Sensitivity Analysis of Tool Wear in Drilling of Titanium Aluminides

Abstract

1. Introduction

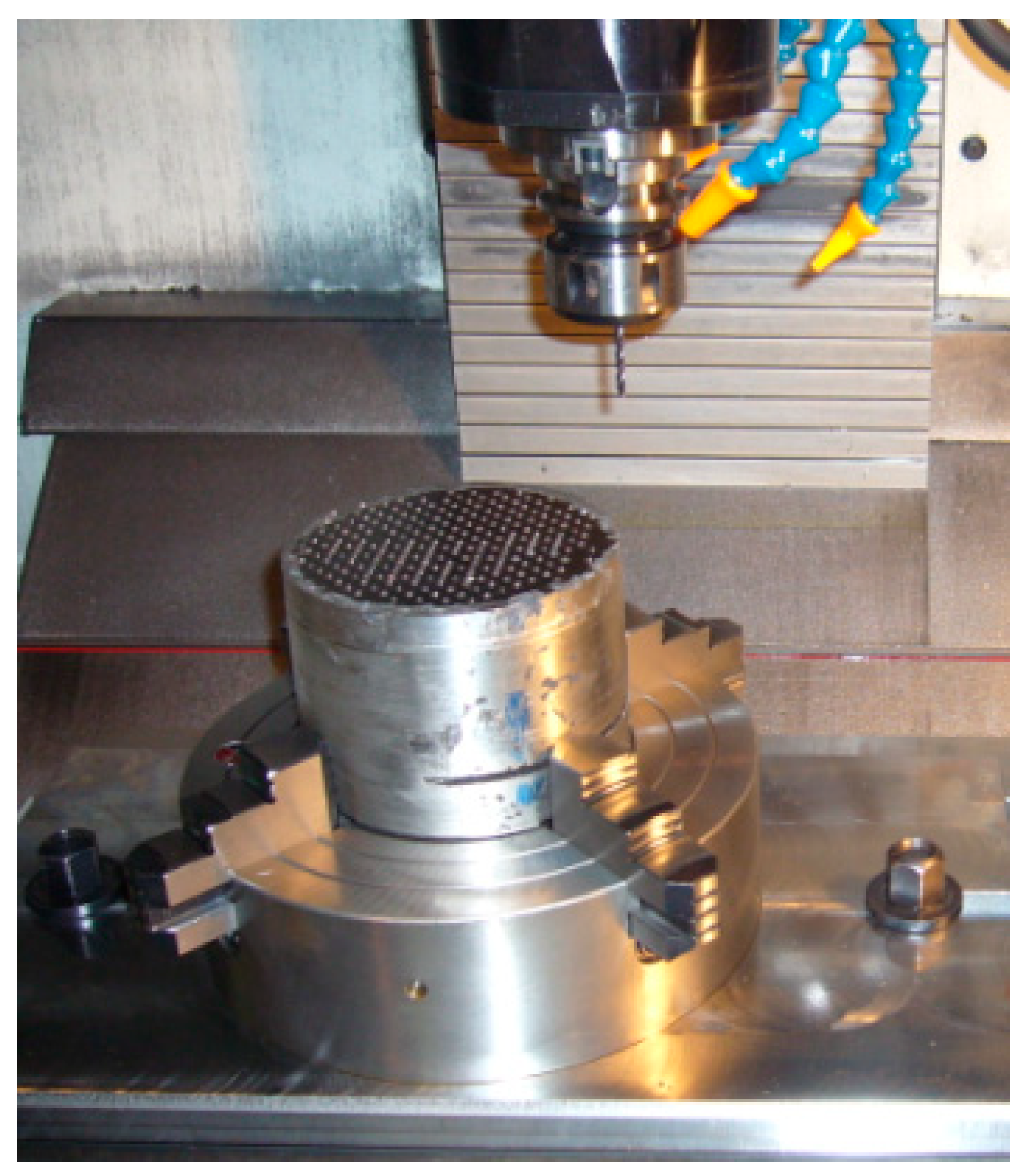

2. Machinability of Gamma TiAl Alloys

3. Experimental Procedure

