Ultrasonic Bonding of Multi-Layered Foil Using a Cylindrical Surface Tool

Abstract

:1. Introduction

2. Experimental Procedure

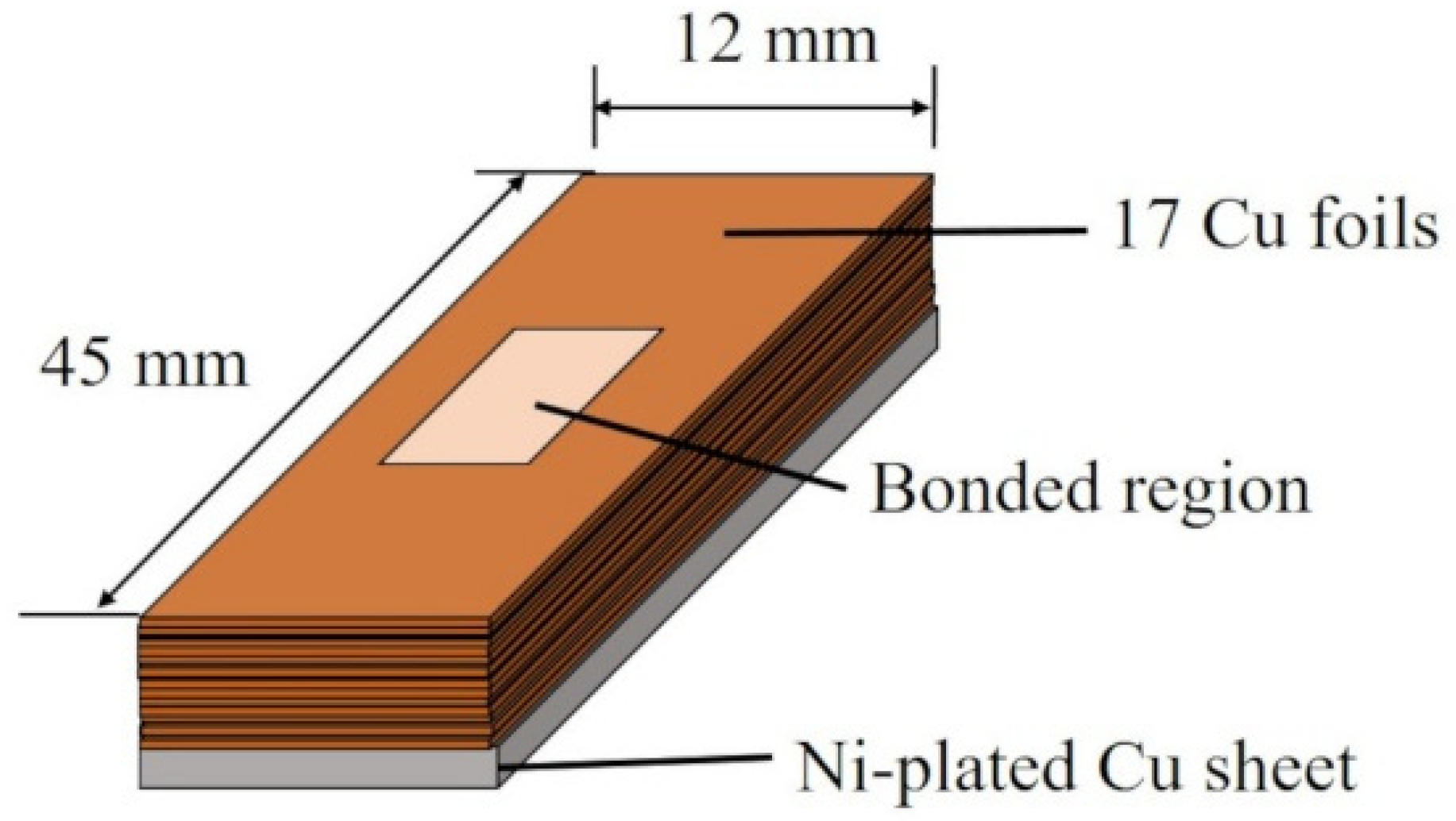

2.1. Specimen

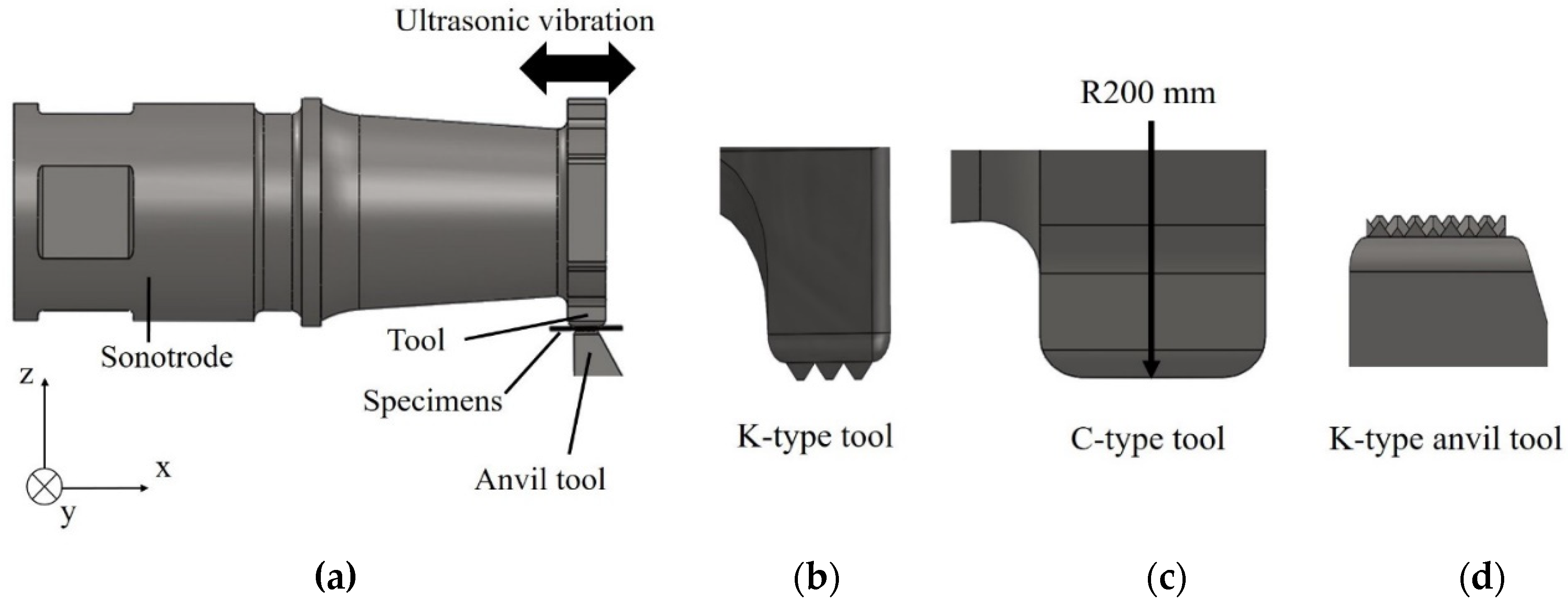

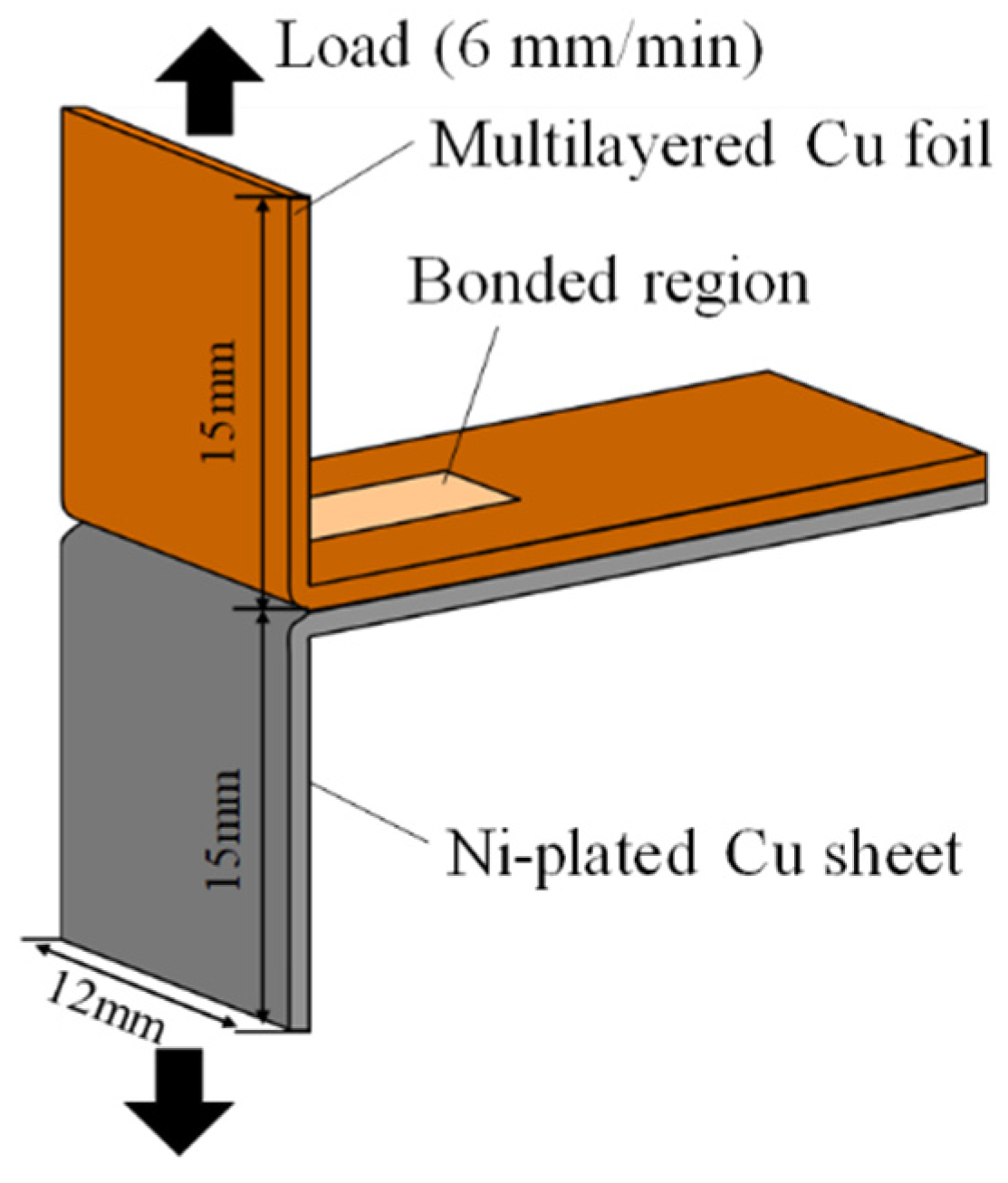

2.2. Bonding Test

