Fundamental Mechanisms for Irradiation-Hardening and Embrittlement: A Review

Abstract

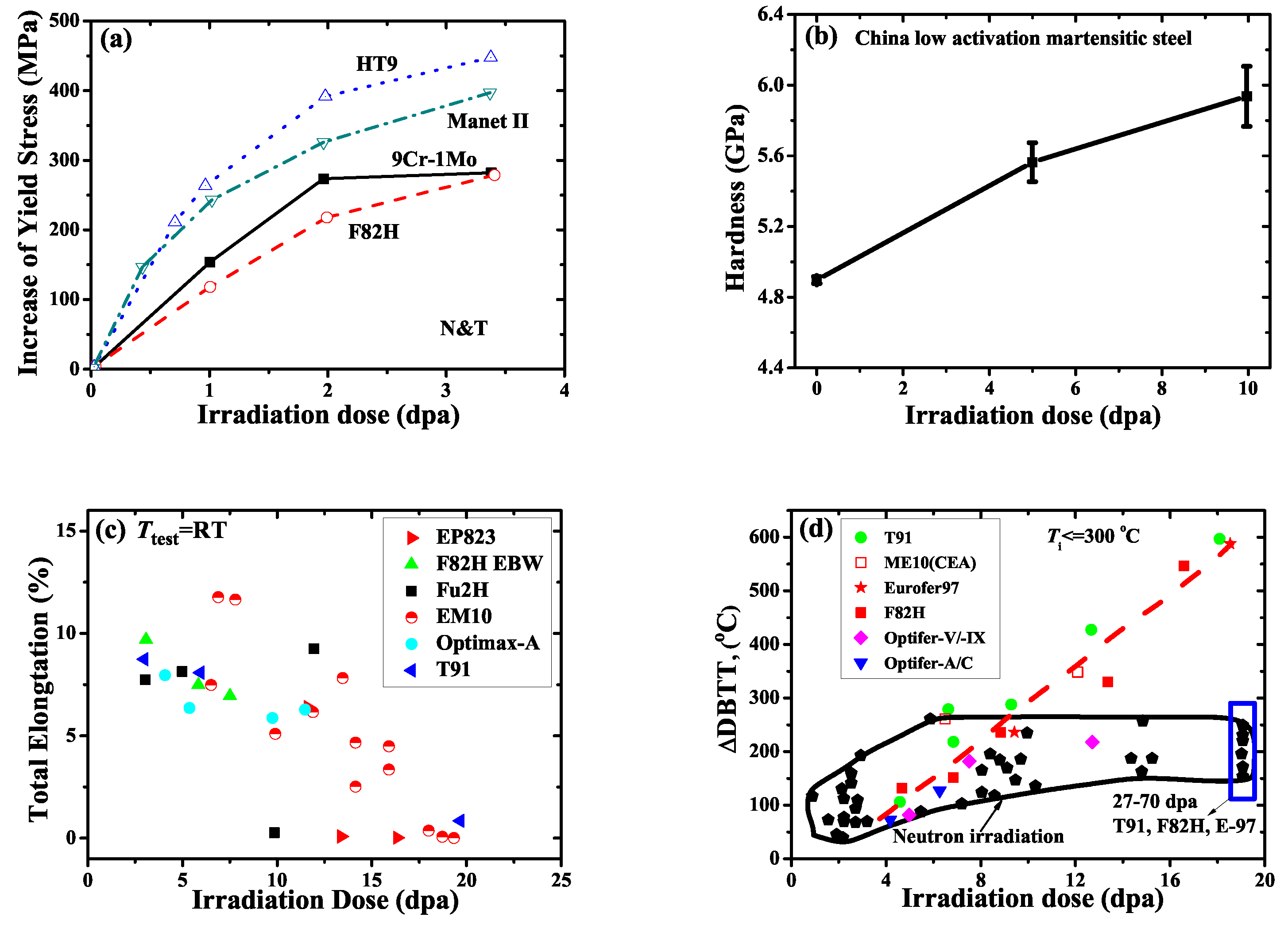

1. Introduction

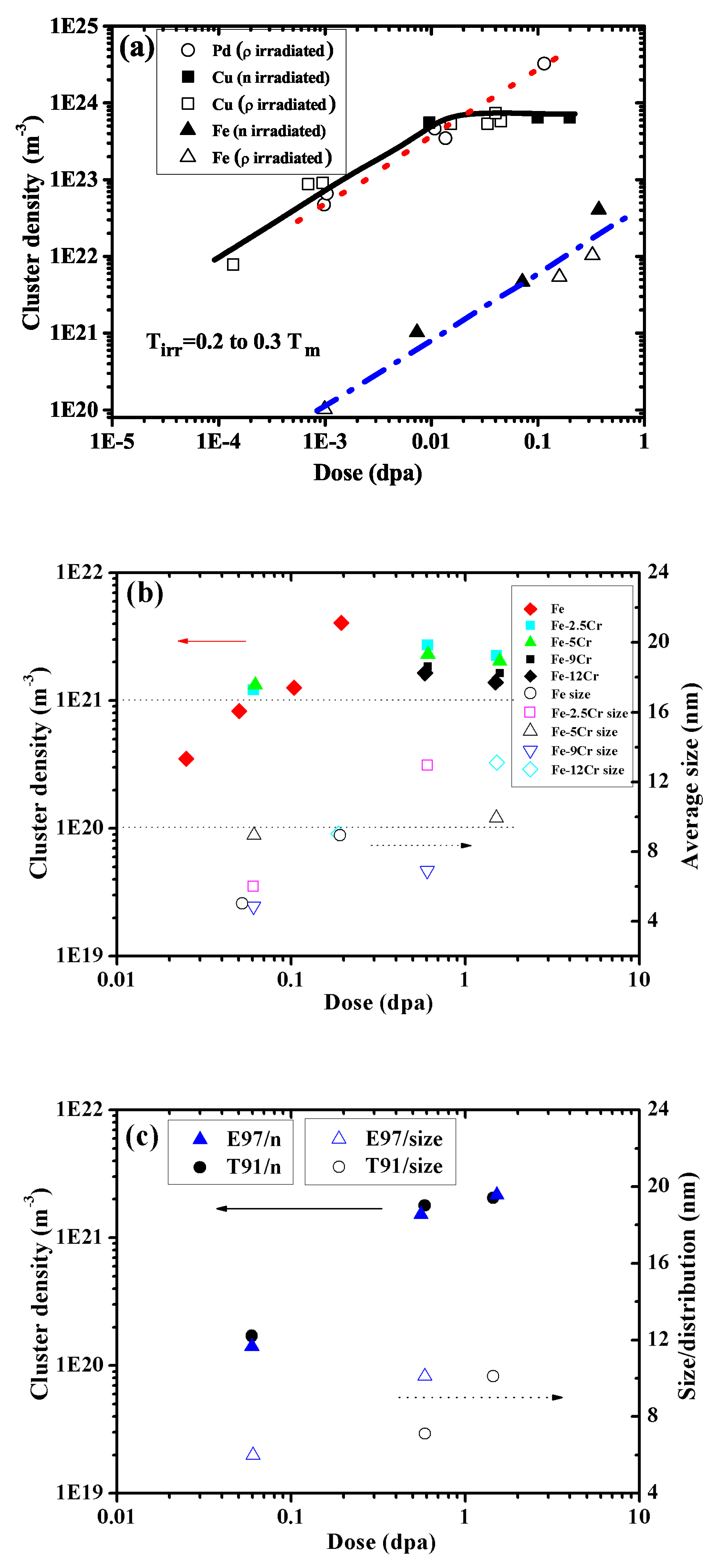

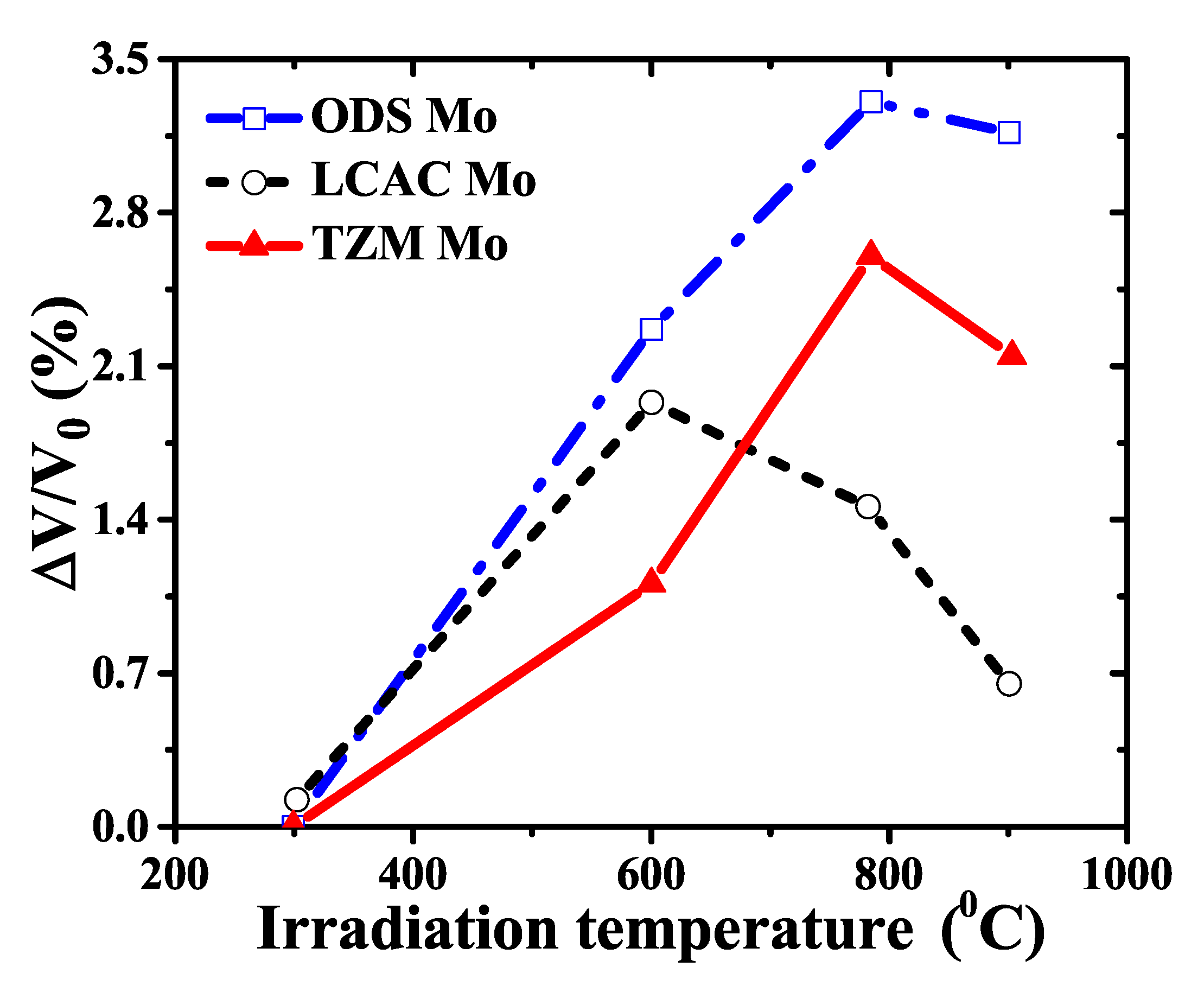

2. Formation of Irradiation-Induced Defects

2.1. Irradiation Condition

2.2. Material Properties

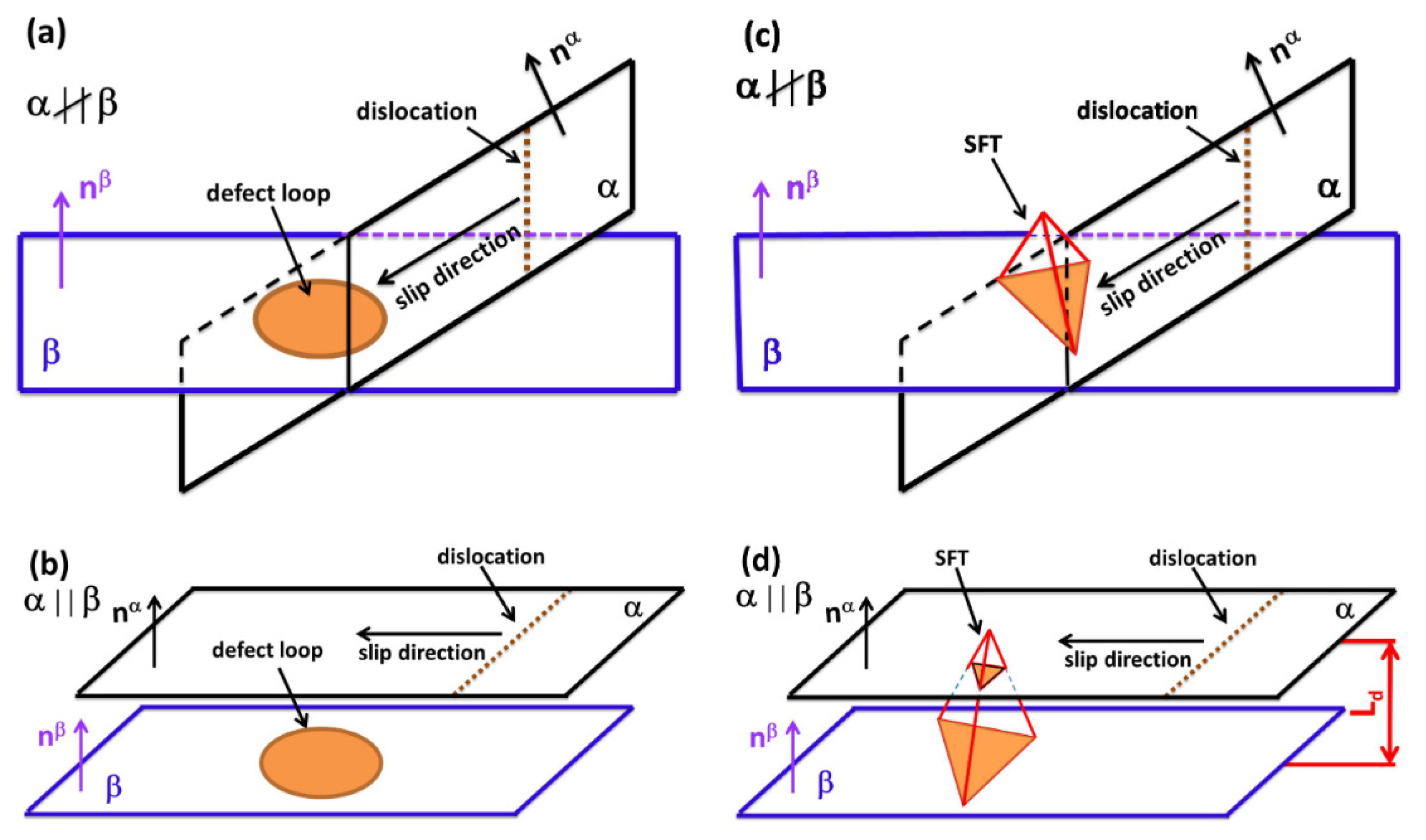

3. Interaction between Defects and Dislocations