4. Experimental Procedure

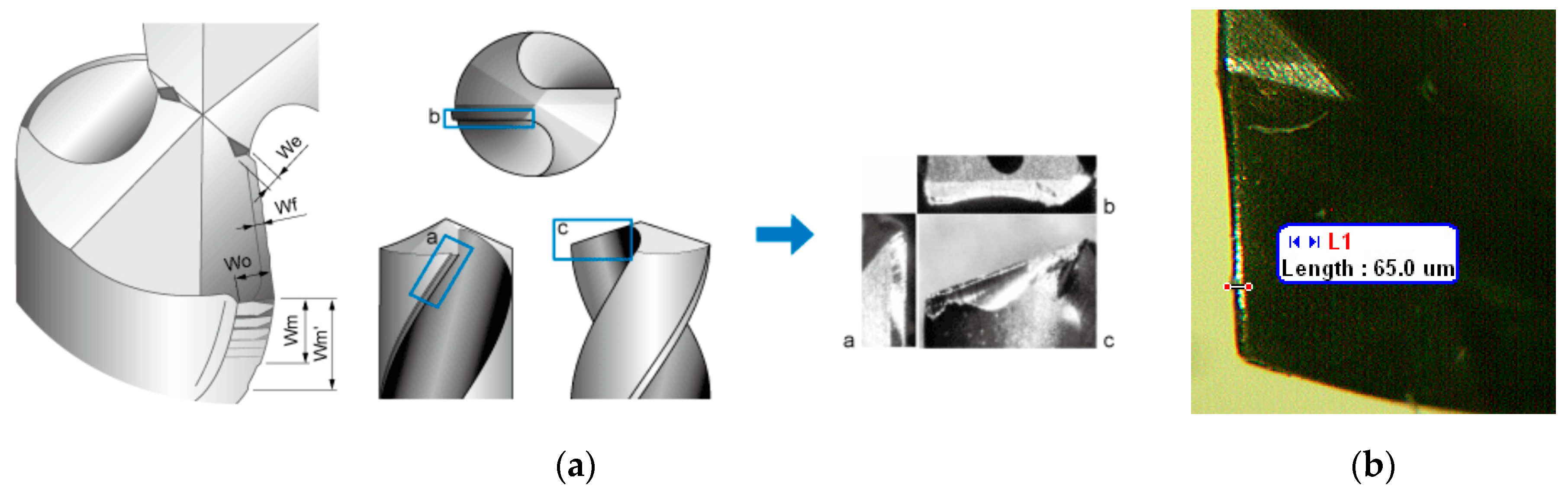

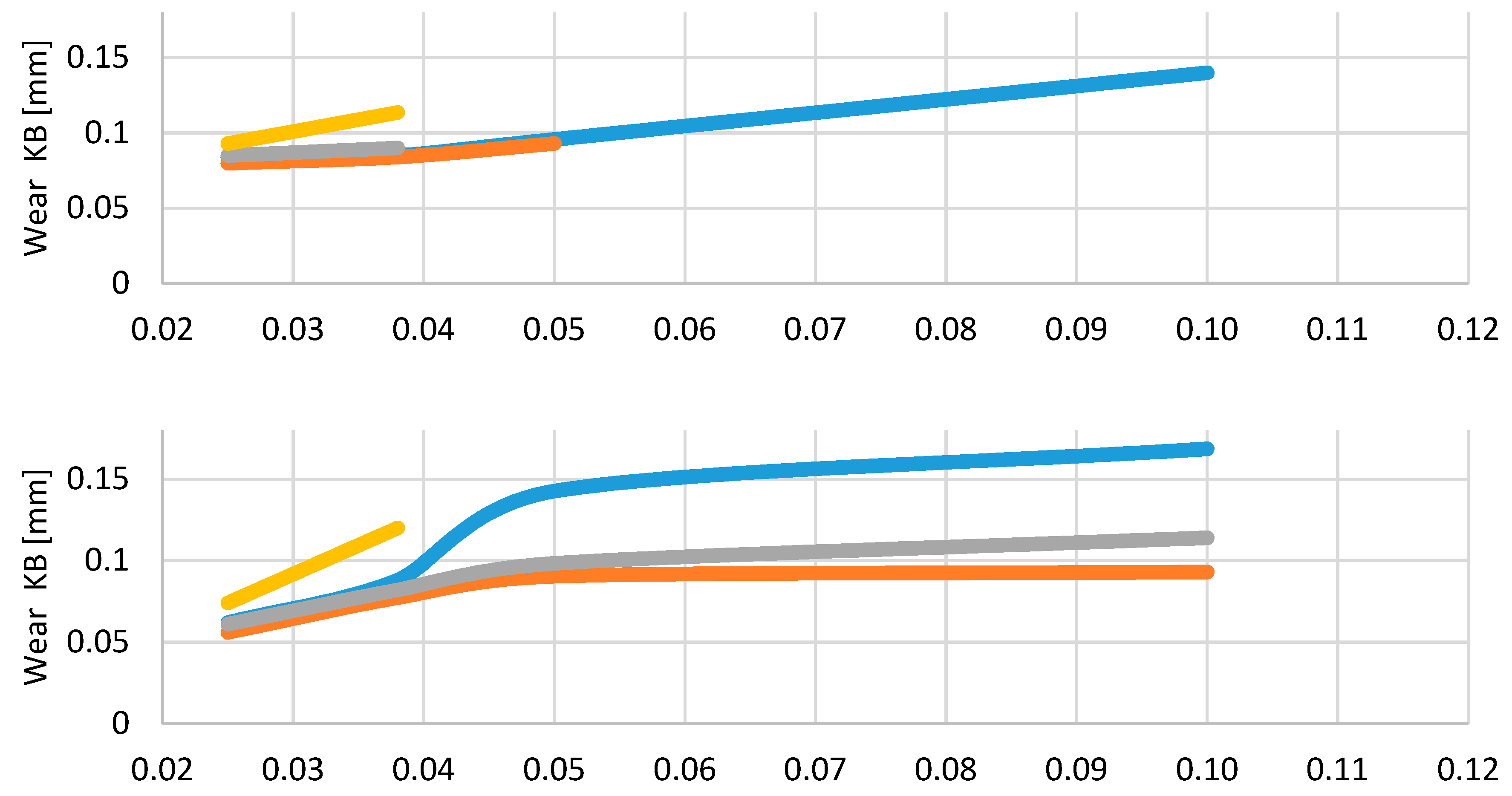

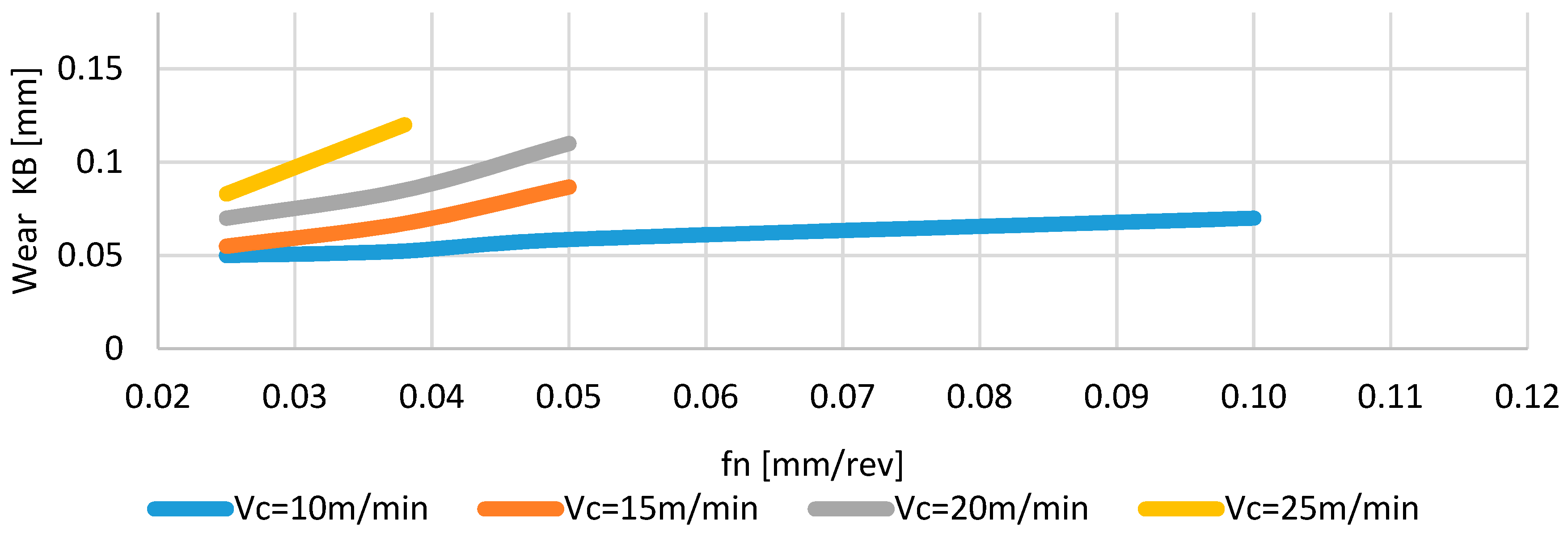

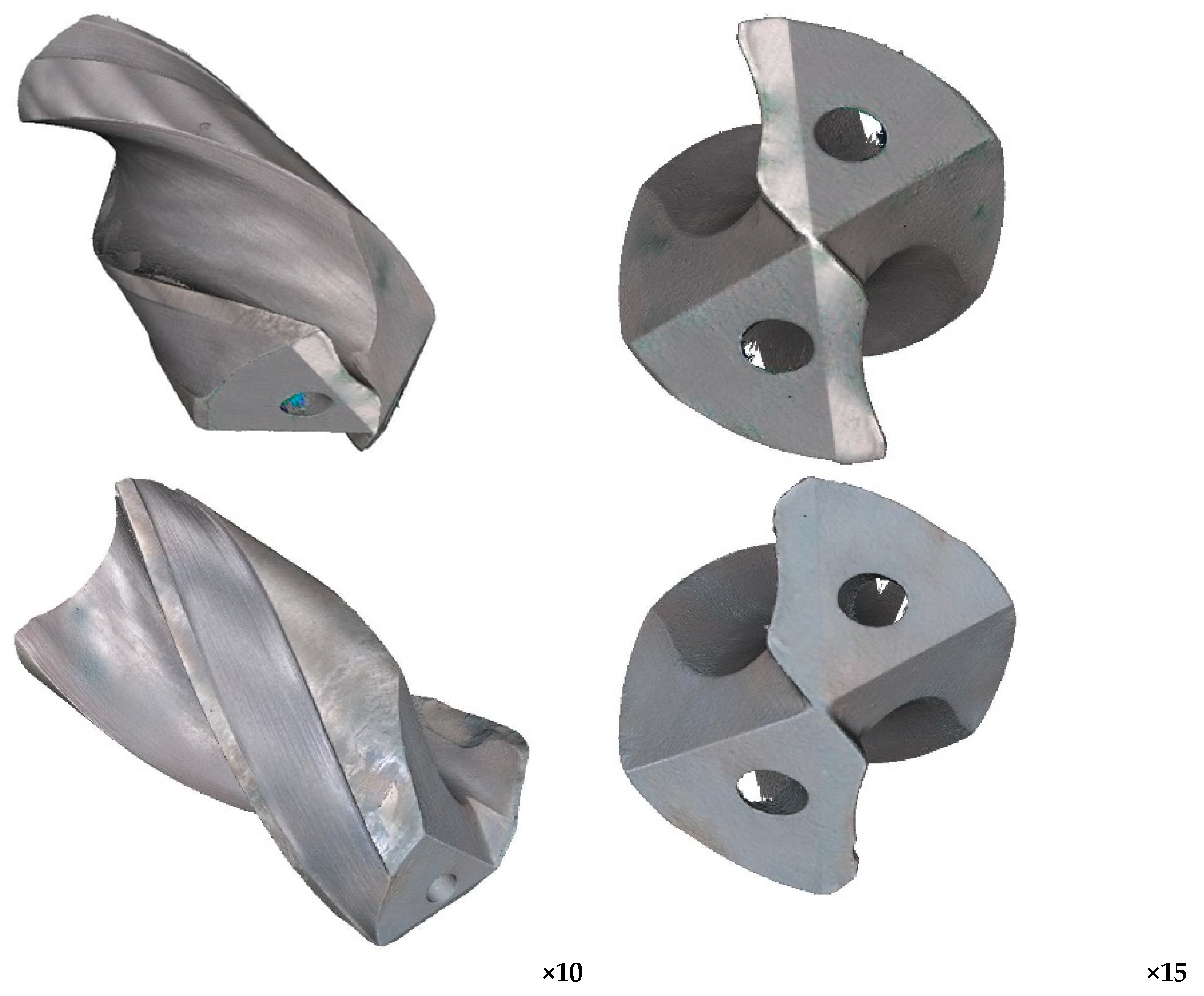

4.1. Tool Wear

- -

- TNB alloy: vc = 10 m/min, fn = 0.025 mm/rev.

- -

- Ingot MoCuSi: vc = 10–15 m/min, fn = 0.038 mm/rev.

- -

- Extruded MoCuSi: vc = 10–15 m / min, fn = 0.025 mm/rev.

