Case Depth Prediction of Nitrided Samples with Barkhausen Noise Measurement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Description

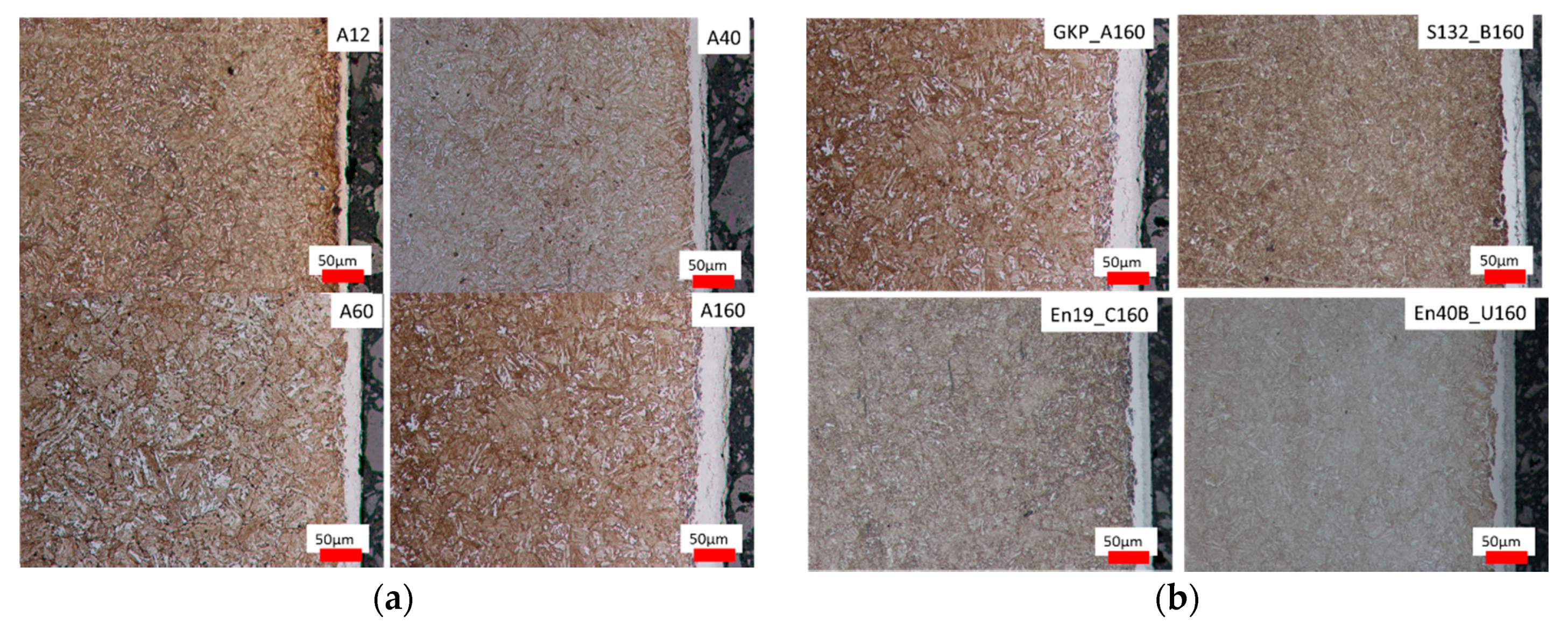

2.2. Sample Preparation

2.3. Measurement Devices

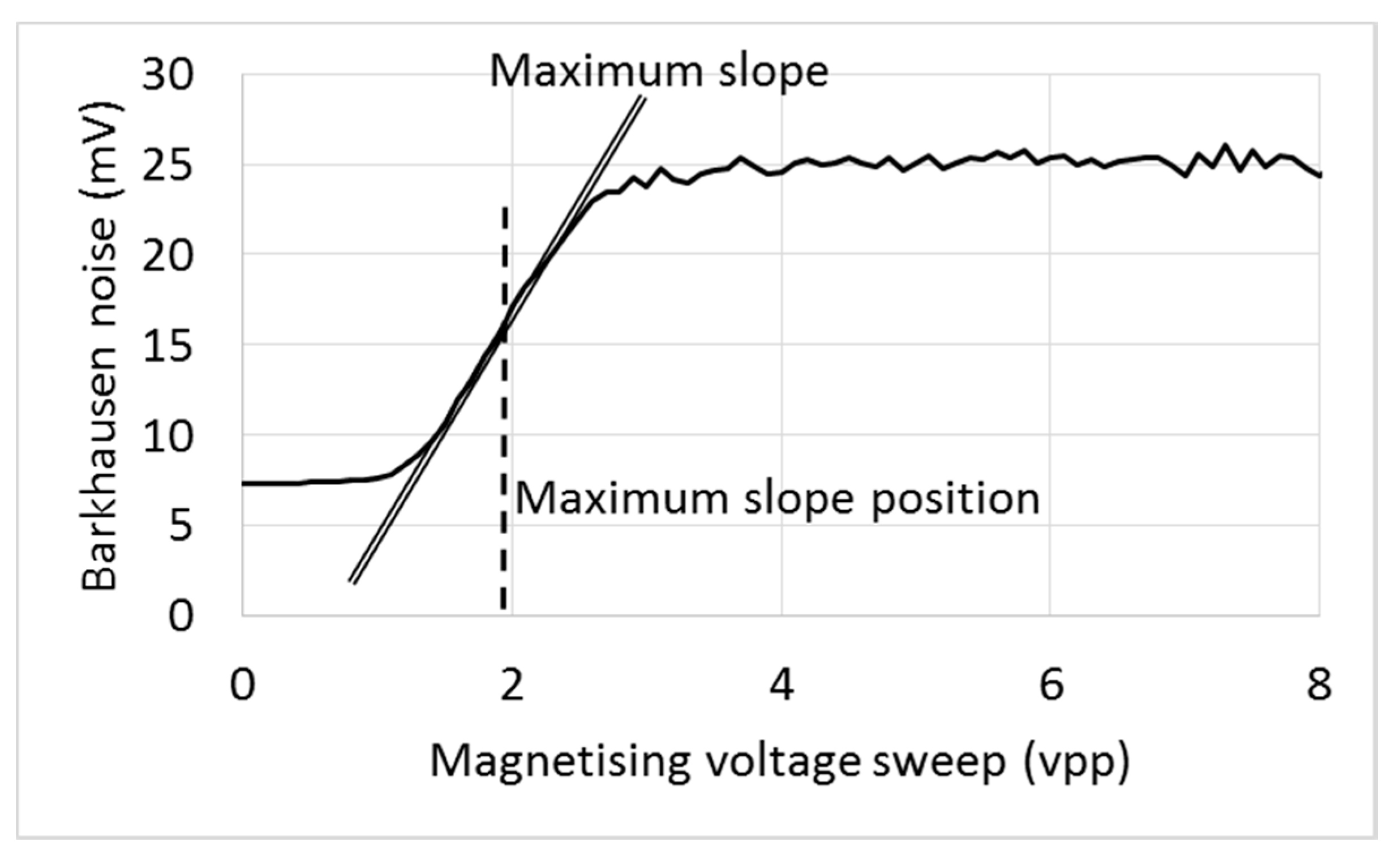

2.4. Measurements and Data Pre-Processing

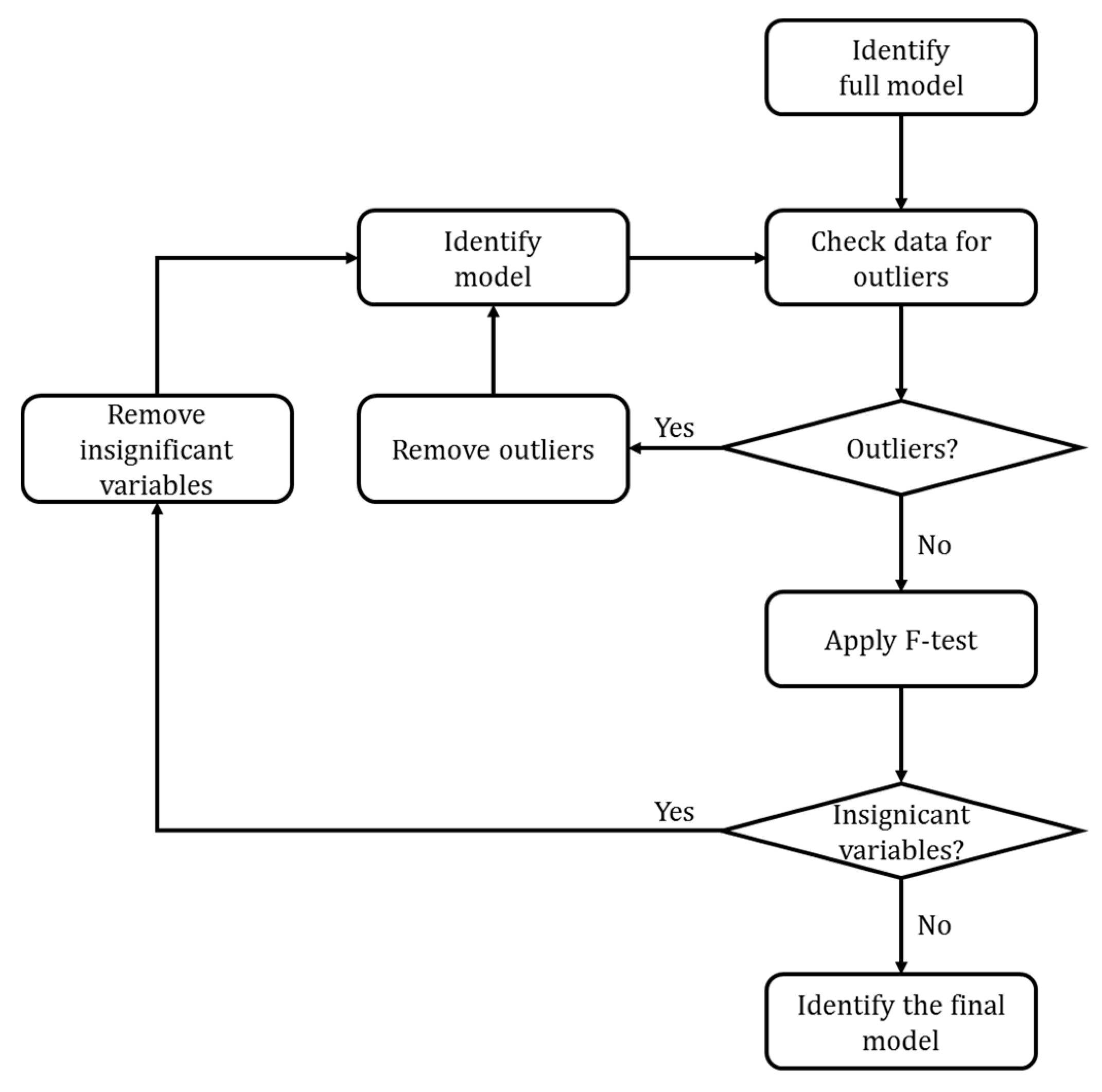

2.5. Modelling Approach

- Identification of the full model (all features and their two-variable interactions);

- Detection of outliers;

- Elimination of excess terms from the model;

- Identification of the model with the appropriate terms excluding the detected outliers;

- Evaluation of the model performance and structure.

