Effects of Powder Preparation and Sintering Temperature on Properties of Spark Plasma Sintered Ti-48Al-2Cr-8Nb Alloy

Abstract

1. Introduction

2. Materials and Methods

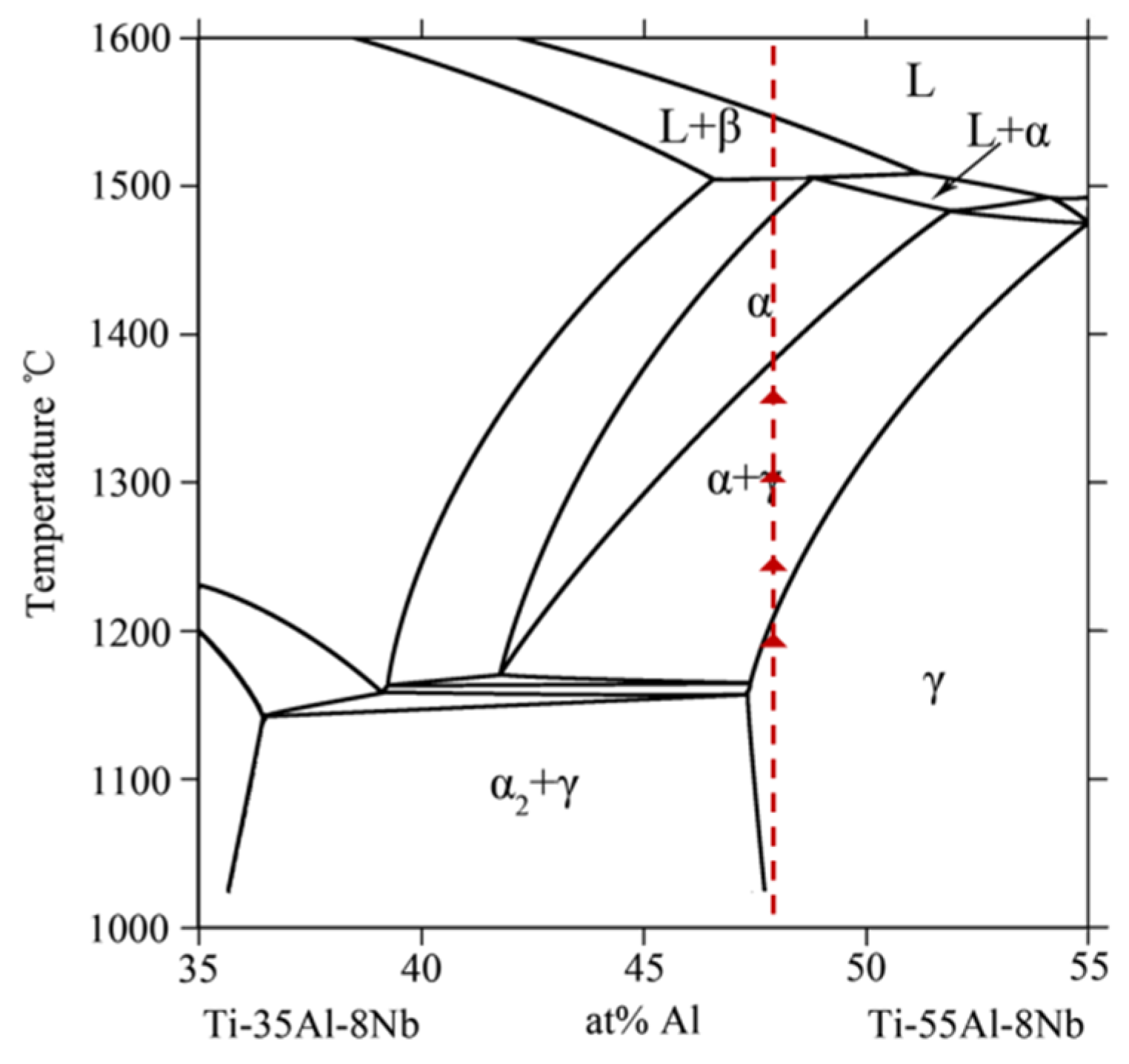

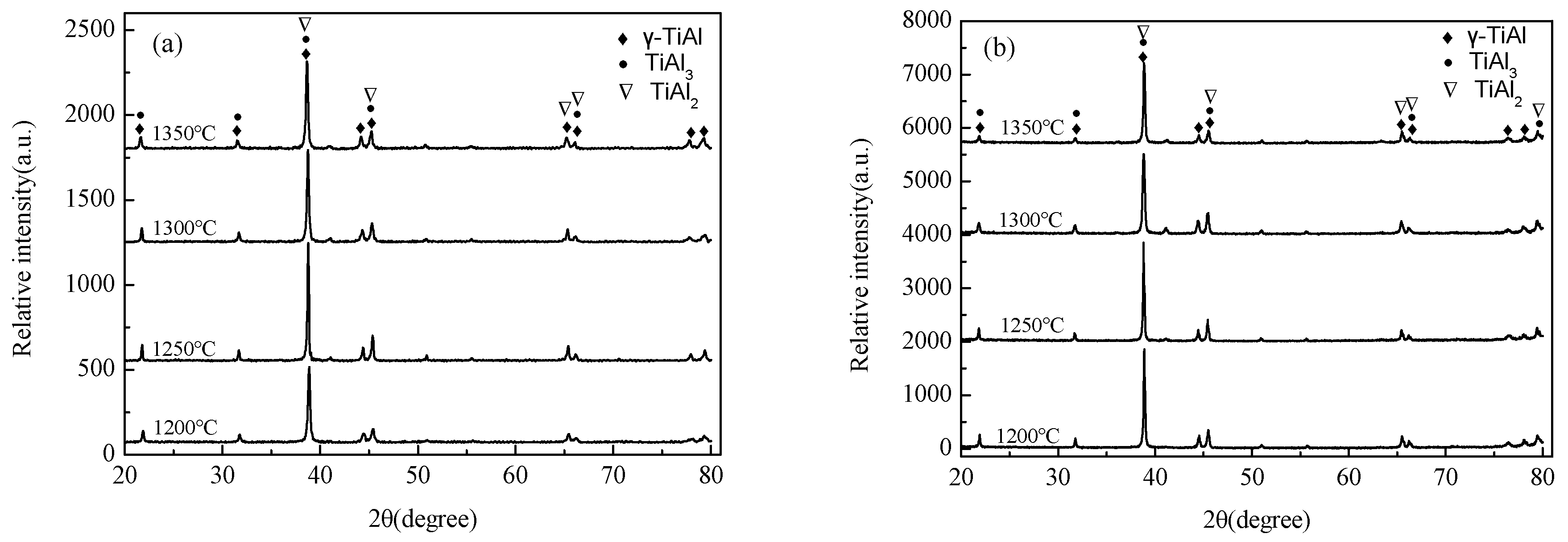

3. Results and Discussion

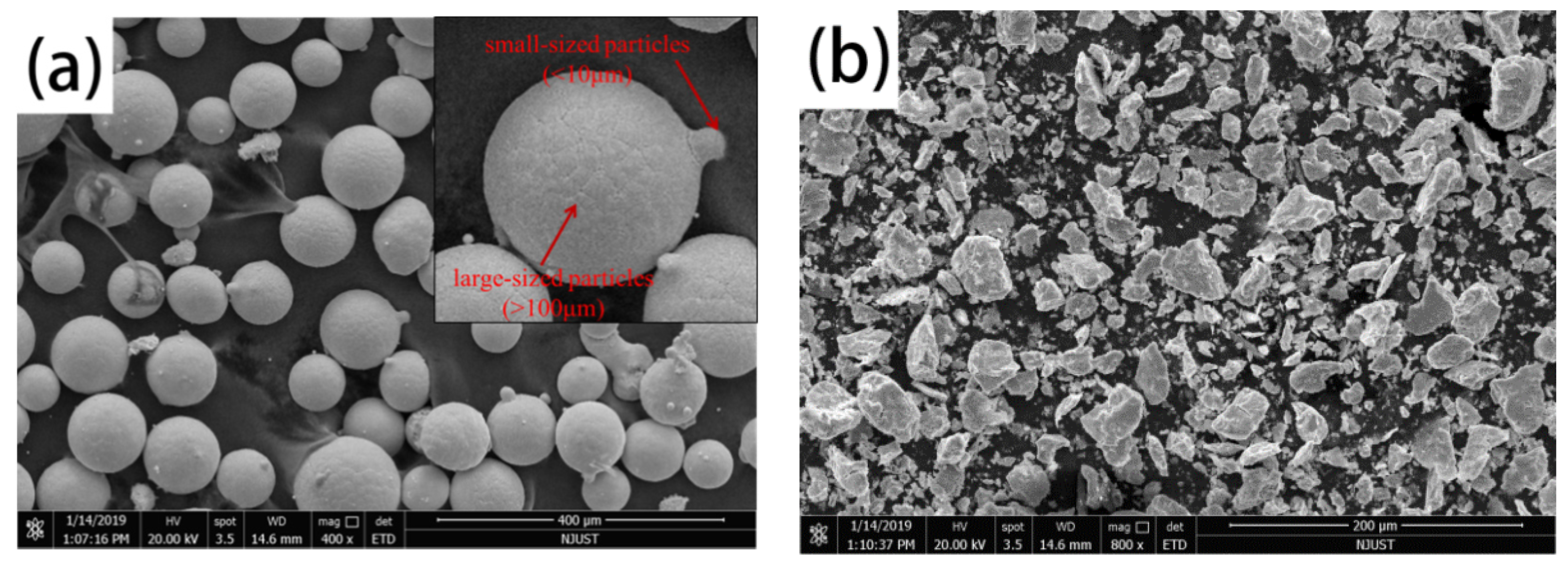

