Physical and Numerical Modelling on the Mixing Condition in a 50 t Ladle

Abstract

:1. Introduction

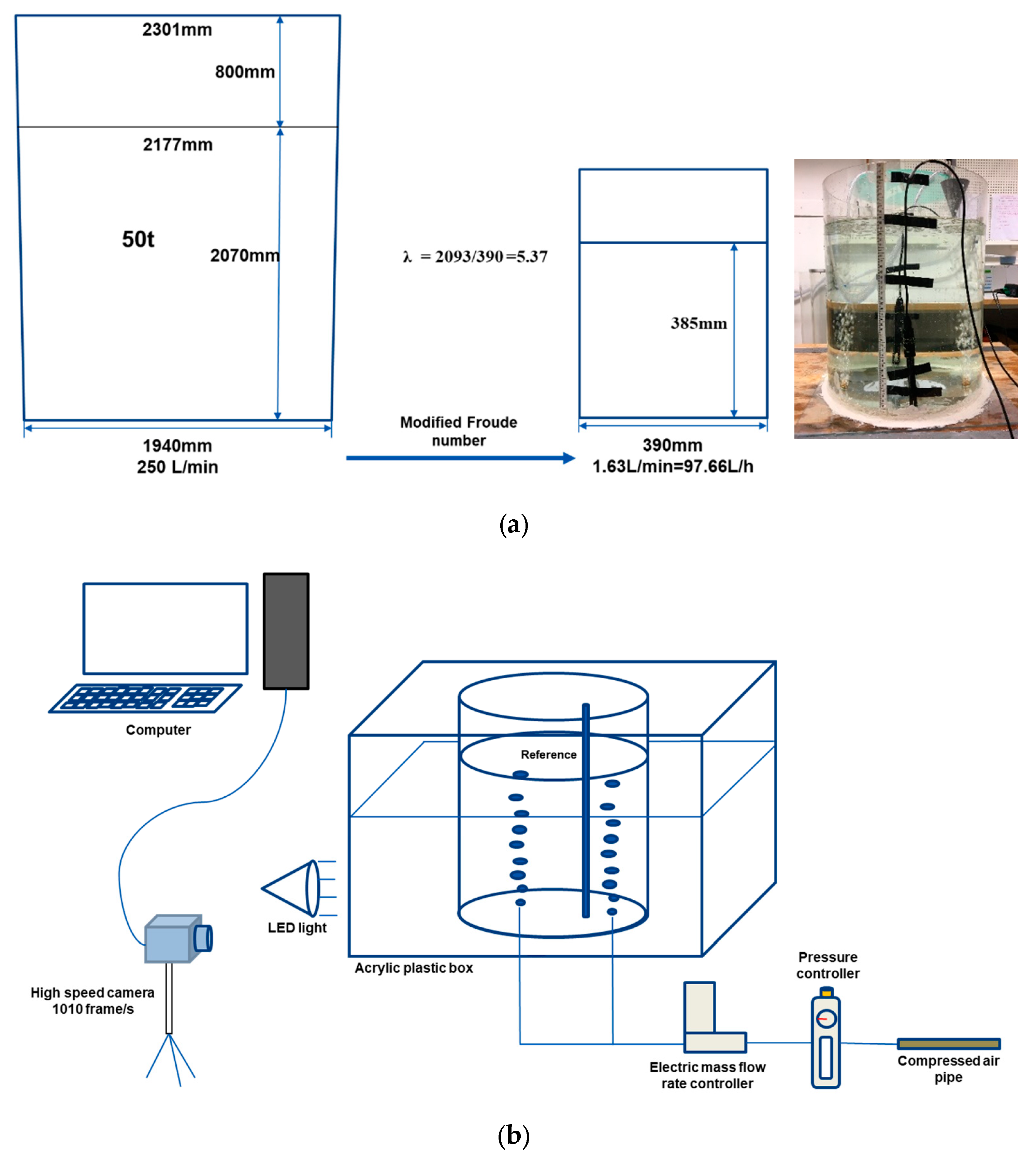

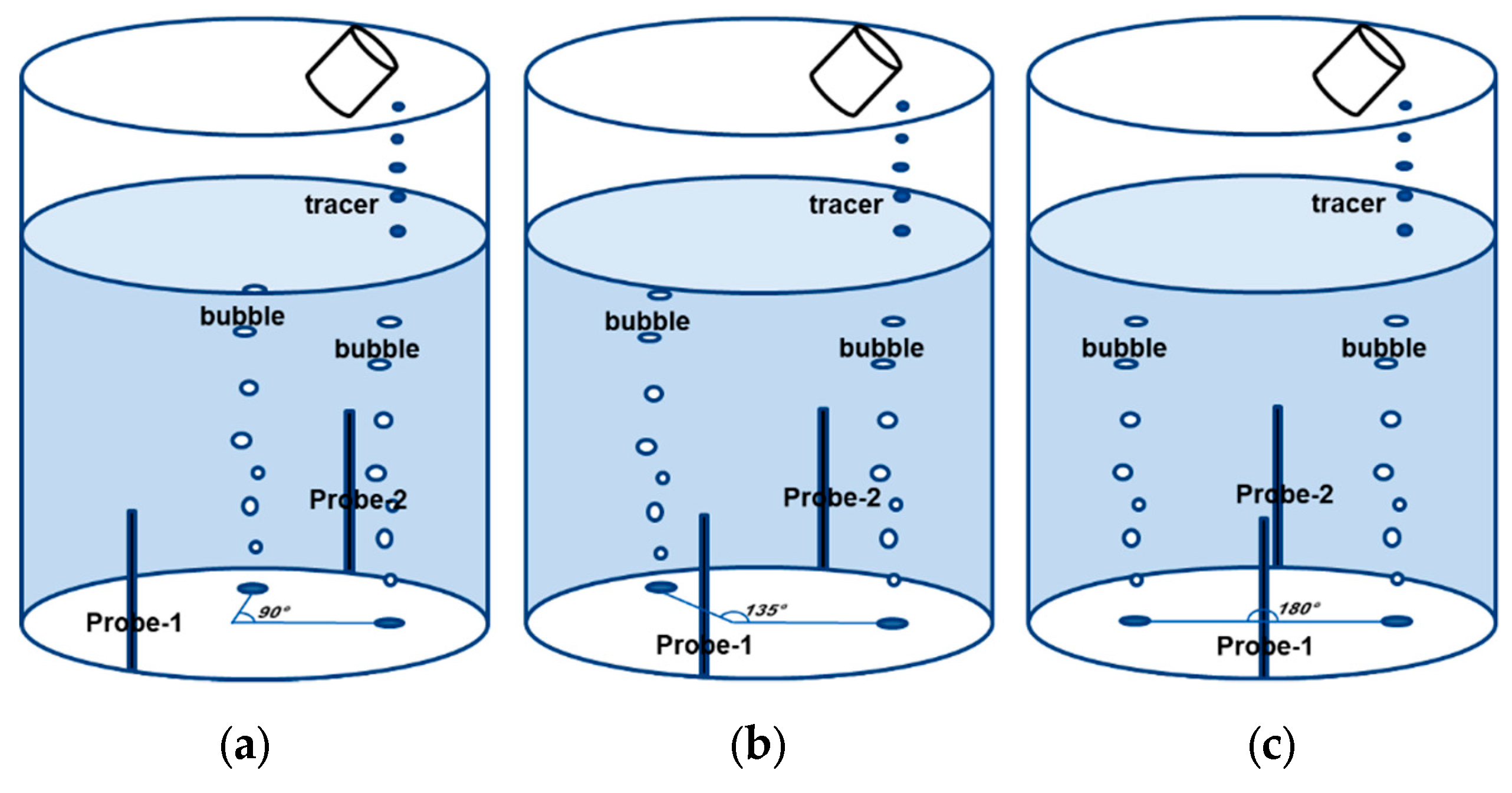

2. Scaling Criterion and Experimental Apparatus

3. Mathematical Modelling and Calculation Methods

4. Results and Discussion

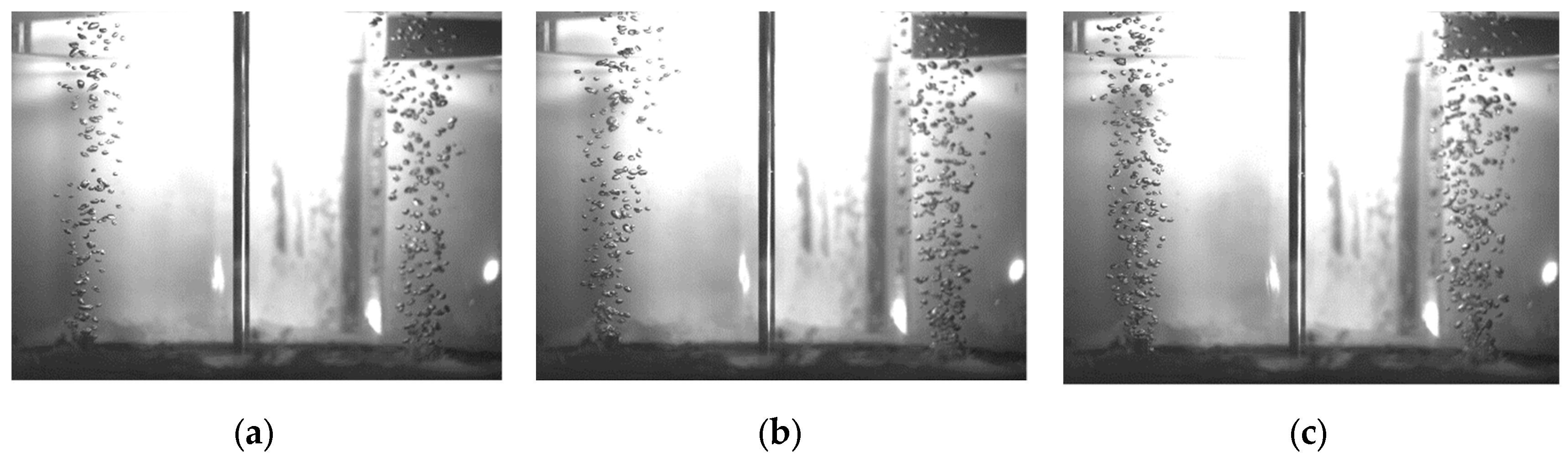

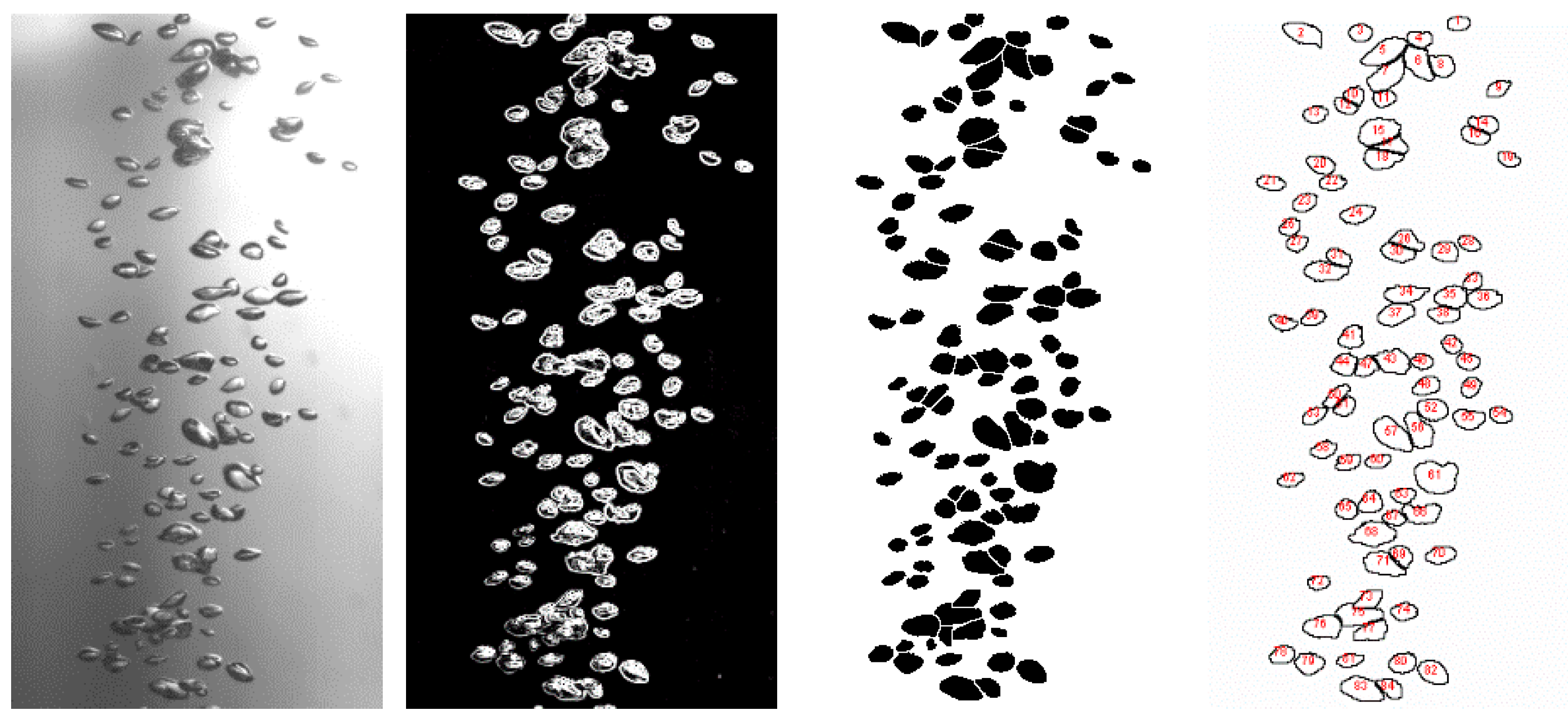

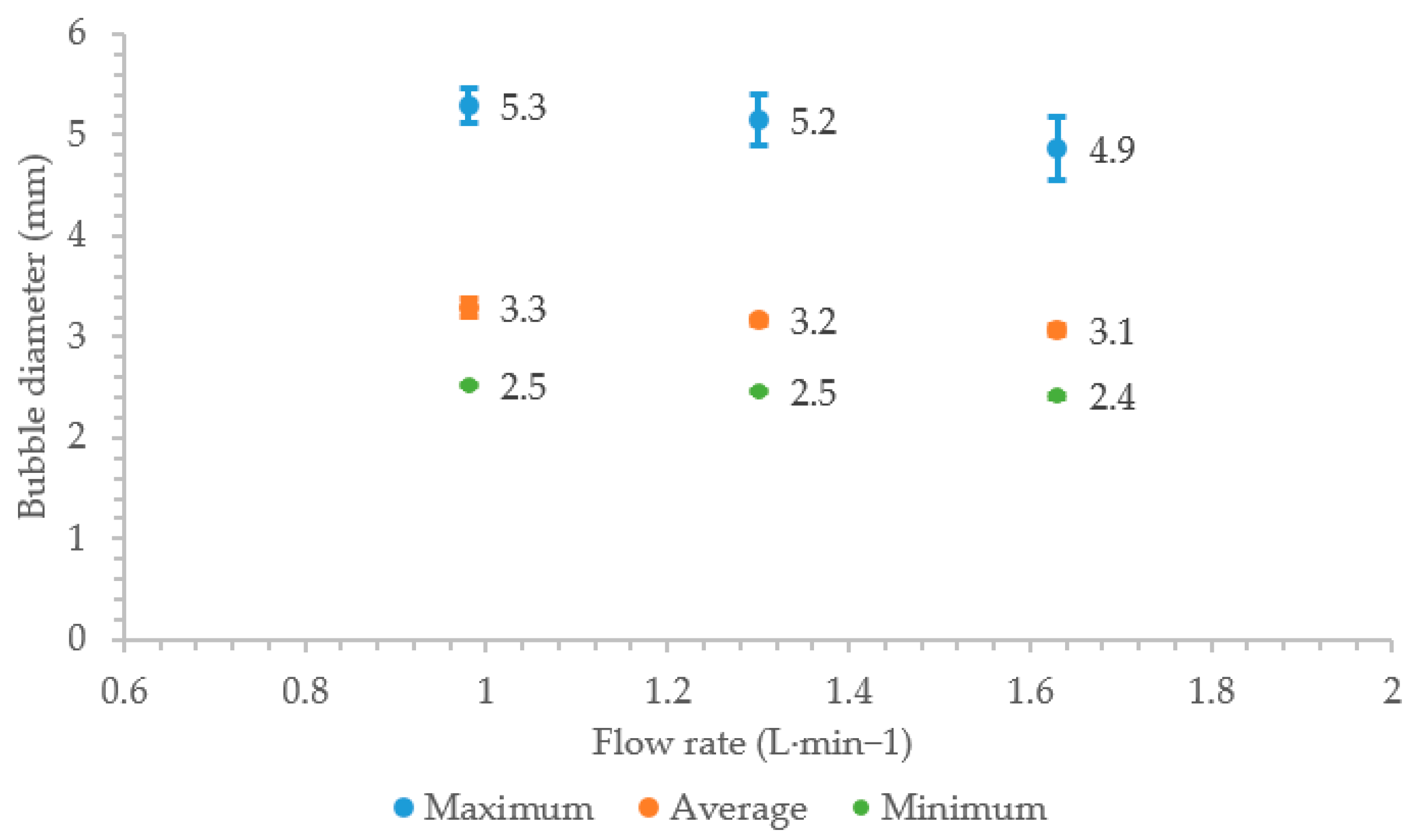

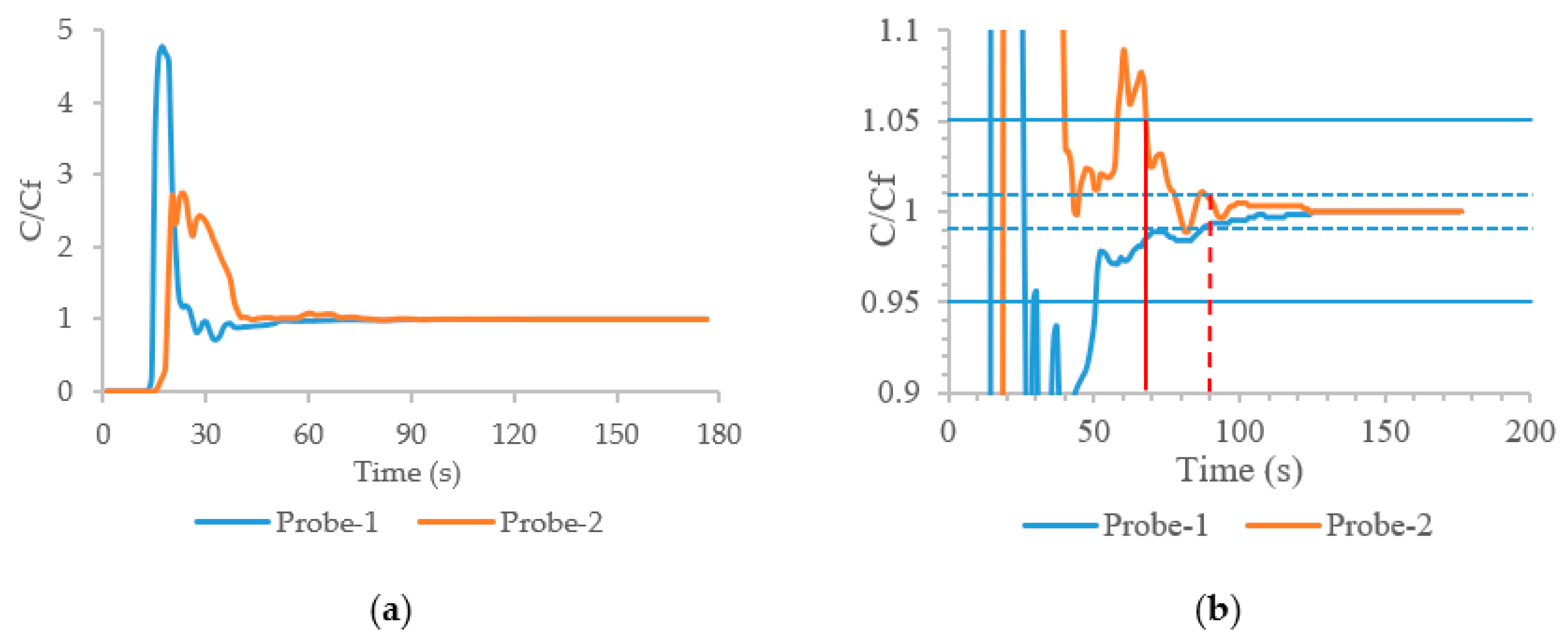

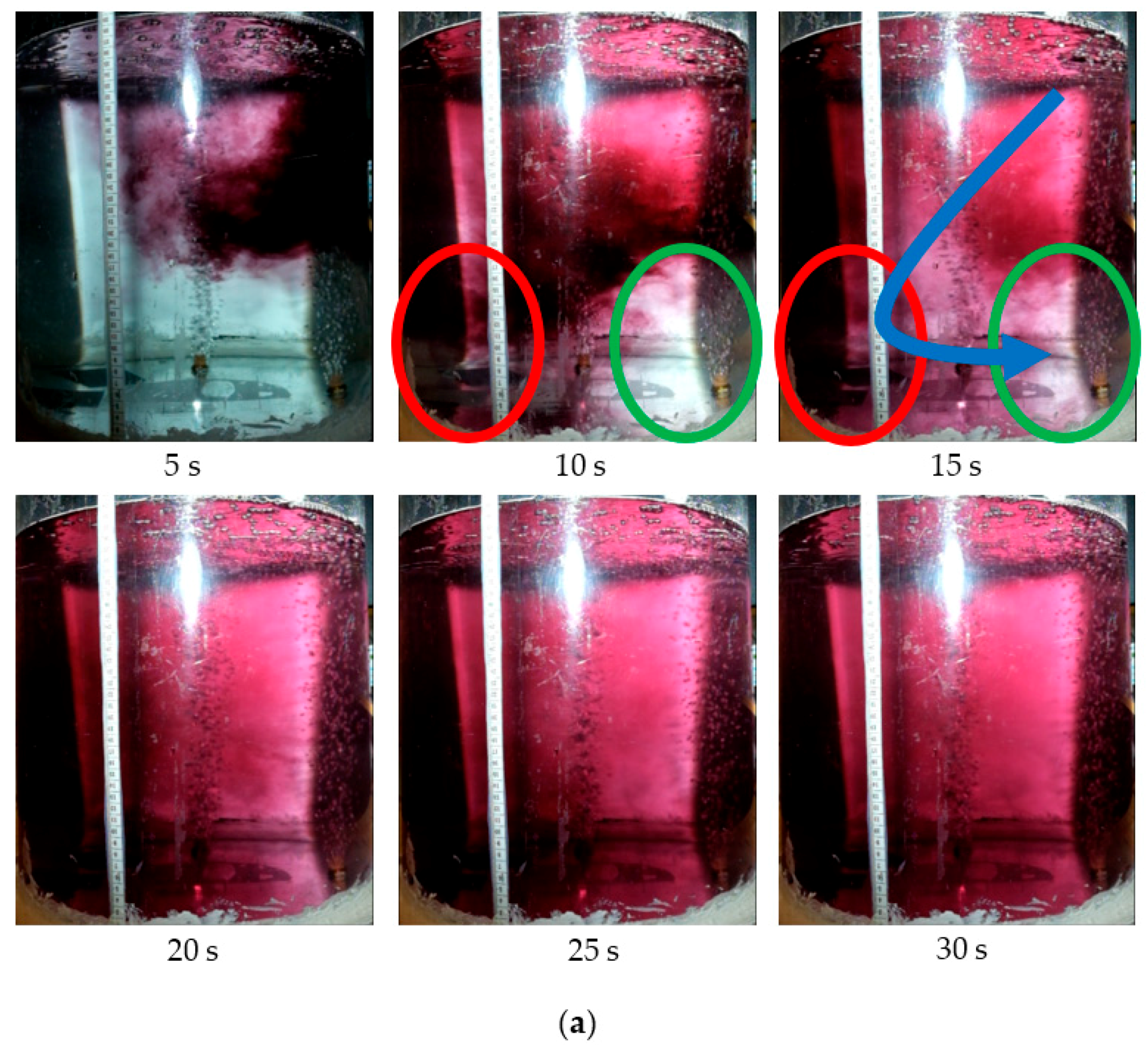

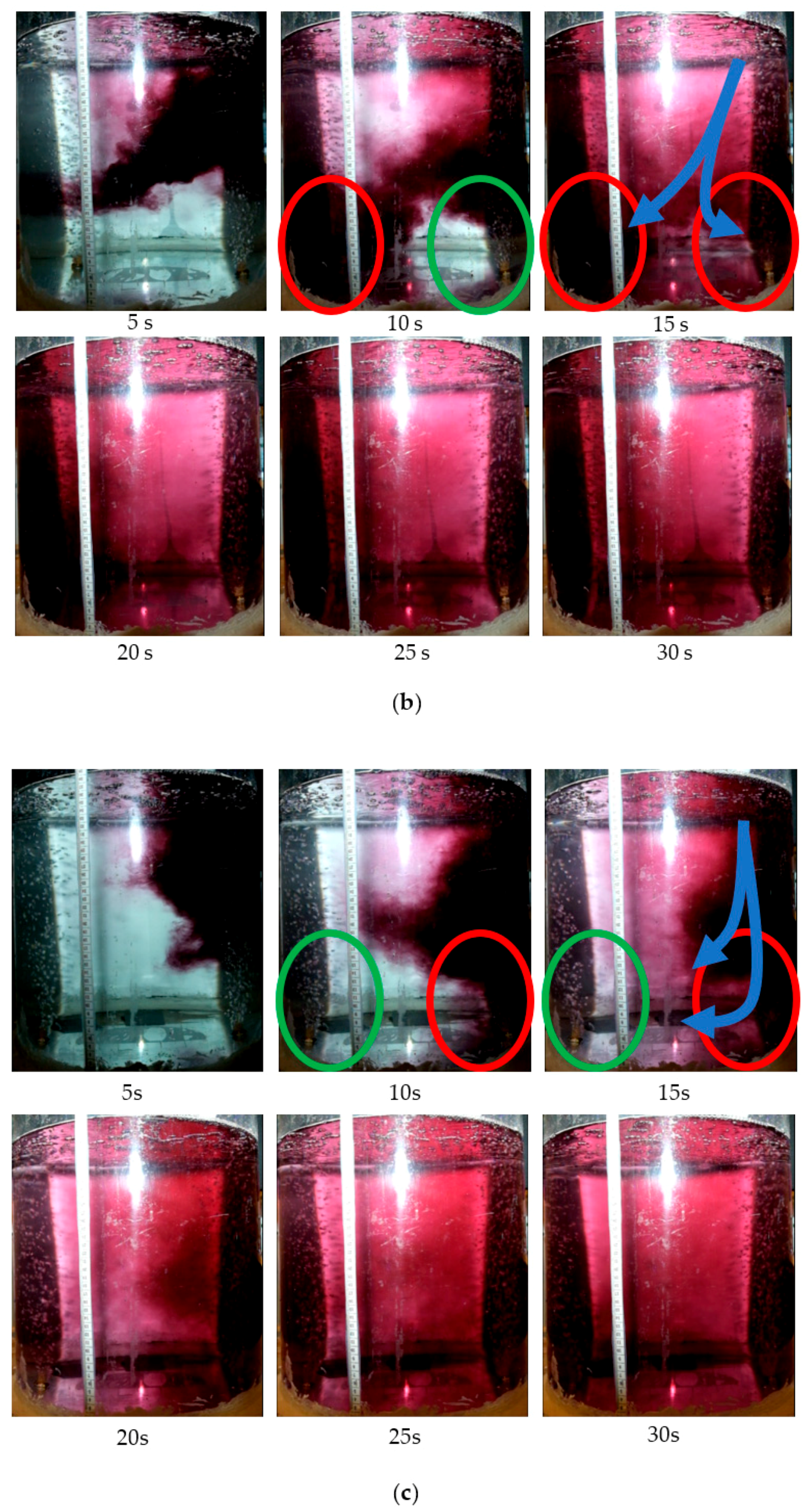

