Research on Lightweight Design and Indirect Hot Stamping Process of the New Ultra-High Strength Steel Seat Bracket

Abstract

1. Introduction

2. Finite Element Model and Optimization Analysis

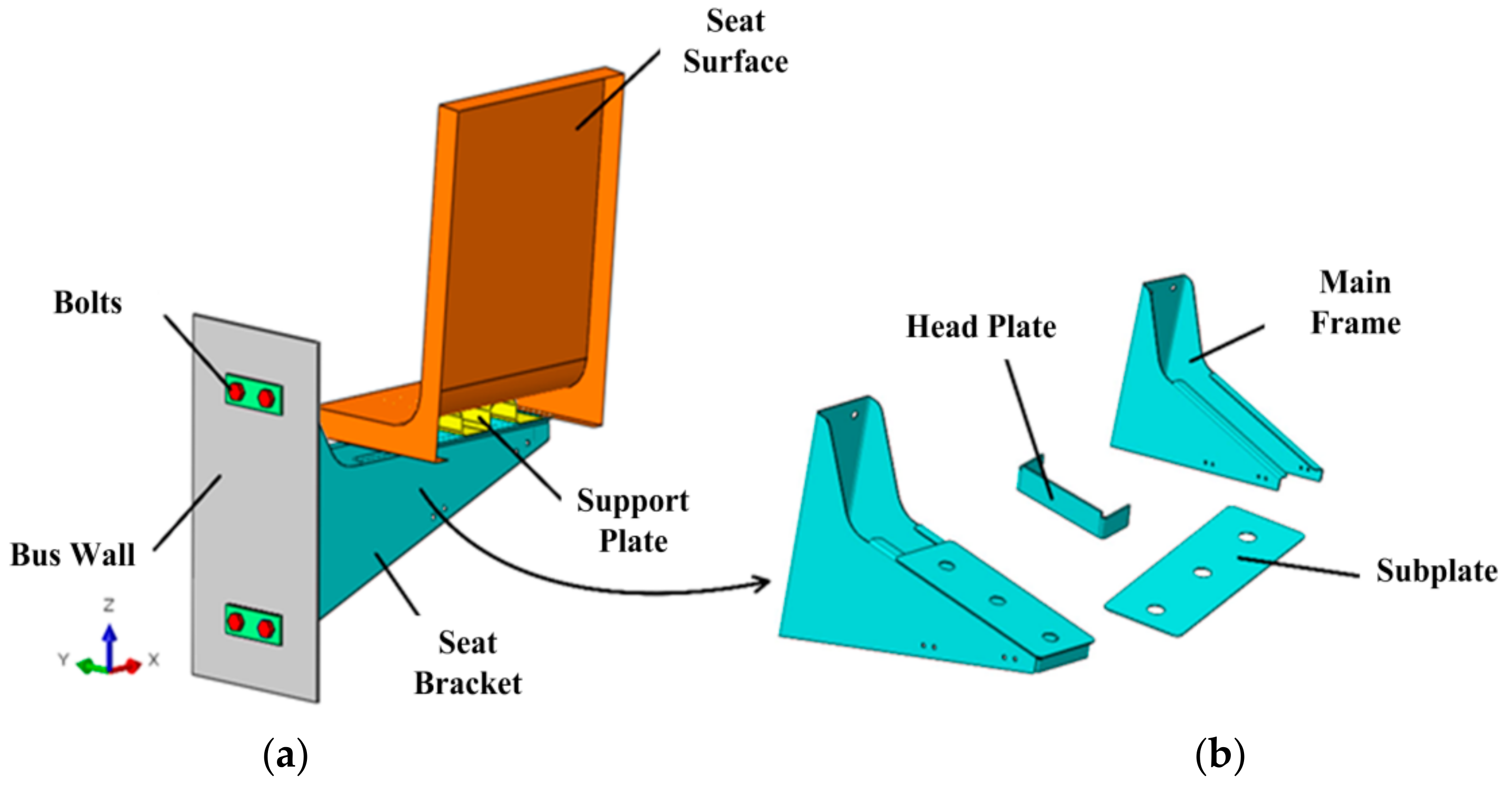

2.1. Finite Element Model

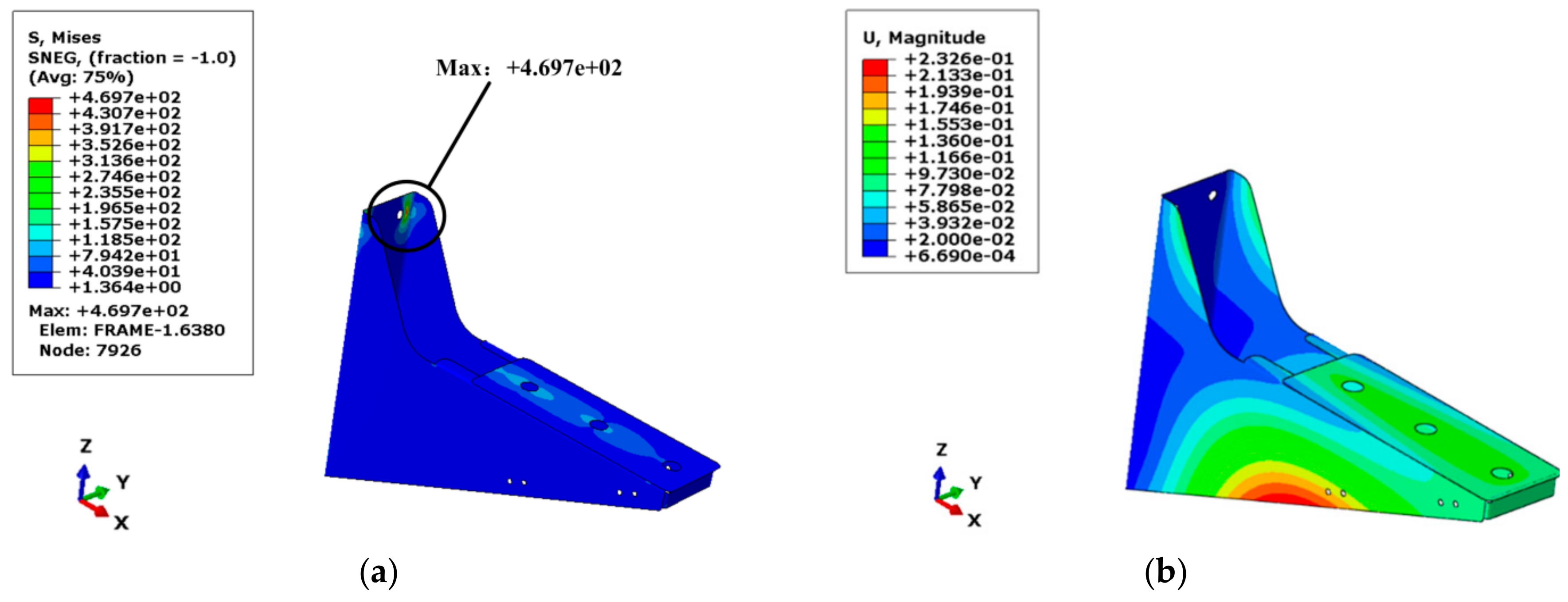

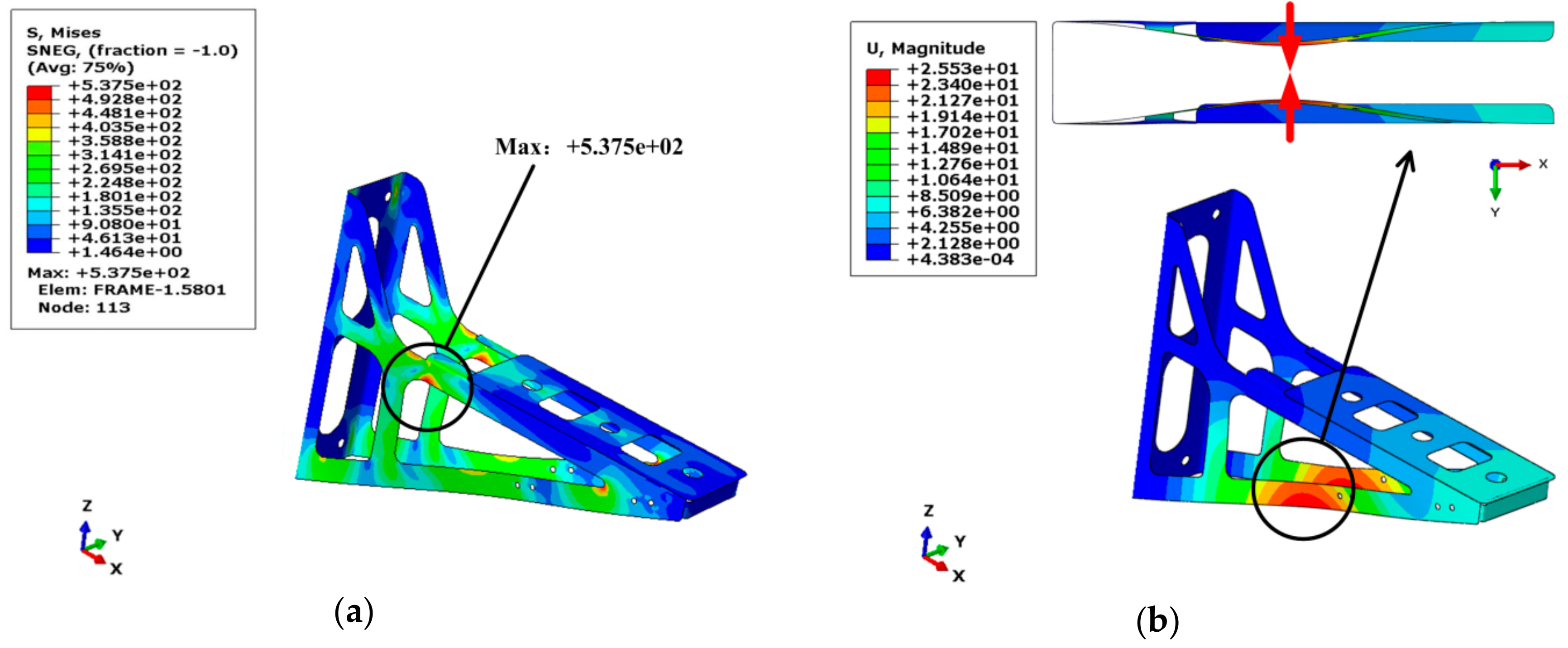

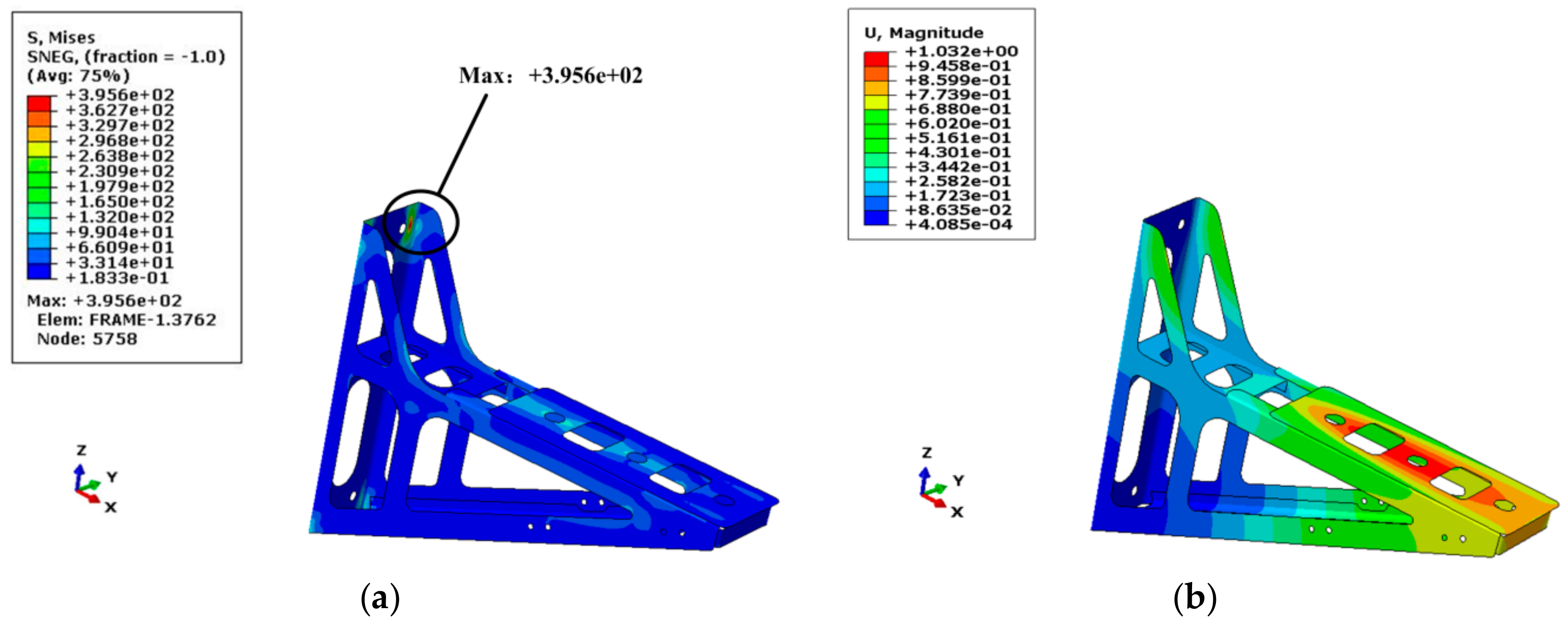

2.2. Finite Element Analysis

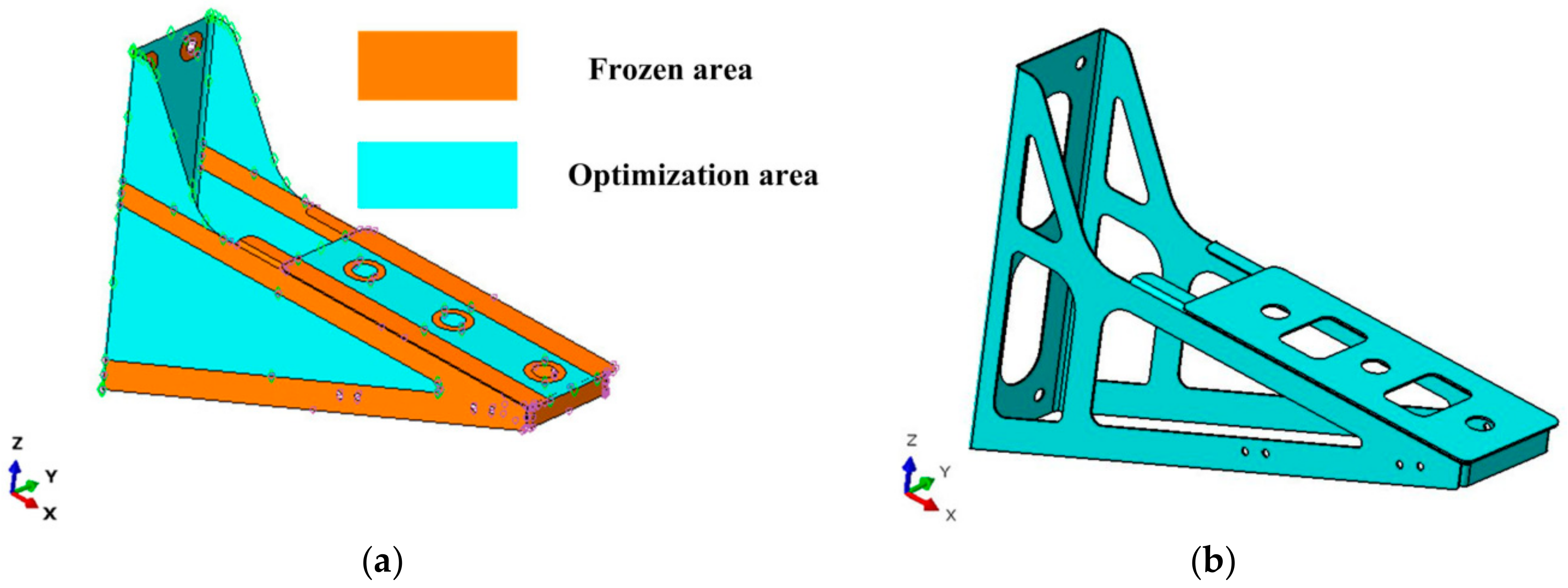

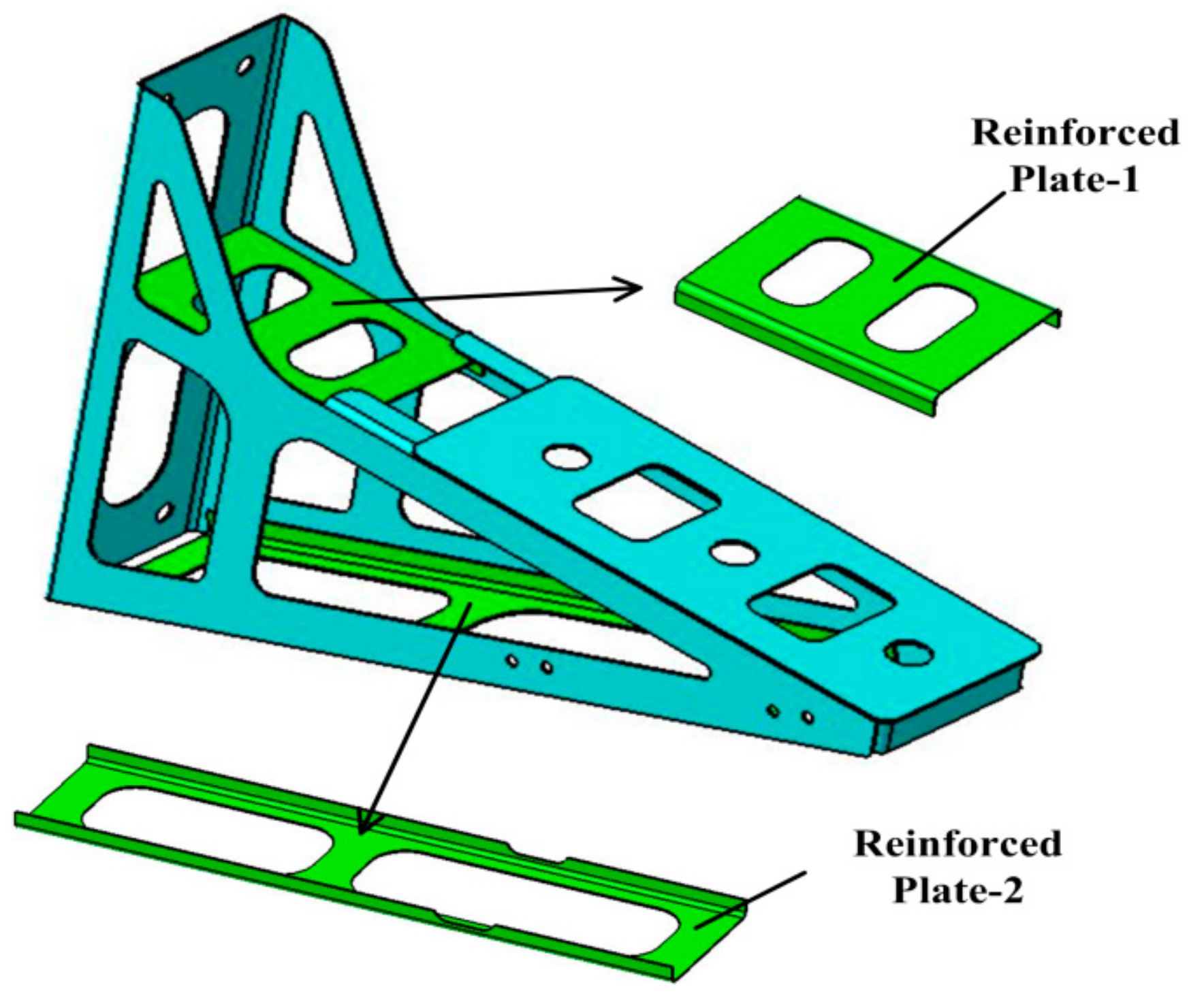

2.3. Topology Optimization Analysis

3. Forming Process and Stiffness Check