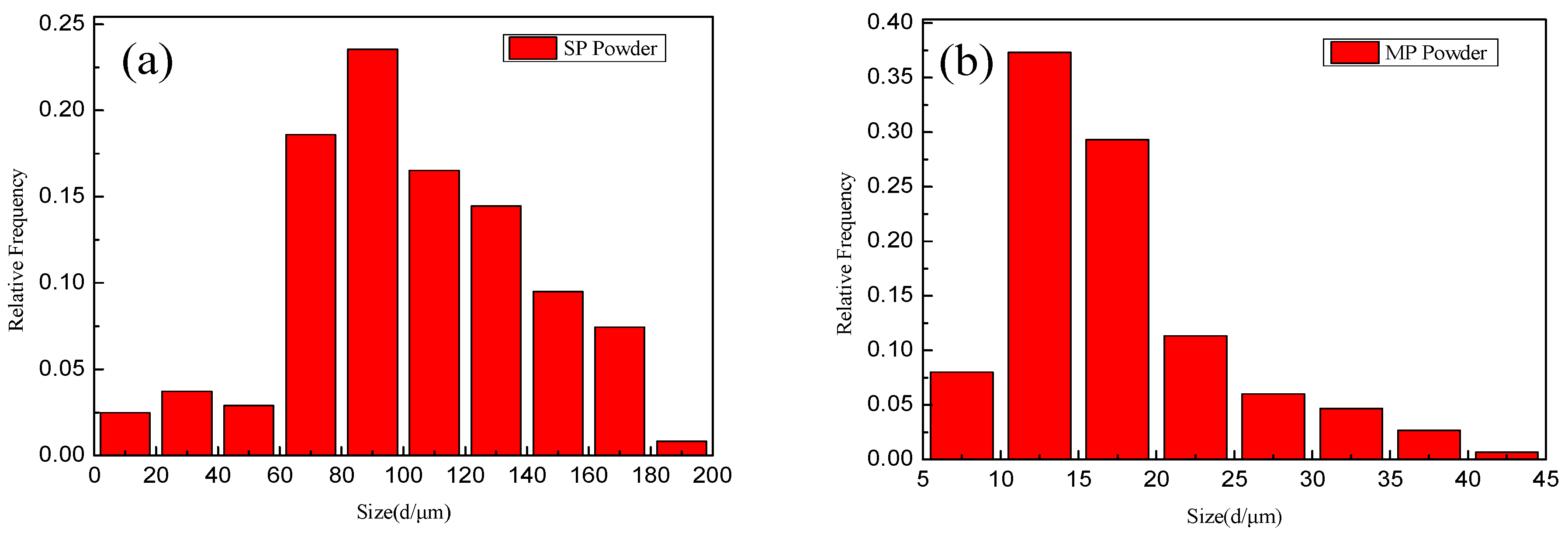

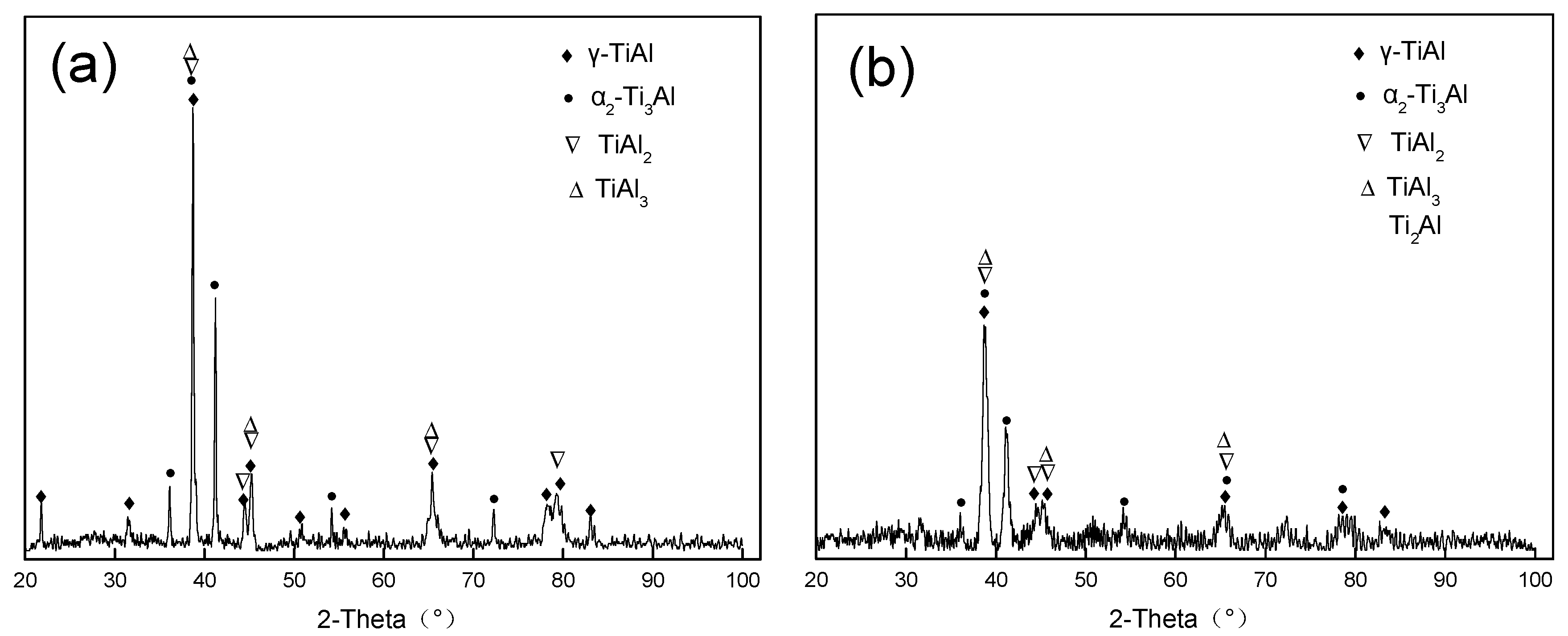

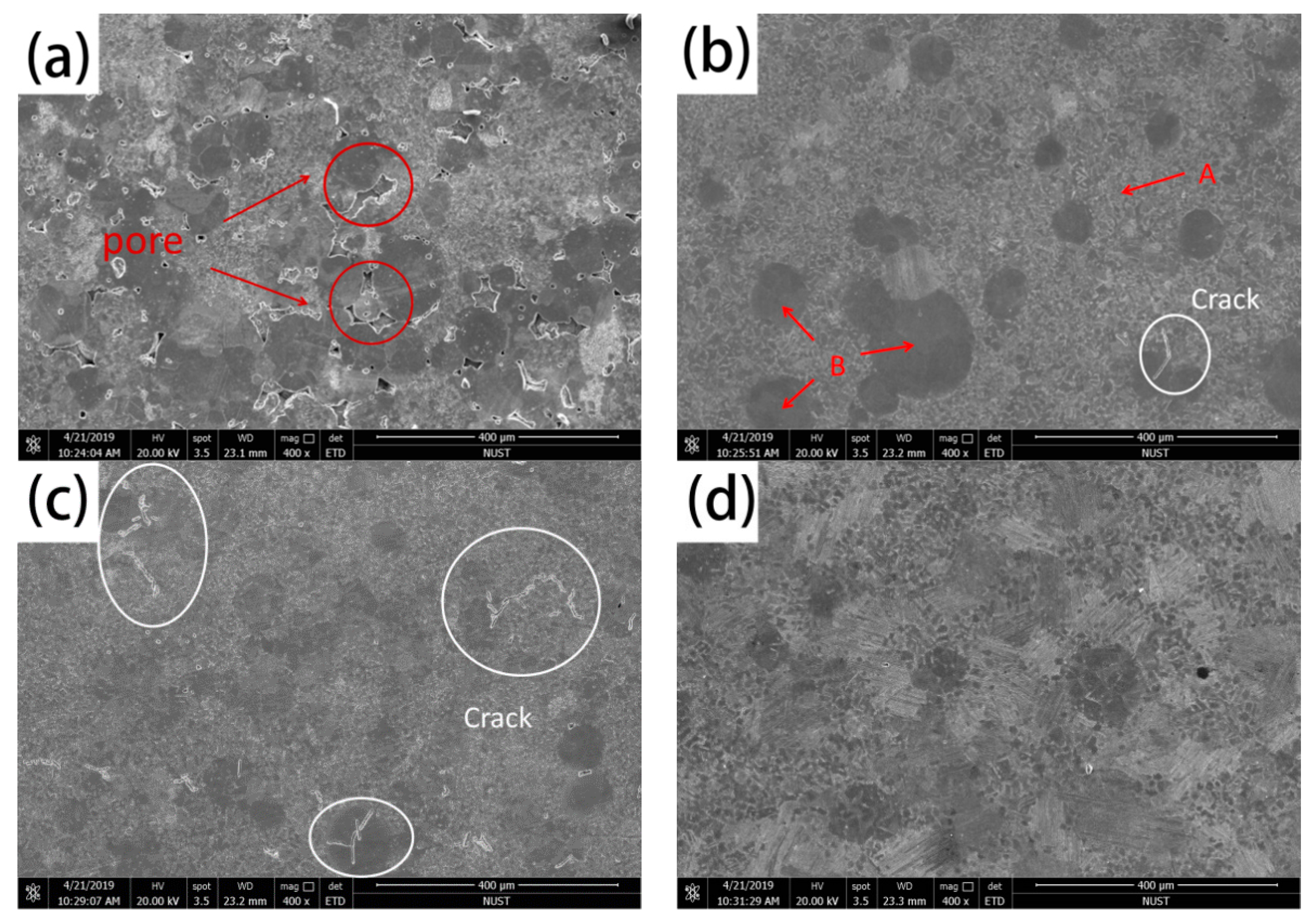

3.1. Characterization of the As-Atomized SP Powder and MP Powder

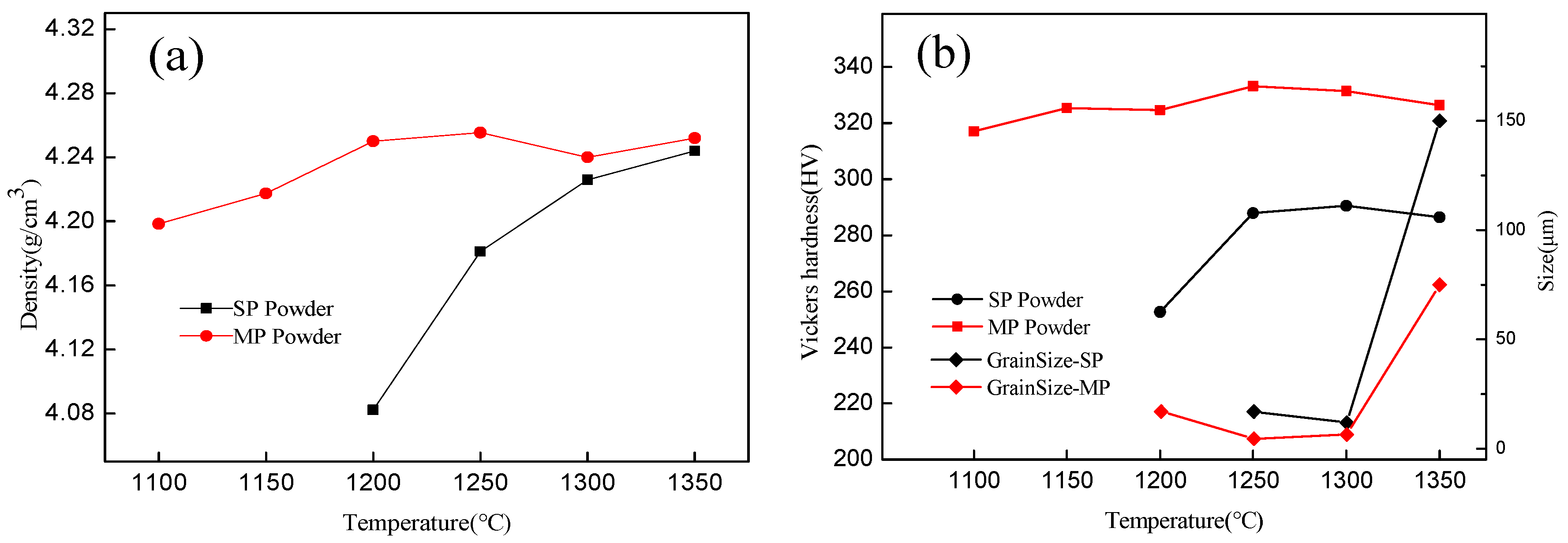

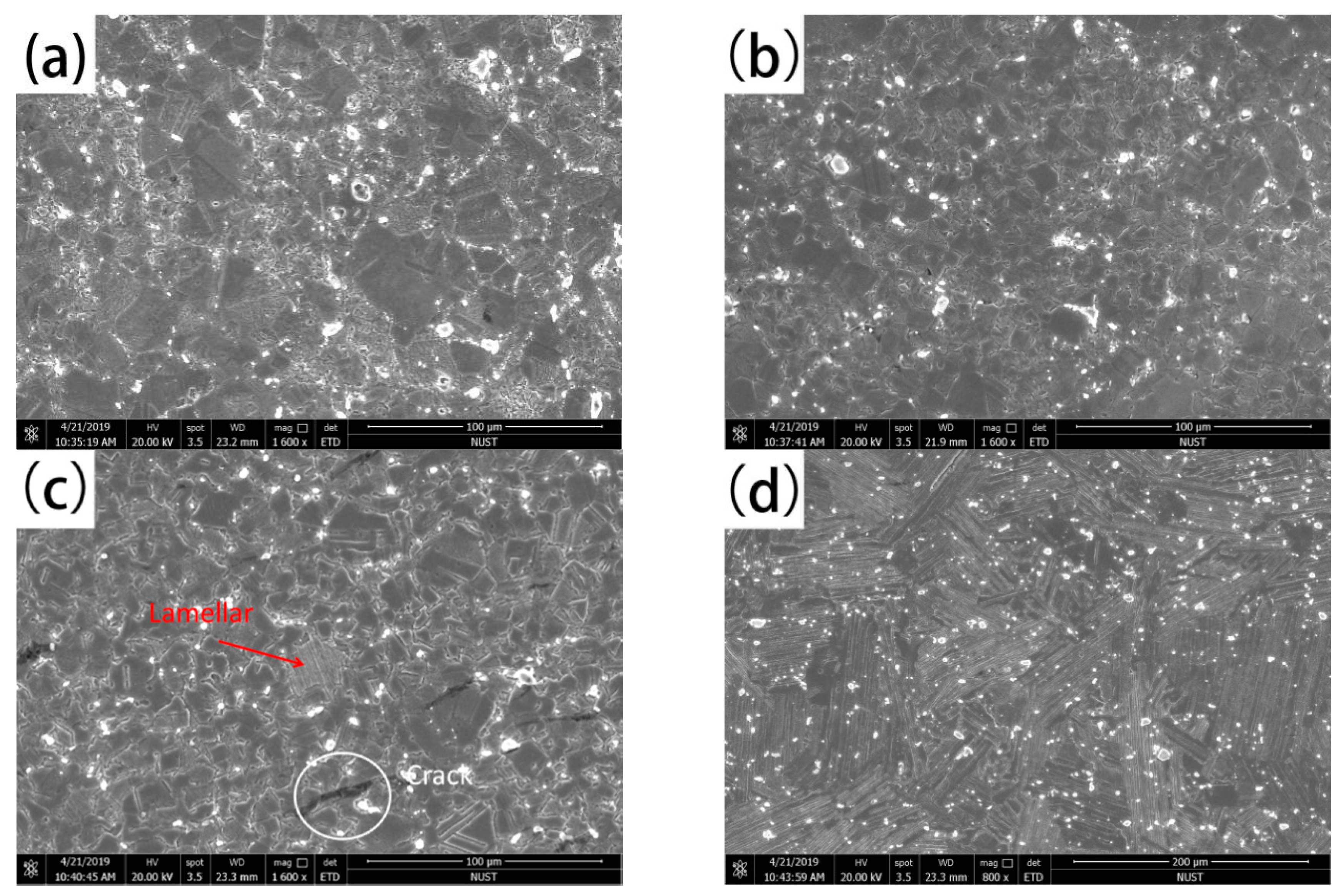