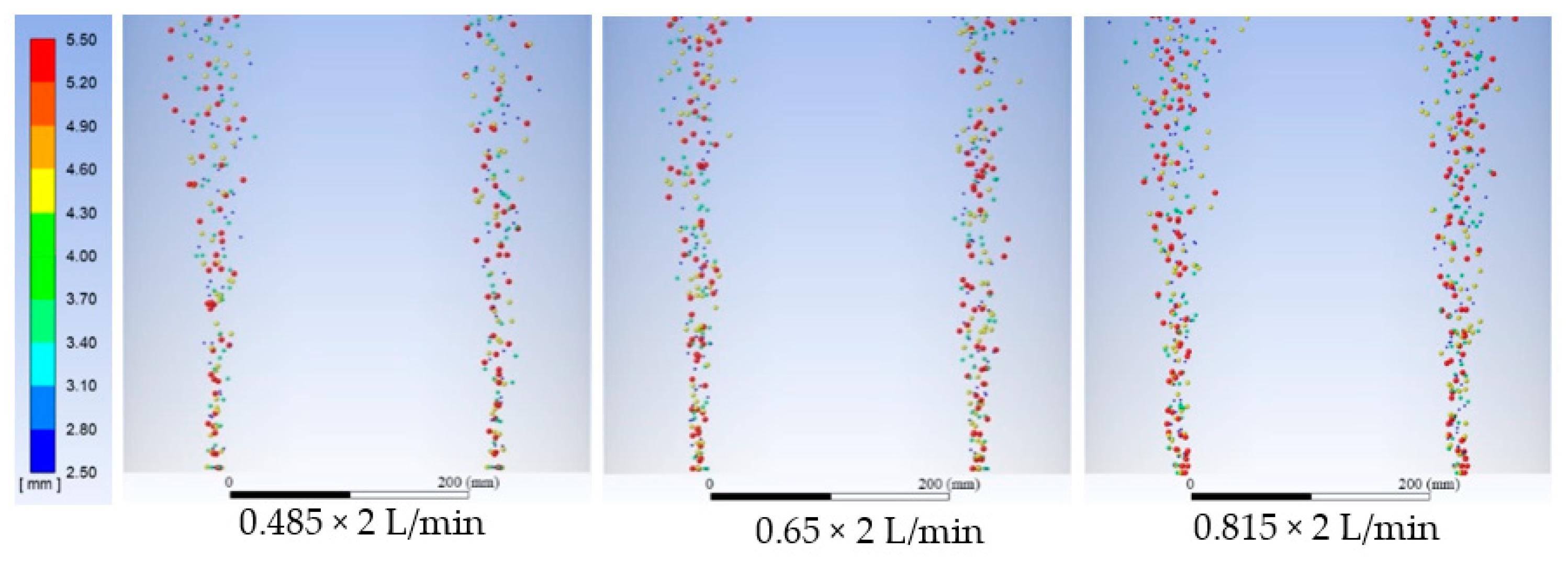

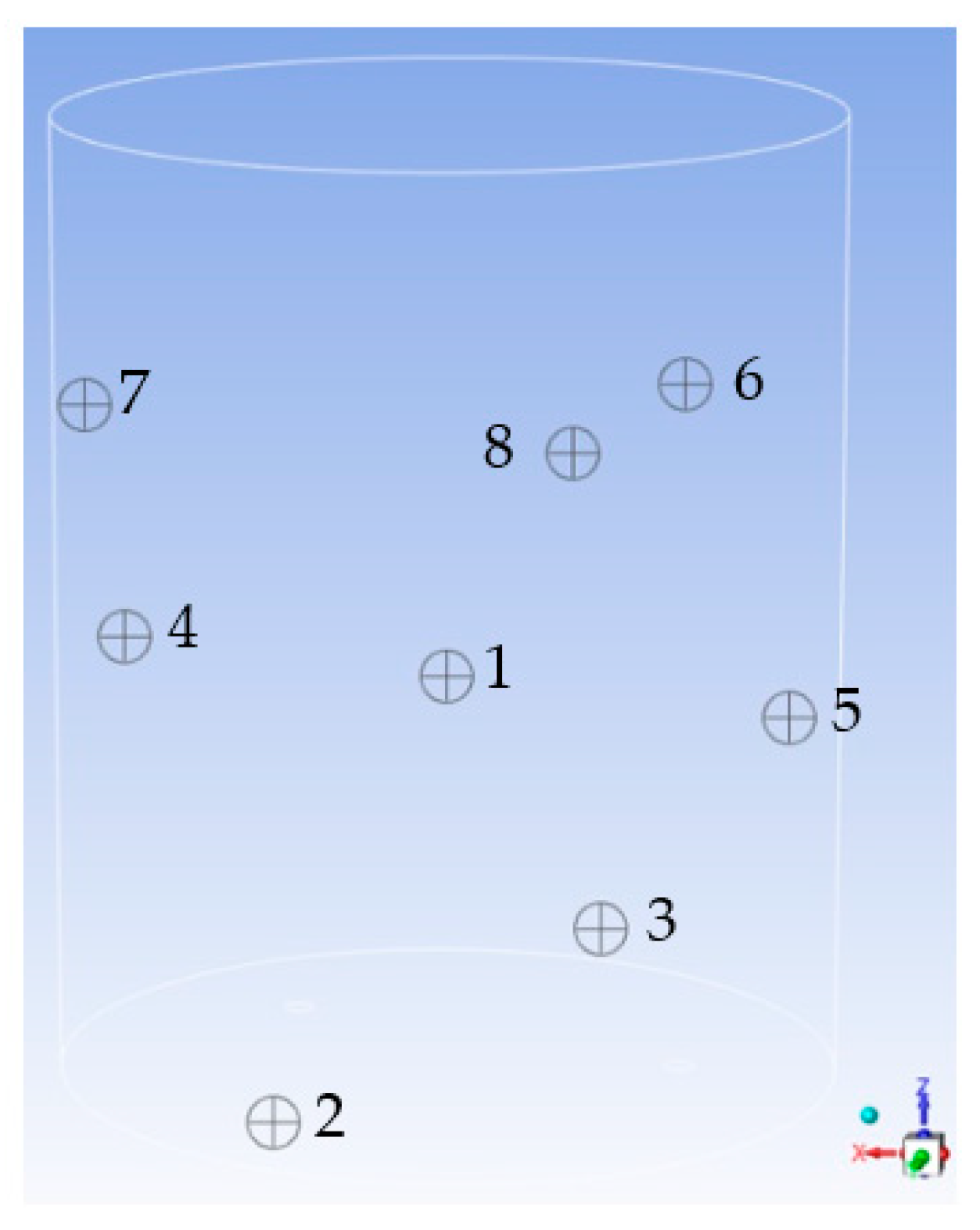

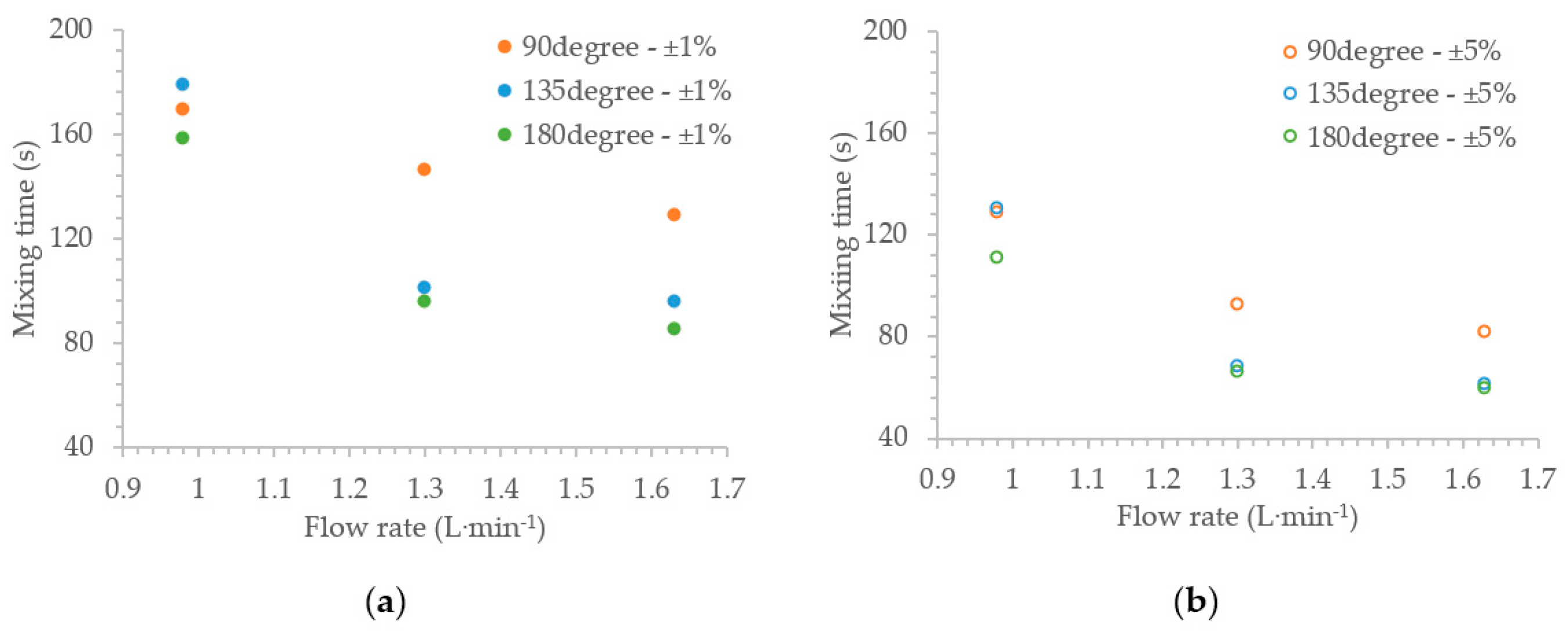

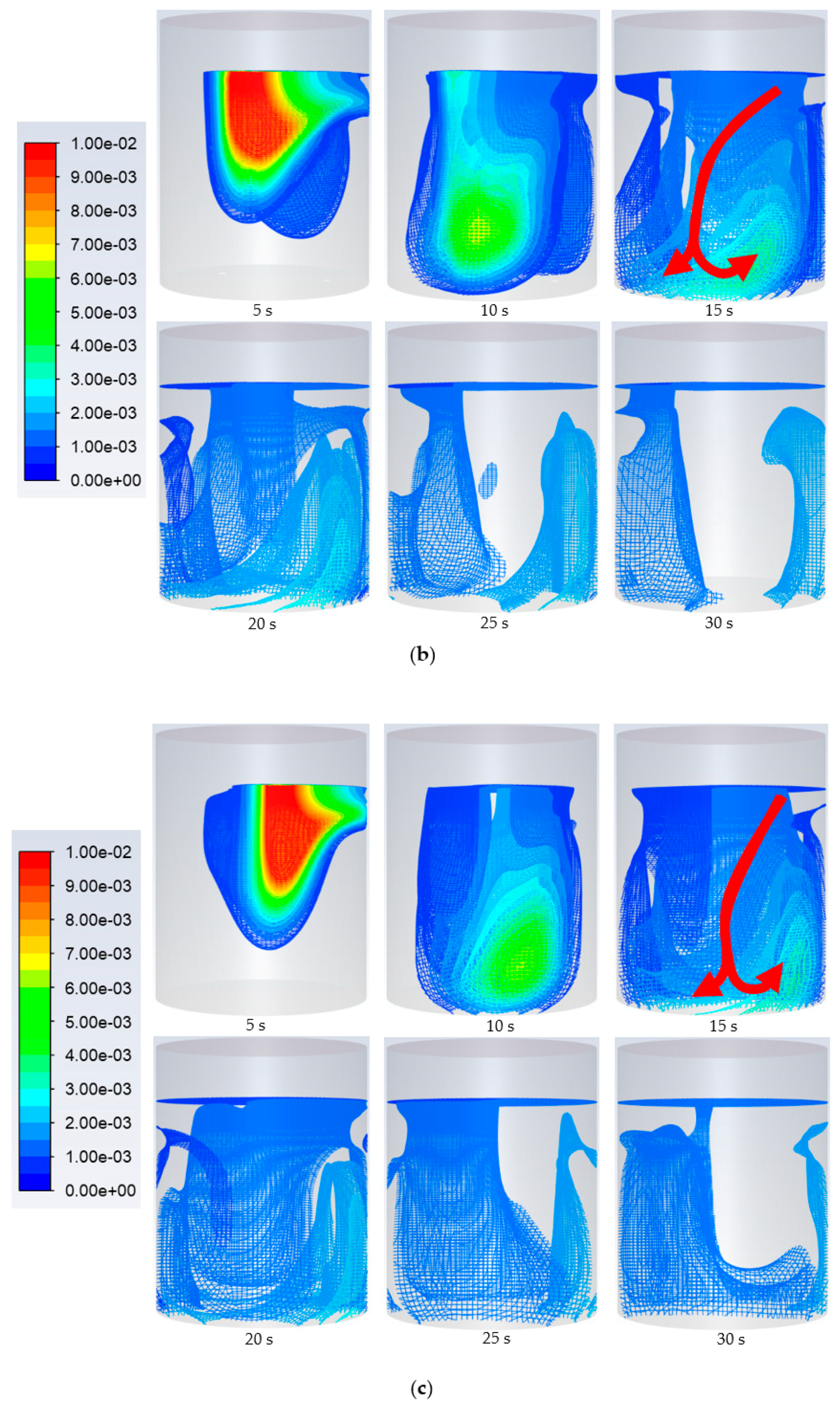

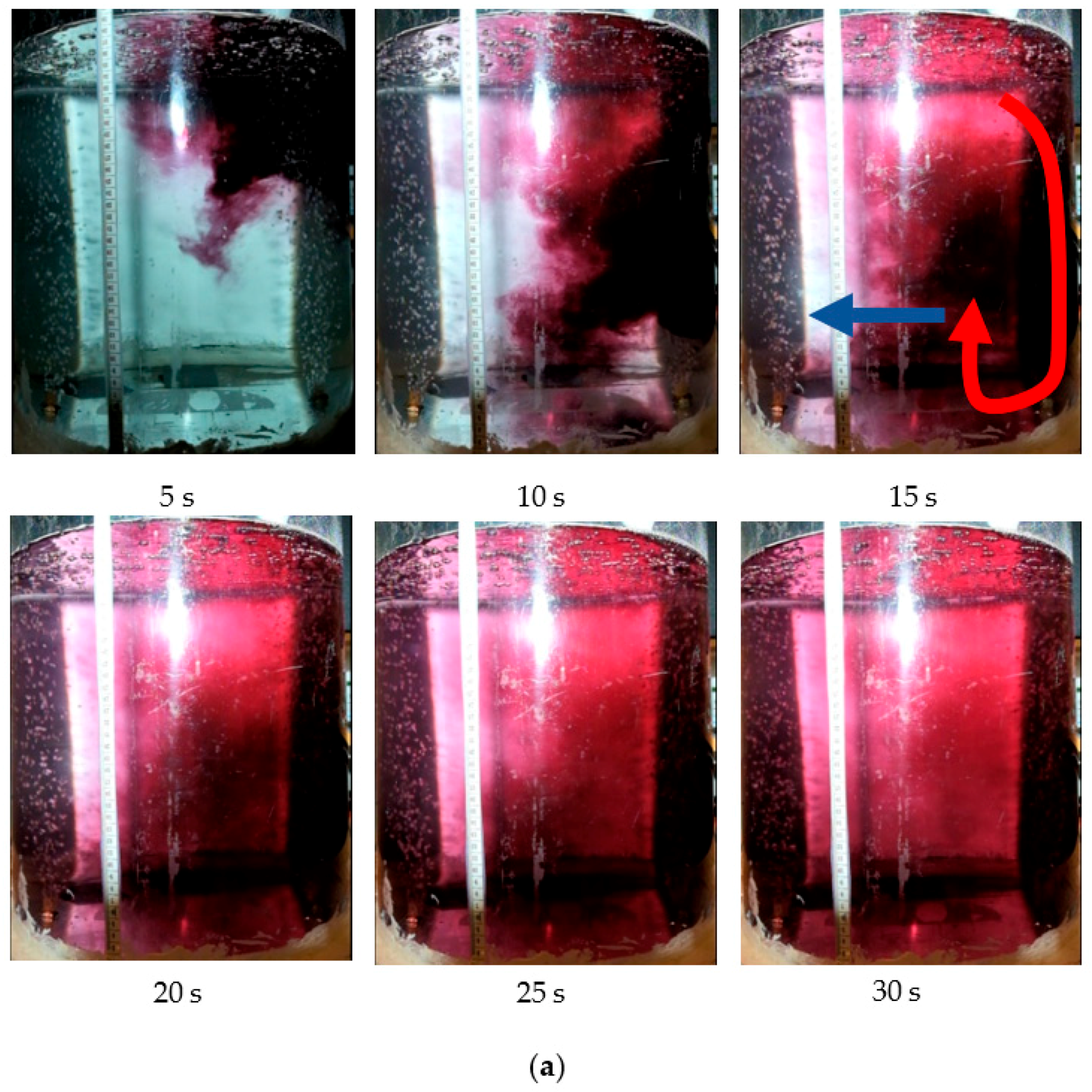

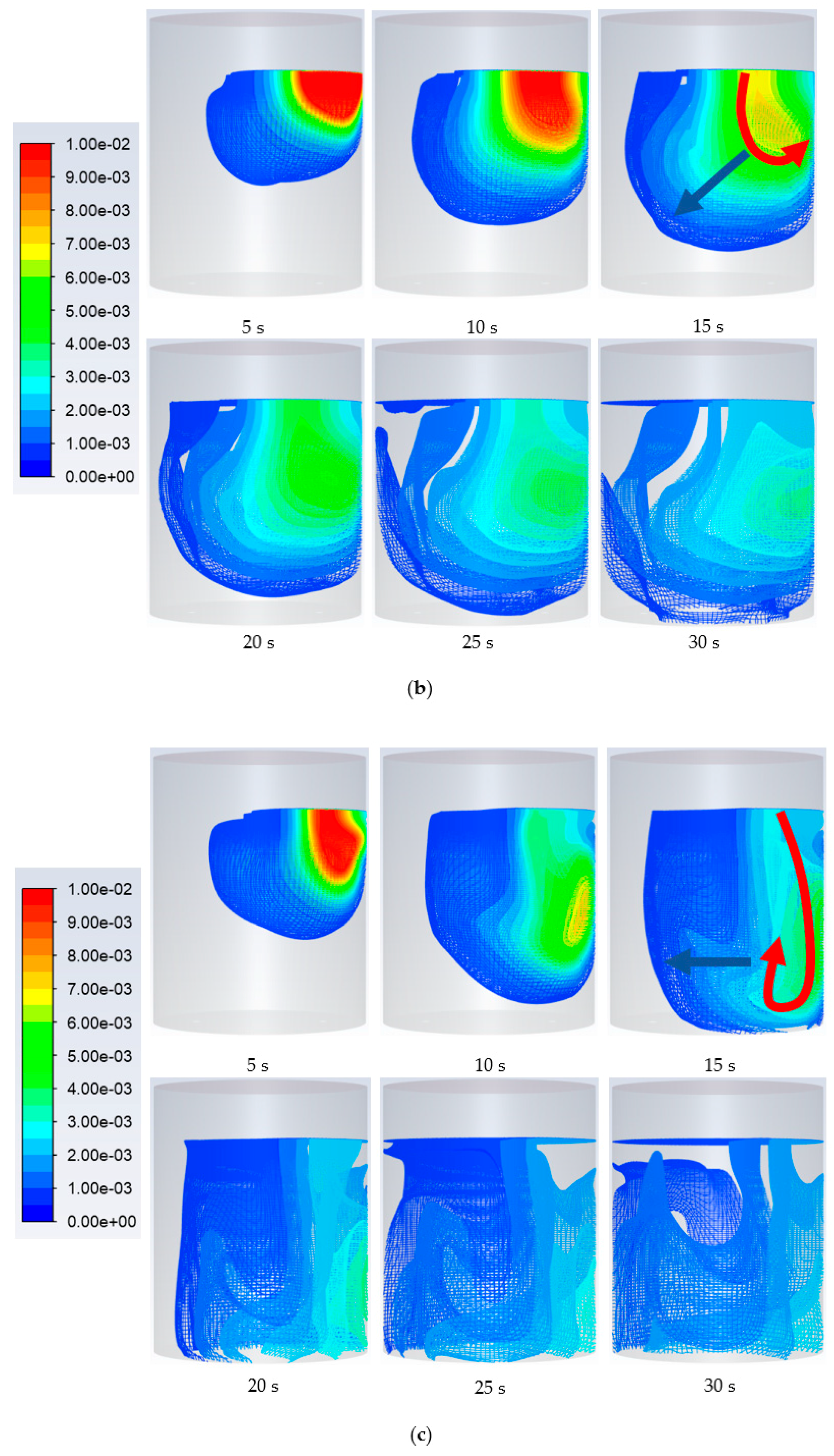

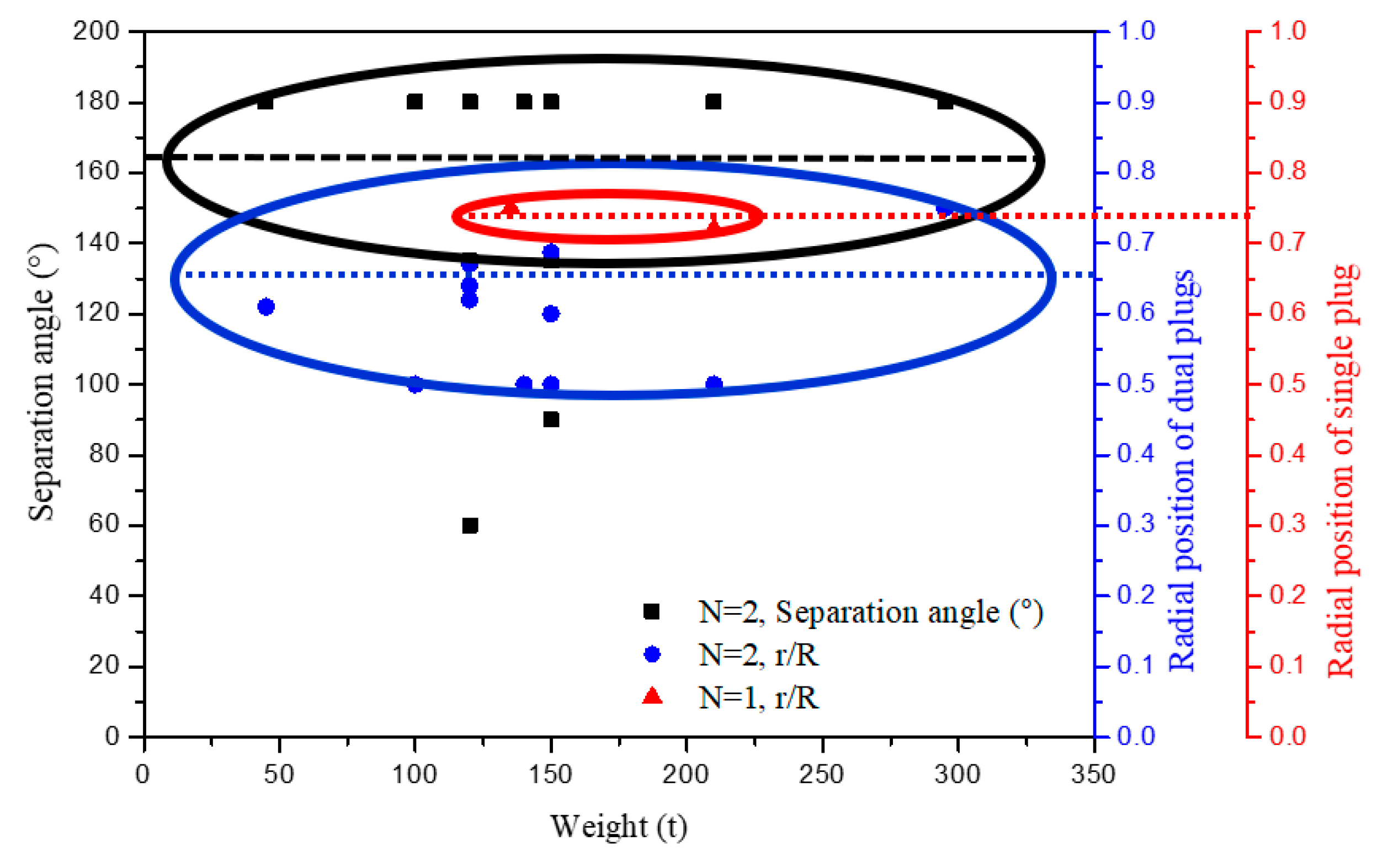

4.1. Gas Bubbling and Mixing Conditions in the Physical Modelling

4.2. Calculated Gas Bubbling and Mixing Conditions Using Mathematical Modelling

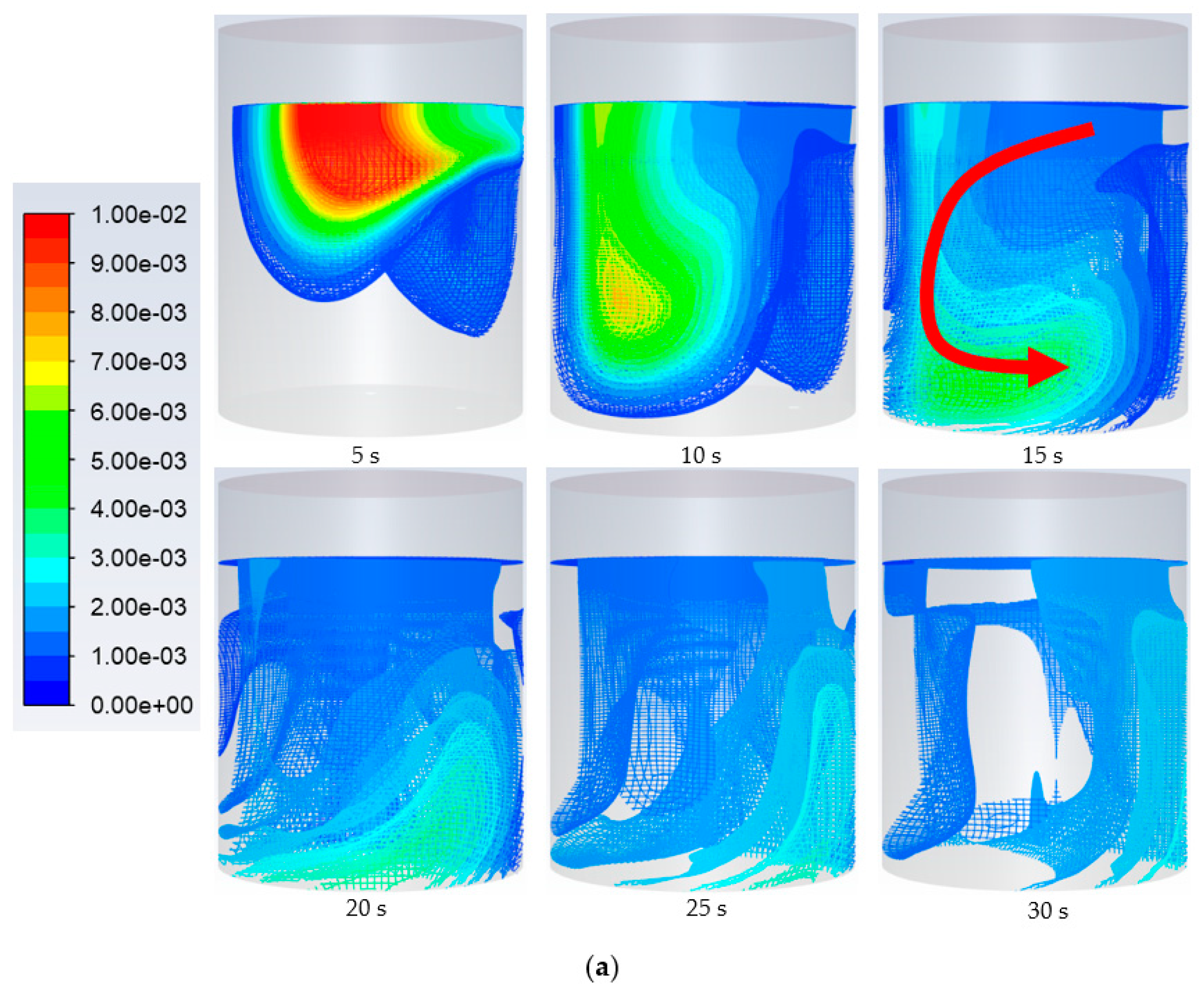

4.3. Convection and Diffusion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sichen, D. Modelling