Numerical Modeling and Experimental Verification for High-Speed Forming of Al5052 with Single Current Pulse

Abstract

1. Introduction

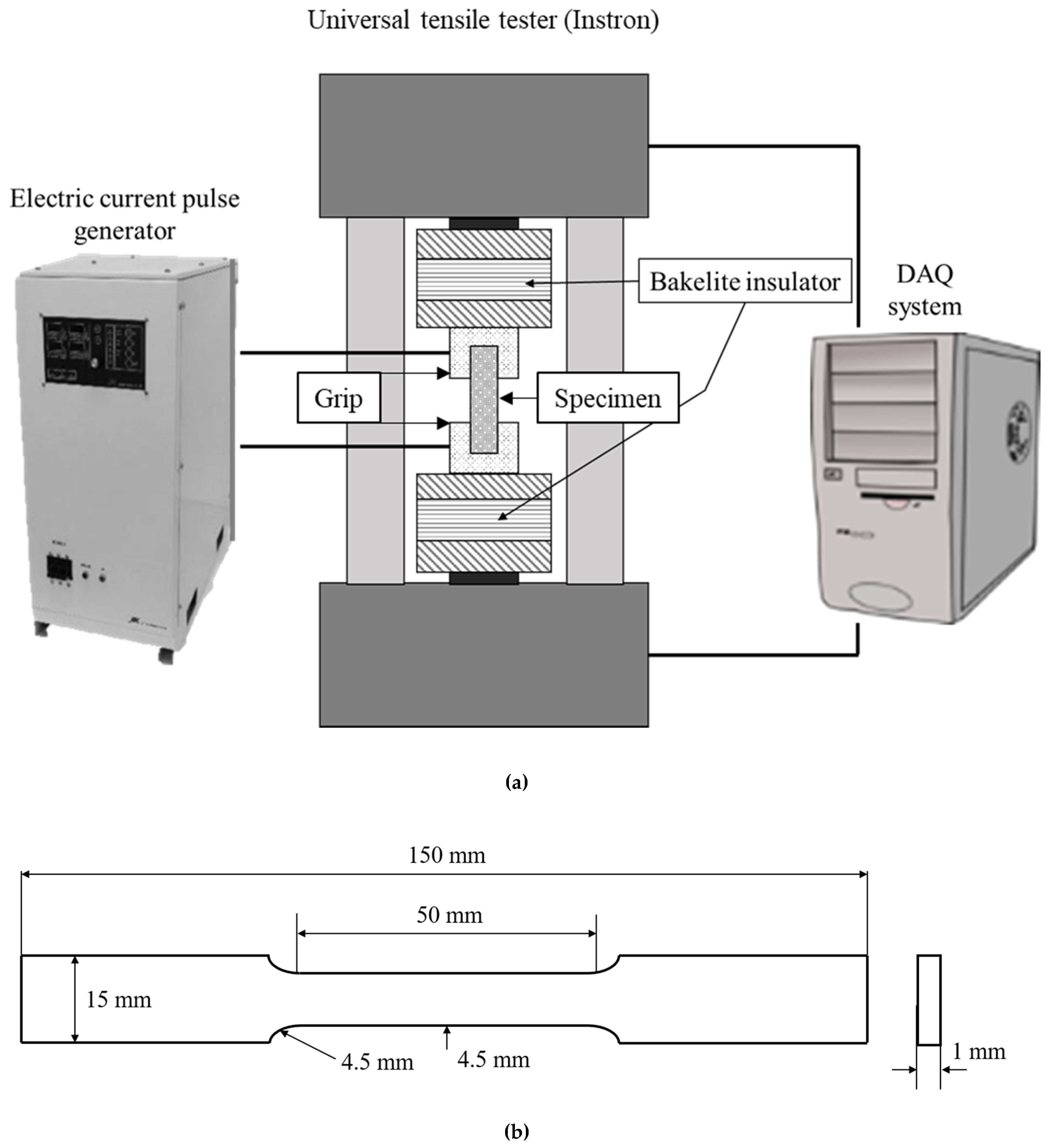

2. Uniaxial Tension Test with Electric Current Pulse

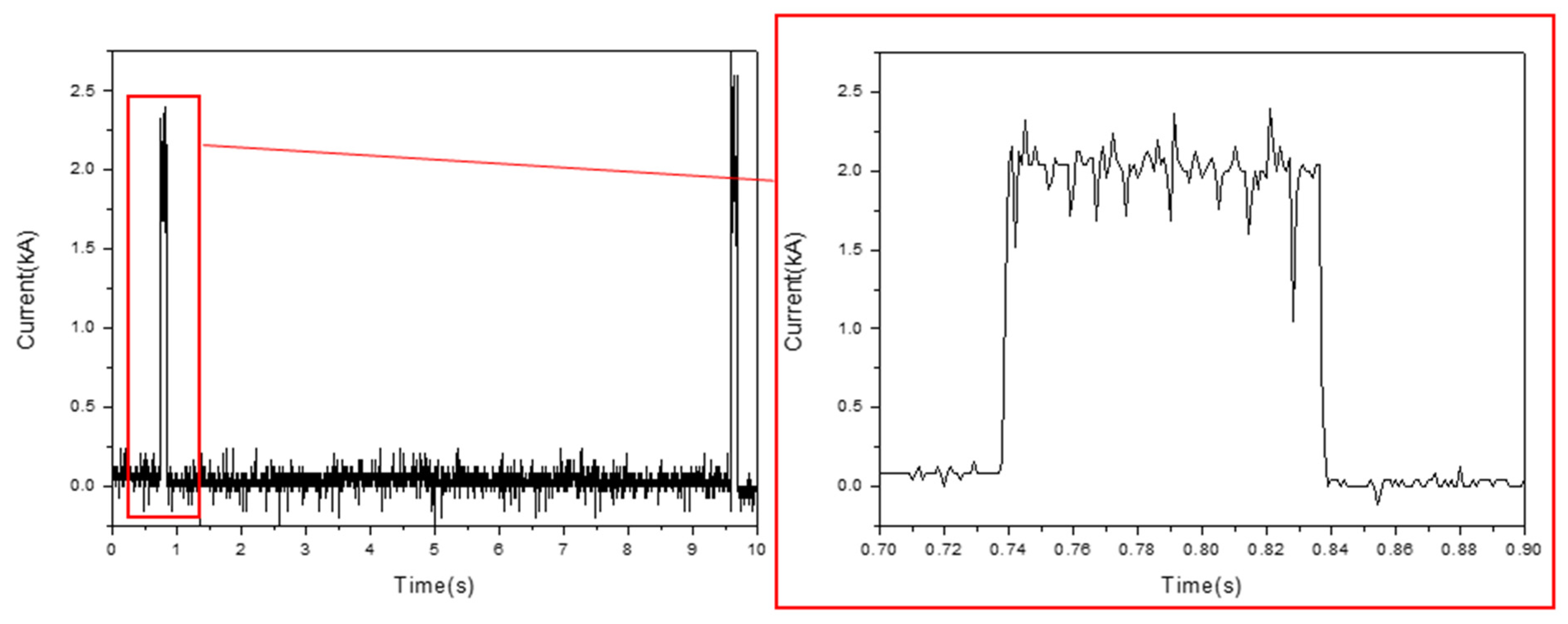

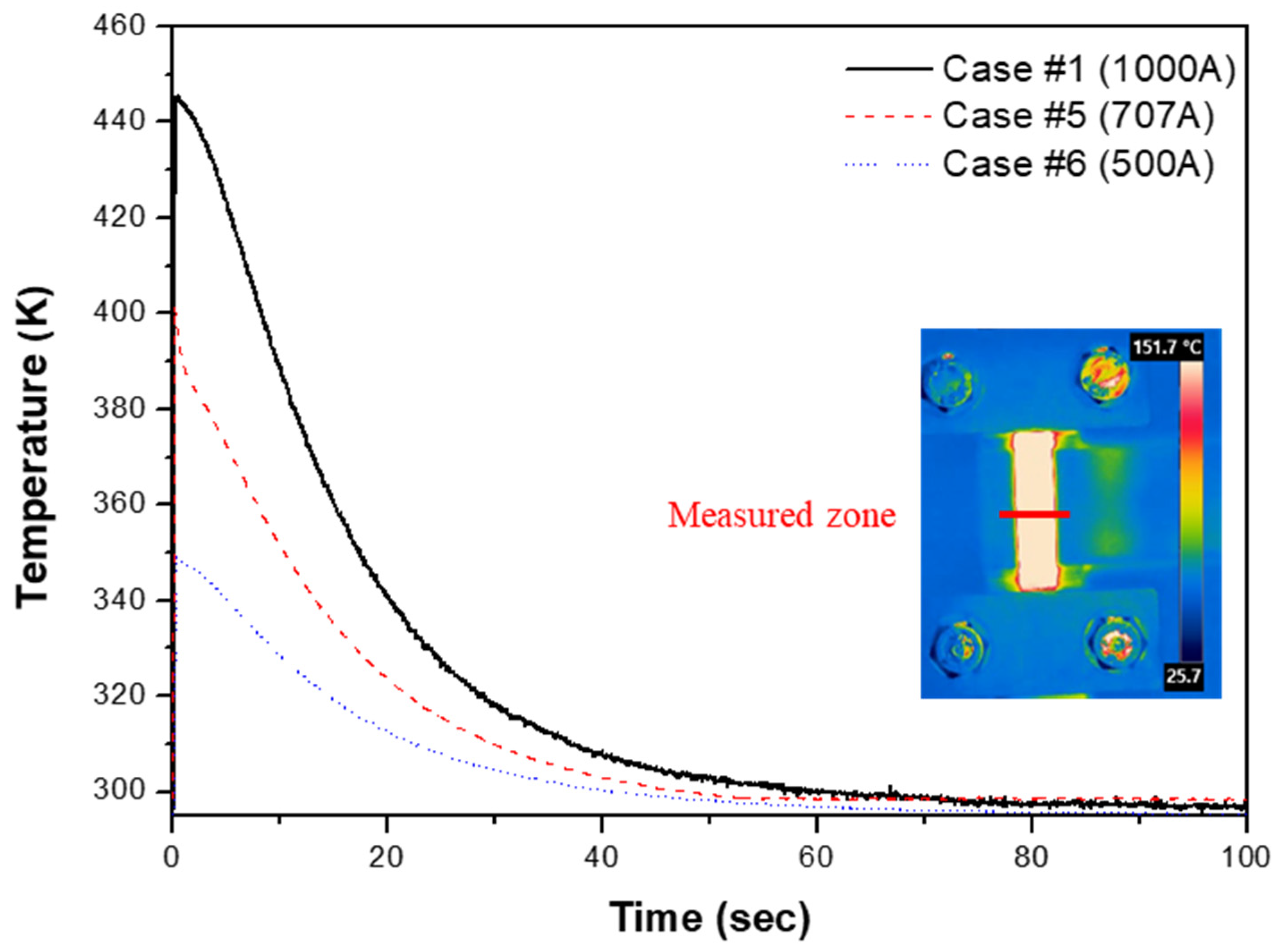

2.1. Experimental Conditions

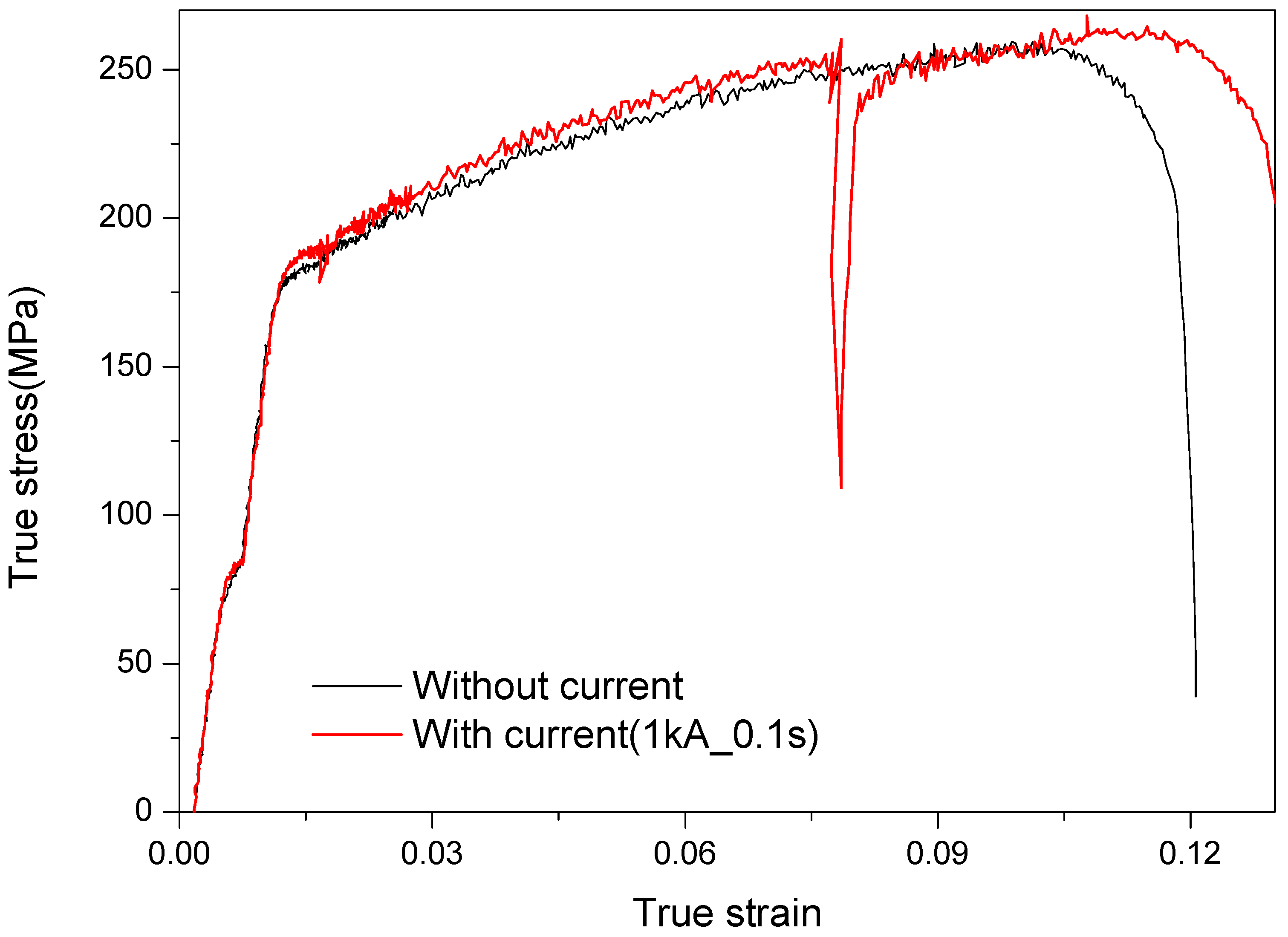

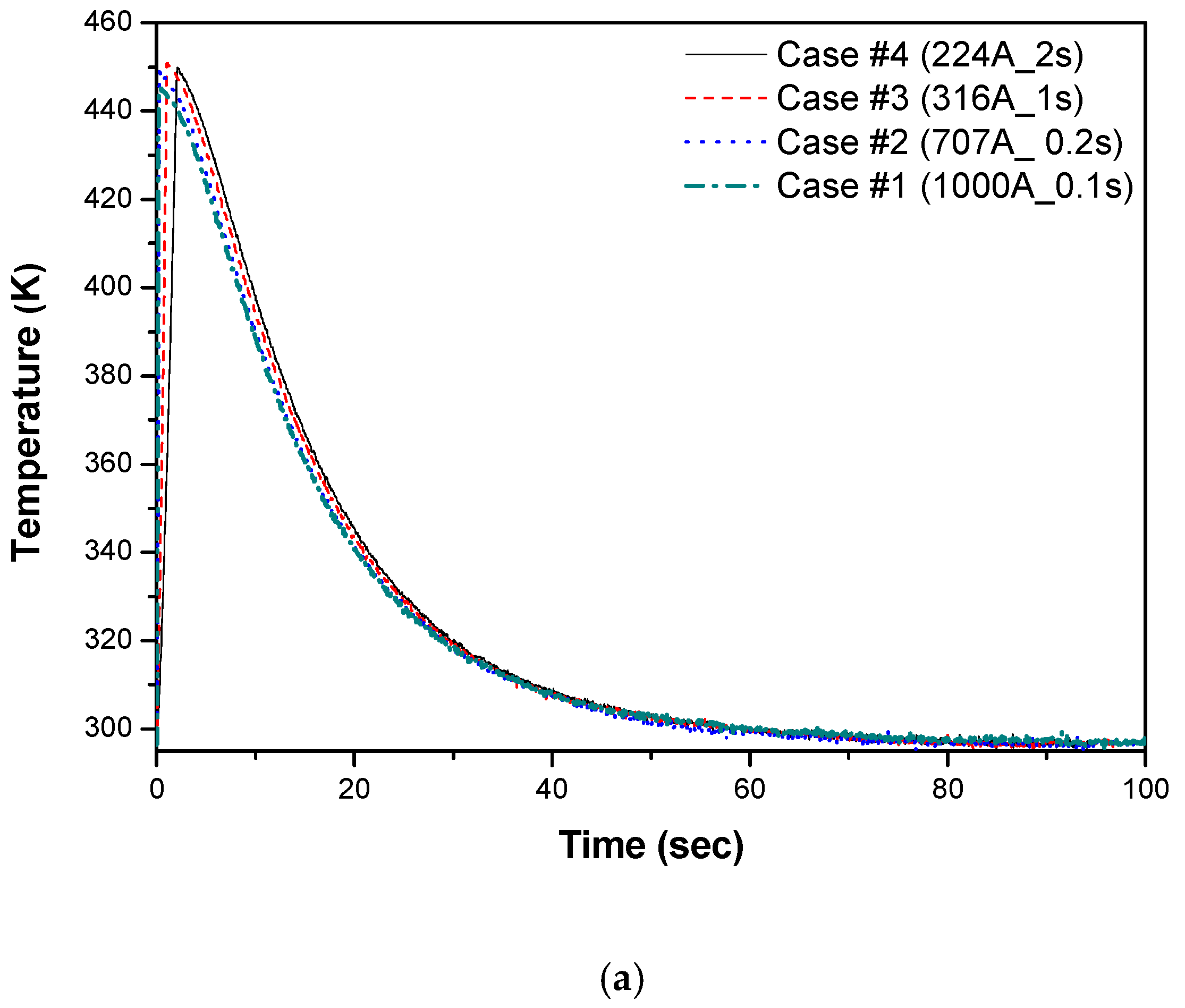

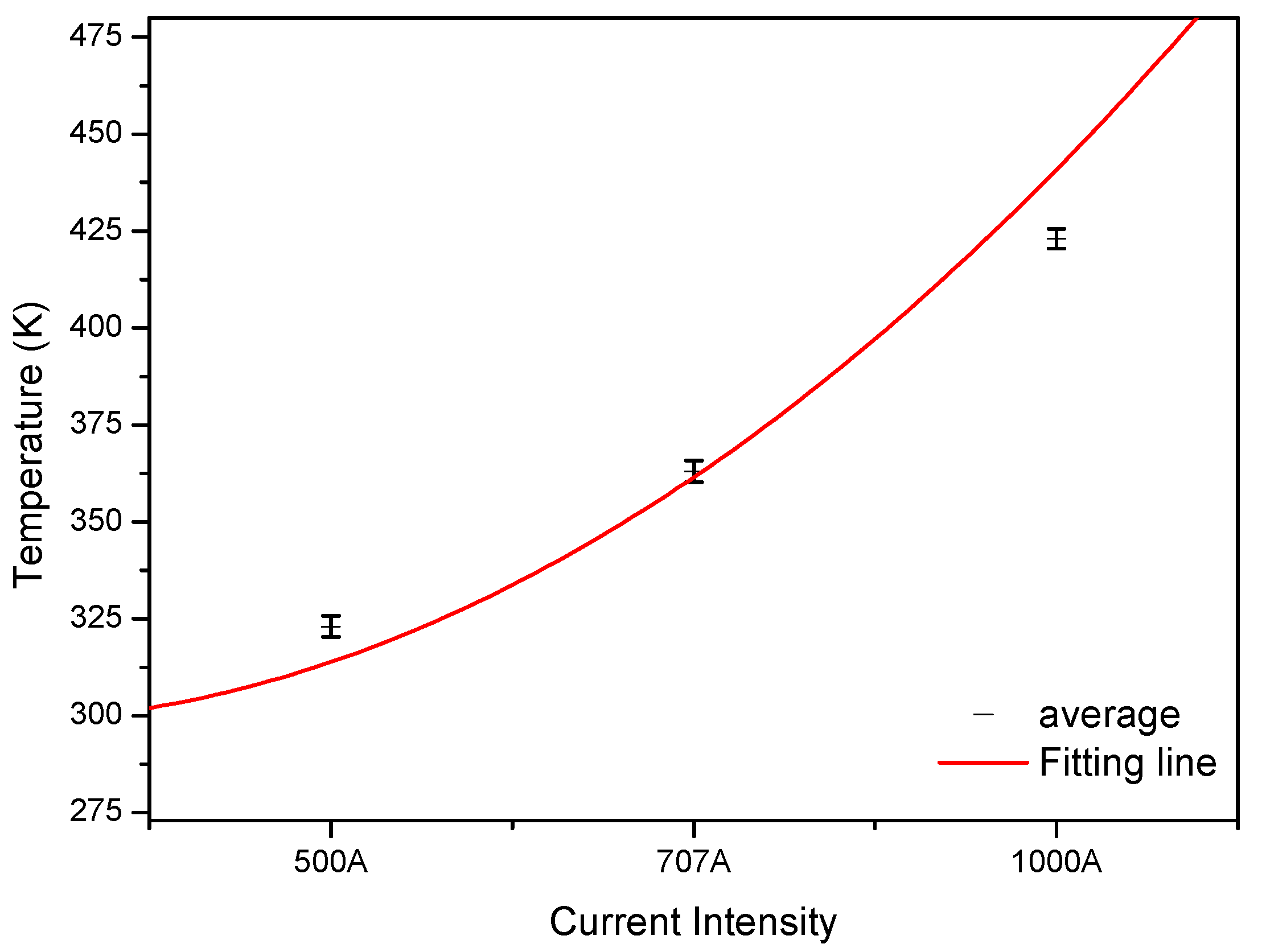

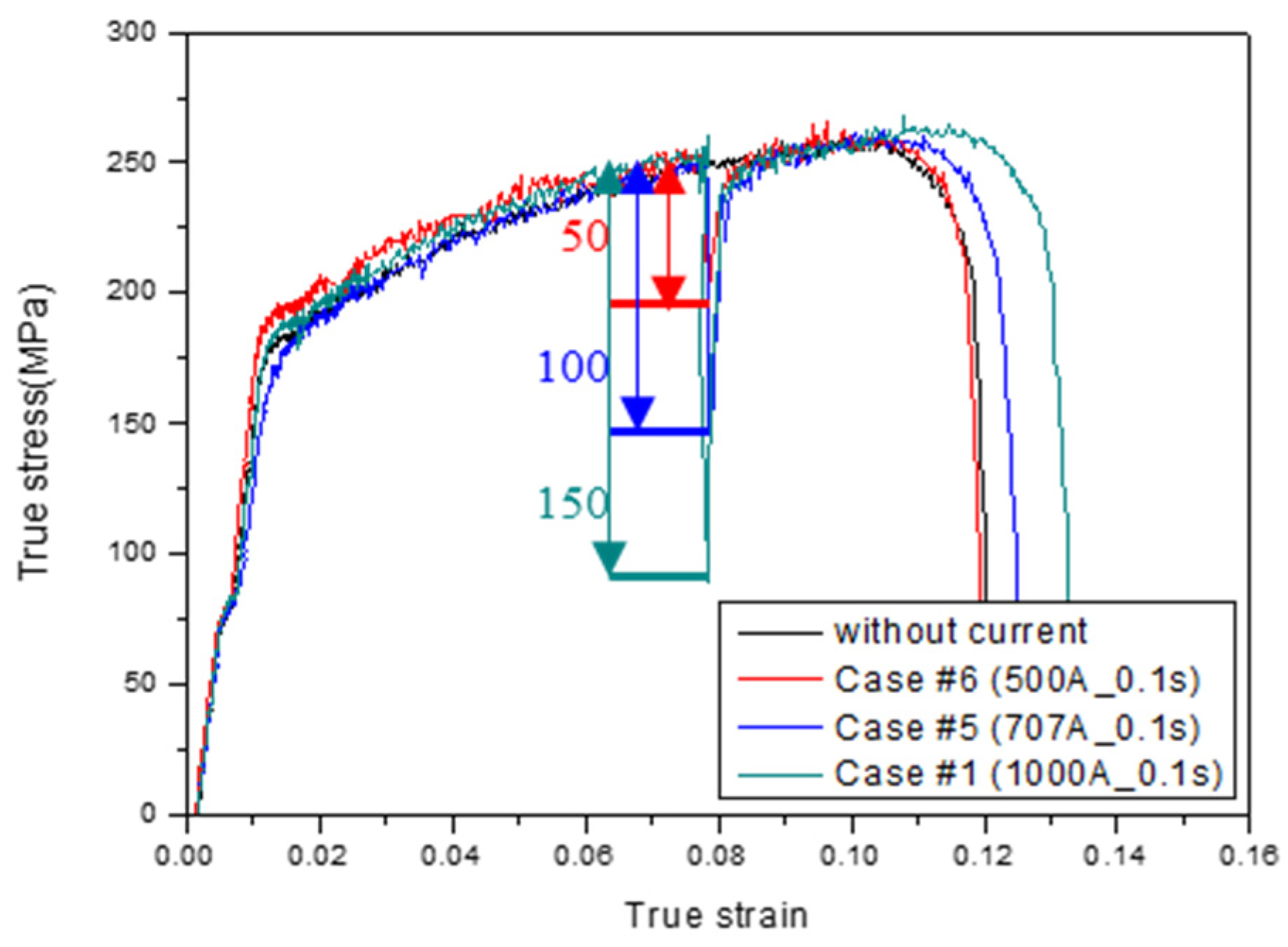

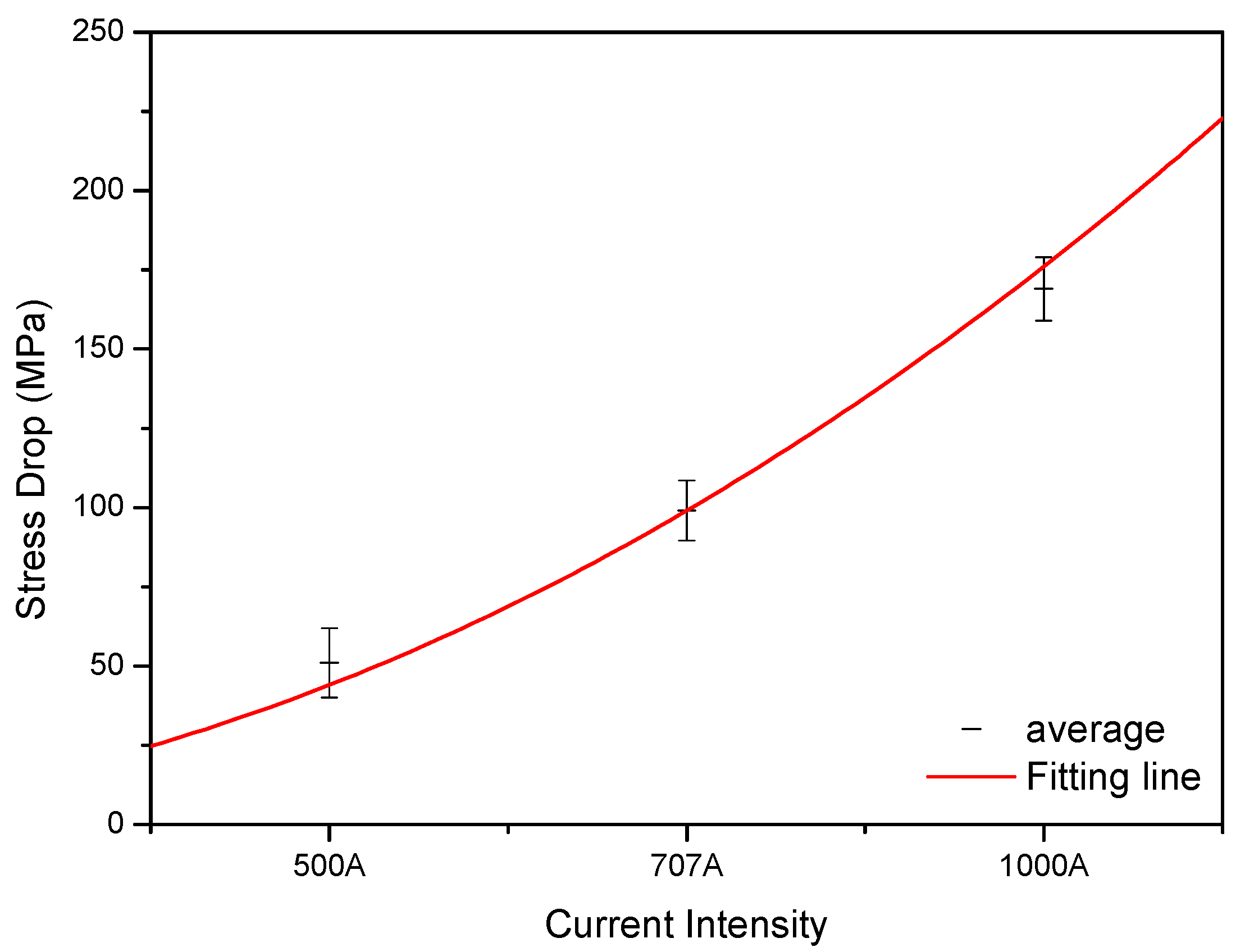

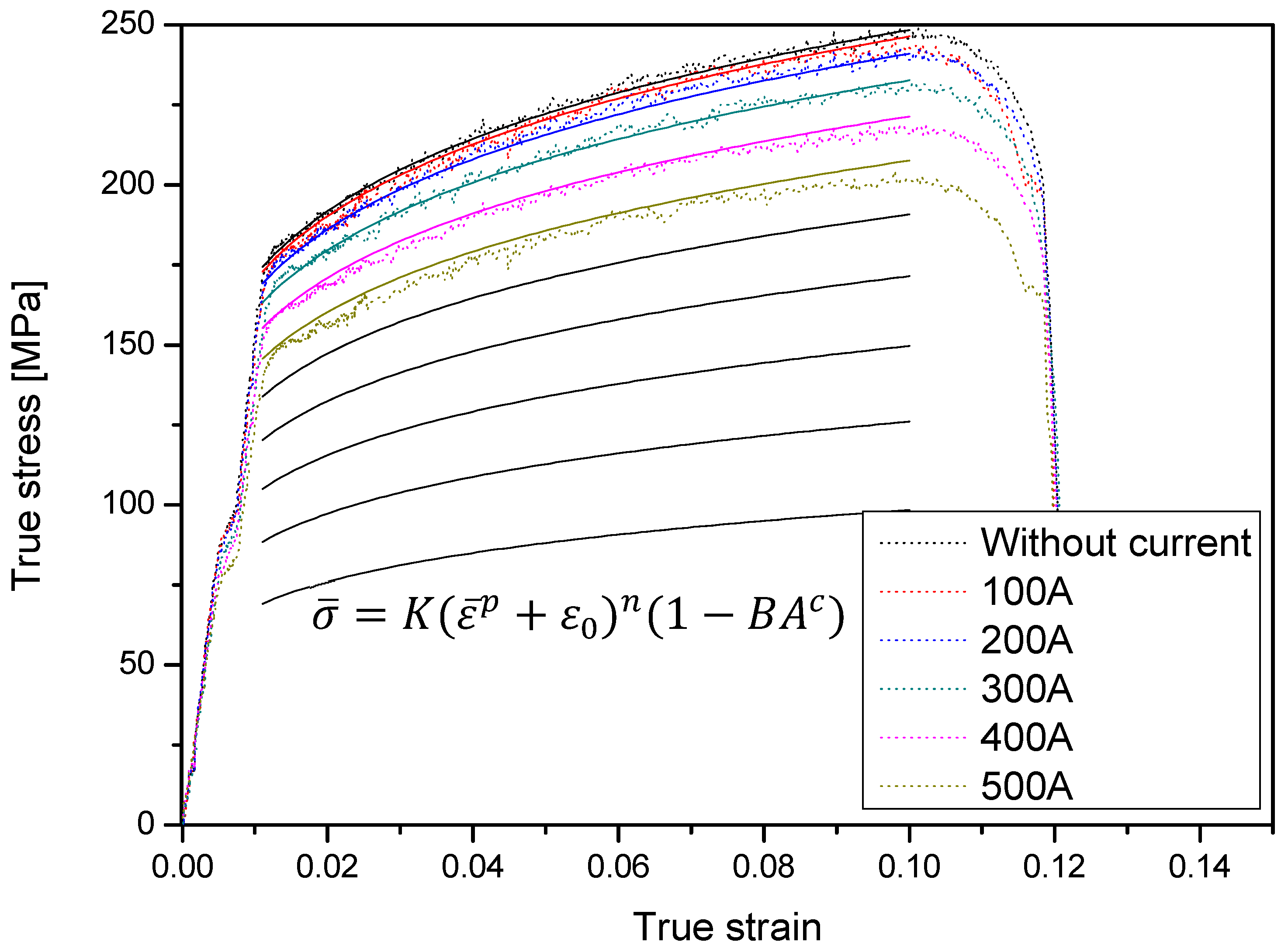

2.2. Experimental Results

3. Development and Verification of Constitutive Model

3.1. Constitutive Model Taking into Account Electro-Plastic Effect

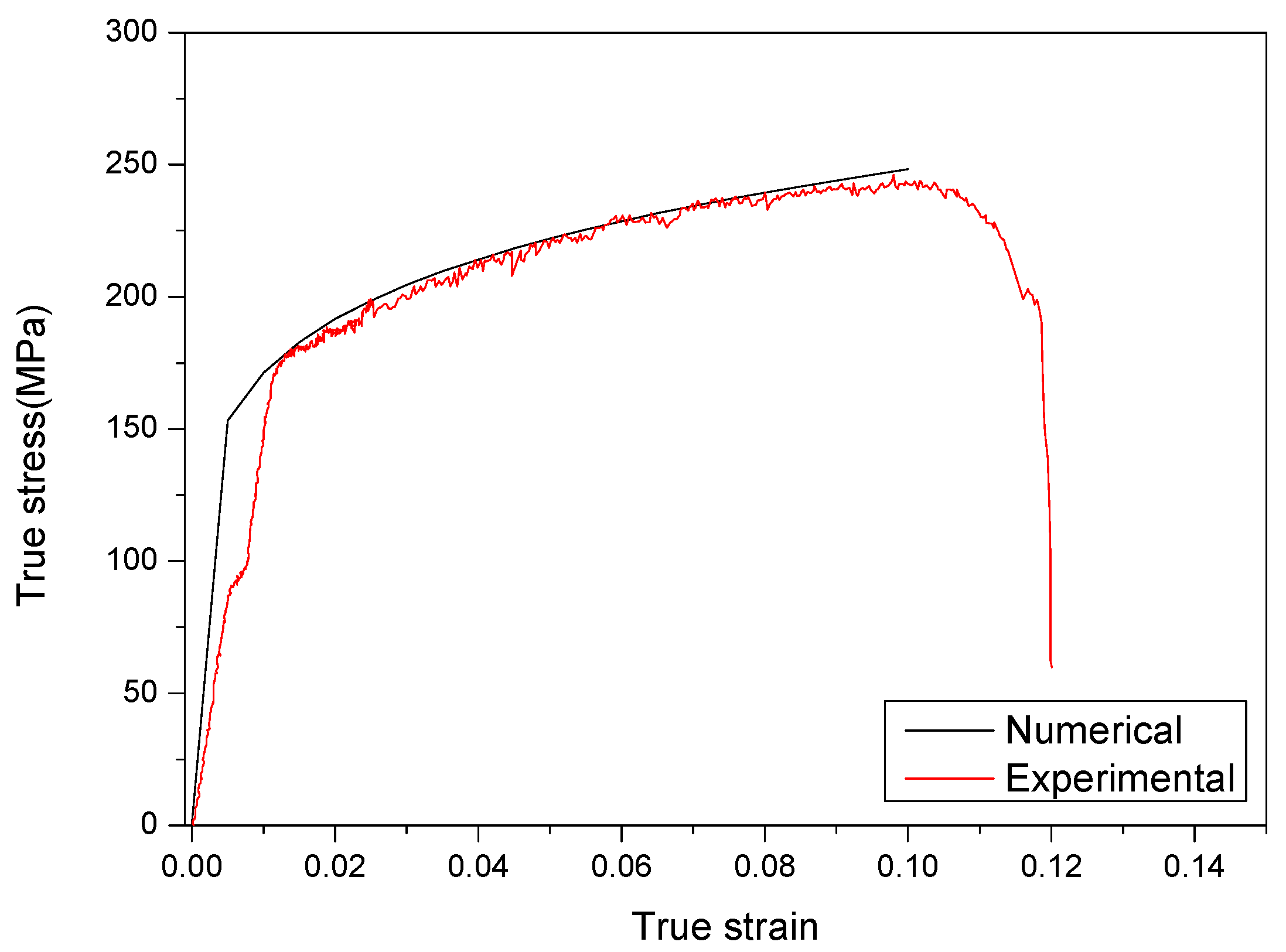

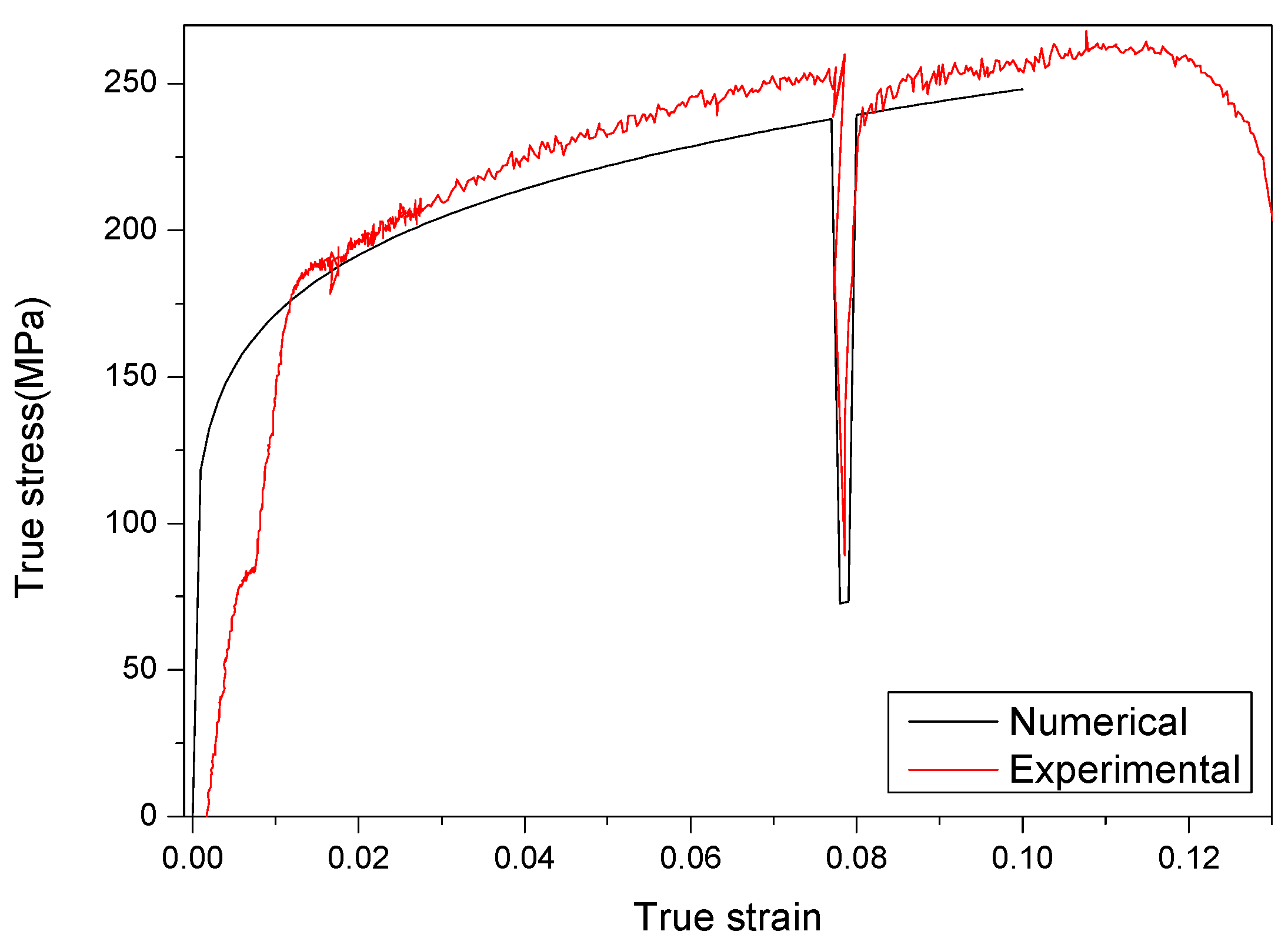