3.2. Effect of Sintering Temperature on Density and Vickers Hardness of Ti-48Al-2Cr-8Nb Alloy

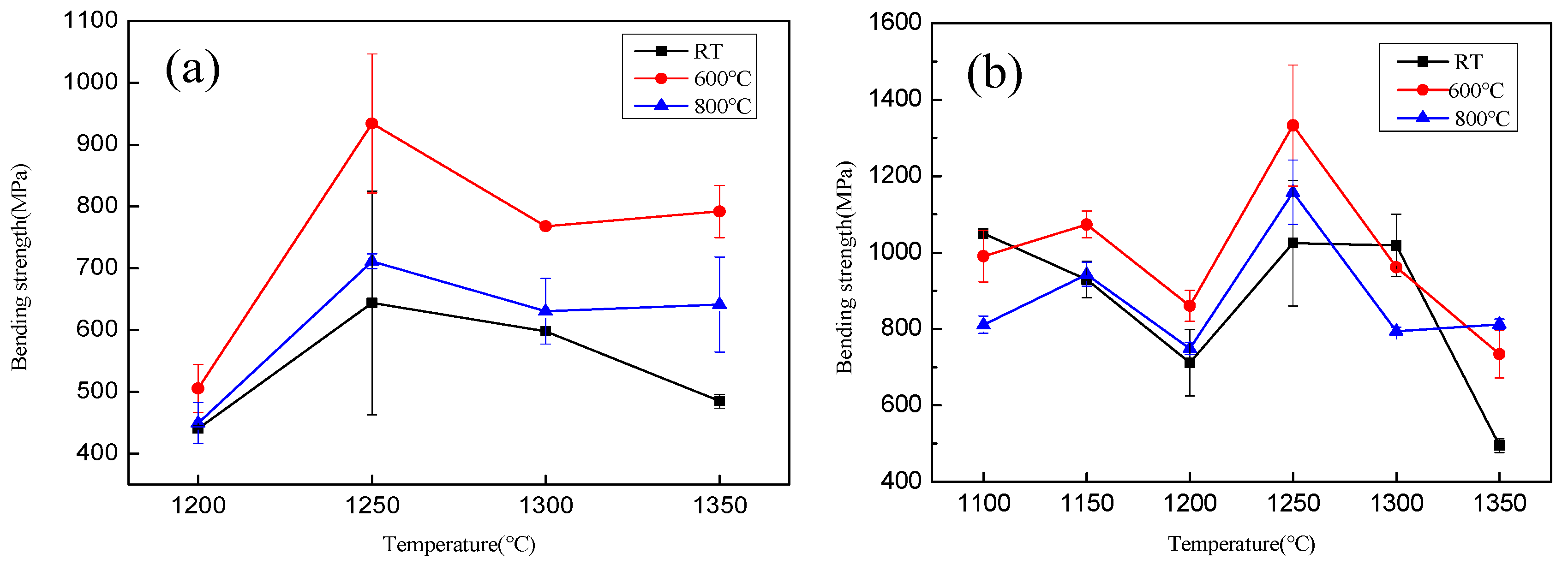

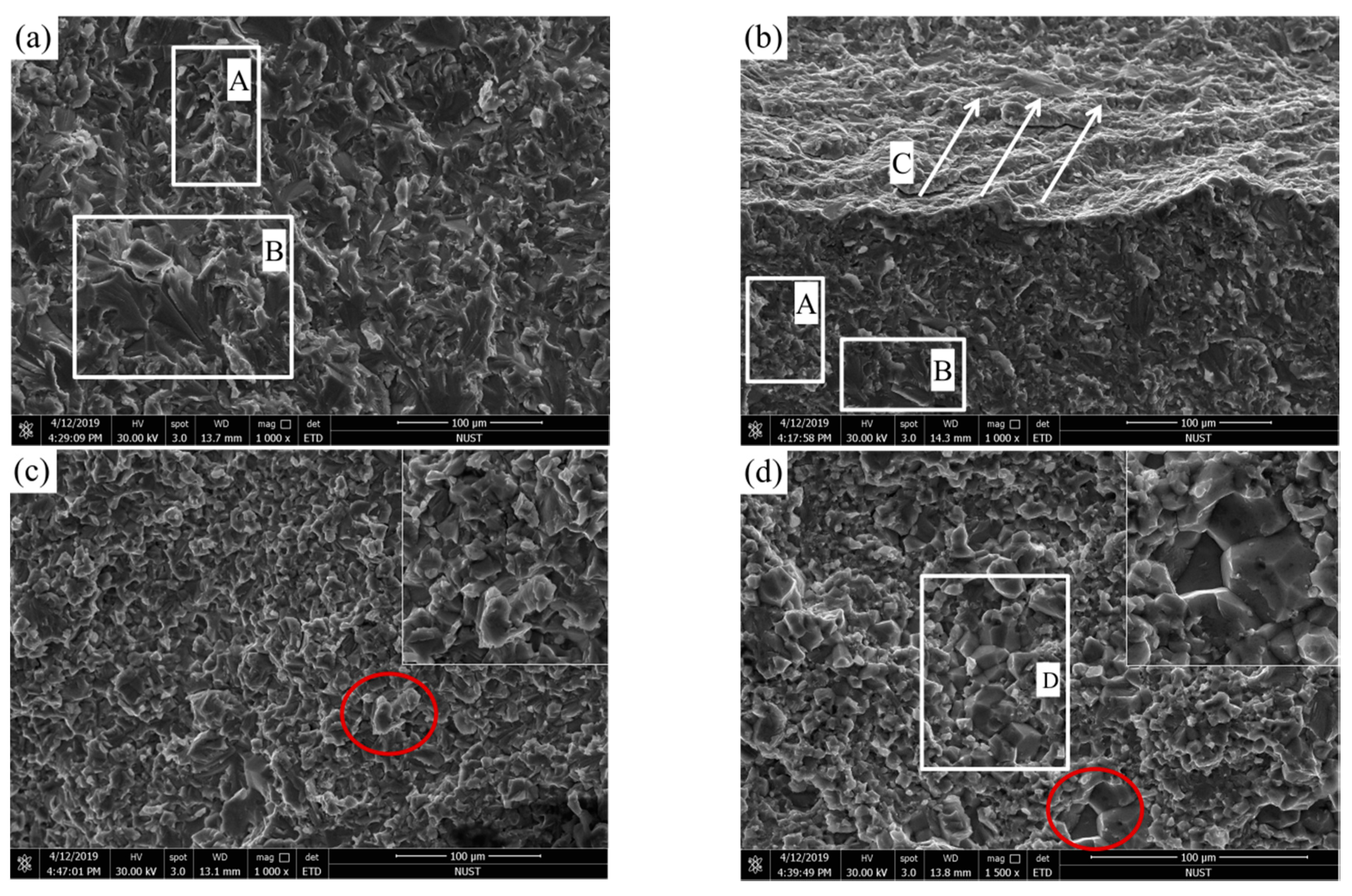

3.3. Bending Strength and Fracture Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, H.W.; Rong, R.; Gao, F.; Li, Z.; Liu, Y.; Wang, Q. Hot deformation behavior and microstructural evolution characteristics of Ti-44Al-5V-1Cr alloy containing (γ+α2 + B2) phases. Metals 2016, 6, 305. [Google Scholar] [CrossRef]

- Wu, X.H. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Deng, H.; Chen, A.J.; Chen, L.Q.; Wei, Y.; Xia, Z.; Tang, J. Bulk nanostructured Ti-45Al-8Nb alloy fabricated by cryomilling and Spark Plasma Sintering. J. Alloys Compd. 2019, 772, 140–149. [Google Scholar] [CrossRef]

- Liu, Y.W.; Hu, R.; Zhang, T.B. Microstructure stability of Ti2AlN/Ti-48Al-2Cr-2Nb composite at 900°C. Trans. Nonferrous Met. Soc. China 2016, 26, 423–430. [Google Scholar] [CrossRef]

- Liang, J.M.; Cao, L.; Xie, Y.H.; Zhou, Y.; Luo, Y.F.; Mudi, K.Q.; Gao, H.Y.; Wang, J. Microstructure and mechanical properties of Ti-48Al-2Cr-2Nb alloy joints producted by transient liquid phase bonding using spark plasma sintering. Mater. Charact. 2019, 147, 116–126. [Google Scholar] [CrossRef]

