Process Optimization on Multilayer Morphology During 316L Double-wire CMT+P Deposition Process

Abstract

1. Introduction

2. Materials and Methods

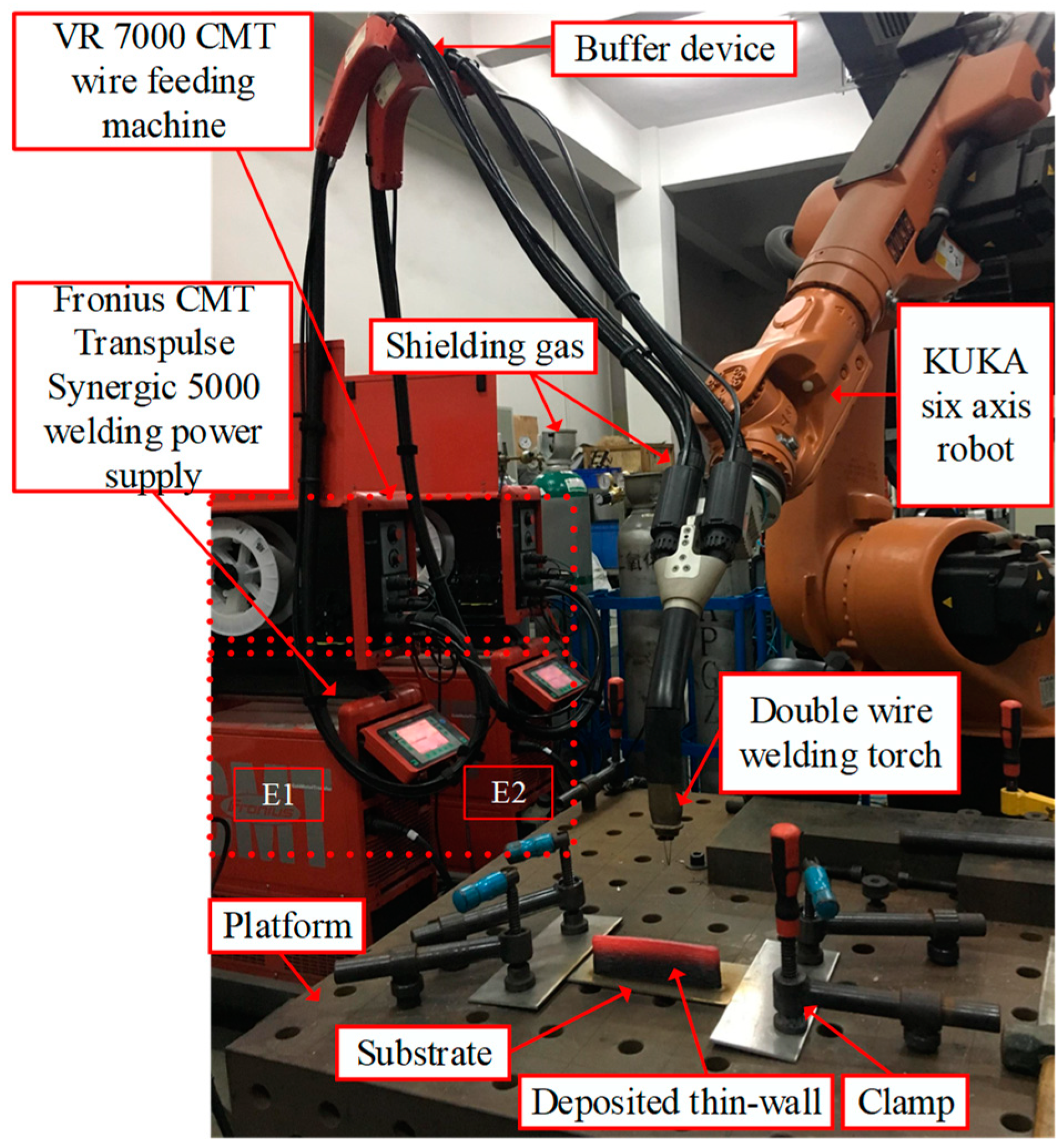

