The Influence of Pre- and Post-Heat Treatment on Mechanical Properties and Microstructures in Friction Stir Welding of Dissimilar Age-Hardenable Aluminum Alloys

Abstract

1. Introduction

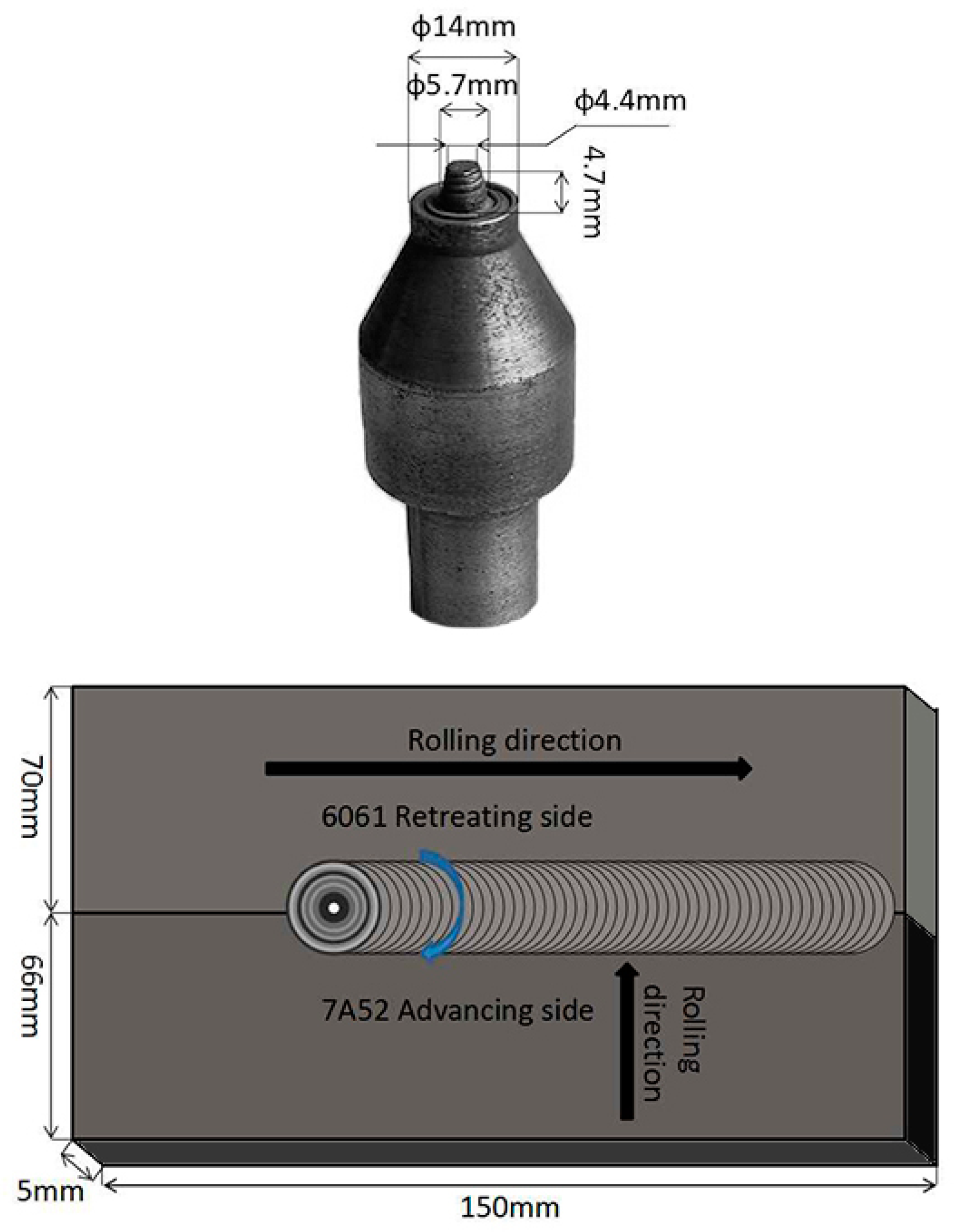

2. Material and Experimental Details

3. Results

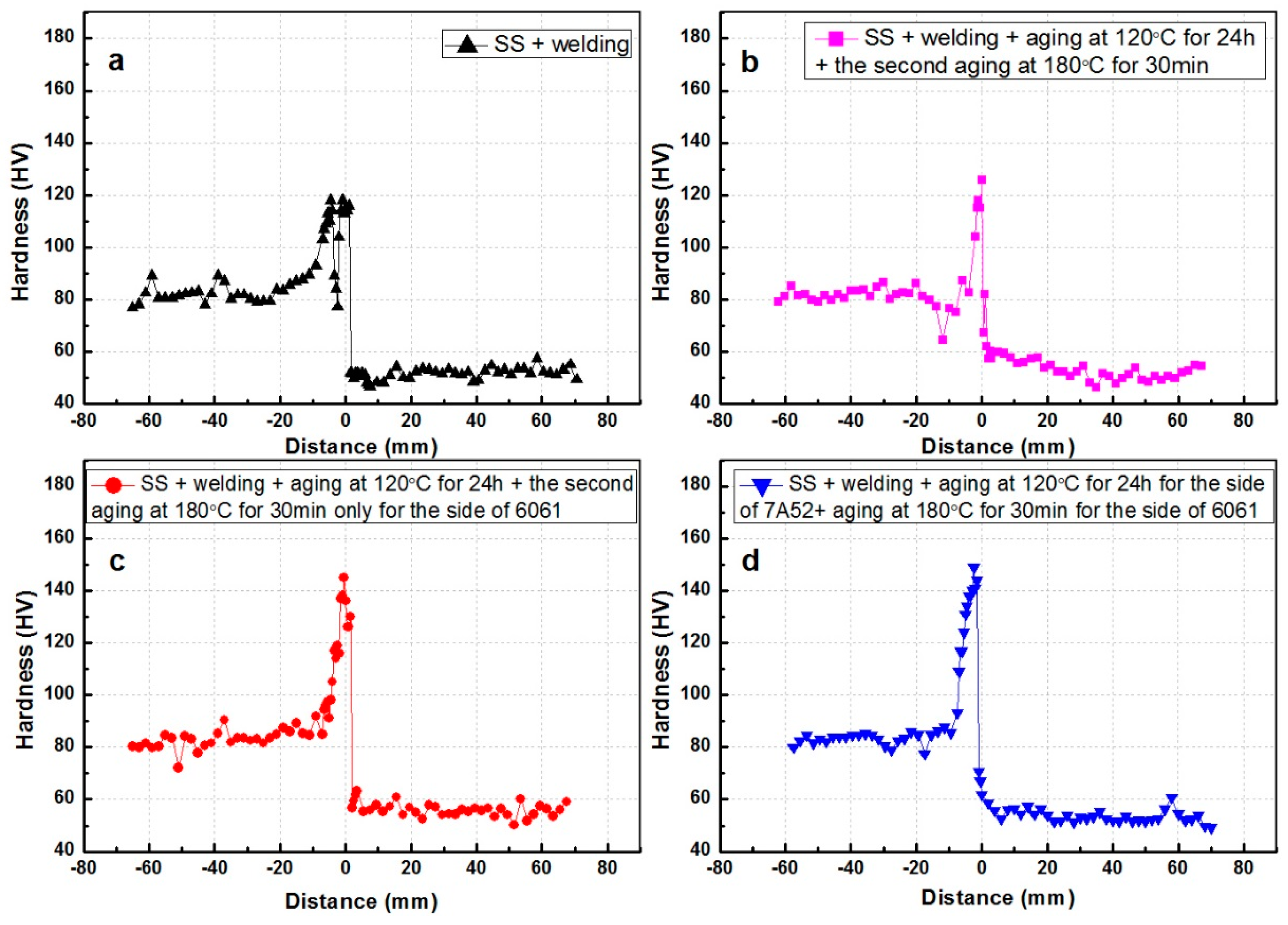

3.1. Hardness Evolution with Different Heat Treatment

