Effects of Hardening Model and Variation of Elastic Modulus on Springback Prediction in Roll Forming

Abstract

:1. Introduction

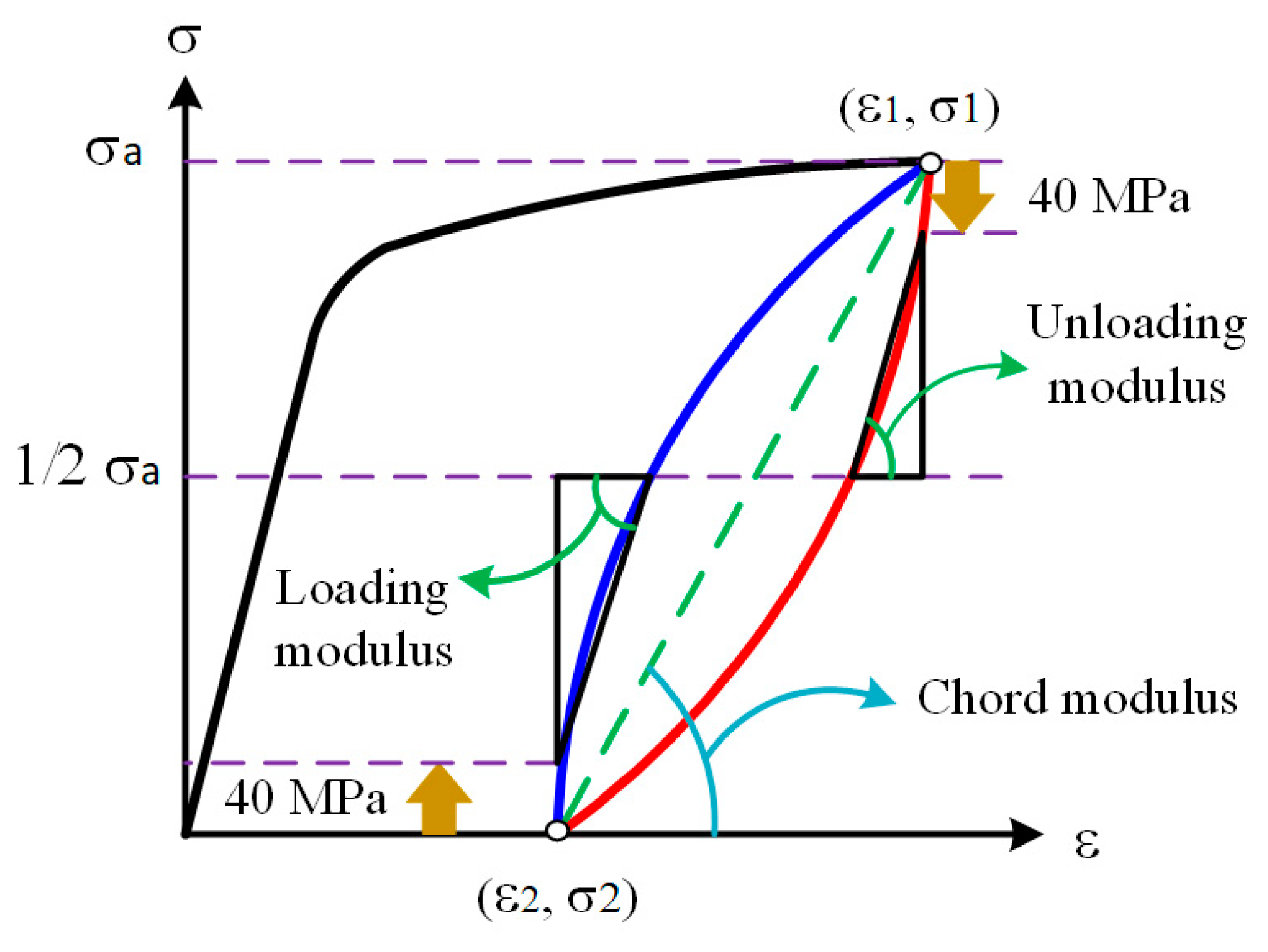

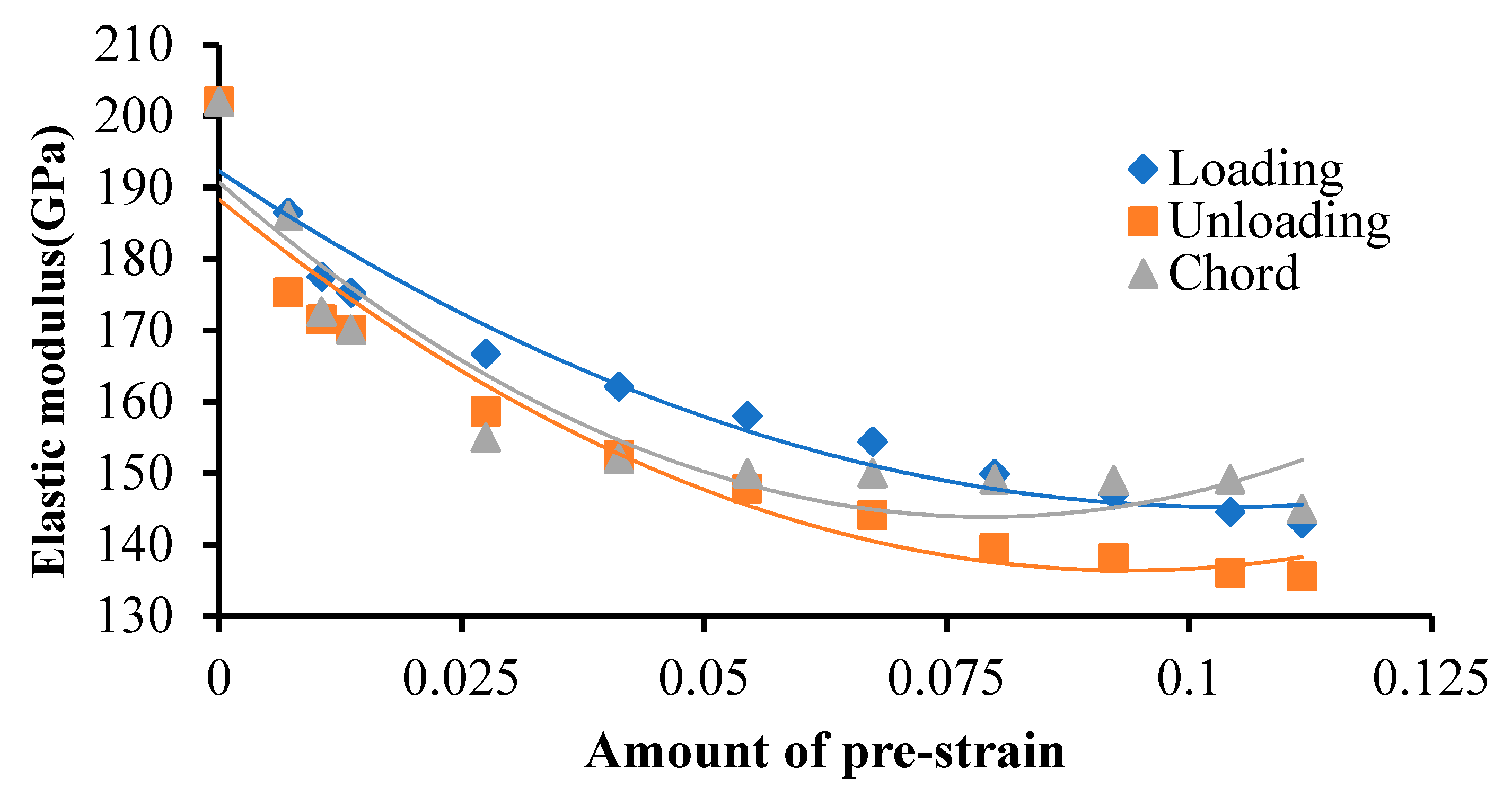

2. Defining the Elastic Modulus Change

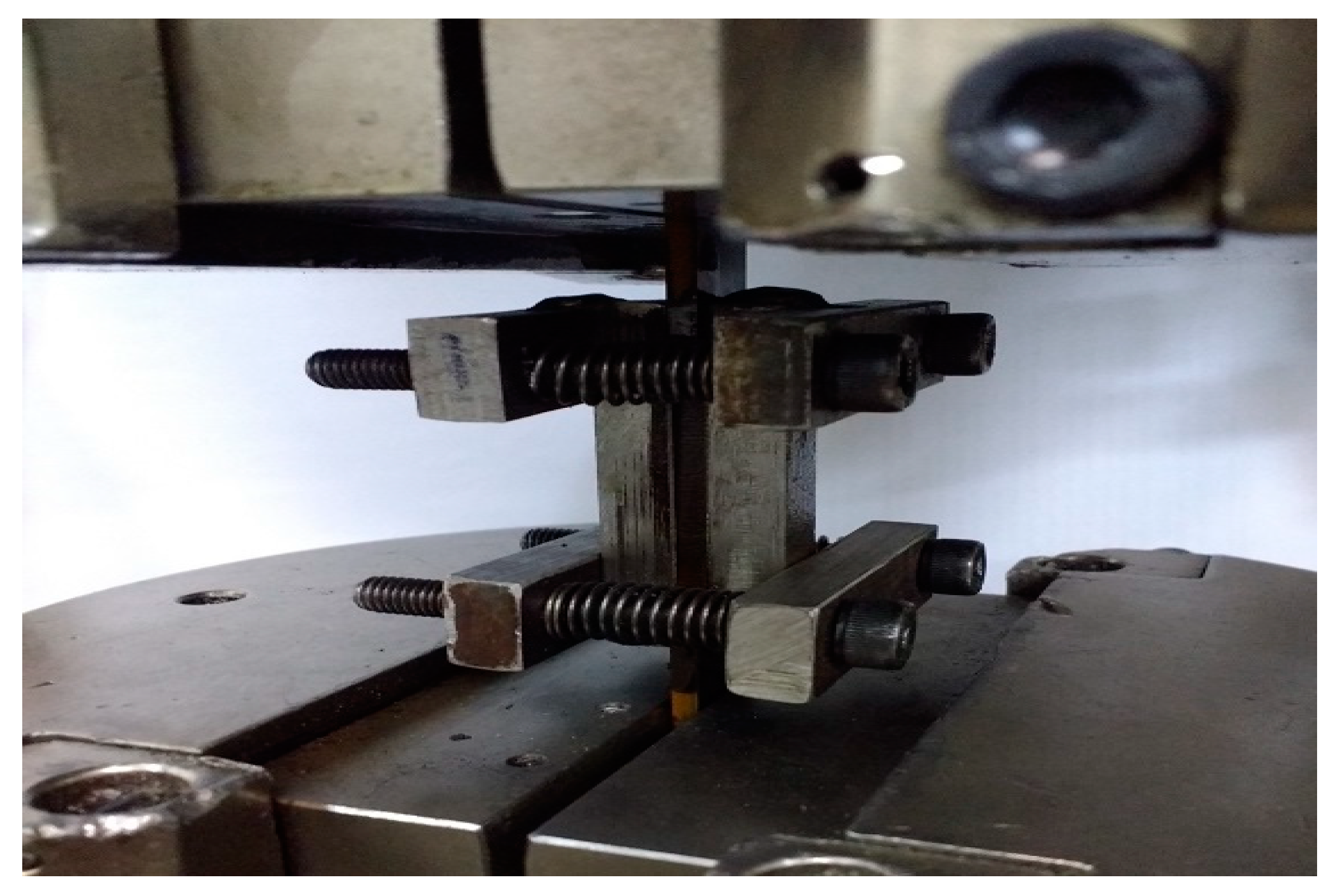