2.1. Test Materials and Equipment

2.2. Experiment Conditions

3. Results and Discussion

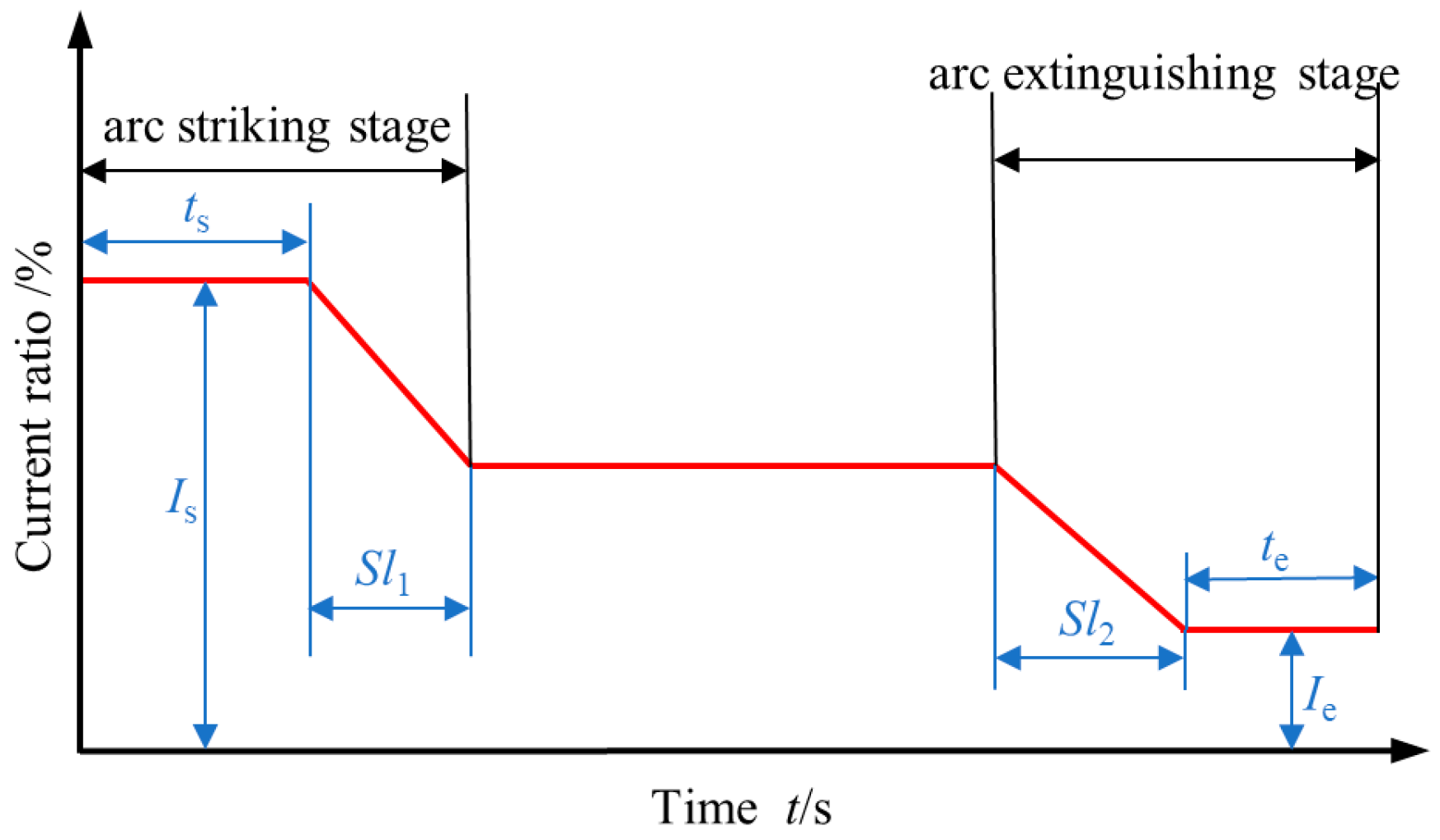

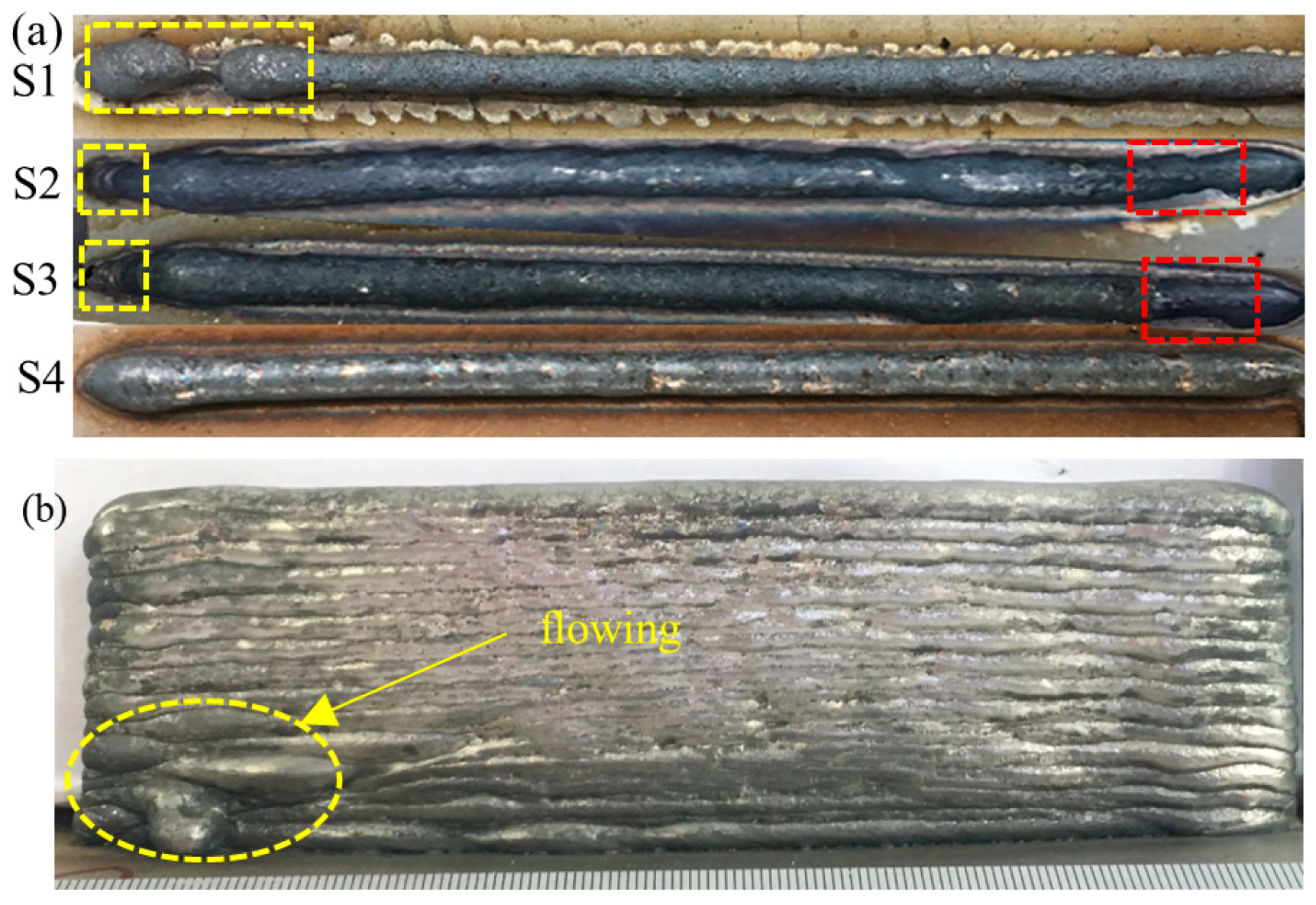

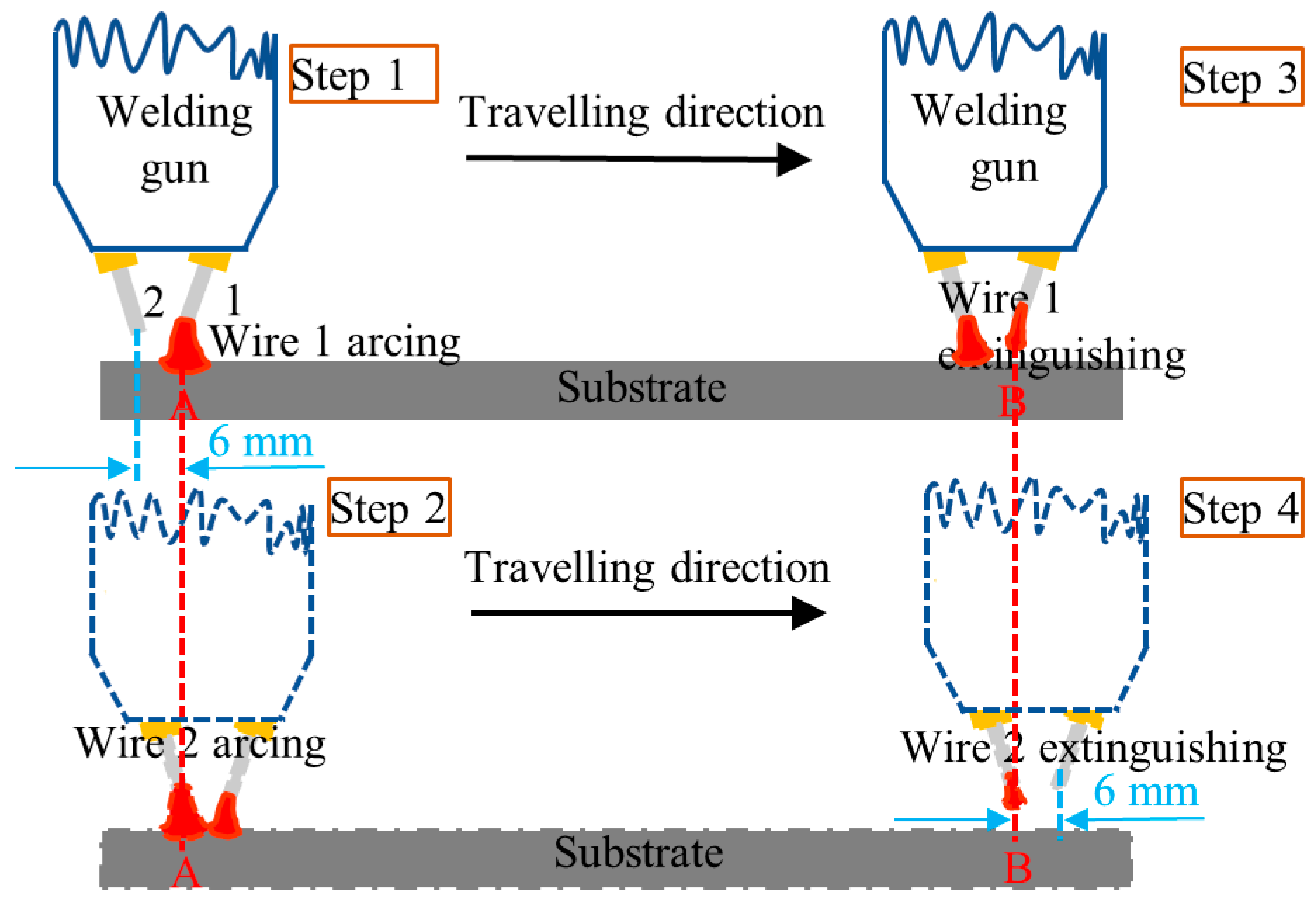