3. Results

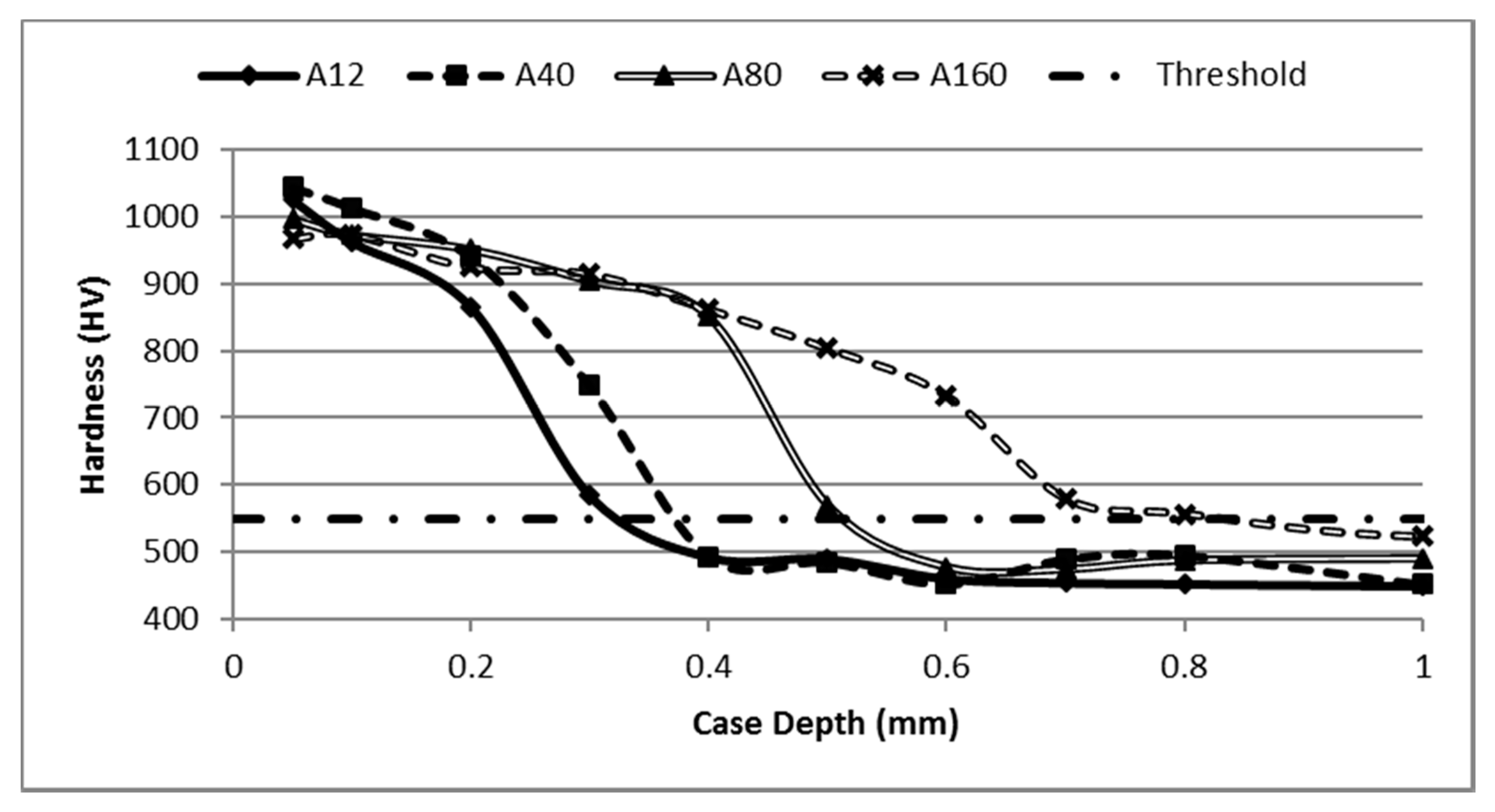

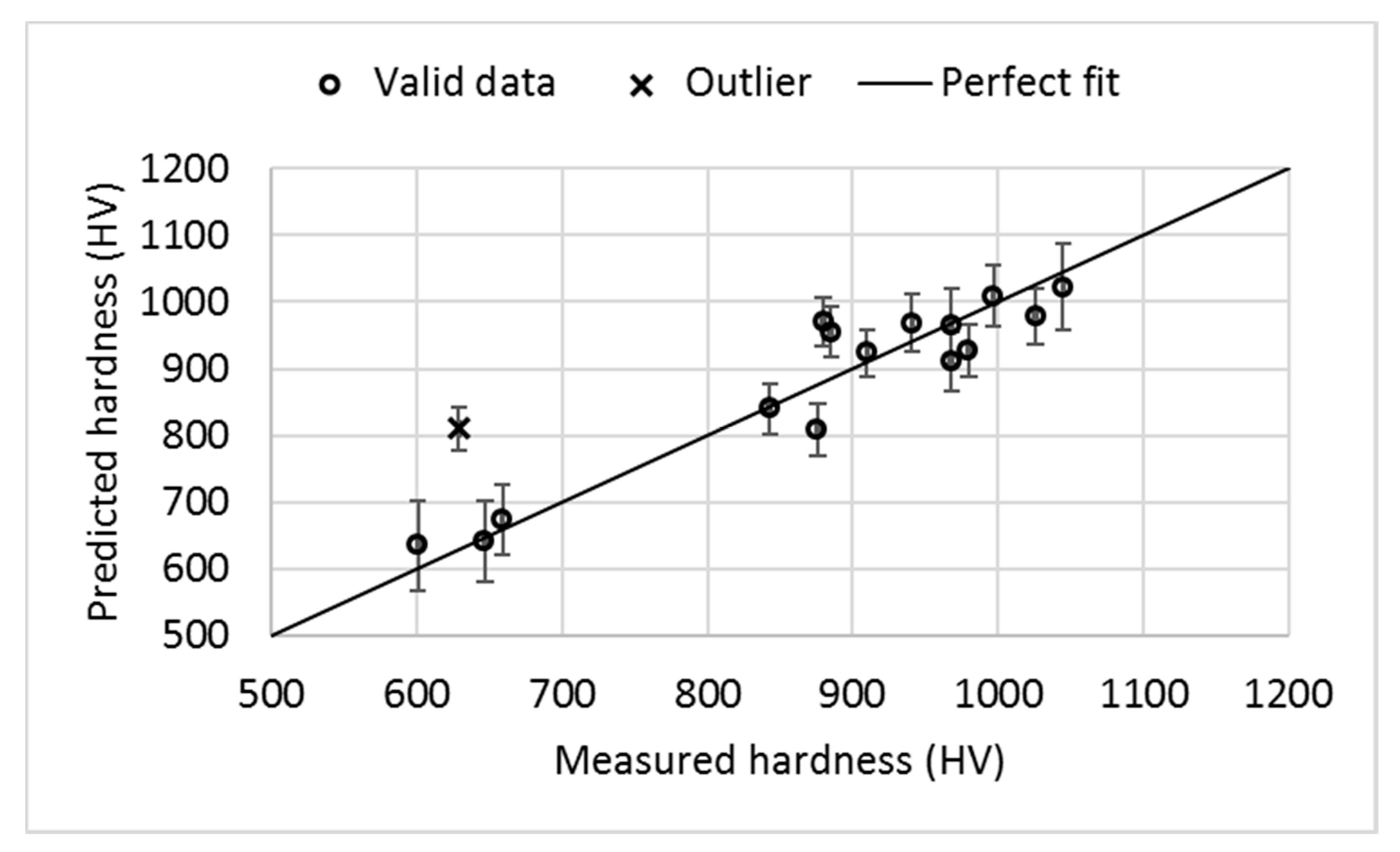

3.1. Modelling of Hardness

3.1.1. Non-Ground Samples with Compound Layer

