Influences of Al2O3 and TiO2Content on Viscosity and Structure of CaO–8%MgO–Al2O3–SiO2–TiO2–5%FeO Blast Furnace Primary Slag

Abstract

:1. Introduction

2. Material and Methods

2.1. Preparation of SlagSamples

2.2. Viscosity Measurement

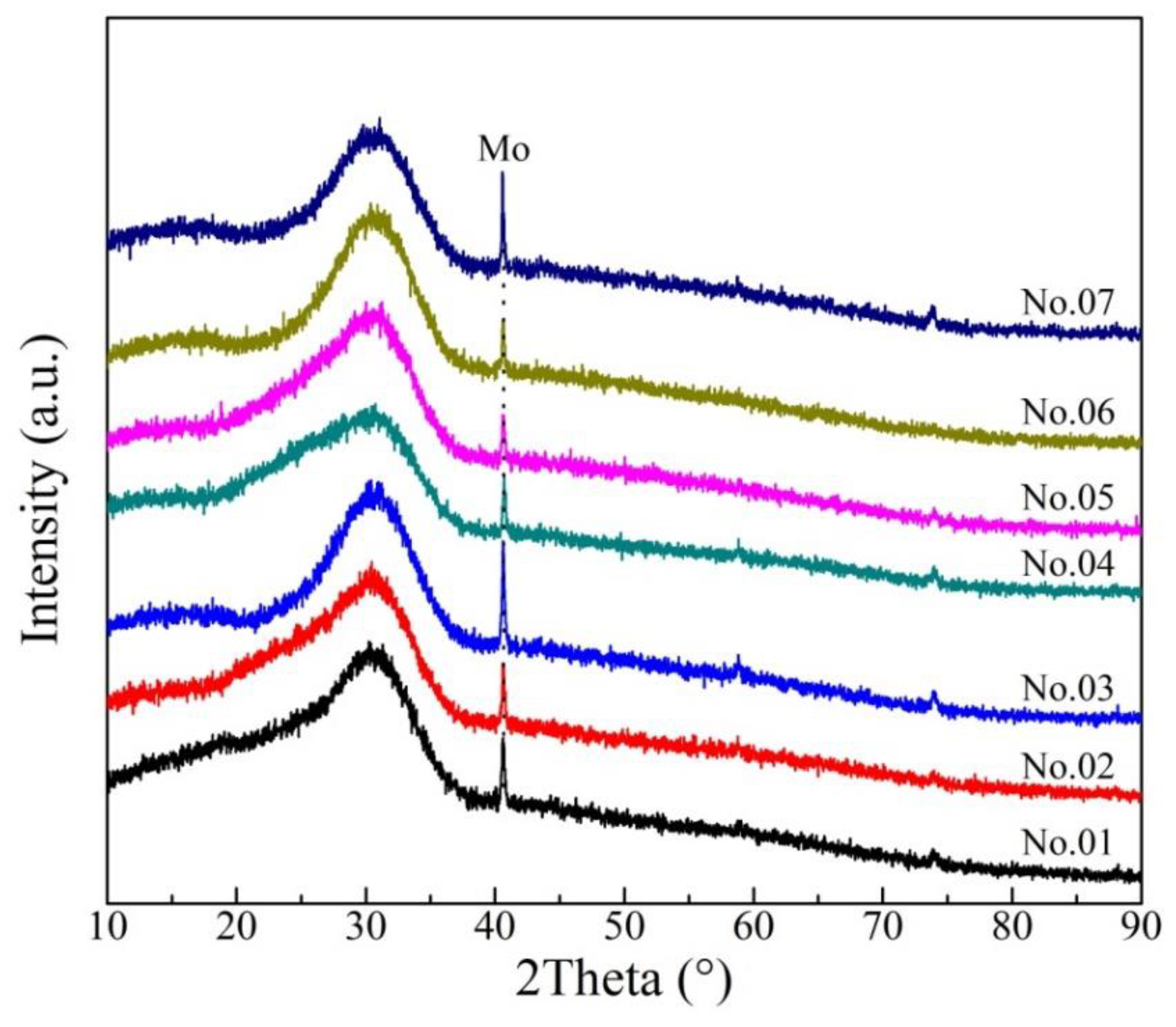

2.3. Phase Compositions and Structure Investigation

3. Results and Discussion

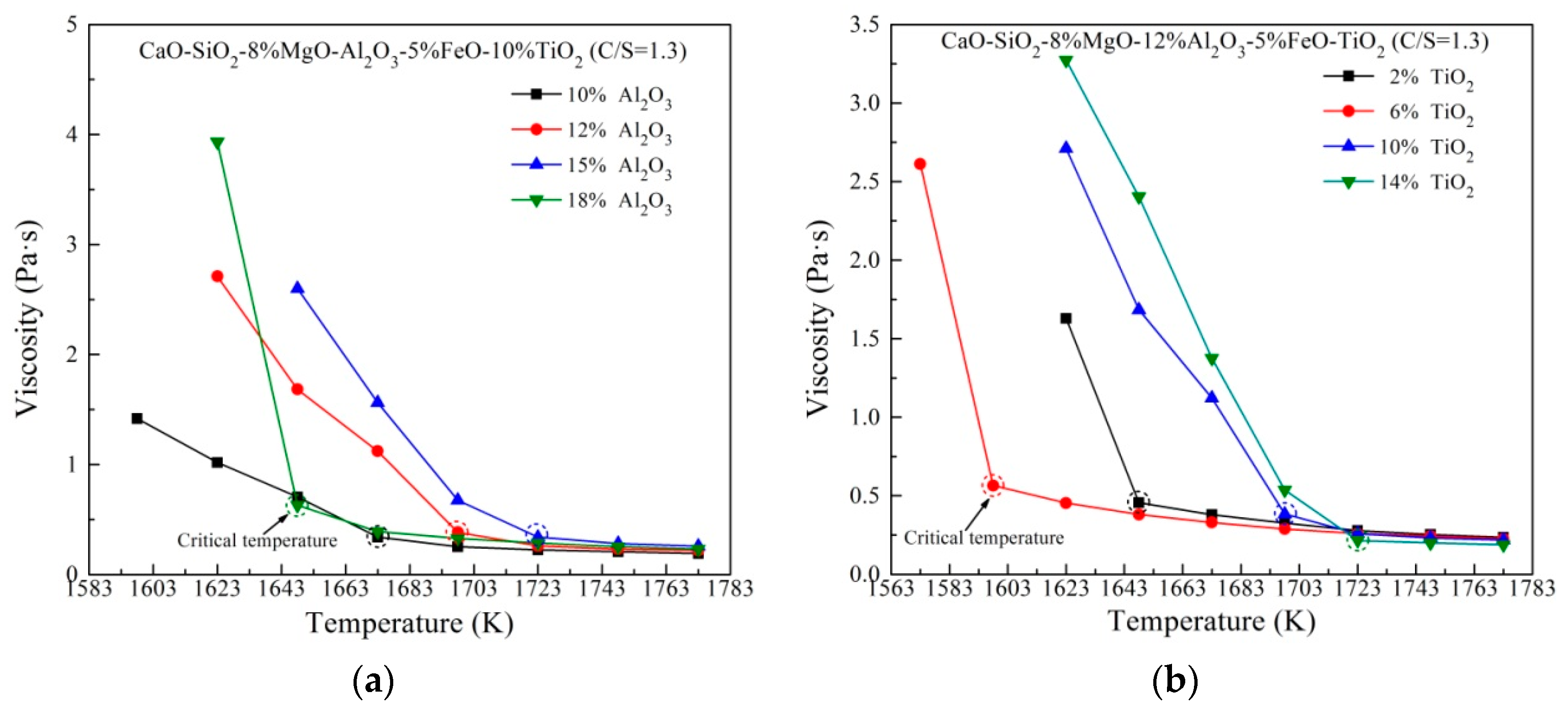

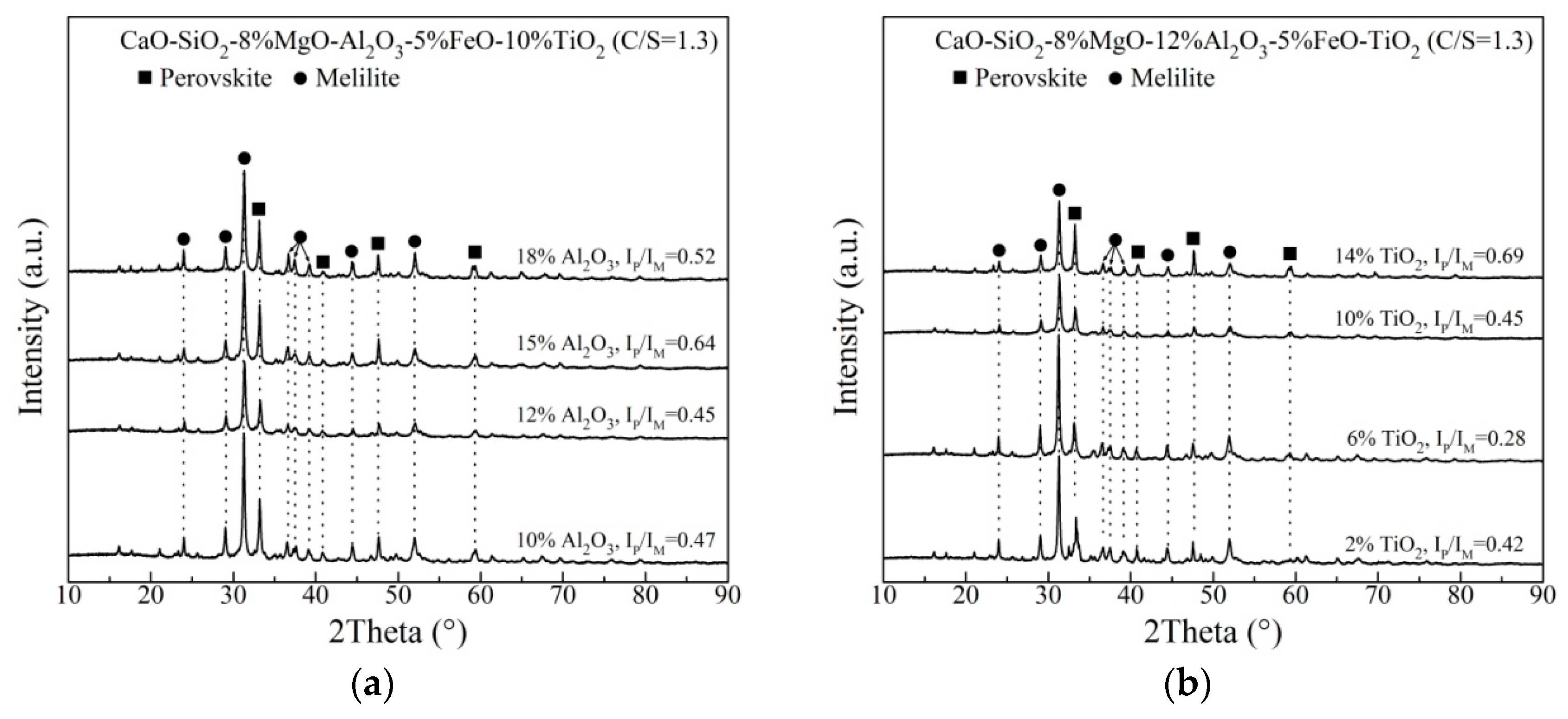

3.1. The Critical Temperatures

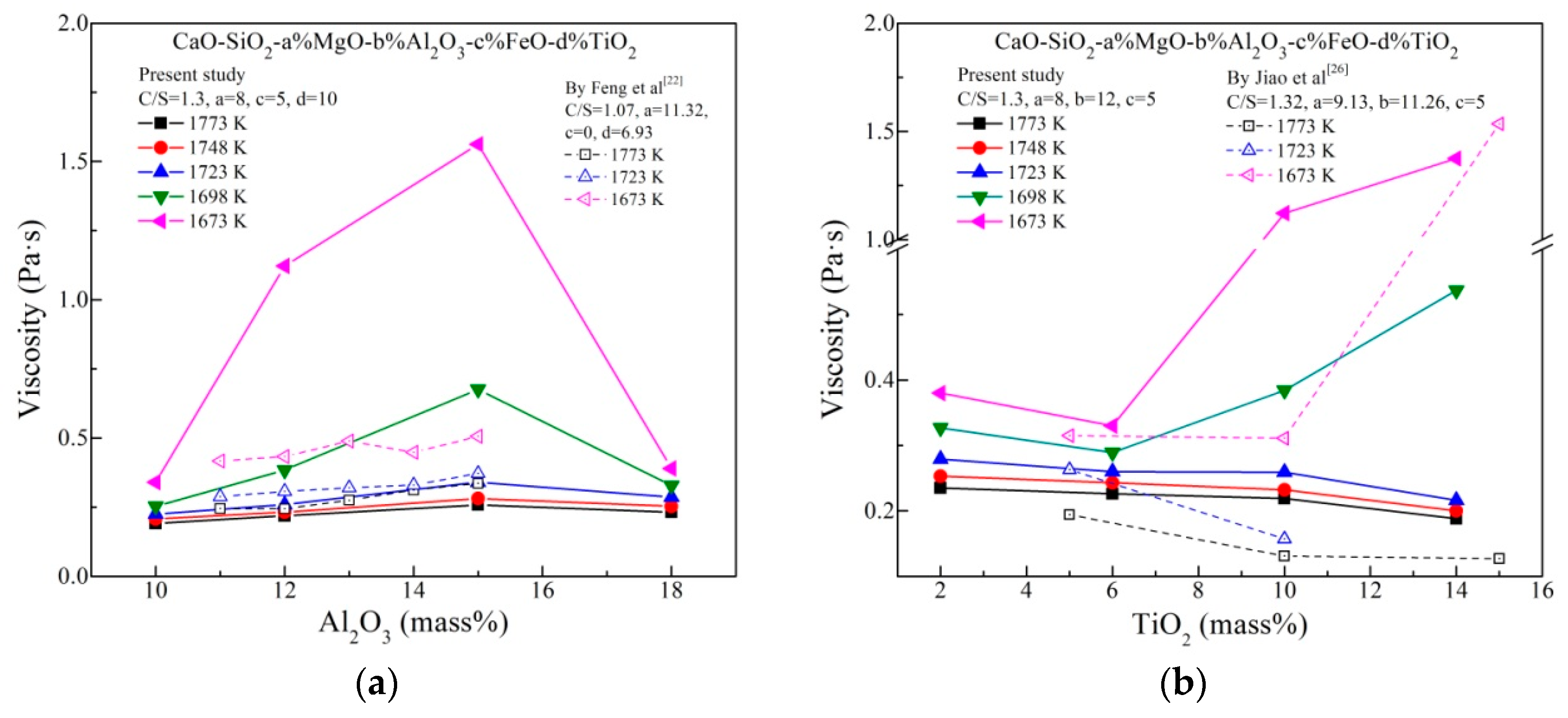

3.2. Effects of Al2O3 and TiO2 on Viscosity

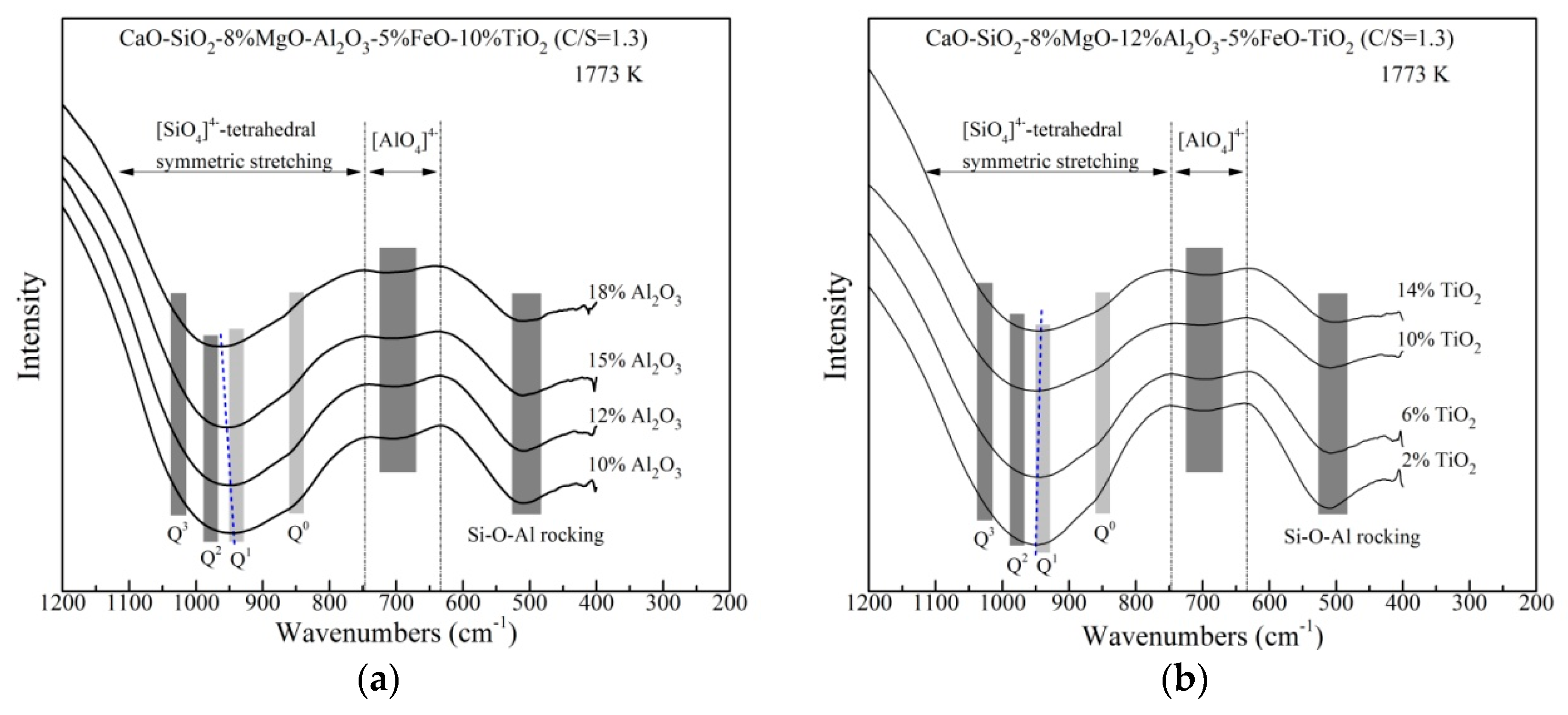

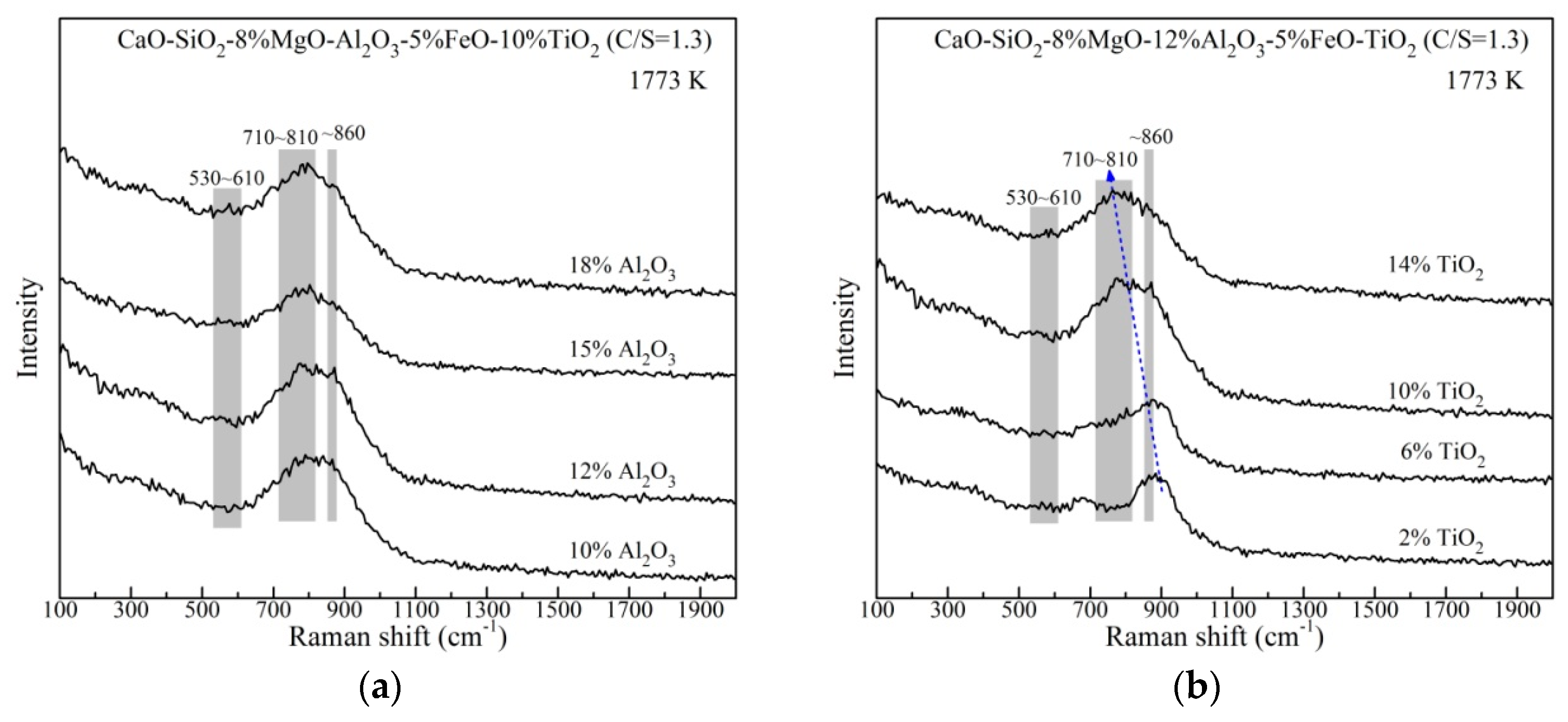

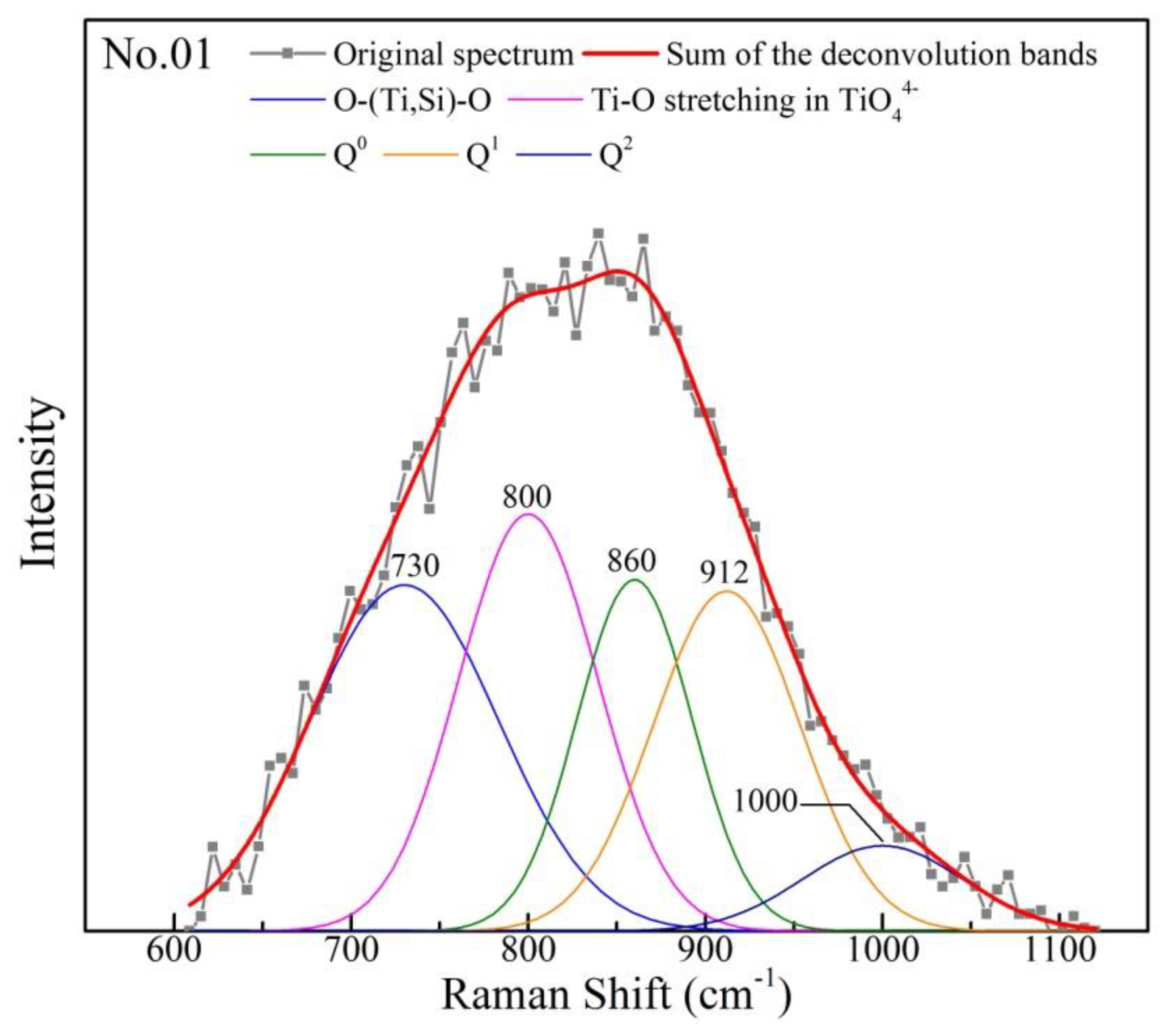