3.2. Verification of the Constitutive Model Using UMAT in LS-DYNA

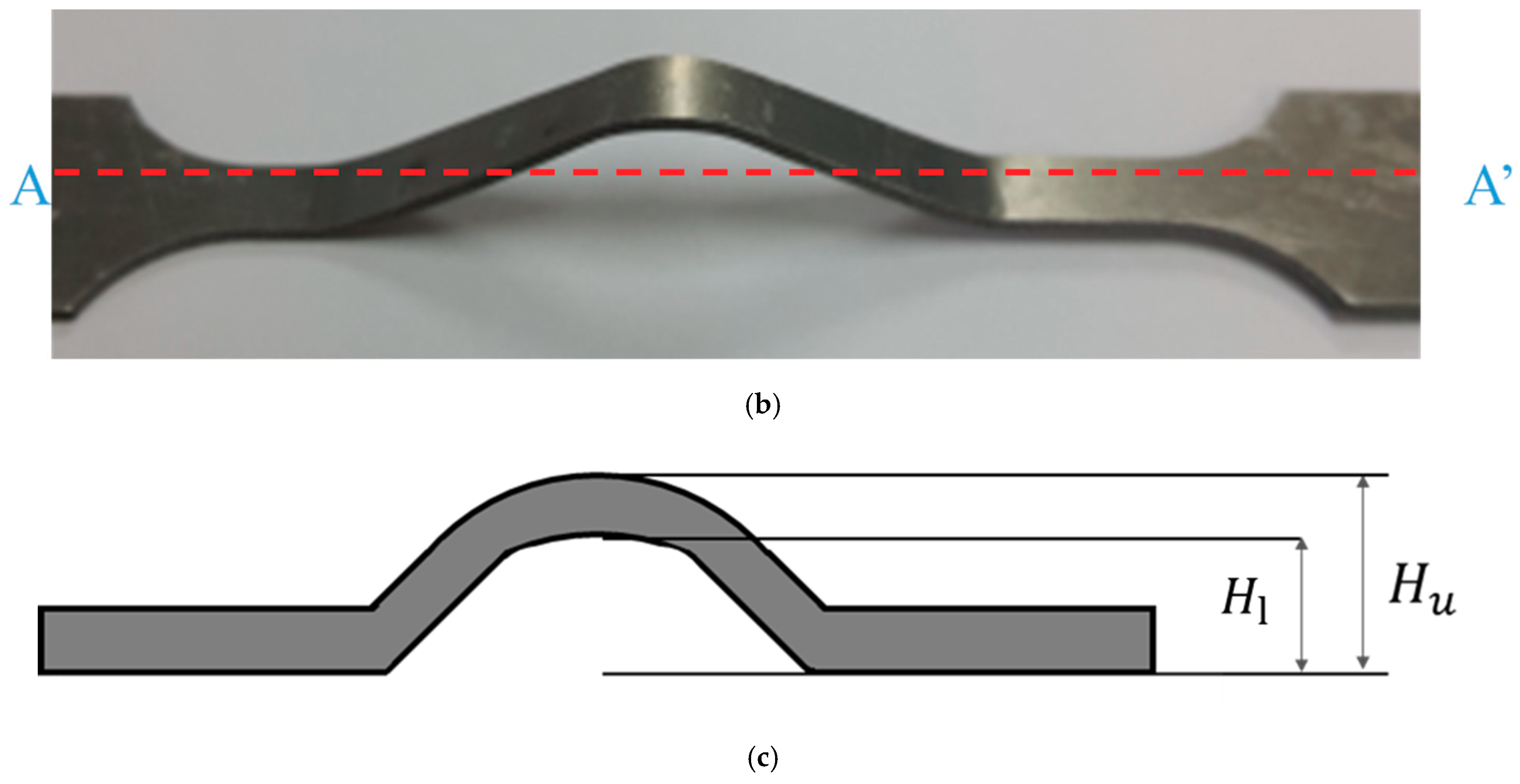

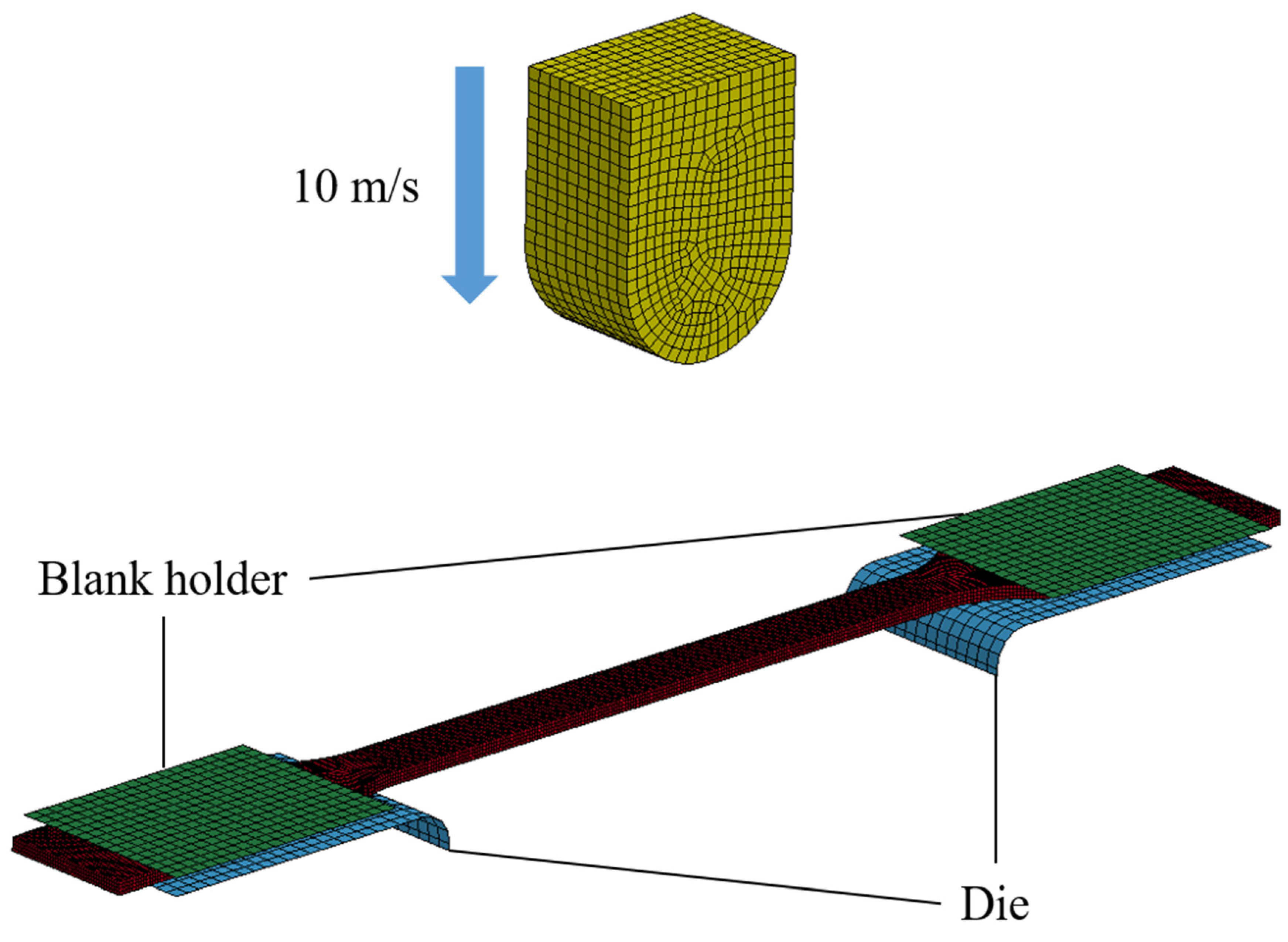

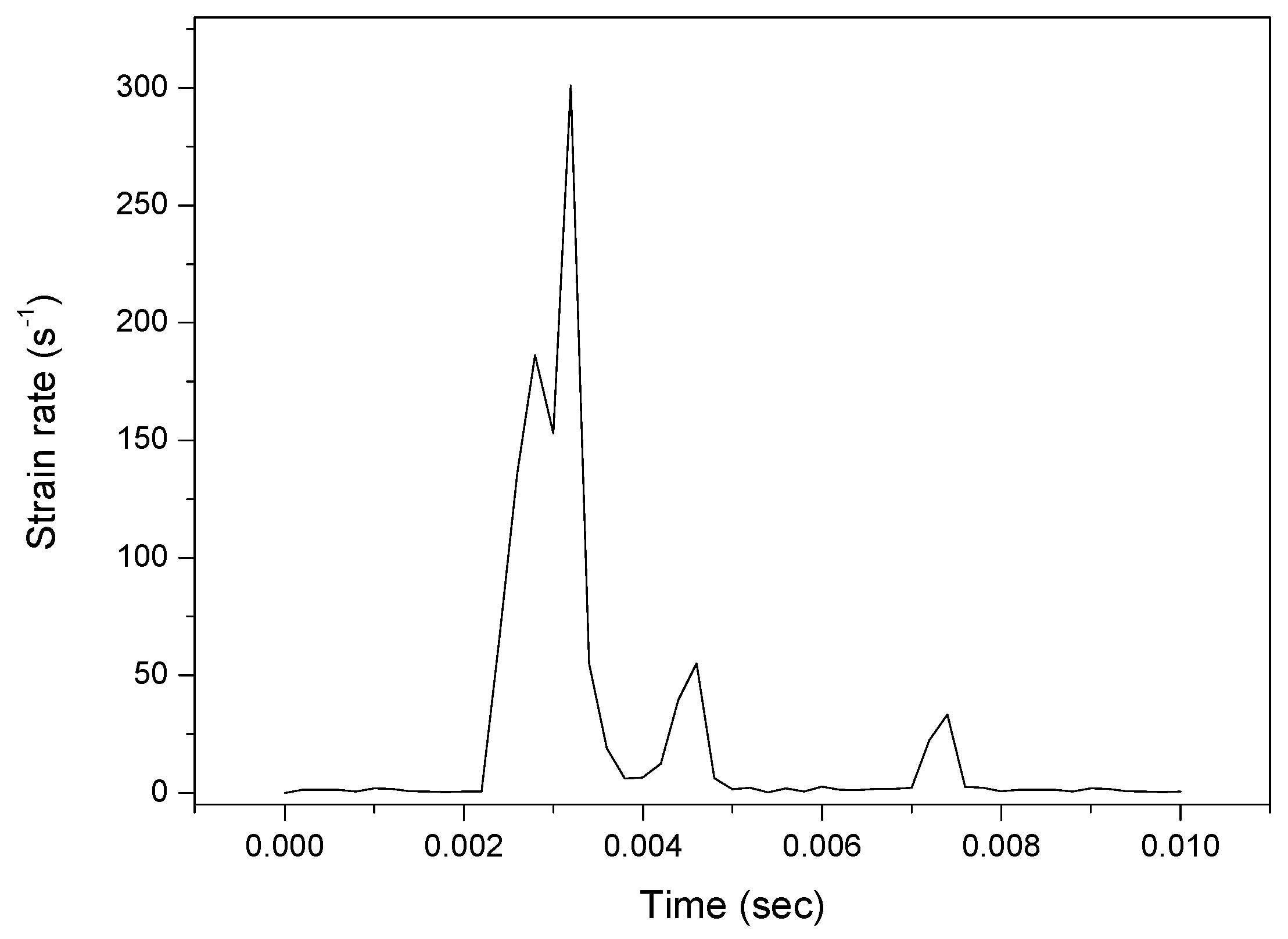

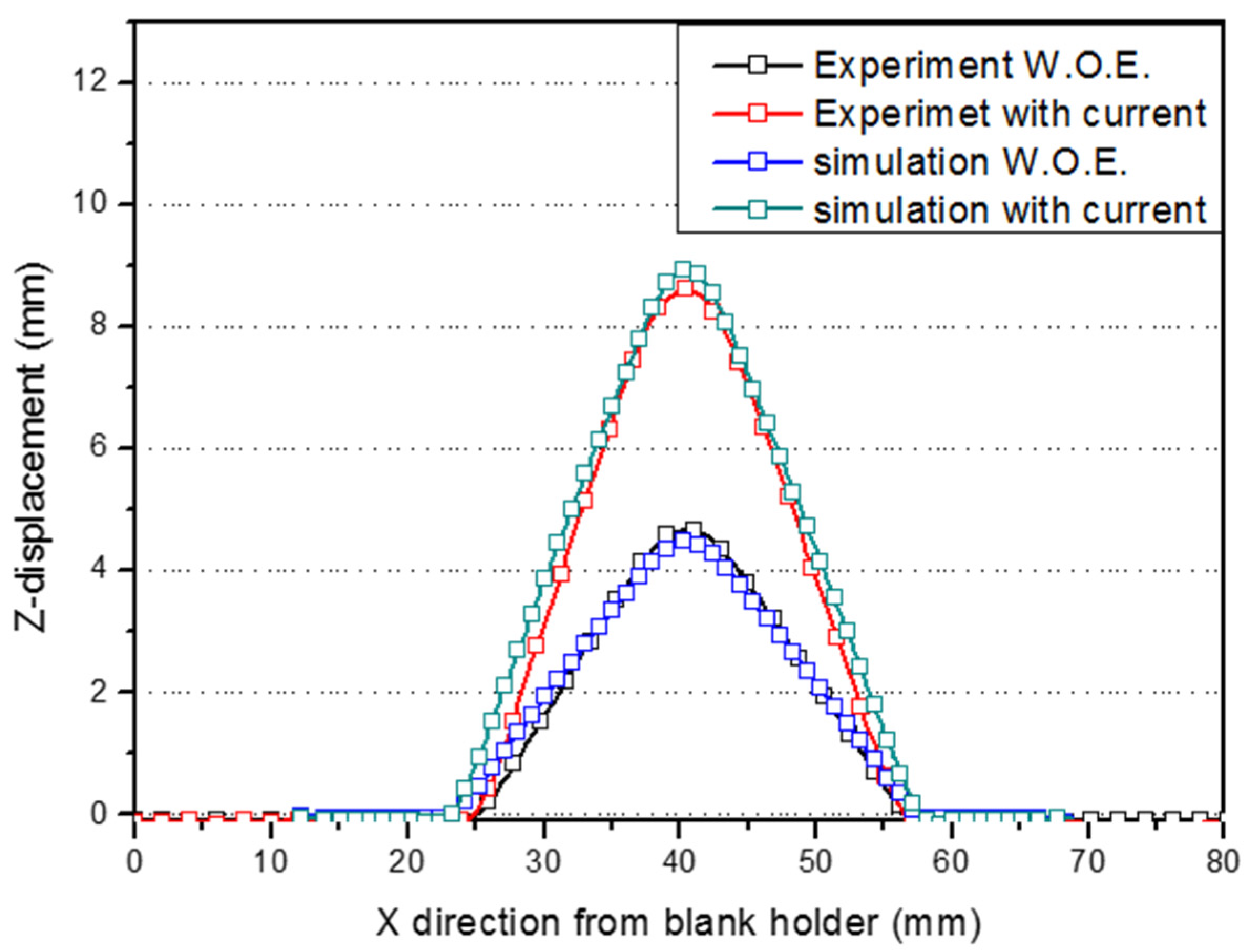

4. High-Speed Forming with Single Current Pulse

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tang, G.; Zheng, M.; Zhu, Y.; Zhang, J.; Fang, W.; Li, Q. The application of the electro-plastic technique in the cold-drawing of steel wires. J. Mater. Process. Technol. 1998, 84, 268–270. [Google Scholar] [CrossRef]

- Zimniak, Z.; Radkiewicz, G. The electroplastic effect in the cold-drawing of copper wires for the automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 173–179. [Google Scholar] [CrossRef]

