Classification and Quantitative Evaluation of Eddy Current Based on Kernel-PCA and ELM for Defects in Metal Component

Abstract

1. Introduction

2. Methods

2.1. Kernel-PCA

2.2. Extreme Learning Machine

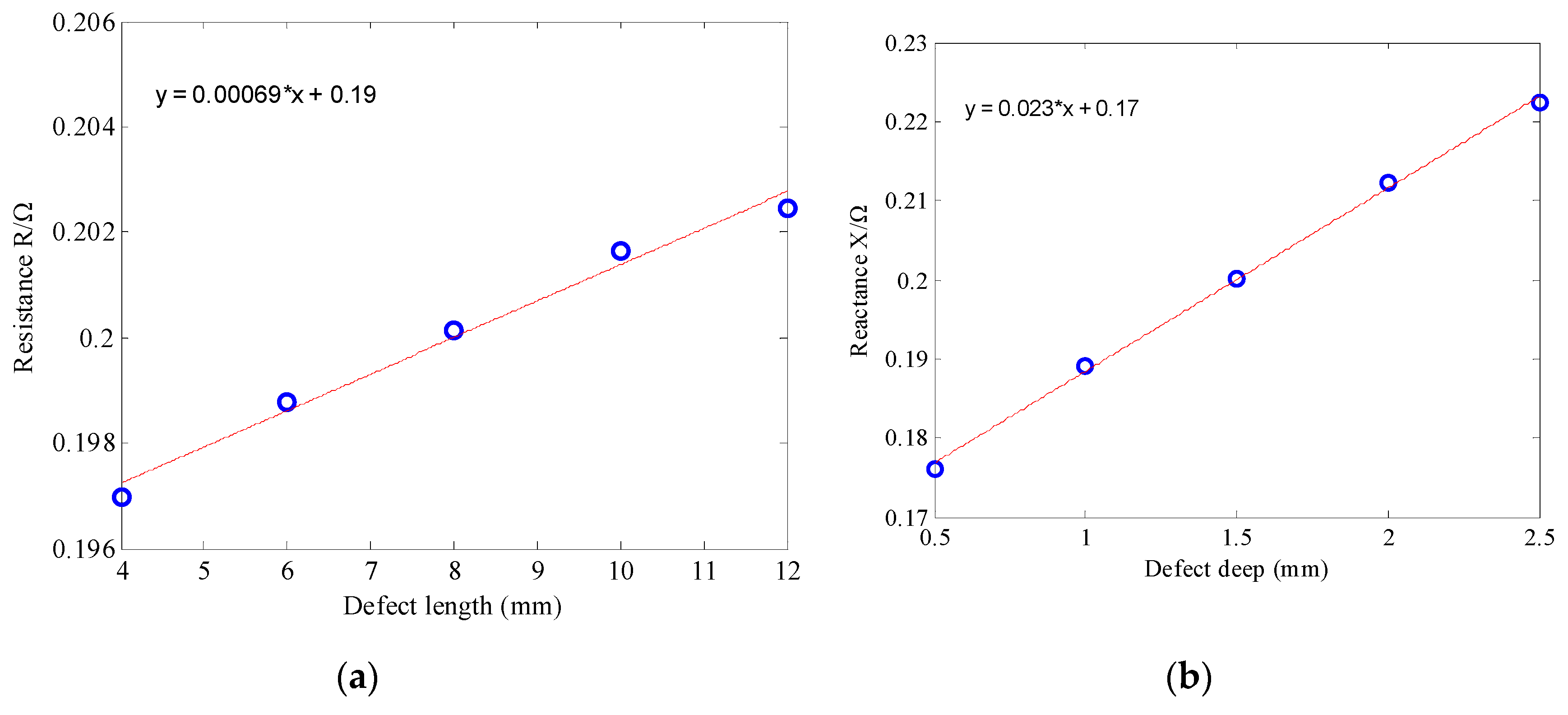

2.3. Linear Least-Squares Fitting

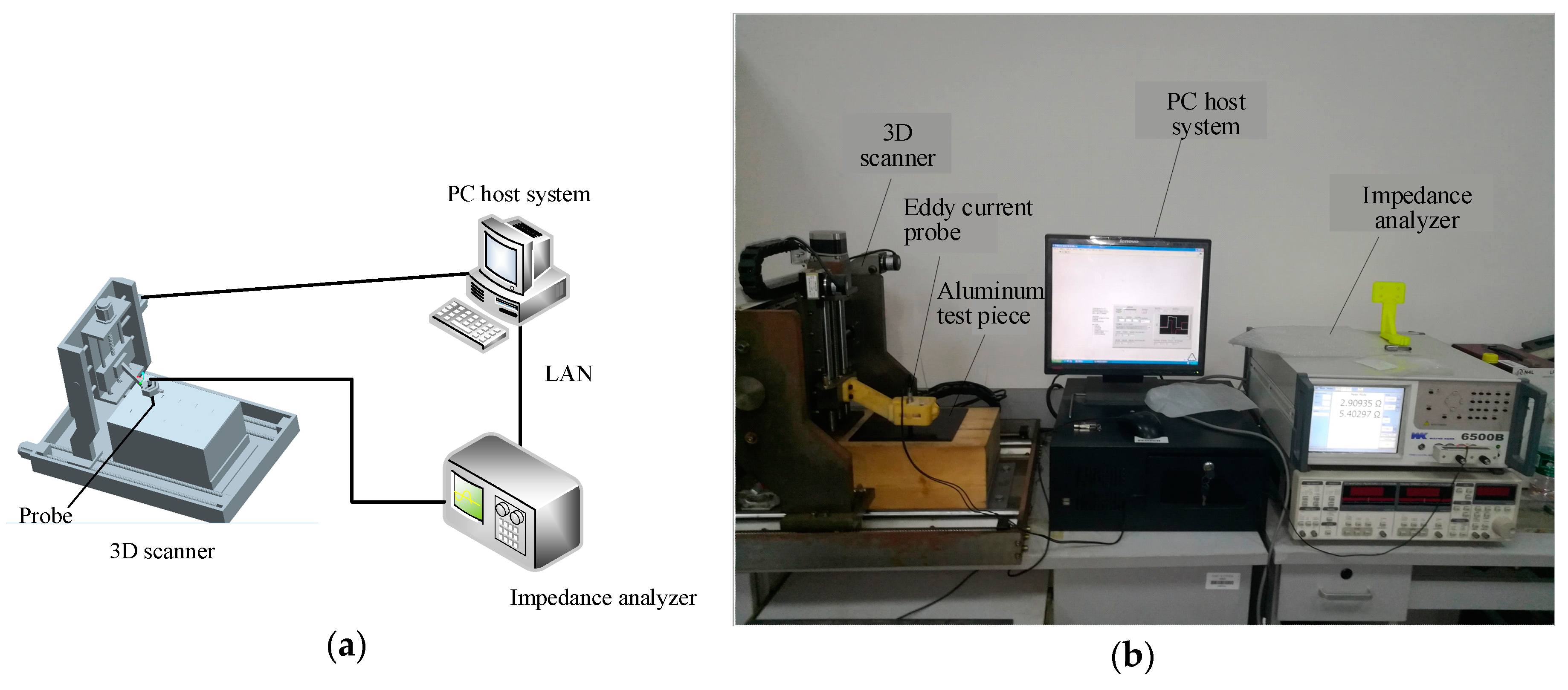

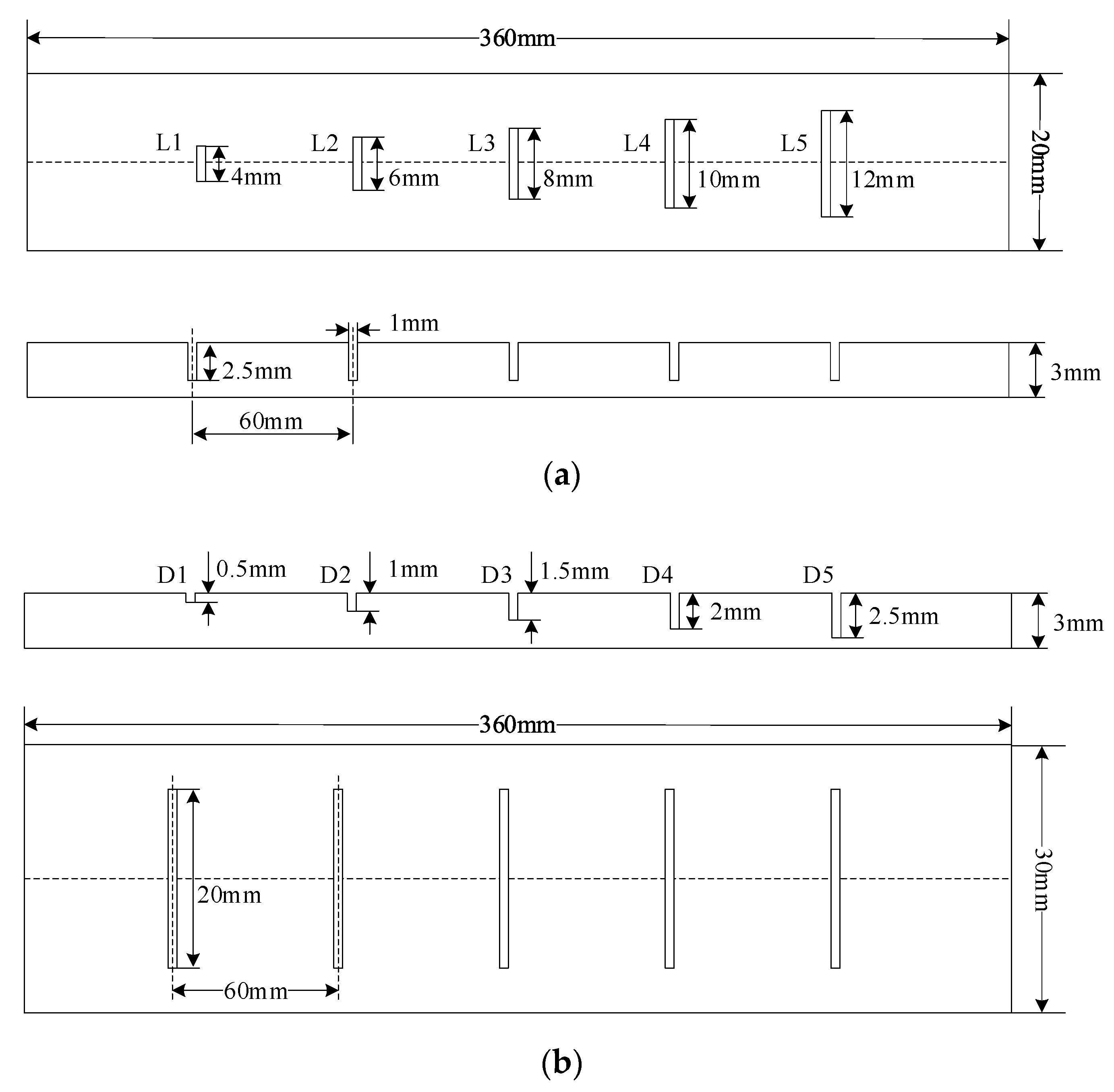

3. Experimental Setup and Materials

4. Results and Discussion

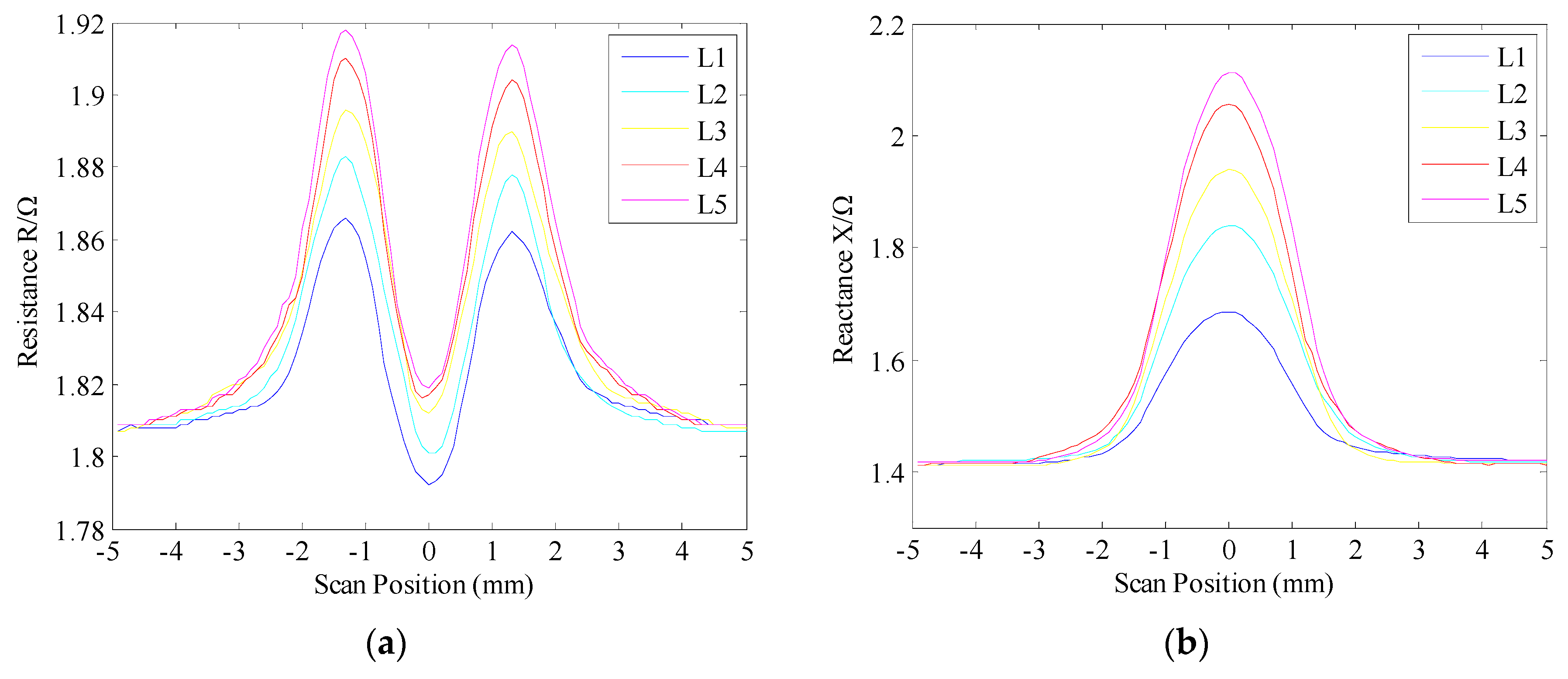

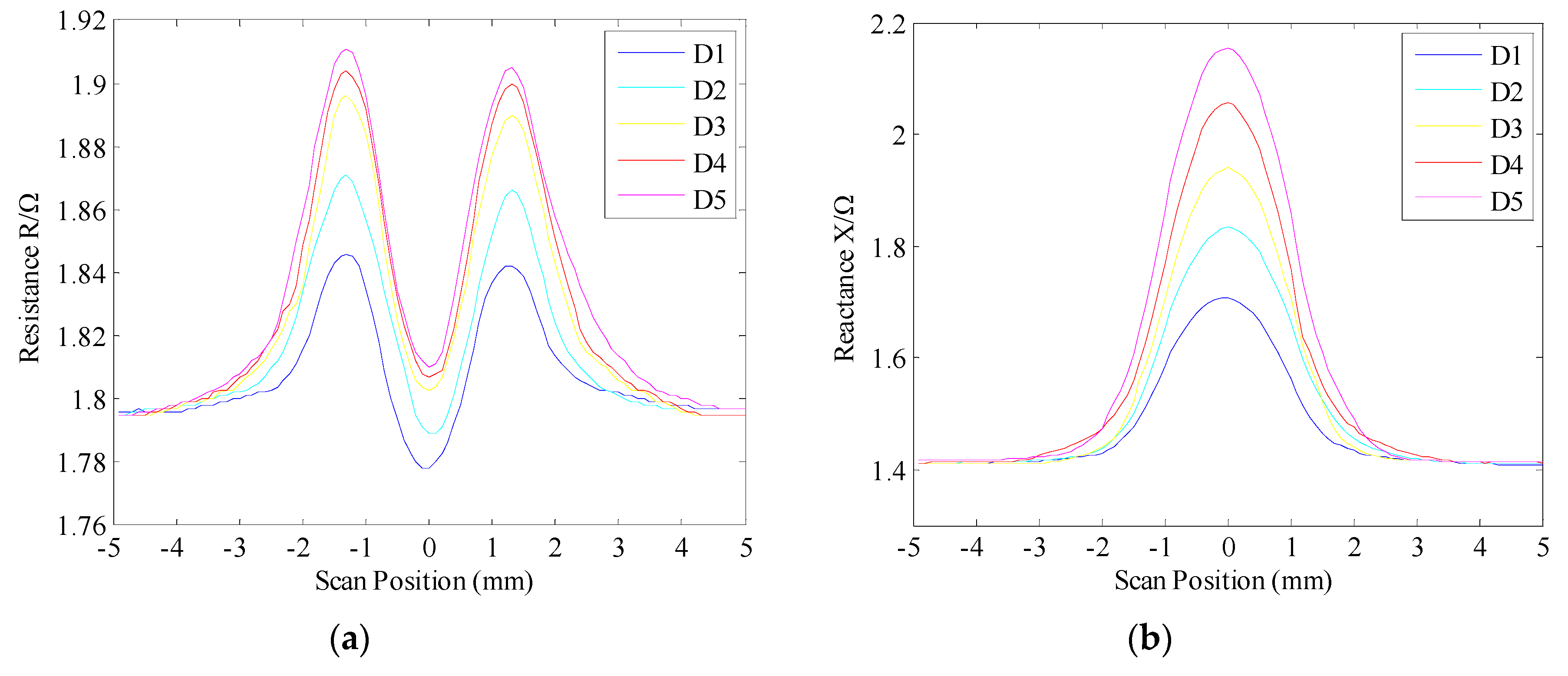

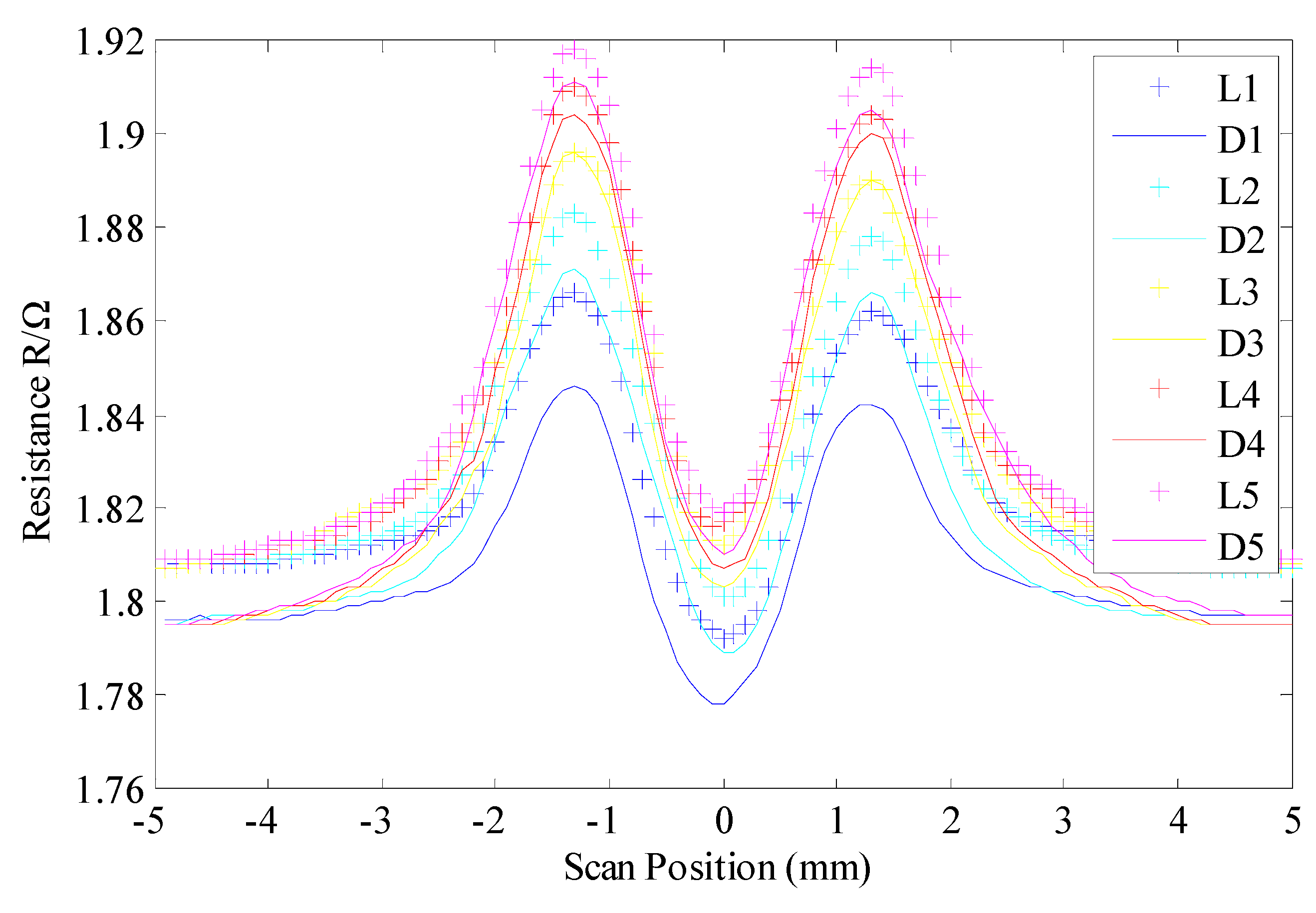

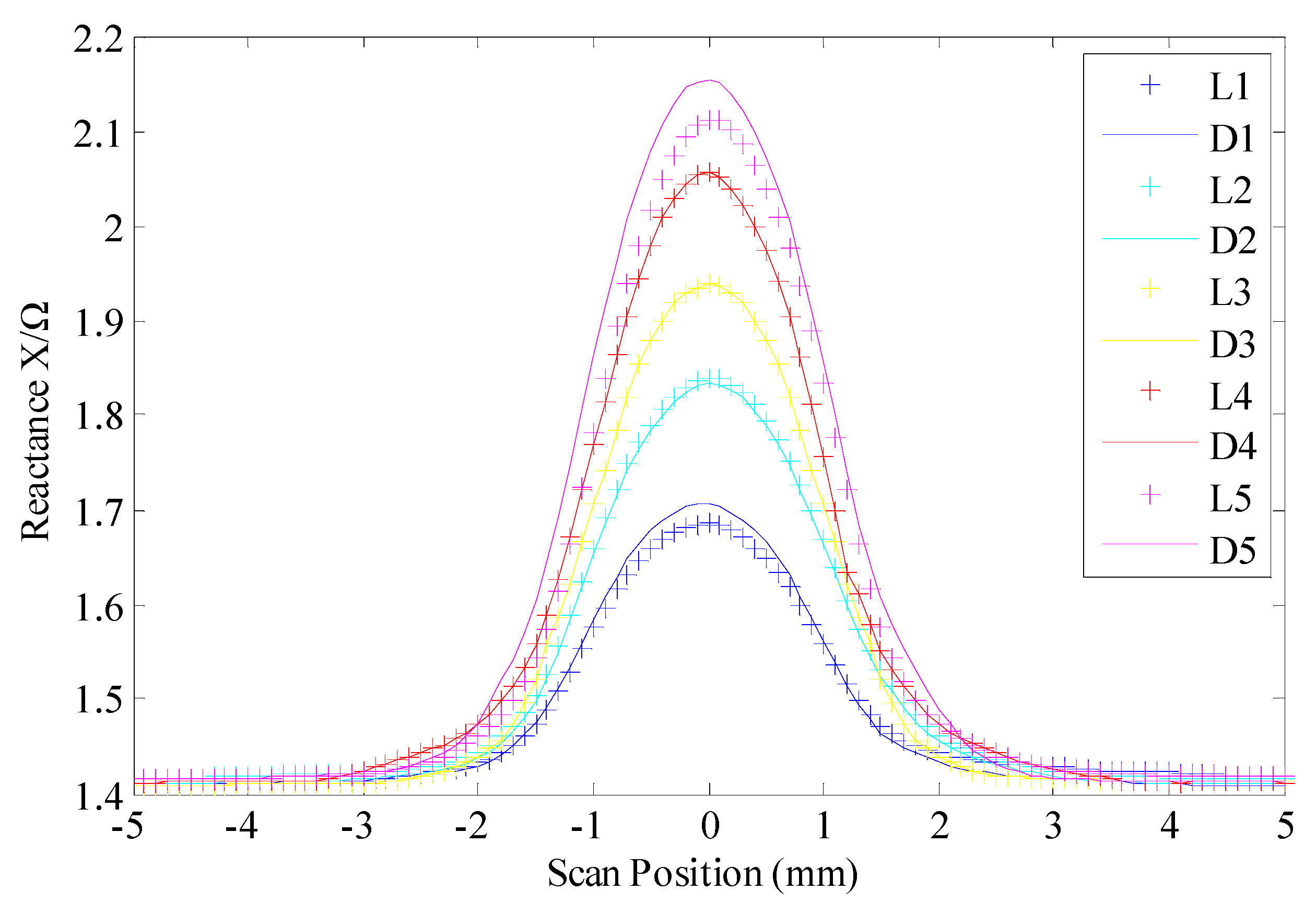

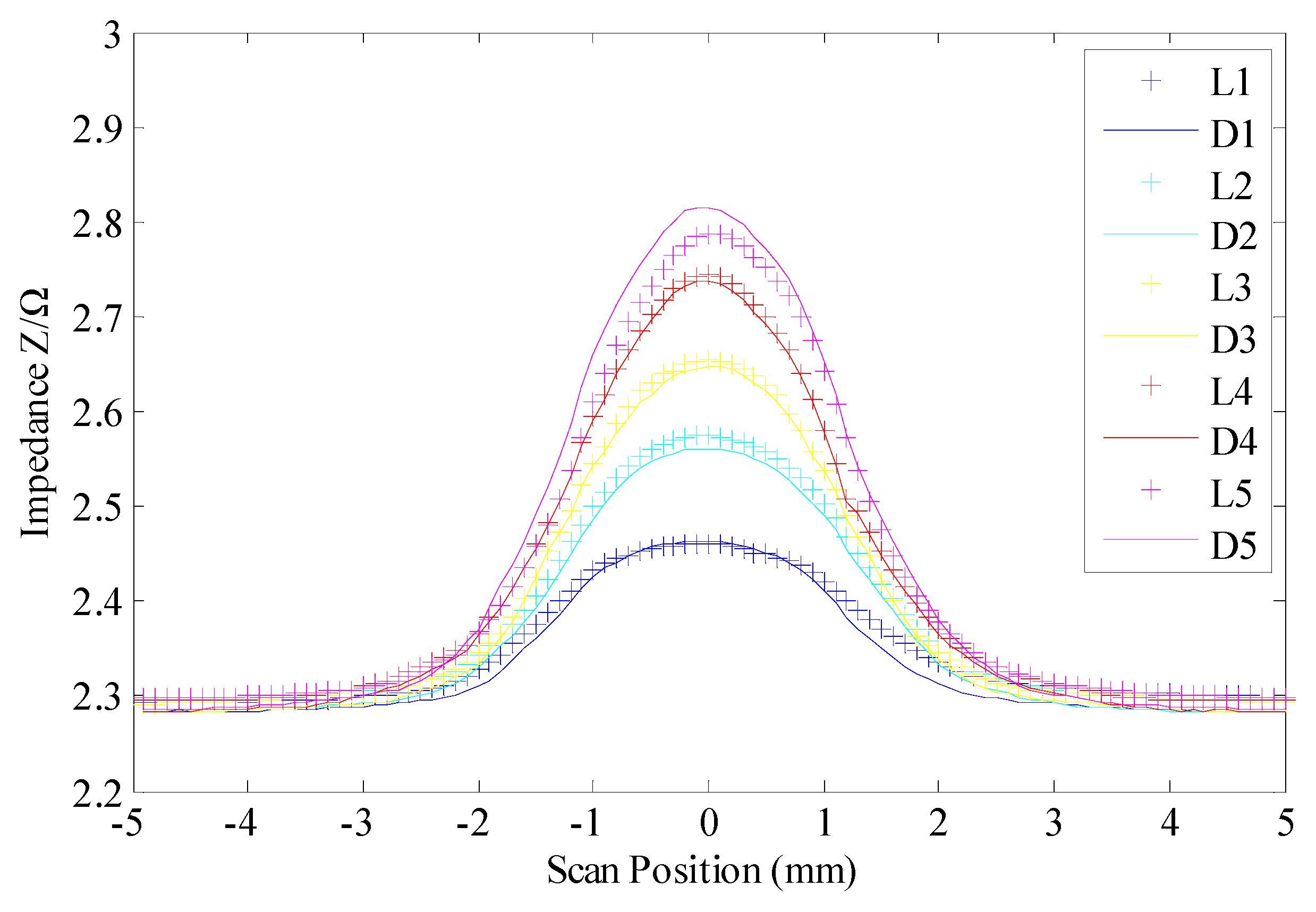

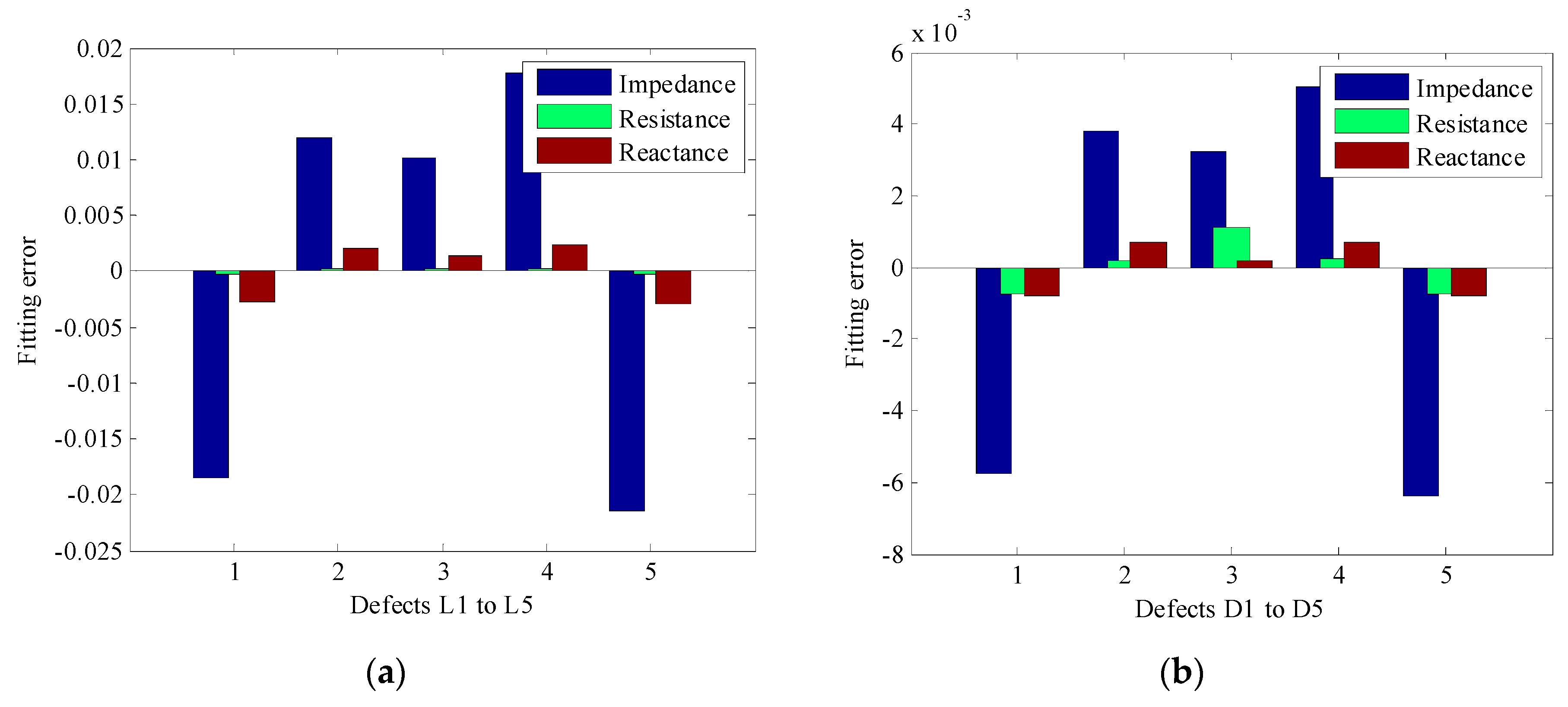