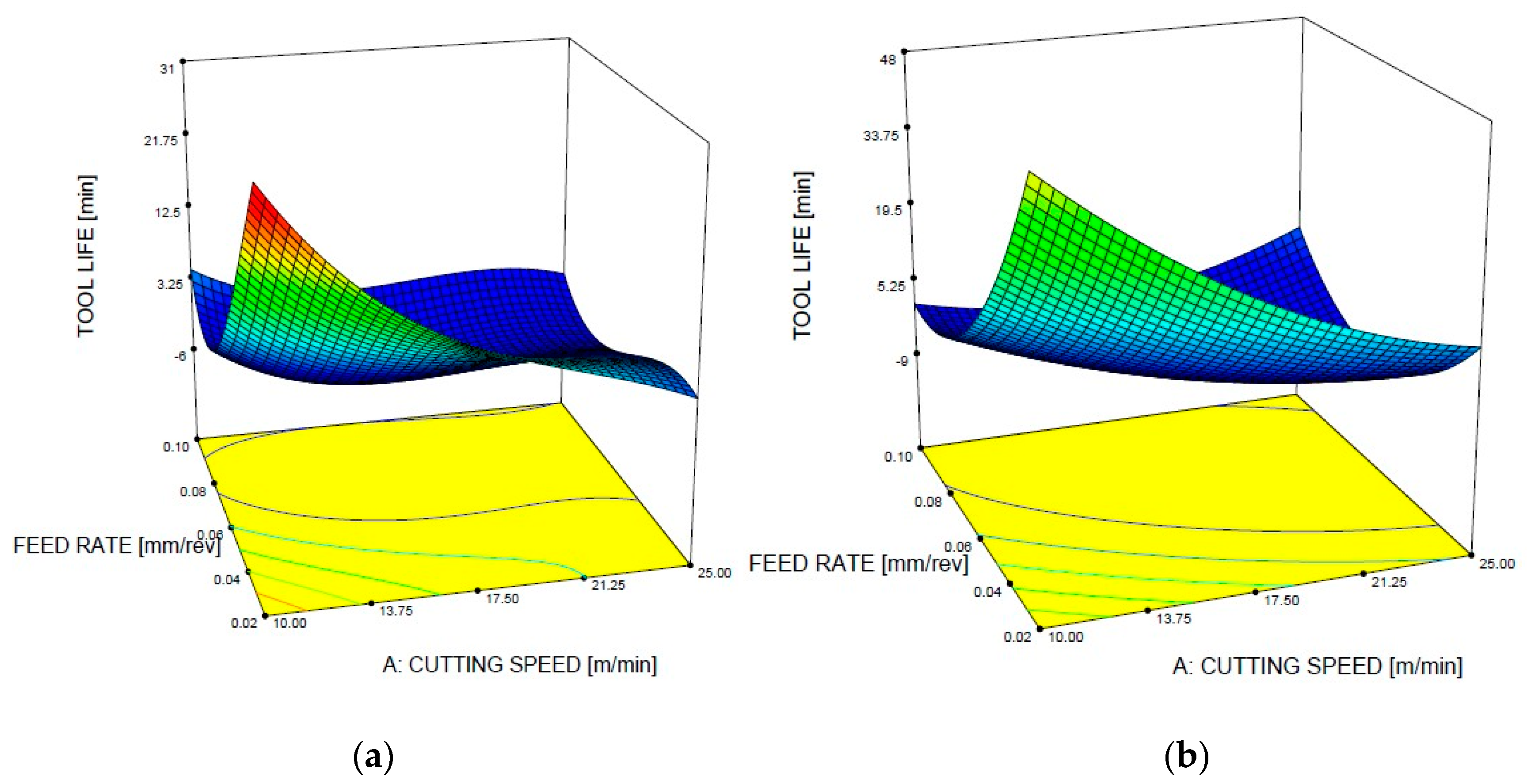

4.2. Tool Life Prediction Using DoE

5. Conclusions

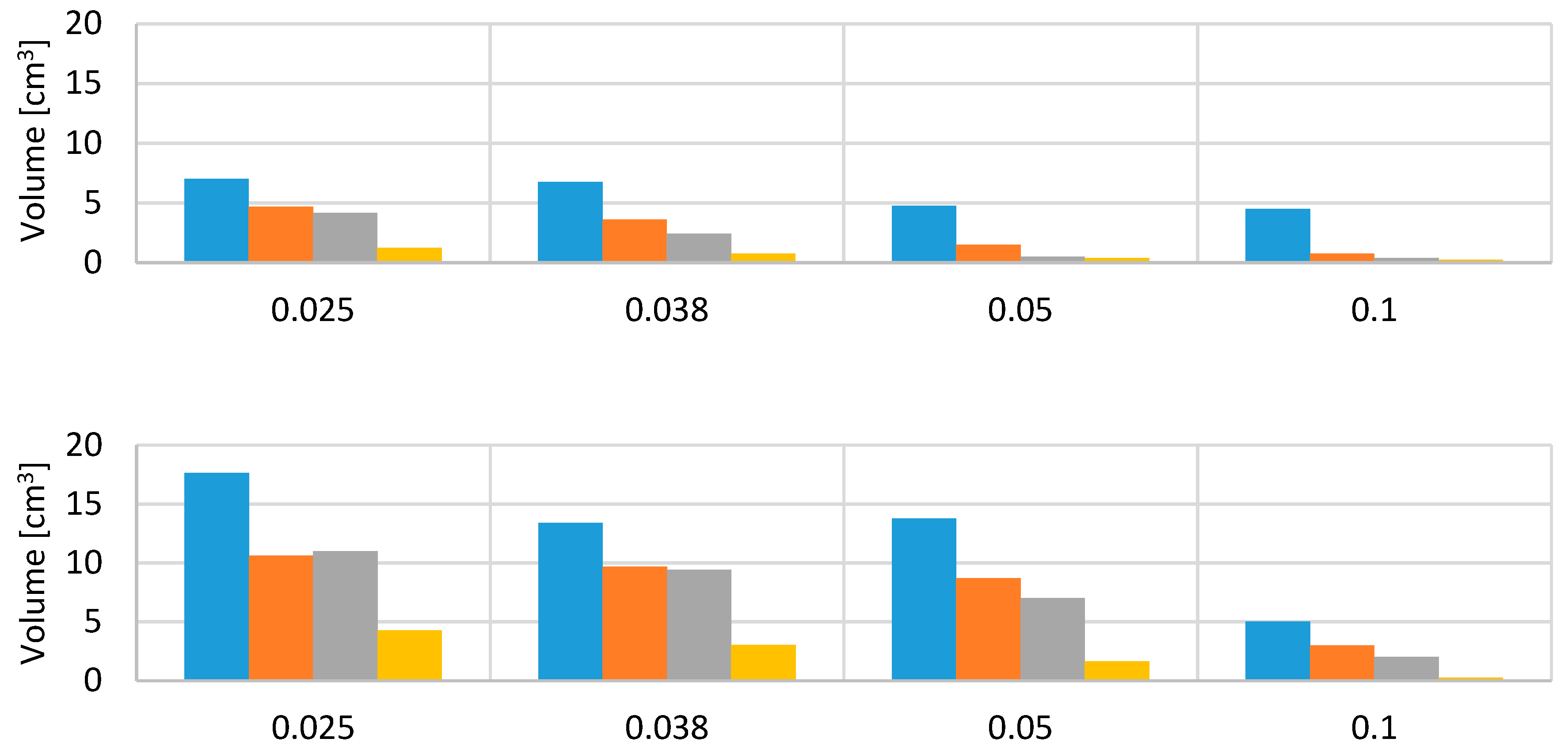

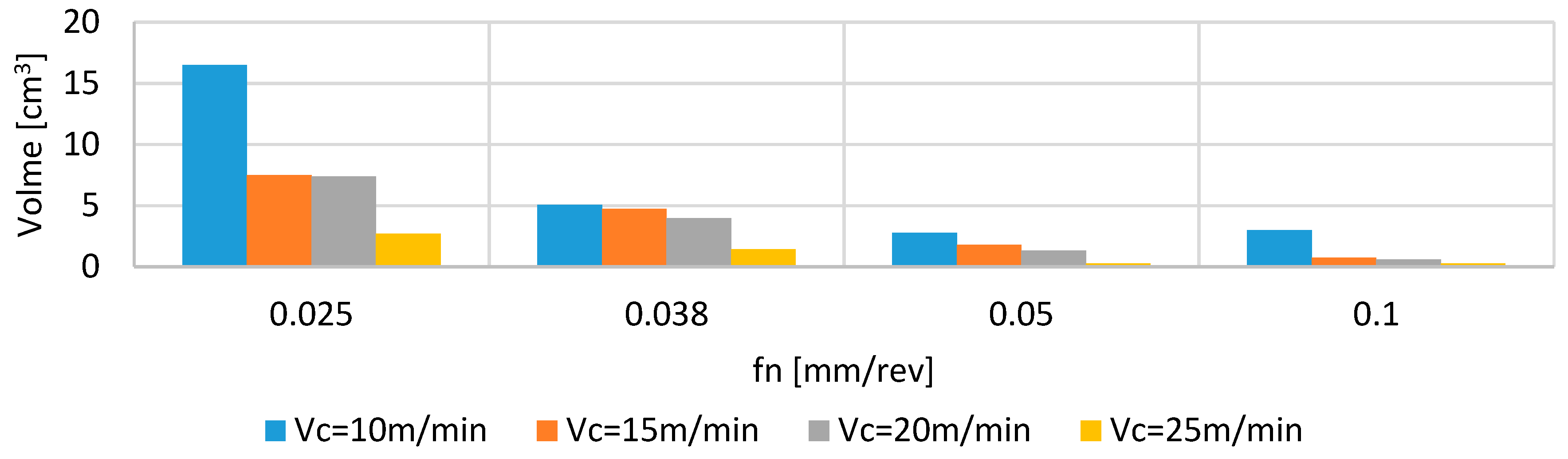

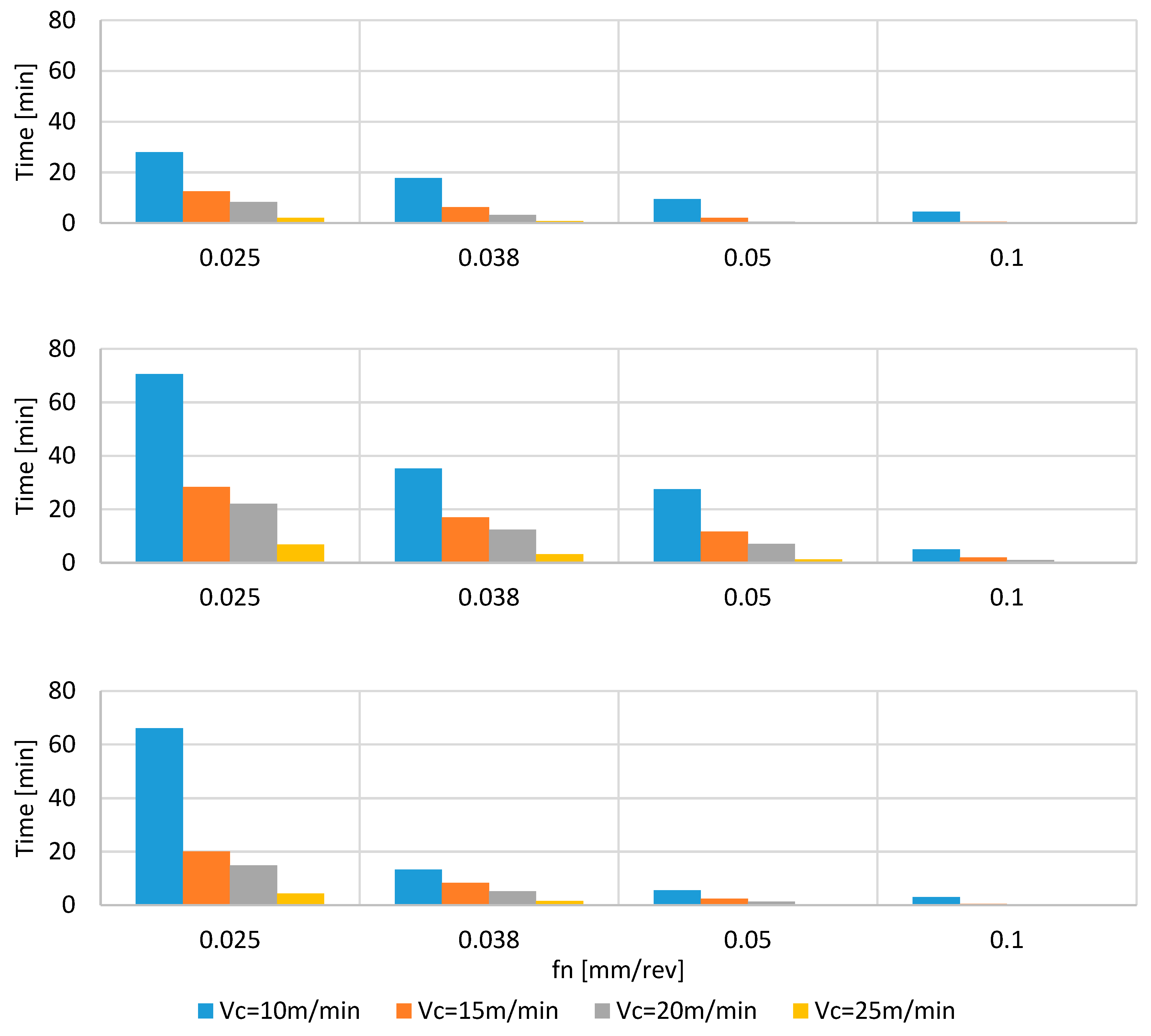

- A set of drilling tests was carried out, obtaining the relationship between tool wear, cutting speed, and feed per revolution. In summary, cutting speed must be between 10 and 15 m/min and feed per revolution 0.025 mm/rev, for coated tungsten drills. The tested materials are highly dependent on cutting speed. This parameter should not be higher than 15 m/min for an acceptable tool degradation rate. For the same cutting conditions, the tool has a longer life, 2–3 times higher when machining MoCuSi ingot than in TNB. The feed per revolution also has an important effect on tool life and should not surpass the value 0.038–0.050 mm/rev. Feed value fn = 0.1 mm/rev was prohibitive in all cases.

- These alloys present a much smaller machinability (higher specific cutting energy ps) than conventional titanium alloys such as Ti6Al4V. However, differences were noted between them. Among the three materials, the extruded and ingot MoCuSi alloys presented a similar behavior, while the TNB alloy led to more pronounced degradation. Cutting tests revealed that the most difficult-to-cut material is the TNB alloy, followed