Fatigue Behavior of Metastable Austenitic Stainless Steels in LCF, HCF and VHCF Regimes at Ambient and Elevated Temperatures †

Abstract

1. Introduction

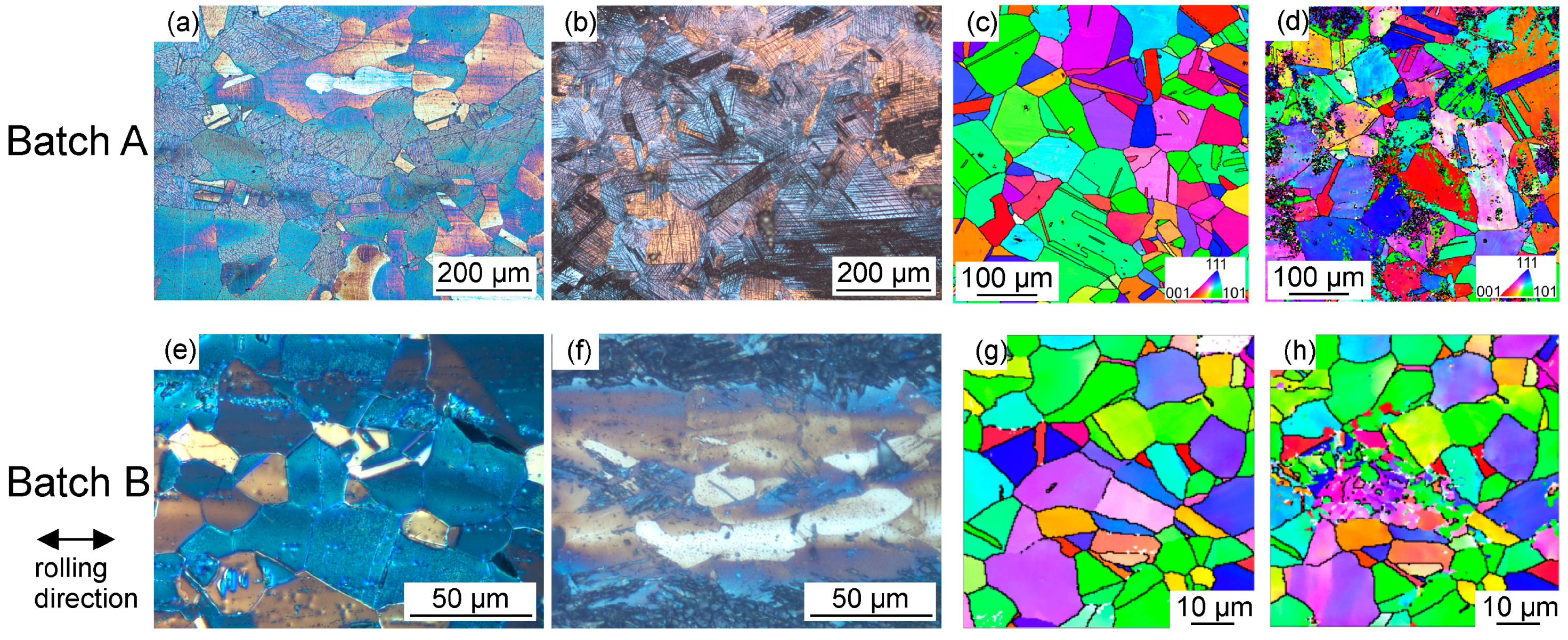

2. Materials

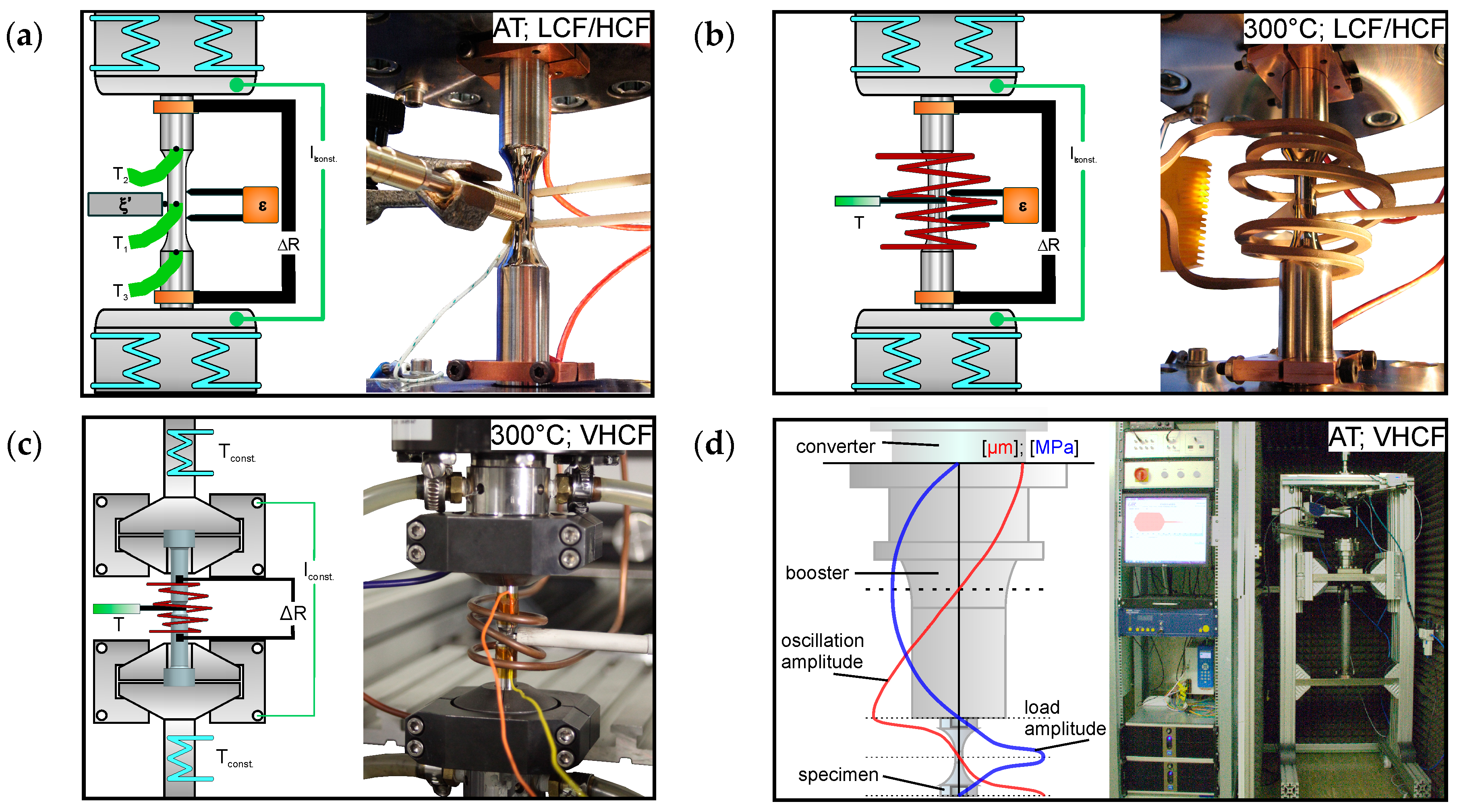

