Investigation of Filling Phase Percentages on the Performance of WC-Cu Based Hot-Pressing Diamond Bit Matrices

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Samples Preparation

2.3. Tests

3. Results and Discussion

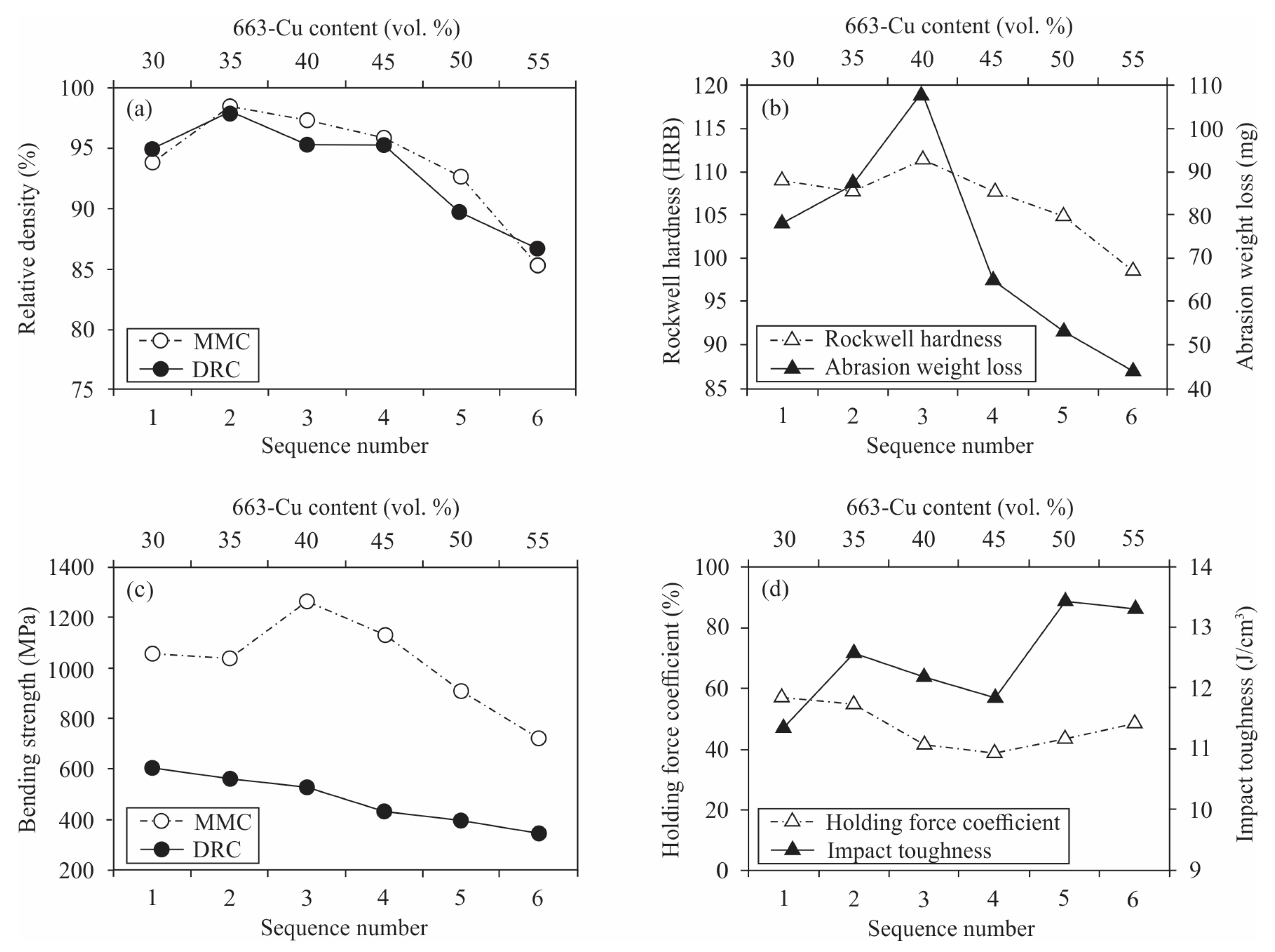

3.1. Mechanical Properties

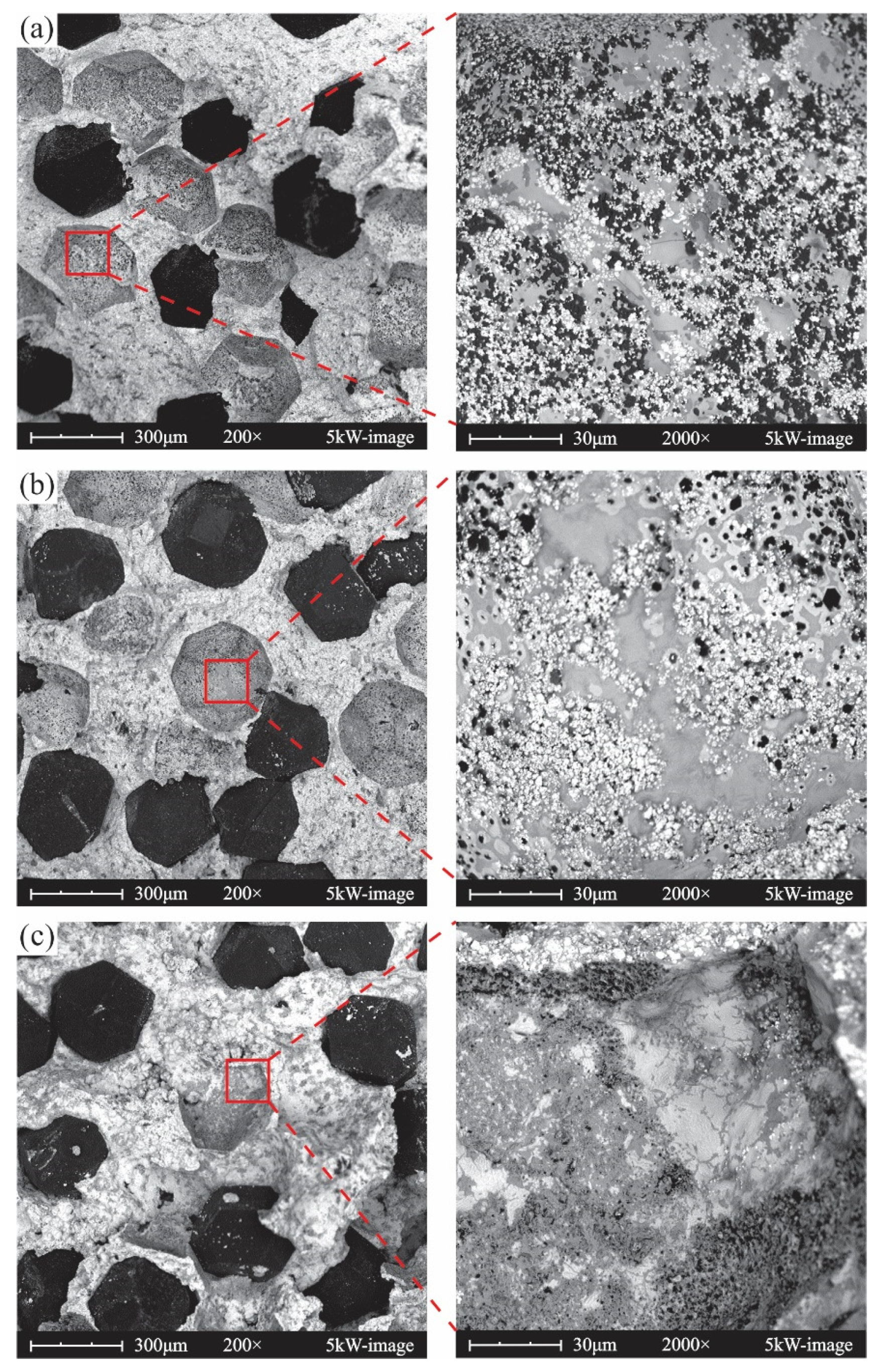