3.1. Arcing and Extinguishing Process Optimization of Double-Wire CMT Welding

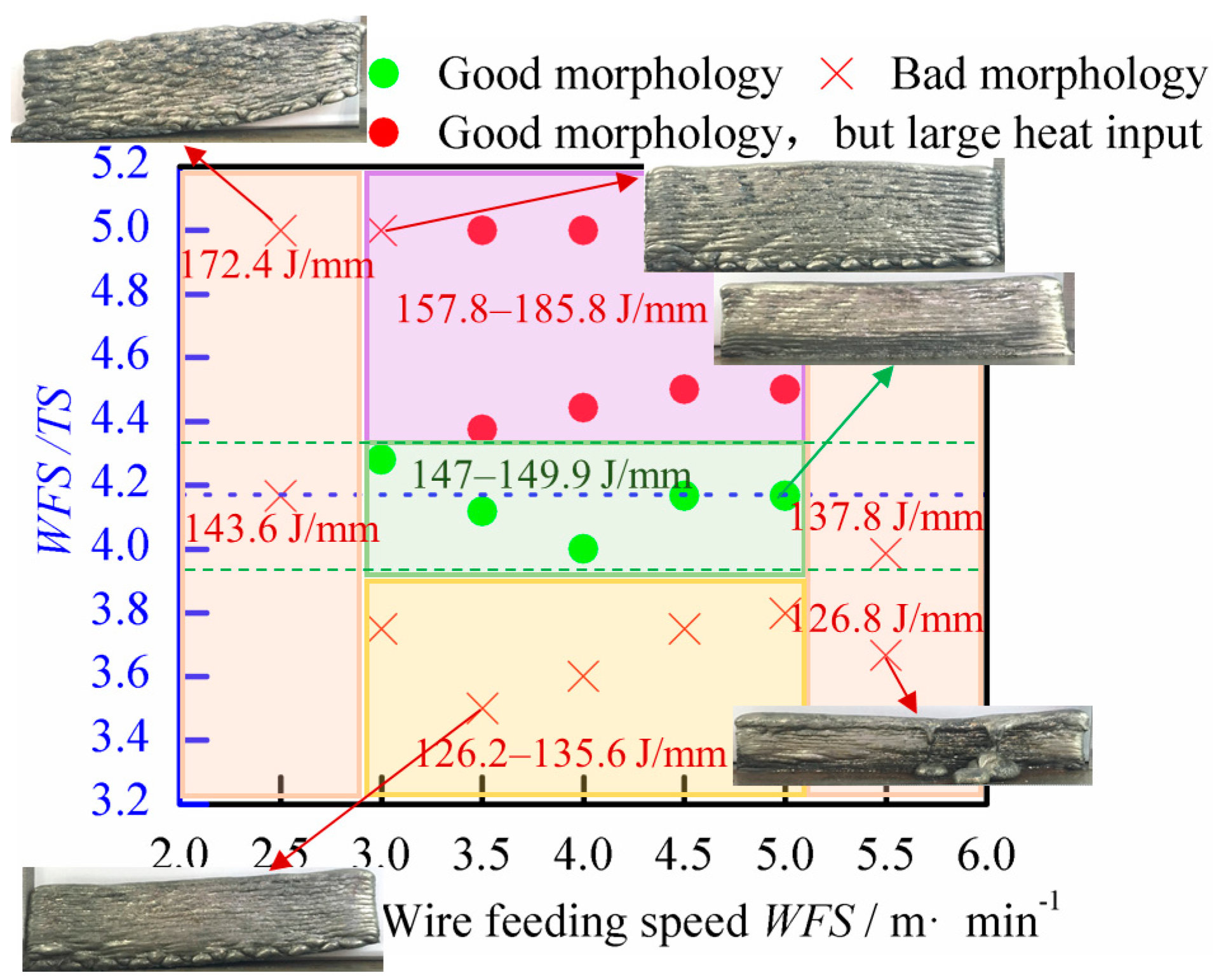

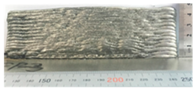