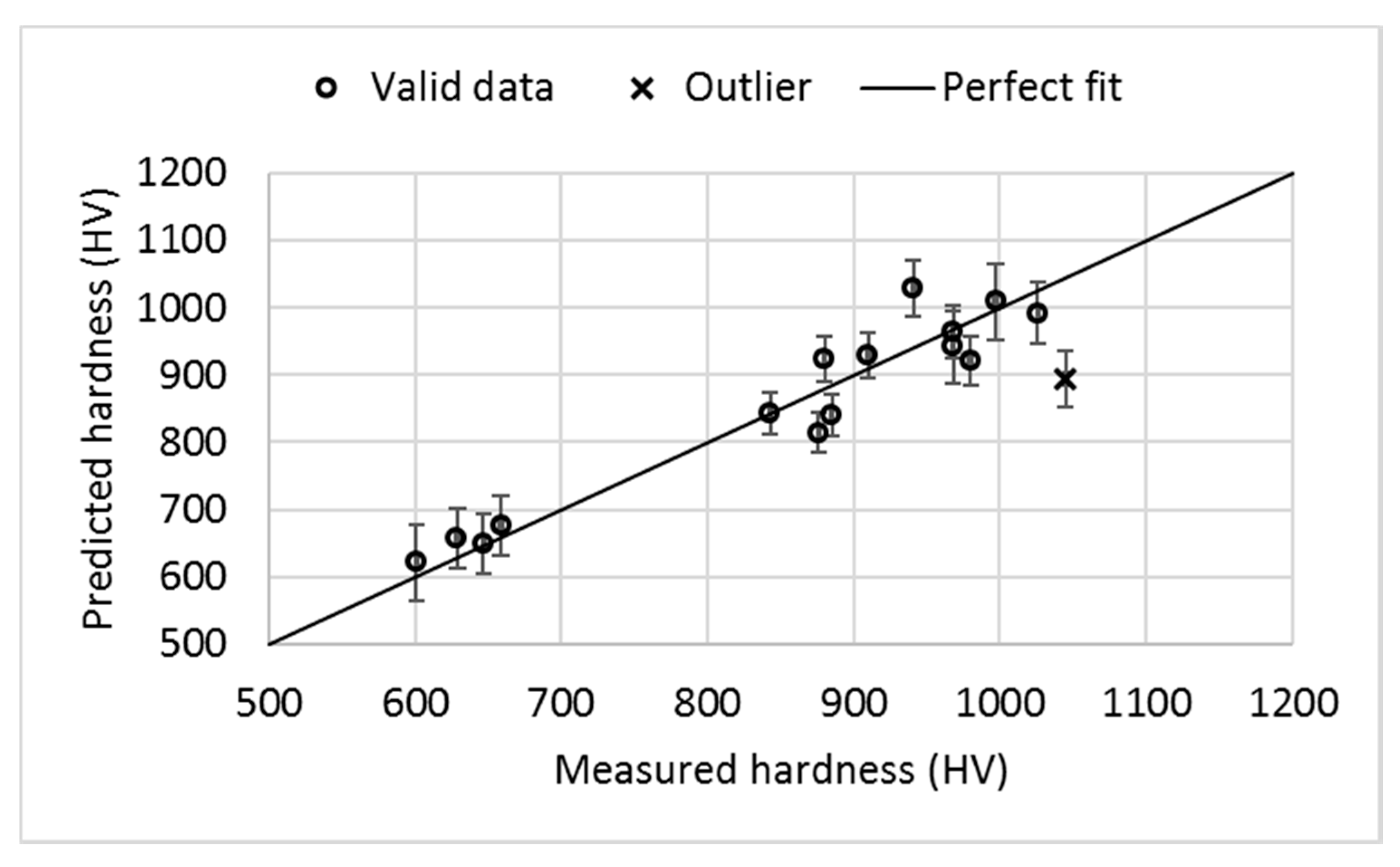

3.1.2. Ground Samples

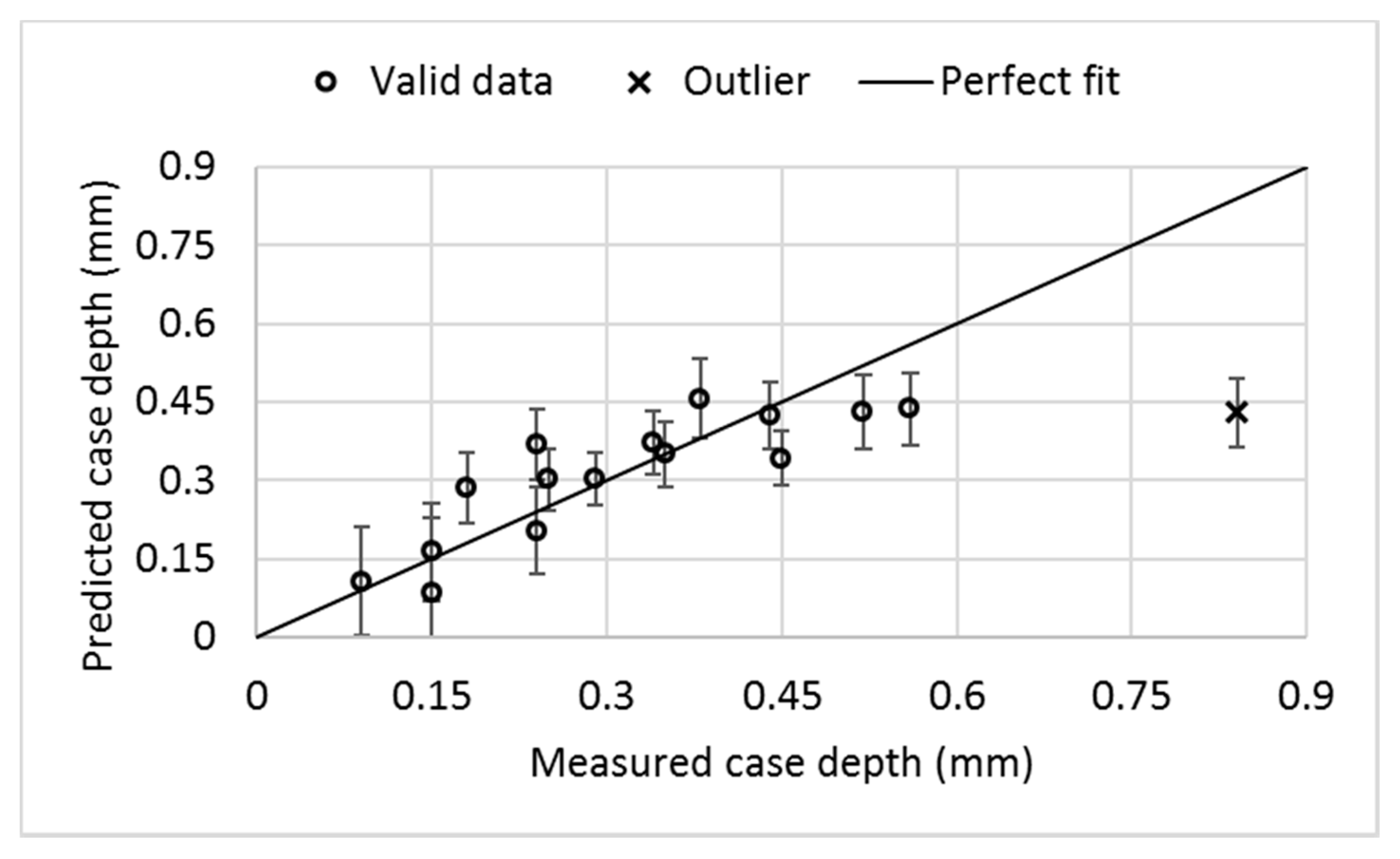

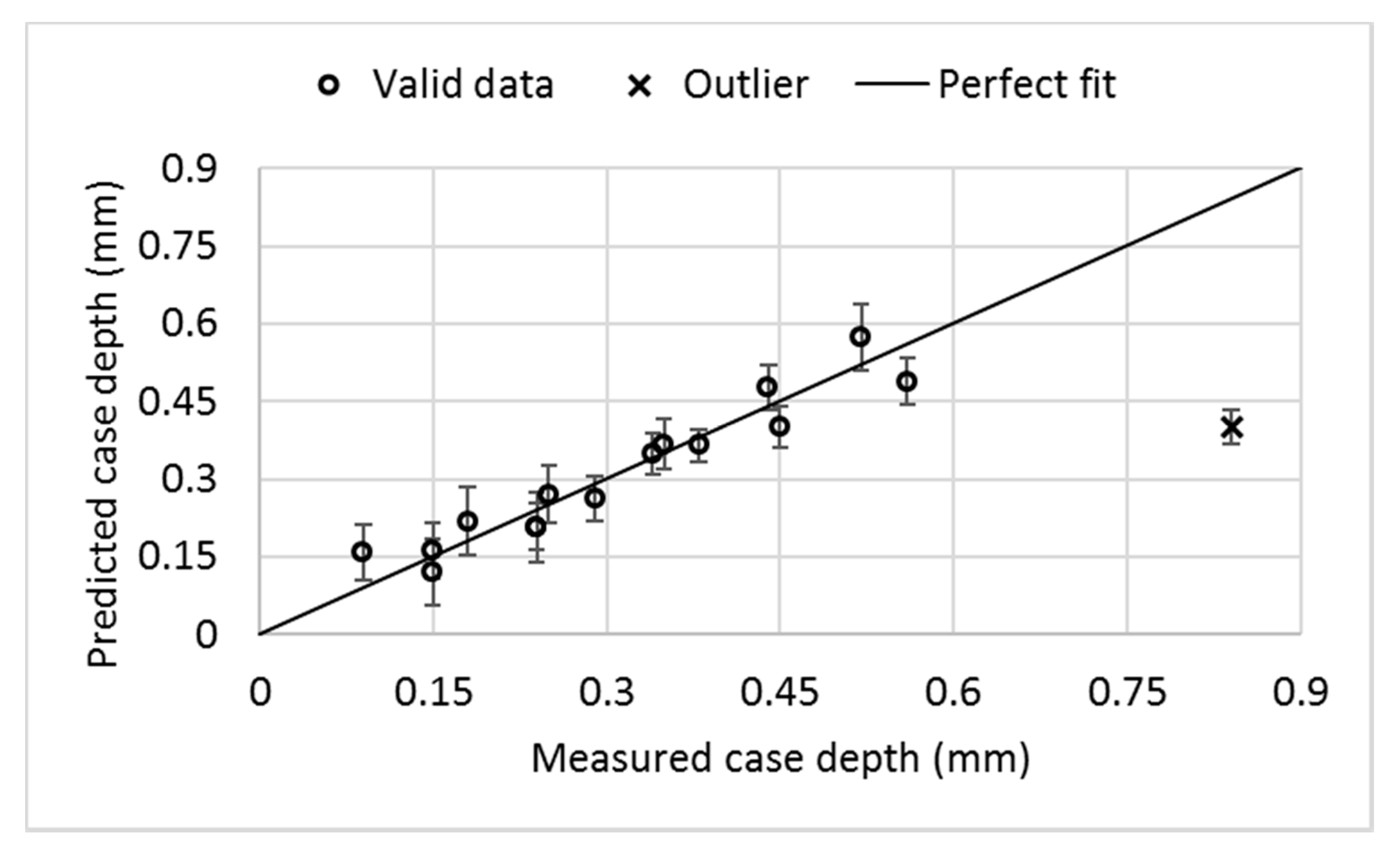

3.2. Modelling of Case Depths

