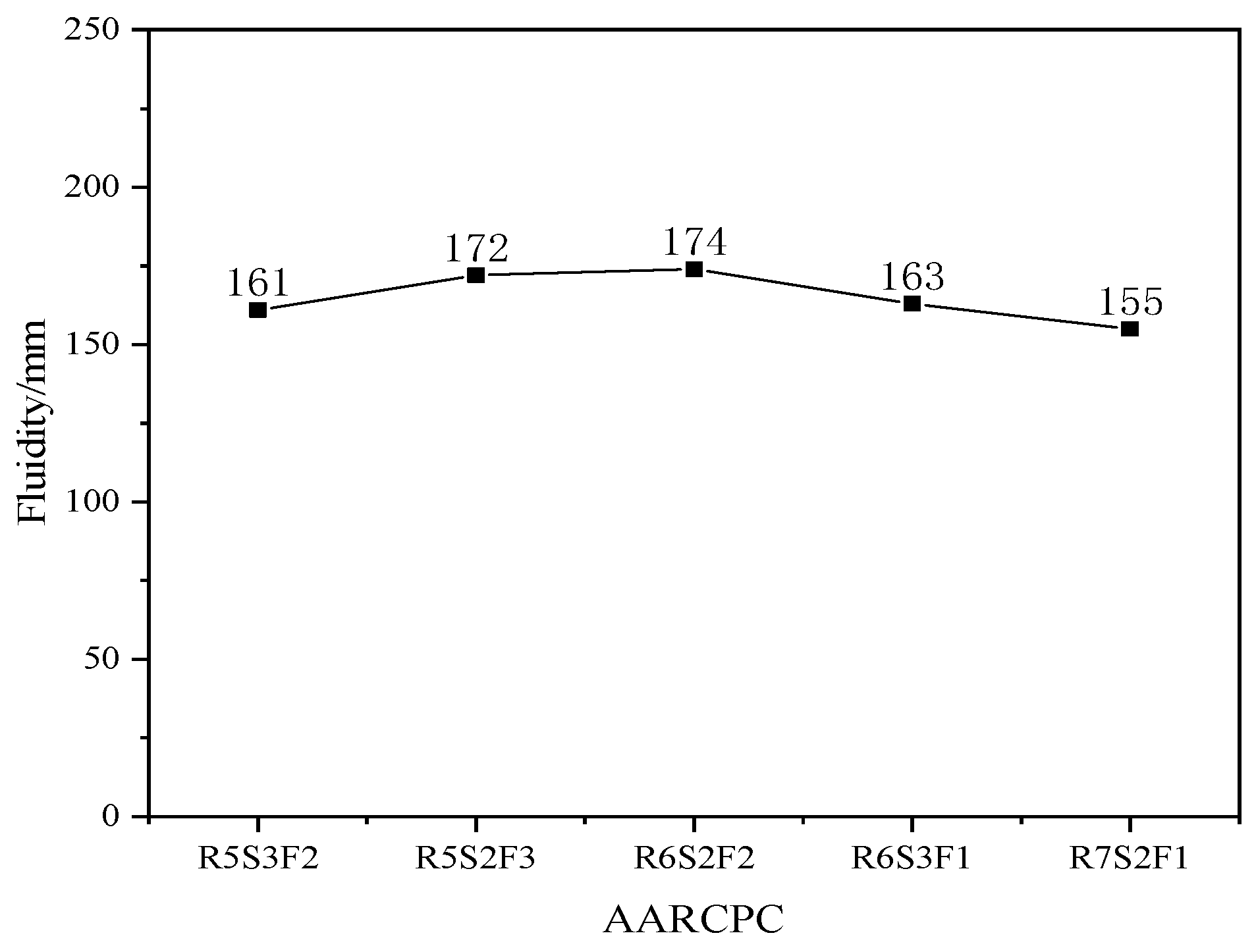

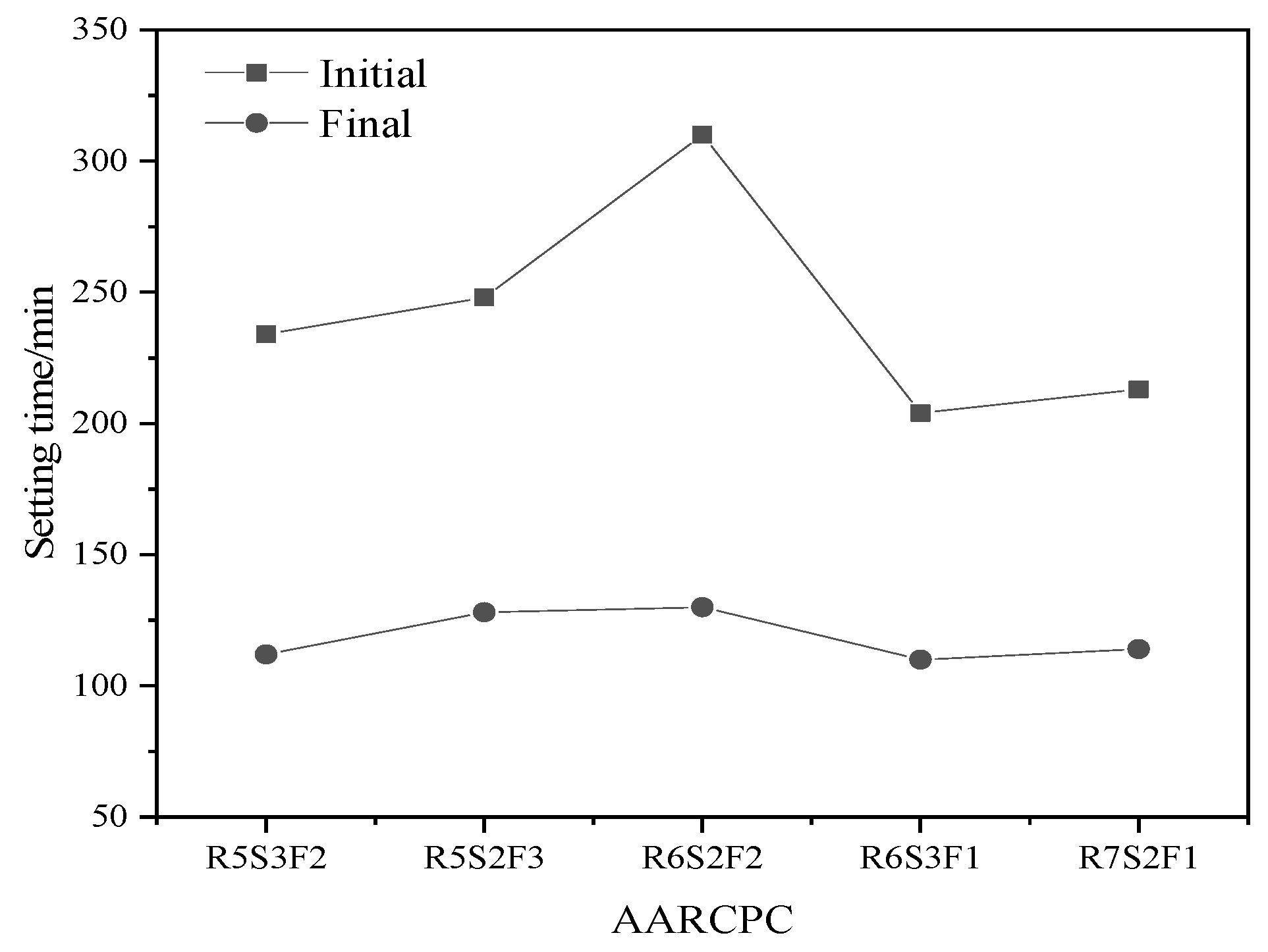

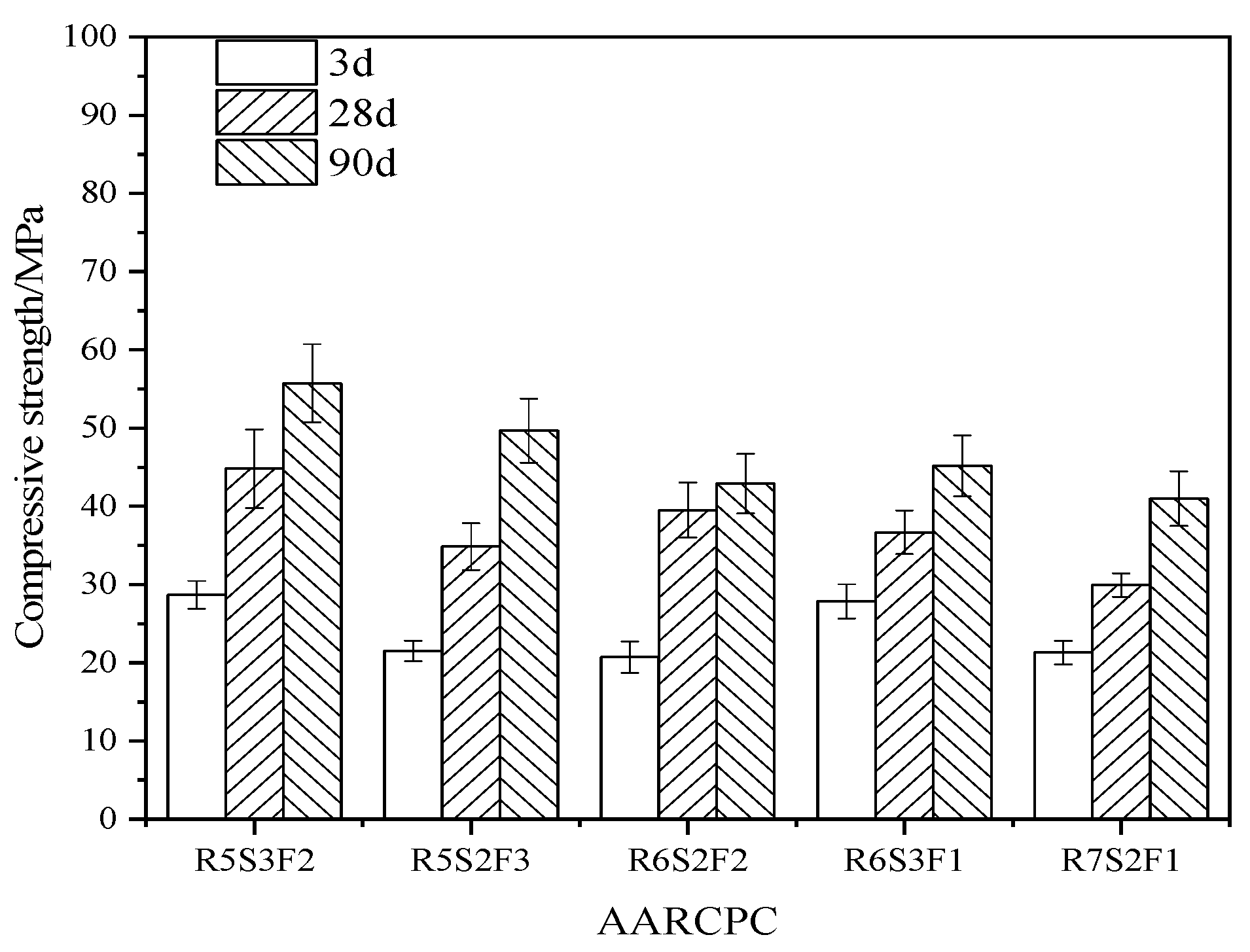

3.3. Composite Fly Ash and Slag

3.3.1. Fluidity

3.3.2. Setting Time

3.3.3. Strength

3.4. Micro-Structure

3.4.1. FTIR

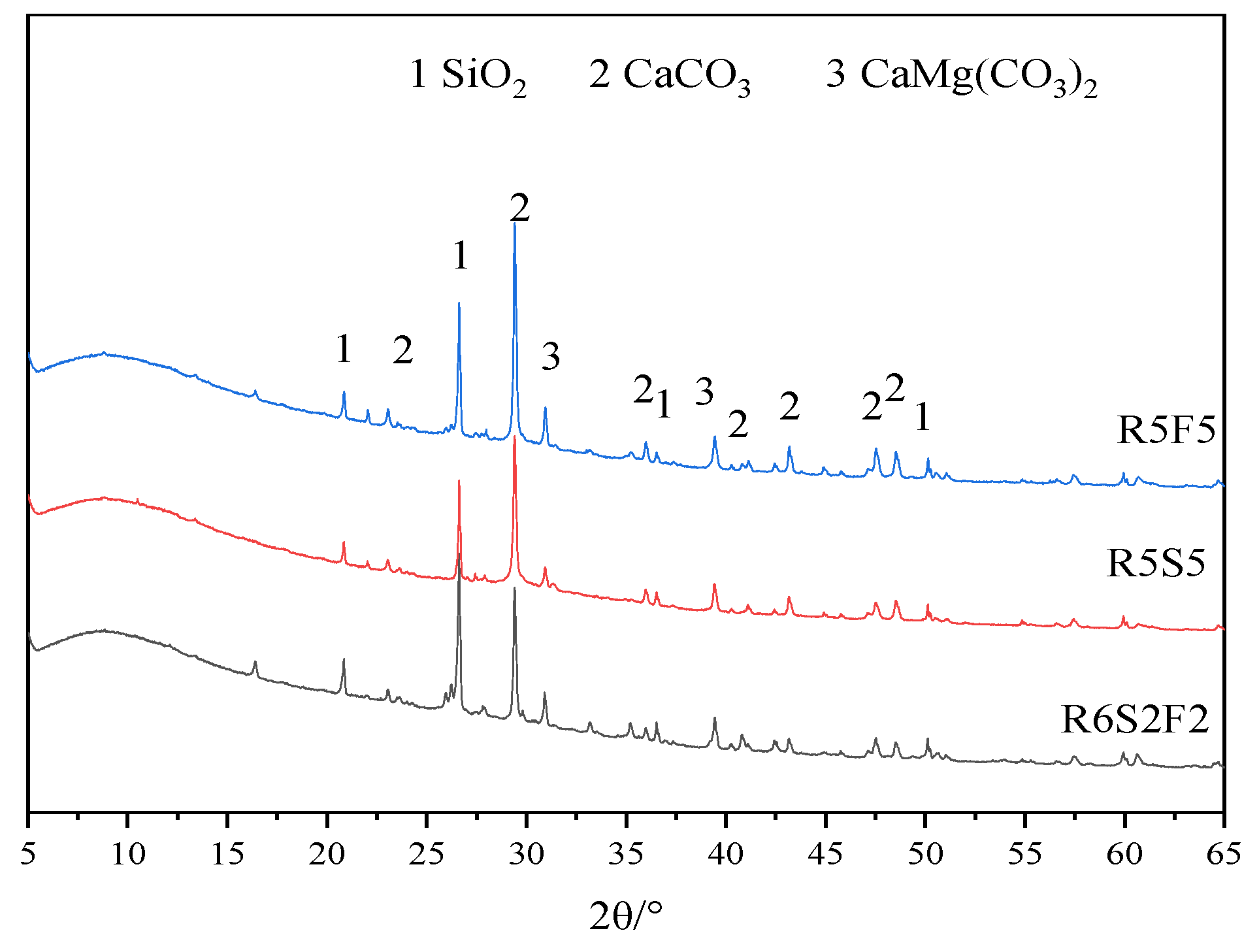

3.4.2. XRD

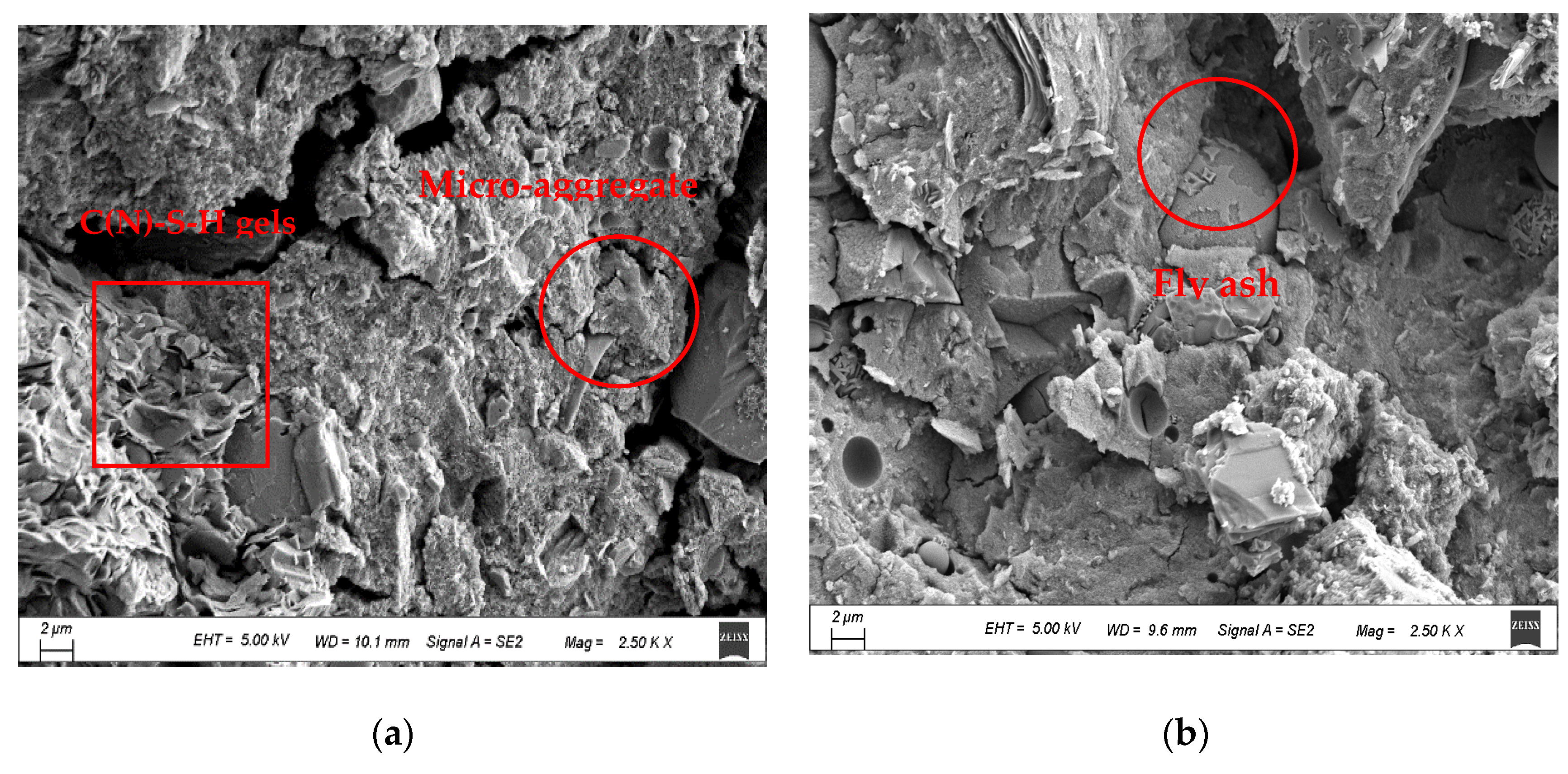

3.4.3. SEM

4. Discussion

4.1. Effect of Fly Ash on Hydration and Hardening of AARCPC

4.2. Effect of Slag on Hydration and Hardening of AARCPC

5. Conclusions

- (1)