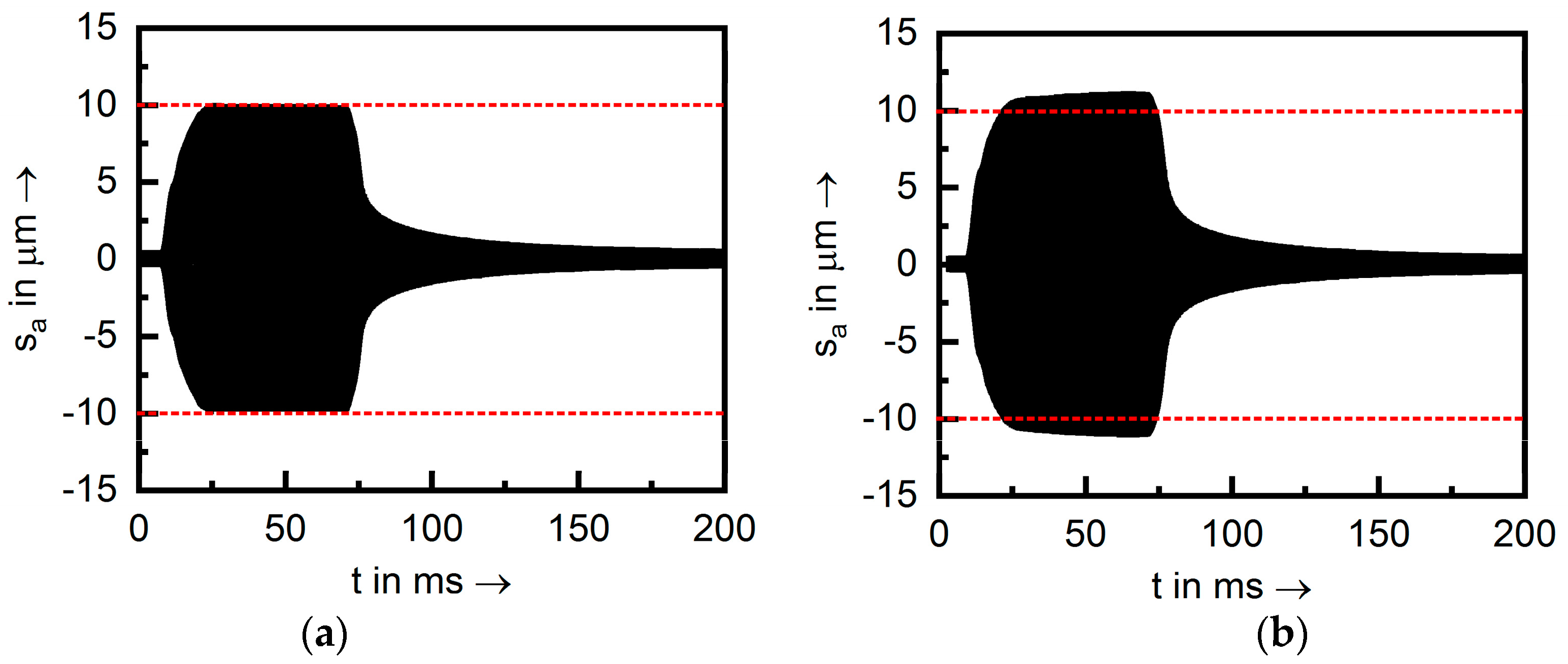

3. Methods

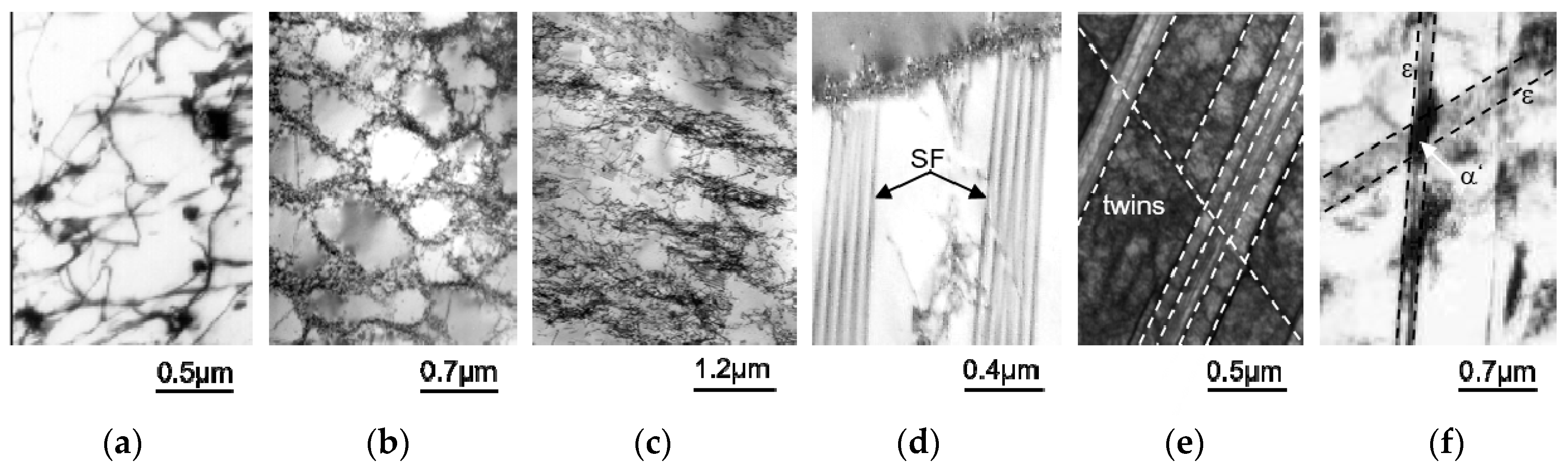

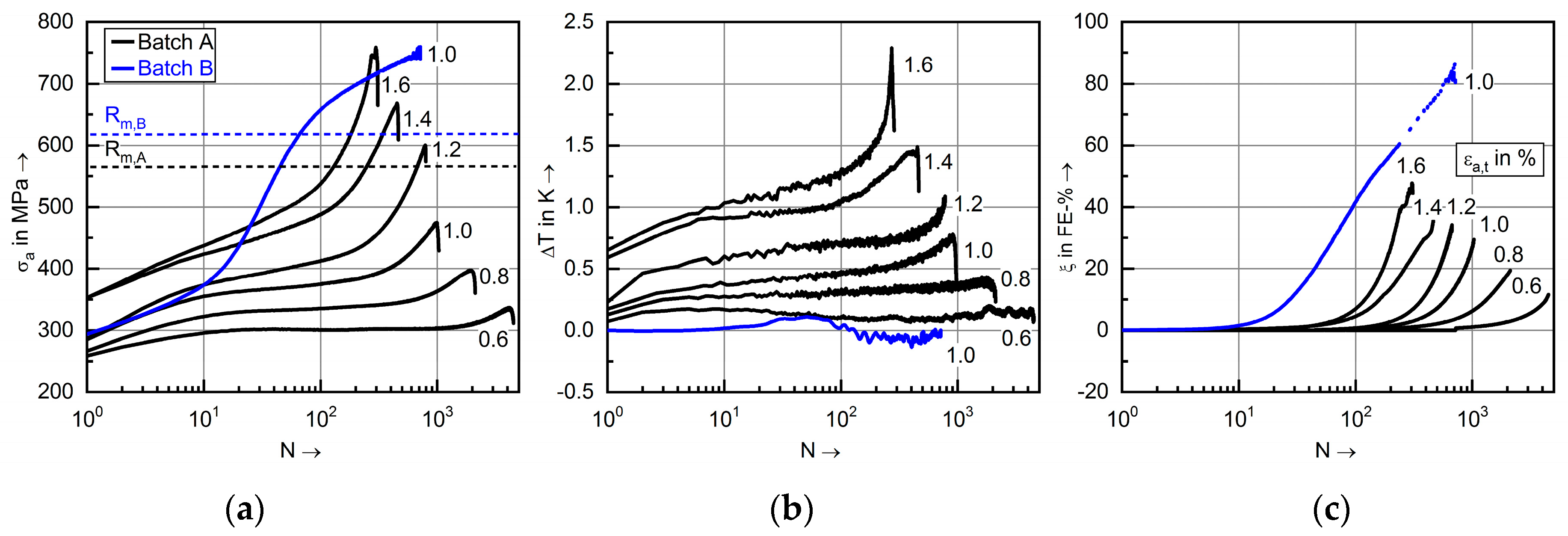

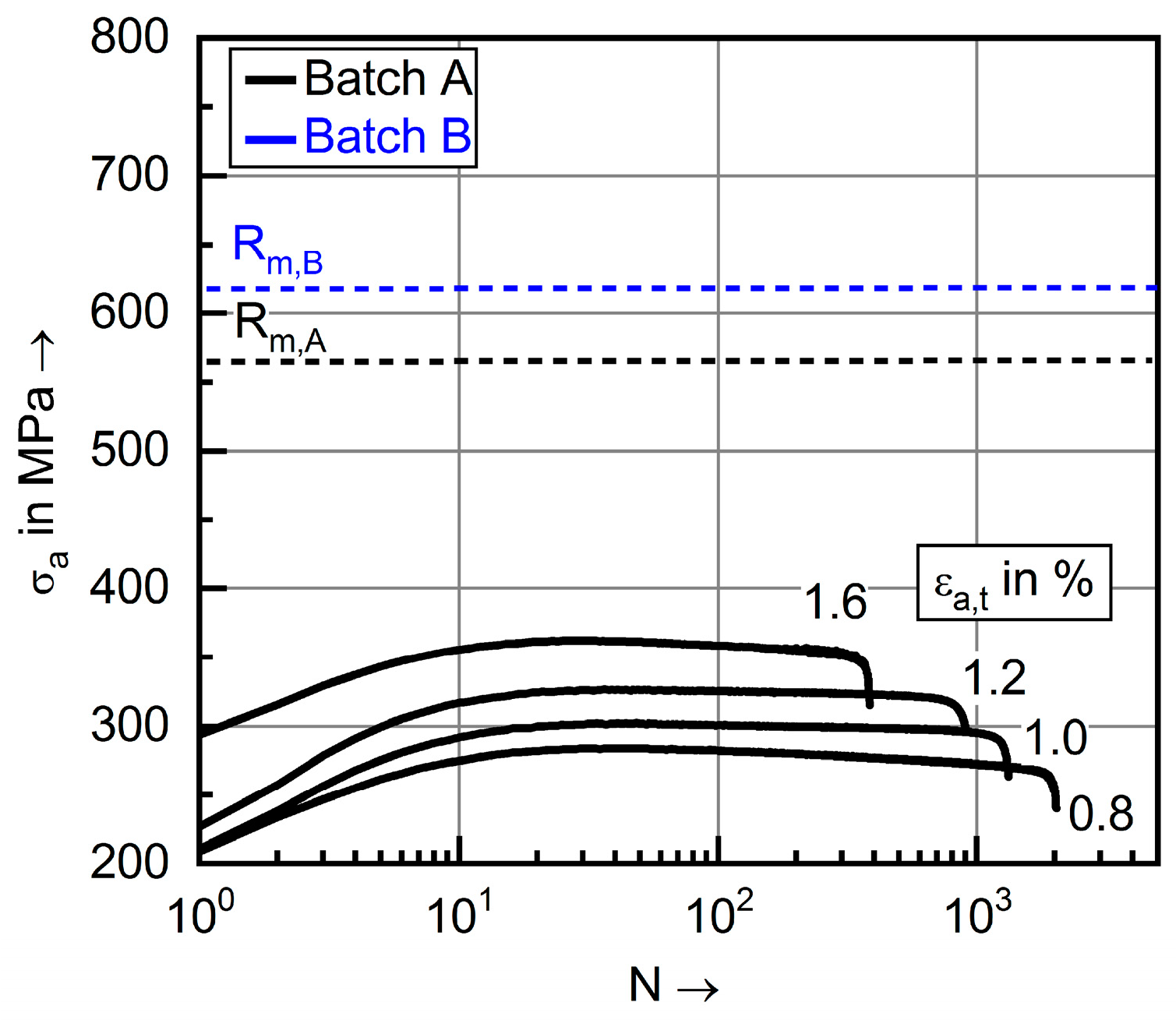

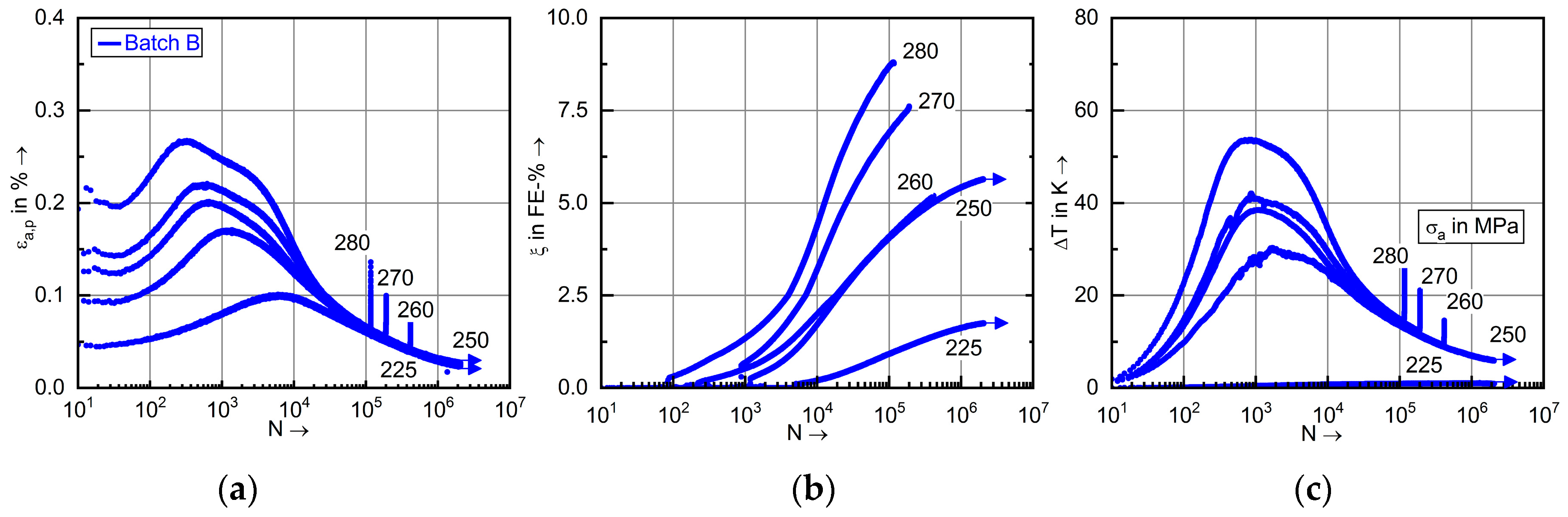

4. Results