by the MoCuSi alloy in ingot form. Another point is the strong tendency of the drill to torsion failure, which is very sensitive to an increase in the cutting speed. This failure occurs at approximately 45° of the drill’s section.

- An ANOVA analysis of the drilling test allows us to identify the influence of the considered cutting parameters in the drill’s wear. This analysis also supports the hypothesis of a different behavior between the drill’s wear for the three gamma TiAl alloys. Two of the alloys studied, MoCuSi ingot and TBN, show that the cutting speed and the coupled term of cutting speed times feed per revolution provide the main contribution to the wear model, while the other three terms of the model make a lower contribution. In some cases, the contribution of some terms is very low (<3%) and does not have statistical significance, a fact that does not affect the significance of the model due to their low contribution to the drill’s wear. For these two alloys, the high contribution of the coupled term, vc × fn, and only one of the linear terms, vc in both cases, will make the intuitive process optimization by the process engineer difficult because the relationship between each input and the drill’s wear is mostly not independent of the other input. In the case of the extruded MoCuSi, a balanced situation is found in the model, with four terms that contribute in the same range (20–30%). This kind of balanced model can be more easily optimized by the process engineer because all terms contribute equally.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Glossary

| Term | Units |

| Creep max. temperature, Tcr | °C |

| Cutting speed, vc | m/min |

| Chisel edge wear width, We | mm |

| Density, ρ | kg/m3 |

| Elongation, e | % |

| Feed per revolution, fn | mm/rev |

| Feed speed, vf | mm/min |

| Feed per tooth, fz | mm/ Z |

| Flank wear, Wf | mm |

| Margin wear width, Wm | mm |

| Machined volume, V | cm3 |

| Outer corner wear width, Wo | mm |

| Oxidation max. temperature, Tox | °C |

| Crater wear depth, KT | mm |

| Crater wear length, KB | mm |

| Specific cutting energy, ps | MPa |

| Spindle speed, n | rpm |

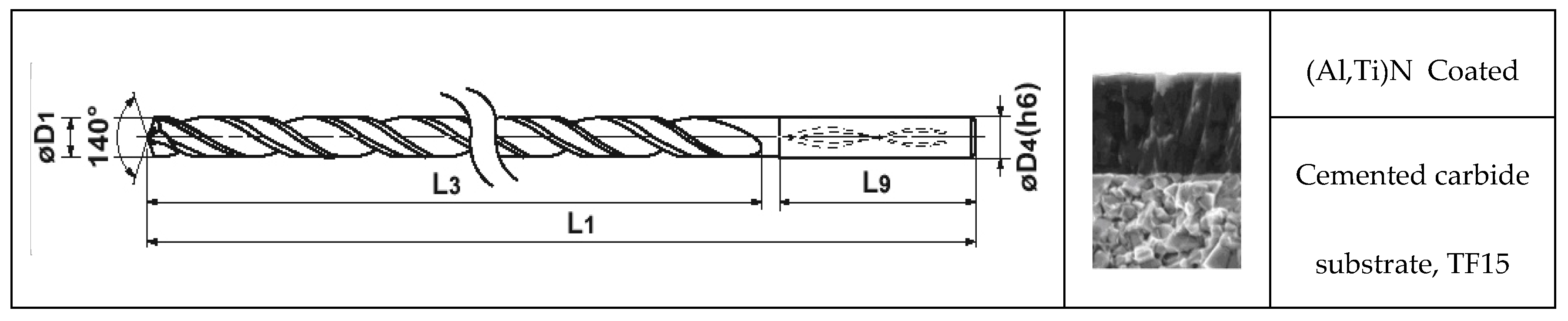

| Tool diameter, D1 | mm |

| Tool length, L1 | mm |

| Tool life, TL | min |

| Tool overhang, D4 | mm |

| Young modulus, E | GPa |

References

- Loria, E.A. Quo vadis gamma titanium aluminide. Intermetallics 2001, 9, 997–1001. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aeros. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Nasa Technical Reports Server. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20050192158.pdf (accessed on 17 November 2018).

