Global and High-Resolution Damage Quantification in Dual-Phase Steel Bending Samples with Varying Stress States

Abstract

1. Introduction

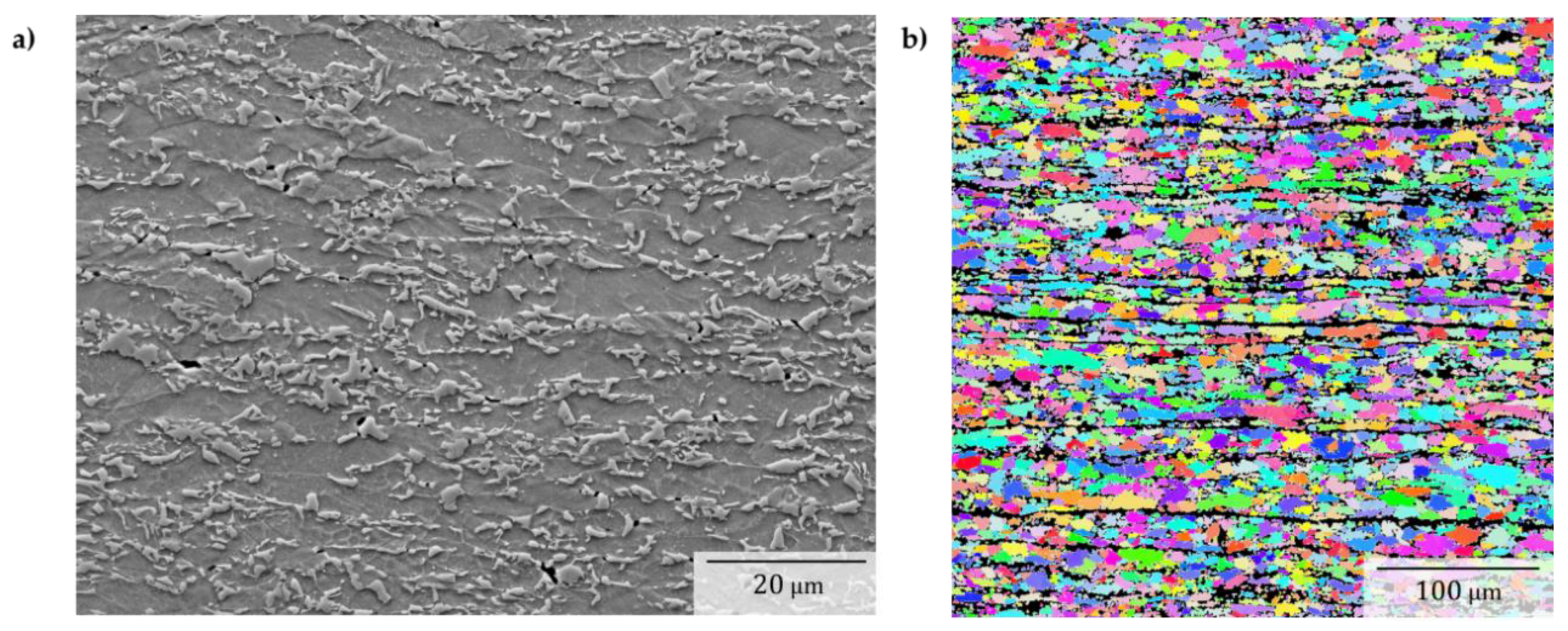

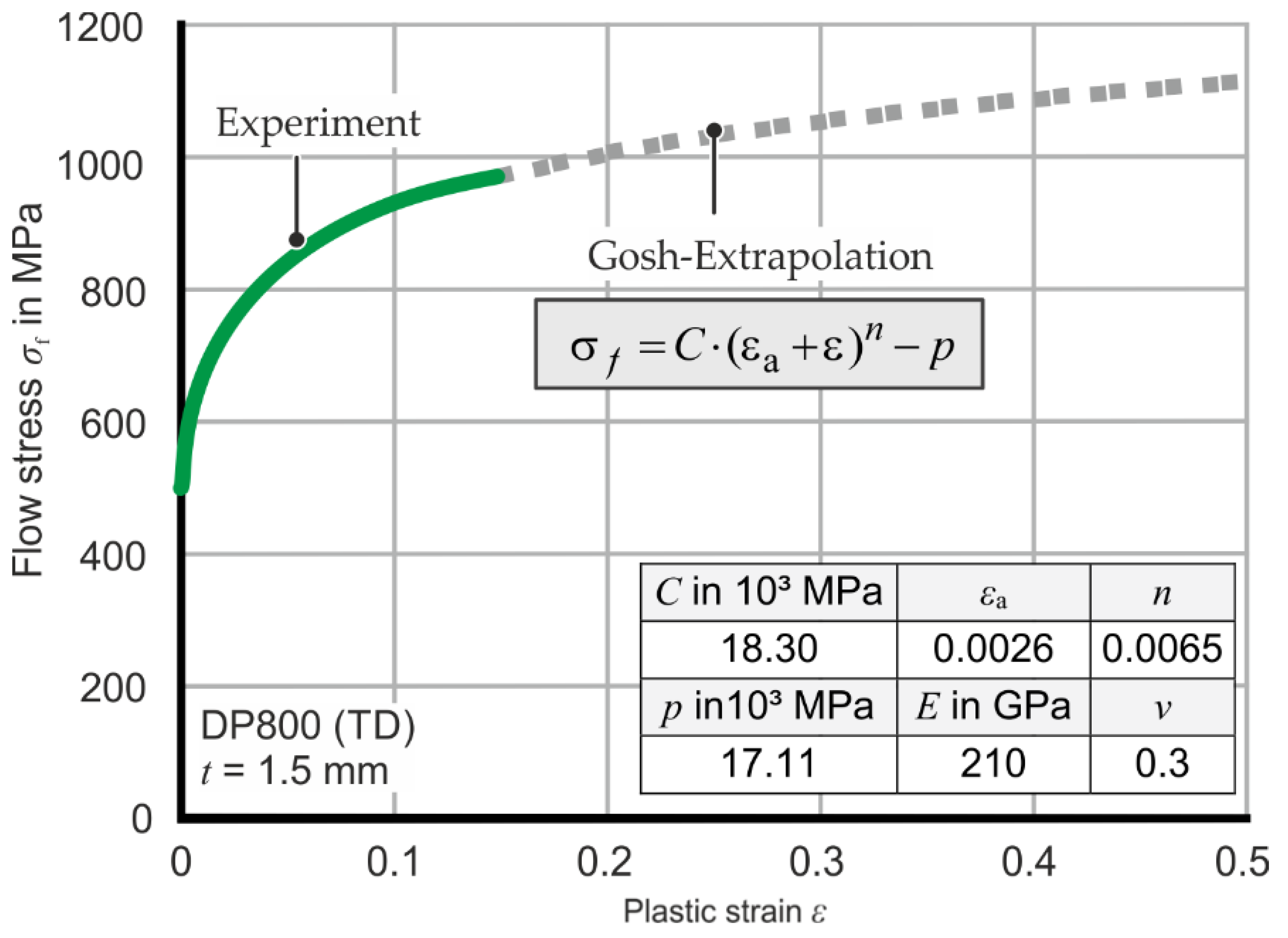

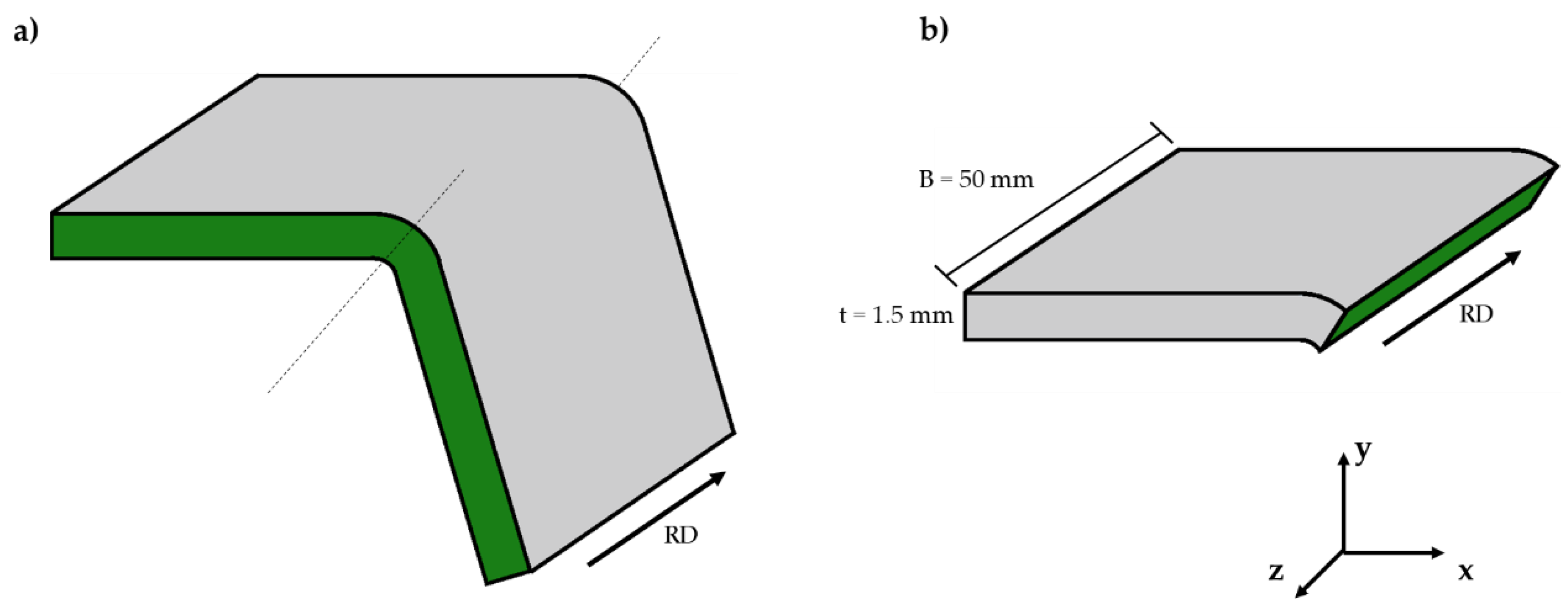

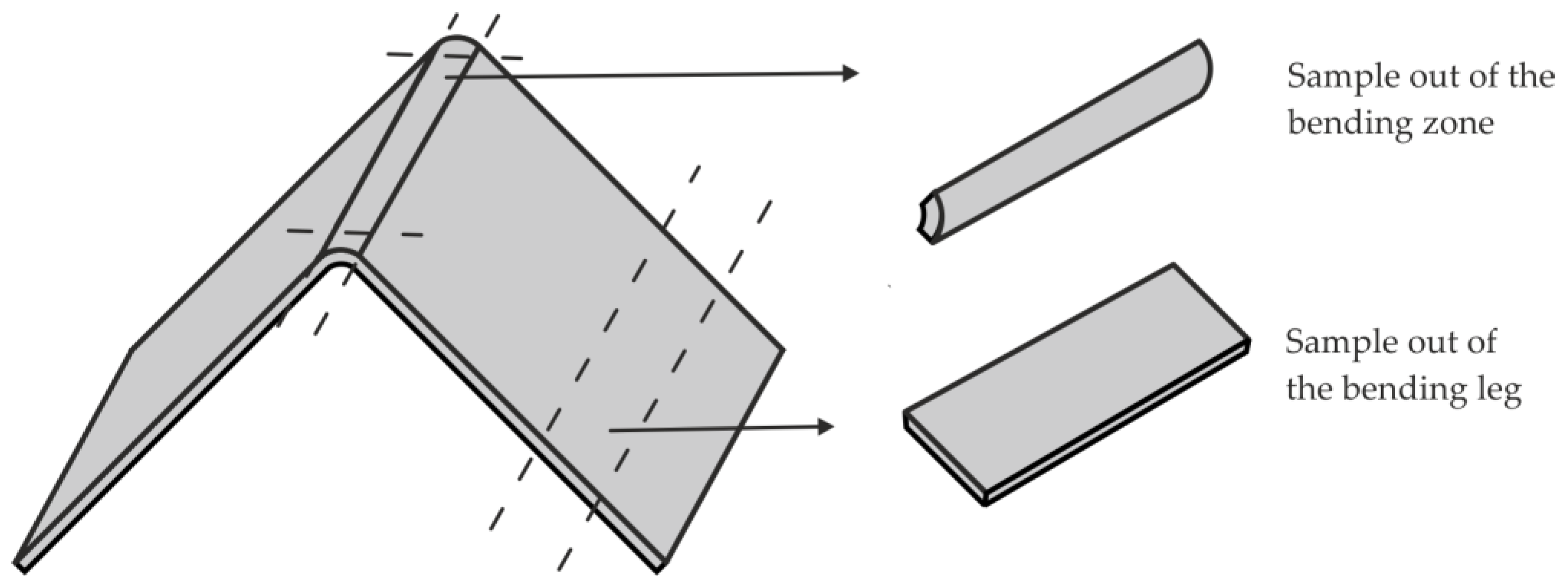

2. Materials and Methods

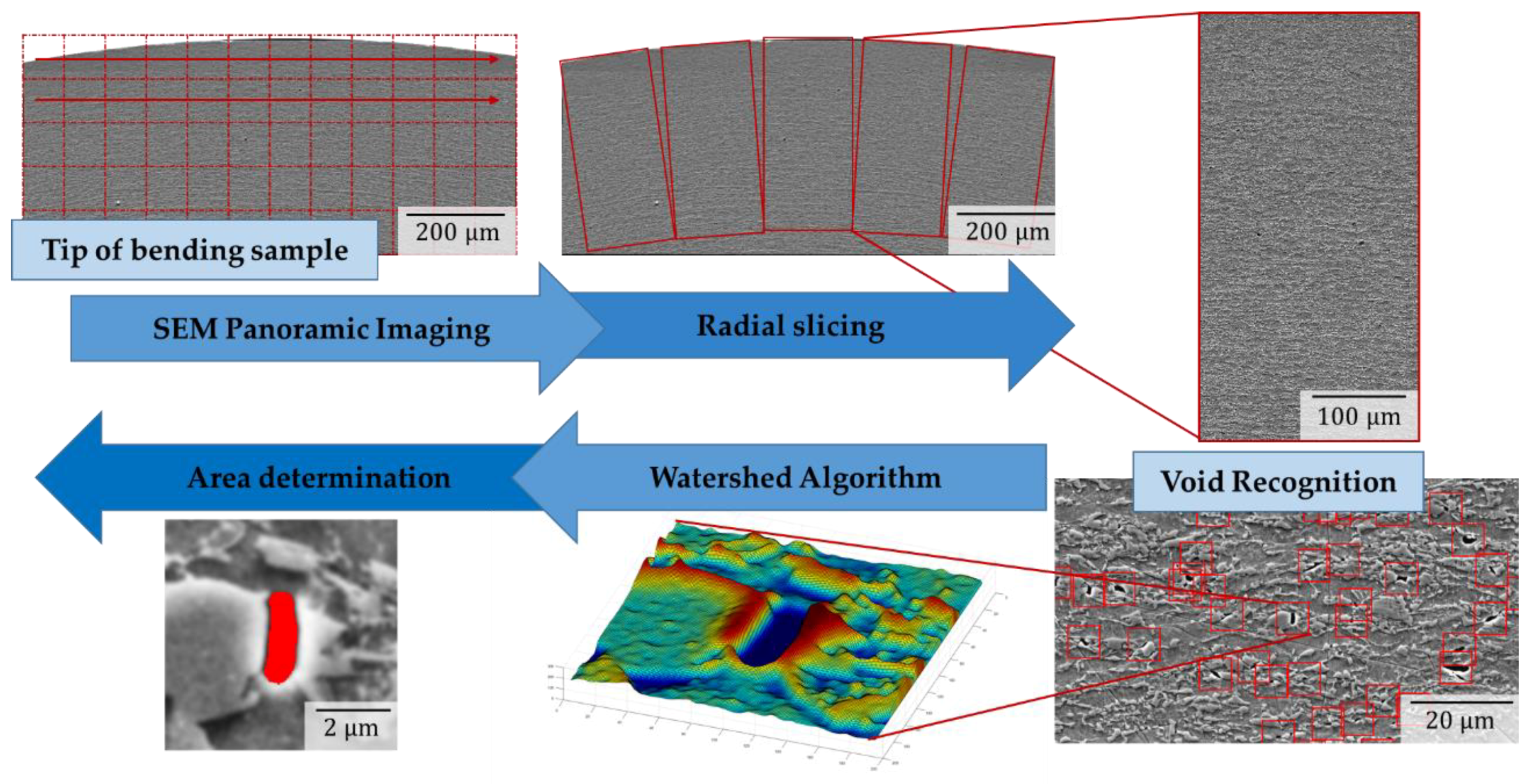