3.2. Microstructure Characterization

3.3. Diamond Retention

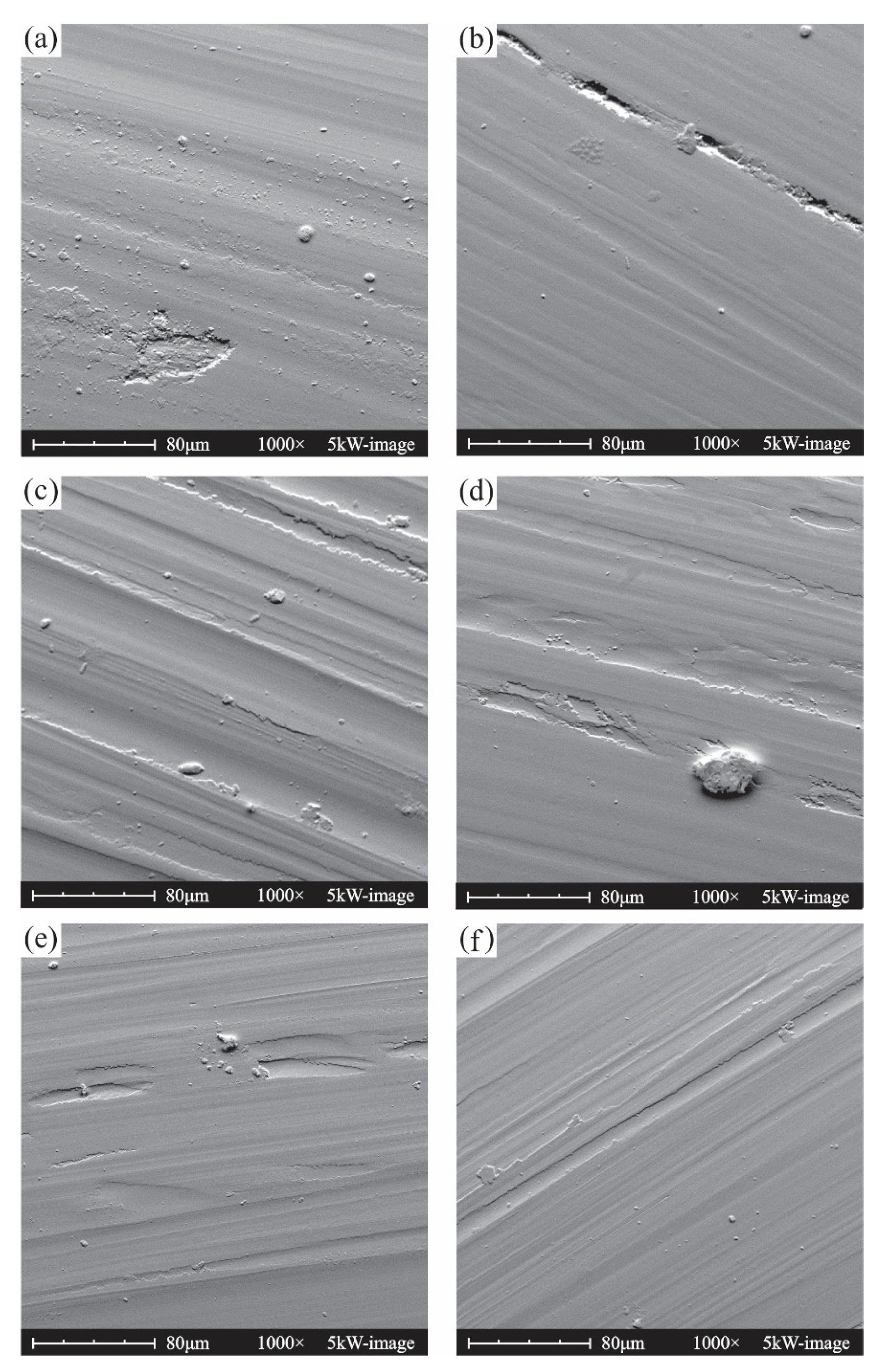

3.4. Wear Behavior

4. Conclusions

- (1)

- Increasing filling phase amount could improve MMC’s mechanical properties when it was no more than 40 vol.%, though a higher amount would result in a monotonously decline of the properties except impact toughness.

- (2)

- The filling phase amount was significant to the microstructure characteristics of MMC’s fracture surface, and the appearance of micro crevices, or pores.

- (3)

- Retention capacity of MMC to diamond declined with the increase of 663-Cu at first, and then improved slightly.