3.2. Microstructures

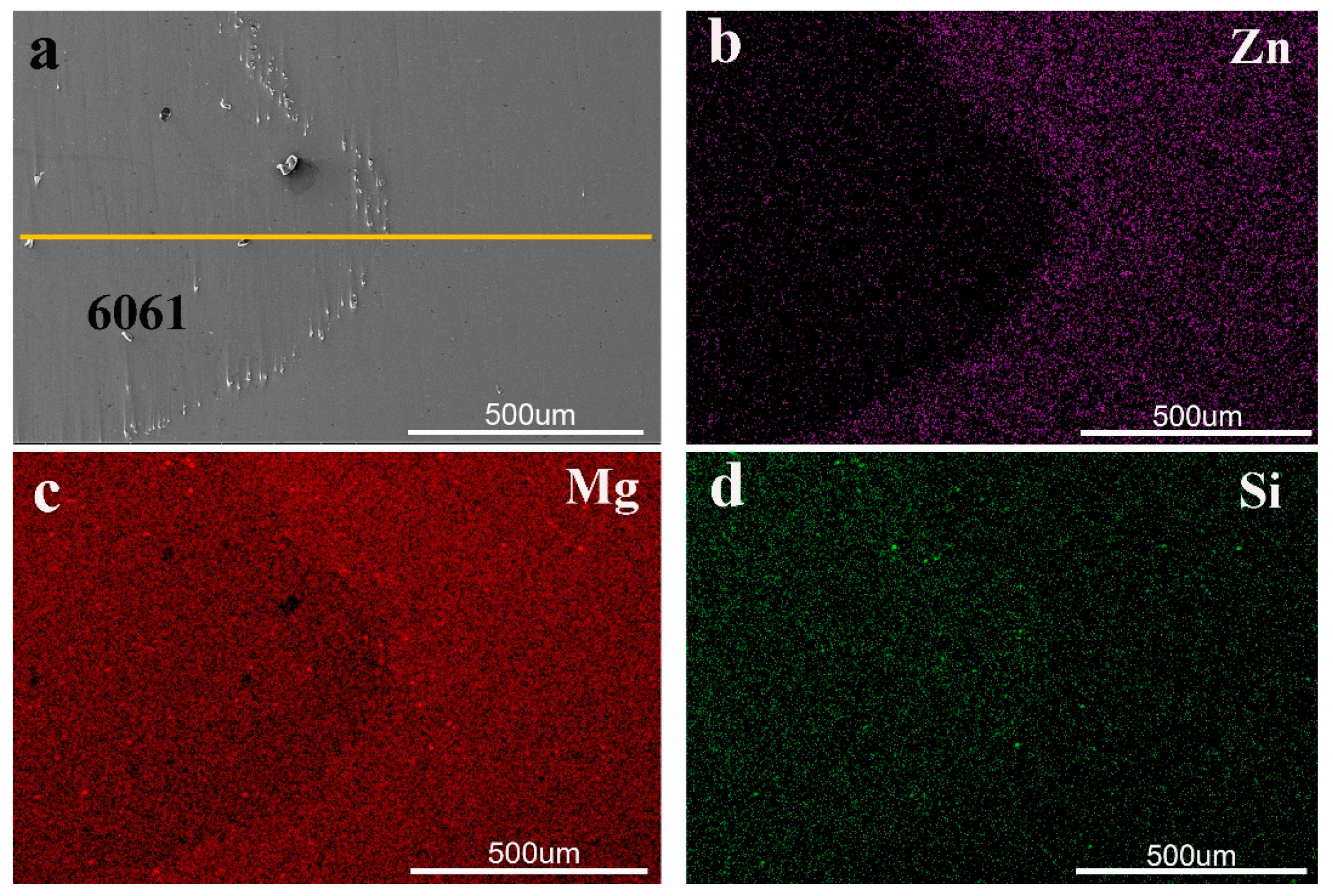

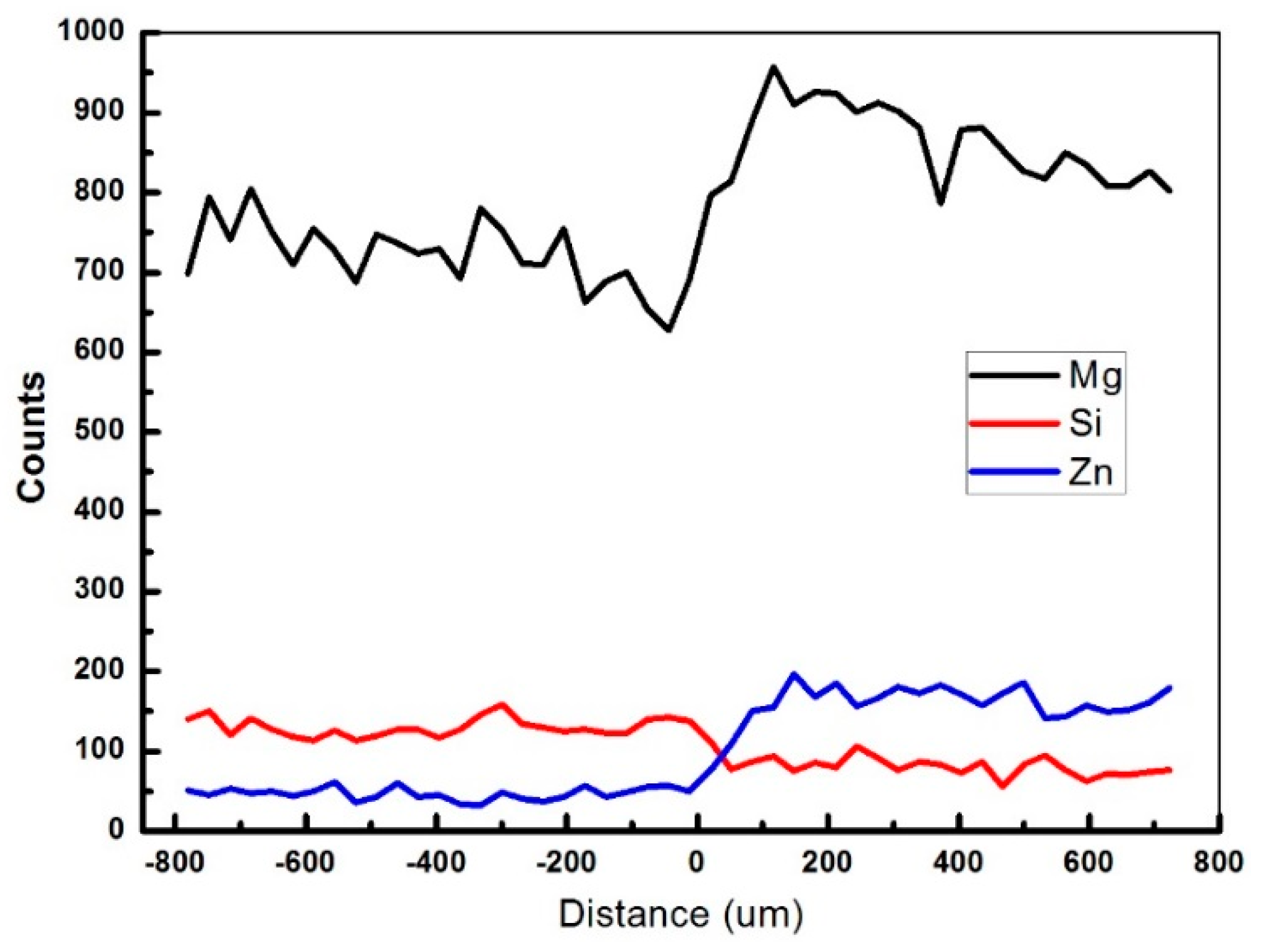

3.2.1. Alloying Elements Redistribution in WNZ

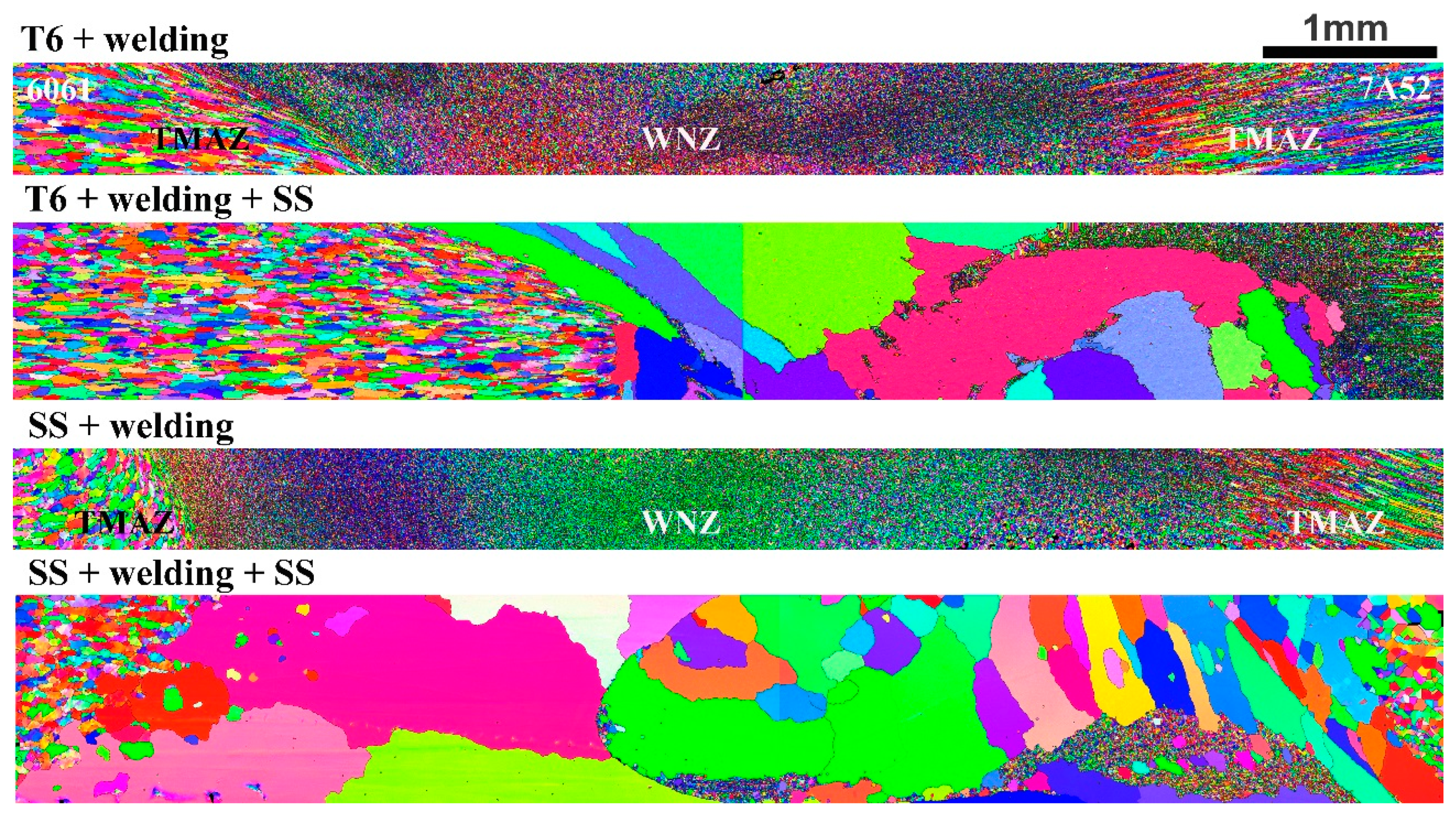

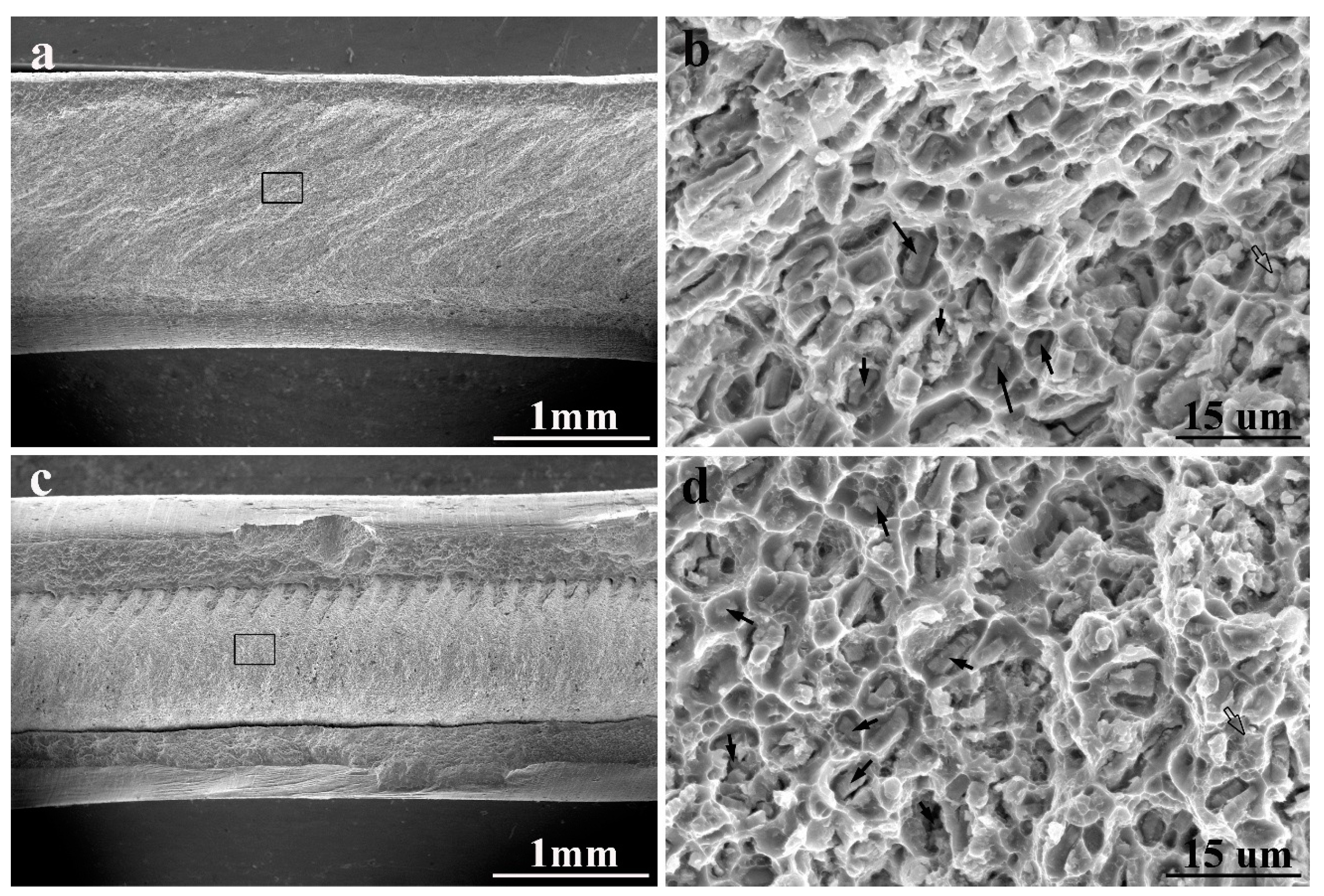

3.2.2. Grains

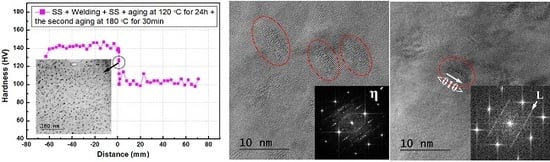

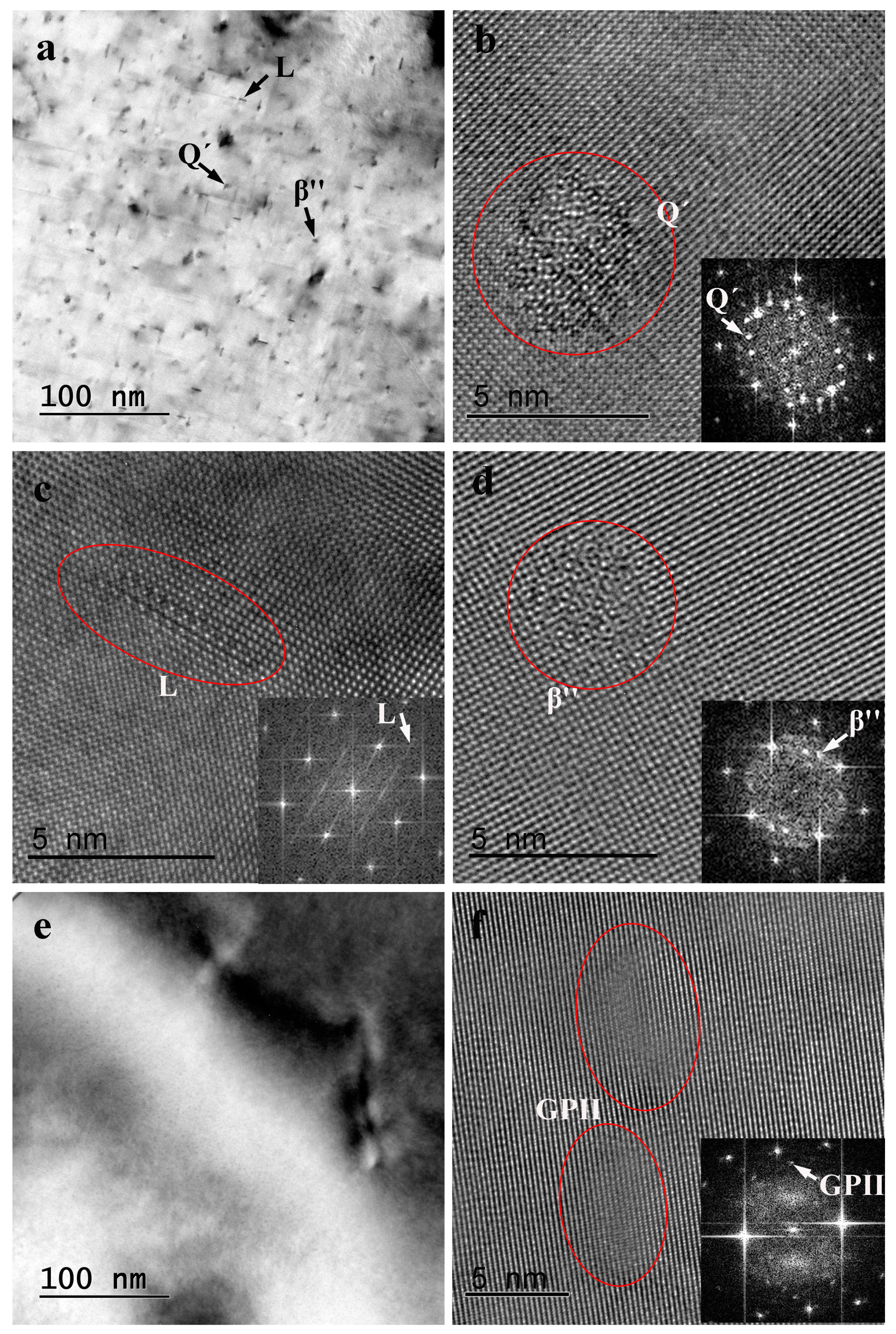

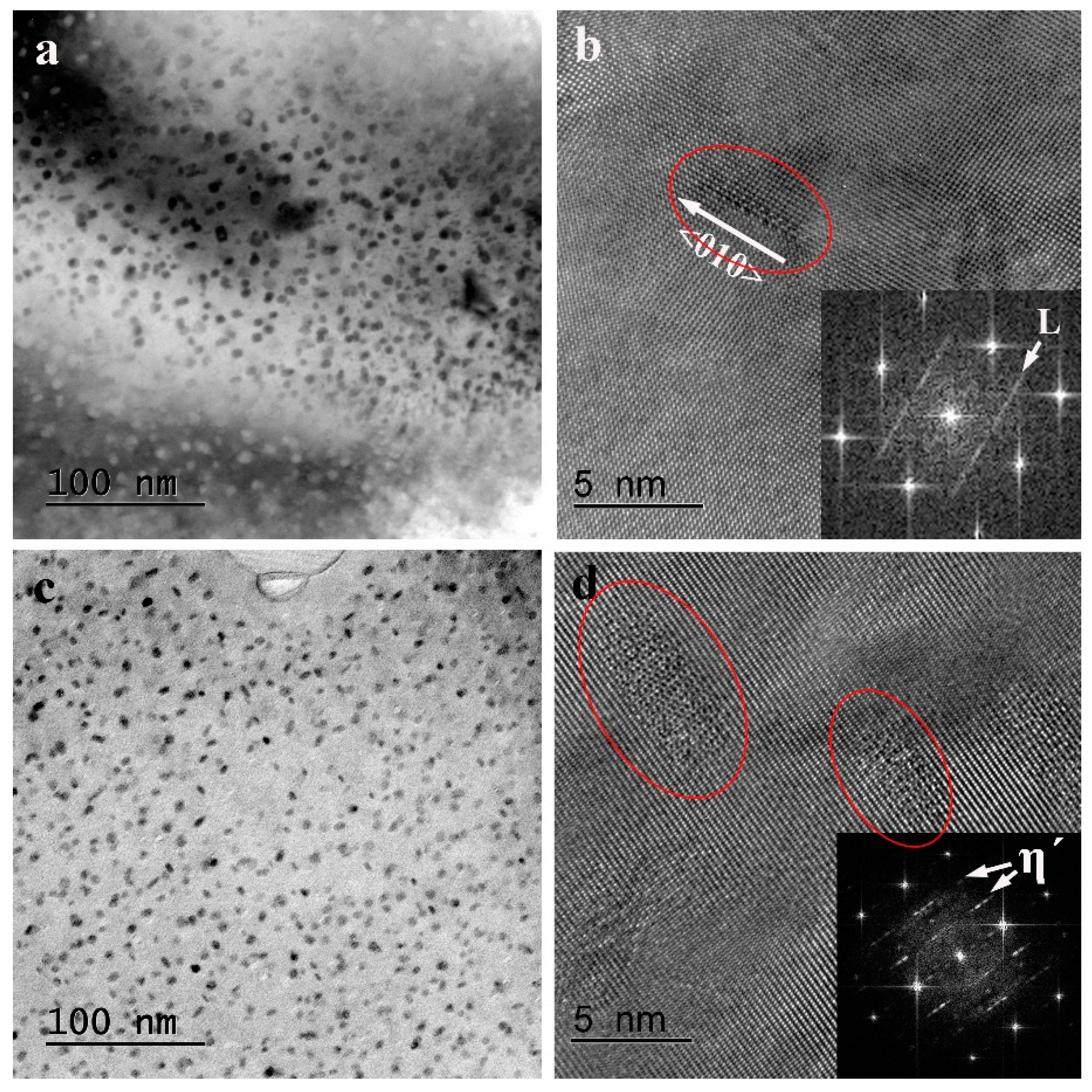