3.2. Morphology Optimization of Deposited Samples

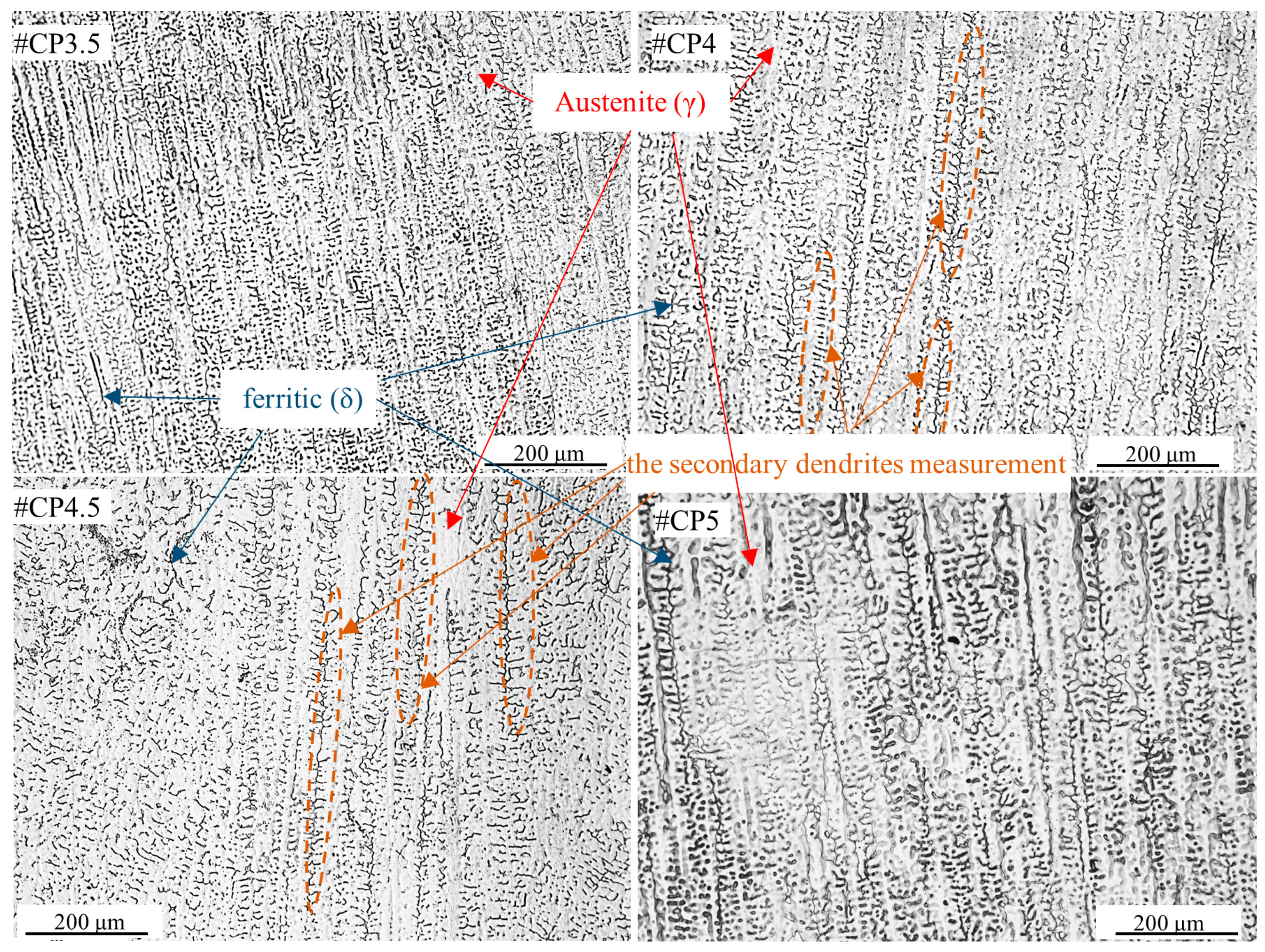

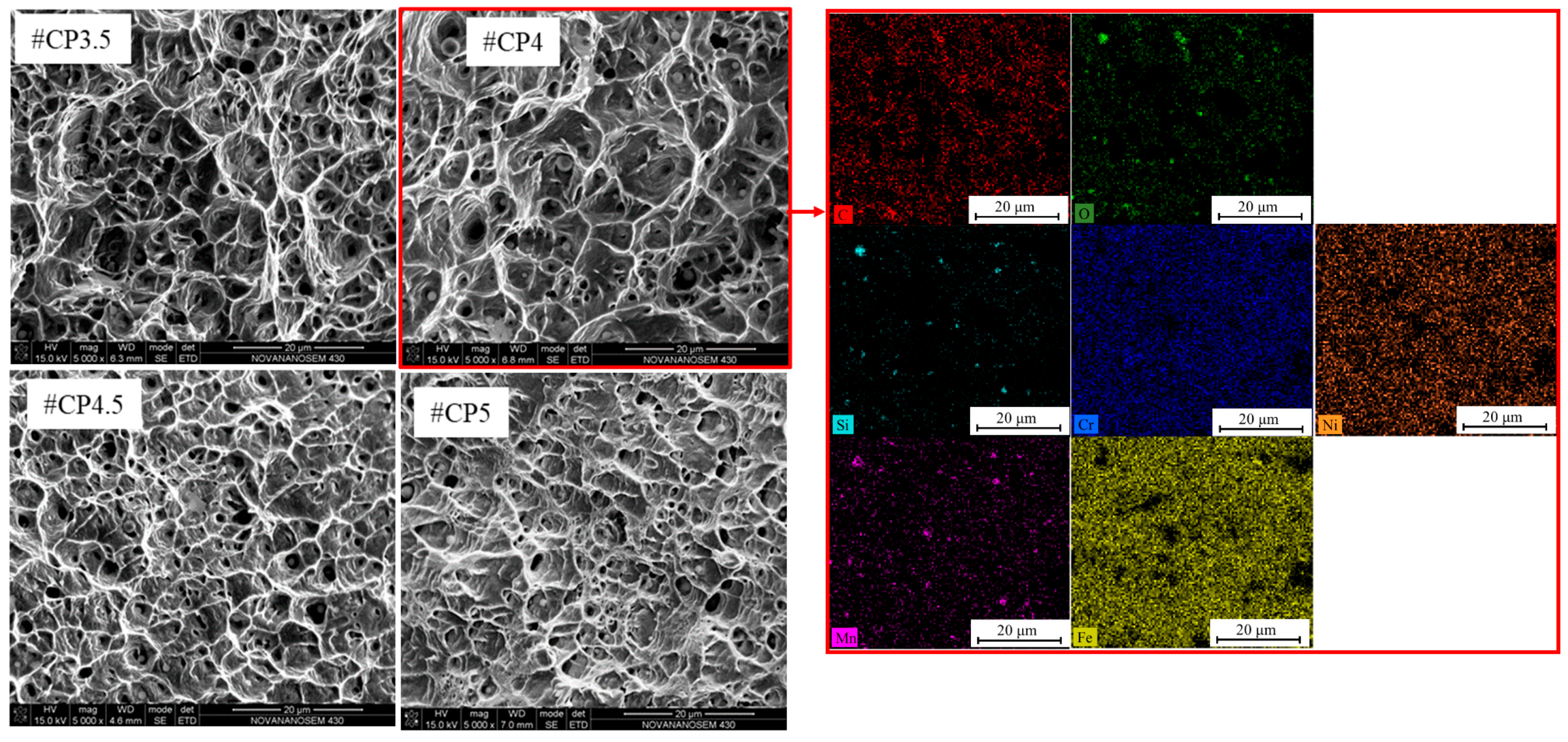

3.3. Microstructure of Deposited Samples

3.4. Comparison and Analysis of Mechanical Performance