- (4)

- Wear mechanism of a typical WC based MMC was mainly dominated by abrasive wear, while it tended to be altered into adhesive wear if it contained too much stiff WC, or self-lubricated Cu.

Author Contributions

Funding

Conflicts of Interest

References

- Tonshoff, H.K.; Hillmann-Apmann, H. Diamond tools for wire sawing metal components. Diam. Relat. Mater. 2002, 11, 742–748. [Google Scholar] [CrossRef]

- Konstanty, J. Production parameters and materials selection of powder metallurgy diamond tools. Powder Metall. 2006, 4, 299–306. [Google Scholar] [CrossRef]

- Franca, L.F.P.; Mostofi, M.; Richard, T. Interface laws for impregnated diamond tools for a given state of wear. Int. J. Rock Mech. Min. 2015, 73, 184–193. [Google Scholar] [CrossRef]

- Sathish, S.; Ramkumar, S.; Geetha, M. Drilling performances and wear characteristics of coated drill bits during drilling reinforced concrete. Int. J. Appl. Ceram. Technol. 2018, 16, 1–10. [Google Scholar] [CrossRef]

- Brook, B. Principles of diamond tool technology for sawing rock. Int. J. Rock Mech. Min. 2002, 39, 41–58. [Google Scholar] [CrossRef]

- Tonshoff, H.K.; Hillmann-Apmann, H.; Asche, J. Diamond tools in stone and civil engineering industry: Cutting principles, wear and applications. Diam. Relat. Mater. 2002, 11, 736–741. [Google Scholar] [CrossRef]

- Huang, H.; Huang, G.; Xu, X.; Huang, H. An experimental study of machining characteristics and tool wear in the diamond wire sawing of granite. Proc. Inst. Mech. Eng. Part J. Eng. Manuf. 2013, 7, 943–953. [Google Scholar] [CrossRef]

- Wang, J.-L.; Zhang, S.-H. A new diamond bit for extra-hard, compact and nonabrasive rock formation. J. Cent. South Univ. 2015, 22, 1456–1462. [Google Scholar] [CrossRef]

- Oliveira, F.A.C.; Anjinho, C.A.; Coelho, A.; Amaral, P.M.; Coelho, M. PM materials selection: The key for improved performance of diamond tools. Met. Powder. Rep. 2017, 5, 339–344. [Google Scholar] [CrossRef]

- Liu, W.; Pan, F.; Yang, H.; Yu, G.; Chen, Z.; Tan, S. Influence of magnetic treatment parameters on mechanical properties of hot-pressing sintering iron-based diamond bit matrix. Geol. Sci. Technol. Inf. 2018, 5, 269–274. [Google Scholar] [CrossRef]

- Nitkiewicz, Z.; Swierzy, M. Tin influence on diamond-metal matrix hot-pressed tools for stone cutting. J. Mater. Process. Tech. 2006, 175, 306–315. [Google Scholar] [CrossRef]

- del Villar, M.; Muro, P.; Sanchez, J.M.; Iturriza, I.; Castro, F. Consolidation of diamond tools using Cu-Co-Fe based alloys as metallic binders. Powder Metall. 2001, 1, 82–90. [Google Scholar] [CrossRef]

- Spriano, S.; Chen, Q.; Settineri, L.; Bugliosi, S. Low content and free cobalt matrixes for diamond tools. Wear 2005, 259, 1190–1196. [Google Scholar] [CrossRef]

- Zak-Szwed, M.; Konstanty, J.; Ratuszek, W. Properties of Fe-Cu matrices for diamond impregnated tools. Industrial Diamond Review. 2008, 8, 31–34. [Google Scholar]

- Dai, H.; Wang, L.; Zhang, J.; Liu, Y.; Wang, Y.; Wang, L.; Wan, X. Iron based partially pre-alloyed powders as matrix materials for diamond tools. Powder Metall. 2015, 2, 83–86. [Google Scholar] [CrossRef]

- Yu, G.; Jiao, X.; Li, J.; Chen, H.; Tan, S.; Fang, X. Effect mechanism of formula pre-alloying on improving hot-pressed diamond bit iron-rich matrix performance. Geol. Sci. Tech. Inf. 2018, 5, 260–268. [Google Scholar]