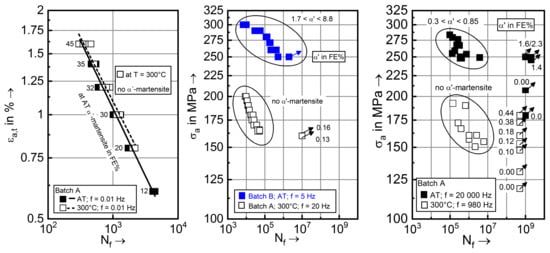

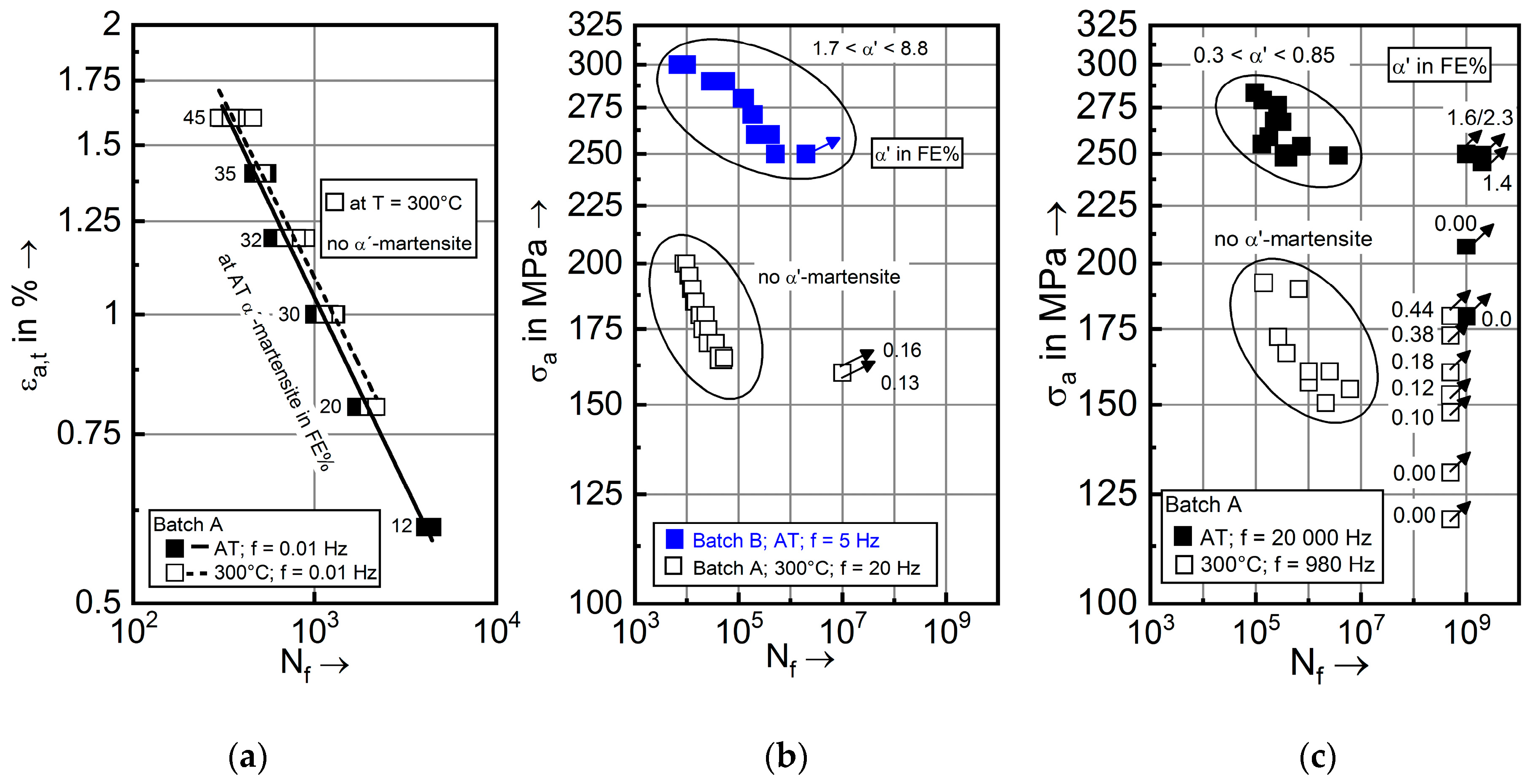

4.1. LCF Behavior

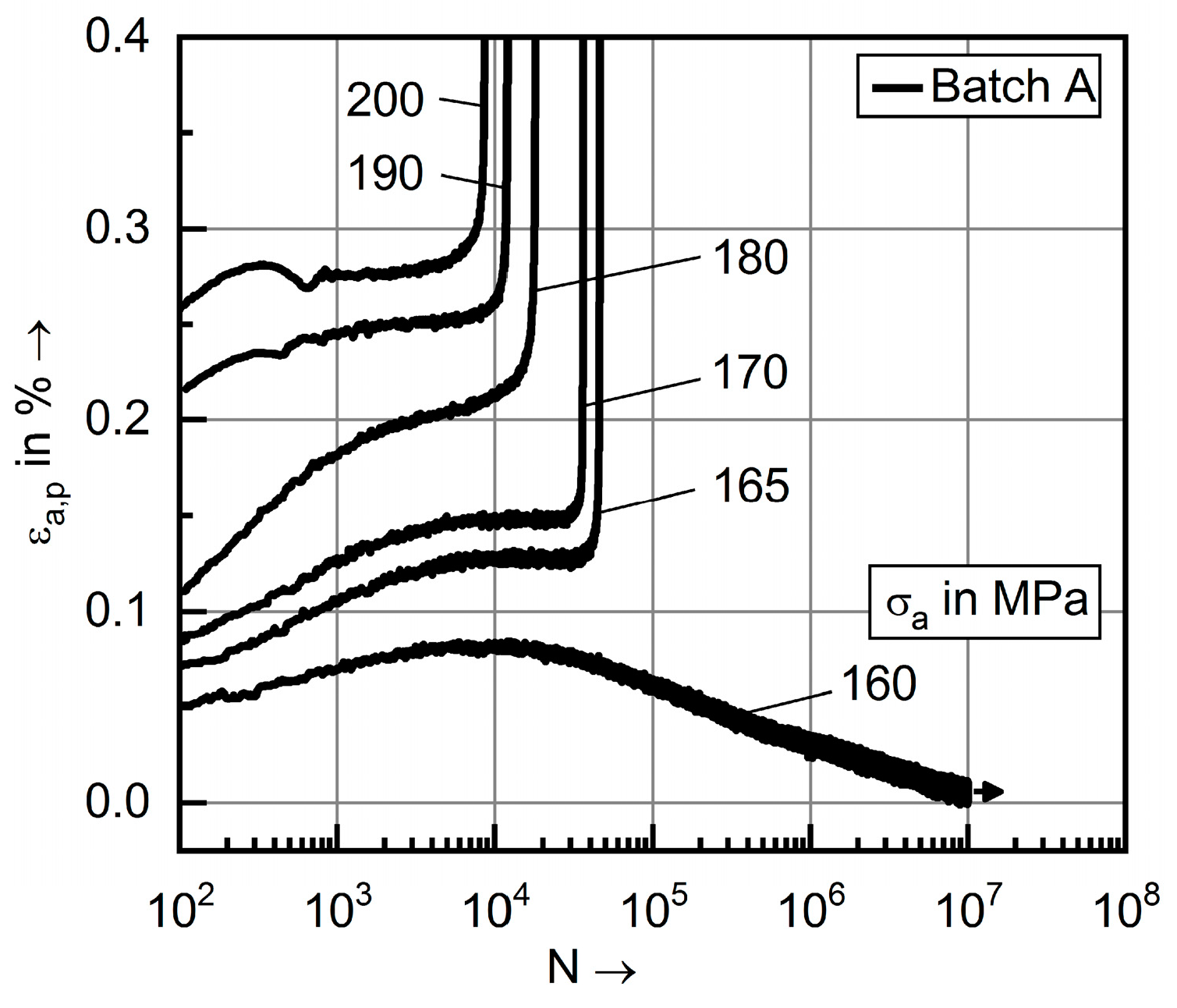

4.1.1. Ambient Temperature

4.1.2. Elevated Temperature T = 300 °C

4.2. HCF Behavior