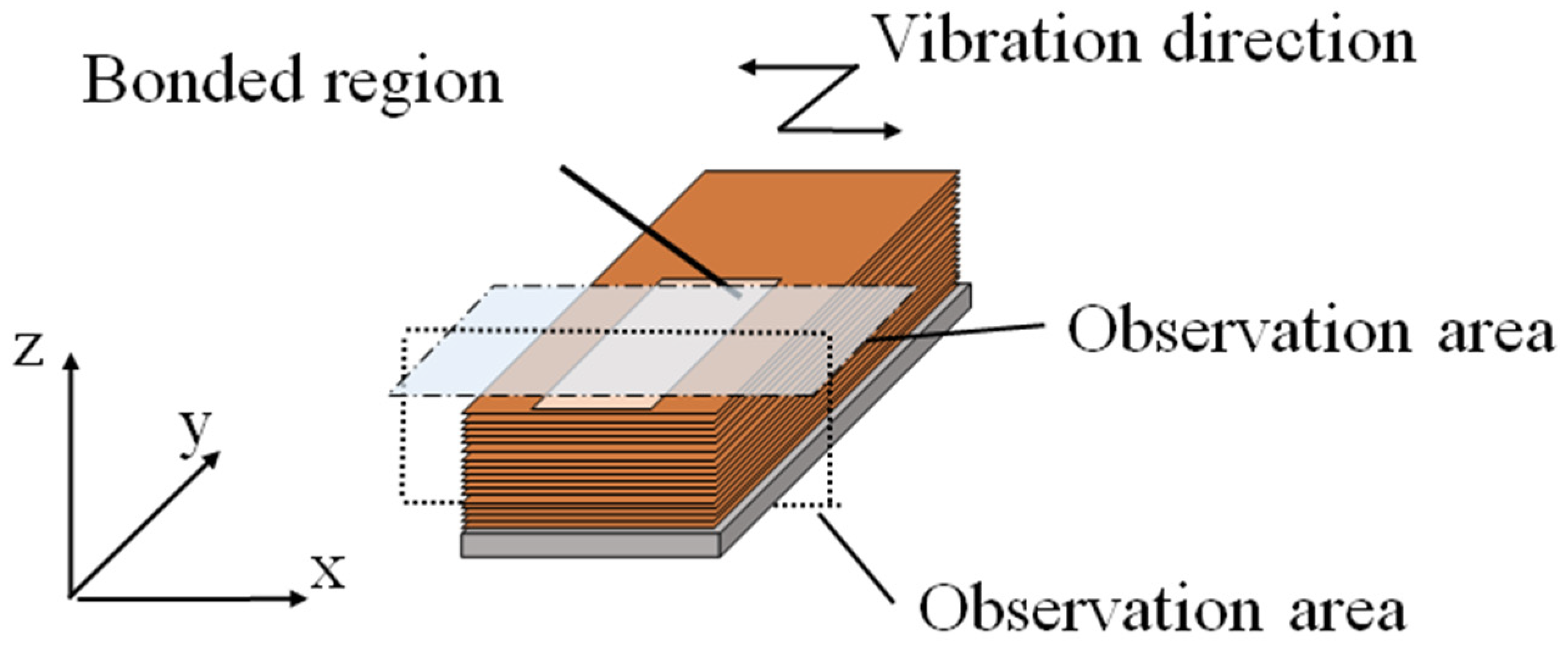

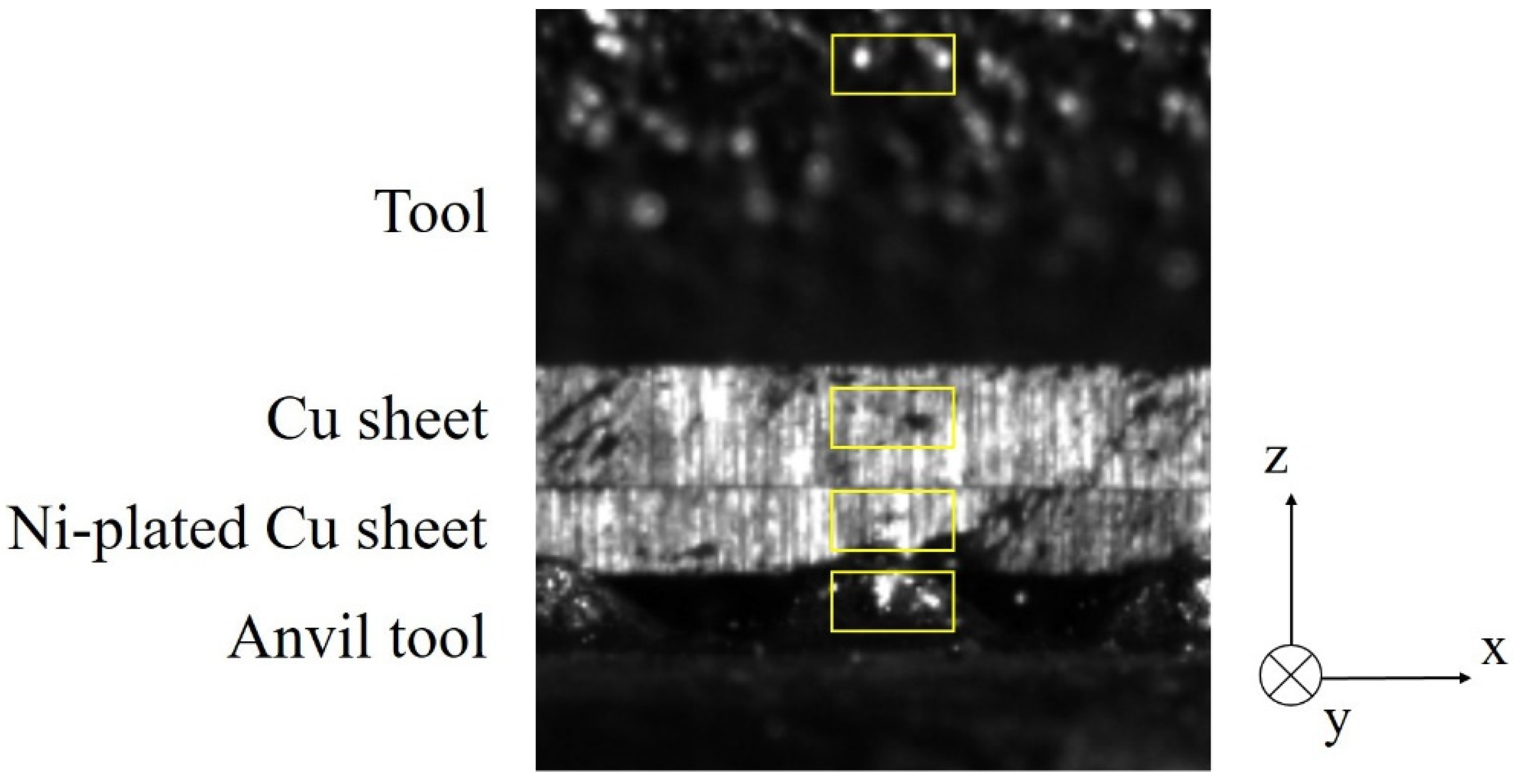

2.3. Relative Motion Analysis

3. Results and Discussions

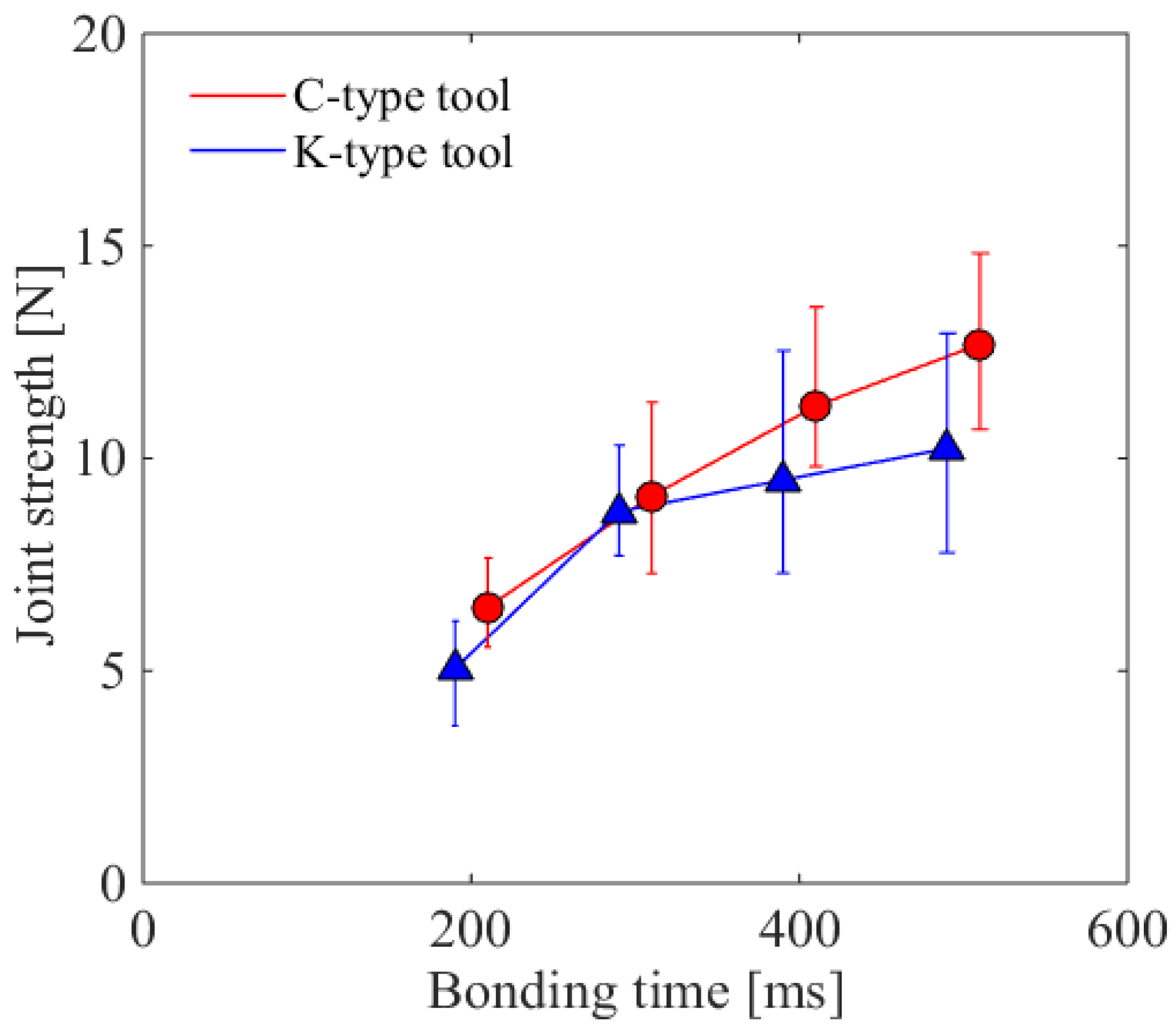

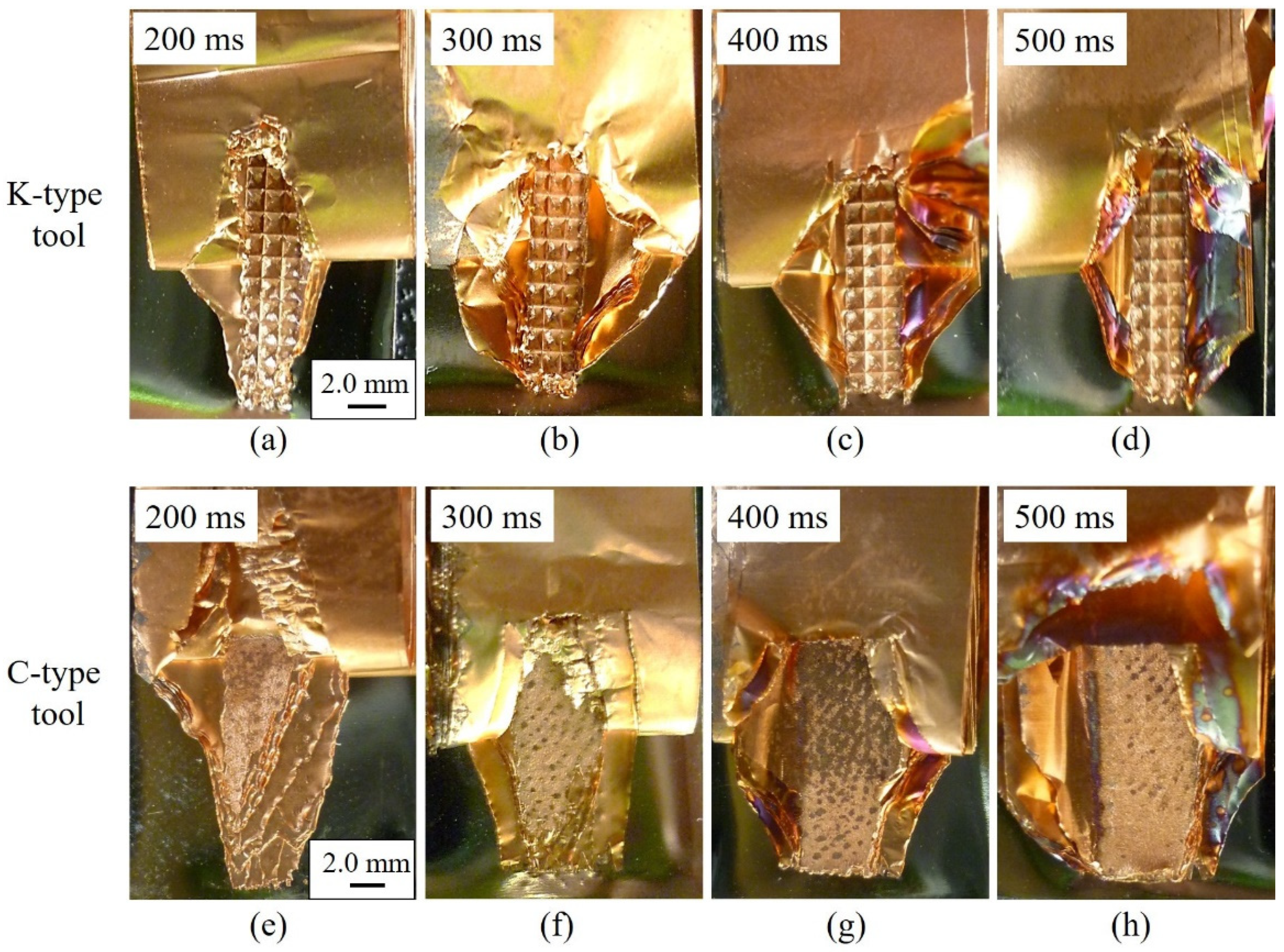

3.1. Joint Strength and Damage to Multi-Layered Foil

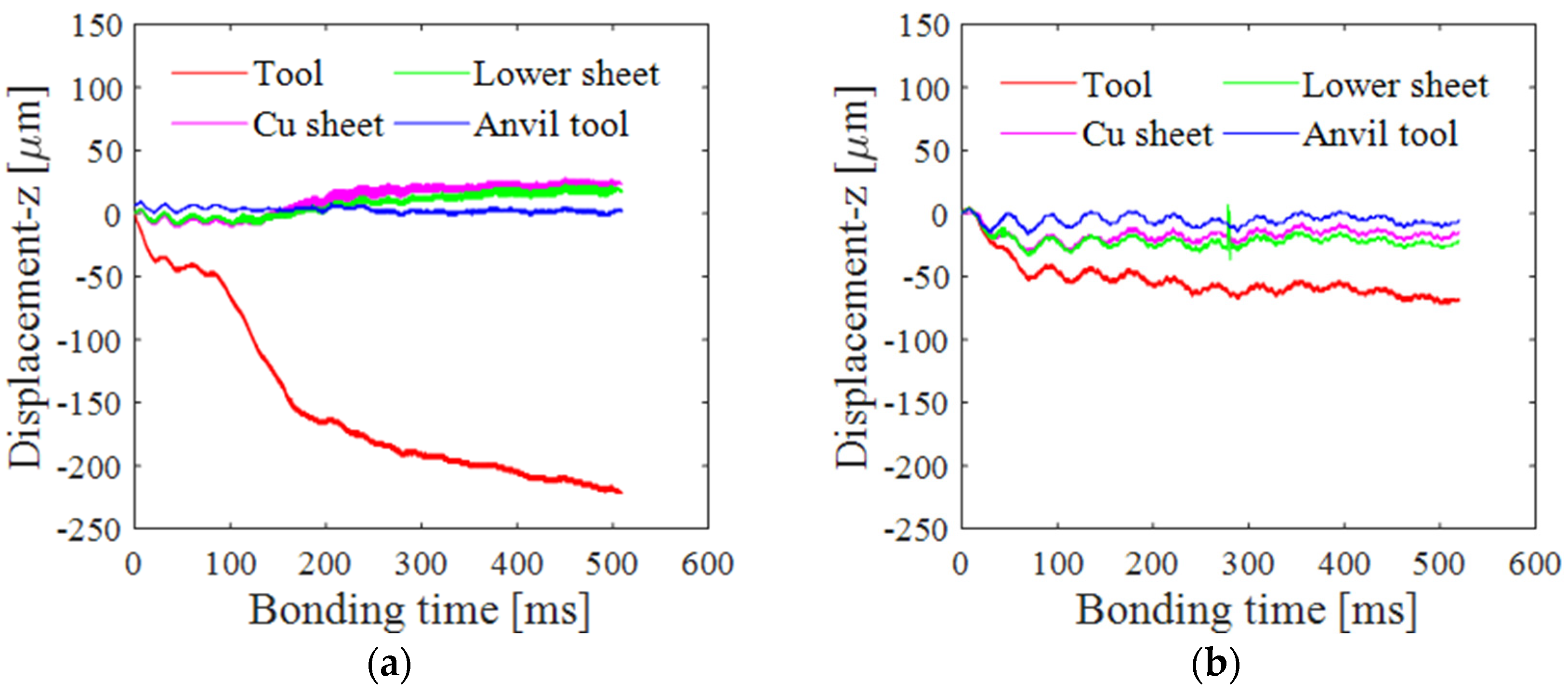