- Loginov, P.A.; Sidorenko, D.A.; Shvyndian, N.V.; Sviridova, T.A.; Churyumov, A.Y.; Levashov, E.A. Effect of Ti and TiH2 doping on mechanical and adhesive properties of Fe-Co-Ni binder to diamond in cutting tools. Int. J. Refract. Met. Hard Mater. 2019, 79, 69–78. [Google Scholar] [CrossRef]

- Konstanty, J.; Ramanski, A.; Baczek, E.; Tyrala, D. New wear resistant iron-base matrix materials for the fabrication of sintered diamond tools. Arch. Metall. Mater. 2015, 2, 633–637. [Google Scholar] [CrossRef]

- Konstanty, J.S.; Baczek, E.; Romanski, A.; Tyrala, D. Wear-resistant iron-based Mn-Cu-Sn matrix for sintered diamond tools. Powder Metall. 2018, 1, 43–49. [Google Scholar] [CrossRef]

- Sidorenko, D.; Mishnaevsky, L., Jr.; Levashov, E.; Loginov, P.; Petrzhik, M. Carbon nanotube reinforced metal binder for diamond cutting tools. Mater. Design. 2015, 83, 536–544. [Google Scholar] [CrossRef]

- Zaitsev, A.A.; Sidorenko, D.A.; Levashov, E.A.; Kurbatkina, V.V.; Andreev, V.A.; Rupasov, S.I.; Sevast’yanov, P.V. Diamond tools in metal bonds dispersion- strengthened with nanosized particles for cutting highly reinforced concrete. J. Superhard Mater. 2010, 6, 423–431. [Google Scholar] [CrossRef]

- de Oliveira, L.J.; Bobrovnitchii, G.S.; Filgueira, M. Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int. J. Refract. Hard Mater. 2007, 25, 328–335. [Google Scholar] [CrossRef]

- Zeren, M.; Karagöz, Ş. Sintering of polycrystalline diamond cutting tools. Mater. Design. 2007, 28, 1055–1058. [Google Scholar] [CrossRef]

- Huusgard, P.; Caycedo, A.; Cai, M. Diamond-impregnated drill bit performance in the lower basalt series offshore the Faroe Islands. A case study based on basalt outcrop testing. In Proceedings of the SPE North Africa Technical Conference and Exhibition, Cairo, Egypt, 14–16 September 2015. SPE-175880-MS. [Google Scholar]

- Murillo, R.; Guzman Rangel, F.G.; Melo, E.; Luna Gonzalez, O.; Romero, D.A.; Beltran, D. Turbodrilling system and diamond-impregnated bit saved three trips in a hard carbonate reservoir. In Proceedings of the SPE Latin America and Caribbean Mature Fields Symposium, Salvador, Brazil, 15–16 March 2017. SPE-184924-MS. [Google Scholar]

- Tan, S.; Zhang, W.; Duan, L.; Pan, B.; Rabiei, M.; Li, C. Effects of MoS2 and WS2 on the matrix performance of WC based impregnated diamond bit. Tribol. Int. 2019, 131, 174–183. [Google Scholar] [CrossRef]

- Wang, J.; Li, N. The Complete Book of Latest Standards and Applied Technologies of Diamond and Diamond Products, 1st ed.; Heilongjiang Culture & Audio & Video Publishing House: Harbin, China, 2004; pp. 32–35. [Google Scholar]

- Sun, Y.; Song, Y. Manufacturing Theory and Practice of Diamond Tools, 1st ed.; Zhengzhou University Press: Zhengzhou, China, 2004; pp. 3–9. [Google Scholar]

- Zhao, X.; Duan, L. A review of the diamond retention capacity of metal bond matrices. Metals. 2018, 8, 307. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Duan, L.; Tan, S.; Fang, X. Effect of Fe-based pre-alloyed powder on the microstructure and holding strength of impregnated diamond bit matrix. Int. J. Refract. Met. Hard Mater. 2019, 79, 115–122. [Google Scholar] [CrossRef]

- Liu, M.; Liu, S. Mechanical Performance Handbook of Metal Materials, 1st ed.; China Machine Press: Beijing, China, 2011; pp. 75–84. [Google Scholar]

- Zeren, M.; Karagöz, Ş. Defect characterization in the diamond cutting tools. Mater. Charact. 2006, 57, 111–114. [Google Scholar] [CrossRef]