4.2.1. At Nominally Ambient Temperature

4.2.2. Elevated Temperature T = 300 °C

4.3. VHCF Behavior

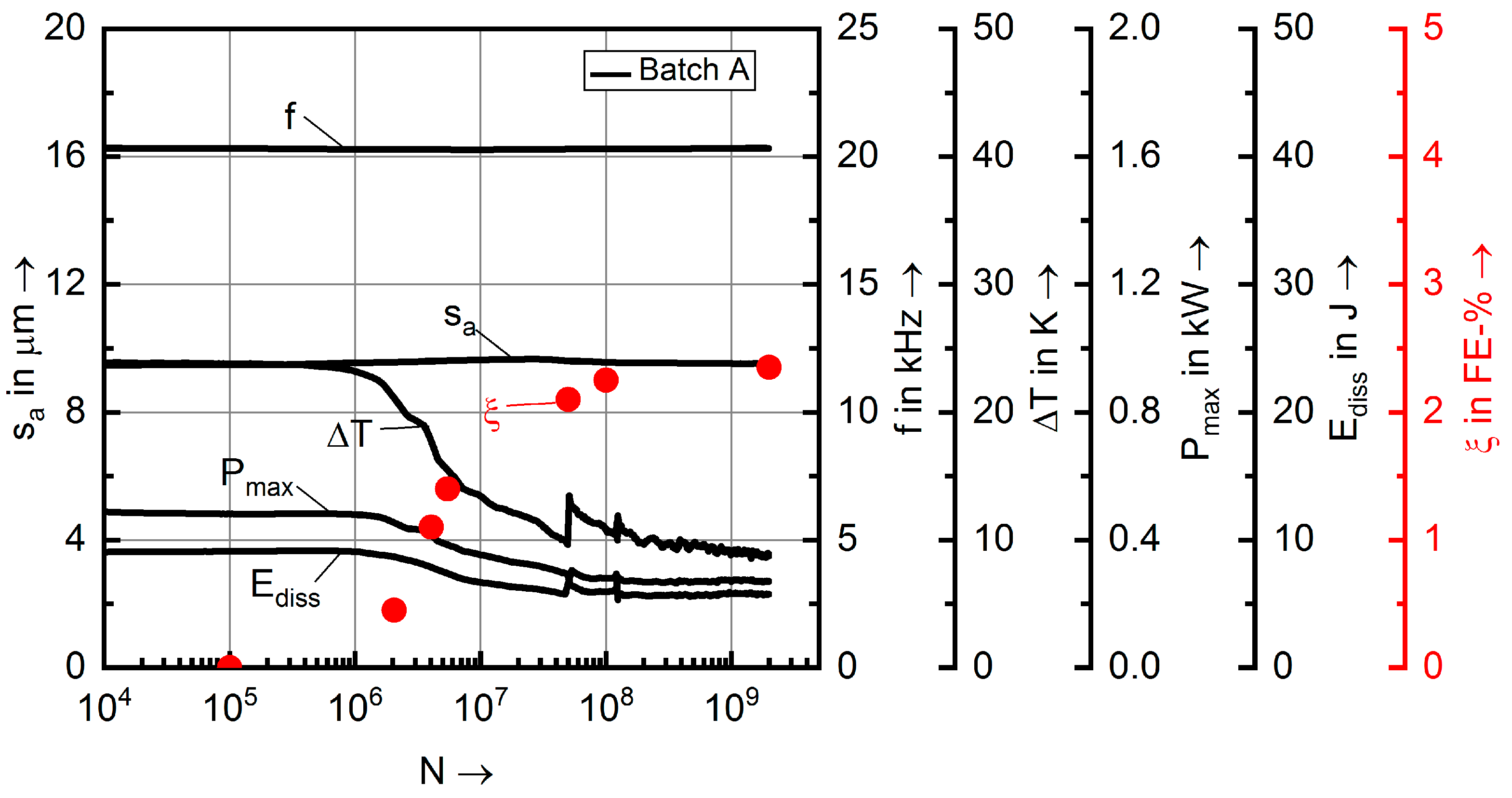

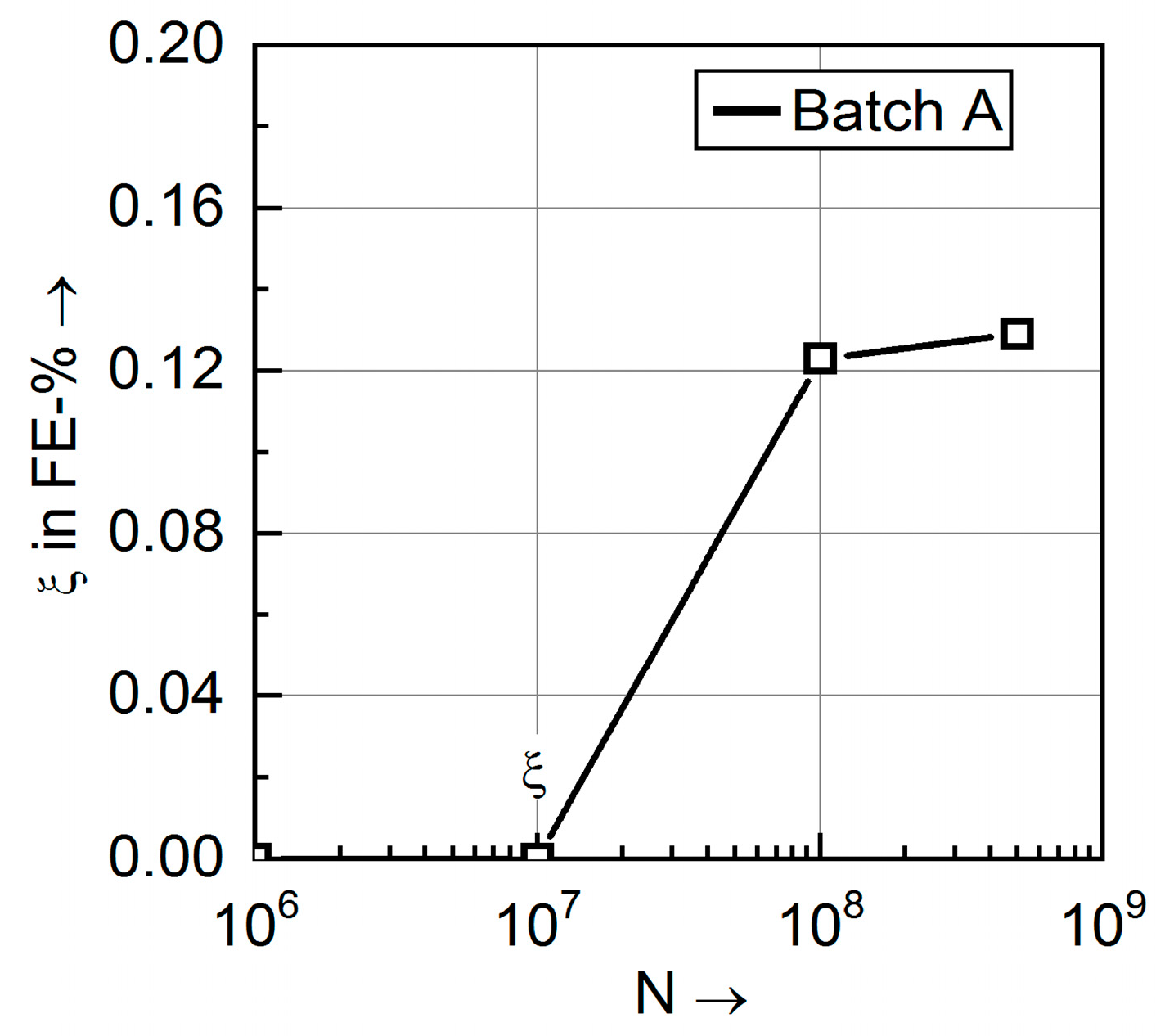

4.3.1. Ambient Temperature

4.3.2. Elevated Temperature T = 300 °C

5. Summary

6. Conclusions

- The metastability of austenitic Cr-Ni steels can, even within the specifications given in international standards, e.g. for AISI 347 stainless steel, strongly vary due to relatively small changes in chemical composition.