related to secondary steel making. Steel Res. Int. 2012, 83, 825–841. [Google Scholar] [CrossRef]

- Liu, Y.; Ersson, M.; Liu, H.P.; Jönsson, P.G.; Gan, Y. A review of physical and numerical approaches for the study of gas stirring in ladle metallurgy. Metall. Mater. Trans. B 2019, 50, 555–577. [Google Scholar] [CrossRef]

- Mazumdar, D.; Guthrie, R.I.L. Mixing models for gas stirred metallurgical reactors. Metall. Trans. B 1986, 17, 725–733. [Google Scholar] [CrossRef]

- Mazumdar, D.; Kim, H.B.; Guthrie, R.I.L. Modelling criteria for flow simulation in gas stirred ladles: Experimental study. Ironmak. Steelmak. 2000, 27, 302–309. [Google Scholar] [CrossRef]

- Joo, S.; Guthrie, R.I.L. Modelling flows and mixing in steelmaking ladles designed for single-plug and dual-plug bubbling operations. Metall. Trans. B 1992, 23, 765–778. [Google Scholar] [CrossRef]

- Krishnakumar, K.; Ballal, N.B.; Sinha, P.K.; Sardar, M.K.; Jha, K.N. Water model experiments on mixing phenomena in a VOD ladle. ISIJ Int. 1999, 39, 419–425. [Google Scholar] [CrossRef]