- Romanski, A. Factors affecting diamond retention in powder metallurgy diamond tools. Arch. Metall. Mater. 2010, 4, 1073–1081. [Google Scholar] [CrossRef][Green Version]

- Artini, C.; Muolo, M.L.; Passerone, A. Diamond-metal interfaces in cutting tools: A review. J. Mater. Sci. 2012, 47, 3252–3264. [Google Scholar] [CrossRef]

- Lin, C.-S.; Yang, Y.-L.; Lin, S.-T. Performances of metal-bond diamond tools in grinding alumina. J. Mater. Process. Tech. 2008, 201, 612–617. [Google Scholar] [CrossRef]

- Dhokey, N.B.; Utpat, K.; Gosavi, A.; Dhoka, P. Hot-press sintering temperature response of diamond cutting tools and its correlation with wear mechanism. Int. J. Refract Met. Hard Mater. 2013, 36, 289–293. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Solid lubricant coatings: Recent developments and future trends. Tribol. Lett. 2004, 3, 389–397. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

| Properties | Metal Powders for WC Based Matrix | ||||

|---|---|---|---|---|---|

| WC | 663-Cu 1 | Ni | Co | Mn | |

| Density (g/cm3) | 15.63 | 8.82 | 8.90 | 8.70 | 7.43 |

| Melting temperature (°C) | 2785 | 900 | 1455 | 1495 | 1246 |

| Average size (μm) | 4 | 75 | 45 | 2 | 75 |

| Sequence Number | MMC Sequences | Average Copper Foil Thickness (μm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (vol.%) | (wt.%) | ||||||||||

| WC | 663-Cu | Ni | Co | Mn | WC | 663-Cu | Ni | Co | Mn | ||

| 1 | 50 | 30 | 10 | 5 | 5 | 64 | 22 | 9 | 4 | 4 | 0.56 |

| 2 | 45 | 35 | 10 | 5 | 5 | 60 | 26 | 8 | 4 | 3 | 0.69 |

| 3 | 40 | 40 | 10 | 5 | 5 | 54 | 31 | 8 | 4 | 3 | 0.83 |

| 4 | 35 | 45 | 10 | 5 | 5 | 49 | 36 | 8 | 4 | 3 | 0.98 |

| 5 | 30 | 50 | 10 | 5 | 5 | 43 | 41 | 8 | 4 | 3 | 1.16 |

| 6 | 25 | 55 | 10 | 5 | 5 | 37 | 46 | 7 | 4 | 3 | 1.36 |

| Tests | Hardness/Abrasion Weight Loss | Bending Strength/Relative Density | Impact Toughness |

|---|---|---|---|

| Dimensions (mm × mm × mm) | 8.5 × 8.5 × 15 | 30 × 5 × 5 | 55 × 10 × 10 |

| Sintering temperature (°C) | 985 | 985 | 985 |

| Sintering pressure (MPa) | 15 | 15 | 15 |

| Sintering retention time (min) | 3 | 2.5 | 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.; Li, C.; Fang, X.; Shi, H.; Duan, L.; Li, C. Investigation of Filling Phase Percentages on the Performance of WC-Cu Based Hot-Pressing Diamond Bit Matrices. Metals 2019, 9, 1305. https://doi.org/10.3390/met9121305

Tan S, Li C, Fang X, Shi H, Duan L, Li C. Investigation of Filling Phase Percentages on the Performance of WC-Cu Based Hot-Pressing Diamond Bit Matrices. Metals. 2019; 9(12):1305. https://doi.org/10.3390/met9121305

Chicago/Turabian StyleTan, Songcheng, Changping Li, Xiaohong Fang, Hengchao Shi, Longchen Duan, and Chenglong Li. 2019. "Investigation of Filling Phase Percentages on the Performance of WC-Cu Based Hot-Pressing Diamond Bit Matrices" Metals 9, no. 12: 1305. https://doi.org/10.3390/met9121305

APA StyleTan, S., Li, C., Fang, X., Shi, H., Duan, L., & Li, C. (2019). Investigation of Filling Phase Percentages on the Performance of WC-Cu Based Hot-Pressing Diamond Bit Matrices. Metals, 9(12), 1305. https://doi.org/10.3390/met9121305