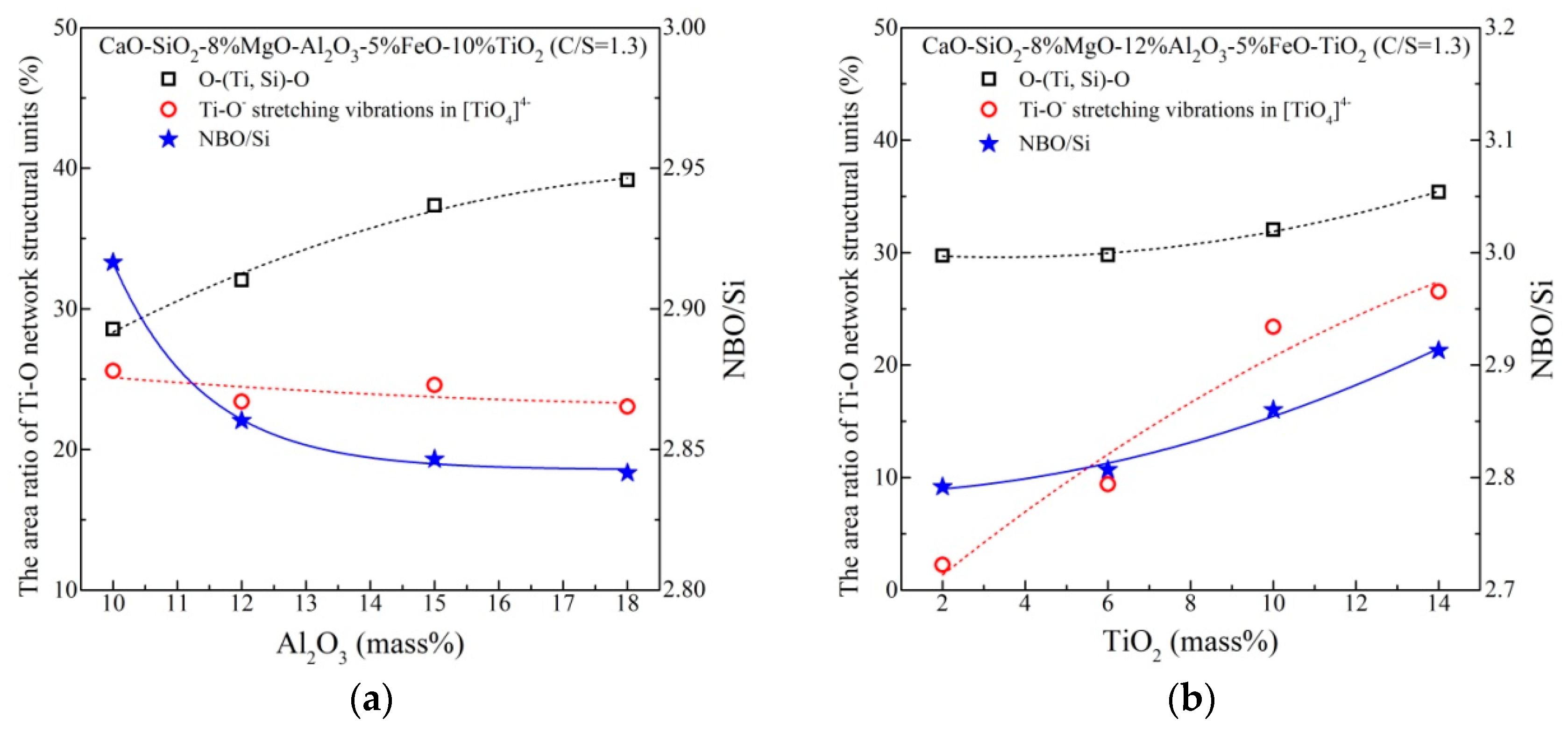

3.3. Structure Analysis by FTIR and Raman

4. Conclusions

- (1).

- The change of critical temperatures can be attributed to the variation trend of melting temperature and crystallization capacity, which is able to be explained by the relative amounts of basic phases including perovskite and melilite.

- (2).

- The viscosity of the slag containing 10 mass% TiO2 first increases and then decreases with increasing Al2O3 content from 10 to 18 mass%, exhibiting the maximum value at 15% Al2O3, while an increase in TiO2 content from 2 to 14 mass% causes a decrease in the viscosity of the slag at 12 mass % Al2O3.