- Hood, R.; Aspinwall, D.K.; Soo, S.L.; Mantle, A.L.; Novovic, D. Workpiece surface integrity when slot milling γ-TiAl intermetallic alloy. CIRP Annals-Manuf. Tech. 2014, 63, 53–56. [Google Scholar] [CrossRef]

- Olvera, D.; López de Lacalle, L.N.; Urbikain, G.; Lamikiz, A.; Rodal, P.; Zamakona, I. Hole making using ball helical milling on titanium alloys. Mach. Sci. Tech. 2012, 16, 173–188. [Google Scholar] [CrossRef]

- Ezugwu, E.O. Key improvements in the machining of difficult-to-cut aerospace superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Sharman, A.R.C.; Aspinwall, D.K.; Dewes, R.C.; Bowen, P. Workpiece surface integrity considerations when finish turning gamma titanium aluminide. Wear 2001, 249, 473–481. [Google Scholar] [CrossRef]

- Aspinwal, D.K.; Dewes, R.C.; Mantle, A.L. The machining of y-TiAl intermetallic alloys. CIRP Ann. Manuf. Technol. 2005, 54, 99–104. [Google Scholar] [CrossRef]

- Komanduri, R.; Von Turkovich, B.F. New observations on the mechanism of chip formation when machining titanium alloys. Wear 1981, 69, 179–188. [Google Scholar] [CrossRef]

- Nakayama, K. The Formation of Saw-tooth Chip. In Proceedings of the First International Conference on Production Engineering, Tokyo, Japan, 1974; pp. 572–1572. [Google Scholar]

- Puerta Velásquez, J.D.; Bolle, B.; Chewier, P.; Geandier, G.; Tidu, A. Metallurgical Study on Chips Obtained by High Speed Machining of a Ti-6wt.%Al-4wt.%V Alloy. Mater. Sci. Eng. A 2007, 452–453, 469–474. [Google Scholar] [CrossRef]

- Li, R.; Riester, L.; Watkins, T.R.; Blau, P.J.; Shih, A.J. Metallurgical analysis and nanoindentation characterization of Ti-6Al-4V workpiece and chips in high-throughput drilling. Mater. Sci. Eng. 2008, 472, 115–124. [Google Scholar] [CrossRef]

- Corduan, N.; Himbert, T.; Poulachon, G.; Dessoly, M.; Lambertin, M.; Vigneau, J.; Payoux, B. Wear mechanisms of new tool materials for Ti–6Al–4 V high performance machining. CIRP Annals-Man. Tech. 2003, 52, 73–76. [Google Scholar] [CrossRef]

- Hartung, P.D.; Kramer, B.F.; von Turkovich, B.F. Tool Wear in Titanium Machining. CIRP Annals 1982, 31, 75–80. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F.; Coupard, D. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359–1368. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Kirsch, J.; Sun, S.; Palanisamy, S.; Dargusch, M.S. New observations on tool life, cutting forces and chip morphology in cryogenic machining Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2011, 51, 500–511. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; López de Lacalle, L.N.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Proc. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Beranoagirre, A.; Urbikain, G.; Calleja, A.; López de Lacalle, L.N. Hole making by electrical discharge machining (EDM) of γ-TiAl intermetallic alloys. Metals 2018, 8, 543. [Google Scholar] [CrossRef]

- Beranoagirre, A.; Urbikain, G.; Calleja, A.; López de Lacalle, L.N. Drilling process in γ-TiAl intermetallic alloys. Materials 2018, 11, 2379. [Google Scholar] [CrossRef] [PubMed]

- Kuczmaszewski, J.; Zaleski, K.; Matuszak, J.; Pałka, T.; Mądry, J. Studies on the effect of mill microstructure upon tool life during slot milling of Ti6Al4V alloy parts. Eksploat. Niezawodn. Maint. Reliab. 2017, 19, 590. [Google Scholar] [CrossRef]

- Józwik, J. Evaluation of tribological properties and condition of Ti6Al4V Titanium alloy surface. Tech. Gazette. 2018, 25, 170. [Google Scholar] [CrossRef]

- Józwik, J.; Ostrowski, D.; Milczarczyk, R.; Krolczyk, G.M. Analysis of relation between the 3D printer laser beam power and the surface morphology properties in Ti-6Al-4V titanium alloy parts. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 215. [Google Scholar] [CrossRef]

- Uddin, M.; Basak, A.; Pramanik, A.; Singh, S.; Krolczyk, G.M.; Prakash, C. Evaluating hole quality in drilling of Al 6061 alloys. Materials 2018, 11, 2443. [Google Scholar] [CrossRef] [PubMed]

- Bharatish, A.; Narasimha Murthy, H.N.; Anand, B.; Subramanya, K.N.; Krishna, M.; Srihari, P.V. Assessment of drilling characteristics of alumina coated on aluminium using CO2 laser. Measurement 2017, 100, 164–175. [Google Scholar] [CrossRef]

- Balaji, M.; Venkata Rao, K.; Mohan Rao, N.; Murthy, B.S.N. Optimization of drilling parameters for drilling of TI-6Al-4V based on surface roughness, flank wear and drill vibration. Measurement 2018, 114, 332–339. [Google Scholar] [CrossRef]

- Monroy, K.; Delgado, J.; Sereno, L.; Ciurana, J.; Hendrichs, N.J. Geometrical feature analysis of Co-Cr-Mo single tracks after selective laser melting processing. Rapid Prot. J. 2015, 21, 287300. [Google Scholar] [CrossRef]

- Imeri, A.; Fidan, I.; Allen, M.; Wilson, D.A.; Canfield, S. Fatigue analysis of the fiber reinforced additively manufactured objects. Int. J. Adv. Manuf. Tech. 2018, 98, 2717–2724. [Google Scholar] [CrossRef]

- Rubio, E.M.; Villeta, M.; Valencia, J.L.; de Pipaón, J.M.S. Cutting parameter selection for efficient and sustainable repair of holes made in hybrid Mg-Ti-Mg component stacks by dry drilling operations. Materials 2018, 11, 1369. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.H.; Tamin, N.F.; Ahmad, M.N.; Ab. Rahman, M.H.; Wahid, M.K.; Maidin, N.A.; Abu Bakar, M.H.; Azahar, A.A. Effect of cutting parameters on surface roughness in dry drilling of AISI D2 tool steel by using Taguchi method. J. Adv. Manuf. Tech. 2018, 12, 535–546. [Google Scholar]