3.2.3. Microstructures in the Interior of Grains

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hornbogen, E. Hundred years of precipitation hardening. J. Light Met. 2001, 1, 127–132. [Google Scholar] [CrossRef]

- Lendvai, J. Precipitation and Strengthening in Aluminium Alloys. Mater. Sci. Forum 1996, 217, 43–56. [Google Scholar] [CrossRef]

- Ding, L.; Jia, Z.; Nie, J.-F.; Weng, Y.; Cao, L.; Chen, H.; Wu, X.; Liu, Q. The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy. Acta Mater. 2018, 145, 437–450. [Google Scholar] [CrossRef]

- Murayama, M.; Hono, K. Pre-precipitate clusters and precipitation processes in Al–Mg–Si alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Murr, L.E. Friction-Stir Welding and Processing, Handbook of Materials Structures, Properties, Processing and Performance; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–18. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Nurch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Stir Butt Welding. GB Patent Application No. 9125978.8, 6 December 1991. [Google Scholar]

- Jafari, H.; Mansouri, H.; Honarpisheh, M. Investigation of residual stress distribution of dissimilar Al-7075-T6 and Al-6061-T6 in the friction stir welding process strengthened with SiO2 nanoparticles. J. Manuf. Process. 2019, 43, 145–153. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Shihab, S.K. Investigations on tunneling and kissing bond defects in FSW joints for dissimilar aluminum alloys. J. Alloy. Compd. 2015, 648, 360–367. [Google Scholar] [CrossRef]