- Egea, A.S.; Peiró, J.J.; Signorelli, J.W.; Rojas, H.G.; Celentano, D.J. On the microstructure effects when using electropulsing versus furnace treatments while drawing inox 308L. J. Mater. Res. Technol. 2019, 8, 2269–2279. [Google Scholar] [CrossRef]

- Ross, C.D.; Irvin, D.B.; Roth, J.T. Manufacturing aspects relating to the effects of direct current on the tensile properties of metals. J. Eng. Mater. Technol. 2007, 129, 342–347. [Google Scholar] [CrossRef]

- Potapova, A.A.; Stolyarov, V.V. Relaxation effect of pulse current on Ti50.0Ni50.0 structure during rolling. Mater. Sci. Technol. 2015, 31, 1541–1544. [Google Scholar] [CrossRef]

- Wang, X.; Sánchez Egea, A.; Xu, J.; Meng, X.; Wang, Z.; Shan, D.; Guo, B.; Cao, J. Current-induced ductility enhancement of a magnesium alloy AZ31 in uniaxial micro-tension below 373 K. Materials 2019, 12, 111. [Google Scholar] [CrossRef] [PubMed]

- Egea, A.J.S.; Rojas, H.A.G.; Celentano, D.J.; Travieso-Rodríguez, J.A.; i Fuentes, J.L. Electroplasticity-assisted bottom bending process. J. Mater. Process. Technol. 2014, 214, 2261–2267. [Google Scholar] [CrossRef]

- Green, C.R.; McNeal, T.A.; Roth, J.T. Springback elimination for Al-6111 alloys using electrically-assisted manufacturing (EAM). Trans. N. Am. Manuf. Res. Inst. 2009, 37, 403–410. [Google Scholar]

- Kim, W.; Yeom, K.H.; Thien, N.T.; Hong, S.T.; Min, B.K.; Oh, S.I.; Kim, M.J.; Han, H.N.; Lee, H.W. Electrically assisted blanking using the electroplasticity of ultra-high strength metal alloys. CIRP Ann. Manuf. Technol. 2014, 63, 273–276. [Google Scholar] [CrossRef]

- Andrawes, J.S.; Kronenberger, T.J.; Perkins, T.A.; Roth, J.T.; Warley, R.L. Effects of DC current on the mechanical behavior of AlMg1SiCu. Mater. Manuf. Process. 2007, 22, 91–101. [Google Scholar] [CrossRef]