- González-Bernal, R.; Solorio-Diaz, G.; Ramos-Banderas, A.; Torres-Alonso, E.; Hernández-Bocanegra, C.A.; Zenit, R. Effect of the fluid-dynamic structure on the mixing time of a ladle furnace. Steel Res. Int. 2017, 89, 1700281. [Google Scholar] [CrossRef]

- Mandal, J.; Patil, S.; Madan, M.; Mazumdar, D. Mixing time and correlation for ladles stirred with dual porous plugs. Metall. Mater. Trans. B 2005, 36, 479–487. [Google Scholar] [CrossRef]

- Mazumdar, N.; Mahadevan, A.; Madan, M.; Mazumdar, D. Impact of ladle design on bath mixing. ISIJ Int. 2005, 45, 1940–1942. [Google Scholar] [CrossRef]

- Patil, S.P.; Satish, D.; Peranandhanathan, M.; Mazumdar, D. Mixing models for slag covered, argon stirred ladles. ISIJ Int. 2010, 50, 1117–1124. [Google Scholar] [CrossRef]

- Amaro-Villeda, A.M.; Ramirez-Argaez, M.A.; Conejo, A.N. Effect of slag properties on mixing phenomena in gas-stirred ladles by physical modelling. ISIJ Int. 2014, 54, 1–8. [Google Scholar] [CrossRef]

- Tang, H.Y.; Guo, X.C.; Wu, G.H.; Wang, Y. Effect of gas blown modes on mixing phenomena in a bottom stirring ladle with dual plugs. ISIJ Int. 2016, 56, 2161–2170. [Google Scholar]

- Liu, Z.Q.; Li, L.M.; Li, B.K. Modelling of gas-steel-slag three-phase flow in ladle metallurgy: Part I. physical modelling. ISIJ Int. 2017, 57, 1971–1979. [Google Scholar] [CrossRef]

- Gómez, A.S.; Conejo, A.N.; Zenit, R. Effect of separation angle and nozzle radial position on mixing time in ladles with two nozzles. J. Appl. Fluid Mech. 2018, 11, 11–20. [Google Scholar] [CrossRef]

- Fan, C.M.; Hwang, W.S. Study of optimal Ca-Si injection position in gas stirred ladle based on water model experiment and flow simulation. Ironmak. Steelmak. 2002, 29, 415–426. [Google Scholar] [CrossRef]