2.1. SEM Panoramic Imaging, Void Recognition and Area Determination

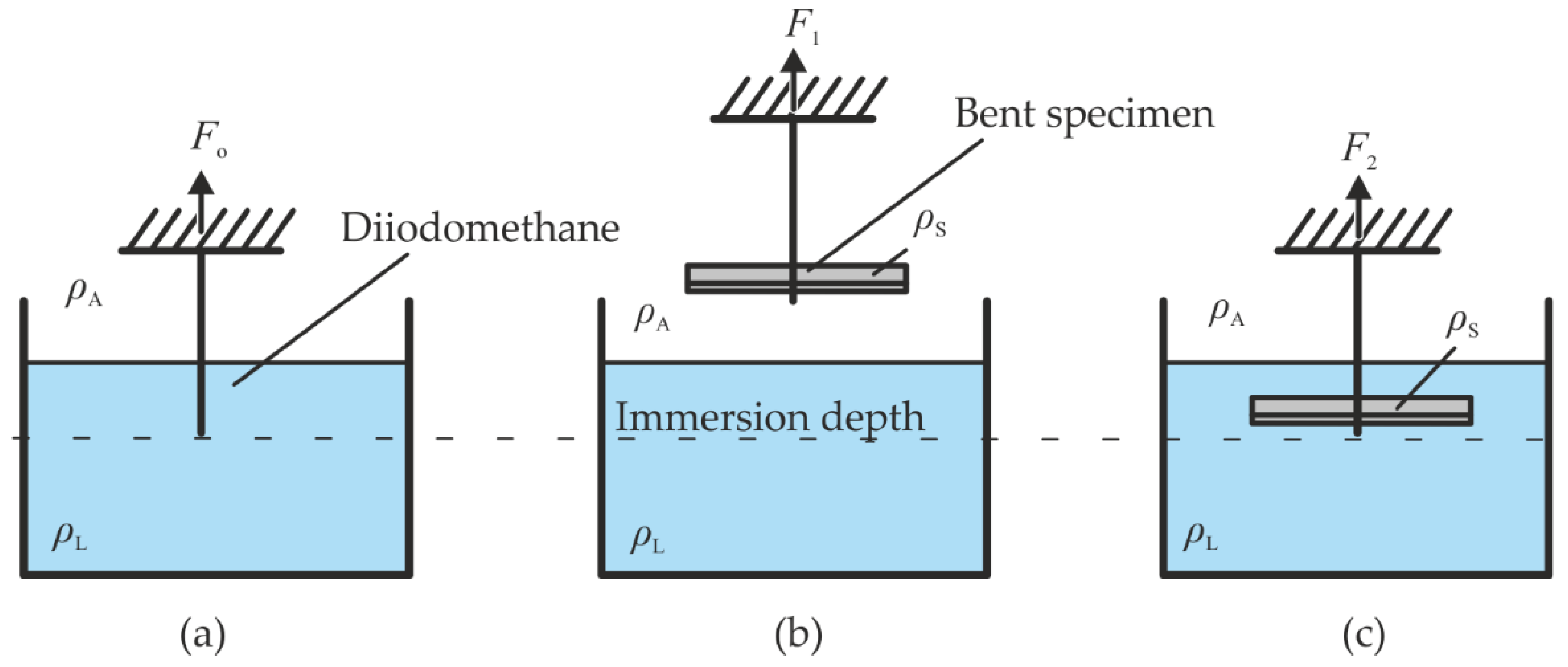

2.2. Density Measurement Method

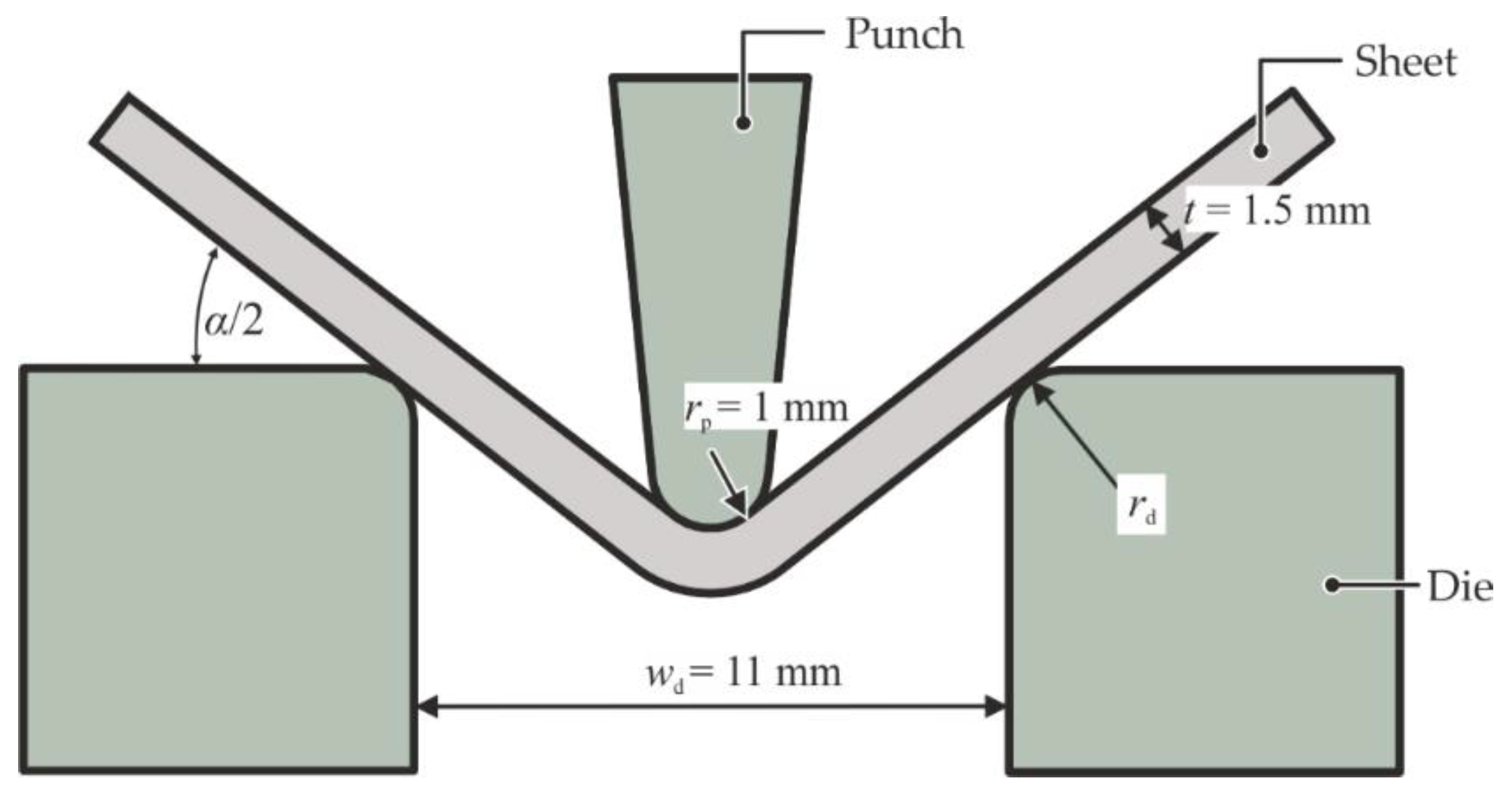

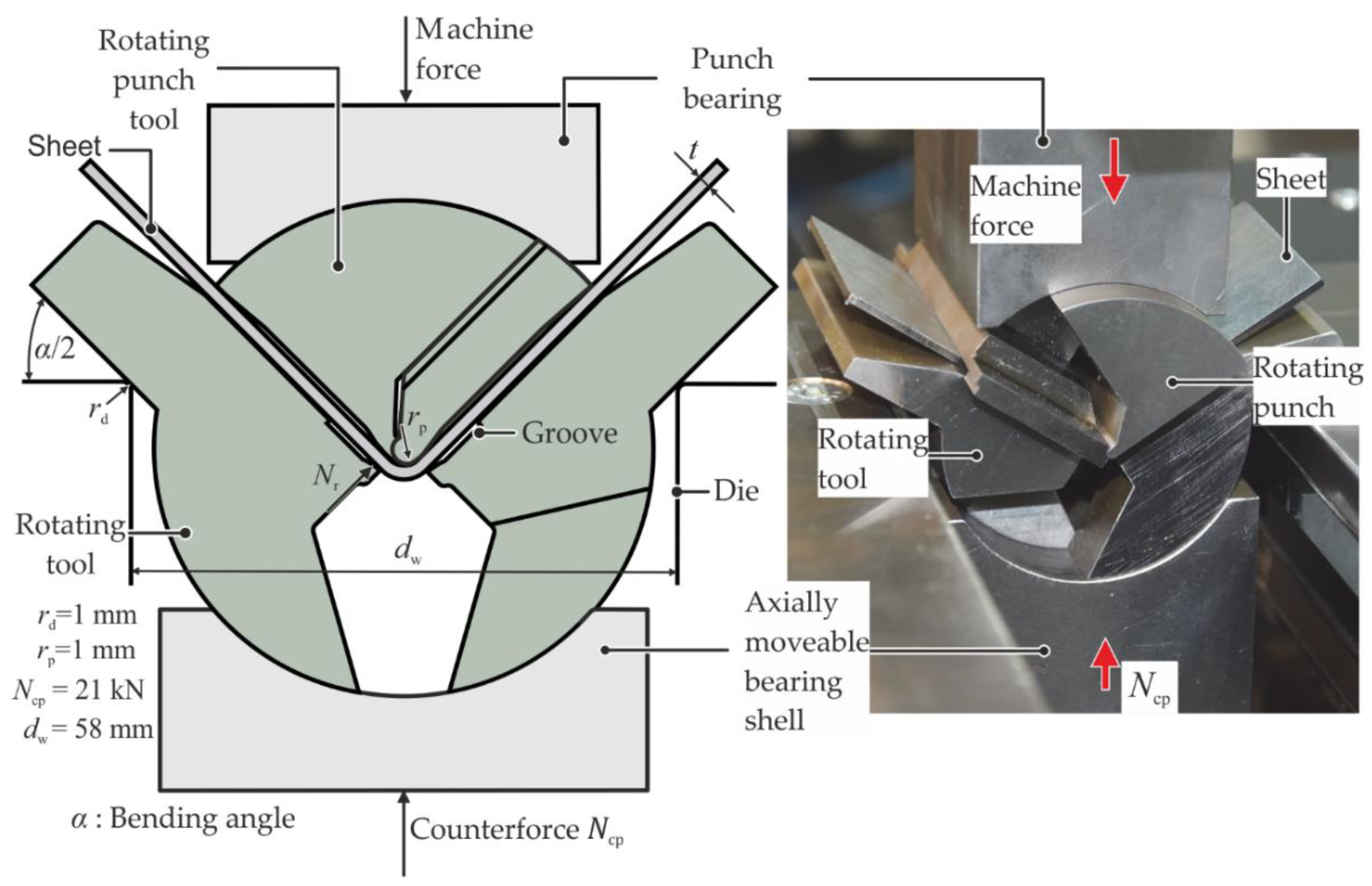

2.3. Air and Stress Superposed Bending Processes

3. Results

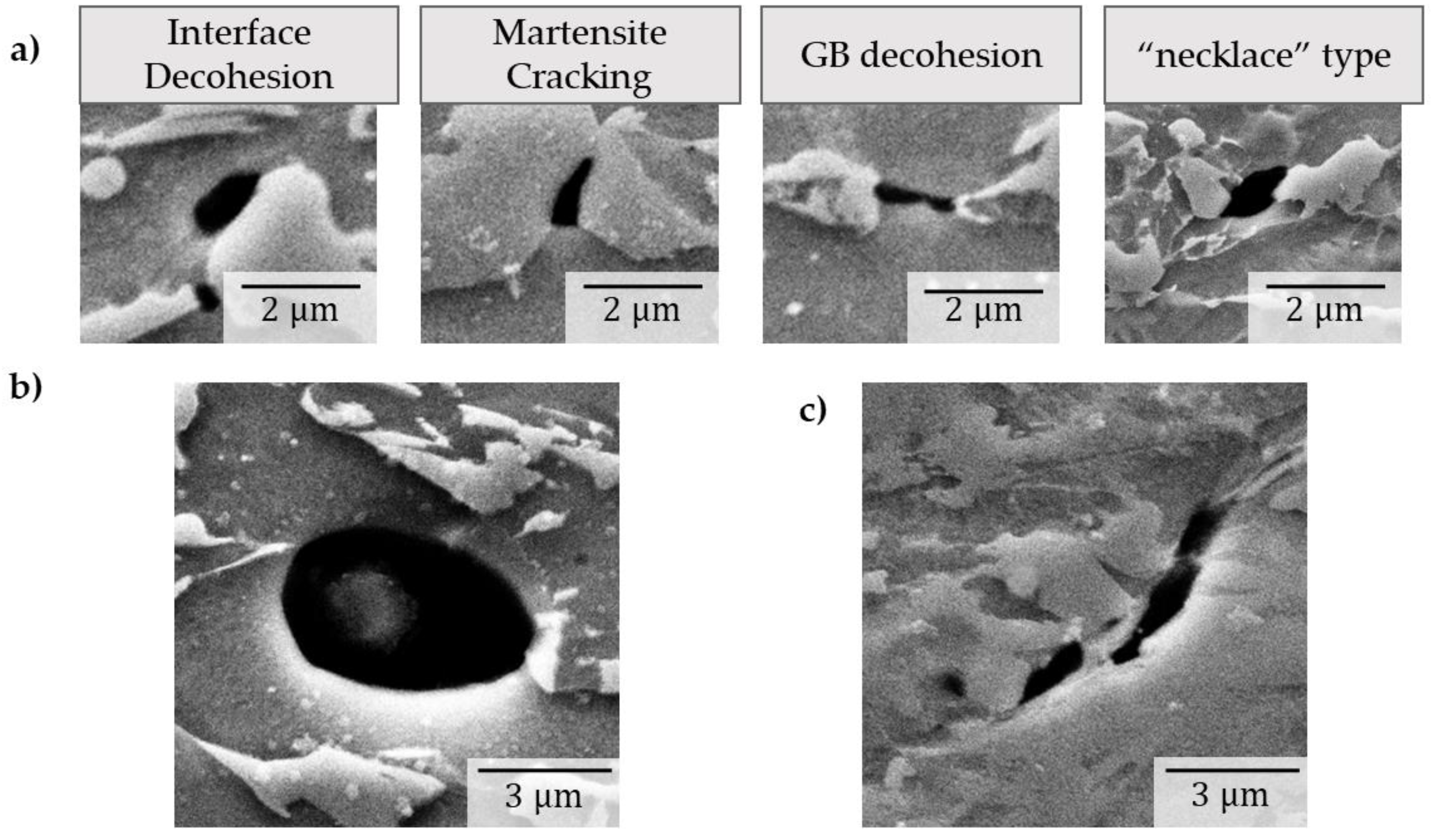

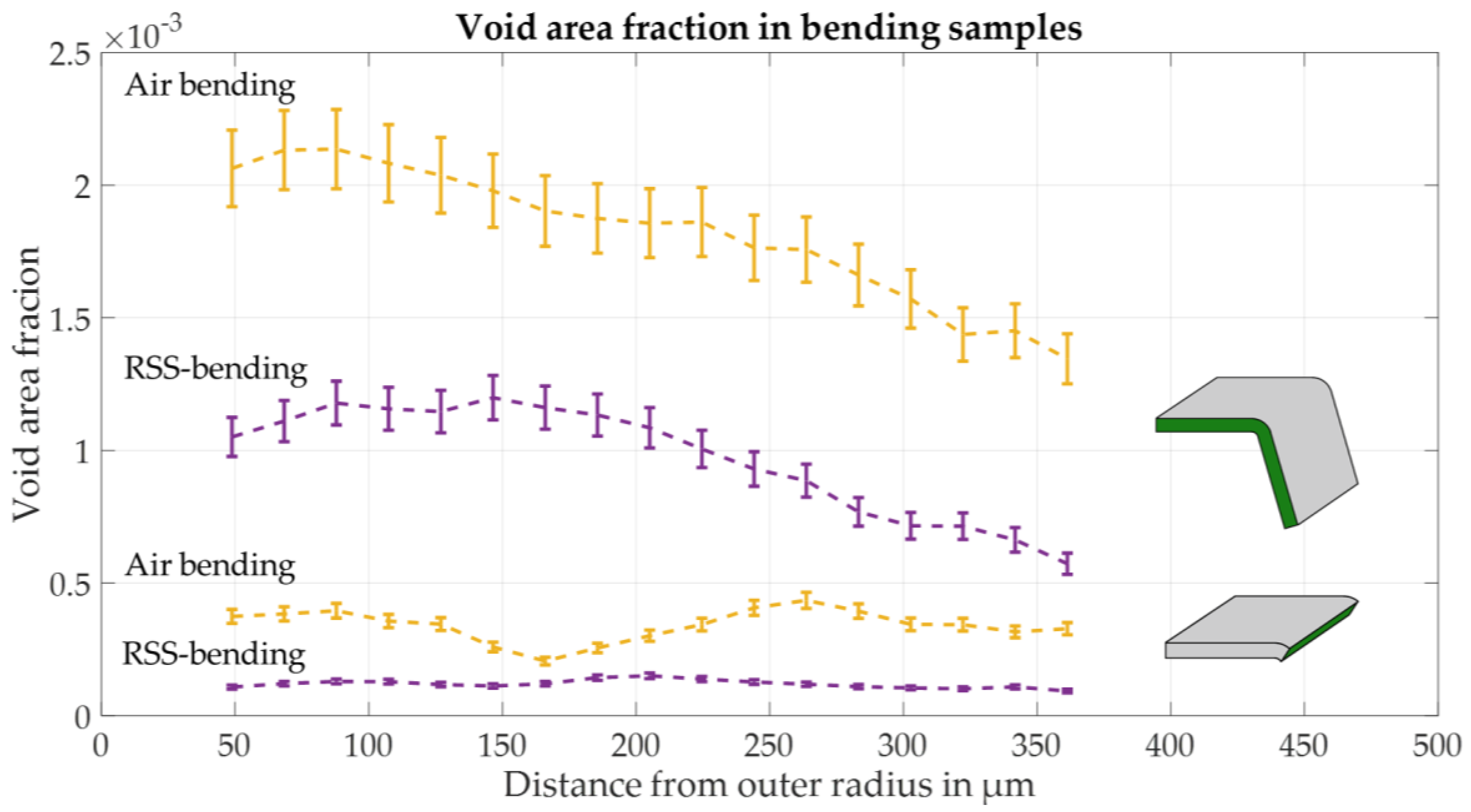