- Fan, R.; Magargee, J.; Hu, P.; Cao, J. Influence of grain size and grain boundaries on the thermal and mechanical behavior of 70/30 brass under electrically-assisted deformation. Mater. Sci. Eng. 2013, 574, 218–225. [Google Scholar] [CrossRef]

- Breda, M.; Calliari, I.; Bruschi, S.; Forzan, M.; Ghiotti, A.; Michieletto, F.; Spezzapria, M.; Gennari, C. Influence of stacking fault energy in electrically assisted uniaxial tension of FCC metals. Mater. Sci. Technol. 2017, 33, 317–325. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Grimm, T.; Ragai, I.; Mears, L.; Roth, J.T. A review of electrically-assisted manufacturing with emphasis on modeling and understanding of the electroplastic effect. J. Manuf. Sci. Eng. 2017, 139, 110801. [Google Scholar] [CrossRef]

- Conrad, H. Electroplasticity in metals and ceramics. Mater. Sci. Eng. 2000, 287, 276–287. [Google Scholar] [CrossRef]

- ASTM International. ASTM E8/E8M-09. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Gronostajski, Z. The constitutive equations for FEM analysis. J. Mater. Process. Technol. 2000, 106, 40–44. [Google Scholar] [CrossRef]

- Kim, J.; Kang, B.S.; Noh, H.G. Ultra-High-Speed Forming Method Using Electroplasticity Effect. U.S. Patent Application No. 15/533,149, 16 November 2017. [Google Scholar]

- Yi, F.; Zhu, Z.; Zu, F.; Hu, S.; Yi, P. Strain rate effects on the compressive property and the energy-absorbing capacity of aluminum alloy foams. Mater. Charact. 2001, 47, 417–422. [Google Scholar] [CrossRef]

| Alloying Element | Mg | Fe | Si | Mg | Cu | Mn | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| Al5052 | 2.2–2.28 | 0.40 | 0.25 | 2.2–2.28 | 0.10 | 0.10 | 0.10 | Bal. |