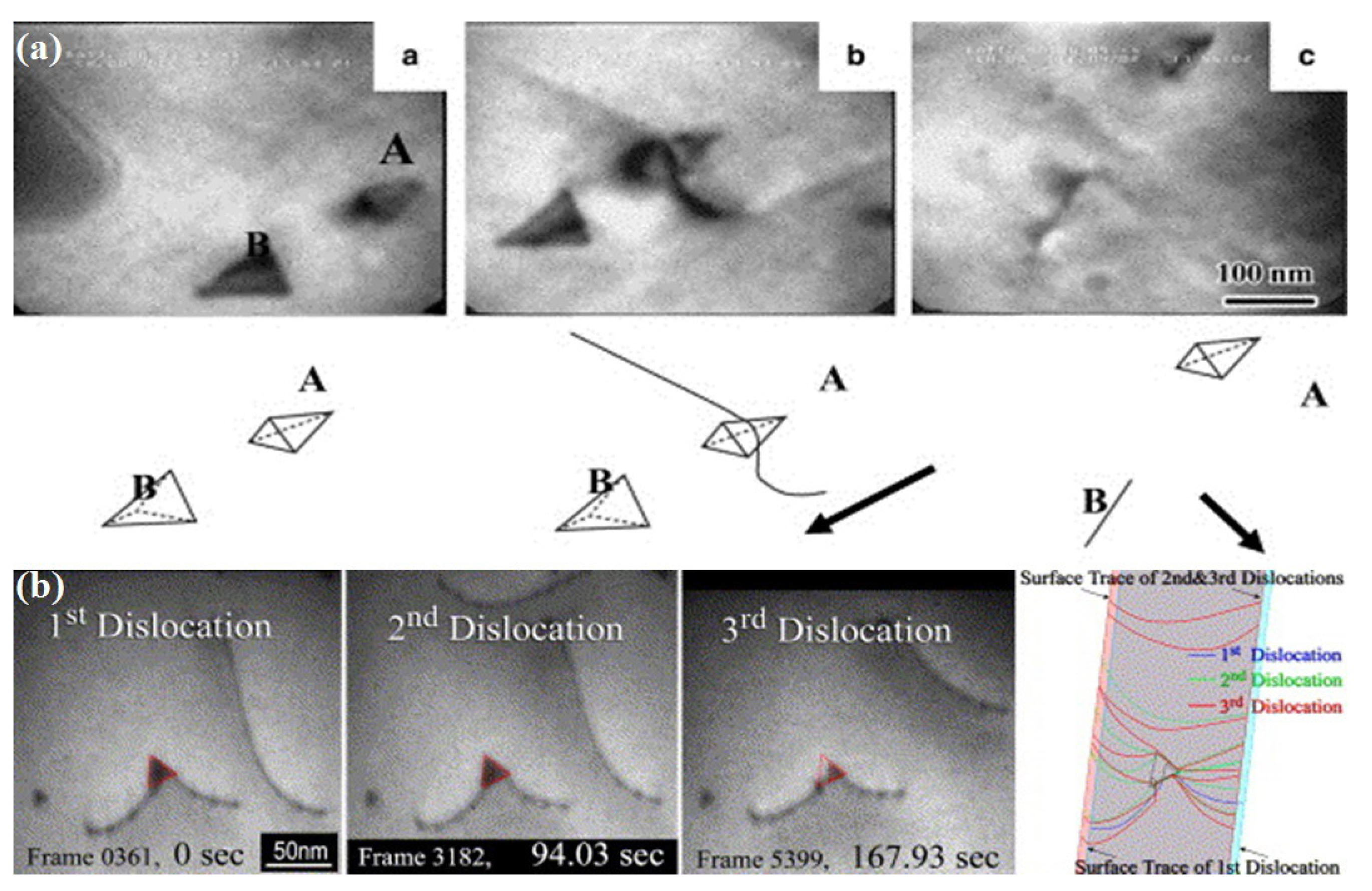

3.1. Interaction Process

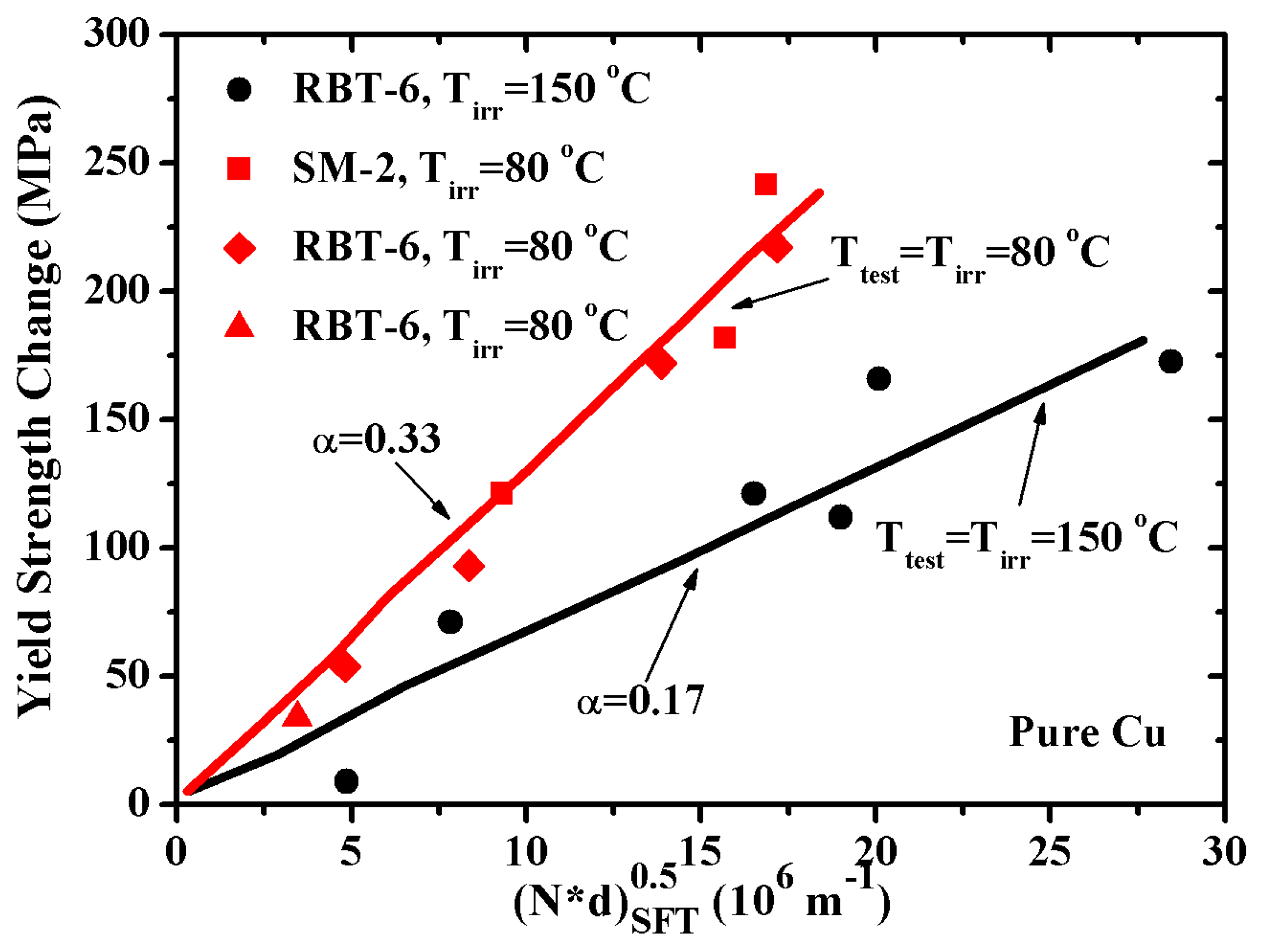

3.2. Interaction Strength

4. Evolution of Defects and Dislocations

4.1. Annihilation of Defects

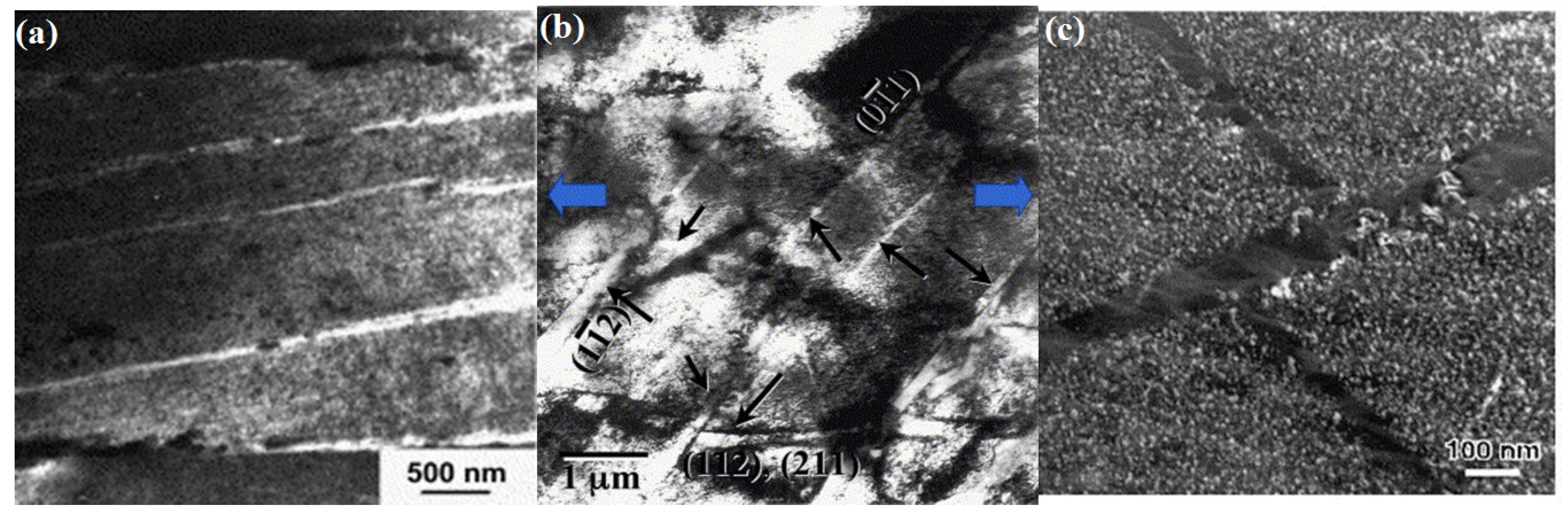

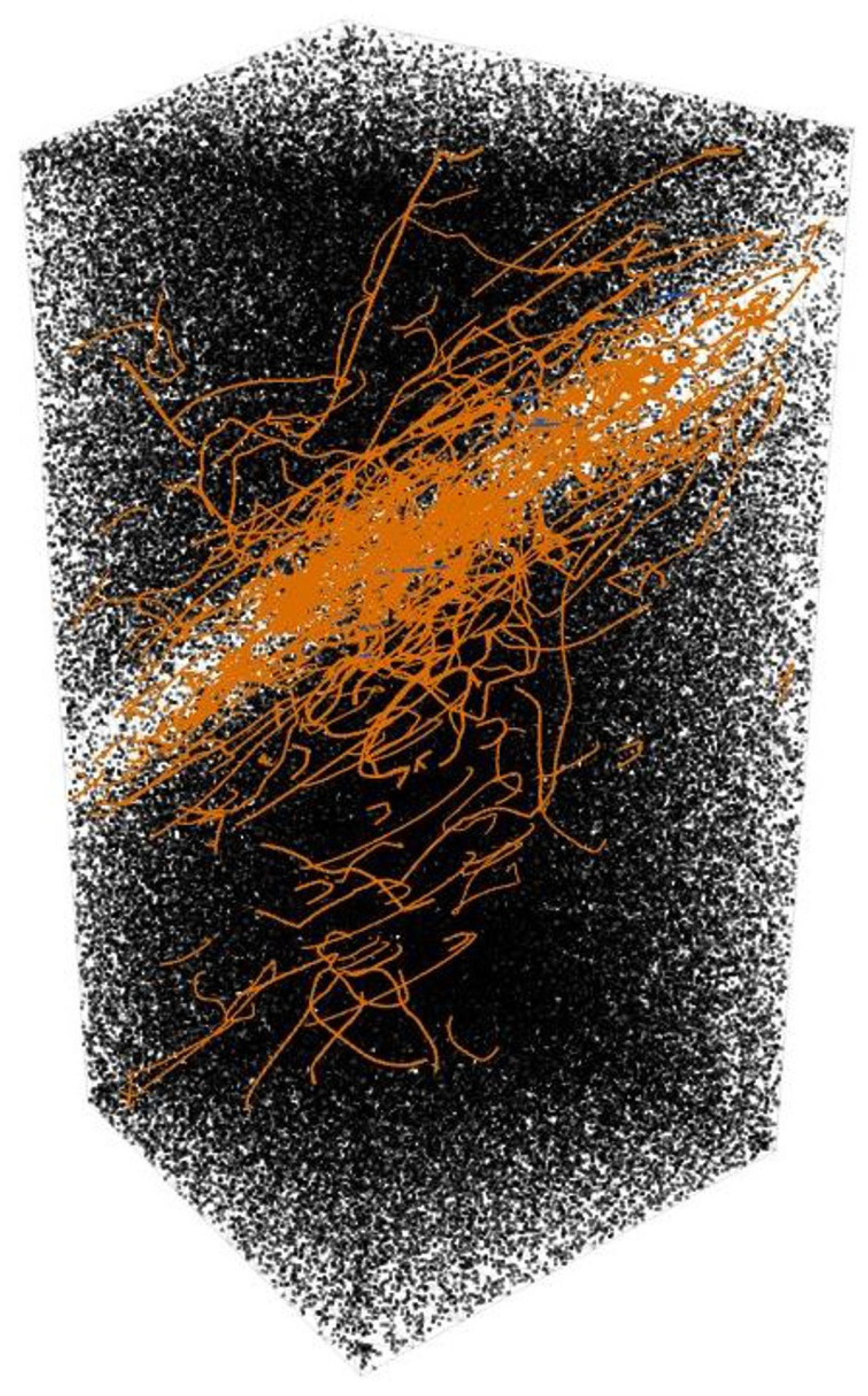

4.2. Formation of Defect-Free Channels

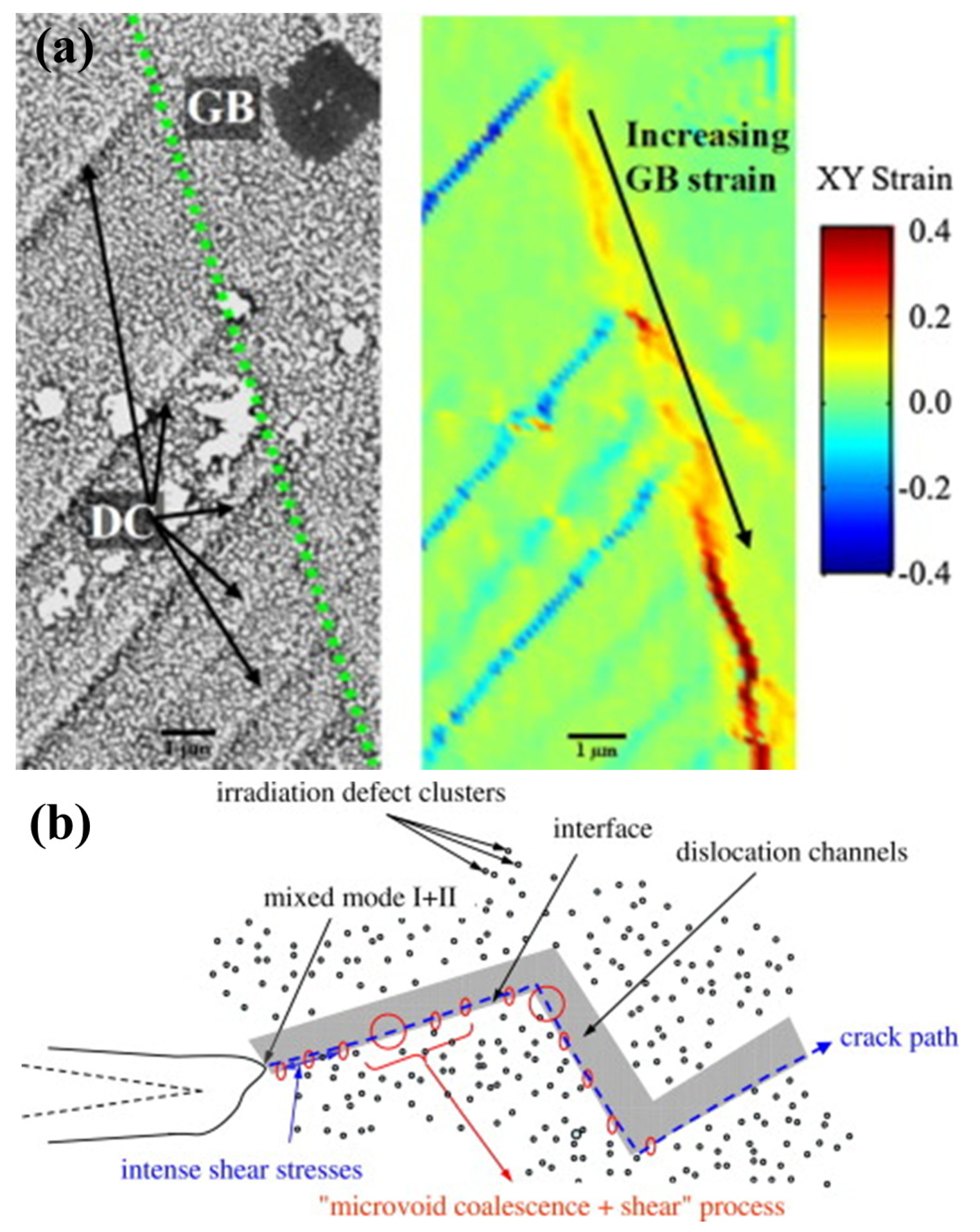

4.3. Generation of Microvoids and Cracks

5. Summary and Outlook

