Study on Microstructure and Properties of Tailored Hot-Stamped U-shaped Parts Based on Temperature Field Control

Abstract

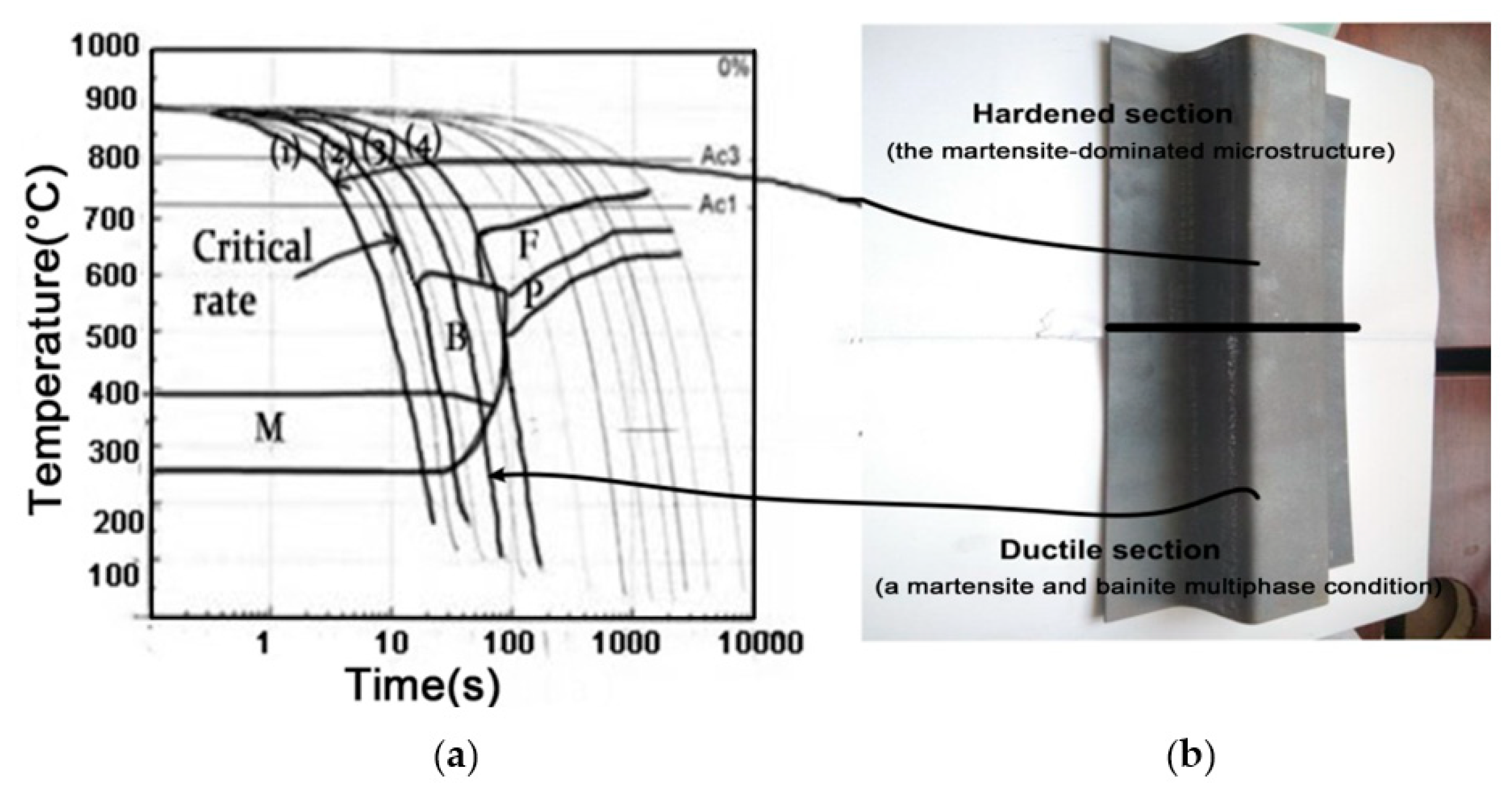

:1. Introduction