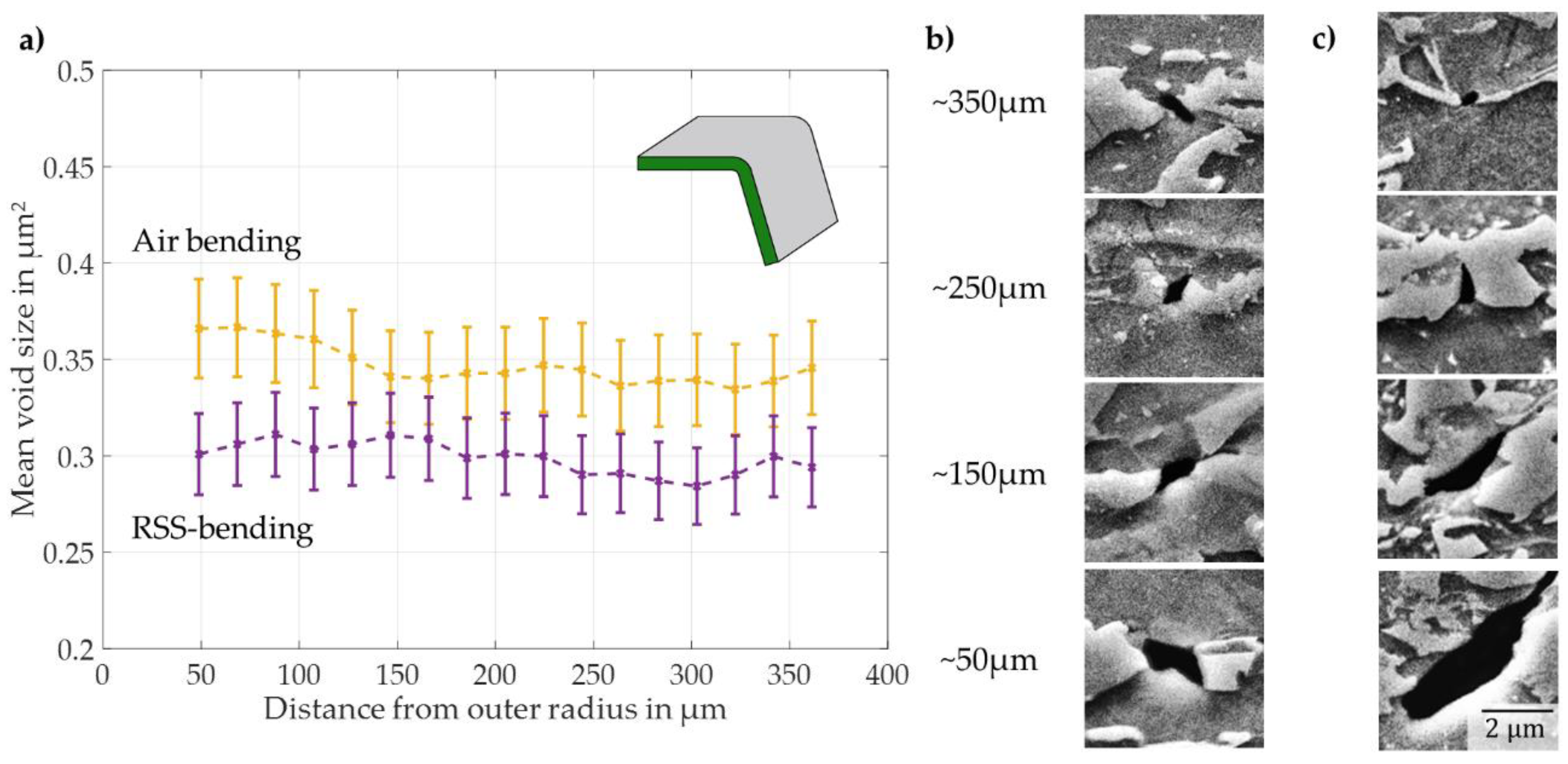

3.1. SEM-Based Damage Characterisation and Quantification

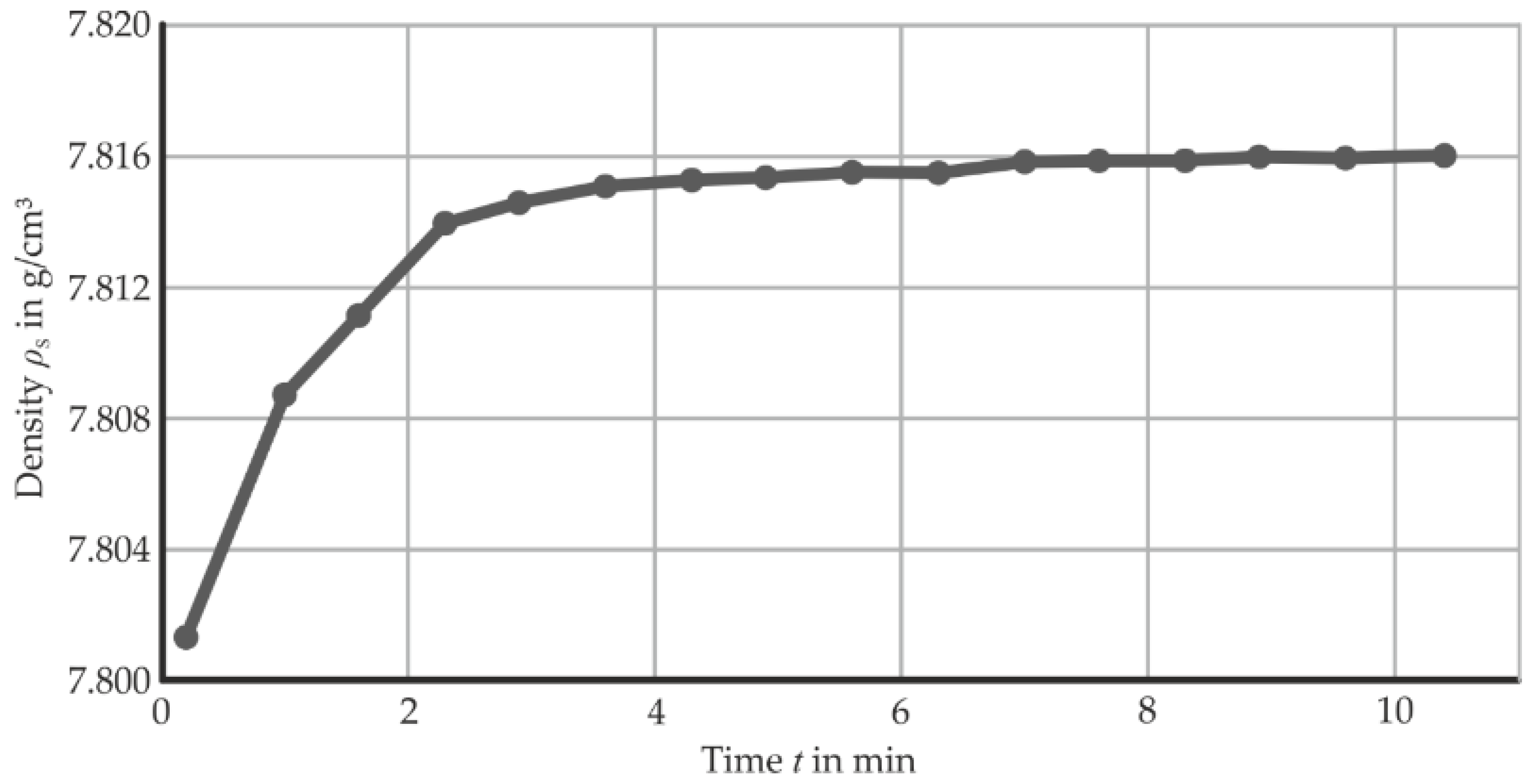

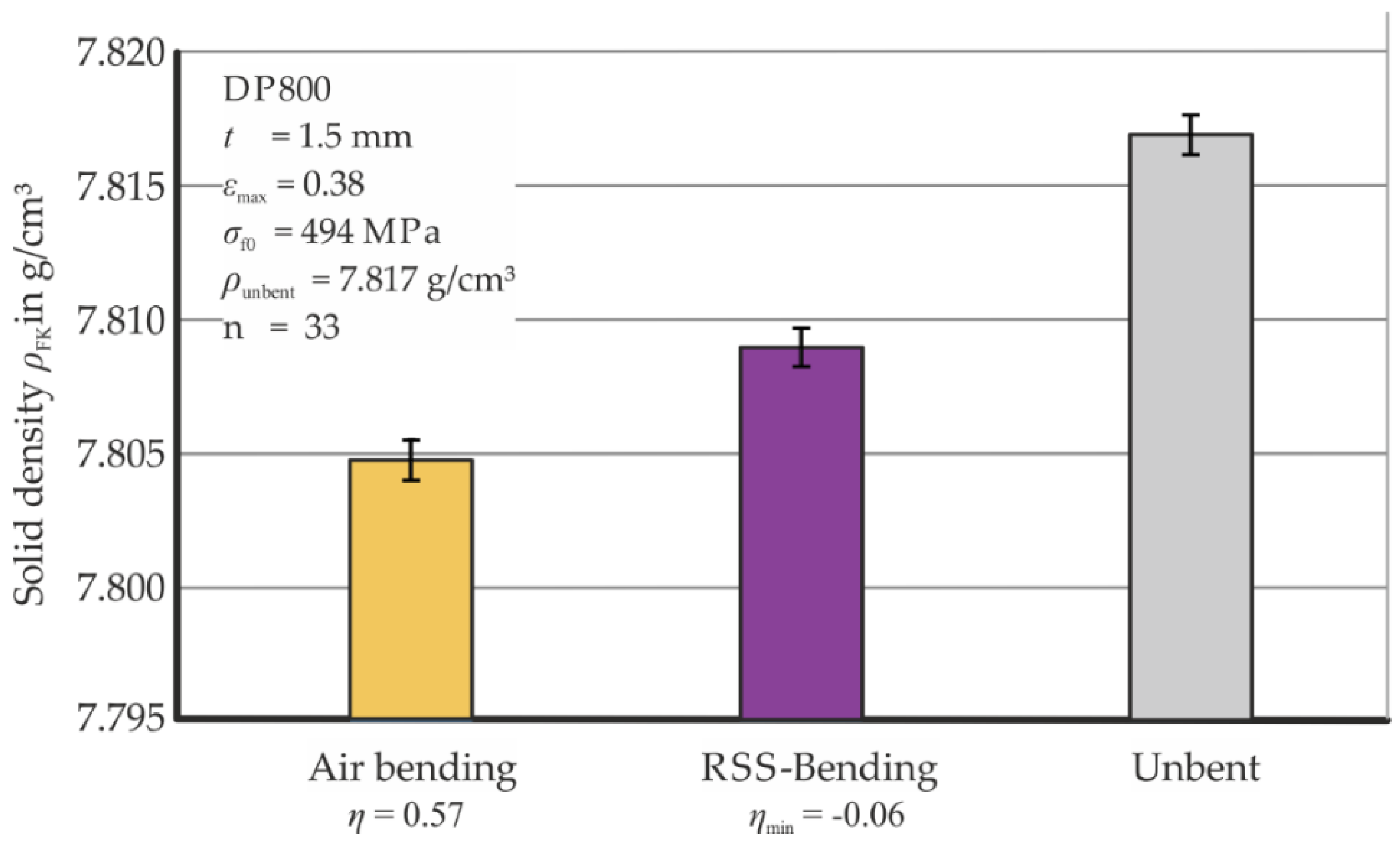

3.2. Density Measurements

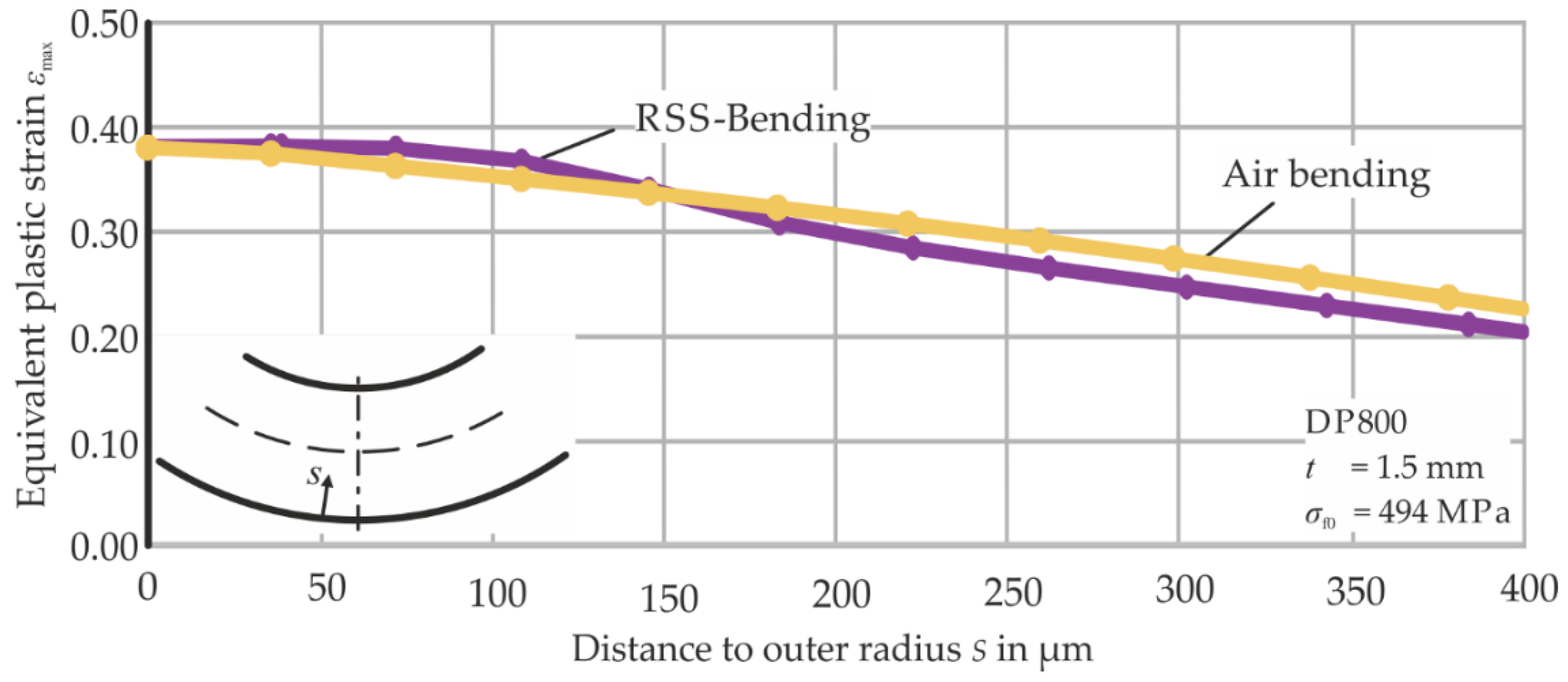

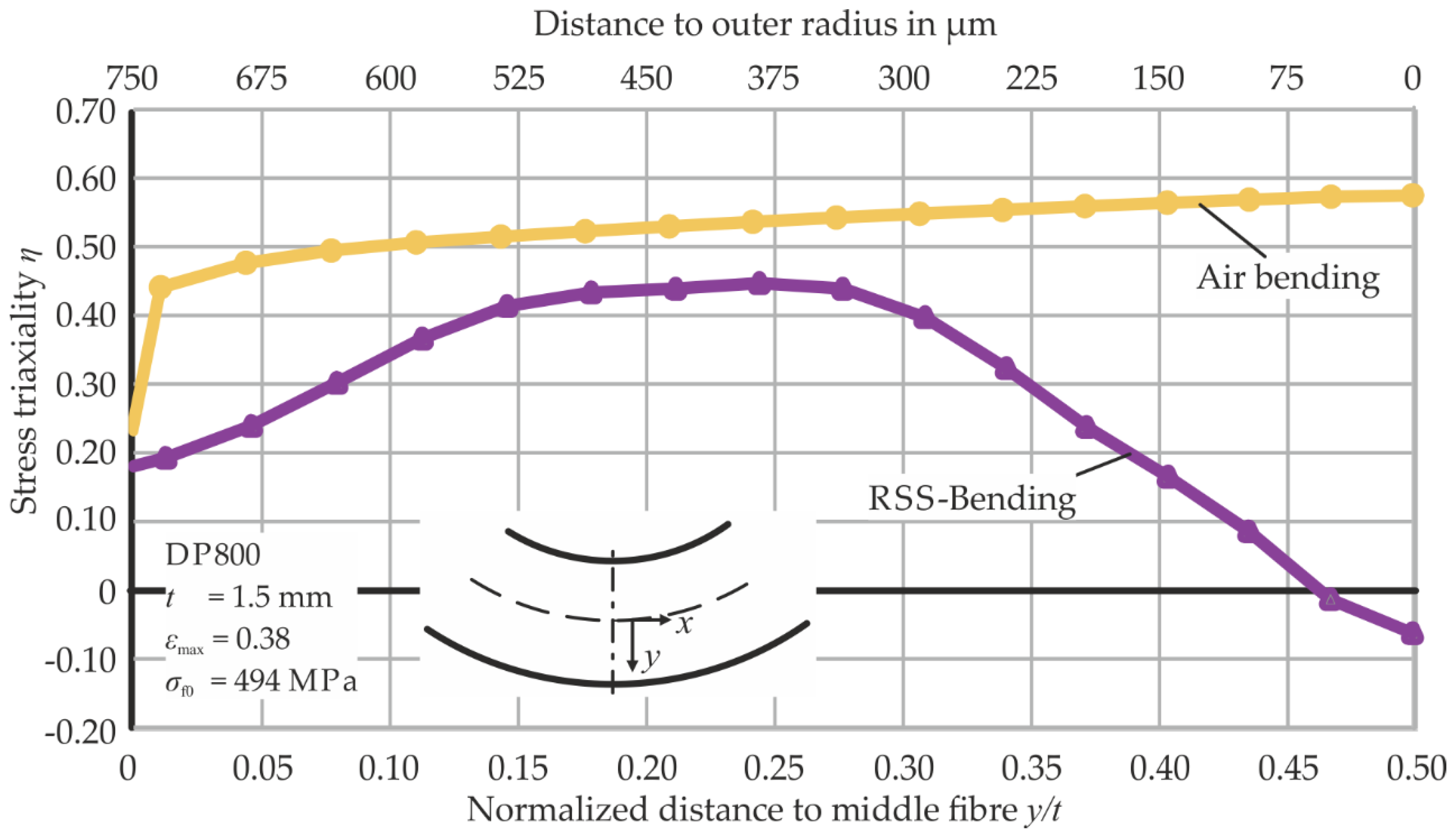

3.3. Resulting Strains and Stresses in Bending

