Resistance Spot Welding of SUS316L Austenitic/SUS425 Ferritic Stainless Steels: Weldment Characteristics, Mechanical Properties, Phase Transformation and Solidification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Welding Process

2.2. Metallographic Assessment

3. Results and Discussion

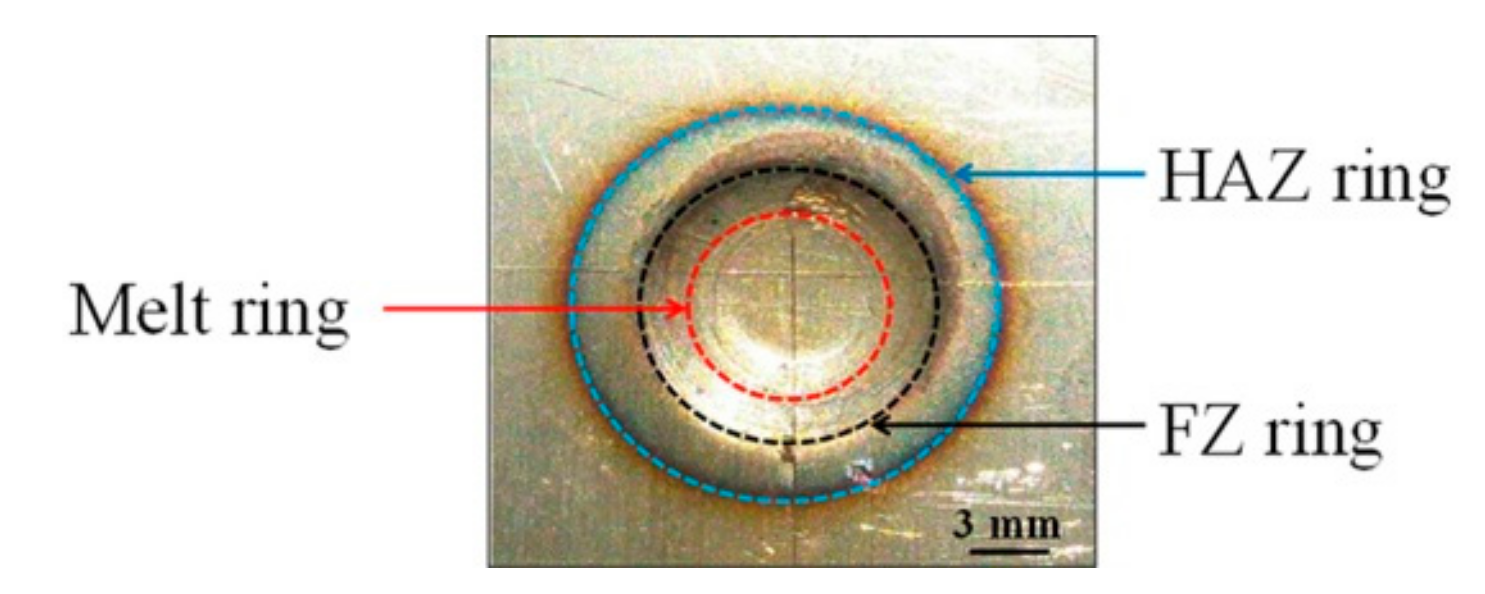

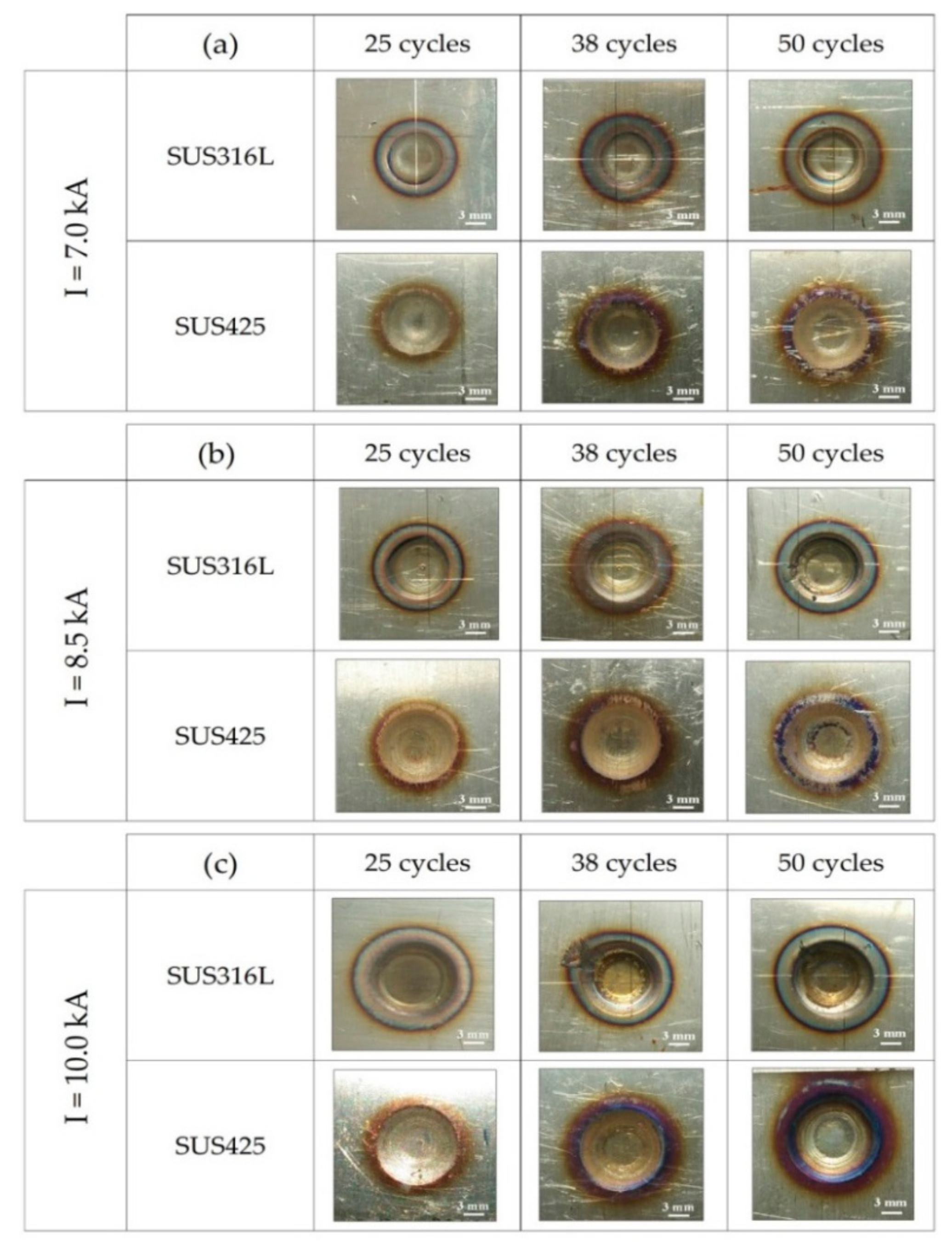

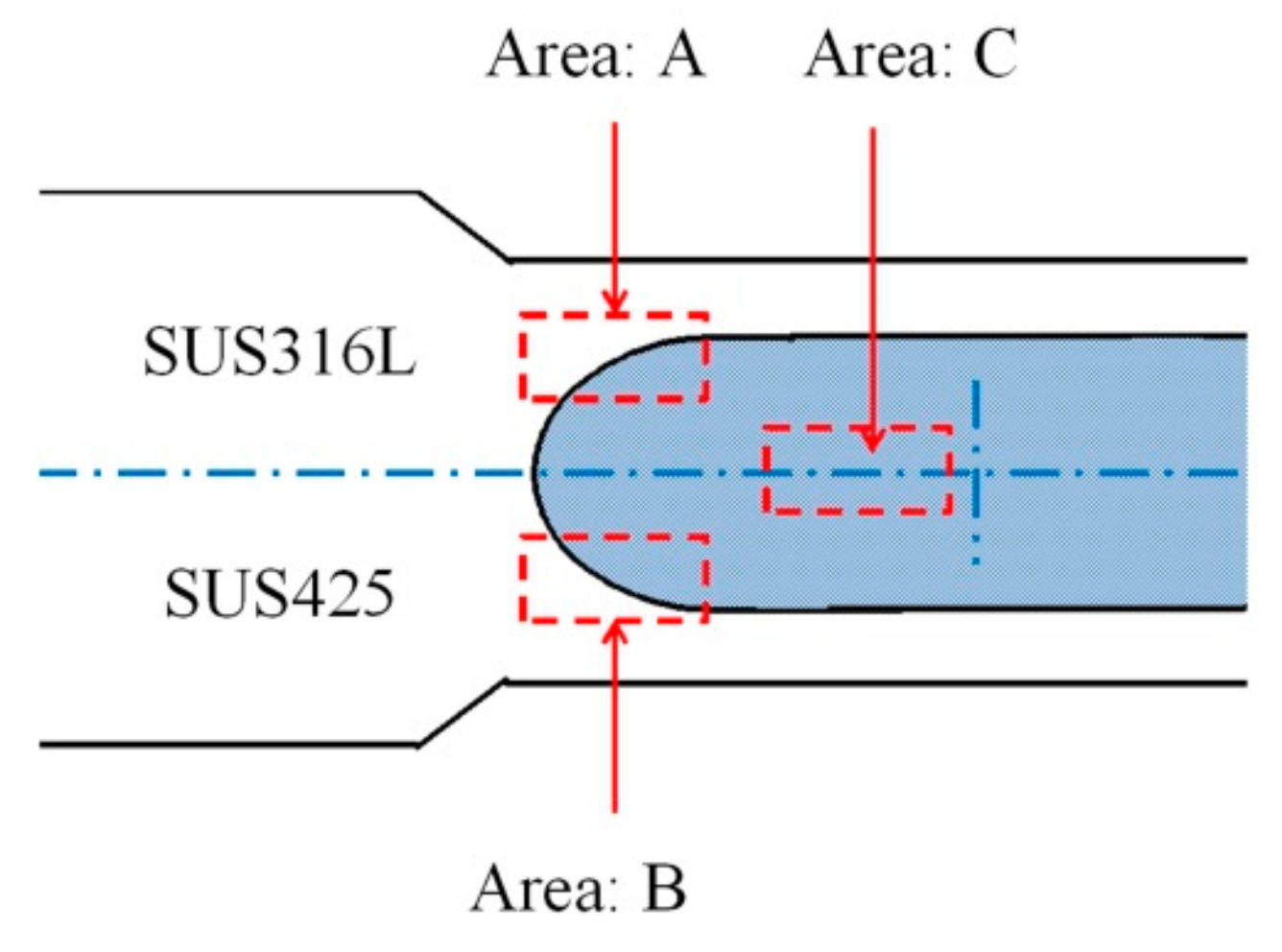

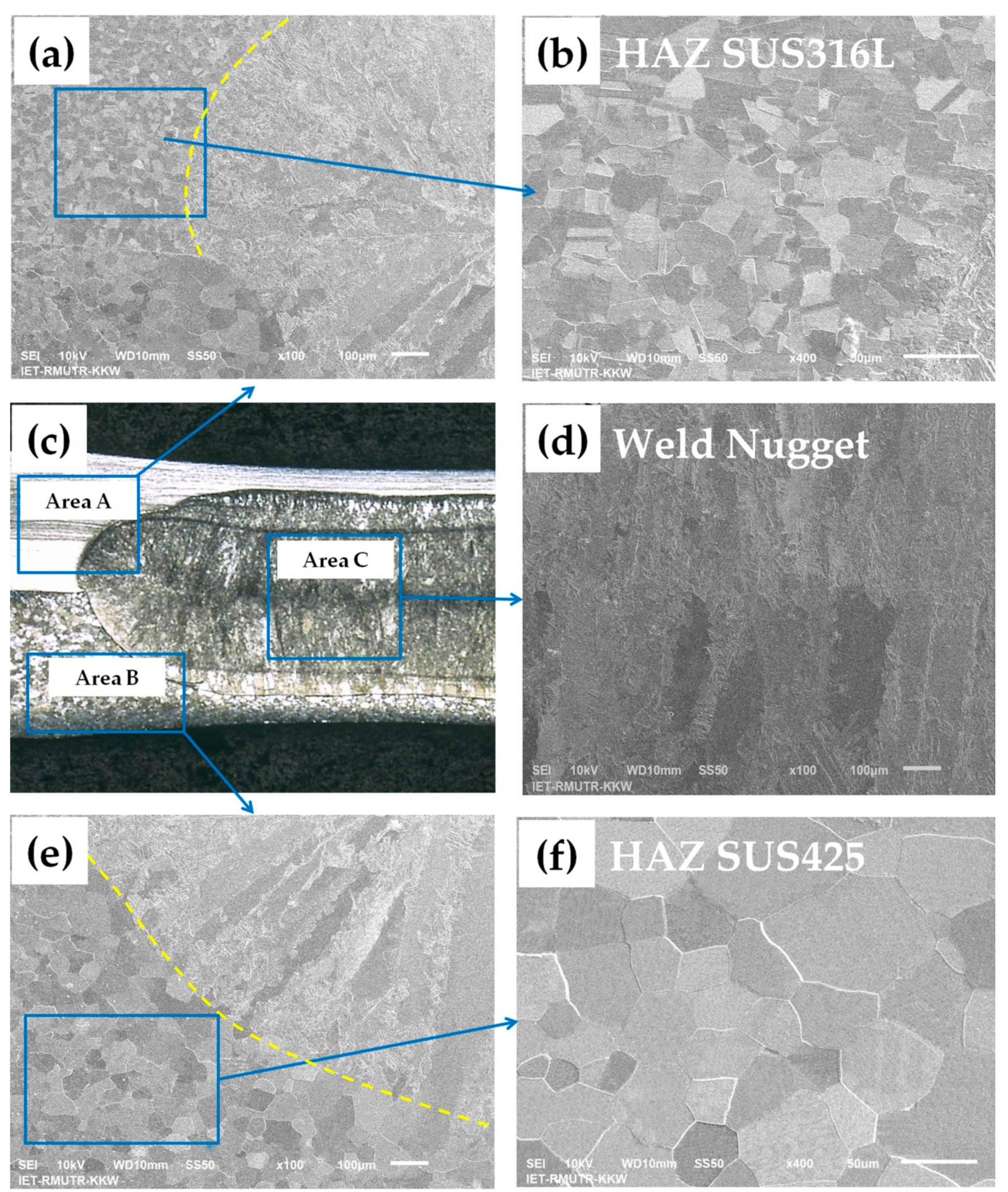

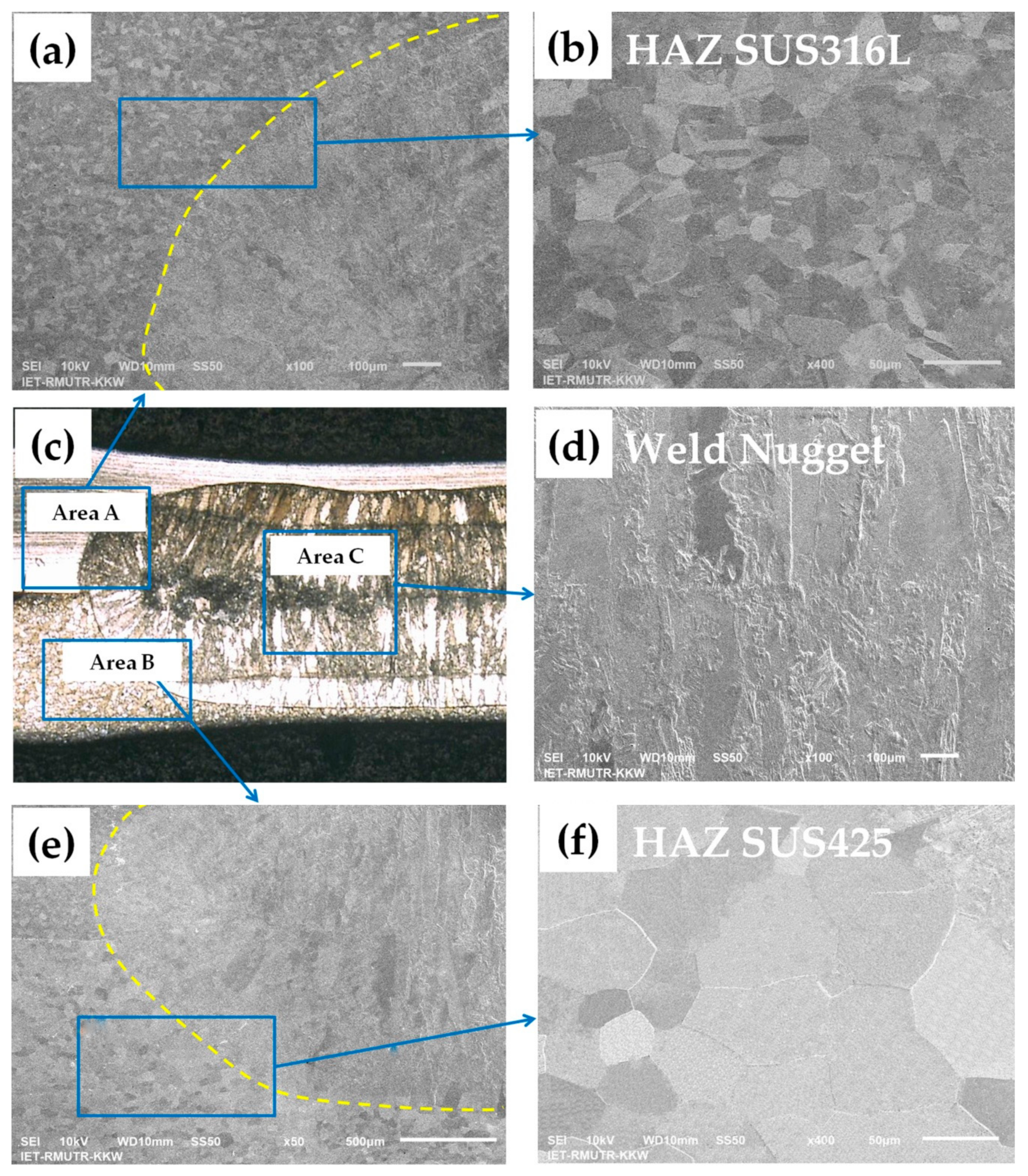

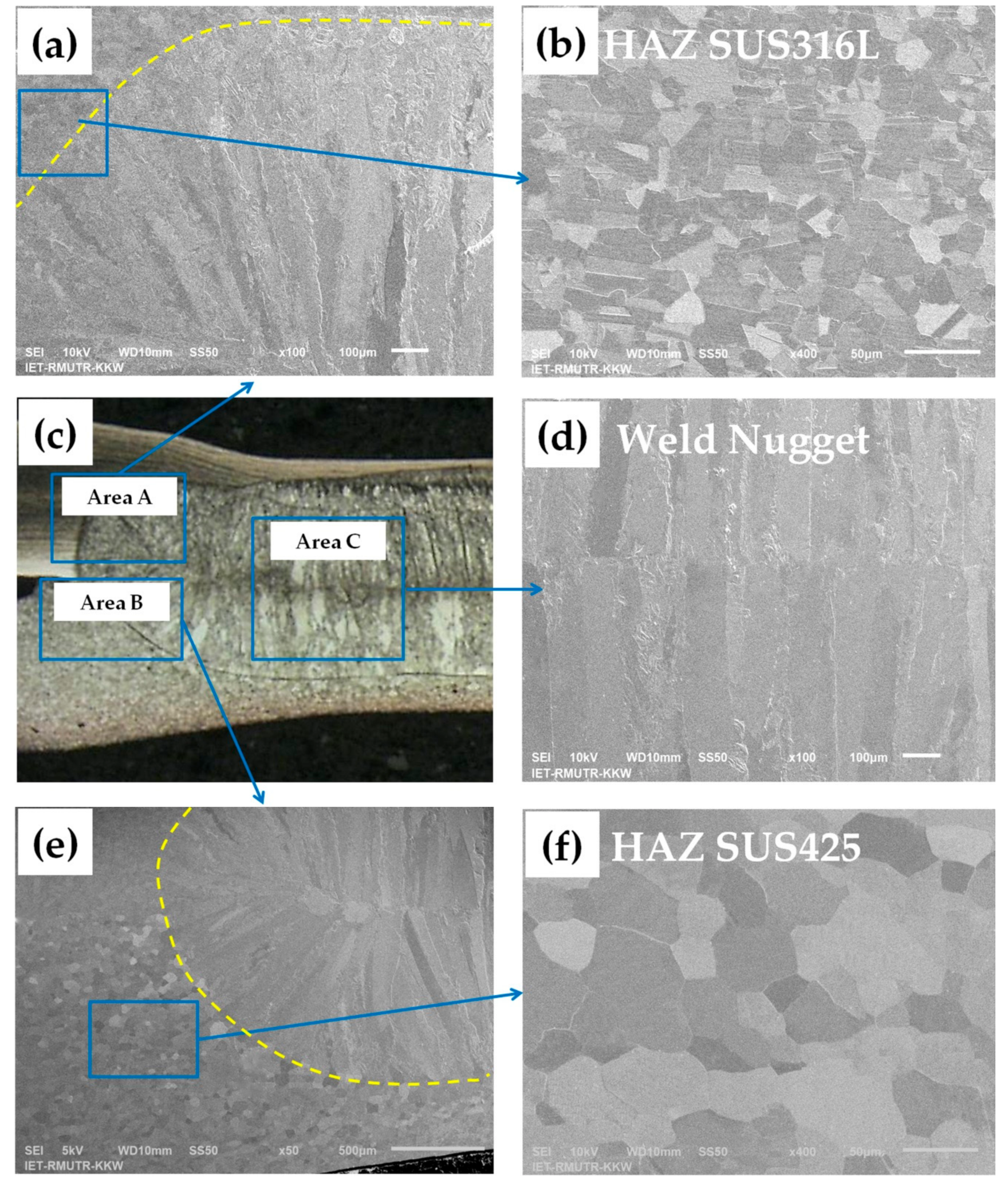