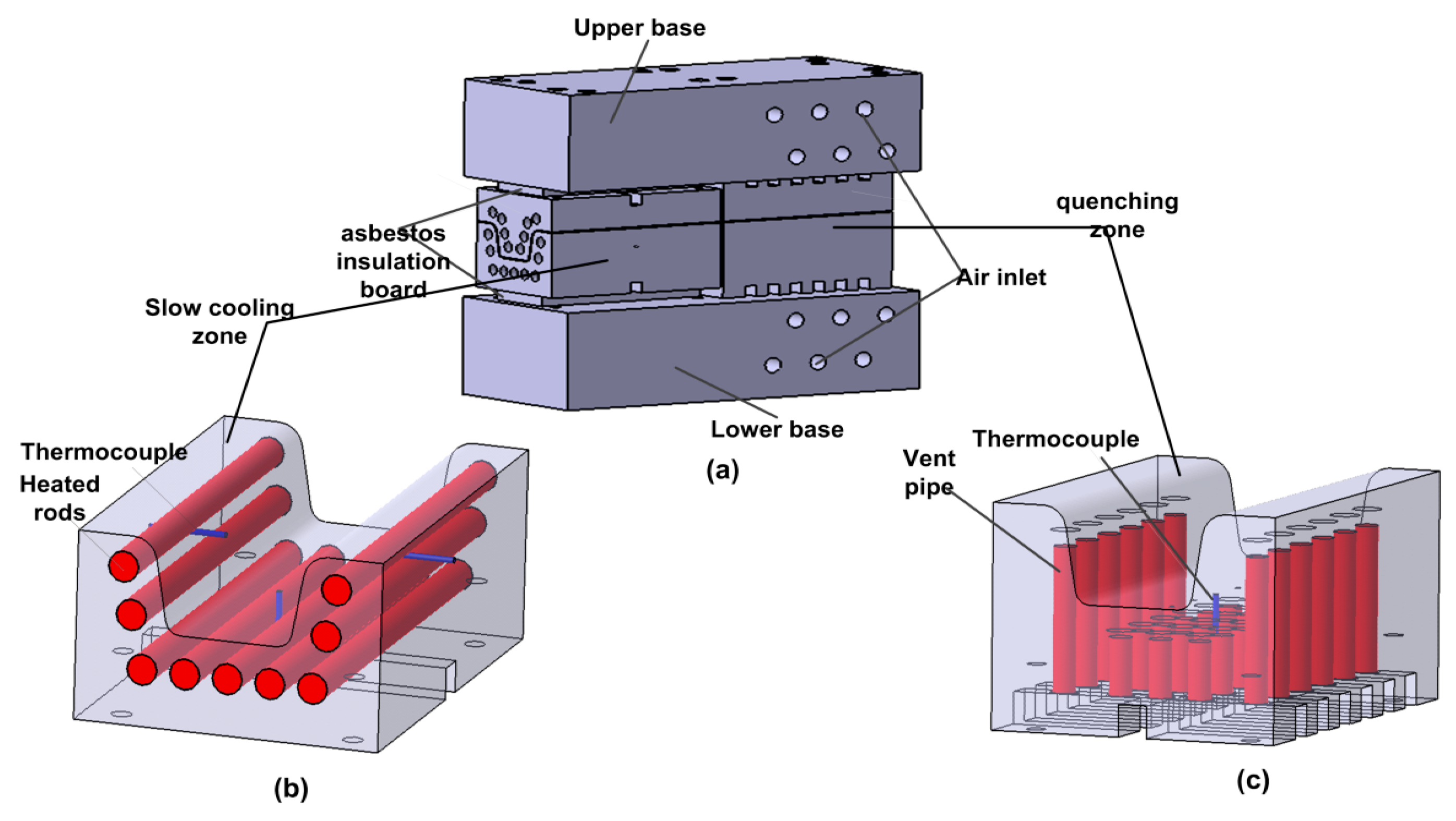

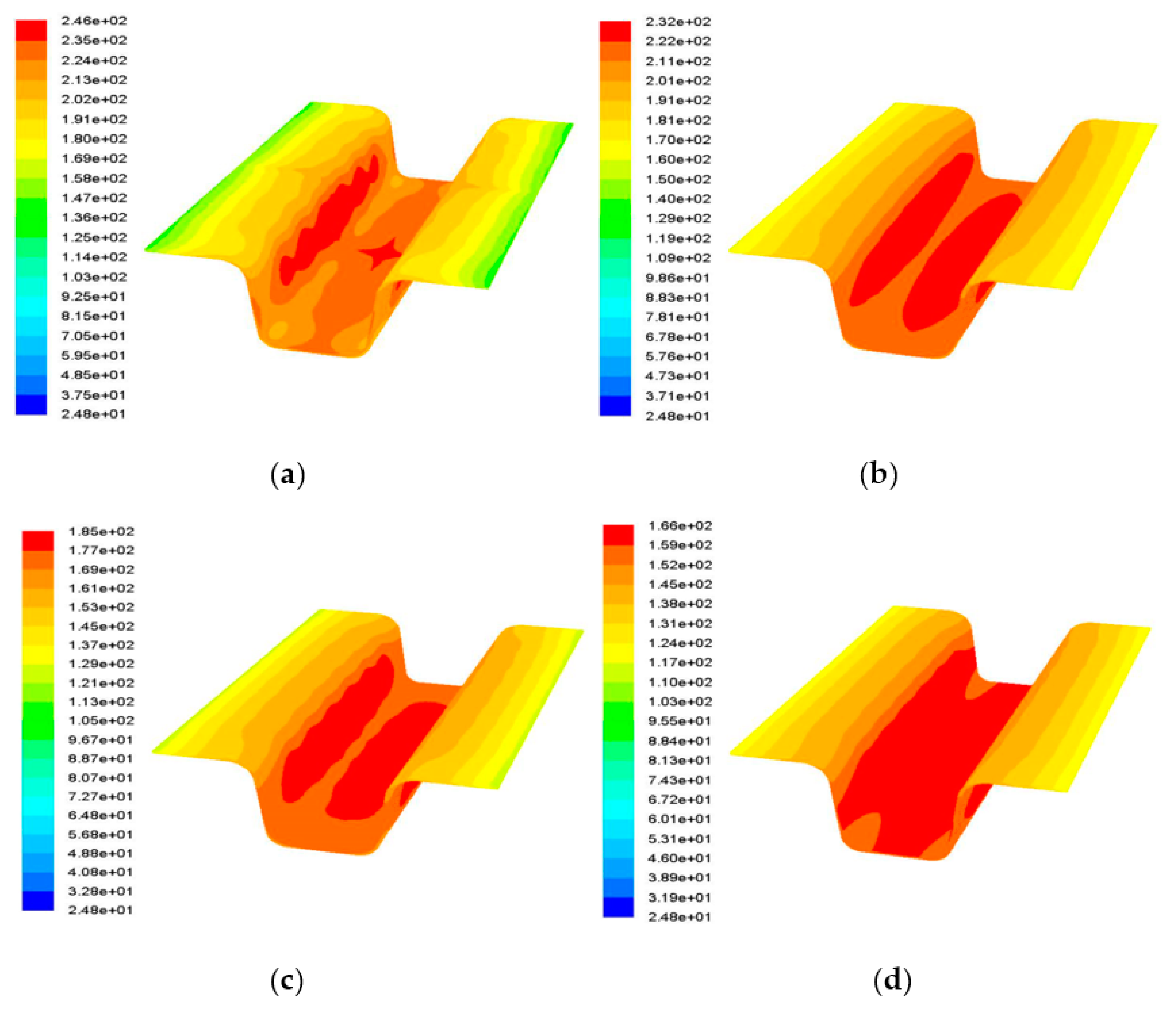

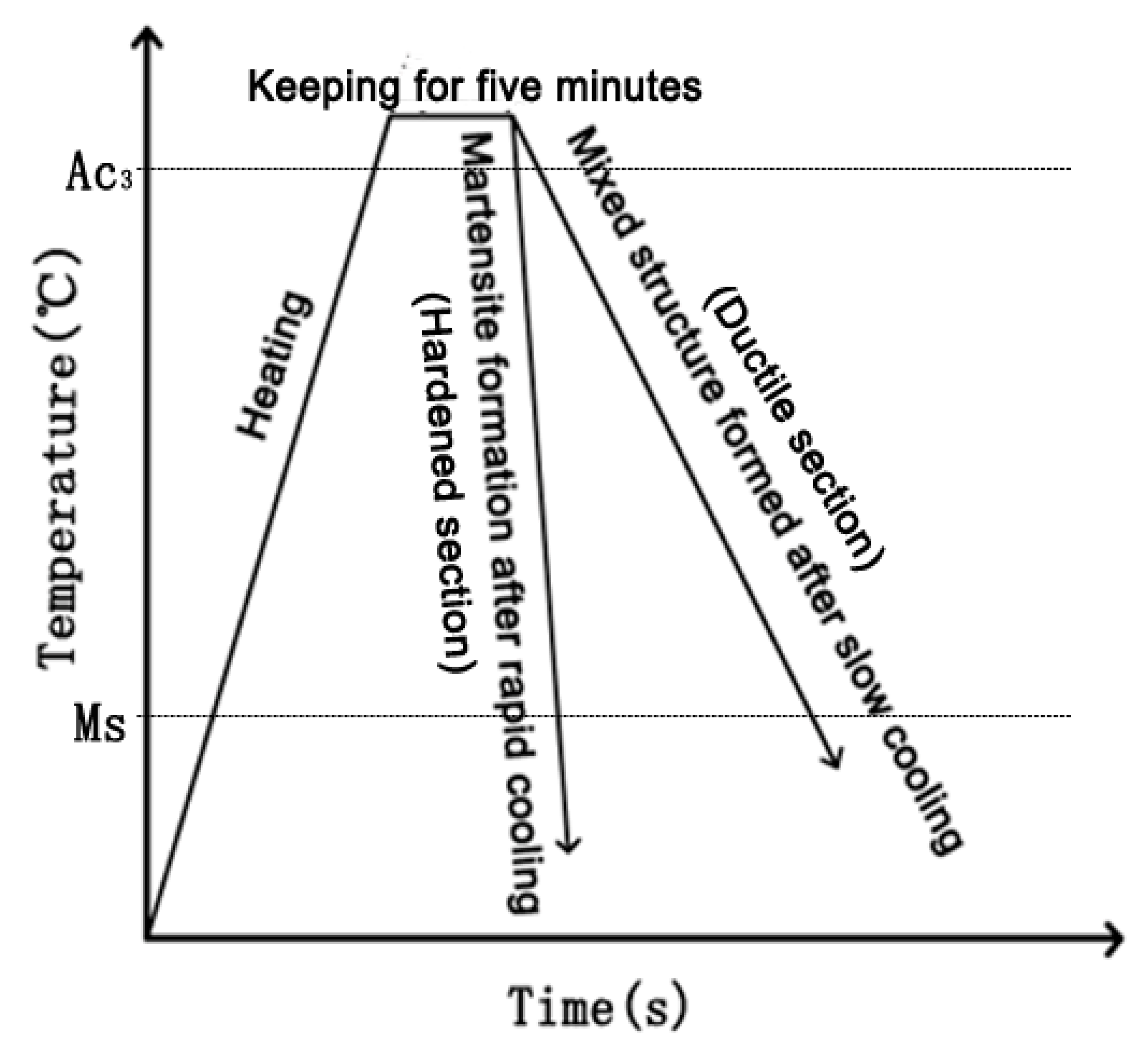

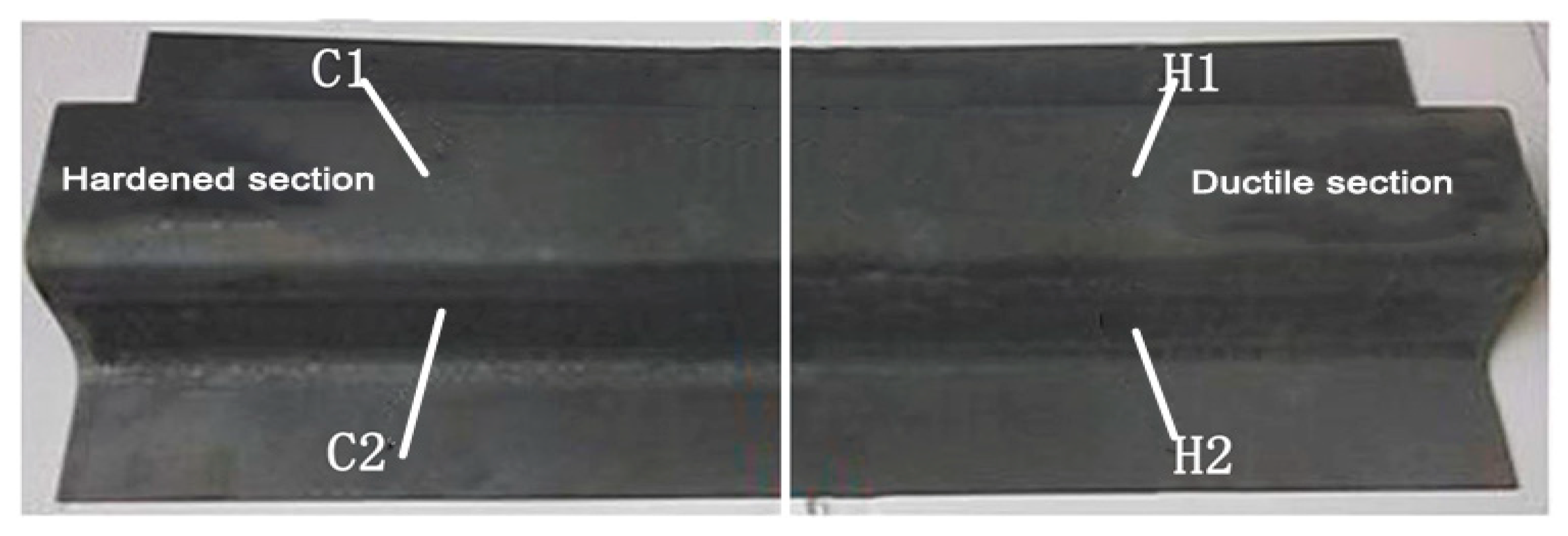