3.1. Materials

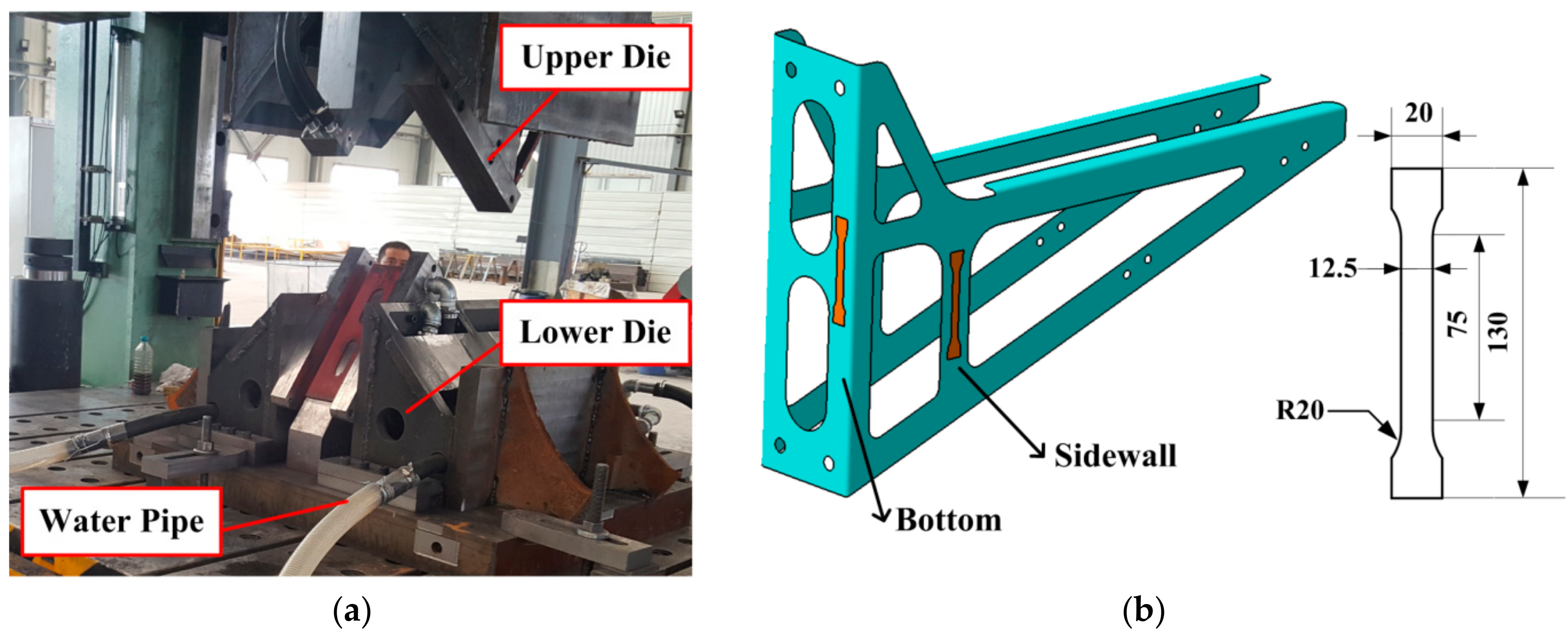

3.2. Indirect Hot Stamping Process

3.3. Microstructures Analysis

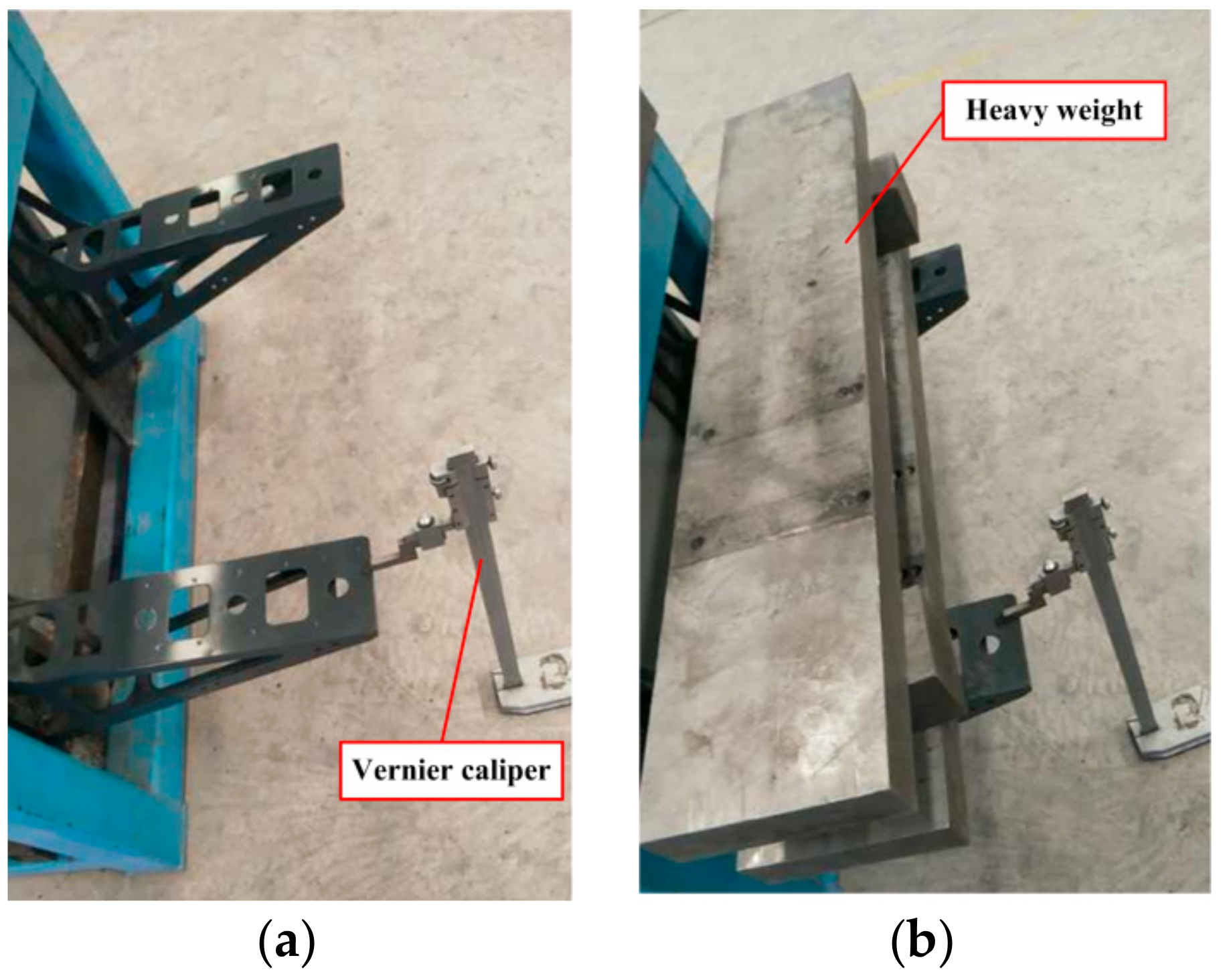

3.4. Stiffness Check Test

4. Conclusions

- (1)

- A new seat bracket was designed according to finite element analysis and topology optimization results; the results showed that the new seat bracket can reduce the weight by 17.04% after topology optimization.

- (2)

- The reasonable parameters during the indirect hot stamping process were that the main frame was heated to 950 °C and held at this temperature for 5 min. During