3.1. Weldment Appearance

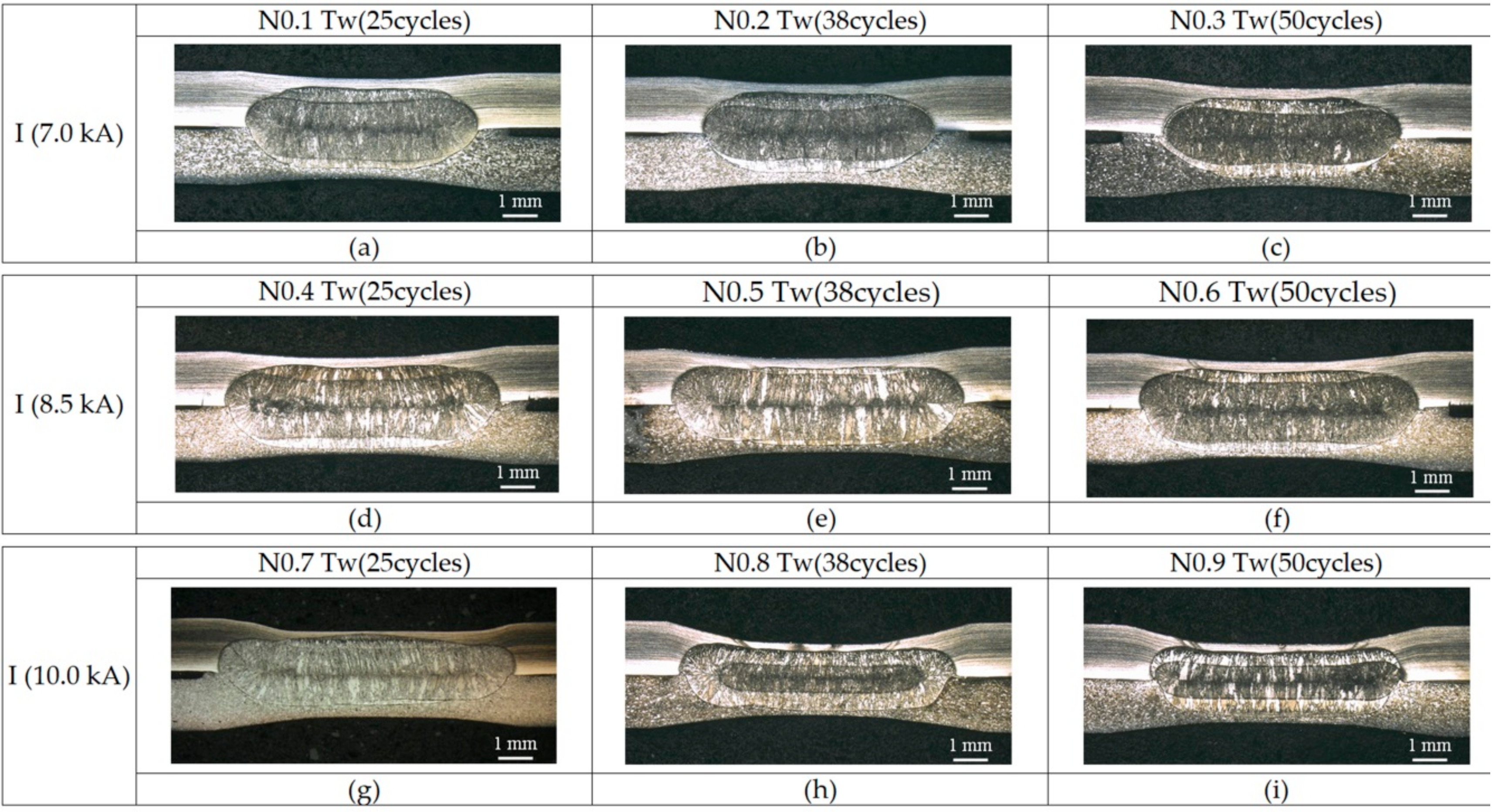

3.2. Weldment Quality Metrics

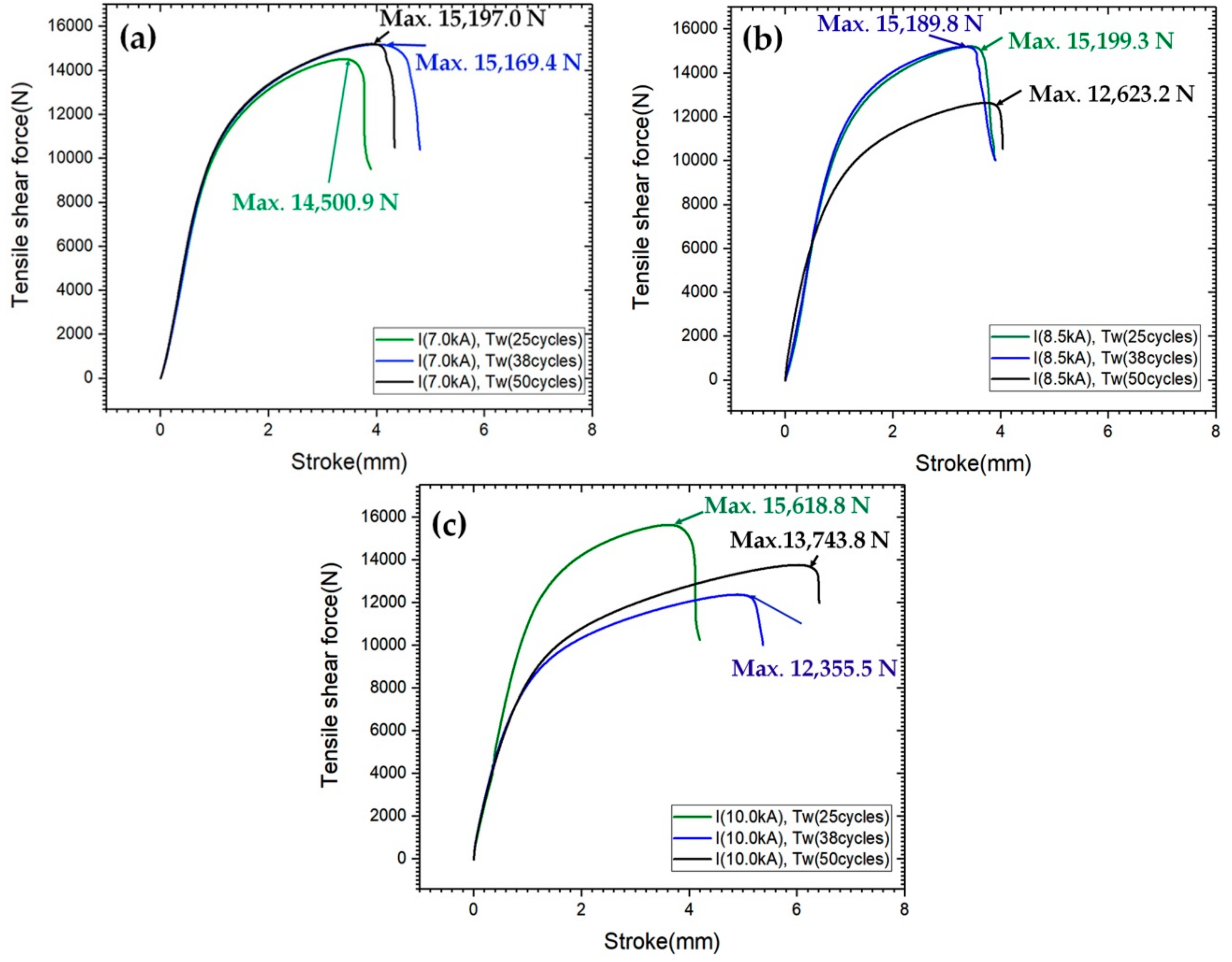

3.3. Tensile Shear Force

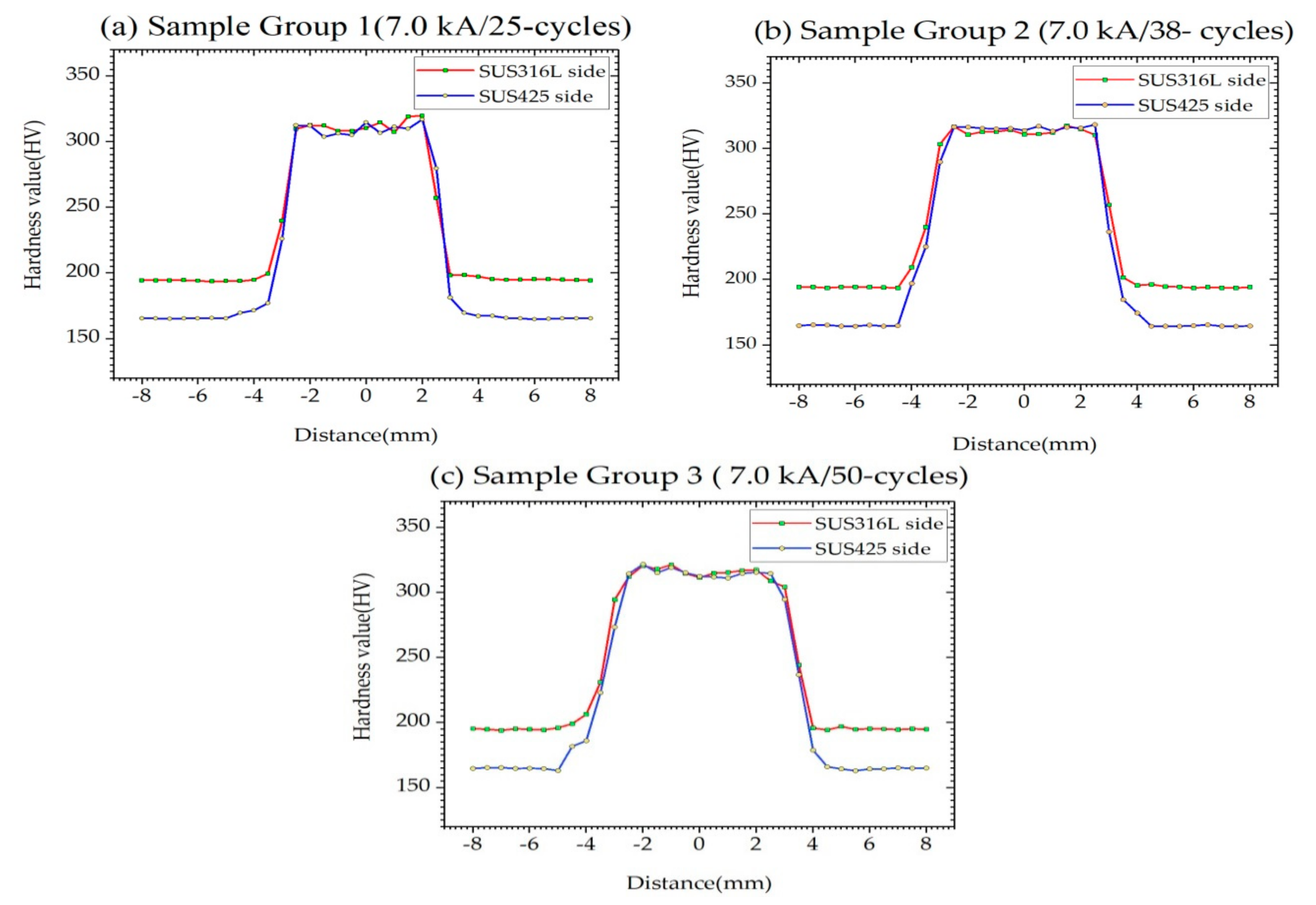

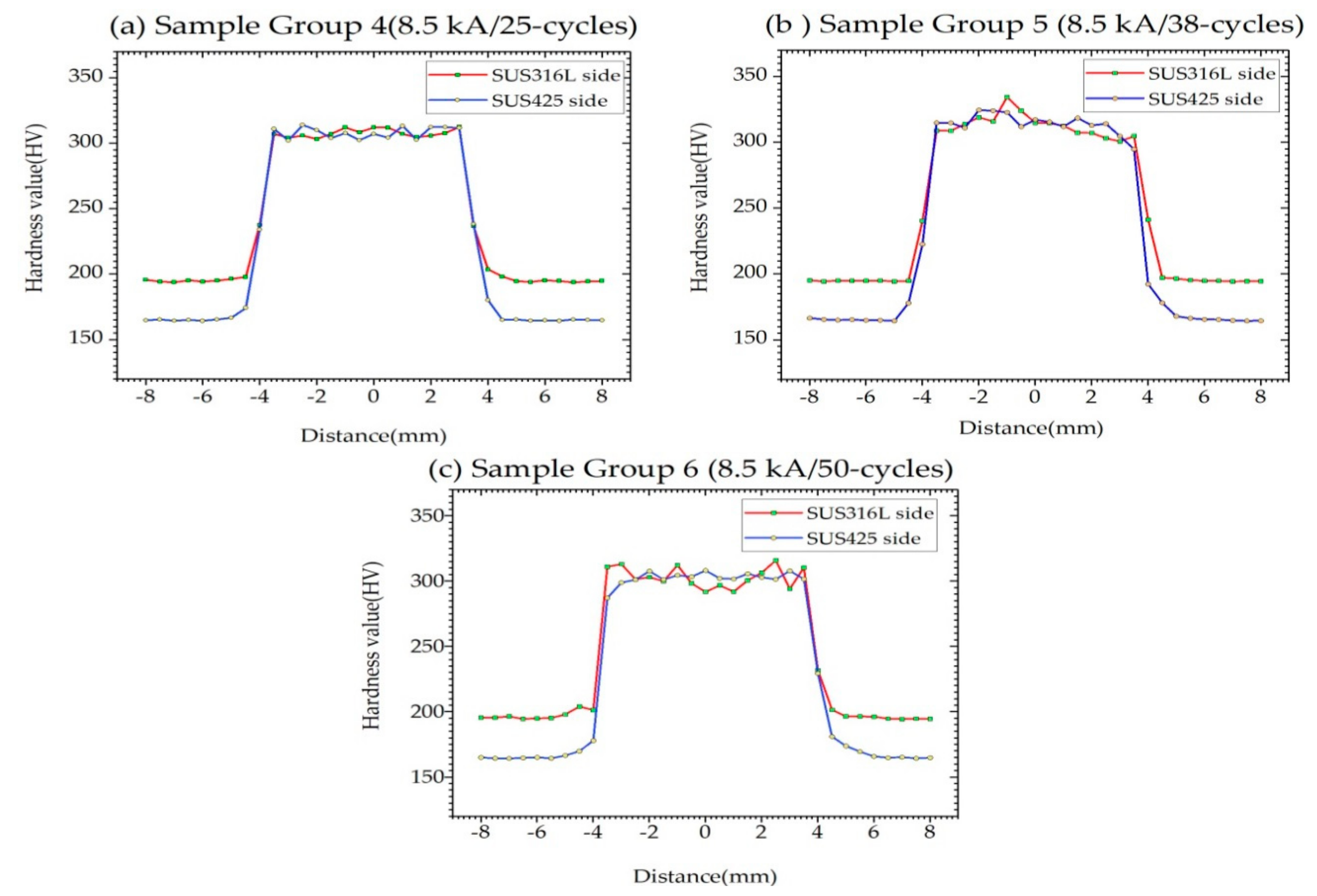

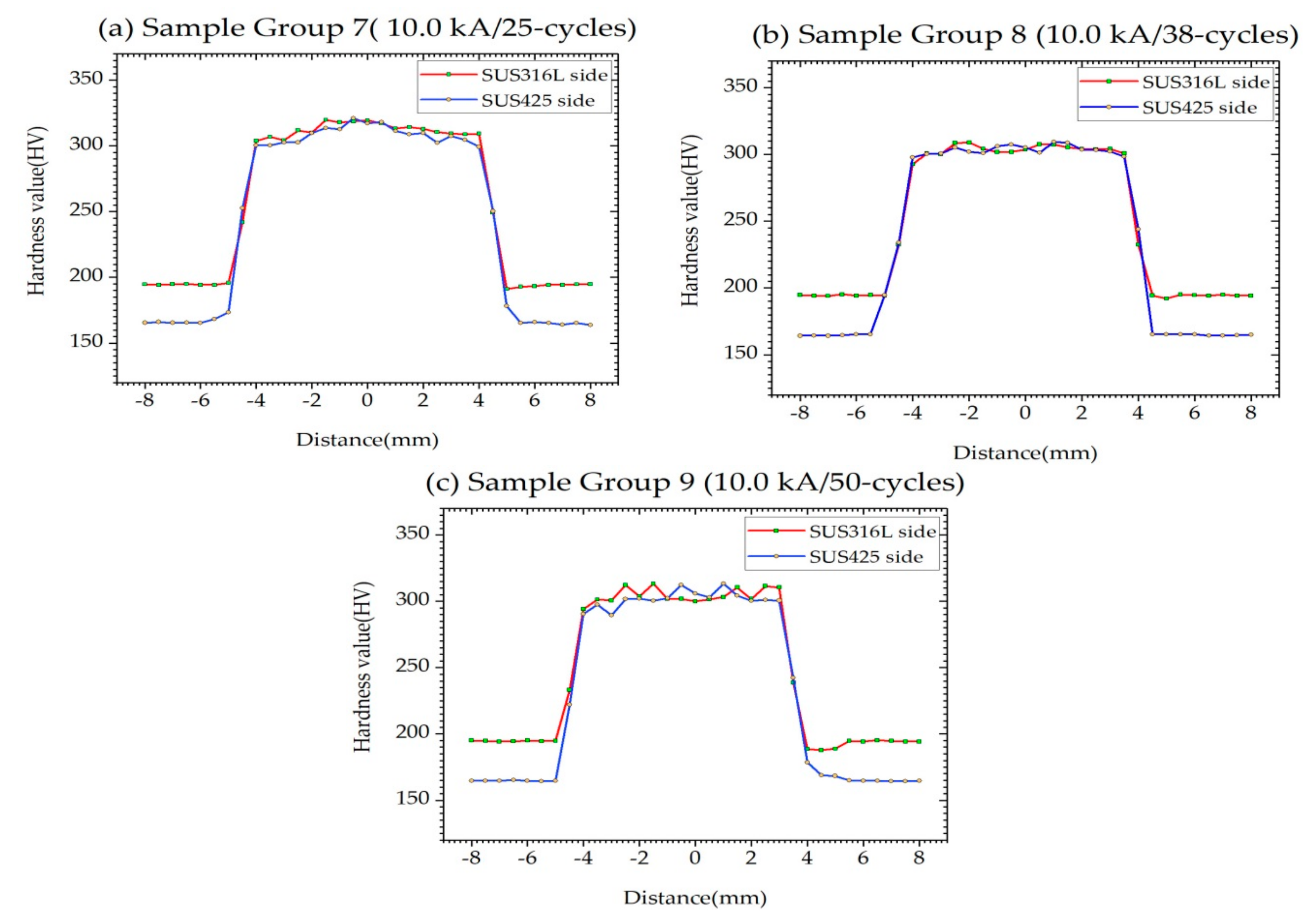

3.4. Weldment Micro Hardness

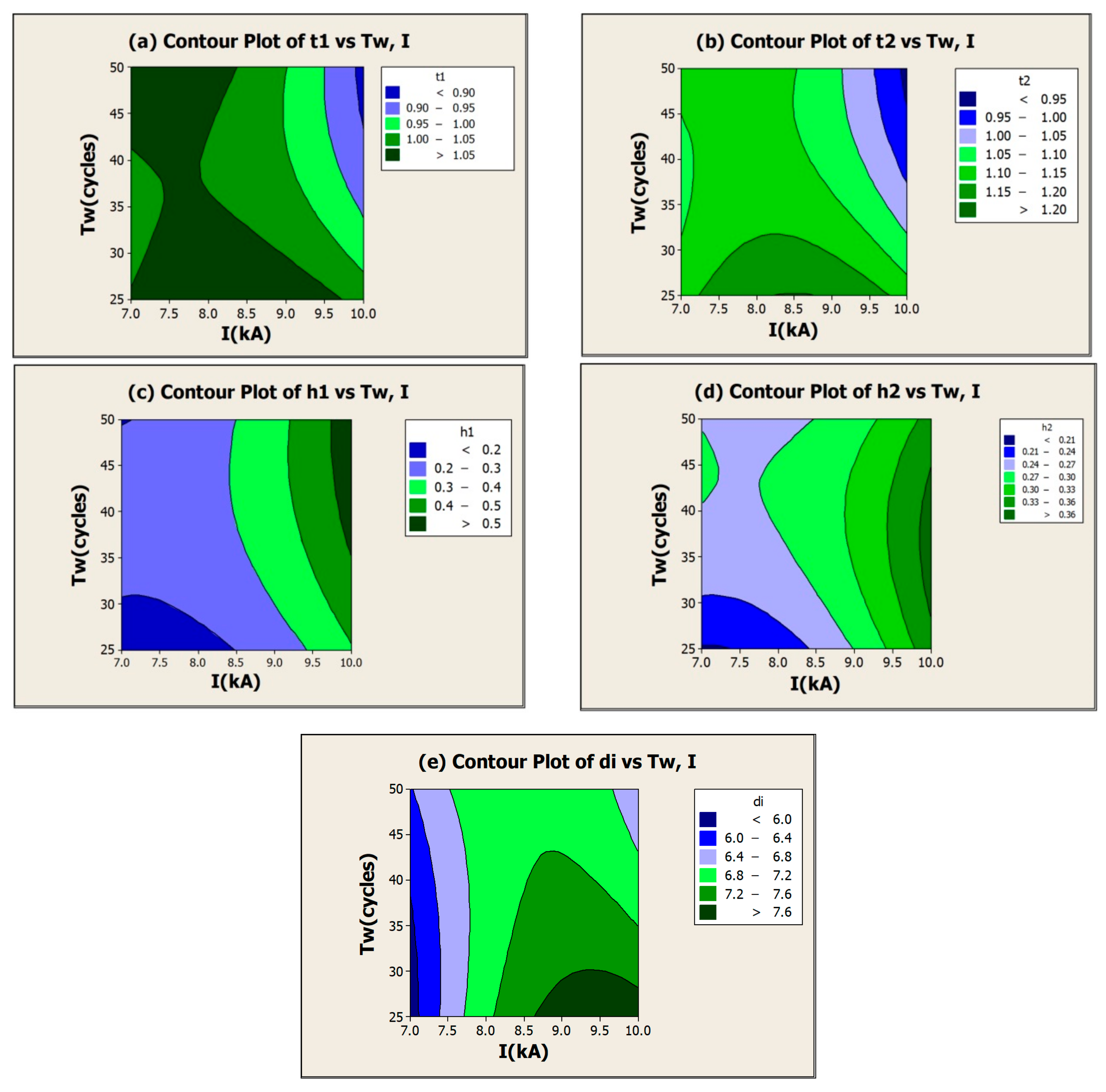

3.5. Optimization of Welding Parameters

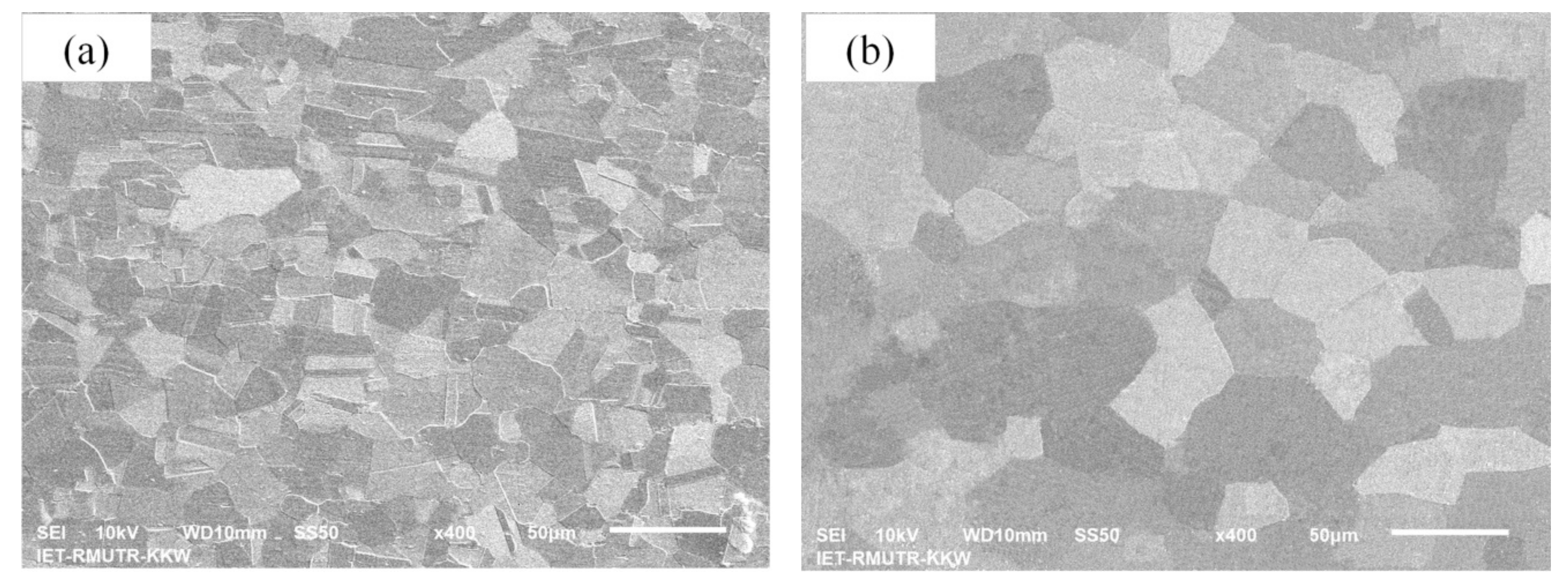

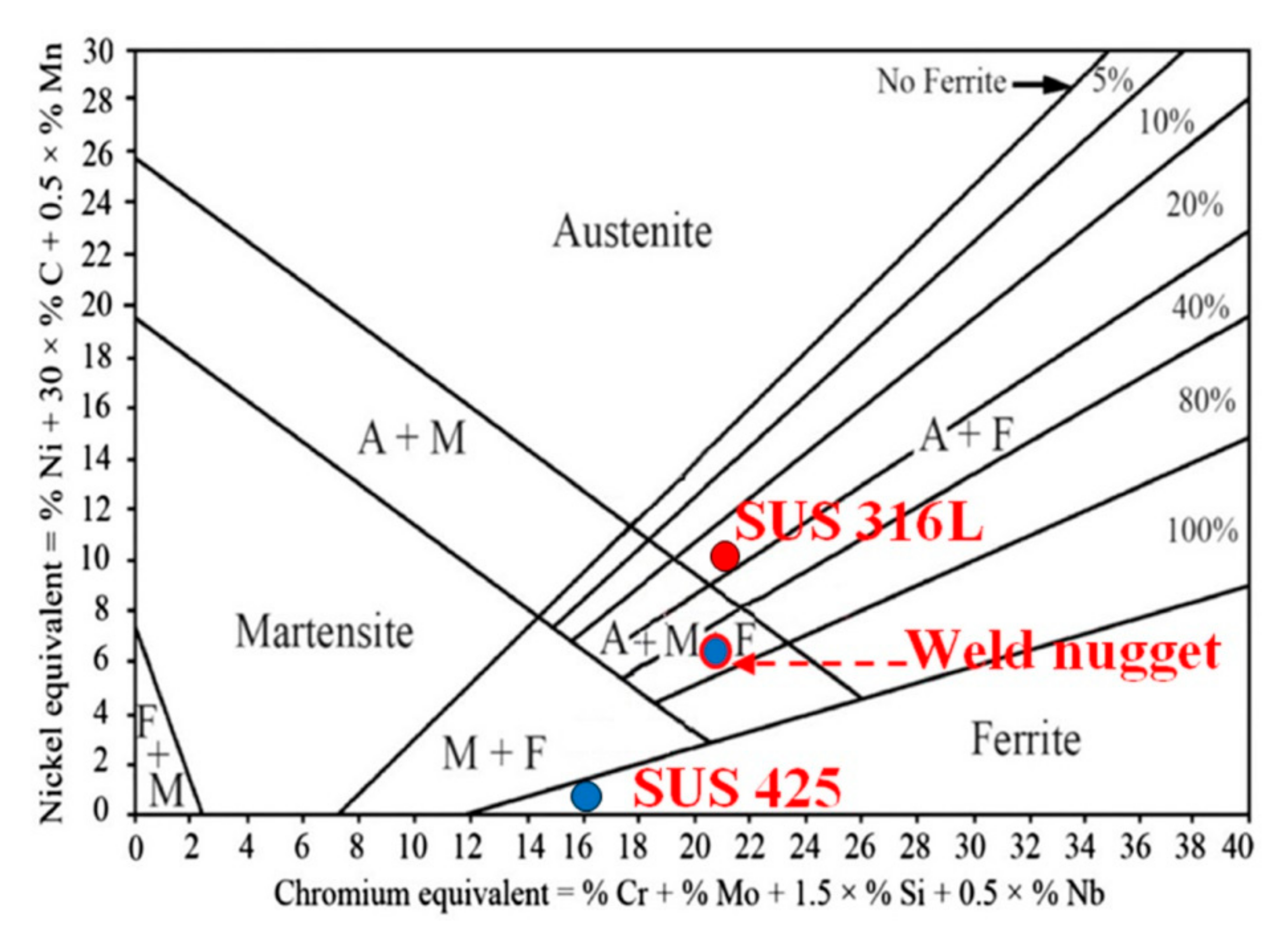