- (3).

- FTIR and Raman analysis confirm that Si–O and Ti–O networks are more complex with increasing Al2O3 or decreasing TiO2 content, causing higher viscosity. The dampening of Si–O–Al trough observed in FTIR indicates a decrease in the linkagebetween [SiO4]4− and [AlO4]5− tetrahedrals, which may be the reason for the lower viscosity with excess Al2O3 content.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fan, H.L.; Chen, D.F.; Liu, T.; Duan, H.M.; Huang, Y.W.; Long, M.J.; He, W.J. Crystallization behaviors of anosovite and silicate crystals in high CaO and MgO titanium slag. Metals 2018, 8, 754. [Google Scholar] [CrossRef]

- Tang, J.; Chu, M.S.; Xue, X.X. Optimized use of MgO flux in the agglomeration of high–chromium vanadium–titanium magnetite. Int. J. Miner. Metall. Mater. 2015, 22, 371–380. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, J.L.; Jiao, K.X. Economical and efficient protection for blast furnace hearth. ISIJ Int. 2018, 58, 1198–1203. [Google Scholar] [CrossRef]

- Sun, J.; Wang, S.; Chu, M.S.; Chen, M.; Zhao, Z.X.; Zhao, B.J.; Liu, Z.G. Titanium distribution between blast furnace slag and iron for blast furnace linings protection. Ironmak. Steelmak. 2018, 45, 1–8. [Google Scholar] [CrossRef]