2. Materials and Methods

2.1. Materials and Die

2.2. Experimental Method

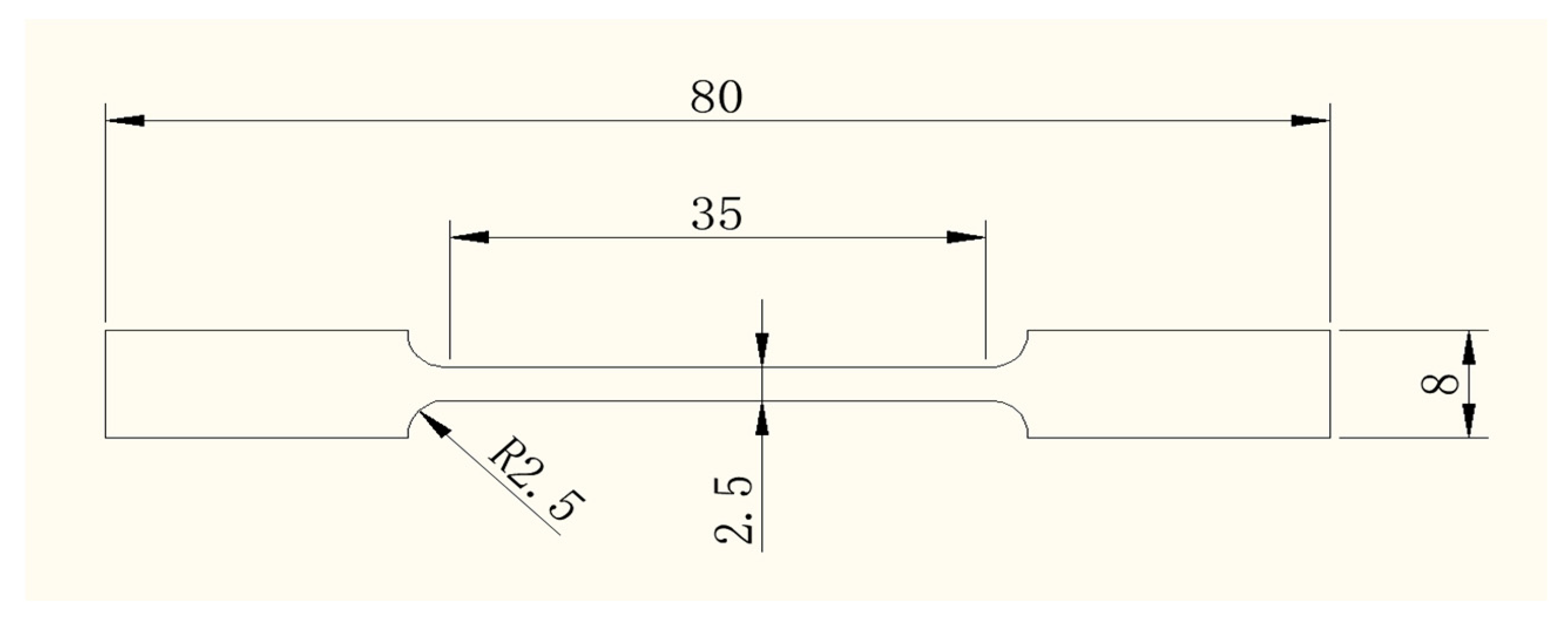

2.3. Microstructure and Mechanical Properties Testing

3. Results and Discussion

3.1. Metallographic Analysis Results

3.2. Performance Results

3.3. Fracture Behavior

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Gu, Z.W.; Lv, M.M.; Zhao, L.H.; Xu, H.; Li, X.; Lu, G.H. Optimization of quenching parameters of ultra high strength steel in hot stamping process. Jilin Univ. (Eng. Technol. Ed.) 2016, 46, 853–858. [Google Scholar]