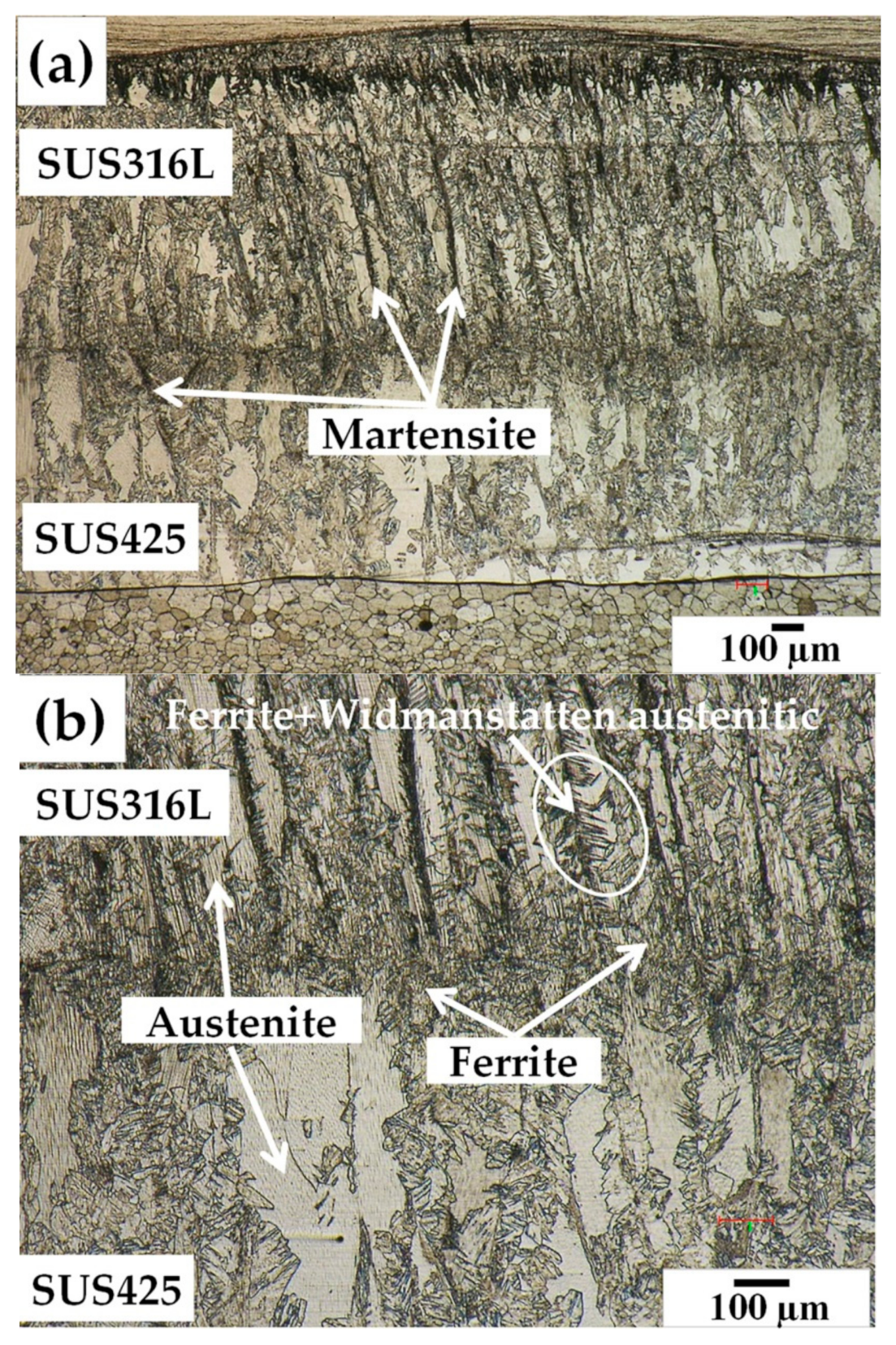

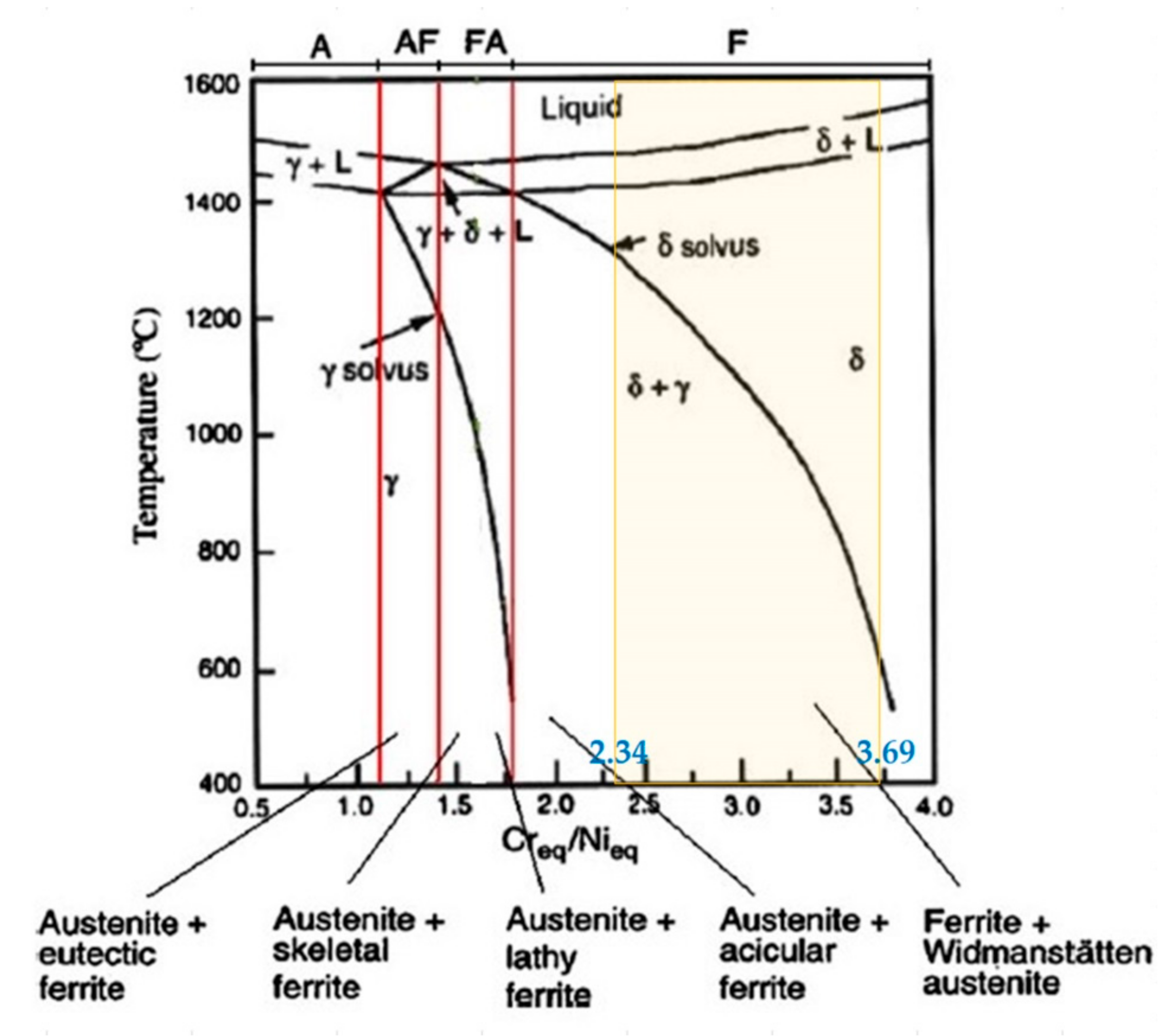

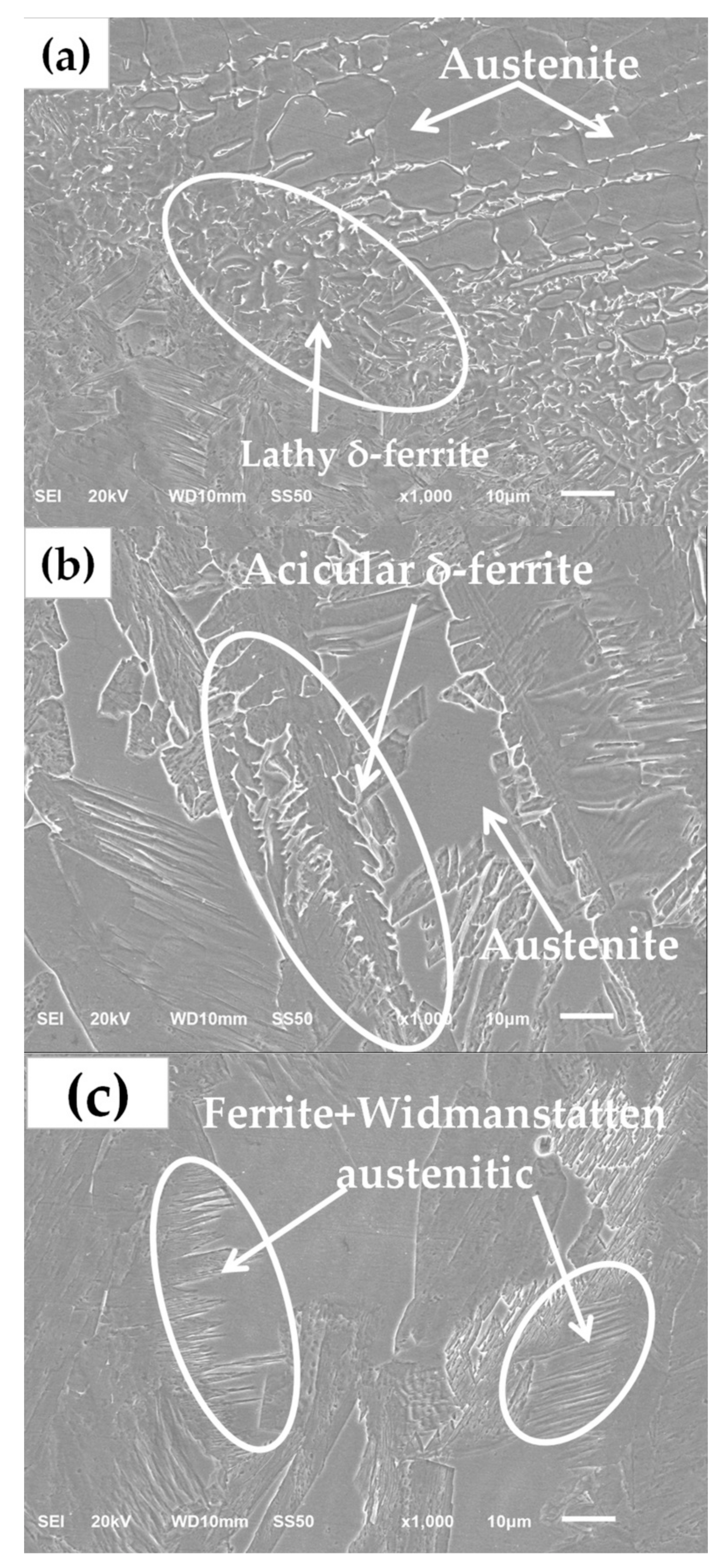

3.6. The Weldment Microstructure

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wei, P.S.; Wu, T.H. Workpiece property effects on nugget microstructure determined by heat transfer and solidification rate during resistance spot welding. Int. J. Therm. Sci. 2014, 86, 421–429. [Google Scholar] [CrossRef]

- Kim, J.H.; Cho, Y.; Jang, Y.H. Estimation of the weldability of single-sided resistance spot welding. J. Manuf. Syst. 2013, 32, 505–512. [Google Scholar] [CrossRef]