- Shen, C.; Liss, K.D.; Reid, M.; Pan, Z.; Ma, Y.; Li, X.; Li, H. In-situ neutron diffraction characterization on the phase evolution of γ-TiAl alloy during the wire-arc additive manufacturing process. J. Alloys Compd. 2019, 778, 280–287. [Google Scholar] [CrossRef]

- Shishkin, A.; Drozdova, M.; Kozlov, V.; Hussainova, I.; Lehmhus, D. Vibration-Assisted sputter coating of cenospheres: A new approach for realizing Cu-Based metal matrix syntactic foams. Metals 2017, 7, 16. [Google Scholar] [CrossRef]

- Shishkin, A.; Hussainova, I.; Kozlov, V.; Lisnanskis, M.; Leroy, P.; Lehmhus, D. Metal-coated cenospheres obtained via magnetron sputter coating: A new precursor for syntactic foams. JOM 2018, 70, 1319–1325. [Google Scholar] [CrossRef]

- Minasyan, T.; Kirakosyan, H.; Aydinyan, S.; Liu, L.; Kharatyan, S.; Hussainova, I. Mo-Cu pseudoalloys by combustion synthesis and Spark Plasma Sintering. J. Mater. Sci. 2018, 53, 16598–16608. [Google Scholar] [CrossRef]

- Chen, K.; Xiao, W.; Li, Z.; Wu, J.; Hong, K.; Ruan, X. Effect of grapheme and carbon nanotubes on the thermal conductivity of WC-Co cemented carbide. Metals 2019, 9, 377. [Google Scholar] [CrossRef]

- Roy, P.; Pal, V.; Maiti, T. Effect of Spark Plasma Sintering (SPS) on the thermoelectric properties of SrTiO3: 15 at% Nb. Ceram. Int. 2017, 43, 12809. [Google Scholar] [CrossRef]

- Wang, L.; Shu, X.; Yi, F.; Shao, D.; Zhang, K.; Zhang, H.; Lu, X. Rapid fabrication and phase transition of Nd and Ce co-doped Gd2Zr2O7 ceramics by SPS. J. Eur. Ceram. Soc. 2018, 38, 2863–2870. [Google Scholar] [CrossRef]

- Glenda, T.M.; Sophie, G.F.; Geoffroy, C.; Mxolisi, B.S.; Peter, A.O.; Claude, E. Microstructural evolution and mechanical properties of pure titanium powders processed by spark plasma sintering. Powder Technol. 2019, 345, 415–424. [Google Scholar]

- Yang, C.; Mo, D.G.; Lu, H.Z.; Li, X.Q.; Zhang, W.W.; Fu, Z.Q.; Zhang, L.C.; Lavernia, E.J. Reaction diffusion rate coefficient derivation by isothermal heat treatment in spark plasma sintering system. Scr. Mater. 2017, 134, 91–94. [Google Scholar] [CrossRef]

- Bai, L.; Ge, C.C.; Shen, W.P. Discharge Plasma Sintering Technology. PM Technol. 2007, 25, 217–223. [Google Scholar]

- Lin, J.P.; Chen, G.L. Development of TiAl based metal parts compounds. Met. Chin. 2009, 1, 31–37. [Google Scholar]

- Malecka, J.; Grzesik, W.; Hernas, A. An investigation on oxidation wear mechanisms of Ti46Al7Nb0.7Cr0.1Si0.2Ni intermetallic-based alloy. Corros. Sci. 2010, 52, 263–272. [Google Scholar] [CrossRef]

- Kim, B.G.; Kim, G.M.; Kim, C.J. Oxidation behavior of TiAl-X (X=Cr,V,Si,Mo,or Nb) intermetallics at elevated temperature. Scr. Metall. Mater. 1995, 33, 1117–1125. [Google Scholar] [CrossRef]

- Zhang, W.J.; Appel, F. Effect of Al content and Nb addition on the strength and fault energy of TiAl alloys. Mater. Sci. Eng. A 2002, 329, 649–652. [Google Scholar] [CrossRef]

- Lu, X.; He, X.B. Microstructure and mechanical properties of a spark plasma sintered Ti45Al8.5Nb0.2W0.2B0.1Y alloy. Intermetallics 2009, 17, 775–872. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Zhang, C.J.; Hou, Z.P. Research Progress of ω Phase in High Nb Containing TiAl Based Alloy. Rare Met. Mat. Eng. 2016, 45, 1903–1909. [Google Scholar]

- Guyon, J.; Hazotte, A. Effect of powder state on spark plasma sintering of TiAl alloys. Intermetallics 2013, 34, 94–100. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Li, Y.; Zhao, S.X.; Li, J. Microstructure characterization and mechanical properties of TiAl based alloys prepared by mechanical milling and spark plasma sintering. Mater. Charact. 2017, 128, 75–84. [Google Scholar] [CrossRef]

- Sanjay, K.V.; Kei, A. A novel powder metallurgy processing approach to prepare fine-grained Ti rich TiAl-based alloys from pre-alloyed powders. Intermetallics 2013, 42, 146–155. [Google Scholar]

- Bhattacharya, P.; Bellon, P.; Averback, R.S.; Hales, S.J. Nanocrystalline TiAl powders synthesized by high-energy ball milling: Effects of milling parameters on yield and contamination. J. Alloys Compd. 2004, 368, 187–196. [Google Scholar] [CrossRef]

- He, W.; Liu, Y.; Tang, H.; Li, Y.; Liu, B.; Liang, X.; Xi, Z. Microstructural characteristics and densification behavior of high-Nb TiAl powder produced by plasma rotating electrode process. Mater. Des. 2017, 132, 275–282. [Google Scholar] [CrossRef]

- He, W.W.; Tang, H.P.; Liu, Y.; Xi, Z. Preparation of high-temperature TiAl pre-alloyed powder by PREP and its densification microstructure research. Rare Met. Mater. Eng. 2014, 43, 2768–2773. [Google Scholar]