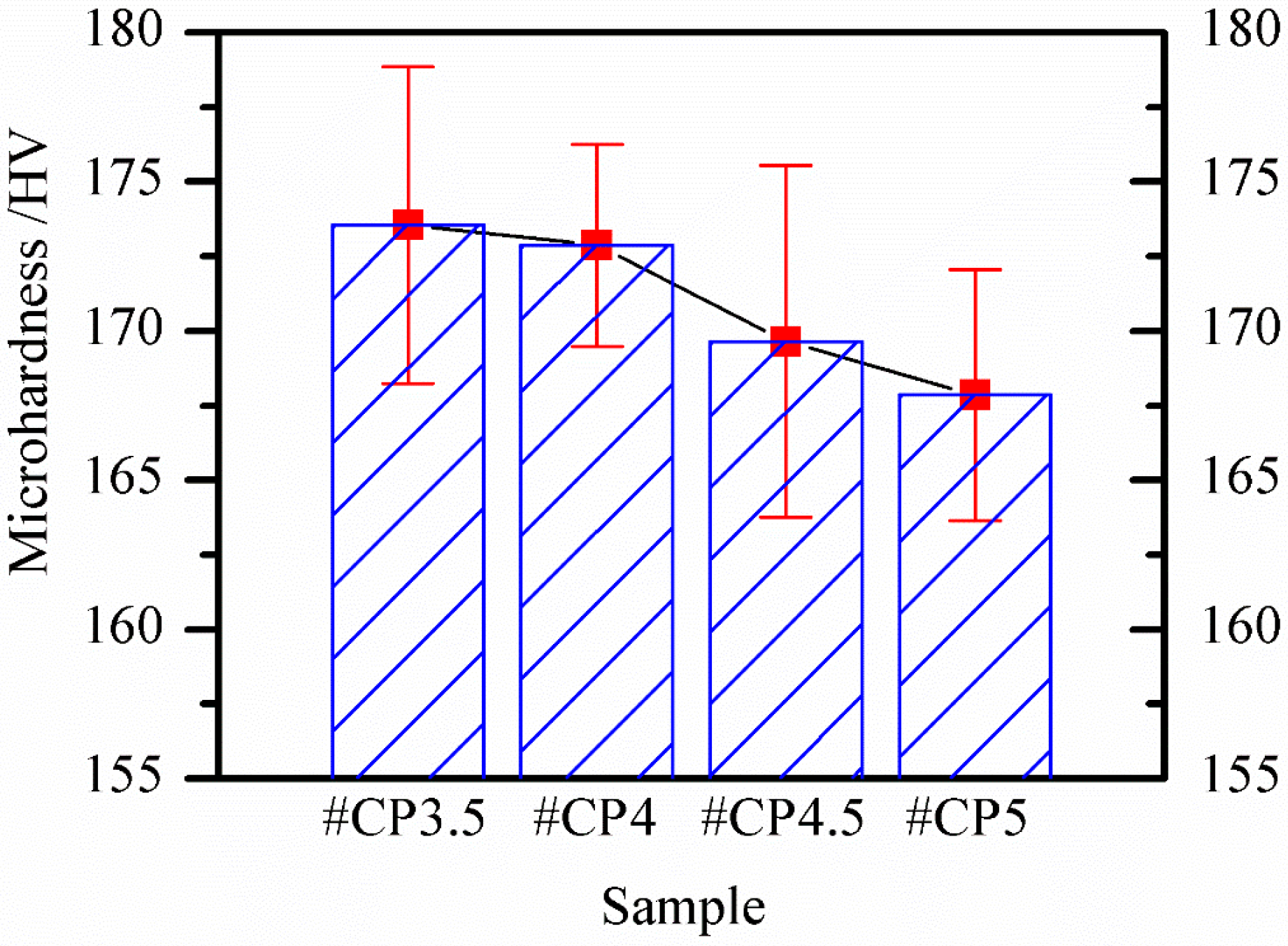

3.4.1. Microhardness Analysis

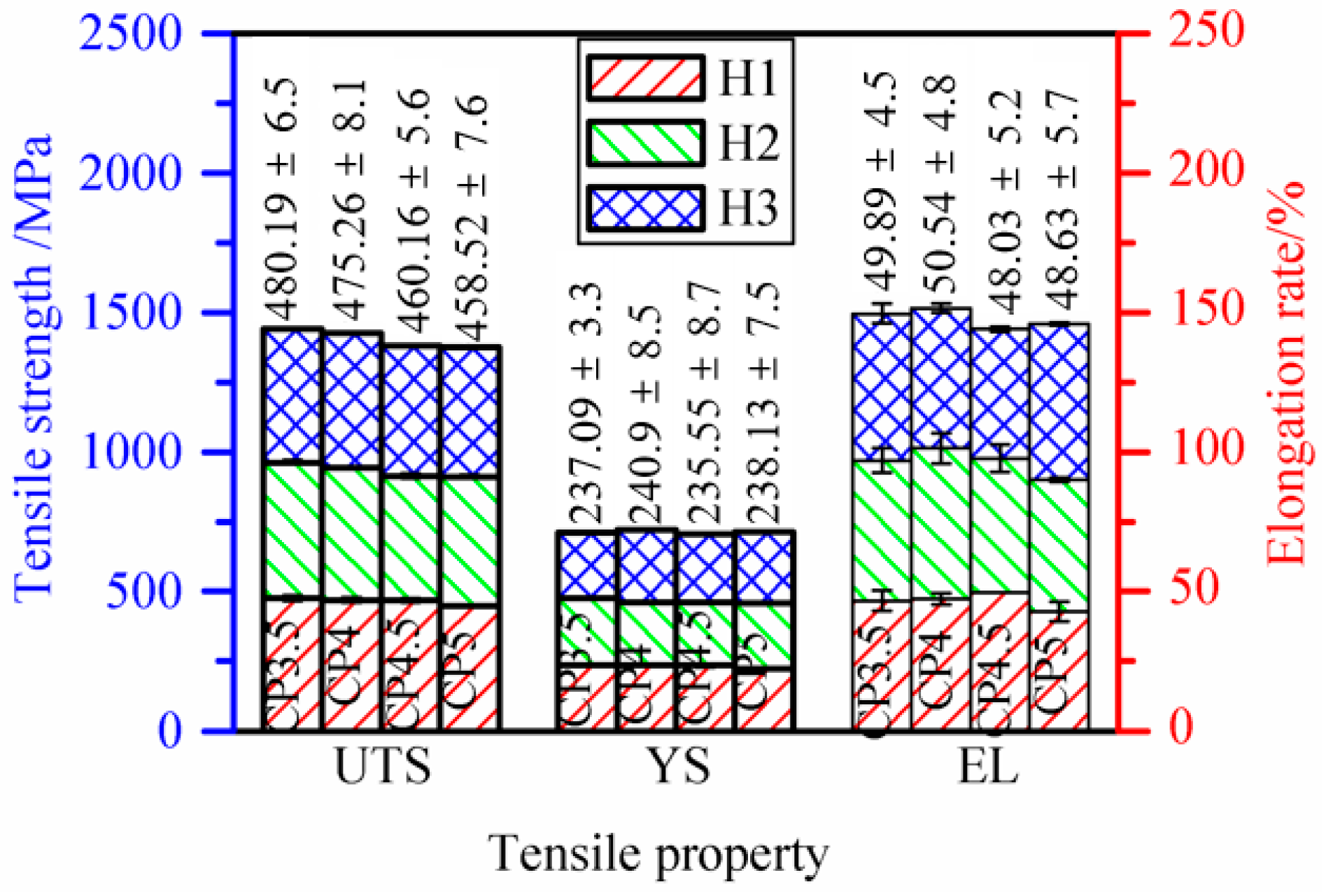

3.4.2. Tensile Properties Analysis

4. Conclusions

- The non-synchronous striking and extinguishing arc process adopted in double-wire and double-arc deposition could ensure two arcs starting and ending at the same point, which can improve the deposition morphology.