- Different metastability of austenitic stainless steel affects the cyclic deformation and, consequently, the fatigue lifetime behavior.

- This is caused by the fact that during fatigue, various deformation (planar or wavy slip character, formation of stacking faults, twinning) and transformation (γ -> ε, γ -> ε -> α´, γ -> α´) mechanisms with different peculiarity take place.

- The investigated metastable austenitic stainless steel AISI 347 showed a true fatigue limit in the VHCF regime at AT and 300 °C.

- Further microstructural investigations have to be performed with focus on the development of deformation/transformation mechanism maps dependent on metastability parameters, e.g. stacking fault energy and loading parameters, in the LCF, HCF and VHCF regimes in accordance with deformation maps known in the literature [52,53,54] for stable materials.

Author Contributions

Funding

Acknowledgment

Conflicts of Interest

References

- Strauß, B.; Maurer, E. Die hochlegierten Chrom-Nickel-Stähle als nichtrostende Stähle. Kruppsche Monatshefte 1920, 1, 129–146. [Google Scholar]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. 2009, R65, 39–104. [Google Scholar] [CrossRef]

- Leuk Lai, J.K.; Lo, K.H.; Shek, C.H. Stainless Steels: An Introduction and Their Recent Developments; Bentham Science Publishers: Sharjah, United Arab Emirates, 2012. [Google Scholar]

- Marshall, P. Austenitic stainless steels: Microstructure and Mechanical Properties. Springer Science & Business Media: Berlin, Germany, 1984. [Google Scholar]

- Chopra, O.K.; Shack, W.J. Effect of LWR coolant environments on the fatigue life of reactor materials. In Final Report, NUREG/CR-6909; Argon National Laboratory: Lemont, IL, USA, 2007. [Google Scholar]

- Deutsche Edelstahlwerke Rost-, säure- und hitzebeständige Stähle. 2010. Available online: https://www.dew-stahl.com/fileadmin/files/dew-stahl.com/documents/Publikationen/Broschueren/014_DEW_RSH_D.pdf (accessed on 30 May 2019).

- Hull, F.C. Delta ferrite and martensite formation in stainless steels. Weld. J. Res. Suppl. 1973, 179, 193–203. [Google Scholar]

- Padilha, A.F.; Martorano, M.A. Predicting delta ferrite content in stainless steel castings. ISIJ INT 2012, 52, 1054–1065. [Google Scholar]

- Padilha, A.F.; Tavares, C.F.; Martorano, M.A. Delta ferrite formation in austenitic stainless steel castings. Mater. Sci. Forum 2013, 730–732, 733–738. [Google Scholar] [CrossRef]

- Graham, C.D.; Loren, B.E. Delta ferrite is ubiquitous in type 304 stainless steel: Consequences for magnetic characterization. J. Magn. Magn. Mater. 2018, 458, 15–18. [Google Scholar] [CrossRef]

- Schäffler, A.L. Constitution diagram for stainless steel weld metal. Met. Prog. 1949, 56, 608–680B. [Google Scholar]

- Becker, H.; Brandis, H.; Küppers, W. Zur Verfestigung instabil austenitischer nichtrostender Stähle und ihre Auswirkung auf das Umformverhalten von Feinblechen. Thyssen Edelst. Techn. Berichte 1986, 12, 35–54. [Google Scholar]

- Eichelman, G.H.; Hull, F.C. The effect of composition in the temperature of spontaneous transformation of austenite to martensite in 18-8 type stainless steel. Trans. ASM 1952, 45, 77–104. [Google Scholar]

- Angel, T. Formation of martensite in austenitic stainless steels—Effects of deformation, temperature and composition. J. Iron. Steel Inst. 1954, 177, 165–174. [Google Scholar]

- Man, J.; Smaga, M.; Kuběna, I.; Eifler, D.; Polák, J. Effect of metallurgical variables on the austenite stability in fatigued AISI 304 type steels. Eng. Fract. Mech. 2017, 185, 139–159. [Google Scholar] [CrossRef]

- Smaga, M.; Boemke, A.; Daniel, T.; Klein, M.W. Metastability and fatigue behavior of austenitic stainless steels. MATEC Web Conf. 2018, 165, 04010. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC → HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part II. General concepts and the FCC → HCP transformation. Metall. Trans. A 1976, 7, 1905–1914. [Google Scholar]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part III. General concepts and the FCC → HCP transformation. Metall. Trans. A 1976, 7, 1915–1923. [Google Scholar] [CrossRef]

- Schumann, H. Verformungsinduzierte Martensitbildung in metastabilen austenitischen Stählen. Krist. Tech. 1975, 10, 401–411. [Google Scholar] [CrossRef]

- Sinclair, C.W.; Hoagland, R.G. A molecular dynamics study of the fcc -> bcc transformation at fault intersections. Acta Mater. 2008, 56, 4160–4171. [Google Scholar] [CrossRef]

- Shimizu, K.; Tanaka, Y. The γ→ε→α′ martensitic transformations in an Fe–Mn–C Alloy. Trans. Jpn. Inst. Met. 1978, 19, 685–693. [Google Scholar] [CrossRef]

- Spencer, K.; Embury, J.D.; Conlon, K.T.; Véron, M.; Bréchet, Y. Strengthening via the formation of strain-induced martensite in stainless steels. Mater. Sci. Eng. A 2004, 387–389, 873–881. [Google Scholar] [CrossRef]

- Venables, J.A. Martensite transformation in stainless steels. Philo. Mag. 1962, 7, 35–44. [Google Scholar] [CrossRef]

- Scheil, E. Uber die Umwandlung des Austenits in Martensit in Eisen-Nickellegierungen unter Belastung. Z. Anorg. Allg. Chem. 1932, 207, 21–40. [Google Scholar] [CrossRef]

- Smaga, M.; Eifler, D. Fatigue life calculation of metastable austenitic stainless steels on the basis of magnetic measurements. Mater. Test. 2009, 51, 370–375. [Google Scholar] [CrossRef]

- Biermann, H.; Solarek, J.; Weidner, A. SEM Investigation of High-Alloyed Austenitic Stainless Cast Steels With Varying Austenite Stability at Room Temperature and 100 degrees C. Steel Res. Int. 2012, 83, 512–520. [Google Scholar] [CrossRef]

- Hahnenberger, F.; Smaga, M.; Eifler, D. Influence of γ-α′-phase transformation in metastable austenitic steels on the mechanical behavior during tensile and fatigue loading at ambient and lower temperatures. Adv. Eng. Mater. 2012, 14, 853–858. [Google Scholar] [CrossRef]

- Hahnenberger, F.; Smaga, M.; Eifler, D. Microstructural investigation of the fatigue behavior and phase transformation in metastable austenitic steels at ambient and lower temperatures. Int J. Fatigue 2014, 69, 36–48. [Google Scholar] [CrossRef]