- The addition of fly ash prolongs the setting time of cementitious materials to a certain extent and increases fluidity but does not significantly improve the strength of the pastes at various ages. When the fly ash content was 50%, the 90 d compressive strength was 19.2 MPa.

- (2)

- The addition of slag can also increase fluidity, and it shortens the setting time. Most importantly, slag significantly improves the strength of the pastes at various ages. When the slag content was 50%, the 3 d, 28 d and 90 d compressive strength values were 38.6 MPa, 79.5 MPa and 84.4 MPa, respectively.

- (3)

- The mechanical properties and workability of the pastes were the strongest when 60% RCP was mixed with 20% slag and 20% fly ash. The fluidity was 174 mm, the initial setting time was 130 min and the final setting time was 310 min. The 3 d, 28 d and 90 d compressive strength values were 20.7 MPa, 39.5 MPa and 42.9 MPa, respectively.

- (4)

- The strength and workability of AARCPC can be controlled by adjusting the proportion of mineral admixtures content. AARCPC has the potential to replace Portland cement and can be applied to concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, Q.; Ma, Z.M.; Wu, H.X.A.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Xu, J.; Kang, A.H.; Wu, Z.G.; Gong, Y.F.; Xiao, P. The effect of mechanical-thermal synergistic activation on the mechanical properties and microstructure of recycled powder geopolymer. J. Clean. Prod. 2021, 327, 129477. [Google Scholar] [CrossRef]

- Polyka, B.; Martin, C.; Priscillia, L.; Kim, N.B.; Rachida, I. Concrete made of 100% recycled materials—Feasibility study. Resour. Conserv. Recycl. 2022, 180, 106199. [Google Scholar]

- Sergio, M.; Sergio, L.; Fernando, P.T.; Adelino, L. Advantages and shortcomings of the utilization of recycled wastes as aggregates in structural concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar]

- Jan, F.; Eva, V.; Dana, K.; Nikol, A.; Monika, C.; Martin, K.; Pavla, R.; Robert, C. Application of waste brick powder in alkali activated aluminosilicates: Functional and environmental aspects. J. Clean. Prod. 2018, 194, 714–725. [Google Scholar]