4.1. Original Signal Analysis

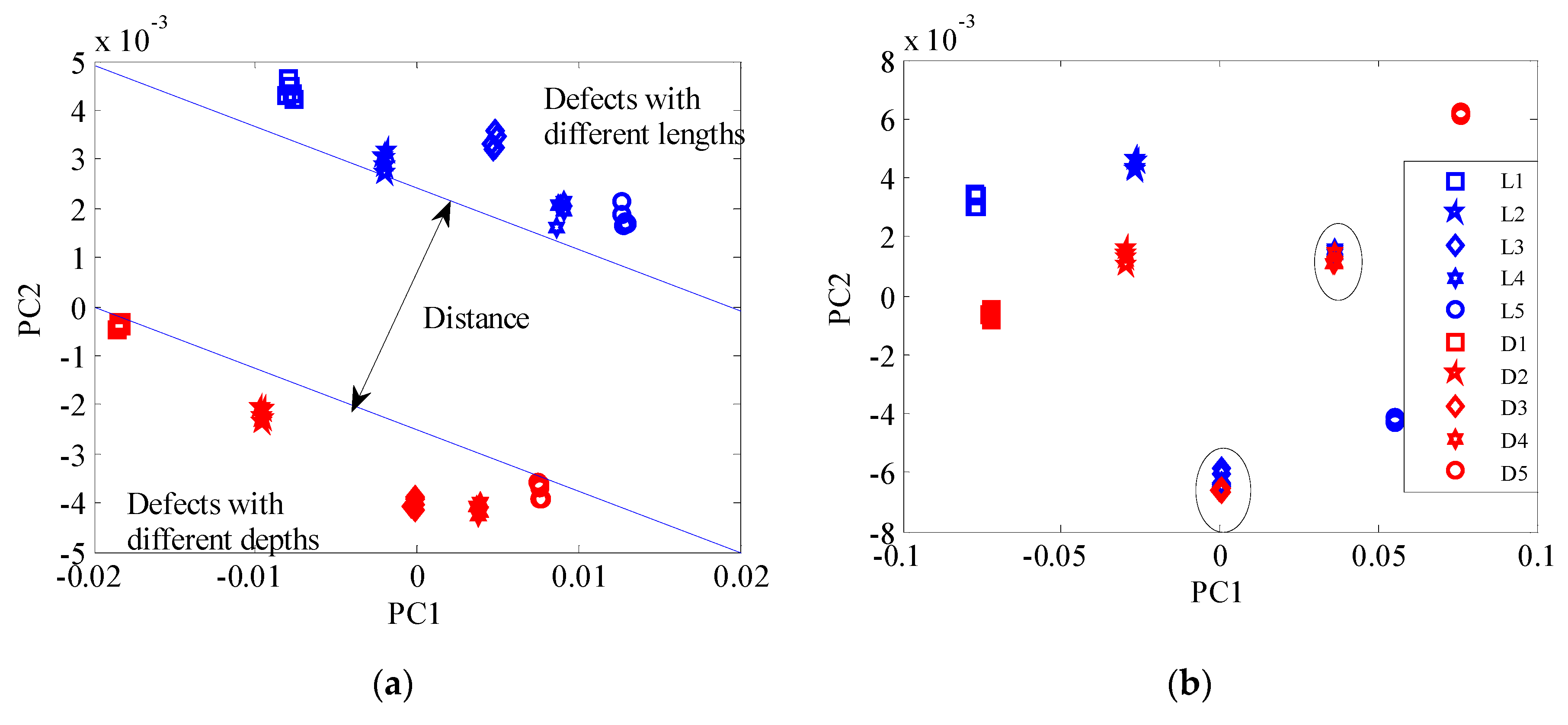

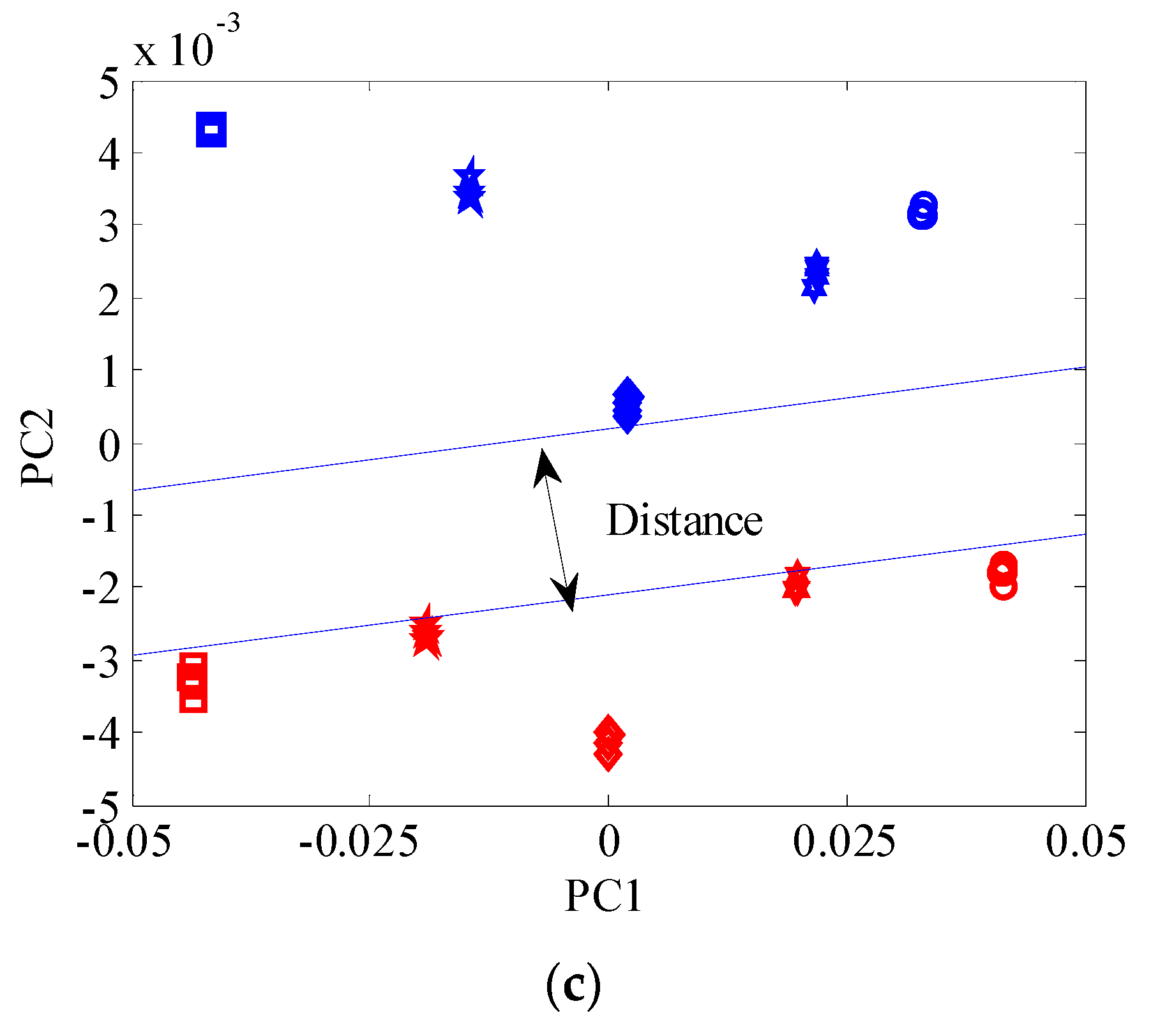

4.2. Feature Extraction and Classification

5. Conclusions and Future Work

- For the defective eddy current signals collected, the resistance signal has the farthest distance between different defects after feature extraction, followed by the impedance signal, while the reactance signal still has aliasing after feature extraction. Therefore, in the process of the eddy current detection of metal component defects, the analysis of resistance signals is more conducive to the identification and classification of defects.