- Smaga, M.; Hahnenberger, F.; Sorich, A.; Eifler, D. Cyclic deformation behavior of austenitic steels in the temperature range −60 C ≤ T ≤ 550 °C. Key Eng. Mater. 2011, 465, 439–442. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Jun, J.H.; Choi, C.-S. Variation of stacking fault energy with austenite grain size and its effect on the MS temperature of γ→ε martensitic transformation in Fe–Mn alloy. Mater. Sci. Eng. A 1998, 257, 353–356. [Google Scholar] [CrossRef]

- Llewellyn, D.T. Work hardening effects in austenitic stainless steels. Mater. Sci. Technol. 1997, 13, 389–400. [Google Scholar] [CrossRef]

- Martin, S.; Fabrichnaya, O.; Rafaja, D. Prediction of the local deformation mechanisms in metastable austenitic steels from the local concentration of the main alloying elements. Mater. Lett. 2015, 159, 484–488. [Google Scholar] [CrossRef]

- Otte, H.M. The transformation of stacking faults in austenite and its relation to martensite. Acta Metall. 1957, 5, 614–627. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Thompson, A.W. The composition dependence of stacking fault energy in austenitic stainless steels. Metall. Mater. Trans. A 1977, 8, 1901–1906. [Google Scholar] [CrossRef]

- Rémy, L.; Pineau, A.; Thomas, B. Temperature dependence of stacking fault energy in close-packed metals and alloys. Mater. Sci. Eng. 1978, 36, 47–63. [Google Scholar] [CrossRef]

- Shen, Y.F.; Li, X.X.; Sun, X.; Wang, Y.D.; Zuo, L. Twinning and martensite in a 304 austenitic stainless steel. Mater. Sci. Eng A 2012, 552, 514–522. [Google Scholar] [CrossRef]

- Schramm, R.E.; Reed, R.P. Stacking-fault energies of 7 commercial austenitic stainless steels. Metall. Trans. A 1975, 6, 1345–1351. [Google Scholar] [CrossRef]

- Basu, K.; Das, M.; Bhattacharjee, D.; Chakraborti, P.C. Effect of grain size on austenite stability and room temperature low cycle fatigue behavior of solution annealed AISI 316LN austenitic stainless steel. Mater. Sci. Technol. 2007, 23, 1278–1284. [Google Scholar] [CrossRef]

- Gonzáles, J.L.; Aranda, R.; Jonapá, M. The influence of grain size on the kinetics of strain induced martensite in type 304 stainless steel. In Applications of Stainless Steel; Nordberg, H., Björklund, J., Eds.; ASM International: Stockholm, Sweden, 1992; pp. 1009–1016. [Google Scholar]

- Shrinivas, V.; Varma, S.K.; Murr, L.E. Deformation-Induced martensitic characteristics in 304 stainless and 316 stainless steels during room temperature rolling. Metall. Mater. Trans. A 1995, 26, 661–671. [Google Scholar] [CrossRef]

- Yang, H.S.; Bhadeshia, H.K.D.H. Austenite grain size and the martensite–Start temperature. Scr. Mater. 2009, 60, 493–495. [Google Scholar] [CrossRef]

- Bayerlein, M.; Christ, H.J.; Mughrabi, H. Plasticity-induced martensitic transformation during cyclic deformation of AISI 304L stainless steel. Mater. Sci. Eng. A 1989, 114, L11–L16. [Google Scholar] [CrossRef]

- Smaga, M.; Walther, F.; Eifler, D. Deformation-induced martensitic transformation in metastable austenitic steels. Mater. Sci. Eng. A 2008, 483–484, 394–397. [Google Scholar] [CrossRef]

- Sorich, A.; Smaga, M.; Eifler, D. Fatigue monitoring of austenitic steels with electromagnetic acoustic transducers (EMATs). Mater. Performance Charact. 2014, 4, 263–274. [Google Scholar] [CrossRef]

- Sorich, A.; Smaga, M.; Eifler, D. Influence of cyclic deformation induced phase transformation on the fatigue behavior of the austenitic steel X6CrNiNb1810. Adv. Mater. Res. 2014, 891–892, 1231–1236. [Google Scholar] [CrossRef]

- Das, A.; Sivaprasad, S.; Ghosh, M.; Chakraborti, P.C.; Tarafder, S. Morphologies and characteristics of deformation induced martensite during tensile deformation of 304 LN stainless steel. Mater. Sci. Eng. A 2008, 486, 283–286. [Google Scholar] [CrossRef]

- Murr, L.E.; Staudhammer, K.P.; Hecker, S.S. Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: part ii. microstructural study. Metall. Trans. A 1982, 13, 627–635. [Google Scholar] [CrossRef]

- Staudhammer, K.P.; Murr, L.E.; Hecker, S.S. Nucleation and evolution of strain-induced martensitic (bcc) embryos and substructure in stainless-steel—A transmission electron-microscope study. Acta Metall. 1983, 31, 267–274. [Google Scholar] [CrossRef]

- Hecker, S.S.; Stout, M.G.; Staudhammer, K.P.; Smith, J.L. Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: Part I. Magnetic measurements and mechanical behavior. Metall. Trans. A 1982, 13, 619–626. [Google Scholar] [CrossRef]

- Klesnil, M.; Lukas, P. Fatigue of metallic materials. Mater. Sci. Monogr. 1980, 7. [Google Scholar]

- Lukáš, P.; Klesnil, M. Dislocation structures in fatigued single crystals of Cu-Zn system. Phys. Stat. Sol. (a) 1971, 5, 247–258. [Google Scholar] [CrossRef]

- Mughrabi, H. Fatigue, an everlasting materials problem—still en vogue. Proc. Eng. 2 2010, 2, 3–26. [Google Scholar] [CrossRef]

- Karaman, I.; Sehitoglu, H.; Chumlyakov, Y.I.; Maier, H.J. The deformation of low-stacking-fault-energy austenitic steels. JOM 2002, 7, 31–37. [Google Scholar] [CrossRef]

- Lee, T.-H.; Shin, E.; Oh, C.-S.; Ha, H.-Y.; Kim, S.-J. Correlation between stacking fault energy and deformation microstructure in high-interstitial-alloyed austenitic steels. Acta Mater. 2010, 58, 3173–3186. [Google Scholar] [CrossRef]

- Xie, X.; Ninga, D.; Suna, J. Strain-controlled fatigue behavior of cold-drawn type 316 austenitic stainless steel at room temperature. Mater. Charact. 2016, 120, 195–202. [Google Scholar] [CrossRef]

- Nebel, T. Verformungsverhalten und Mikrostruktur zyklisch beanspruchter metastabiler austenitischer Stähle. Ph.D. Thesis, Technical University of Kaiserslautern, Kaiserslautern, Germany, September 2002. [Google Scholar]

- Bassler, H.J. Wechselverformungsverhalten und verformungsinduzierte Martensitbildung bei dem metastabilen austenitischen Stahl X6CrNiTi1810. Ph.D. Thesis, Technical University of Kaiserslautern, Kaiserslautern, Germany, December 1999. [Google Scholar]

- German version EN 10088-1:2014 Stainless steels – Part 1: List of stainless steels; DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2014.