- The deposition forming was affected by the interaction of heat input and heat accumulation. The well-formed process of WFS by CMT+P process was in the range of 3–5 m/min. Along with the increase of WFS and TS, although the heat input was unchanged, the interval time between deposition points was shortened, which led to the increase of heat accumulation, and then decreased the height and increased the width of the depositions.

- The optimized WFS/TS ratio of each 316L welding wire during double-wire CMT+P deposition was about 4.2. The highest deposition rate could reach to 5.4 kg/h when the travelling speed was 120 cm/min.

- Increasing the wire feeding speed and the scanning speed could improve the deposition rate and keep the thermal input unchanged, but the influence of heat accumulation would result in coarse grain and slight decreasing mechanical property.

Author Contributions

Funding

Conflicts of Interest

References

- Almangour, B.; Grzesiak, D.; Borkar, T.; Yang, J.M. Densification behavior, microstructural evolution, and mechanical properties of TIC/316L stainless steel nanocomposites fabricated by selective laser melting. Mater. Des. 2018, 138, 119–128. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. In-process thermal treatment of polylactic acid in fused deposition modelling. Mater. Manuf. Processes 2019, 34, 701–713. [Google Scholar] [CrossRef]

- Kürnsteiner, P.; Wilms, M.B.; Weisheit, A.; Barriobero-Vila, P.; Jaegle, E.A.; Raabe, D. Massive nanoprecipitation in an Fe-19Ni- x Al maraging steel triggered by the intrinsic heat treatment during laser metal deposition. Acta Mater. 2017, 129, 52–60. [Google Scholar] [CrossRef]

- Pere, B.-V.; Joachim, G.; Andreas, S.; Norbert, S.; Jan, H.; Guillermo, R. Peritectic titanium alloys for 3D printing. Nat. Commun. 2018, 9, 3426. [Google Scholar] [CrossRef]

- Zhou, K.; Yao, P. Overview of recent advances of process analysis and quality control in resistance spot welding. Mech. Syst. Signal. Pr. 2019, 124, 170–198. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Pickin, C.G.; Young, K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 583–585. [Google Scholar] [CrossRef]

- Sequeira Almeida, P.M.; Williams, S.W. Innovative process model of Ti-6Al-4V additive layer manufacturing using Cold Metal Transfer (CMT). In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 1 January 2010. [Google Scholar]

- Yao, P.; Zhou, K.; Zhu, Q. Quantitative evaluation method of arc sound spectrum based on sample entropy. Mech. Syst. Signal. Pr. 2017, 92, 379–390. [Google Scholar] [CrossRef]

- Su, C.; Chen, X.; Gao, C.; Wang, Y. Effect of heat input on microstructure and mechanical properties of al-mg alloys fabricated by WAAM. Appl. Surf. Sci. 2019, 486, 431–440. [Google Scholar] [CrossRef]

- Gomez Ortega, A.; Corona Galvan, L.; Deschaux-Beaume, F.; Mezrag, B.; Rouquette, S. Effect of process parameters on the quality of aluminium alloy Al5Si deposits in wire and arc additive manufacturing using a cold metal transfer process. Sci. Technol. Weld. Join. 2017, 23, 316–332. [Google Scholar] [CrossRef]

- Kazanas, P.; Deherkar, P.; Almeida, P.; Lockett, H.; Williams, S. Fabrication of geometrical features using wire and arc additive manufacture. Proc. Inst. Mech. Eng. Part B 2012, 226, 1042–1051. [Google Scholar] [CrossRef]

- Xu, X.; Ding, J.; Ganguly, S.; Diao, C.; Williams, S. Preliminary Investigation of Building Strategies of Maraging Steel Bulk Material Using Wire + Arc Additive Manufacture. J. Mater. Eng. Perform. 2018, 28, 594–600. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3% Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Ayarkwa, K.F.; Williams, S.; Ding, J. Investigation of pulse advance cold metal transfer on aluminium wire arc additive manufacturing. Int. J. Rapid Manuf. 2015, 5, 44–57. [Google Scholar] [CrossRef]

- Qi, Z.; Qi, B.; Cong, B.; Sun, H.; Zhao, G.; Ding, J. Microstructure and mechanical properties of wire + arc additively manufactured 2024 aluminum alloy components: As-deposited and post heat-treated. J. Manuf. Processes 2019, 40, 27–36. [Google Scholar] [CrossRef]

- Yang, D.; Wang, G.; Zhang, G.A. Comparative study of GMAW- and DE-GMAW-based additive manufacturing techniques: Thermal behavior of the deposition process for thin-walled parts. Int. J. Adv. Manuf. Technol. 2016, 91, 2175–2184. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, P.; Chen, Y.; Male, A.T. Automated system for welding-based rapid prototyping. Mechatronics 2002, 12, 37–53. [Google Scholar] [CrossRef]

- Wu, W.; Xue, J.; Zhang, Z.; Yao, P. Comparative study of 316L depositions by two welding current processes. Mater. Manuf. Processes 2019, 34, 1502–1508. [Google Scholar] [CrossRef]

- Abioye, T.E.; Medrano-Tellez, A.; Farayibi, P.K.; Oke, P.K. Laser metal deposition of multi-track walls of 308LSi stainless steel. Mater. Manuf. Processes 2017, 32, 1660–1666. [Google Scholar] [CrossRef]

- Xiong, J. Forming Characteristics in Multi-Layer Single-Bead GMA Additive Manufacturing and Control for Deposition Dimension. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 1 June 2014. [Google Scholar]

- Wu, W.; Xue, J.; Wang, L.; Zhang, Z.; Hu, Y.; Dong, C. Forming Process, Microstructure, and Mechanical Properties of Thin-Walled 316L Stainless Steel Using Speed-Cold-Welding Additive Manufacturing. Metals 2019, 9, 109. [Google Scholar] [CrossRef]

- Liberini, M.; Astarita, A.; Campatelli, G.; Scippa, A.; Montevecchi, F.; Venturini, G. Selection of optimal process parameters for wire arc additive manufacturing. Procedia CIRP 2017, 62, 470–474. [Google Scholar] [CrossRef]