quenching, the contact pressure was 10 MPa and held at this pressure for 8 s, and then the main frame was transformed to martensite. After indirect hot stamping, the seat bracket was showed with accurate size and no springback.

- (3)

- During the quenching stage of the indirect hot stamping, the bottom region is fully quenchable compared to the sidewall region. The cooling rate of the bottom region reached 27 °C/s, thus the austenite was completely transformed into martensite. However, the cooling rate of the sidewall region was less than 27 °C/s, then before the martensite transformation, some austenite transformed into ferrite and bainite.

- (4)

- According to the stiffness check test, the seat bracket has tiny deformation under the specified load, and the inspect results were basically consented to the finite element results, which verified the rationality of the seat bracket design.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Adheesh, S.R.; Vasisht, S.M.; Ramasesha, S.K. Air-pollution and economics: diesel bus versus electric bus. Curr. Sci. 2016, 110, 858–862. [Google Scholar]

- Li, J.Q. Battery-electric transit bus developments and operations: A review. Int. J. Sustainable Transp. 2016, 10, 157–169. [Google Scholar] [CrossRef]

- Dvorak, P. Fea and Optimization Leads to a More-Efficient Design Process. Mach. Des. 2001, 73, 54. [Google Scholar]

- Li, C.; Kim, I.Y.; Jeswiet, J. Conceptual and detailed design of an automotive engine cradle by using topology, shape, and size optimization. Struct. Multi. Optim. 2014, 51, 547–564. [Google Scholar] [CrossRef]

- Li, C.; Kim, I.Y. Topology, size and shape optimization of an automotive cross car beam. Proc. Inst. Mech. Eng. D 2014, 229, 1361–1378. [Google Scholar] [CrossRef]