- Ausschuss, K. Sicherheitstechnische Regel des KTA – KTA 3204 Reaktordruckbehälter-Einbauten; Carl Heymanns Verlag: Cologne, Germany, 2015. [Google Scholar]

- Smaga, M.; Sorich, A.; Eifler, D.; Beck, T. Very high cycle fatigue behavior of metastable austenitic steel X6CrNi1810 at 300 °C. In Proceedings of the 7th Internaltional Conference on Very High Cycle Fatigue (VHCF-7), Dresden, Germany, 3–5 July 2017. [Google Scholar]

- Sorich, A. Charakterisierung des Verformungs- und Umwandlungsverhaltens des zyklisch beanspruchten metastabilen austenitischen Stahls X6CrNiNb1810. Ph.D. Thesis, Technical University of Kaiserslautern, Kaiserslautern, Germany, July 2006. [Google Scholar]

- Ritz, F.; Beck, T. Influence of mean stress and notches on the very high cycle fatigue behavior and crack initiation of a low-pressure steam turbine steel. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1762–1771. [Google Scholar] [CrossRef]

- Daniel, T.; Boemke, A.; Smaga, M.; Beck, T. Investigations of very high cycle fatigue behavior of metastable austenitic steels using servohydraulic and ultrasonic testing systems. In Proceedings of the ASME 2018 Pressure Vessels and Piping Conference, Prague, Czech Republic, 15–20 July 2018. [Google Scholar]

- Biallas, G.; Piotrowski, A.; Eifler, D. Cyclic stress-strain, stress-temperature and stress-electrical resistance response of NiCuMo alloyed sintered steel. Fatigue Fract. Eng. Mat. Struct. 1995, 18, 605–615. [Google Scholar] [CrossRef]

- Piotrowski, A.; Eifler, D. Characterization of cyclic deformation behaviour by mechanical, thermometrical and electrical methods. Materialwiss. Werkstofftech. 1995, 26, 121–127. [Google Scholar]

- Talonen, J.; Aspegren, P.; Hänninen, H. Comparison of different methods for measuring strain induced alpha ’-martensite content in austenitic steels. Mater. Sci. Technol. 2004, 20, 1506–1512. [Google Scholar] [CrossRef]

- Boemke, A.; Smaga, M.; Beck, T. Influence of surface morphology on the very high cycle fatigue behavior of metastable and stable austenitic Cr-Ni steels. MATEC Web Conf. 2018, 165, 20008. [Google Scholar] [CrossRef]

- Nikitin, B.; Besel, M. Effect of low-frequency on fatigue behavior of austenitic steel AISI 304 at room temperature and 25 °C. Int. J. Fatigue 2008, 30, 2044–2049. [Google Scholar] [CrossRef]

- Pessoa, D.F.; Kirchhoff, G.; Zimmermann, M. Influence of loading frequency and role of surface micro-defects on fatigue behavior of metastable austenitic stainless steel AISI 304. Int. J. Fatigue 2017, 103, 48–59. [Google Scholar] [CrossRef]

- De Backer, F.; Schoss, V.; Maussner, G. Investigations on the evaluation of the residual fatigue life-time in austenitic stainless steels. Nucl. Eng. Des. 2001, 206, 201–219. [Google Scholar] [CrossRef]

- Le Duff, J.-A.; Lefrançois, A.; Meyzaud, Y.; Vernot, J.-Ph.; Martin, D.; Mendez, J.; Lehericy, Y. High cycle thermal fatigue issues in PWR nuclear power plants, lifetime improvement of some austenitic stainless steel components. Metall. Res. Technol. 2007, 104, 156–162. [Google Scholar]

- Laamouri, A.; Sidhom, H.; Braham, C. Evaluation of residual stress relaxation and its effect on fatigue strength of AISI 316L stainless steel ground surfaces: Experimental and numerical approaches. Int J. Fatigue 2013, 48, 109–121. [Google Scholar] [CrossRef]

- Vincent, L.; Le Roux, J.-C.; Taheri, S. On the high cycle fatigue behavior of a type 304L stainless steel at room temperature. Int. J. Fatigue 2012, 38, 84–91. [Google Scholar] [CrossRef]

- Puchi-Cabrera, E.S.; Staia, M.H.; Tova, C.; Ochoa-Pérez, E.A. High cycle fatigue behavior of 316L stainless steel. Int. J. Fatigue 2008, 30, 2140–2146. [Google Scholar] [CrossRef]

- Roth, I.; Kübbeler, M.; Krupp, U.; Christ, H.-J.; Fritzen, C.-P. Crack initiation and short crack growth in metastable austenitic stainless steel in the high cycle fatigue regime. Proc. Eng. 2010, 2, 941–948. [Google Scholar] [CrossRef]

- Soo, P.; Chow, J.G.Y. High cycle fatigue behavior of solution annealed and thermally aged Type 304 stainless steel. J. Eng. Mater. Technol. 1980, 102, 141–146. [Google Scholar] [CrossRef]

- Herrera-Solaz, V.; Niffenegger, M. Application of hysteresis energy criterion in a microstructure-based model for fatigue crack initiation and evolution in austenitic stainless steel. Int. J. Fatigue 2017, 100, 84–93. [Google Scholar] [CrossRef]

- Müller-Bollenhagen, C.; Zimmermann, M.; Christ, H.-J. Adjusting the very high cycle fatigue properties of a metastable austenitic stainless steel by means of the martensite content. Proc. Eng. 2010, 2, 1663–1672. [Google Scholar] [CrossRef]

- Grigorescu, A.; Kolyshkin, A.; Zimmermann, M.; Christ, H.-J. Effect of martensite content and geometry of inclusions on the VHCF properties of predeformed metastable austenitic stainless steels. Procedia Struct. Integrity 2016, 2, 1093–1100. [Google Scholar] [CrossRef]

| AISI 347 | C | N | Nb | Cr | Ni | Mn | Mo | Si | Md30 °C | MS °C | SFE mJ/m2 | Iξ FE% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Batch A | 0.040 | 0.007 | 0.62 | 17.6 | 10.6 | 1.83 | 0.29 | 0.41 | 25 | −189 | 39 | 0.25 |

| Batch B | 0.024 | 0.019 | 0.41 | 17.3 | 9.3 | 1.55 | 0.19 | 0.63 | 46 | −81 | 27 | 0.66 |

| AISI 347 | Rp0.2 in MPa | UTS in MPa | A in % | ξ in FE% |

|---|---|---|---|---|

| Batch A, AT | 242 | 569 | 66 | 4.41 |

| Batch A, 300 °C | 180 | 357 | 36 | 0.00 |

| Batch B, AT | 220 | 621 | 51 | 33.22 |

| Batch B, 300 °C | 155 | 428 | 37 | 0.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smaga, M.; Boemke, A.; Daniel, T.; Skorupski, R.; Sorich, A.; Beck, T. Fatigue Behavior of Metastable Austenitic Stainless Steels in LCF, HCF and VHCF Regimes at Ambient and Elevated Temperatures. Metals 2019, 9, 704. https://doi.org/10.3390/met9060704

Smaga M, Boemke A, Daniel T, Skorupski R, Sorich A, Beck T. Fatigue Behavior of Metastable Austenitic Stainless Steels in LCF, HCF and VHCF Regimes at Ambient and Elevated Temperatures. Metals. 2019; 9(6):704. https://doi.org/10.3390/met9060704

Chicago/Turabian StyleSmaga, Marek, Annika Boemke, Tobias Daniel, Robert Skorupski, Andreas Sorich, and Tilmann Beck. 2019. "Fatigue Behavior of Metastable Austenitic Stainless Steels in LCF, HCF and VHCF Regimes at Ambient and Elevated Temperatures" Metals 9, no. 6: 704. https://doi.org/10.3390/met9060704

APA StyleSmaga, M., Boemke, A., Daniel, T., Skorupski, R., Sorich, A., & Beck, T. (2019). Fatigue Behavior of Metastable Austenitic Stainless Steels in LCF, HCF and VHCF Regimes at Ambient and Elevated Temperatures. Metals, 9(6), 704. https://doi.org/10.3390/met9060704