- Eisazadeh, H.; Hamedi, M.; Halvaee, A. New parametric study of nugget size in resistance spot welding process using finite element method. Mater. Des. 2010, 31, 149–157. [Google Scholar] [CrossRef]

- Kocabekir, B.; Kaçar, R.; Gündüz, S.; Hayat, F. An effect of heat input, weld atmosphere and weld cooling conditions on the resistance spot weldability of 316L austenitic stainless steel. J. Mater. Process. Technol. 2008, 195, 327–335. [Google Scholar] [CrossRef]

- Kianersi, D.; Mostafaei, A.; Amadeh, A.A. Resistance spot welding joints of AISI 316L austenitic stainless steel sheets: Phase transformations, mechanical properties and microstructure characterizations. Mater. Des. 2014, 61, 251–263. [Google Scholar] [CrossRef]

- Hsieh, C.-C.; Lin, D.-Y.; Chen, M.-C.; Wu, W. Microstructure, Recrystallization, and Mechanical Property Evolutions in the Heat-Affected and Fusion Zones of the Dissimilar Stainless Steels. Mater. Trans. 2007, 48, 2898–2902. [Google Scholar] [CrossRef]

- Min, D.; Liu, S.; Hong, H.; Tao, P.; Zhang, P. Strength and infrared assessment of spot-welded sheets on ferrite steel. Mater. Des. 1980-2015 2013, 52, 353–358. [Google Scholar] [CrossRef]

- Liu, W.; Wang, R.; Han, J.; Xu, X.; Li, Q. Microstructure and mechanical performance of resistance spot-welded cold-rolled high strength austenitic stainless steel. J. Mater. Process. Technol. 2010, 210, 1956–1961. [Google Scholar] [CrossRef]

- Moshayedi, H.; Sattari-Far, I. Resistance spot welding and the effects of welding time and current on residual stresses. J. Mater. Process. Technol. 2014, 214, 2545–2552. [Google Scholar] [CrossRef]

- Jagadeesha, T. Experimental studies in weld nugget strength of resistance spot-welded 316L austenitic stainless steel sheet. Int. J. Adv. Manuf. Technol. 2017, 93, 505–513. [Google Scholar] [CrossRef]

- Alizadeh-Sh, M.; Marashi, S.P.H.; Pouranvari, M. Resistance spot welding of AISI 430 ferritic stainless steel: Phase transformations and mechanical properties. Mater. Des. 1980-2015 2014, 56, 258–263. [Google Scholar] [CrossRef]