- Ek, M.; Wu, L.; Valentin, P.; Sichen, D. Effect of inert gas flow rate on homogenization and inclusion removal in a gas stirred ladle. Steel Res. Int. 2010, 81, 1056–1063. [Google Scholar] [CrossRef]

- Geng, D.Q.; Lei, H.; He, J.C. Optimization of mixing time in a ladle with dual plugs. Int. J. Miner. Metall. Mater. 2010, 17, 709–714. [Google Scholar] [CrossRef]

- Liu, H.P.; Qi, Z.Y.; Xu, M.G. Numerical simulation of fluid flow and interfacial behavior in three-phase argon-stirred ladles with one plug and dual plugs. Steel Res. Int. 2011, 82, 440–458. [Google Scholar] [CrossRef]

- Lou, W.T.; Zhu, M.Y. Numerical simulations of inclusion behavior and mixing phenomena in gas-stirred ladles with different arrangement of tuyeres. ISIJ Int. 2014, 54, 9–18. [Google Scholar] [CrossRef]

- Duan, H.J.; Zhang, L.F.; Thomas, B.G.; Conejo, A.N. Fluid flow, dissolution, and mixing phenomena in argon-stirred steel ladles. Metall. Mater. Trans. B 2018, 49, 2722–2743. [Google Scholar] [CrossRef]

- Krishnapisharody, K.; Irons, G.A. A critical review of the modified froude number in ladle metallurgy. Metall. Mater. Trans. B 2013, 44, 1486–1498. [Google Scholar] [CrossRef]

- Liu, Y.; Ersson, M.; Liu, H.P.; Jönsson, P.; Gan, Y. Comparison of Euler-Euler approach and Euler–Lagrange approach to model gas injection in a ladle. Steel Res. Int. 2019, 90, 1–13. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Li, B.K. Scale-adaptive analysis of Euler-Euler large eddy simulation for laboratory scale dispersed bubbly flows. Chem. Eng. J. 2018, 338, 465–477. [Google Scholar] [CrossRef]

- ANSYS FLUENT Theory Guide Version 19.2; ANSYS Inc.: Canonsburg, PA, USA, 2017.

- Castillejos, A.H.; Brimacombe, J.K. Measurement of physical characteristics of bubbles in gas-liquid plumes. 2. local properties of turbulent air-water plumes in vertically injected jets. Metall. Trans. B 1987, 18, 659–671. [Google Scholar] [CrossRef]

- Leonard, A. Overview of Turbulent and Laminar Diffusion and Mixing; Springer Vienna: Udine, Italy, 2009; pp. 2–17. [Google Scholar]

| Author | Weight | Scale | Gas Injection Pattern | Plug Position | Plug Radial Angle | Liquid Metal | Gas | Physical Modelling | Mathematical Modelling | Optimal Plug Number and Position |

|---|---|---|---|---|---|---|---|---|---|---|

| Water-based solutions | ||||||||||

| Liu et al. [13] | 45 t | 1/3 | porous plug | 0R, 0.5R, 0.56R, 0.62R, 0.67R, 0.73R | 60°, 90°, 120°, 150°, and 180° | water | N2 | NaCl above the exposed eye | - | N = 2, 0.5R~0.73R-180° |

| Joo and Guthrie [5] | 100 t | 1/3 | porous plug | 0R, 0.33R, 0.5R, 0.67R | 45°, 90°, 135°, and 180° | water | air | KCl above the plume | Euler–Euler + species (own code) | N = 2, 0.5R-180° |

| Tang et al. [12] | 120 t | 1/3 | porous plug | 0.55R, 0.64R, 0.70R | 45°, 90°, 135°, and 180° | water | N2 | KCl above the exposed eye | VOF + species (Fluent) | N = 2, 0.7R-180°, 0.64R-135°, and 0.55R-180° |

| Gómez et al. [14] | 120 t | 1/8 | nozzle | 1/3R, 1/2R, and 2/3R | 60°, 120°, and 180° | water | air | KCl above the exposed eye | - | N = 2, 0.67R-60° |

| González-Bernal et al. [7] | 135 t | 1/7 | Tuyere | 1/3R, 2/3R, and 3/4R | 60° | water | air | vegetal red colorant at the central bottom | - | N = 1, 3/4R |

| Mandal et al. [8] | 140 t | 1/5 | tuyere/nozzle | 0R, 0.5R | - | water | air/N2 | NaCl or H2SO4 axis of symmetry | - | N = 2, 0.5R-180° |

| Amaro-Villeda et al. [11] | 140 t | 1/6 | Nozzle | 0R, 0.33R, 0.5R, 0.67R, 0.8R | 120°, 180° | water | air | NaOH or HCl | - | N = 2, 0.5R-180° |

| Mazumdar et al. [9] | 210 t | 0.17 | Nozzle | 0R, 0.5R, and 0.64R | 90°, 180° | water | air/N2 | NaCl or H2SO4 axis of symmetry | - | N = 2, 0.5R-180° |

| Ek. et al. [16] | 200 t | 1/5 | porous plug | 0.72R | - | water | air | NaCl above the plume | Euler–Euler + species (Comsol) | N = 1, 0.72R |

| This work | 50 t | 1/5.37 | porous plug | 0.65R | 90°, 135°, and 180° | water | air | NaCl and red dye above the open eye | Euler–Lagrange + species (Fluent) | - |

| Steel-based solutions | ||||||||||

| Liu et al. [18] | 150 t | - | porous plug | 0.687R | 90°, 135°, 180° | steel | argon | - | Euler–Lagrange + species (Fluent) | N = 2, 0.687R-180° |

| Luo et al. [19] | 150 t | - | Nozzle | 0.3R, 0.4R, 0.5R, 0.6R, 0.7R, 0.8R | 45°, 90°, 135°, and 180° | steel | argon | - | Euler–Euler + species (Fluent) | N= 2, 0.6R-135° |

| Duan et al. [20] | 150 t | - | porous plug | 0.34R, 0.5R, 0.68R, 0.75R | 45°, 90°, 135°, and 180° | steel | argon | - | Euler–Lagrange + species (Fluent) | N = 2, 0.5R-90° |

| Geng et al. [17] | 295 t | - | Nozzle | 0.25R, 0.33R, 0.5R, 0.75R, and 0.8R | 90°, 120°, 150°, and 180° | steel | argon | - | Euler–Euler +species (CFX) | N = 2, 0.75R-180° |

| Cases | Flow Rate (L·min−1) | ||

|---|---|---|---|

| Industrial Process | 150 | 200 | 250 |

| Water experiment | 0.98 | 1.30 | 1.63 |

| - | Flow Rate (L·min−1) | Mixing Time (s) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 90 degree | 135 degree | 180 degree | ||||||||

| Physical | Numerical | Error | Physical | Numerical | Error | Physical | Numerical | Error | ||

| ±5% | 0.98 | 66 | 129.3 | 96% | 74 | 130.5 | 76% | 62 | 111 | 79% |

| 1.3 | 62 | 92.3 | 49% | 65 | 68.7 | 6% | 60 | 66.2 | 10% | |

| 1.63 | 57 | 82 | 44% | 53 | 61 | 15% | 57 | 60 | 5% | |

| ±1% | 0.98 | 88 | 169 | 92% | 107 | 179 | 67% | 96 | 158 | 64% |

| 1.3 | 80 | 146 | 83% | 89 | 101 | 13% | 83 | 96 | 16% | |

| 1.63 | 66 | 129 | 95% | 73 | 85 | 16% | 76 | 85 | 12% | |

| Species Transport | Factor | Expression |

|---|---|---|

| Mass diffusion | Laminar diffusion | |

| Turbulent diffusion | ||

| Convection | Bubbly flow forced convection | |

| Natural convection |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Bai, H.; Liu, H.; Ersson, M.; Jönsson, P.G.; Gan, Y. Physical and Numerical Modelling on the Mixing Condition in a 50 t Ladle. Metals 2019, 9, 1136. https://doi.org/10.3390/met9111136

Liu Y, Bai H, Liu H, Ersson M, Jönsson PG, Gan Y. Physical and Numerical Modelling on the Mixing Condition in a 50 t Ladle. Metals. 2019; 9(11):1136. https://doi.org/10.3390/met9111136

Chicago/Turabian StyleLiu, Yu, Haitong Bai, Heping Liu, Mikael Ersson, Pär G. Jönsson, and Yong Gan. 2019. "Physical and Numerical Modelling on the Mixing Condition in a 50 t Ladle" Metals 9, no. 11: 1136. https://doi.org/10.3390/met9111136

APA StyleLiu, Y., Bai, H., Liu, H., Ersson, M., Jönsson, P. G., & Gan, Y. (2019). Physical and Numerical Modelling on the Mixing Condition in a 50 t Ladle. Metals, 9(11), 1136. https://doi.org/10.3390/met9111136