- The method of feature extraction and classification of defective eddy current signals based on KPCA and ELM has a better practicability than traditional methods.

- In the process of fitting defects with linear least squares, the resistance and reactance signal are used to fit the length and depth defect, respectively, as their fitting errors are minimal.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, Y.; Luo, F.; Pan, M.; Weng, F.; Hu, X.; Gao, J.; Liu, B. Pulsed eddy current technique for defect detection in aircraft riveted structures. NDT E Int. 2010, 43, 176–181. [Google Scholar] [CrossRef]

- Angani, C.S.; Park, D.G.; Kim, C.G.; Leela, P.; Kollu, P.; Cheong, Y.M. The pulsed eddy current differential probe to detect a thickness variation in an insulated stainless steel. J. Nondestruct. Eval. 2010, 29, 248–252. [Google Scholar] [CrossRef]

- Yang, G.; Tamburrino, A.; Udpa, L.; Udpa, S.S.; Zeng, Z.; Deng, Y.; Que, P. Pulsed eddy-current based giant magnetoresistive system for the inspection of aircraft structures. IEEE Trans. Magn. 2010, 46, 910–917. [Google Scholar] [CrossRef]

- Miorelli, R.; Reboud, C.; Lesselier, D.; Theodoulidis, T. Eddy current modeling of narrow cracks in planar-layered metal structures. IEEE Trans. Magn. 2012, 48, 2551–2559. [Google Scholar] [CrossRef]