- Yildiz, A.R. Optimal structural design of vehicle components using topology design and optimization. Mater. Test. 2008, 50, 224–228. [Google Scholar] [CrossRef]

- Yildiz, A.R. A new hybrid particle swarm optimization approach for structural design optimization in the automotive industry. Proc. Inst. Mech. Eng. D 2012, 226, 1340–1351. [Google Scholar] [CrossRef]

- Choi, H.S.; Kim, B.M.; Nam, K.J.; Ha, S.Y.; Cha, S.H.; Kang, C.G. Development of hot stamped center pillar using form die with channel type indirect blank holder. Int. J. Automot. Technol. 2011, 12, 887–894. [Google Scholar] [CrossRef]

- Hafenstein, S.; Werner, E.; Wilzer, J.; Theisen, W.; Weber, S.; Sunderkötter, C.; Bachmann, M. Influence of temperature and tempering conditions on thermal conductivity of hot work tool steels for hot stamping applications. Steel Res. Int. 2015, 86, 1628–1635. [Google Scholar] [CrossRef]

- Pedraza, J.P.; Landa-Mejia, R.; García-Rincon, O.; Isaac Garcia, C. The effect of rapid heating and fast cooling on the transformation behavior and mechanical properties of an advanced high strength steel (AHSS). Metals 2019, 9, 545. [Google Scholar] [CrossRef]