- Bardelcik, A.; Salisbury, C.P.; Winkler, S.; Wells, M.A.; Worswick, M.J. Effect of cooling rate on the high strain rate properties of boron steel. Int. J. Impact Eng. 2010, 37, 694–702. [Google Scholar] [CrossRef]

- Munera, D.D.; Lacassin, L.; Pinard, F. Very and Ultra High Strength Steels based Tailored Blanks: a step further towards vehicle crash performances improvement. Rev. Metall. Int. J. Metall. 2007, 104, 613–624. [Google Scholar] [CrossRef]

- Mori, K.; Maeno, T.; Mongkolkaji, K. Tailored die quenching of steel parts having strength distribution using bypass resistance heating in hot stamping. J. Mater. Process. Technol. 2013, 213, 508–514. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, P.; Xu, Y.; Wang, Y.; Zhang, Y. Hot stamping of high strength steel with tailored properties by two methods. Procedia Eng. 2014, 81, 1725–1730. [Google Scholar] [CrossRef]

- Yang, X.D. Effect of High Temperature Deformation on Phase Transformation of Hot-Formed Boron Steel B1500HS; Shandong University of Science and Technology: Shandong, China, 2015. [Google Scholar]

- George, R.; Bardelcik, A.; Worswick, M.J. Hot forming of boron steels using heated and cooled tooling for tailored properties. J. Mater. Process. Technol. 2012, 212, 2386–2399. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Yu, J.H.; Meng, S.F.; Zhao, Y.; He, D.Y. Effect of tool temperature on microstructure and properties of tailored hot stamping components. J. Mater. Eng. Perform. 2018, 27, 4838–4845. [Google Scholar] [CrossRef]

- Zhou, M.B.; Tang, J.L.; Yang, J.; Wang, G.Y. Tailored properties of a novelly-designed press-hardened 22MnMoB steel. J. Iron Steel Res. Int. 2017, 24, 508–512. [Google Scholar] [CrossRef]

- Omer, K.; Kortenaar, L.T.; Butcher, C.; Worswick, M.; Malcolm, S.; Detwiler, D. Testing of a hot stamped axial crush member with tailored properties experiments and models international. Impact. Eng. 2017, 103, 12–18. [Google Scholar] [CrossRef]

- Naylor, J.P. Influence of the Lath Morphology on the Yield Stress and Transition-Temperature of Martensitic-Bainitic Steels. Metall. Mater. Trans. 1979, 10, 861–873. [Google Scholar] [CrossRef]

- Feng, C.; Fang, H.S.; Zheng, Y.K.; Bai, B.Z. Mn-series low-carbon air-cooled bainitic steel containing niobium of 0.02%. J. Iron Steel Res. Int. 2010, 17, 53–58. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Xiao, L.; Zheng, Q.; Zhang, H.; Gu, Y. Study on Microstructure and Properties of Tailored Hot-Stamped U-shaped Parts Based on Temperature Field Control. Metals 2019, 9, 593. https://doi.org/10.3390/met9050593

Li X, Xiao L, Zheng Q, Zhang H, Gu Y. Study on Microstructure and Properties of Tailored Hot-Stamped U-shaped Parts Based on Temperature Field Control. Metals. 2019; 9(5):593. https://doi.org/10.3390/met9050593

Chicago/Turabian StyleLi, Xiangji, Limei Xiao, Qifeng Zheng, Huan Zhang, and Yanjiao Gu. 2019. "Study on Microstructure and Properties of Tailored Hot-Stamped U-shaped Parts Based on Temperature Field Control" Metals 9, no. 5: 593. https://doi.org/10.3390/met9050593

APA StyleLi, X., Xiao, L., Zheng, Q., Zhang, H., & Gu, Y. (2019). Study on Microstructure and Properties of Tailored Hot-Stamped U-shaped Parts Based on Temperature Field Control. Metals, 9(5), 593. https://doi.org/10.3390/met9050593