| Case No. | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Current (A) | 1000 | 707 | 316 | 224 | 707 | 500 |

| Current density (A/mm2) | 222 | 157 | 70 | 48 | 157 | 111 |

| Duration time (s) | 0.1 | 0.2 | 1 | 2 | 0.1 | 0.1 |

| Coefficient | K [MPa] | n | B [1/A] | c |

|---|---|---|---|---|

| Al5052 | 359.6302 | 0.16063 | 8.1425E-7 | 1.8673 |

| Case No. | Al5052 | Improvement Rate | |

|---|---|---|---|

| With Current | Without Current | ||

| #1 | Hu: 9.61 | Hu: 5.31 | 181% |

| Hl: 8.62 | Hl: 4.31 | 200% | |

| #2 | Hu: 9.57 | Hu: 5.25 | 182% |

| Hl: 8.57 | Hl: 4.26 | 201% | |

| #3 | Hu: 9.56 | Hu: 5.25 | 182% |

| Hl: 8.56 | Hl: 4.25 | 201% | |

| Avg. | Hu: 9.58 | Hu: 5.27 | 182% |

| Hl: 8.58 | Hl: 4.26 | 201% | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.-G.; Kang, B.-S.; Kim, J. Numerical Modeling and Experimental Verification for High-Speed Forming of Al5052 with Single Current Pulse. Metals 2019, 9, 1311. https://doi.org/10.3390/met9121311

Park H-G, Kang B-S, Kim J. Numerical Modeling and Experimental Verification for High-Speed Forming of Al5052 with Single Current Pulse. Metals. 2019; 9(12):1311. https://doi.org/10.3390/met9121311

Chicago/Turabian StylePark, Hyeong-Gyu, Beom-Soo Kang, and Jeong Kim. 2019. "Numerical Modeling and Experimental Verification for High-Speed Forming of Al5052 with Single Current Pulse" Metals 9, no. 12: 1311. https://doi.org/10.3390/met9121311

APA StylePark, H.-G., Kang, B.-S., & Kim, J. (2019). Numerical Modeling and Experimental Verification for High-Speed Forming of Al5052 with Single Current Pulse. Metals, 9(12), 1311. https://doi.org/10.3390/met9121311