- Jenarthanan, M.P.; Varma, C.V.; Manohar, V.K. Impact of friction stir welding (FSW) process parameters on tensile strength during dissimilar welds of AA2014 and AA6061. Mater. Today Proc. 2018, 5, 14384–14391. [Google Scholar] [CrossRef]

- Moradi, M.M.; Aval, H.J.; Jamaati, R. Effect of pre and post welding heat treatment in SiC-fortified dissimilar AA6061-AA2024 FSW butt joint. J. Manuf. Process. 2017, 30, 97–105. [Google Scholar] [CrossRef]

- Avinash, P.; Manikandan, M.; Arivazhagan, N.; Ramkumar, K.D.; Narayanan, S. Friction Stir Welded Butt Joints of AA2024 T3 and AA7075 T6 Aluminum Alloys. Procedia Eng. 2014, 75, 98–102. [Google Scholar] [CrossRef]

- Barbini, A.; Carstensen, J.; Santos, J.F.D. Influence of a non-rotating shoulder on heat generation, microstructure and mechanical properties of dissimilar AA2024/AA7050 FSW joints. J. Mater. Sci. Technol. 2018, 34, 119–127. [Google Scholar] [CrossRef]

- Sidhar, H.; Mishra, R.S. Aging kinetics of friction stir welded Al-Cu-Li-Mg-Ag and Al-Cu-Li-Mg alloys. Mater. Des. 2016, 110, 60–71. [Google Scholar] [CrossRef]

- Eskandari, M.; Aval, H.J.; Jamaati, R. The study of thermomechanical and microstructural issues in dissimilar FSW of AA6061 wrought and A390 cast alloys. J. Manuf. Process. 2019, 41, 168–176. [Google Scholar] [CrossRef]

- Choudhary, S.; Choudhary, S.; Vaish, S.; Upadhyay, A.K.; Singla, A.; Singh, Y. Effect of welding parameters on microstructure and mechanical properties of friction stir welded Al 6061 aluminum alloy joints. Mater. Today Proc. 2013, 50, 872–878. [Google Scholar] [CrossRef]

- Elnabi, M.M.A.; Elshalakany, A.B.; Abdel-Mottaleb, M.M.; Osman, T.A.; el Mokadem, A. Influence of friction stir welding parameters on metallurgical and mechanical properties of dissimilar AA5454–AA7075 aluminum alloys. J. Mater. Res. Technol. 2019, 8, 1684–1693. [Google Scholar] [CrossRef]

- Milagre, M.X.; Mogili, N.V.; Donatus, U.; Giorjão, R.A.R.; Terada, M.; Araujo, J.V.S.; Machado, C.S.C.; Costa, I. On the microstructure characterization of the AA2098-T351 alloy welded by FSW. Mater. Charact. 2018, 140, 233–246. [Google Scholar] [CrossRef]

- Devaiah, D.; Kishore, K.; Laxminarayana, P. Optimal FSW process parameters for dissimilar aluminium alloys (AA5083 and AA6061) using Taguchi Technique. Mater. Today Proc. 2018, 5, 4607–4614. [Google Scholar] [CrossRef]

- Mishra, R.S.; Sidhar, H. Chapter 4—FSW of Al–Cu and Al–Cu–Mg Alloys. In Friction Stir Welding of 2XXX Aluminum Alloys Including Al-Li Alloys; Mishra, R.S., Sidhar, H., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 47–77. [Google Scholar]

- Dehghani, M.; Amadeh, A.; Mousavi, S.A.A.A. Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel. Mater. Des. 2013, 49, 433–441. [Google Scholar] [CrossRef]

- Astarita, A.; Squillace, A.; Scala, A.; Prisco, A. On the Critical Technological Issues of Friction Stir Welding T-Joints of Dissimilar Aluminum Alloys. J. Mater. Eng. Perform. 2012, 21, 1763–1771. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng. B 2008, 148, 82–87. [Google Scholar] [CrossRef]

- Astarita, A.; Squillace, A.; Carrino, L. Experimental Study of the Forces Acting on the Tool in the Friction-Stir Welding of AA 2024 T3 Sheets. J. Mater. Eng. Perform. 2014, 23, 3754–3761. [Google Scholar] [CrossRef]

- Astarita, A.; Squillace, A.; Armentani, E.; Ciliberto, S. Friction stir welding of AA 2198 T3 rolled sheets in butt configuration. Metall. Ital. 2012, 7, 31–40. [Google Scholar]

- Kumar, S.R.; Rao, V.S.; Pranesh, R.V. Effect of Welding Parameters on Macro and Microstructure of Friction Stir Welded Dissimilar Butt Joints between AA7075-T651 and AA6061-T651 Alloys. Procedia Mater. Sci. 2014, 5, 1726–1735. [Google Scholar] [CrossRef]

- Kalemba-Rec, I.; Kopyściański, M.; Miara, D.; Krasnowski, K. Effect of process parameters on mechanical properties of friction stir welded dissimilar 7075-T651 and 5083-H111 aluminum alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 2767–2779. [Google Scholar] [CrossRef]

- Jia, Y.; Qin, Y.; Ou, Y.; Wang, K.; Liu, J. The Influence of Microstructural Heterogeneity on Mechanical Properties of Friction Stir Welded Joints of T6-Treated Al-Zn-Mg Alloy 7A52. Metals 2018, 8, 527. [Google Scholar] [CrossRef]