3.2.1. Non-Ground Samples with Compound Layer

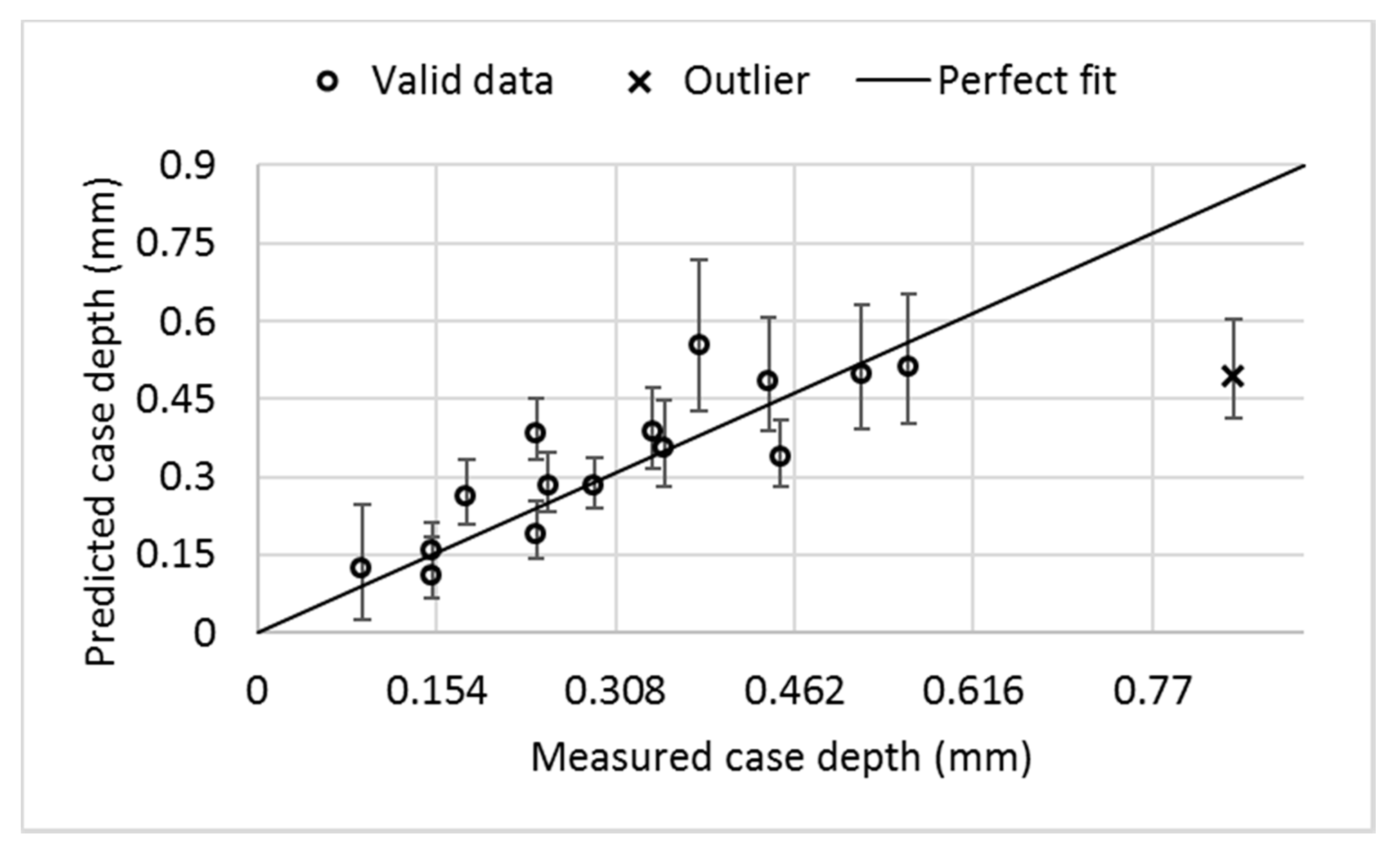

3.2.2. Ground Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- O’Sullivan, D.; Cotterell, M.; Tanner, D.A.; Mészáros, I. Characterisation of ferritic stainless steel by Barkhausen techniques. NDT & E Int. 2004, 37, 489–496. [Google Scholar]