- Yang, R.; He, Y.; Zhang, H. Progress and trends in nondestructive testing and evaluation for wind turbine composite blade. Renew. Sustain. Energy Rev. 2016, 60, 1225–1250. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Burleigh, D.D. Review of pulsed thermal NDT: Physical principles, theory and data processing. NDT E Int. 2015, 73, 28–52. [Google Scholar] [CrossRef]

- Lee, K.H.; Baek, M.K.; Park, I.H. Estimation of deep defect in ferromagnetic material by low frequency eddy current method. IEEE Trans. Magn. 2012, 48, 3965–3968. [Google Scholar] [CrossRef]

- Wang, C.; Fan, M.; Cao, B.; Ye, B.; Li, W. Novel Noncontact Eddy Current Measurement of Electrical Conductivity. IEEE Sens. J. 2018, 18, 9352–9359. [Google Scholar] [CrossRef]

- Wen, D.; Fan, M.; Cao, B.; Ye, B.; Tian, G. Extraction of LOI Features From Spectral Pulsed Eddy Current Signals for Evaluation of Ferromagnetic Samples. IEEE Sens. J. 2019, 19, 189–195. [Google Scholar] [CrossRef]

- Ali, K.B.; Abdalla, A.N.; Rifai, D.; Faraj, M.A. Review on system development in eddy current testing and technique for defect classification and characterization. IET Circuits Devices Syst. 2017, 11, 330–343. [Google Scholar] [CrossRef]

- Bai, L.; Tian, G.Y.; Simm, A.; Tian, S.; Cheng, Y. Fast crack profile reconstruction using pulsed eddy current signals. NDT E Int. 2013, 54, 37–44. [Google Scholar] [CrossRef]

- Chen, H.; Wang, C.; Zuo, X. Research on methods of defect classification based on metal magnetic memory. NDT E Int. 2017, 92, 82–87. [Google Scholar] [CrossRef]

- Li, K.; Ma, Z.; Fu, P.; Krishnaswamy, S. Quantitative evaluation of surface crack depth with a scanning laser source based on particle swarm optimization-neural network. NDT E Int. 2018, 98, 208–214. [Google Scholar] [CrossRef]

- Rowshandel, H.; Nicholson, G.L.; Shen, J.L.; Davis, C.L. Characterisation of clustered cracks using an ACFM sensor and application of an artificial neural network. NDT E Int. 2018, 98, 80–88. [Google Scholar] [CrossRef]