- Velotti, C.; Astarita, A.; Buonadonna, P.; Dionoro, G.; Langella, A.; Paradiso, V.; Prisco, U.; Scherillo, F.; Squillace, A.; Tronci, A. FSW of AA 2139 Plates: Influence of the Temper State on the Mechanical Properties. Key Eng. Mater. 2013, 554, 1065–1074. [Google Scholar] [CrossRef]

- Prisco, U.; Squillace, A.; Astarita, A.; Velotti, C. Influence of Welding Parameters and Post-weld Aging on Tensile Properties and Fracture Location of AA2139-T351 Friction-stir-welded Joints. Mater. Res. 2013, 16, 1106–1112. [Google Scholar] [CrossRef]

- Astarita, A.; Prisco, U.; Squillace, A.; Velotti, C.; Tronci, A. Mechanical characterization by DOE analysis of AA6156-T4 friction stir welded joints in as-welded and post-weld aged condition. Mater. Test. 2015, 57, 192–199. [Google Scholar] [CrossRef]

- Singh, R.K.R.; Sharma, C.; Dwivedi, D.K.; Mehta, N.K.; Kumar, P. The microstructure and mechanical properties of friction stir welded Al–Zn–Mg alloy in as welded and heat treated conditions. Mater. Des. 2011, 32, 682–687. [Google Scholar] [CrossRef]

- Safarbali, B.; Shamanian, M.; Eslami, A. Effect of post-weld heat treatment on joint properties of dissimilar friction stir welded 2024-T4 and 7075-T6 aluminum alloys. Trans. Nonferrous Met. Soc. China 2018, 28, 1287–1297. [Google Scholar] [CrossRef]

- Sharma, C.; Dwivedi, D.K.; Kumar, P. Effect of post weld heat treatments on microstructure and mechanical properties of friction stir welded joints of Al–Zn–Mg alloy AA7039. Mater. Des. 2013, 43, 134–143. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H. Distribution of tensile property and microstructure in friction stir weld of 6063 aluminum. Metall. Mater. Trans. A 2001, 32, 3023–3031. [Google Scholar] [CrossRef]

- Bayazid, S.M.; Farhangi, H.; Asgharzadeh, H.; Radan, L.; Ghahramani, A.; Mirhaji, A. Effect of cyclic solution treatment on microstructure and mechanical properties of friction stir welded 7075 Al alloy. Mater. Sci. Eng. A 2016, 649, 293–300. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Bingel, W.H.; Spurling, R.A. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Sullivan, A.; Robson, J.D. Microstructural properties of friction stir welded and post-weld heat-treated 7449 aluminium alloy thick plate. Mater. Sci. Eng. A 2008, 478, 351–360. [Google Scholar] [CrossRef]

- Liu, J.Z.; Chen, J.H.; Yang, X.B.; Ren, S.; Wu, C.L.; Xu, H.Y.; Zou, J. Revisiting the precipitation sequence in Al–Zn–Mg-based alloys by high-resolution transmission electron microscopy. Scr. Mater. 2010, 63, 1061–1064. [Google Scholar] [CrossRef]

- Li, X.Z.; Hansen, V.; GjØnnes, J.; Wallenberg, L.R. HREM study and structure modeling of the η′ phase, the hardening precipitates in commercial Al–Zn–Mg alloys. Acta Mater. 1999, 47, 2651–2659. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

| Alloys | Al | Zn | Mg | Mn | Cr | Zr | Ti | V | Cu | Fe | Si |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7A52 | Bal. | 4.40 | 2.33 | 0.27 | 0.18 | 0.083 | 0.09 | 0.008 | 0.10 | 0.21 | 0.07 |

| 6061 | Bal. | 0.18 | 1.05 | 0.10 | 0.22 | - | 0.01 | - | 0.25 | 0.18 | 0.51 |

| Samples | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| SS + welding | 174 | 5.66 |

| SS + welding + aging at 120 °C for 24 h + the second aging at 180 °C for 30 min | 260 | 4.89 |

| SS + welding + aging at 120 °C for 24 h + the second aging at 180 °C for 30 min. only for the side of 6061 | 250 | 4.73 |

| SS + welding + aging at 120 °C for 24 h for the side of 7A52 + the second aging at 180 °C for 30 min. for the side of 6061 | 210 | 4.99 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Y.; Lin, S.; Liu, J.; Qin, Y.; Wang, K. The Influence of Pre- and Post-Heat Treatment on Mechanical Properties and Microstructures in Friction Stir Welding of Dissimilar Age-Hardenable Aluminum Alloys. Metals 2019, 9, 1162. https://doi.org/10.3390/met9111162

Jia Y, Lin S, Liu J, Qin Y, Wang K. The Influence of Pre- and Post-Heat Treatment on Mechanical Properties and Microstructures in Friction Stir Welding of Dissimilar Age-Hardenable Aluminum Alloys. Metals. 2019; 9(11):1162. https://doi.org/10.3390/met9111162

Chicago/Turabian StyleJia, Yang, Sicong Lin, Jizi Liu, Yonggui Qin, and Kehong Wang. 2019. "The Influence of Pre- and Post-Heat Treatment on Mechanical Properties and Microstructures in Friction Stir Welding of Dissimilar Age-Hardenable Aluminum Alloys" Metals 9, no. 11: 1162. https://doi.org/10.3390/met9111162

APA StyleJia, Y., Lin, S., Liu, J., Qin, Y., & Wang, K. (2019). The Influence of Pre- and Post-Heat Treatment on Mechanical Properties and Microstructures in Friction Stir Welding of Dissimilar Age-Hardenable Aluminum Alloys. Metals, 9(11), 1162. https://doi.org/10.3390/met9111162