- Vignesh, K.; Elaya Perumal, A.; Velmurugan, P. Optimization of resistance spot welding process parameters and microstructural examination for dissimilar welding of AISI 316L austenitic stainless steel and 2205 duplex stainless steel. Int. J. Adv. Manuf. Technol. 2017, 93, 455–465. [Google Scholar] [CrossRef]

- Bina, M.H.; Jamali, M.; Shamanian, M.; Sabet, H. Investigation on the resistance spot-welded austenitic/ferritic stainless steel. Int. J. Adv. Manuf. Technol. 2014, 75, 1371–1379. [Google Scholar] [CrossRef]

- Essoussi, H.; Elmouhri, S.; Ettaqi, S.; Essadiqi, E. Microstructure and mechanical performance of resistance spot welding of AISI 304 stainless steel and AISI 1000 series steel. Procedia Manuf. 2019, 32, 872–876. [Google Scholar] [CrossRef]

- Alenius, M.; Pohjanne, P.; Somervuori, M.; Hanninen, H. Exploring the Mechanical Properties of Spot Welded Dissimilar Joints for Stainless and Galvanized Steels. Weld. J. 2006, 85, 305–313. [Google Scholar]

- Sun, X.; Stephens, E.V.; Khaleel, M.A. Effects of fusion zone size and failure mode on peak load and energy absorption of advanced high strength steel spot welds under lap shear loading conditions. Eng. Fail. Anal. 2008, 15, 356–367. [Google Scholar] [CrossRef]

- Zhang, H.; Senkara, J. Resistance Welding Fundamentals and Applications, 2nd ed.; Taylor & Francis Group: Abingdon, UK, 2011. [Google Scholar]

- Khuenkaew, T.; Kanlayasiri, K. Selection of electrode tips for the resistance spot welding of dissimilar stainless steels. MATEC Web Conf. 2018, 192, 01007. [Google Scholar] [CrossRef][Green Version]

- Tutar, M.; Aydin, H.; Bayram, A. Effect of weld current on the microstructure and mechanical properties of a resistance spot-welded TWIP steel sheet. Metals 2017, 7, 519. [Google Scholar] [CrossRef]

- Moshayedi, H.; Sattari-Far, I. Numerical and experimental study of nugget size growth in resistance spot welding of austenitic stainless steels. J. Mater. Process. Technol. 2012, 212, 347–354. [Google Scholar] [CrossRef]

- Hayat, F. The effects of the welding current on heat input, nugget geometry, and the mechanical and fractural properties of resistance spot welding on Mg/Al dissimilar materials. Mater. Des. 2011, 32, 2476–2484. [Google Scholar] [CrossRef]

- Yuan, X.; Li, C.; Chen, J.; Li, X.; Liang, X.; Pan, X. Resistance spot welding of dissimilar DP600 and DC54D steels. J. Mater. Process. Technol. 2017, 239, 31–41. [Google Scholar] [CrossRef]

- Khuenkaew, T.; Kanlayasiri, K. Optimizing the resistance spot-welding process for dissimilar stainless steels. IOP Conf. Ser. Mater. Sci. Eng. 2018, 361, 012005. [Google Scholar] [CrossRef]

- Li, Y.; Wei, Z.; Li, Y.; Shen, Q.; Lin, Z. Effects of cone angle of truncated electrode on heat and mass transfer in resistance spot welding. Int. J. Heat Mass Transf. 2013, 65, 400–408. [Google Scholar] [CrossRef]

- Charde, N.; Rajkumar, R. Investigating spot weld growth on 304 austenitic stainless steel (2 mm) sheets. J. Eng. Sci. Technol. 2013, 8, 69–76. [Google Scholar]

- Mohammed, G.R.; Ishak, M.; Aqida, S.N.; Abdulhadi, H.A. Effects of heat input on microstructure, corrosion and mechanical characteristics of welded austenitic and duplex stainless steels: A review. Metals 2017, 7, 39. [Google Scholar] [CrossRef]

| Material | Element | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | Fe | |

| SUS316L | 0.02 | 0.25 | 0.75 | 0.01 | 0.0003 | 17.07 | 10.46 | 1.64 | Balance |

| SUS425 | 0.01 | 0.83 | 0.09 | 0.01 | 0.003 | 13.48 | 0.06 | 0.02 | Balance |

| Material | Hardness | Yield Strength | Tensile Strength | Elongation |

|---|---|---|---|---|

| (HV) | (N/mm2) | (N/mm2) | (%) | |

| SUS316L | 218(max) | 205(min) | 520(min) | 35(min) |

| SUS425 | 200(max) | 205(min) | 410(min) | 25(min) |

| Material | Specific Heat | Density | Electrical Resistivity | Thermal Expansion | Thermal Conductivity |

|---|---|---|---|---|---|

| (J/kg °C) | (kg/m3) | (μΩ·m) | (°C−1) | (W/m °C) | |

| SUS316L | 500 | 8000 | 75 | 1.7 × 10−5 | 15 |

| SUS425 | 460 | 7720 | 61 | 1.6 × 10−5 | 24.2 |

| Electrode Force | Squeeze Time | Holding Time | Weld Atmosphere |

|---|---|---|---|

| (kN) | (cycles/s) | (cycles/s) | |

| 3.3 | 45/0.9 | 50/1.0 | ambient |

| Welding Parameters Weld Current (kA)/ Welding Time (cycles) | Average Values of Weldment Quality Metrics (mm) | ||||

|---|---|---|---|---|---|

| Depth of Fusion 1 (t1) | Depth of Fusion 2 (t2) | Indentation Depth 1 (h1) | Indentation Depth 2 (h2) | Nugget Diameter (di) | |

| 7.0/25 | 1.05 | 1.12 | 0.17 | 0.22 | 6.01 |

| 7.0/38 | 1.06 | 1.11 | 0.17 | 0.24 | 6.03 |

| 7.0/50 | 1.08 | 1.09 | 0.24 | 0.28 | 6.16 |

| 8.5/25 | 1.05 | 1.19 | 0.25 | 0.24 | 7.13 |

| 8.5/38 | 1.06 | 1.16 | 0.26 | 0.27 | 7.53 |

| 8.5/50 | 1.03 | 1.07 | 0.29 | 0.29 | 7.22 |

| 10.0/25 | 1.06 | 1.16 | 0.33 | 0.34 | 8.03 |

| 10.0/38 | 0.97 | 0.98 | 0.52 | 0.35 | 7.02 |

| 10.0/50 | 0.91 | 0.94 | 0.61 | 0.39 | 6.38 |

| Electrode Force | Weld Current | Welding Time | Squeeze Time | Holding Time | Weld Atmosphere |

|---|---|---|---|---|---|

| (kN) | (kA) | (cycles/s) | (cycles/s) | (cycles/s) | |

| 3.3 | 10.0 | 25/0.5 | 45/0.9 | 50/1.0 | ambient |

| Material | Weld | Element | |||||

|---|---|---|---|---|---|---|---|

| Current (kA) | Cr | Ni | Mo | Si | Fe | Other | |

| SUS316L | 7.0 | 18.16 | 7.64 | 0.14 | 0.96 | 72.68 | 0.42 |

| 8.5 | 18.65 | 7.66 | 0.32 | 0.67 | 72.01 | 0.69 | |

| 10.0 | 20.69 | 5.83 | 0.27 | 0.61 | 71.99 | 0.61 | |

| SUS425 | 7.0 | 16.43 | 6.96 | 1.37 | 1.38 | 71.01 | 2.85 |

| 8.5 | 17.47 | 8.16 | 1.00 | 0.91 | 71.48 | 1.00 | |

| 10.0 | 19.27 | 6.85 | 1.27 | 0.90 | 68.66 | 3.05 | |

| Weld Current (kA) | Creq | Nieq | Creq/Nieq | |||

|---|---|---|---|---|---|---|

| SUS316L | SUS425 | SUS316L | SUS425 | SUS316L | SUS425 | |

| 7.0 | 19.74 | 20.13 | 7.64 | 8.06 | 2.58 | 2.50 |

| 8.5 | 20.06 | 19.96 | 7.86 | 8.53 | 2.55 | 2.34 |

| 10.0 | 21.89 | 21.98 | 5.93 | 8.05 | 3.69 | 2.73 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khuenkaew, T.; Kanlayasiri, K. Resistance Spot Welding of SUS316L Austenitic/SUS425 Ferritic Stainless Steels: Weldment Characteristics, Mechanical Properties, Phase Transformation and Solidification. Metals 2019, 9, 710. https://doi.org/10.3390/met9060710

Khuenkaew T, Kanlayasiri K. Resistance Spot Welding of SUS316L Austenitic/SUS425 Ferritic Stainless Steels: Weldment Characteristics, Mechanical Properties, Phase Transformation and Solidification. Metals. 2019; 9(6):710. https://doi.org/10.3390/met9060710

Chicago/Turabian StyleKhuenkaew, Teerawut, and Kannachai Kanlayasiri. 2019. "Resistance Spot Welding of SUS316L Austenitic/SUS425 Ferritic Stainless Steels: Weldment Characteristics, Mechanical Properties, Phase Transformation and Solidification" Metals 9, no. 6: 710. https://doi.org/10.3390/met9060710

APA StyleKhuenkaew, T., & Kanlayasiri, K. (2019). Resistance Spot Welding of SUS316L Austenitic/SUS425 Ferritic Stainless Steels: Weldment Characteristics, Mechanical Properties, Phase Transformation and Solidification. Metals, 9(6), 710. https://doi.org/10.3390/met9060710