- Sorsa, A.; Leiviskä, K.; Santa-aho, S.; Lepistö, T. Quantitative prediction of residual stress and hardness in case-hardened steel based on the Barkhausen noise measurement. NDT & E Int. 2012, 46, 100–106. [Google Scholar]

- Lindgren, M.; Lepistö, T. Application of Barkhausen noise to biaxial residual stress measurements in welded steel tubes. Mater. Sci. Technol. Ser. 2002, 18, 1369–1376. [Google Scholar] [CrossRef]

- Sorsa, A. Prediction of Material Properties Based on Nondestructive Barkhausen Noise Measurement. Ph.D. Thesis, University of Oulu, Oulu, Finland, 2013. [Google Scholar]

- Sorsa, A.; Leiviskä, K.; Santa-aho, S.; Lepistö, T. A data-based modelling scheme for estimating residual stress from Barkhausen noise measurements. Insight 2012, 54, 278–283. [Google Scholar] [CrossRef]

- Ghanei, S.; Saheb Alam, A.; Kashefi, M.; Mazinani, M. Nondestructive characterization of microstructure and mechanical properties of intercritically annealed dual-phase steel by magnetic Barkhausen noise technique. Mater. Sci. Eng. A 2014, 607, 253–260. [Google Scholar] [CrossRef]

- Sorsa, A.; Ruusunen, M.; Leiviskä, K.; Santa-aho, S.; Vippola, M.; Lepistö, T. An attempt to find an empirical model between Barkhausen noise and stress. Mater. Sci. Forum 2014, 768–769, 209–216. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, L.; Zhu, Q.; Ji, X.; Wanga, H.; Tian, G.; Yao, E. An application of backpropagation neural network for the steel stress detection based on Barkhausen noise theory. NDT & E Int. 2013, 55, 9–14. [Google Scholar]

- Ghanei, S.; Vafaeenezhad, H.; Kashefi, M.; Eivani, A.R.; Mazinani, M. Design of an expert system based on neuro-fuzzy inference analyzer for on-line microstructural characterization using magnetic NDT. J. Magn. Magn. Mater. 2015, 379, 131–136. [Google Scholar] [CrossRef]

- Santa-aho, S.; Vippola, M.; Sorsa, A.; Leiviskä, K.; Lindgren, M.; Lepistö, T. Utilization of Barkhausen noise magnetizing sweeps for case-depth detection from hardened steel. NDT & E Int. 2012, 52, 95–102. [Google Scholar]

- Santa-aho, S.; Sorsa, A.; Hakanen, M.; Leiviskä, K.; Vippola, M.; Lepistö, T. Barkhausen noise magnetising voltage sweep measurement in evaluation of residual stress in hardened components. Meas. Sci. Technol. 2014, 25, 085602. [Google Scholar] [CrossRef]

- Dubois, M.; Fiset, M. Evaluation of case depth on steels by Barkhausen noise measurements. Mater. Sci. Technol. Ser. 1995, 11, 264–267. [Google Scholar] [CrossRef]

- Jacob, P.; Marrone, S.; Suominen, L.; Honkamäki, V. Non-Destructive Evaluation of Residual Stress Depth-profiles by Barkhausen Noise Analysis and their Validation by XRD Method Combined with Electrochemical (destructive) Surface Removal. In Proceedings of the 4th International Conference on Barkhausen Noise and Micromagnetic Testing (ICBM), Brescia, Italy, 3–4 July 2003. [Google Scholar]

- Albieri, S.; Wojtas, A. Barkhausen Noise Control of a Grinding Process of Nitrided Camshafts. In Proceedings of the 4th International Conference on Barkhausen Noise and Micromagnetic Testing (ICBM), Brescia, Italy, 3–4 July 2003. [Google Scholar]

- Vrkoslavová, L.; Ganev, N.; Santa-aho, S.; Vippola, M.; Lepistö, T. Study of Case-hardened and Nitrided Samples Using Barkhausen Noise Analysis and X-ray Diffraction. In Proceedings of the 9th International Conference on Barkhausen Noise and Micromagnetic Testing, Liberec, Czech Republic, 28–30 June 2011. [Google Scholar]

- Holmberg, J.; Lundin, P.; Olavisson, J.; Sevim, S. Non destructive testing of surface characteristics after nitrocarburizing of three different steel grades. In Proceedings of the 12th International Conference on Barkhausen Noise and Micromagnetic Testing, Dresden, Germany, 25–26 September 2017. [Google Scholar]

- Stupakov, A.; Farda, R.; Neslusan, M.; Perevertov, A.; Uchimoto, T. Evaluation of a Nitrided Case Depth by the Magnetic Barkhausen Noise. J. Nondestruct. Eval. 2017, 36, 73. [Google Scholar] [CrossRef]

- Davis, J.R. Surface Engineering of Carbon and Alloy Steels. Surface Engineering; ASM Handbook; ASM International: Novelty, OH, USA, 1994; Volume 5, pp. 701–740. [Google Scholar]

- British Standard. British Standard 970: Part 1: 1983: Wrought Steels for Mechanical and Allied Engineering Purposes Steels Supplied as Bright Bar; British Standard: London, UK, 1983. [Google Scholar]

- Finnish Standard Association. SFS-ISO 6336-1: Calculation of Load Capacity of Spur and Helical Gears. Part 1: Basic Principles, Introduction and General Influence Factors; Finnish Standard Association: Helsinki, Finland, 2006. [Google Scholar]