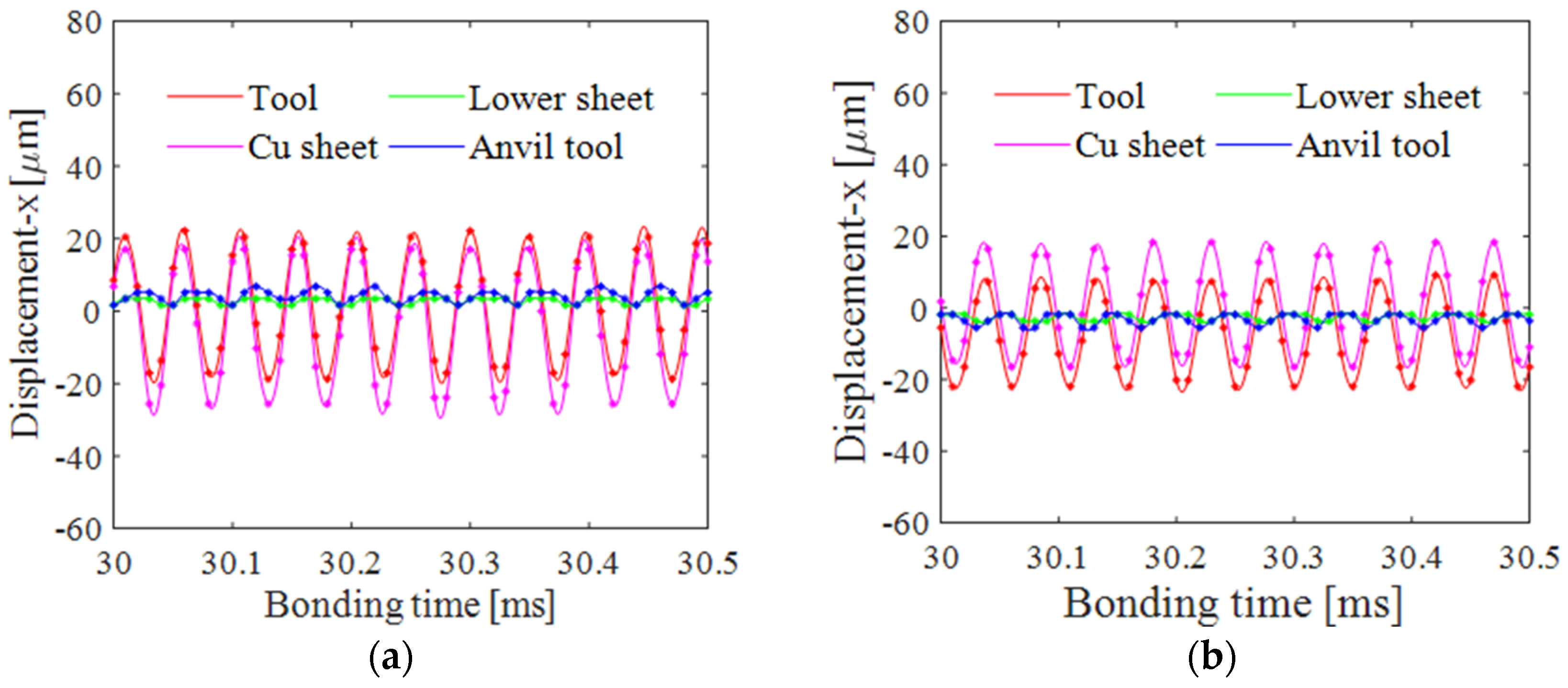

3.2. Relative Motion Behaviors of Tools and Bonding Metals

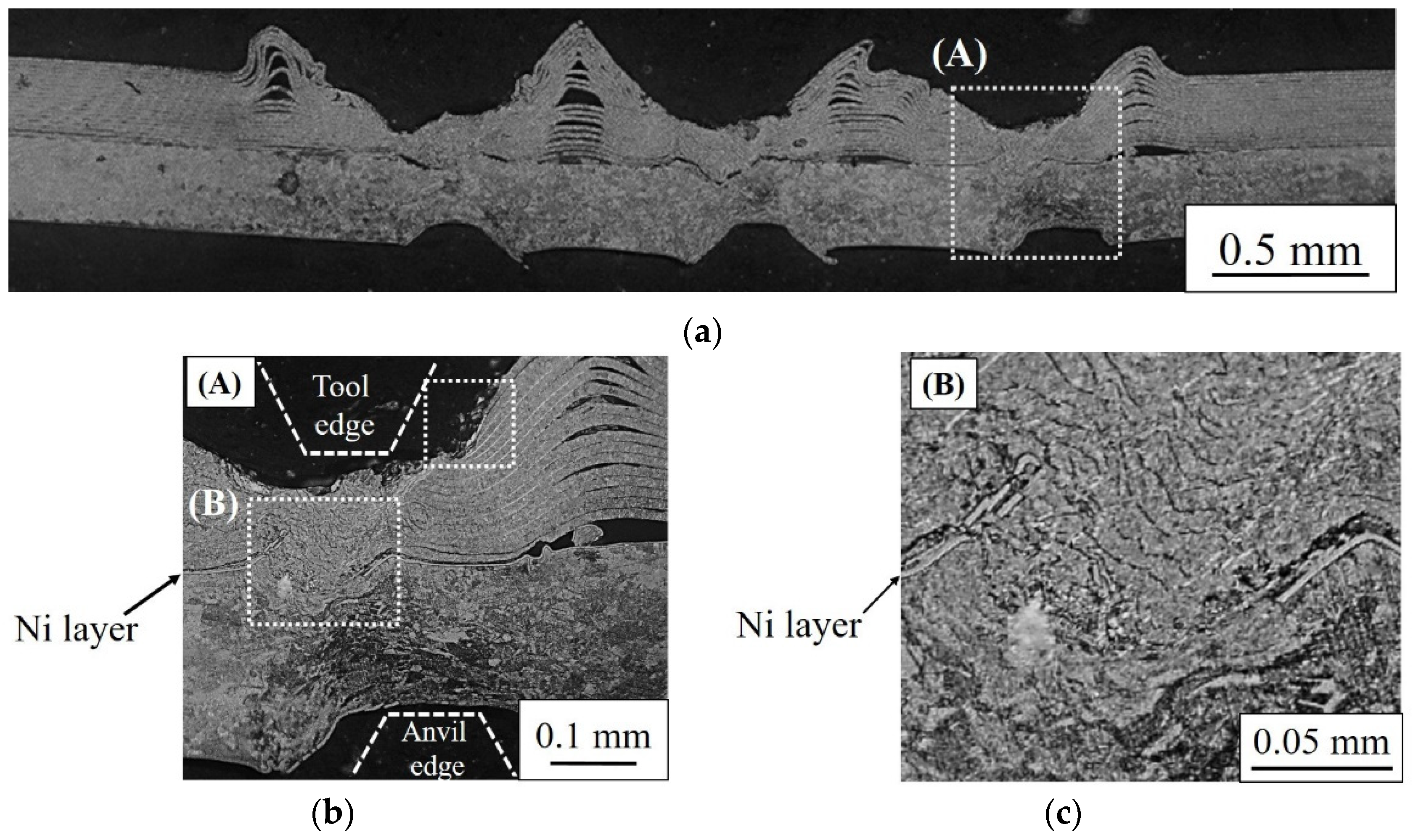

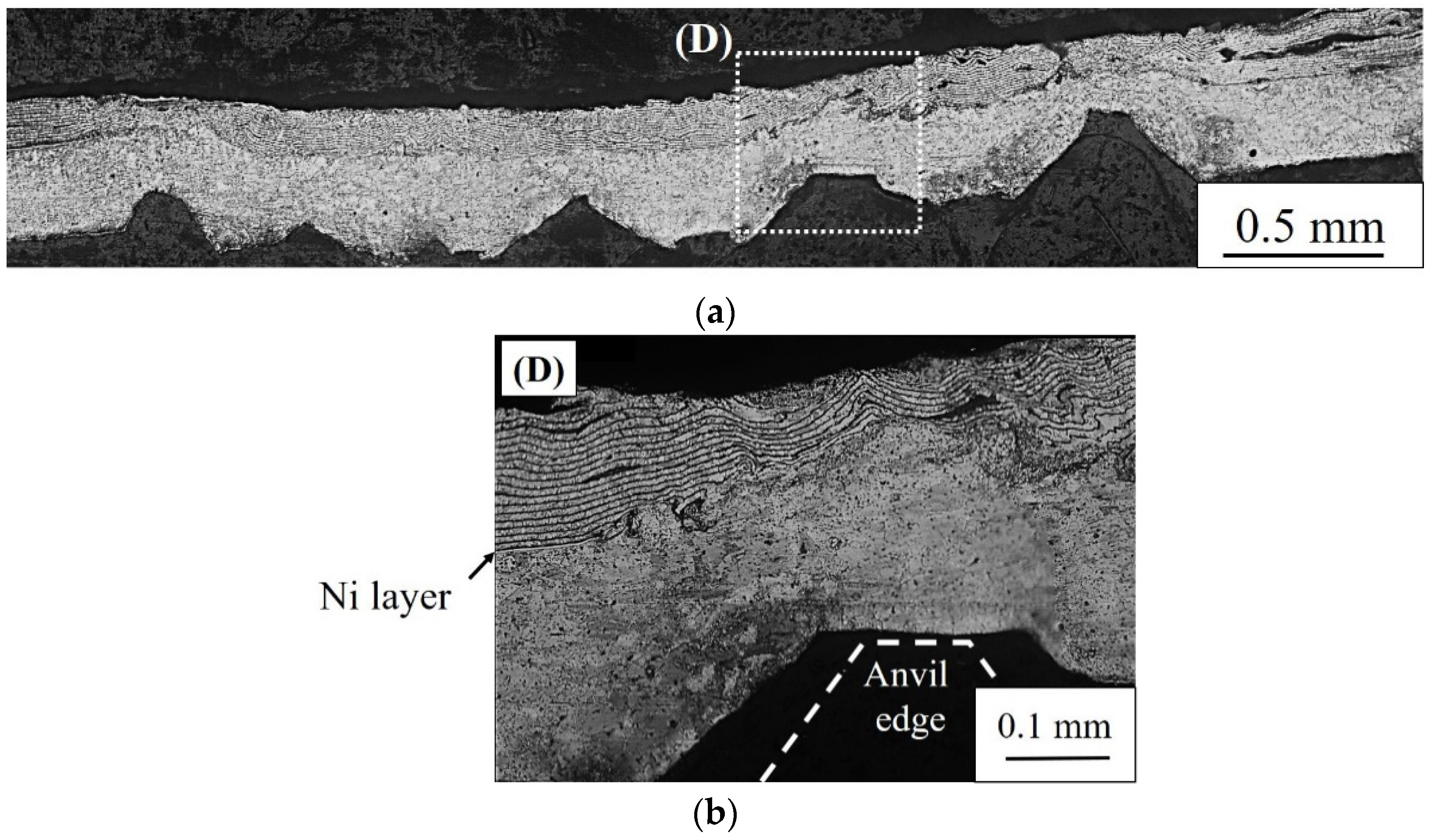

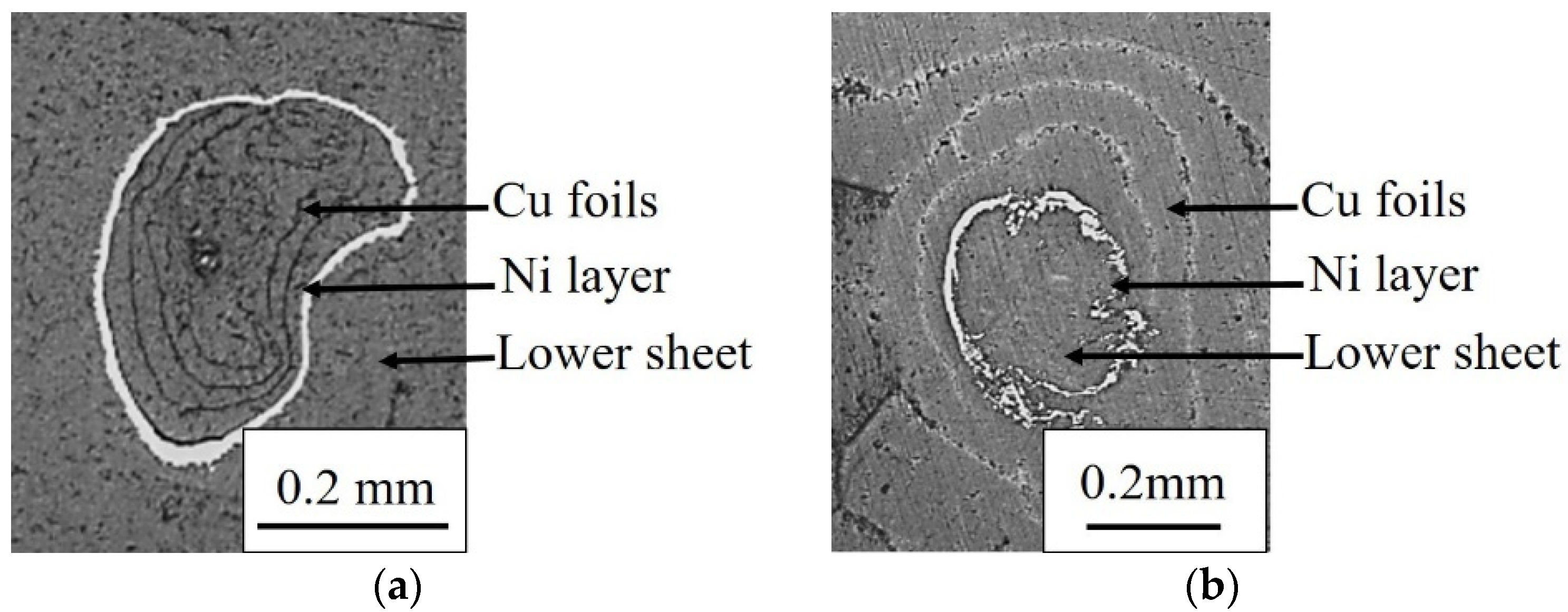

3.3. Evolution of Microstructure

4. Conclusions