- López de Lacalle, L.N.; Pérez, J.; Llorente, J.I.; Sánchez, J.A. Advanced cutting conditions for the milling of aeronautical alloys. J. Mater Process Technol. 2000, 100, 1–11. [Google Scholar] [CrossRef]

- Teixidor, D.; Grzenda, M.; Bustillo, A.; Ciurana, J. Modeling pulsed laser micromachining of 370 micro geometries using machine-learning Techniques. J. Int. Manuf. 2015, 26, 801–814. [Google Scholar] [CrossRef]

| Property | Ti Alloys | α-2 | γ | Other Superalloys |

|---|---|---|---|---|

| Density ρ (gr/cm3) | 4.54 | 4.84 | 4.04 | 8.3 |

| Young modulus E (GPa) | 110 | 145 | 176 | 207 |

| Creep max. temperature Tcr (°C) | 540 | 730 | 900 | 1090 |

| Oxidation max. temp. Tox (°C) | 590 | 705 | 815 | 1090 |

| Ductility or elongation (in %) | 15 | 2–4 | 1–3 | 3–10 |

| Elongation, operating Temperature % | 15 | 5–12 | 5–12 | 10–20 |

| vc [m/min] | fn [mm/rev] | n [rpm] | vf [mm/min] |

|---|---|---|---|

| 10 | 0.025, 0.038, 0.050, 0.100 | 796 | 19.9, 30.2, 39.8, 79.6 |

| 15 | 0.025, 0.038, 0.050, 0.100 | 1194 | 29.9, 45.4, 59.7, 119.4 |

| 20 | 0.025, 0.038, 0.050, 0.100 | 1592 | 39.8, 60.5, 79.6, 159.2 |

| 25 | 0.025, 0.038, 0.050, 0.100 | 1989 | 49.7, 75.6, 99.5, 198.9 |

| Materials | Tool Life [min] |

|---|---|

| TNB alloy | TL = 149.97 − 16.603 × vc − 1312.081 × fn + 102.475 × vc × fn + 0.6758 × vc2 − 491.231 × fn2 |

| MoCuSi alloy (ingot) | TL = 161.94 − 8.8328 × vc − 821.629 × fn + 42.350 × vc × fn + 0.130471 × vc2 + 5861.472 × fn2 |

| MoCuSi alloy (extruded) | TL=139.21−7.25716×vc − 2069.066×fn + 36.759×vc×fn + 0.11391×vc2 + 9281.094×fn2 |

| Materials | Source | Sum of Squares | Degrees of Freedom | Mean Square | F Value | P Value | Contribution (%) |

|---|---|---|---|---|---|---|---|

| TNB alloy | Model | 906.09 | 9 | 100.68 | 79.64 | < 0.0001 | - |

| vc | 36.23 | 1 | 36.23 | 28.66 | 0.0017 | 38.51 | |

| fn | 2.64 | 1 | 2.64 | 2.09 | 0.1986 | 2.81 | |

| vc × fn | 31.93 | 1 | 31.93 | 25.26 | 0.0024 | 33.94 | |

| vc2 | 15.81 | 1 | 15.81 | 12.50 | 0.0123 | 16.798.11 | |

| fn2 | 7.48 | 1 | 7.48 | 5.92 | 0.0510 | 7.95 | |

| Residual | 7.58 | 6 | 1.26 | - | - | - | |

| MoCuSi ingot | Model | 4552.02 | 5 | 910.40 | 18.60 | <0.0001 | - |

| vc | 987.15 | 1 | 987.15 | 20.17 | 0.0012 | 41.32 | |

| fn | 262.44 | 1 | 262.44 | 5.36 | 0.0431 | 10.98 | |

| vc × fn | 749.86 | 1 | 749.86 | 15.32 | 0.0029 | 31.39 - | |

| vc2 | 170.05 | 1 | 170.05 | 3.47 | 0.0919 | 7.11 | |

| fn2 | 219.71 | 1 | 219.71 | 4.49 | 0.0602 | 9.20 | |

| Residual | 489.46 | 10 | 48.95 | - | - | - | |

| Extruded MoCuSi | Model | 2790.29 | 5 | 558.06 | 4.73 | 0.0178 | - |

| vc | 714.57 | 1 | 714.57 | 6.05 | 0.0336 | 27.87 | |

| fn | 602.24 | 1 | 602.24 | 5.10 | 0.0475 | 23.49 | |

| vc × fn | 564.95 | 1 | 564.95 | 4.79 | 0.0535 | 22.06 | |

| vc2 | 129.61 | 1 | 129.61 | 1.10 | 0.3194 | 5.07 | |

| fn2 | 550.85 | 1 | 550.85 | 4.67 | 0.0561 | 21.51 | |

| Residual | 2790.29 | 5 | 558.06 | 4.73 | 0.0178 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beranoagirre, A.; Urbikain, G.; Marticorena, R.; Bustillo, A.; López de Lacalle, L.N. Sensitivity Analysis of Tool Wear in Drilling of Titanium Aluminides. Metals 2019, 9, 297. https://doi.org/10.3390/met9030297

Beranoagirre A, Urbikain G, Marticorena R, Bustillo A, López de Lacalle LN. Sensitivity Analysis of Tool Wear in Drilling of Titanium Aluminides. Metals. 2019; 9(3):297. https://doi.org/10.3390/met9030297

Chicago/Turabian StyleBeranoagirre, Aitor, Gorka Urbikain, Raúl Marticorena, Andrés Bustillo, and Luis Norberto López de Lacalle. 2019. "Sensitivity Analysis of Tool Wear in Drilling of Titanium Aluminides" Metals 9, no. 3: 297. https://doi.org/10.3390/met9030297

APA StyleBeranoagirre, A., Urbikain, G., Marticorena, R., Bustillo, A., & López de Lacalle, L. N. (2019). Sensitivity Analysis of Tool Wear in Drilling of Titanium Aluminides. Metals, 9(3), 297. https://doi.org/10.3390/met9030297