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Q.; Shen, Y.; Zhu, J.; Huang, X.; Shang, Z. Evaluation of Irradiation Hardening of P92 Steel under Ar Ion Irradiation. Metals 2018, 8, 94. [Google Scholar] [CrossRef]

- Bai, X.; Wu, S.; Liaw, P.K.; Shao, L.; Gigax, J. Effect of Heavy Ion Irradiation Dosage on the Hardness of SA508-IV Reactor Pressure Vessel Steel. Metals 2017, 7, 25. [Google Scholar] [CrossRef]

- Jitsukawa, S.; Suzuki, K.; Okubo, N.; Ando, M.; Shiba, K. Irradiation effects on reduced activation ferritic/martensitic steels-tensile, impact, fatigue properties and modelling. Nucl. Fusion 2009, 49, 733–737. [Google Scholar] [CrossRef]

- Alamo, A.; Horsten, M.; Averty, X.; Materna-Morris, E.I.; Rieth, M.; Brachet, J.C. Mechanical behavior of reduced-activation and conventional martensitic steels after neutron irradiation in the range 250–450 degrees C. J. Nucl. Mater. 2000, 283, 353–357. [Google Scholar] [CrossRef]

- Hojna, A. Overview of Intergranular Fracture of Neutron Irradiated Austenitic Stainless Steels. Metals 2017, 7, 392. [Google Scholar] [CrossRef]

- Li, M.; Sokolov, M.A.; Zinkle, S.J. Tensile and fracture toughness properties of neutron-irradiated CuCrZr. J. Nucl. Mater. 2009, 393, 36–46. [Google Scholar] [CrossRef]