3. Uniaxial Tensile

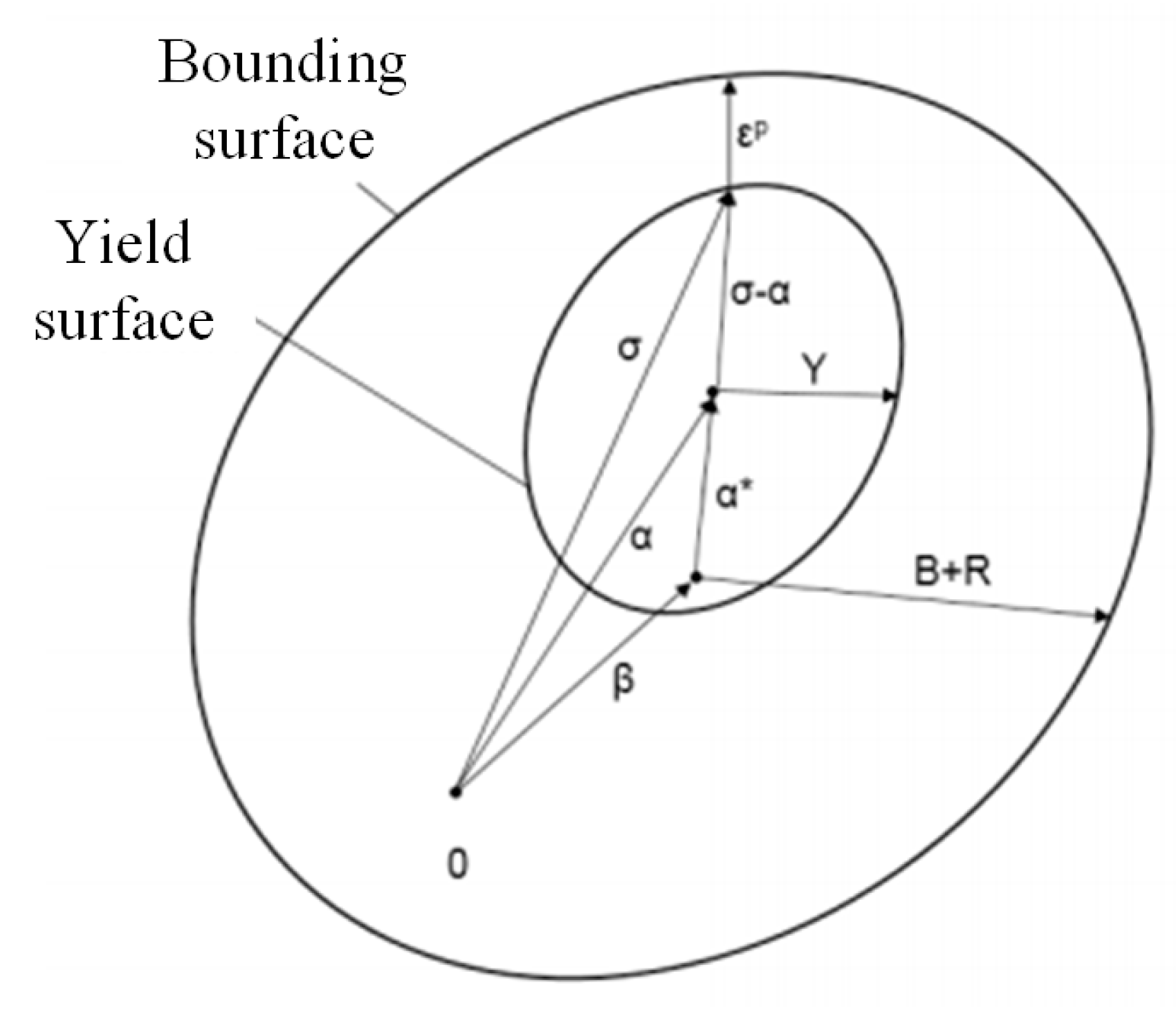

4. Yoshida-Uemori Model and Cyclic Tension–Compression Test

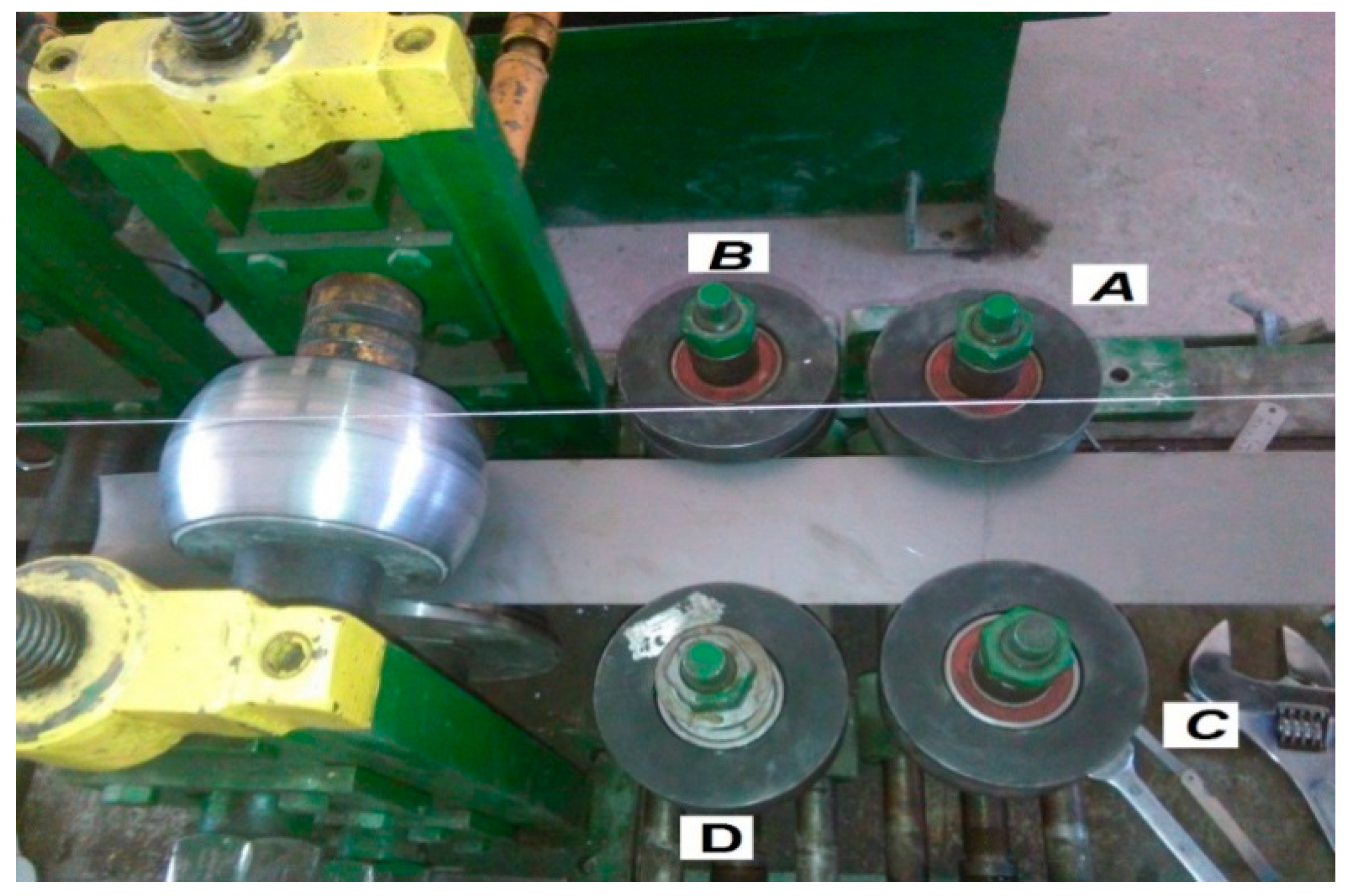

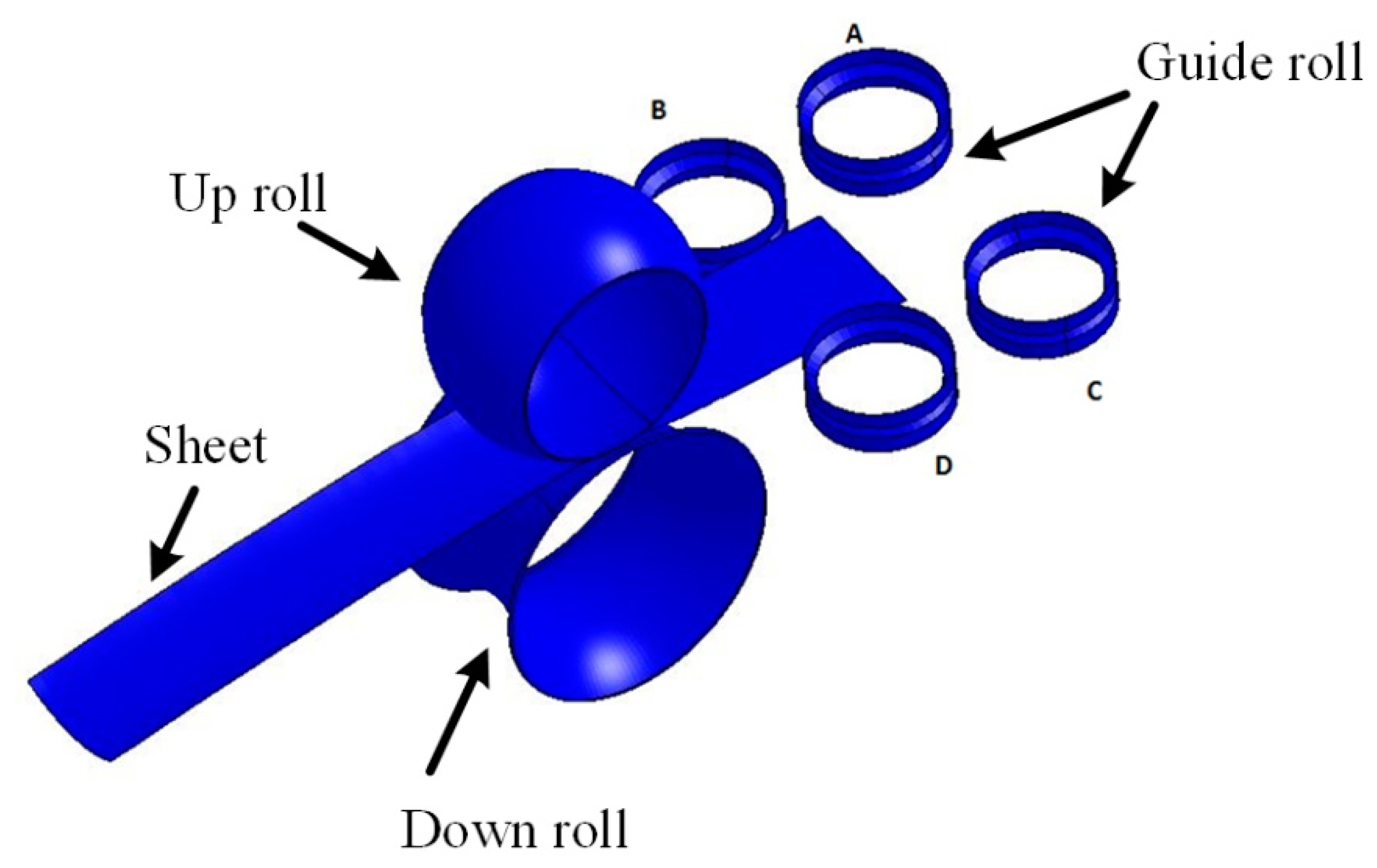

5. Experimental Tests

6. Finite Element Analysis Model

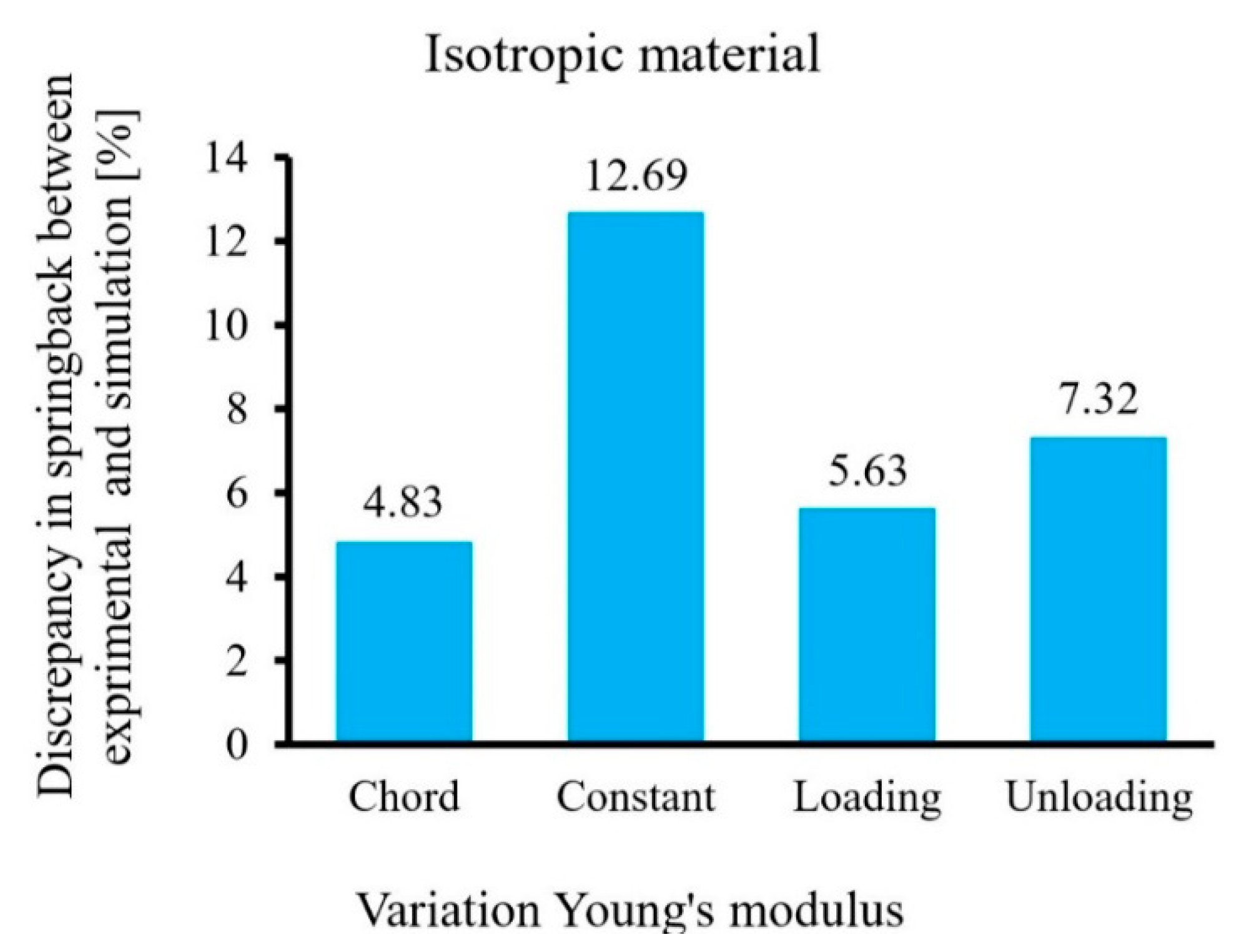