- Ye, T.H.; Xiao, J.Z.; Duan, Z.H.; Li, S.S. Geopolymers made of recycled brick and concrete powder—A critical review. Constr. Build. Mater. 2022, 330, 127232. [Google Scholar] [CrossRef]

- Tang, Y.X.; Xiao, J.Z.; Zhang, H.H.; Duan, Z.H.; Xia, B. Mechanical properties and uniaxial compressive stress-strain behavior of fully recycled aggregate concrete. Constr. Build. Mater. 2022, 323, 126546. [Google Scholar] [CrossRef]

- Bolborea, B.; Baera, C.; Dan, S.; Gruin, A.; Burduhos-Nergis, D.-D.; Vasile, V. Concrete Compressive Strength by Means of Ultrasonic Pulse Velocity and Moduli of Elasticity. Materials 2021, 14, 7018. [Google Scholar] [CrossRef]

- Liu, X.Y.; Liu, L.L.; Yu, K.; Li, T.Y.; Zhao, P.Z.; Liu, R.D.; Zuo, J.Q.; Fu, F.; Shah, S.P. Enhanced early hydration and mechanical properties of cement-based materials with recycled concrete powder modified by nano-silica. J. Build. Eng. 2022, 50, 104175. [Google Scholar] [CrossRef]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- Naganna, S.R.; Jayakesh, K.; Anand, V.R. Nano-TiO2 particles: A photocatalytic admixture to amp up the performance effificiency of cementitious composite. Sādhanā 2022, 45, 280. [Google Scholar] [CrossRef]

- Ramesh, B.M.; Vongole, R.M.; Nagraj, Y.; Naganna, S.R.; Sreedhara, B.M.; Mailar, G.; Ramesh, P.S.; Yaseen, Z.M. Valorization of incinerator bottom ash for the production of resource-effiffifficient eco-friendly concrete: Performance and toxicological characterization. Archit. Stu. Constr. 2021, 1, 65–78. [Google Scholar] [CrossRef]

- Kim, J.; Jang, H. Closed-loop recycling of C&D waste: Mechanical properties of concrete with the repeatedly recycled C&D powder as partial cement replacement. J. Clean. Prod. 2022, 343, 130977. [Google Scholar]

- Yang, D.Y.; Liu, M.; Zhang, Z.B.; Yao, P.P.; Ma, Z.M. Properties and modification of sustainable foam concrete including eco-friendly recycled powder from concrete waste. Case. Stu. Constr. Mater. 2022, 16, 00826. [Google Scholar] [CrossRef]

- Chen, X.Y.; Zhang, D.; Cheng, S.K.; Xu, X.; Zhao, C.; Wang, X.Q.; Wu, Q.Y.; Bai, X.X. Sustainable reuse of ceramic waste powder as a supplementary cementitious material in recycled aggregate concrete: Mechanical properties, durability and microstructure assessment. J. Build. Eng. 2022, 52, 104418. [Google Scholar] [CrossRef]

- Ma, Z.M.; Li, W.; Wu, H.X.; Cao, C.W. Chloride permeability of concrete mixed with activity recycled powder obtained from C&D waste. Constr. Build. Mater. 2019, 199, 652–663. [Google Scholar]

- Xiao, J.Z.; Ma, Z.M.; Sui, T.B.; Ali, A.; Duan, Z.H. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Kugler, F.; Aumüller, J.; Krcmar, W.; Teipel, U. Construction and demolition residuals as raw materials for the production of novel geopolymer building materials. Crystals 2022, 12, 678. [Google Scholar] [CrossRef]

- Kong, L.; Fan, Z.; Ma, W.; Lu, J.; Liu, Y. Effect of curing conditions on the strength development of alkali-activated mortar. Crystals 2021, 11, 1455. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, D.; Fang, C.; Jiao, Y.; Kang, D.; Yan, C.; Zhang, J. Hydration nechanisms of alkali-activated cementitious materials with ternary solid waste composition. Materials 2022, 15, 3616. [Google Scholar] [CrossRef]

- Borrachero, M.V.; Paya, J.; Brito, S.; Segura, Y.P.; Soriano, L.; Tashima, M.M.; Monzo, J.M. Reusing construction and demolition waste to prepare alkali-activated cement. Materials 2022, 15, 3437. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.F.; Fang, Y.H. Preparation of belite cement from stockpiled high-carbon fly ash using granule-hydrothermal synthesis method. Constr. Build. Mater. 2016, 111, 175–181. [Google Scholar] [CrossRef]