- Mori, K.; Bariani, P.F.; Behrens, B.A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Naderi, M.; Ketabchi, M.; Abbasi, M.; Bleck, W. Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping. J. Mater. Process. Technol. 2011, 211, 1117–1125. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Chowdhury, M.N.; Kim, J.-R.; Hong, S.-T.; Jung, J.-W.; Han, H.-N.; So, S.-W. Tailoring of mechanical properties of indirect hot stamping steel tubes by laser assisted local rapid heating. J. Iron. Steel Res. Int. 2016, 23, 949–954. [Google Scholar] [CrossRef]

- Hippchen, P.; Lipp, A.; Grass, H.; Craighero, P.; Fleischer, M.; Merklein, M. Modelling kinetics of phase transformation for the indirect hot stamping process to focus on car body parts with tailored properties. J. Mater. Process. Technol. 2016, 228, 59–67. [Google Scholar] [CrossRef]

- Hwang, J.S.; Moon, J.H.; Kang, C.-G. Prediction of springback during indirect hot press forming through tensile test with simultaneous cooling. Proc. Inst. Mech. Eng. B 2013, 227, 1013–1022. [Google Scholar] [CrossRef]

- Seo, H.Y.; Jin, C.K.; Kang, C.G. Effect on blank holding force on blank deformation at direct and indirect hot deep drawings of boron steel sheets. Metals 2018, 8, 574. [Google Scholar] [CrossRef]

- Rietz, A. Sufficiency of a finite exponent in simp (power law) methods. Struct. Multi. Optim. 2001, 21, 159–163. [Google Scholar] [CrossRef]

- Belblidia, F.; Lee, J.E.B.; Rechak, S.; Hinton, E. Topology optimization of plate structures using a single- or three-layered artificial material model. Adv. Eng. Software 2001, 32, 159–168. [Google Scholar] [CrossRef]

- Sigmund, O. Materials with prescribed constitutive parameters: An inverse homogenization problem. Int. J. Solids Struct. 1994, 31, 2313–2329. [Google Scholar] [CrossRef]

| Materials | Density (g/cm3) | Elasticity Modulus (GPa) | Poisson’s Ratio | U.T.S (MPa) |

|---|---|---|---|---|

| SUS304 | 7.94 | 194 | 0.3 | 264 |

| Q345 | 7.85 | 210 | 0.3 | 345 |

| 22MnB5 | 7.89 | 212 | 0.3 | 1152 |

| C | Mn | Si | Cr | B | P |

|---|---|---|---|---|---|

| 0.22–0.25 | 1.2–1.4 | 0.2–0.3 | 0.11–0.2 | 0.002–0.004 | ≤0.02 |

| Mechanical Properties | Specimen 1 | Standard Deviation | Specimen 2 | Standard Deviation |

|---|---|---|---|---|

| Tensile strength (MPa) | 1560 | 3.32 | 1422 | 5.54 |

| Microhardness (HV) | 513.5 | 0.46 | 489.5 | 1.05 |

| Elongation (%) | 4.8 | 0.02 | 6.9 | 0.04 |

| Elasticity modulus (GPa) | 211.06 | 9.8 | 190.66 | 10.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Z.; Gu, Z.; Jia, L.; Li, X.; Zhu, L.; Xu, H.; Yu, G. Research on Lightweight Design and Indirect Hot Stamping Process of the New Ultra-High Strength Steel Seat Bracket. Metals 2019, 9, 833. https://doi.org/10.3390/met9080833

Tang Z, Gu Z, Jia L, Li X, Zhu L, Xu H, Yu G. Research on Lightweight Design and Indirect Hot Stamping Process of the New Ultra-High Strength Steel Seat Bracket. Metals. 2019; 9(8):833. https://doi.org/10.3390/met9080833

Chicago/Turabian StyleTang, Ziming, Zhengwei Gu, Lei Jia, Xin Li, Lijuan Zhu, Hong Xu, and Ge Yu. 2019. "Research on Lightweight Design and Indirect Hot Stamping Process of the New Ultra-High Strength Steel Seat Bracket" Metals 9, no. 8: 833. https://doi.org/10.3390/met9080833

APA StyleTang, Z., Gu, Z., Jia, L., Li, X., Zhu, L., Xu, H., & Yu, G. (2019). Research on Lightweight Design and Indirect Hot Stamping Process of the New Ultra-High Strength Steel Seat Bracket. Metals, 9(8), 833. https://doi.org/10.3390/met9080833