- The C-type tool is capable of bonding multi-layered Cu foil and Ni-plated sheet without damaging the upper foil in contact with the tool tip, and the joints made using the C-type tool exhibit adequate joint strength.

- The relative motion between the tool and the Cu foil in contact with the tool has a great influence on the bond quality especially in the bonding thin foils, regardless the tool surface geometry. This relative motion facilitates development of the bonded region, while it damages the foil when using the K-type tool. The lower level of penetration of the tool tip in case of the C-type tool led to damage-less bonding.

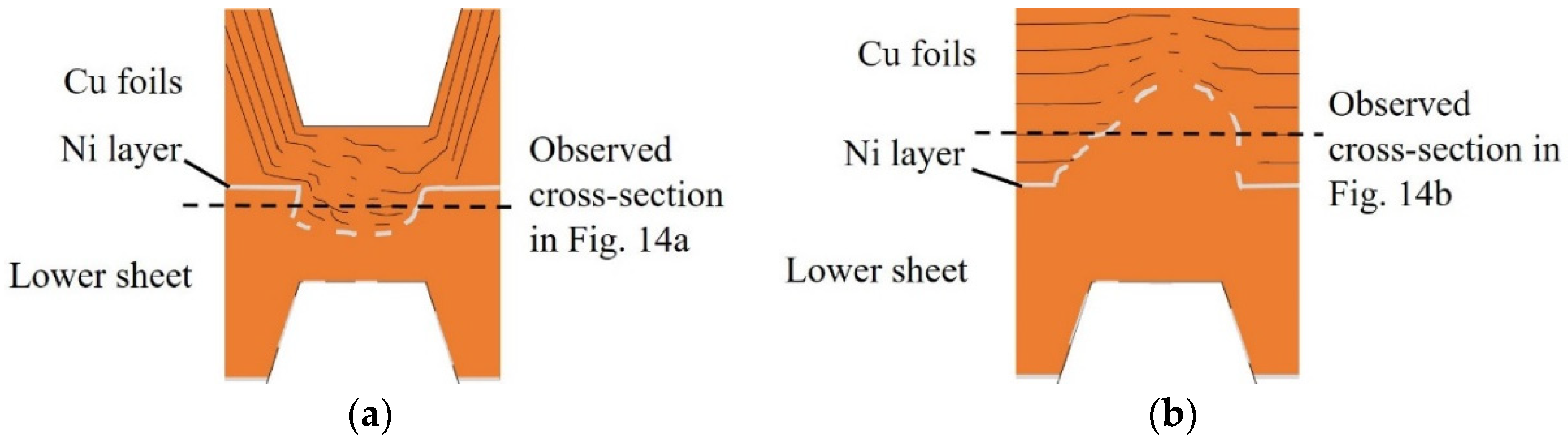

- The micro-bonds formed at the shorter bonding times when the relative motion between pieces of foil, as well as between the foil and the lower sheet, developed along the vibration direction with shear deformation, resulting in macroscopic plastic flow in the bonded region involving the Ni layer for both tool geometries. In case of the K-type tool, plastic flow occurred, especially at the contact point of the edge corner, causing fracture of the foil. Meanwhile, in case of the C-type tool, plastic flow expanded from the lower sheet in contact with the anvil edge.