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghadbeigi, H.; Pinna, C.; Celotto, S.; Yates, J.R. Local plastic strain evolution in a high strength dual-phase steel. Mater. Sci. Eng. A 2010, 527, 5026–5032. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M.; et al. An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Lemaitre, J. A Continuous Damage Mechanics Model for Ductile Fracture. J. Eng. Mater. Technol. 1985, 107, 83–89. [Google Scholar] [CrossRef]

- Gurson, A.L. Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Media. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Zambaldi, C.; Shanthraj, P.; Roters, F.; Raabe, D. Integrated experimental—Simulation analysis of stress and strain partitioning in multiphase alloys. Acta Mater. 2014, 81, 386–400. [Google Scholar] [CrossRef]

- McClintock, F.A. A Criterion for Ductile Fracture by the Growth of Holes. J. Appl. Mech. 1968, 35, 363–371. [Google Scholar] [CrossRef]

- Mukherjee, K.; Hazra, S.S.; Militzer, M. Grain Refinement in Dual-Phase Steels. Metall. Mater. Trans. A 2009, 40, 2145–2159. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Butz, A.; Ziaei Rad, S. Mechanisms of void formation during tensile testing in a commercial, dual-phase steel. Acta Mater. 2011, 59, 2575–2588. [Google Scholar] [CrossRef]

- Archie, F.; Li, X.; Zaefferer, S. Micro-damage initiation in ferrite-martensite DP microstructures: A statistical characterization of crystallographic and chemical parameters. Mater. Sci. Eng. A 2017, 701, 302–313. [Google Scholar] [CrossRef]