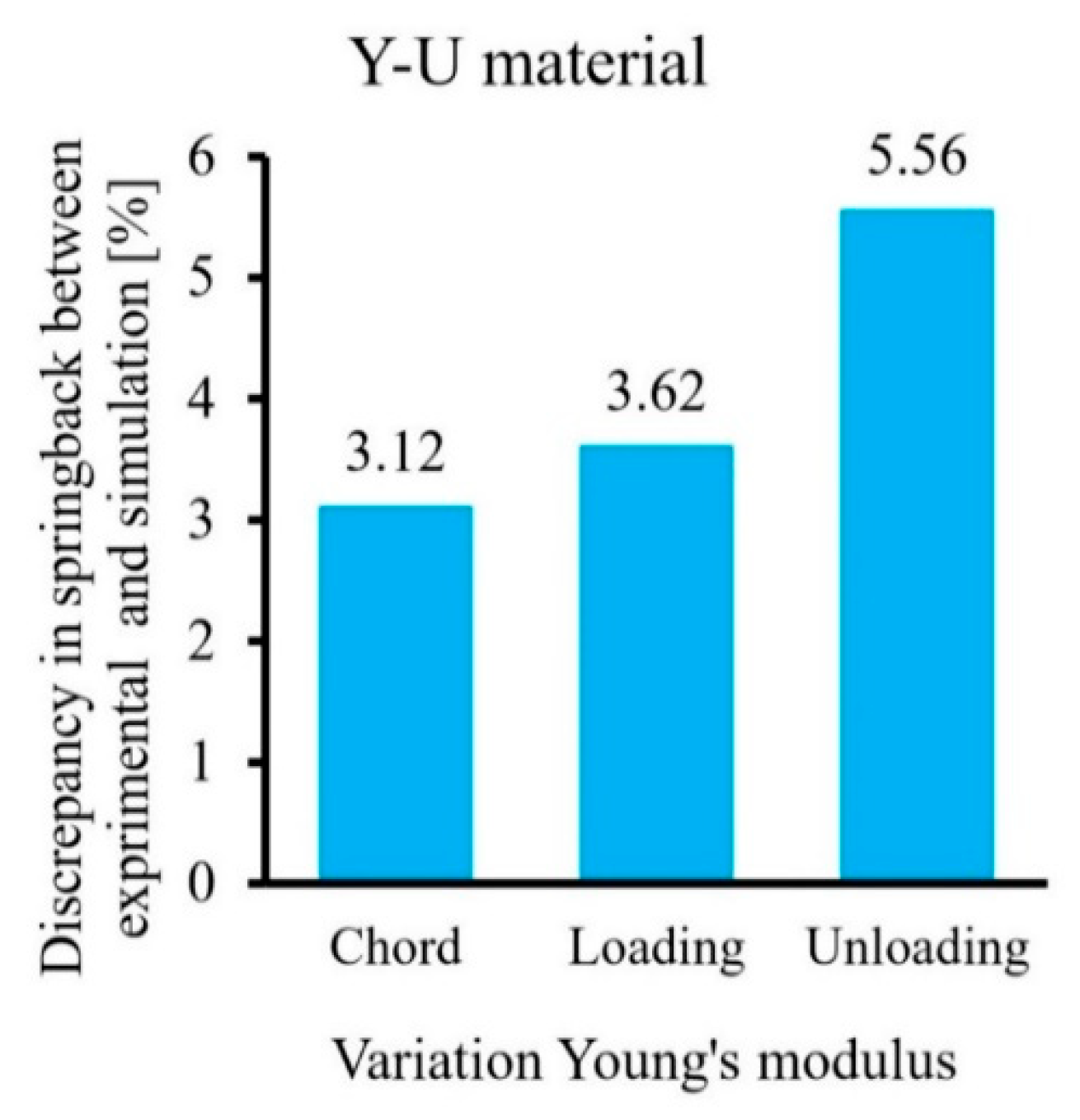

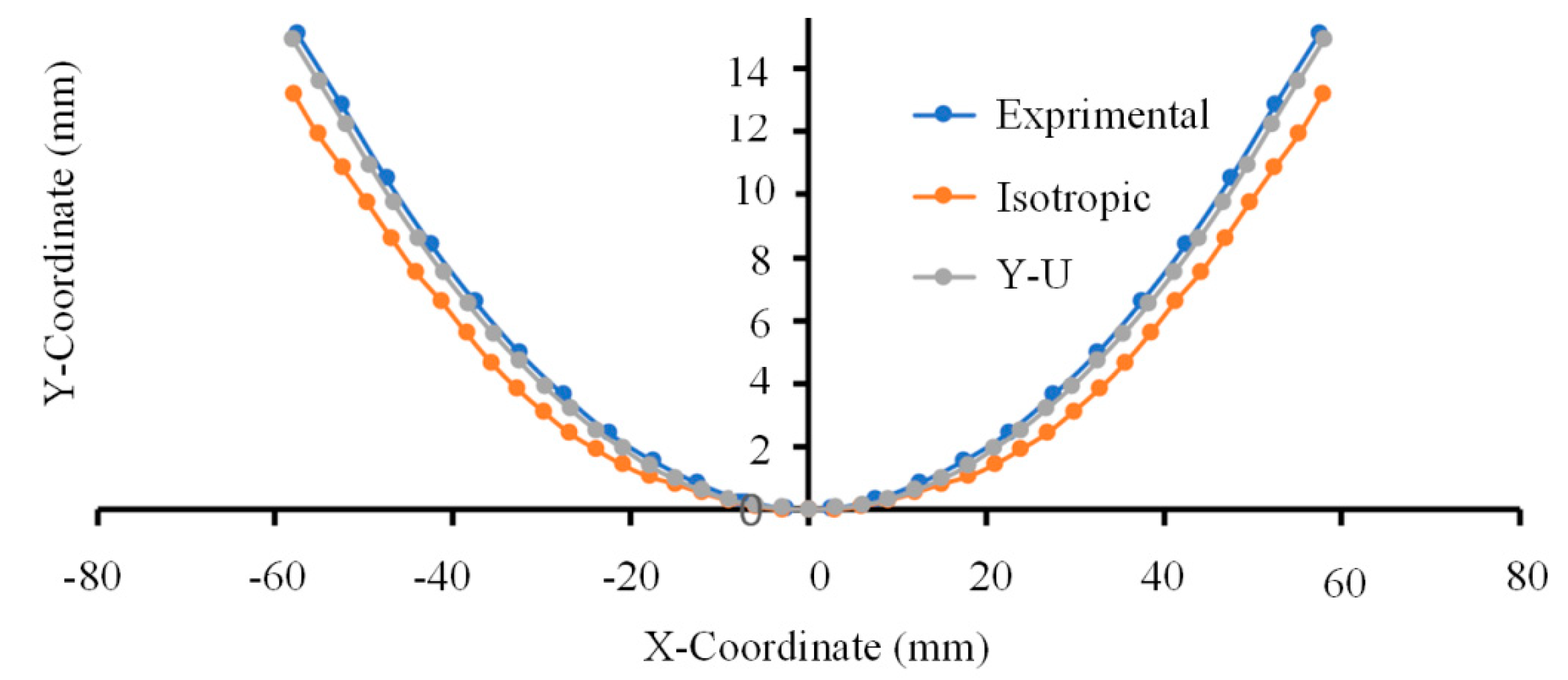

7. Results and Discussion

- (1)

- MAT 37 (Transversely Anisotropic Elastic Plastic) with four types of isotropic hardening [IH]: (a) constant E model, (b) the loading elastic modulus, (c) the unloading elastic modulus, and (d) the chord modulus.

- (2)

- MAT 125 (Kinematic Hardening Transversely Anisotropic (Yoshida-Uemori’s model) with three types [Y-U]: (e) the loading elastic modulus, (f) the unloading elastic modulus, and (g) the chord elastic modulus.

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sheykholeslami, M.; Cinquemani, S.; Mazdak, S. Numerical study of the ultrasonic vibration in deep drawing process of circular sections with rubber die. In Proceedings of the Active and Passive Smart Structures and Integrated Systems XII, Denver, CO, USA, 4–8 March 2018; Volume 10595. [Google Scholar]

- Mulidrán, P.; Šiser, M.; Slota, J.; Spišák, E.; Sleziak, T. Numerical prediction of forming car body parts with emphasis on springback. Metals 2018, 8, 435. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Estrin, Y.; Kulagin, R. Synthesis of hybrid materials by severe plastic deformation: A new paradigm of SPD processing. Adv. Eng. Mater. 2015, 17, 1853–1861. [Google Scholar] [CrossRef]

- Gau, J.T.; Kinzel, G.L. A new model for springback prediction in which the Bauschinger effect is considered. Int. J. Mech. Sci. 2001, 43, 1813–1832. [Google Scholar] [CrossRef]