- Xu, X.; Mi, G.; Luo, Y.; Jiang, P.; Shao, X.; Wang, C. Morphologies, microstructures, and mechanical properties of samples produced using laser metal deposition with 316L stainless steel wire. Opt. Lasers Eng. 2017, 94, 1–11. [Google Scholar] [CrossRef]

- Iván, T.; Paskual, A.; Álvarez, P.; Suárez, A. Study on Arc Welding Processes for High Deposition Rate Additive Manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar] [CrossRef]

- Almangour, B.; Grzesiak, D.; Cheng, J.; Ertas, Y. Thermal behavior of the molten pool, microstructural evolution, and tribological performance during selective laser melting of TIC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Process. Technol. 2018, 257, 288–301. [Google Scholar] [CrossRef]

- ASTM A473-17a, Standard Specification for Stainless Steel Forgings; ASTM International: West Conshohocken, PA, USA, 2017.

| Sample | Deposition Current I/A | Deposition Voltage U/V | Wire Feed Speed WFS/m·min−1 | Traveling Speed TS/cm·min−1 | Heat Input Q/J·mm−1 |

|---|---|---|---|---|---|

| #CP2.5 | 65 | 13 | 2.5 | 60 | 143.6 |

| #CP3 | 73 | 14.1 | 3 | 70 | 149.9 |

| #CP3.5 | 80 | 15.1 | 3.5 | 85 | 148.6 |

| #CP4 | 90 | 16.2 | 4 | 100 | 148.8 |

| #CP4.5 | 96 | 16.5 | 4.5 | 108 | 149.6 |

| #CP5 | 103 | 16.8 | 5 | 120 | 147 |

| #CP5.5-138 | 109 | 17.1 | 5.5 | 138 | 137.8 |

| #CP5.5-150 | 150 | 126.8 |

| Sample | Is/% | ts/s | Sl1/s | Sl2/s | te/s | Ie/% |

|---|---|---|---|---|---|---|

| #S1 (Default) | 135 | off | 1 | 1 | off | 45 |

| #S2 (synchronous wires) | 120 | 1 | 1 | 1 | off | 45 |

| #S3 (synchronous wires) | 120 | 1 | 1 | 1.5 | off | 50 |

| #S4 (asynchronous wires) | 120 | 1 | 1 | 1.5 | off | 50 |

| Sample | Hot and Cold Regions of Samples after Deposition | Deposition Morphology | Heat Effect on the Back of Substrate |

|---|---|---|---|

| #CP2.5 |  |  |  |

| #CP3 |  |  |  |

| #CP3.5 |  |  |  |

| #CP4 |  |  |  |

| #CP4.5 |  |  |  |

| #CP5 |  |  |  |

| #CP5.5 |  |  |  |

| #CP5.5 |  |  |  |

| Tensile results | Sample | H1 | H2 | H3 | Average H |

|---|---|---|---|---|---|

| UTS/MPa | #CP3.5 | 477.42 ± 9.6 | 485.79 ± 8.4 | 477.35 ± 1.3 | 480.19 ± 6.5 |

| #CP4 | 470.08 ± 9.0 | 472.75 ± 4.1 | 482.93 ± 2.9 | 475.26 ± 8.1 | |

| #CP4.5 | 468.87 ± 8.1 | 445.4 ± 8.1 | 466.2 ± 2.5 | 460.16 ± 5.6 | |

| #CP5 | 450.39 ± 4.9 | 461.64 ± 6.1 | 463.53 ± 3.1 | 458.52 ± 7.6 | |

| YS/MPa | #CP3.5 | 236.81 ± 3.7 | 239.95 ± 0.6 | 234.53 ± 1.5 | 237.09 ± 3.3 |

| #CP4 | 236.0 ± 4.5 | 226.9 ± 1.6 | 259.79 ± 5.4 | 240.9 ± 8.5 | |

| #CP4.5 | 234.53 ± 6.0 | 226.91 ± 4.6 | 245.23 ± 1.5 | 235.55 ± 8.7 | |

| #CP5 | 222.35 ± 1.6 | 236.92 ± 2.3 | 255.13 ± 2.3 | 238.13 ± 7.5 | |

| EL/ % | #CP3.5 | 46.76 ± 3.5 | 50.15 ± 4.4 | 52.76 ± 3.5 | 49.89 ± 4.5 |

| #CP4 | 47.31 ± 2.0 | 54.06 ± 5.4 | 50.26 ± 1.7 | 50.54 ± 4.8 | |

| #CP4.5 | 49.5 ± 0 | 48.23 ± 4.8 | 46.36 ± 0.8 | 48.03 ± 5.2 | |

| #CP5 | 42.84 ± 3.6 | 47.36 ± 0.7 | 55.7 ± 0.5 | 48.63 ± 5.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Xue, J.; Zhang, Z.; Ren, X.; Xie, B. Process Optimization on Multilayer Morphology During 316L Double-wire CMT+P Deposition Process. Metals 2019, 9, 1334. https://doi.org/10.3390/met9121334

Wu W, Xue J, Zhang Z, Ren X, Xie B. Process Optimization on Multilayer Morphology During 316L Double-wire CMT+P Deposition Process. Metals. 2019; 9(12):1334. https://doi.org/10.3390/met9121334

Chicago/Turabian StyleWu, Wei, Jiaxiang Xue, Zhanhui Zhang, Xianghui Ren, and Bin Xie. 2019. "Process Optimization on Multilayer Morphology During 316L Double-wire CMT+P Deposition Process" Metals 9, no. 12: 1334. https://doi.org/10.3390/met9121334

APA StyleWu, W., Xue, J., Zhang, Z., Ren, X., & Xie, B. (2019). Process Optimization on Multilayer Morphology During 316L Double-wire CMT+P Deposition Process. Metals, 9(12), 1334. https://doi.org/10.3390/met9121334