- He, Y.; Pan, M.; Chen, D.; Luo, F. PEC defect automated classification in aircraft multi-ply structures with interlayer gaps and lift-offs. NDT E Int. 2013, 53, 39–46. [Google Scholar] [CrossRef]

- Chen, T.; Tian, G.Y.; Sophian, A.; Que, P.W. Feature extraction and selection for defect classification of pulsed eddy current NDT. NDT E Int. 2008, 41, 467–476. [Google Scholar] [CrossRef]

- Chen, X.; Hou, D.; Zhao, L.; Huang, P.; Zhang, G. Study on defect classification in multi-layer structures based on Fisher linear discriminate analysis by using pulsed eddy current technique. NDT E Int. 2014, 67, 46–54. [Google Scholar] [CrossRef]

- Peng, Y.; Qiu, X.; Wei, J.; Li, C.; Cui, X. Defect classification using PEC respones based on power spectral density analysis combined with EMD and EEMD. NDT E Int. 2016, 78, 37–51. [Google Scholar] [CrossRef]

- Rosado, L.S.; Janeiro, F.M.; Ramos, P.M.; Piedade, M. Defect Characterization with Eddy Current Testing Using Nonlinear-Regression Feature Extraction and Artificial Neural Networks. IEEE Trans. Instrum. Meas. 2013, 62, 1207–1214. [Google Scholar] [CrossRef]

- Postolache, O.; Ramos, H.G.; Ribeiro, A.L. Detection and characterization of defects using GMR probes and artificial neural networks. Comput. Stand. Interfaces 2011, 33, 191–200. [Google Scholar] [CrossRef]

- Hu, J.; Xu, W.; Gao, B.; Tian, G.; Wang, Y.; Wu, Y.; Yin, Y.; Chen, J. Pattern Deep Region Learning for Crack Detection in Thermography Diagnosis System. Metals 2018, 8, 612. [Google Scholar] [CrossRef]

- Xu, Y.; Ran, J.; Chen, H. Kohonen neural network classification for failure process of metallic organic coating in corrosion environment. Metals 2017, 7, 147. [Google Scholar]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhou, H.; Ding, X.; Zhang, R. Extreme learning machine for regression and multiclass classification. IEEE Trans. Syst. Man Cybern. Part B 2012, 42, 513–529. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cao, F.; Yuan, Y. A study on effectiveness of extreme learning machine. Neurocomputing 2011, 74, 2483–2490. [Google Scholar] [CrossRef]

- Schölkopf, B.; Smola, A.; Müller, K.R. Kernel principal component analysis. In International Conference on Artificial Neural Networks; Springer: Berlin/Heidelberg, Germany, 1997; pp. 583–588. [Google Scholar]

- Lee, J.M.; Yoo, C.; Choi, S.W.; Vanrolleghem, P.A.; Lee, I.B. Nonlinear process monitoring using kernel principal component analysis. Chem. Eng. Sci. 2004, 59, 223–234. [Google Scholar] [CrossRef]

- Ye, B.; Huang, P.; Fan, M.; Gong, X.; Hou, D.; Zhang, G.; Zhou, Z. Automatic classification of eddy current signals based on kernel methods. Nondestruct. Test. Eval. 2009, 24, 19–37. [Google Scholar] [CrossRef]

- Ding, S.; Zhao, H.; Zhang, Y.; Xu, X.; Nie, R. Extreme learning machine: Algorithm, theory and applications. Artif. Intell. Rev. 2015, 44, 103–115. [Google Scholar] [CrossRef]

- Fan, M.; Wang, Q.; Cao, B.; Ye, B.; Sunny, A.I.; Tian, G. Frequency optimization for enhancement of surface defect classification using the eddy current technique. Sensors 2016, 16, 649. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Inner diameter | 2.0 mm |

| Outer diameter | 2.4 mm |

| Distance between coil bottom and specimen surface | 1.0 mm |

| Distance between coil top and specimen surface | 6.0 mm |

| Lift-off (the gap between the coil and specimen) | 1.0 mm |

| Number of turns | 300 |

| Crack Defects | Specimen Parameters Length × Width × Thickness (mm3) | Defect Length (mm) | Defect Depth (mm) | Defect Width (mm) |

|---|---|---|---|---|

| L1 | 360 × 20 × 3 | 4 | 2.5 | 1.0 |

| L2 | 6 | |||

| L3 | 8 | |||

| L4 | 10 | |||

| L5 | 12 | |||

| D1 | 360 × 30 × 3 | 20 | 0.5 | 1.0 |

| D2 | 1.0 | |||

| D3 | 1.5 | |||

| D4 | 2.0 | |||

| D5 | 2.5 |

| Classifier | Accuracy Rates/% | ||

|---|---|---|---|

| Resistance | Reactance | Impedance | |

| Artificial Neural Network | 30 | 26 | 26 |

| Support Vector Machine | 35 | 30 | 29 |

| Extreme Learning Machine | 60 | 56 | 54 |

| Classifier | Accuracy Rate/% | ||

|---|---|---|---|

| Resistance | Reactance | Impedance | |

| Artificial Neural Network | 95 | 70 | 92 |

| Support Vector Machine | 98 | 75 | 96 |

| Extreme Learning Machine | 100 | 80 | 100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, W.; Ye, B.; Bao, J.; Huang, G.; Wu, J. Classification and Quantitative Evaluation of Eddy Current Based on Kernel-PCA and ELM for Defects in Metal Component. Metals 2019, 9, 155. https://doi.org/10.3390/met9020155

Deng W, Ye B, Bao J, Huang G, Wu J. Classification and Quantitative Evaluation of Eddy Current Based on Kernel-PCA and ELM for Defects in Metal Component. Metals. 2019; 9(2):155. https://doi.org/10.3390/met9020155

Chicago/Turabian StyleDeng, Weiquan, Bo Ye, Jun Bao, Guoyong Huang, and Jiande Wu. 2019. "Classification and Quantitative Evaluation of Eddy Current Based on Kernel-PCA and ELM for Defects in Metal Component" Metals 9, no. 2: 155. https://doi.org/10.3390/met9020155

APA StyleDeng, W., Ye, B., Bao, J., Huang, G., & Wu, J. (2019). Classification and Quantitative Evaluation of Eddy Current Based on Kernel-PCA and ELM for Defects in Metal Component. Metals, 9(2), 155. https://doi.org/10.3390/met9020155