- Gong, Y.; Yang, J.; Sun, H.; Xu, F. Effect of fly ash belite cement on hydration performance of portland cement. Crystals 2021, 11, 740. [Google Scholar] [CrossRef]

- El-Hassan, H.; Hussein, A.; Medljy, J.; El-Maaddawy, T. Performance of steel fiber-reinforced alkali-activated slag-fly ash blended concrete incorporating recycled concrete aggregates and dune sand. Buildings 2021, 11, 327. [Google Scholar] [CrossRef]

- Xie, J.H.; Zhao, J.B.; Wang, J.J.; Fang, C.; Yuan, B.; Wu, Y.H. Impact behaviour of fly ash and slag-based geopolymeric concrete: The effects of recycled aggregate content, water-binder ratio and curing age. Constr. Build. Mater. 2022, 331, 127359. [Google Scholar] [CrossRef]

- Gong, Y.F.; Fang, Y.H.; Yan, Y.Y.; Chen, L.Q. Investigation on alkali activated recycled cement mortar powder cementitious material. Mater. Res. Innov. 2014, 18, 784–787. [Google Scholar] [CrossRef]

- Ren, P.F.; Li, B.; Yu, J.G.; Ling, T.C. Utilization of recycled concrete fines and powders to produce alkali-activated slag concrete blocks. J. Clean. Prod. 2020, 267, 122115. [Google Scholar] [CrossRef]

- Sun, C.; Chen, L.L.; Xiao, J.Z.; Zuo, J.Q.; Wu, H.R. Effects of eco powders from solid waste on freeze-thaw resistance of mortar. Constr. Build. Mater. 2022, 333, 127405. [Google Scholar] [CrossRef]

| No. | Chemical Composition/wt-% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Na2O | Fe2O3 | CaO | TiO2 | K2O | MgO | SO3 | Others | |

| RCP | 34.3 | 8.2 | 1.0 | 6.2 | 42.1 | 1.0 | 1.2 | 4.5 | 0.9 | 0.6 |

| GBFS | 30.0 | 13.6 | 0.3 | 0.6 | 38.1 | 0.6 | 0.4 | 12.5 | - | 3.9 |

| FA | 61.9 | 28.8 | 0.3 | 2.5 | 2.4 | 1.0 | 1.5 | 0.8 | - | 0.8 |

| Sample | RCP/% | GFBS/% | FA/% |

|---|---|---|---|

| R9F1 | 90 | - | 10 |

| R8F2 | 80 | - | 20 |

| R7F3 | 70 | - | 30 |

| R6F4 | 60 | - | 40 |

| R5F5 | 50 | - | 50 |

| R9S1 | 90 | 10 | - |

| R8S2 | 80 | 20 | - |

| R7S3 | 70 | 30 | - |

| R6S4 | 60 | 40 | - |

| R5S5 | 50 | 50 | - |

| R7S2F1 | 70 | 20 | 10 |

| R6S3F1 | 60 | 30 | 10 |

| R6S2F2 | 60 | 20 | 20 |

| R5S3F2 | 50 | 30 | 20 |

| R5S2F3 | 50 | 20 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Yan, Y.; Tong, X.; Gong, Y. Investigation of Mineral Admixtures on Mechanical Properties of Alkali-Activated Recycled Concrete Powders Cement. Buildings 2022, 12, 1234. https://doi.org/10.3390/buildings12081234

Wang X, Yan Y, Tong X, Gong Y. Investigation of Mineral Admixtures on Mechanical Properties of Alkali-Activated Recycled Concrete Powders Cement. Buildings. 2022; 12(8):1234. https://doi.org/10.3390/buildings12081234

Chicago/Turabian StyleWang, Xin, Yurong Yan, Xiaofang Tong, and Yongfan Gong. 2022. "Investigation of Mineral Admixtures on Mechanical Properties of Alkali-Activated Recycled Concrete Powders Cement" Buildings 12, no. 8: 1234. https://doi.org/10.3390/buildings12081234

APA StyleWang, X., Yan, Y., Tong, X., & Gong, Y. (2022). Investigation of Mineral Admixtures on Mechanical Properties of Alkali-Activated Recycled Concrete Powders Cement. Buildings, 12(8), 1234. https://doi.org/10.3390/buildings12081234