- Jiao, K.X.; Zhang, J.L.; Liu, Z.J.; Xu, M.; Liu, F. Formation mechanism of the protective layer in a blast furnace hearth. Int. J. Miner. Metall. Mater. 2015, 22, 1017–1024. [Google Scholar] [CrossRef]

- Li, T.L.; Sun, C.Y.; Lan, D.; Song, J.; Song, S.; Wang, Q. Effect of mineral elements migration on softening–melting properties of Ti–bearing high basicity sinter. ISIJ Int. 2019, 59, 245–252. [Google Scholar] [CrossRef]

- Zhou, X.L.; Luo, Y.H.; Chen, T.J.; Zhu, D.P. Enhancing the reduction of high-aluminum iron ore by synergistic reducing with high-manganese iron ore. Metals 2019, 9, 15. [Google Scholar] [CrossRef]

- Guo, H.; Shen, F.M.; Zhang, H.Y.; Gao, Q.J.; Jiang, X. High–temperature reduction and melting mechanism of sinter with different MgO content. Metals 2019, 9, 510. [Google Scholar] [CrossRef]

- Pang, Z.D.; Lv, X.W.; Yan, Z.M.; Liang, D.; Dang, J. Transition of blast furnace slag from silicate-based to aluminate-based: Electrical conductivity. Metall. Mater. Trans. B 2019, 50, 385–394. [Google Scholar] [CrossRef]

- Xie, H.E.; Yu, W.Z.; You, Z.X.; Lv, X.W.; Bai, C.G. The effect of titanium carbonitride on the viscosity of high–titanium–type blast furnace slag. Metals 2019, 9, 395. [Google Scholar] [CrossRef]

- Yan, Z.M.; Lv, X.W.; He, W.C.; Xu, J. Effect of TiO2 on the liquid zone and apparent viscosity of SiO2–CaO–8wt%MgO–14wt%Al2O3 system. ISIJ Int. 2017, 57, 31–36. [Google Scholar] [CrossRef]