- Jung, J.; Jun, S.; Lee, H.S.; Kim, B.M.; Lee, M.G.; Kim, J. Anisotropic Hardening Behaviour and Springback of Advanced High-Strength Steels. Metals 2017, 7, 480. [Google Scholar] [CrossRef]

- Yang, M.; Akiyama, Y.; Sasaki, T. Evaluation of change in material properties due to plastic deformation. J. Mater. Process. Technol. 2004, 151, 232–236. [Google Scholar] [CrossRef]

- Yoshida, F.; Uemori, T.; Fujiwara, K. Elastic–plastic behavior of steel sheets under in-plane cyclic tension–compression at large strain. Int. J. Plast. 2002, 18, 633–659. [Google Scholar] [CrossRef]

- Yang, X.; Choi, C.; Sever, N.K.; Altan, T. Prediction of springback in air-bending of Advanced High Strength steel (DP780) considering Young’s modulus variation and with a piecewise hardening function. Int. J. Mech. Sci. 2016, 105, 266–272. [Google Scholar] [CrossRef]

- Yu, H.Y. Variation of elastic modulus during plastic deformation and its influence on springback. Mater. Des. 2009, 30, 846–850. [Google Scholar] [CrossRef]

- Lems, W. The change of Young’s modulus of copper and silver after deformation at low temperature and its recovery. Physica 1962, 28, 445–452. [Google Scholar] [CrossRef]

- Ghaei, A. Modeling of nonlinear elastic modulus variation during cyclic loading. Modares Mech. Eng. 2013, 17, 10–17. [Google Scholar]

- Kim, H.; Kimchi, M. Numerical Modeling for Springback Predictions by Considering the Variations of Elastic Modulus in Stamping Advanced High-Strength Steels (AHSS). AIP Conf. Proc. 2011, 1383, 1159–1166. [Google Scholar] [CrossRef]

- Abvabi, A.; Mendiguren, J.; Kupke, A.; Rolfe, B.; Weiss, M. Evolution of elastic modulus in roll forming. Int. J. Mater. Form. 2017, 10, 463–471. [Google Scholar] [CrossRef]

- Eggertsen, P.A.; Mattiasson, K. On the modelling of the bending–unbending behaviour for accurate springback predictions. Int. J. Mech. Sci. 2009, 51, 547–563. [Google Scholar] [CrossRef]

- Hu, K.K.; Peng, X.Q.; Chen, J.; Lu, H.S.; Zhang, J. Auto-body panel springback analysis using Yoshida-Uemori model. Adv. Mater. Res. 2011, 314–316, 815–818. [Google Scholar] [CrossRef]

- Ul Hassan, H.; Maqbool, F.; Güner, A.; Hartmaier, A.; Khalifa, N.B.; Tekkaya, A.E. Springback prediction and reduction in deep drawing under influence of unloading modulus degradation. Int. J. Mater. Form. 2016, 9, 619–633. [Google Scholar] [CrossRef]

- Stander, N.; Craig, K.J. On the robustness of a simple domain reduction scheme for simulation-based optimization. Eng. Comput. 2002, 19, 431–450. [Google Scholar] [CrossRef]

- Eggertsen, P.A.; Mattiasson, K. On the identification of kinematic hardening material parameters for accurate springback predictions. Int. J. Mater. Form. 2011, 4, 103–120. [Google Scholar] [CrossRef]

| - | Chord | Unloading | Loading |

|---|---|---|---|

| E0 (GPa) | 202 | 202 | 202 |

| (GPa) | 149 | 135.5 | 143 |

| ζ | 68.39 | 42.59 | 32.25 |

| Direction | Young’s Modulus (GPa) | r-Lankford Parameter |

|---|---|---|

| Rolling direction (0°) | 201.9 | 0.893 |

| Diagonal direction (45°) | 204 | 0.822 |

| Transverse direction (90°) | 204 | 0.797 |

| h | B | Rsat | m | C | b |

|---|---|---|---|---|---|

| 0.1 | 600 | 197.1 | 3.9 | 279 | 279.16 |

| Strip Thickness (mm) | Strip Length (mm) | Web Width (mm) | Strip Material |

|---|---|---|---|

| 2 | 300 | 12 | st-37 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naofal, J.; Naeini, H.M.; Mazdak, S. Effects of Hardening Model and Variation of Elastic Modulus on Springback Prediction in Roll Forming. Metals 2019, 9, 1005. https://doi.org/10.3390/met9091005

Naofal J, Naeini HM, Mazdak S. Effects of Hardening Model and Variation of Elastic Modulus on Springback Prediction in Roll Forming. Metals. 2019; 9(9):1005. https://doi.org/10.3390/met9091005

Chicago/Turabian StyleNaofal, Jihad, Hassan Moslemi Naeini, and Siamak Mazdak. 2019. "Effects of Hardening Model and Variation of Elastic Modulus on Springback Prediction in Roll Forming" Metals 9, no. 9: 1005. https://doi.org/10.3390/met9091005

APA StyleNaofal, J., Naeini, H. M., & Mazdak, S. (2019). Effects of Hardening Model and Variation of Elastic Modulus on Springback Prediction in Roll Forming. Metals, 9(9), 1005. https://doi.org/10.3390/met9091005