Author Contributions

Conflicts of Interest

References

- Das, A.; Li, D.; Williams, D.; Greenwood, D. Joining technologies for automotive battery systems manufacturing. World Electr. Veh. J. 2018, 9, 22. [Google Scholar] [CrossRef]

- Bakavos, D.; Prangnell, P.B. Mechanisms of joint and microstructure formation in high power ultrasonic spot welding 6111 aluminium automotive sheet. Mater. Sci. Eng. A 2010, 527, 6320–6334. [Google Scholar] [CrossRef]

- Annoni, M.; Carboni, M. Ultrasonic metal welding of AA 6022-T4 lapjoints: Part 1—Technological characterization and static mechanical behaviour. Sci. Technol. Weld. Join. 2011, 16, 107–115. [Google Scholar] [CrossRef]

- Yang, J.W.; Cao, B.; He, X.C.M. Microstructure evolution and mechanical properties of Cu-Al joints by ultrasonic welding. Sci. Technol. Weld. Join. 2014, 19, 500–504. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Robson, J.D.; Ciuca, O. Microstructural characterization and mechanical properties of high power ultrasonic spot welded aluminum alloy AA6111-TiAl6V4 dissimilar joints. Mater. Charact. 2014, 97, 83–91. [Google Scholar] [CrossRef]

- Mirza, F.A.; Macwan, A.; Bhole, S.D. Effect of welding energy on microstructure and strength of ultrasonic spot welded dissimilar joints of aluminum to steel sheets. Mater. Sci. Eng. A 2016, 668, 73–85. [Google Scholar] [CrossRef]

- Zhao, D.; Ren, D.; Zhao, K. Effect of welding parameters on tensile strength of ultrasonic spot welded joints of aluminum to steel—By experimentation and artificial neural network. J. Manuf. Proc. 2017, 30, 63–74. [Google Scholar] [CrossRef]

- Leon, M.D.; Shin, H.S. Weldability assessment of Mg alloy (AZ31B) sheets by an ultrasonic spot welding method. J. Mater. Proc. Technol. 2017, 243, 1–8. [Google Scholar] [CrossRef]

- Chen, K.K.; Zhang, Y.S. Numerical analysis of temperature distribution during ultrasonic welding process for dissimilar automotive alloys. Sci. Technol. Weld. Join. 2015, 20, 522–531. [Google Scholar] [CrossRef]

- Chen, K.K.; Zhang, Y.S.; Whang, H.Z. Study of plastic deformation and interface friction process for ultrasonic welding. Sci. Technol. Weld. Join. 2016, 22, 208–216. [Google Scholar] [CrossRef]

- Kim, T.H.; Yum, J.; Hu, S.J. Process robustness of single lap ultrasonic welding of thin, dissimilar materials. CIRP Ann. 2011, 60, 17–20. [Google Scholar] [CrossRef]

- Shen, N.; Samanta, A.; Ding, H. Simulating microstructure evolution of battery tabs during ultrasonic welding. J. Manuf. Proc. 2016, 23, 306–314. [Google Scholar] [CrossRef]

- Lee, S.S.; Kim, T.H.; Cai, W. Characterization of joint quality in ultrasonic welding of battery tabs. ASME J. Manuf. Sci. Eng. 2013, 135, 021004. [Google Scholar]

- Lee, S.S.; Kim, T.H.; Cai, W. Analysis of weld formation in multilayer ultrasonic metal welding using high-speed images. ASME J. Manuf. Sci. Eng. 2015, 137, 031016. [Google Scholar]

- Wu, X.; Liu, T.; Cai, W. Microstructure, welding mechanism, and failure of Al_Cu ultrasonic welds. J. Manuf. Proc. 2015, 20, 321–331. [Google Scholar] [CrossRef]

- Shin, H.S.; Leon, M.D. Mechanical performance and electrical resistance of ultrasonic welded multiple Cu-Al layers. J. Mater. Proc. Technol. 2017, 241, 143–153. [Google Scholar] [CrossRef]

- Sasaki, T.; Watanabe, Y.; Hosokawa, Y. Analysis for relative motion in ultrasonic welding of aluminium sheet. Sci. Technol. Weld. Join. 2013, 18, 125–132. [Google Scholar] [CrossRef]

- Lu, Y.; Hong, H.; Taber, G.A. In-situ measurement of relative motion during ultrasonic spot welding of aluminum alloy using Photonic Doppler Velocimetry. J. Mater. Proc. Technol. 2016, 231, 431–440. [Google Scholar] [CrossRef]

- Shin, H.S.; Leon, M.D. Parametric study in similar ultrasonic spot welding of A5052-H32 alloy sheets. J. Mater. Proc. Technol. 2015, 224, 222–232. [Google Scholar] [CrossRef]

- Cai, W.; Kee, D. The effect of tool knurl geometry on battery tab ultrasonic welding quality: 2D finite element simulations. J. Manuf. Proc. 2017, 28, 428–441. [Google Scholar]

- Komiyama, K.; Sasaki, T.; Watanabe, Y. Effect of tool edge geometry in ultrasonic welding. J. Mater. Proc. Technol. 2016, 229, 714–721. [Google Scholar] [CrossRef]

- Sasaki, T.; Komiyama, K.; Pramudita, J.A. Influence of tool edge angle on the bondability of aluminum in ultrasonic bonding. J. Mater. Proc. Technol. 2018, 252, 167–175. [Google Scholar] [CrossRef]

- Watanabe, T.; Miyajima, D.; Yanagisawa, A. Effect of weld tip geometry on ultrasonic welding of A6061 aluminum alloy. Q. J. JWS 2009, 27, 7–12. (In Japanese) [Google Scholar]

- Sasaki, T.; Sakata, Y.; Watanabe, T. Effect of tool geometry on ultrasonic welding process. IOP Conf. Ser. Mater. Sci. Eng. 2014, 61, 012006. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arimoto, K.; Sasaki, T.; Doi, Y.; Kim, T. Ultrasonic Bonding of Multi-Layered Foil Using a Cylindrical Surface Tool. Metals 2019, 9, 505. https://doi.org/10.3390/met9050505

Arimoto K, Sasaki T, Doi Y, Kim T. Ultrasonic Bonding of Multi-Layered Foil Using a Cylindrical Surface Tool. Metals. 2019; 9(5):505. https://doi.org/10.3390/met9050505

Chicago/Turabian StyleArimoto, Keisuke, Tomohiro Sasaki, Yuhei Doi, and Taewon Kim. 2019. "Ultrasonic Bonding of Multi-Layered Foil Using a Cylindrical Surface Tool" Metals 9, no. 5: 505. https://doi.org/10.3390/met9050505

APA StyleArimoto, K., Sasaki, T., Doi, Y., & Kim, T. (2019). Ultrasonic Bonding of Multi-Layered Foil Using a Cylindrical Surface Tool. Metals, 9(5), 505. https://doi.org/10.3390/met9050505