- Santa-aho, S.; Vippola, M.; Lepistö, T.; Lindgren, M. Characterisation of case-hardened gear steel by multiparameter Barkhausen noise measurements. Insight 2009, 51, 212–216. [Google Scholar] [CrossRef]

- Stewart, D.M.; Stevens, K.J.; Kaiser, A.B. Magnetic Barkhausen noise analysis of stress in steel. Curr. Appl. Phys. 2004, 4, 308–311. [Google Scholar] [CrossRef]

- Davut, K.; Gür, C.H. Monitoring the Microstructural Changes During Tempering of Quenched SAE 5140 steel by Magnetic Barkhausen Noise. J. Nondestruct. Eval. 2007, 26, 107–113. [Google Scholar] [CrossRef]

- Kinser, E.R.; Lo, C.C.H.; Barsic, A.J.; Jiles, D.C. Modeling microstructural effects on Barkhausen emission in surface-modified magnetic materials. IEEE Trans. Magn. 2005, 41, 3292–3294. [Google Scholar] [CrossRef]

- Moorthy, V.; Shaw, B.A.; Evans, J.T. Evaluation of tempered induced changes in the hardness profile of case-carburised EN36 steel using magnetic Barkhausen noise analysis. NDT&E Int. 2003, 36, 43–49. [Google Scholar]

| Series Name | Material | Samples * | Threshold Values for Case Depth (HV) |

|---|---|---|---|

| A | GKP | A12, A40, A80, A160 | 550 |

| B | S132 | B12, B40, B80, B160 | 520 |

| C | En19 | C12, C40, C80, C160 | 400 |

| U | En40B | U12, U40, U80, U160 | 400 |

| Material | C (wt%) | Cr (wt%) | Mo (wt%) | V (wt%) | Mn (wt%) | Si (wt%) | P (wt%) | S (wt%) |

|---|---|---|---|---|---|---|---|---|

| GKP (32CrMoV5) | 0.3 | 1.4 | 1.2 | 0.3 | ||||

| BS132 | 0.35–0.43 | 3.0–3.5 | 0.8–1.2 | 0.15–0.25 | 0.4–0.7 | 0.1–0.35 | 0.02 | 0.02 |

| En19 (709M40) | 0.36–0.44 | 0.9–1.2 | 0.25–0.35 | 0.7–1.0 | 0.1–0.35 | 0.035 | 0.04 | |

| En40B (722M24) | 0.2–0.28 | 3.0–3.5 | 0.45–0.65 | 0.45–0.7 | 0.1–0.35 | 0.035–0.04 |

| Nitriding Time (h) | A (GKP) | B (S132) | C (En19) | U (En40B) |

|---|---|---|---|---|

| 12 | 0.34 | 0.18 | 0.09 | 0.15 |

| 40 | 0.38 | 0.29 | 0.15 | 0.25 |

| 80 | 0.52 | 0.44 | 0.24 | 0.35 |

| 160 | 0.84 | 0.56 | 0.24 | 0.45 |

| Term | Coefficient | Standard Error | p-Value | Contribution (%) |

|---|---|---|---|---|

| xrms | a1 = −6.70 | 0.76 | 1.28 × 10−6 | 45.5 |

| xrmsxp | a12 = 0.54 | 0.054 | 3.35 × 10−7 | 54.5 |

| Term | Coefficient | Standard Error | p-Value | Contribution (%) |

|---|---|---|---|---|

| xrms | a1 = −5.14 | 0.50 | 2.47 × 10−7 | 41.4 |

| xrmsxp | a12 = 0.42 | 0.036 | 6.27 × 10−8 | 58.6 |

| Term | Coefficient | Standard Error | p-Value | Contribution (%) |

|---|---|---|---|---|

| xHV | b1 = 0.0012 | 0.00022 | 0.00015 | 49.4 |

| xSD | b2 = −0.54 | 0.12 | 0.00068 | 50.6 |

| Term | Coefficient | Standard Error | p-Value | Contribution (%) |

|---|---|---|---|---|

| xHV | b1 = 0.0052 | 0.00076 | 1.64 × 10−6 | 49.0 |

| xSD | b2 = −2.36 | 0.42 | 0.00012 | 51.0 |

| Term | Coefficient | Standard Error | p-Value | Contribution (%) |

|---|---|---|---|---|

| xHV | b1 = −0.0017 | 0.00036 | 0.00056 | 11.1 |

| xSD | b2 = −0.69 | 0.093 | 1.31 × 10−5 | 47.1 |

| xHVxSD | b12 = 0.0010 | 0.00012 | 4.43 × 10−6 | 41.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sorsa, A.; Santa-aho, S.; Aylott, C.; Shaw, B.A.; Vippola, M.; Leiviskä, K. Case Depth Prediction of Nitrided Samples with Barkhausen Noise Measurement. Metals 2019, 9, 325. https://doi.org/10.3390/met9030325

Sorsa A, Santa-aho S, Aylott C, Shaw BA, Vippola M, Leiviskä K. Case Depth Prediction of Nitrided Samples with Barkhausen Noise Measurement. Metals. 2019; 9(3):325. https://doi.org/10.3390/met9030325

Chicago/Turabian StyleSorsa, Aki, Suvi Santa-aho, Christopher Aylott, Brian A. Shaw, Minnamari Vippola, and Kauko Leiviskä. 2019. "Case Depth Prediction of Nitrided Samples with Barkhausen Noise Measurement" Metals 9, no. 3: 325. https://doi.org/10.3390/met9030325

APA StyleSorsa, A., Santa-aho, S., Aylott, C., Shaw, B. A., Vippola, M., & Leiviskä, K. (2019). Case Depth Prediction of Nitrided Samples with Barkhausen Noise Measurement. Metals, 9(3), 325. https://doi.org/10.3390/met9030325