- Xu, R.Z.; Zhang, J.L.; Ma, R.Y.; Jiao, K.X.; Zhao, Y.A. Influence of TiO2 on the viscosity of a high alumina slag and on carbon brick corrosion. Steel Res. Int. 2017, 89, 1700353. [Google Scholar] [CrossRef]

- Feng, C.; Chu, M.S.; Tang, J.; Qin, J.; Li, F.; Liu, Z.G. Effects of MgO and TiO2 on the viscous behaviors and phase compositions of titanium–bearing slag. Int. J. Miner. Metall. Mater. 2016, 23, 868–880. [Google Scholar] [CrossRef]

- Sohn, I.; Wang, W.L.; Matsuura, H.; Tsukihashi, F.; Min, D.J. Influence of TiO2 on the viscous behavior of calcium silicate melts containing 17 mass% Al2O3 and 10 mass% MgO. ISIJ Int. 2012, 52, 158–160. [Google Scholar] [CrossRef]

- Park, H.; Park, J.Y.; Kim, G.H.; Sohn, I. Effect of TiO2 on the viscosity and slag structure in blast furnace type slags. Steel Res. Int. 2012, 83, 150–156. [Google Scholar] [CrossRef]

- Shankar, A.; Görnerup, M.; Lahiri, A.K.; Seetharaman, S. Experimental investigation of the viscosities in CaO–SiO2–MgO–Al2O3 and CaO–SiO2–MgO–Al2O3–TiO2 slags. Metall. Mater. Trans. B 2007, 38, 911–915. [Google Scholar] [CrossRef]

- Zhang, S.F.; Zhang, X.; Liu, W.; Lv, X.W.; Bai, C.G.; Wang, L. Relationship between structure and viscosity of CaO–SiO2–Al2O3–MgO–TiO2 slag. J. Non-Cryst. Solids 2014, 402, 214–222. [Google Scholar] [CrossRef]

- Liao, J.L.; Li, J.; Wang, X.D.; Zhang, Z.T. Influence of TiO2 and basicity on viscosity of Ti bearing slag. Ironmak. Steelmak. 2013, 39, 133–139. [Google Scholar] [CrossRef]

- Feng, C.; Tang, J.; Gao, L.H.; Liu, Z.G.; Chu, M.S. Effects of CaO/SiO2 on viscous behaviors and structure of CaO–SiO2–11.00wt%MgO–11.00wt%Al2O3–43.00wt%TiO2 slag systems. ISIJ Int. 2019, 59, 31–38. [Google Scholar] [CrossRef]

- Liang, H.L.; Chu, M.S.; Feng, C.; Tang, J.; Liu, Z.G.; Wang, W.P. Optimisation study and affecting mechanism of CaO/SiO2 and MgO on viscous behaviours of titanium–bearing blast furnace slag. Ironmak. Steelmak. 2018, 45. [Google Scholar] [CrossRef]

- Yan, Z.M.; Lv, X.W.; Zhang, J.; Qin, Y.; Bai, C.G. Influence of MgO, Al2O3 and CaO/SiO2 on the viscosity of blast furnace type slag with high Al2O3 and 5 wt–% TiO2. Can. Metall. Q. 2016, 55, 186–194. [Google Scholar] [CrossRef]

- Feng, C.; Chu, M.S.; Tang, J.; Tang, Y.T.; Liu, Z.G. Effect of CaO/SiO2 and Al2O3 on viscous behaviors of the titanium–bearing blast furnace slag. Steel Res. Int. 2016, 87, 1274–1283. [Google Scholar] [CrossRef]

- Bian, L.T.; Gao, Y.H. Influence of Al2O3, CaO/SiO2, and B2O3 on viscous behavior of high alumina and medium titania blast furnace slag. J. Chem. 2017, 2017, 6895928. [Google Scholar] [CrossRef]

- Zhen, Y.L.; Zhang, G.H.; Chou, K.C. Influence of Al2O3/TiO2 ratio on viscosities and structure of CaO–MgO–Al2O3–SiO2–TiO2 melts. ISIJ Int. 2014, 54, 985–989. [Google Scholar] [CrossRef]

- Jiao, K.X.; Zhang, J.L.; Wang, Z.Y.; Liu, Y.X.; Xu, R.Z. Melting features and viscosity of TiO2–containing primary slag in a blast furnace. High Temp. Mater. Proc. 2018, 37, 149–156. [Google Scholar] [CrossRef]

- Jiao, K.X.; Zhang, J.L.; Wang, Z.Y.; Chen, C.L.; Liu, Y.X. Effect of TiO2 and FeO on the viscosity and structure of blast furnace primary Slags. Steel Res. Int. 2017, 88, 1600296. [Google Scholar] [CrossRef]

- Park, J.H.; Min, D.J.; Song, H.S. Amphoteric behavior of alumina in viscous flow and structure of CaO–SiO2(–MgO)–Al2O3 slags. Metall. Mater. Trans. B 2004, 35, 269–275. [Google Scholar] [CrossRef]

- Zheng, K.; Zhang, Z.T.; Liu, L.L.; Wang, X.D. Investigation of the viscosity and structural properties of CaO–SiO2–TiO2 slags. Metall. Mater. Trans. B 2014, 45, 1389–1397. [Google Scholar] [CrossRef]

- Qi, J.; Liu, C.J.; Jiang, M.F. Role of Li2O on the structure and viscosity in CaO–Al2O3–Li2O–Ce2O3 melts. J. Non-Cryst. Solids 2017, 475, 101–107. [Google Scholar] [CrossRef]

- Gao, Y.M.; Wang, S.B.; Hong, C.; Ma, X.J.; Yang, F. Effects of basicity and MgO content on the viscosity of the SiO2–CaO–MgO–9wt%Al2O3 slag system. Int. J. Miner. Metall. Mater. 2014, 21, 353–362. [Google Scholar] [CrossRef]