- Wang, D.; Yuan, H.; Qiang, J. The Microstructure Evolution, Mechanical Properties and Densification Mechanism of TiAl-Based Alloys Prepared by Spark Plasma Sintering. Metals 2017, 7, 201. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Bondar, A.A.; Hecht, U.; Velikanova, T.Y. The Al-B-Nb-Ti system IV. Experimental study and thermodynamic re-evaluation of the binary Al-Nb and ternary Al-Nb-Ti systems. J. Alloys Compd. 2009, 472, 133–161. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, K.; Chen, Y.M.; Hou, X.Q.; Shen, Q. Study on Fabrication and properties of Ti/Al2O3 Composites. J. Mater. Sci. Eng. 2004, 35, 3258–3260. [Google Scholar]

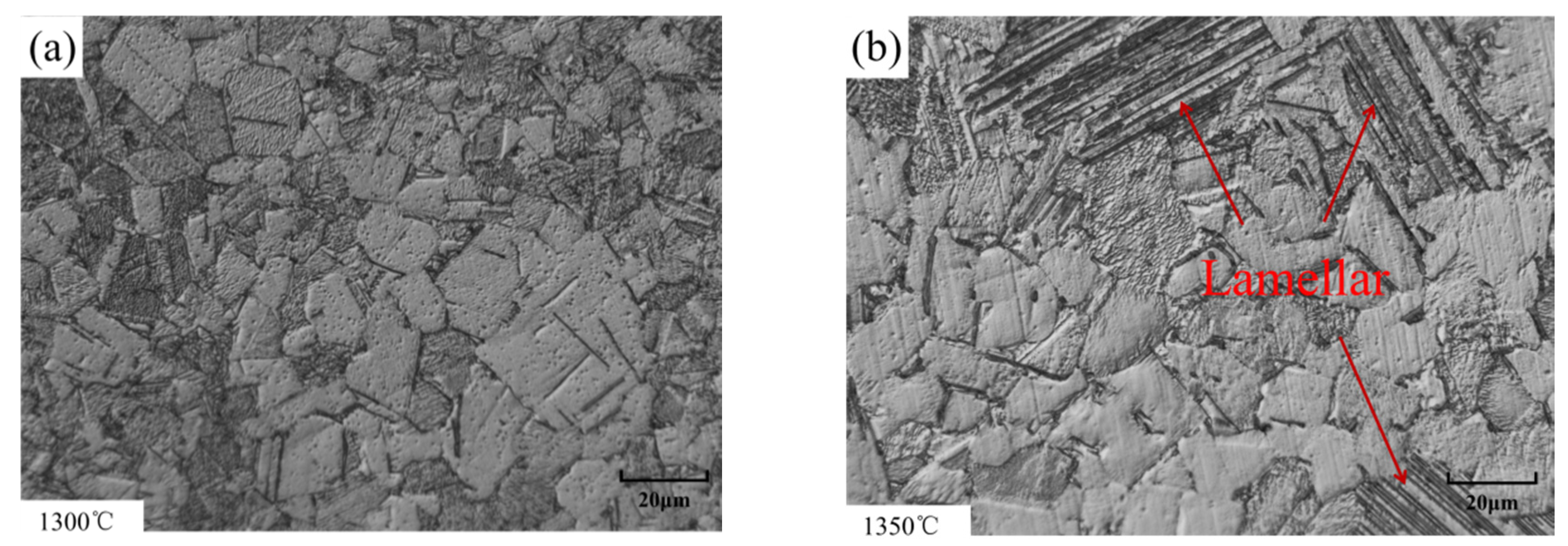

| Temperature (°C) | Time (h) | Density (g/cm3) | Size (μm) | Vickers Hardness (HV) | Troom Bending Strength (MPa) | Microstructure |

|---|---|---|---|---|---|---|

| 1200 | 0 | 4.080 | / | 252.6 | 440.5 | Grain phase |

| 1200 | 12 | 4.250 | 15–20 | 324.6 | 635 | Grain phase |

| 1250 | 0 | 4.181 | 10–15 | 287.9 | 644 | Grain phase |

| 1250 | 12 | 4.254 | 3–6 | 333.2 | 1025 | Grain phase |

| 1300 | 0 | 4.226 | 8–13 | 290.5 | 598 | Grain phase |

| 1300 | 12 | 4.239 | 5–8 | 331.5 | 1018 | Duplex (less lamellar) |

| 1350 | 0 | 4.244 | 200–300 | 286.5 | 485 | Duplex (more lamellar) |

| 1350 | 12 | 4.252 | 50–100 | 326.4 | 494 | Near lamellar |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Sun, H.; Du, Y.; Yuan, J. Effects of Powder Preparation and Sintering Temperature on Properties of Spark Plasma Sintered Ti-48Al-2Cr-8Nb Alloy. Metals 2019, 9, 861. https://doi.org/10.3390/met9080861

Wang Z, Sun H, Du Y, Yuan J. Effects of Powder Preparation and Sintering Temperature on Properties of Spark Plasma Sintered Ti-48Al-2Cr-8Nb Alloy. Metals. 2019; 9(8):861. https://doi.org/10.3390/met9080861

Chicago/Turabian StyleWang, Zhenhua, Haoxuan Sun, Yulei Du, and Juntang Yuan. 2019. "Effects of Powder Preparation and Sintering Temperature on Properties of Spark Plasma Sintered Ti-48Al-2Cr-8Nb Alloy" Metals 9, no. 8: 861. https://doi.org/10.3390/met9080861

APA StyleWang, Z., Sun, H., Du, Y., & Yuan, J. (2019). Effects of Powder Preparation and Sintering Temperature on Properties of Spark Plasma Sintered Ti-48Al-2Cr-8Nb Alloy. Metals, 9(8), 861. https://doi.org/10.3390/met9080861