- Landron, C.; Bouaziz, O.; Maire, E.; Adrien, J. Characterization and modeling of void nucleation by interface decohesion in dual phase steels. Scr. Mater. 2010, 63, 973–976. [Google Scholar] [CrossRef]

- Erdogan, M. The effect of new ferrite content on the tensile fracture behaviour of dual phase steels. J. Mater. Sci. 2002, 37, 3623–3630. [Google Scholar] [CrossRef]

- Lai, Q.; Bouaziz, O.; Gouné, M.; Brassart, L.; Verdier, M.; Parry, G.; Perlade, A.; Bréchet, Y.; Pardoen, T. Damage and fracture of dual-phase steels: Influence of martensite volume fraction. Mater. Sci. Eng. A 2015, 646, 322–331. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Anderson, D.; Butcher, C.; Pathak, N.; Worswick, M.J. Failure parameter identification and validation for a dual-phase 780 steel sheet. Int. J. Solids Struct. 2017, 124, 89–107. [Google Scholar] [CrossRef]

- Cupka, V.; Nakagava, T.; Tiyamoto, H. Fine bending with Counter Pressure. Ann. CIRP 1973, 22, 73–74. [Google Scholar]

- Gänsicke, B. Verbesserung des Formänderungsvermögen bei der Blechumformung Mittels Partiell Überlagerter Druckspannung. Ph.D. Thesis, Ruhr Universität Bochum, Bochum, Germany, 2002. [Google Scholar]

- Schiefenbusch, J. Untersuchungen zur Verbesserung des Umformverhaltens von Blechen beim Biegen. Ph.D. Thesis, Universität Dortmund, Dortmund, Germany, 1983. [Google Scholar]

- Meya, R.; Löbbe, C.; Tekkaya, A.E. Stress State Control by a novel bending process and its effect on damage evolution. In Proceedings of the 2018 Manufacturing Science and Engineering Conference MSEC, College Station, TX, USA, 18–22 June 2018. [Google Scholar]

- Tekkaya, A.E.; Ben Khalifa, N.; Hering, O.; Meya, R.; Myslicki, S.; Walther, F. Forming-induced damage and its effects on product properties. CIRP Ann. Manuf. Technol. 2017, 66, 281–284. [Google Scholar] [CrossRef]

- Meya, R.; Löbbe, C.; Hering, O.; Tekkaya, A.E. New bending process with superposition of radial stresses for damage control. In Proceedings of the Forming Technology Forum, Enschede, The Netherlands, 12–13 October 2017. [Google Scholar]

- Lemaitre, J.; Dufailly, J. Damage measurements. Eng. Fract. Mech. 1987, 28, 643–661. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Geers, M.G.D. Identification of the continuum damage parameter: An experimental challenge in modeling damage evolution. Acta Mater. 2012, 60, 3581–3589. [Google Scholar] [CrossRef]

- Samuels, L.E. The nature of mechanically polished metal surfaces: The surface deformation produced by the abrasion and polishing of 70: 30 brass. Wear 1957, 1, 261. [Google Scholar] [CrossRef]

- Zhong, Z.; Hung, N.P. Grinding of alumina/aluminum composites. J. Mater. Process. Technol. 2002, 123, 13–17. [Google Scholar] [CrossRef]

- Isik, K.; Gerstein, G.; Clausmeyer, T.; Nürnberger, F.; Tekkaya, A.E.; Maier, H.J. Evaluation of Void Nucleation and Development during Plastic Deformation of Dual-Phase Steel DP600. Steel Res. Int. 2016, 87, 1583–1591. [Google Scholar] [CrossRef]

- Maire, E.; Bouaziz, O.; Di Michiel, M.; Verdu, C. Initiation and growth of damage in a dual-phase steel observed by X-ray microtomography. Acta Mater. 2008, 56, 4954–4964. [Google Scholar] [CrossRef]

- Ratcliffe, R.T. The measurement of small density changes in solids. Br. J. Appl. Phys. 1965, 16, 1193–1196. [Google Scholar] [CrossRef]

- Schmitt, J.H.; Jalinier, J.M.; Baudelet, B. Analysis of damage and its influence on the plastic properties of copper. J. Mater. Sci. 1981, 16, 95–101. [Google Scholar] [CrossRef]

- Bompard, D.P. Effets Endommageants de la Porosité sur la Propagation des Fessiures Dans le Nickel Fritté. Ph.D. Thesis, Universite de Technologie de Compiegne, Compiegne, France, 1986. [Google Scholar]

- Lapovok, R. Damage evolution under severe plastic deformation. Int. J. Fract. 2002, 115, 159–172. [Google Scholar] [CrossRef]

- Vedaldi, A.; Fulkerson, B. Vlfeat. In Proceedings of the International Conference on Multimedia—MM 2010, Firenze, Italy, 25–29 October 2010; ACM Press: New York, NY, USA, 2010; p. 1469. [Google Scholar]

- Vincent, L.; Soille, P. Watersheds in digital spaces: An efficient algorithm based on immersion simulations. IEEE Trans. Pattern Anal. Mach. Intell. 1991, 13, 583–598. [Google Scholar] [CrossRef]

- Kusche, C.; Reclik, T.; Freund, M.; Al-Samman, T.; Kerzel, U.; Korte-Kerzel, S. High-resolution, yet statistically relevant, analysis of damage in DP steel using artificial intelligence. arXiv, 2018; arXiv:1809.09657. [Google Scholar]

- Rappoport, Z. CRC Handbook of Tables for Organic Compund Identification; CRC Press: Boca Raton, FL, USA, 1967. [Google Scholar]

- Breitwieser, M. Bestimmungsmethoden der Dichte—IMETER. Available online: www.imeter.de (accessed on 15 January 2019).

- Akeret, R. Versagensmechanismen beim Biegen von Aluminiumblechen und Grenzen der Biegefähigkeit. Aluminium 1978, 54, 117–123. [Google Scholar]

- Meya, R.; Löbbe, C.; Tekkaya, A.E. Stress state analysis of radial stress superposed bending. Int. J. Precis. Eng. Manuf. 2018, 20, 53–66. [Google Scholar] [CrossRef]

- Oyane, M.; Sato, T.; Okimoto, K.; Shima, S. Criteria for ductile fracture and their applications. J. Mech. Work. Technol. 1980, 4, 65–81. [Google Scholar] [CrossRef]

- El Budamusi, M.; Becker, C.; Clausmeyer, T.; Gebhard, J.; Chen, L.; Tekkaya, A.E. Erweiterung der Formänderungsgrenzen von Höherfesten Stahlwerkstoffen bei Biegeumformprozessen Durch Innovative Prozessführung und Werkzeuge; IGF-Nr. 16585 N/FOSTA P930; Verl. Und Vertriebsges. Mb: Düsseldorf, Germany, 2015. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meya, R.; Kusche, C.F.; Löbbe, C.; Al-Samman, T.; Korte-Kerzel, S.; Tekkaya, A.E. Global and High-Resolution Damage Quantification in Dual-Phase Steel Bending Samples with Varying Stress States. Metals 2019, 9, 319. https://doi.org/10.3390/met9030319

Meya R, Kusche CF, Löbbe C, Al-Samman T, Korte-Kerzel S, Tekkaya AE. Global and High-Resolution Damage Quantification in Dual-Phase Steel Bending Samples with Varying Stress States. Metals. 2019; 9(3):319. https://doi.org/10.3390/met9030319

Chicago/Turabian StyleMeya, Rickmer, Carl F. Kusche, Christian Löbbe, Talal Al-Samman, Sandra Korte-Kerzel, and A. Erman Tekkaya. 2019. "Global and High-Resolution Damage Quantification in Dual-Phase Steel Bending Samples with Varying Stress States" Metals 9, no. 3: 319. https://doi.org/10.3390/met9030319

APA StyleMeya, R., Kusche, C. F., Löbbe, C., Al-Samman, T., Korte-Kerzel, S., & Tekkaya, A. E. (2019). Global and High-Resolution Damage Quantification in Dual-Phase Steel Bending Samples with Varying Stress States. Metals, 9(3), 319. https://doi.org/10.3390/met9030319