- Kim, J.R.; Lee, Y.S.; Min, D.J.; Jung, S.M.; Yi, S.H. Influence of MgO and Al2O3 contents on viscosity of blast furnace type slags containing FeO. ISIJ Int. 2004, 44, 1291–1297. [Google Scholar] [CrossRef]

- Shen, X.; Chen, M.; Wang, N.; Wang, D. Viscosity property and melt structure of CaO–MgO–SiO2–Al2O3–FeO Slag System. ISIJ Int. 2019, 59, 9–15. [Google Scholar] [CrossRef]

- Mysen, B.O.; Ryerson, F.J.; Virgo, D. The influence of TiO2 on the structure and derivative properties of silicate melts. Am. Mineral. 1980, 65, 1150–1165. [Google Scholar]

- Bihuniak, P.P.; Condrate, R.A. Structures, spectra and related properties of group IVB–doped vitreous silica. J. Non-Cryst. Solids 1981, 44, 331–343. [Google Scholar] [CrossRef]

- McMillan, P.; Piriou, B. Raman spectroscopy of calcium aluminate glasses and crystals. J. Non-Cryst. Solids 1983, 55, 221–242. [Google Scholar] [CrossRef]

- McMillan, P.F.; Poe, B.T.; Gillet, P.H.; Reynard, B. A study of SiO2 glass and supercooled liquid to 1950 K via high–temperature Raman spectroscopy. Geochim. Cosmochim. Ac. 1994, 58, 3653–3664. [Google Scholar] [CrossRef]

- Deng, L.B.; Zhang, X.F.; Zhang, M.X.; Jia, X.L. Effect of CaF2 on viscosity, structure and properties of CaO–Al2O3–MgO–SiO2 slag glass ceramics. J. Non-Cryst. Solids 2018, 500, 310–316. [Google Scholar] [CrossRef]

- Mysen, B.O.; Virgo, D.; Scarfe, C.M. Relations between the anionic structure and viscosity of silicate melts–A Raman spectroscopic study. Am. Mineral. 1980, 74, 690–710. [Google Scholar]

- Mysen, B.O.; Finger, L.W.; Virgo, D.; Seifert, F.A. Curve–fitting of Raman spectra of silicate glasses. Am. Mineral. 1982, 67, 686–695. [Google Scholar]

- Sun, Y.Q.; Wang, H.; Zhang, Z.T. Understanding the relationship between structure and thermophysical properties of CaO–SiO2–MgO–Al2O3 molten slags. Metall. Mater. Trans. B 2018, 49, 677–687. [Google Scholar] [CrossRef]

- Frantza, J.D.; Mysen, B.O. Raman spectra and structure of BaO–SiO2, SrO–SiO2 and CaO–SiO2 melts to 1600 °C. Chem. Geol. 1995, 121, 155–176. [Google Scholar] [CrossRef]

| No. | Designed | Analyzed | |||||

|---|---|---|---|---|---|---|---|

| FeO | CaO | MgO | Al2O3 | SiO2 | TiO2 | FeO | |

| 01 | 5.00 | 37.87 | 8.00 | 10.00 | 29.13 | 10.00 | 4.62 |

| 02 | 5.00 | 36.74 | 8.00 | 12.00 | 28.26 | 10.00 | 4.43 |

| 03 | 5.00 | 35.04 | 8.00 | 15.00 | 26.96 | 10.00 | 4.71 |

| 04 | 5.00 | 33.35 | 8.00 | 18.00 | 25.65 | 10.00 | 4.57 |

| 05 | 5.00 | 41.26 | 8.00 | 12.00 | 31.74 | 2.00 | 4.28 |

| 06 | 5.00 | 39.00 | 8.00 | 12.00 | 30.00 | 6.00 | 4.46 |

| 07 | 5.00 | 34.48 | 8.00 | 12.00 | 26.52 | 14.00 | 4.59 |

| No. | Factors | Al2O3 (mass%) | TiO2 (mass%) | Eη (kJ/mol) |

|---|---|---|---|---|

| 01 | Al2O3 | 10 | 10 | 92.9 |

| 02 | 12 | 10 | 85.3 | |

| 03 | 15 | 10 | 140.4 | |

| 04 | 18 | 10 | 116.4 | |

| 05 | TiO2 | 12 | 2 | 87.2 |

| 06 | 12 | 6 | 80.7 | |

| 02 | 12 | 10 | 85.3 | |

| 07 | 12 | 14 | 70.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Sun, C.; Song, S.; Wang, Q. Influences of Al2O3 and TiO2Content on Viscosity and Structure of CaO–8%MgO–Al2O3–SiO2–TiO2–5%FeO Blast Furnace Primary Slag. Metals 2019, 9, 743. https://doi.org/10.3390/met9070743

Li T, Sun C, Song S, Wang Q. Influences of Al2O3 and TiO2Content on Viscosity and Structure of CaO–8%MgO–Al2O3–SiO2–TiO2–5%FeO Blast Furnace Primary Slag. Metals. 2019; 9(7):743. https://doi.org/10.3390/met9070743

Chicago/Turabian StyleLi, Tingle, Changyu Sun, Sunny Song, and Qi Wang. 2019. "Influences of Al2O3 and TiO2Content on Viscosity and Structure of CaO–8%MgO–Al2O3–SiO2–TiO2–5%FeO Blast Furnace Primary Slag" Metals 9, no. 7: 743. https://doi.org/10.3390/met9070743

APA StyleLi, T., Sun, C., Song, S., & Wang, Q. (2019). Influences of Al2O3 and TiO2Content on Viscosity and Structure of CaO–8%MgO–Al2O3–SiO2–TiO2–5%FeO Blast Furnace Primary Slag. Metals, 9(7), 743. https://doi.org/10.3390/met9070743