- Fabritsiev, S.A.; Pokrovsky, A.S. Effect of irradiation temperature on microstructure, radiation hardening and embrittlement of pure copper and copper-based alloy. J. Nucl. Mater. 2007, 367, 977–983. [Google Scholar] [CrossRef]

- Sharma, G.; Mukherjee, P.; Chatterjee, A.; Gayathri, N.; Sarkar, A.; Chakravartty, J.K. Study of the effect of alpha irradiation on the microstructure and mechanical properties of nanocrystalline Ni. Acta Mater. 2013, 61, 3257–3266. [Google Scholar] [CrossRef]

- Singh, B.N.; Horsewell, A.; Toft, P. Effects of neutron irradiation on microstructure and mechanical properties of pure iron. J. Nucl. Mater. 1999, 271, 97–101. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Singh, B.N. Microstructure of neutron-irradiated iron before and after tensile deformation. J. Nucl. Mater. 2006, 351, 269–284. [Google Scholar] [CrossRef]

- Fukuda, M.; Hasegawa, A.; Tanno, T.; Nogami, S.; Kurishita, H. Property change of advanced tungsten alloys due to neutron irradiation. J. Nucl. Mater. 2013, 442, S273–S276. [Google Scholar] [CrossRef]

- Cockeram, B.V.; Smith, R.W.; Leonard, K.J.; Byun, T.S.; Snead, L.L. Development of microstructure and irradiation hardening of Zircaloy during low dose neutron irradiation at nominally 358 degrees C. J. Nucl. Mater. 2011, 418, 46–61. [Google Scholar] [CrossRef]

- Onimus, F.; Bechade, J.L.; Duguay, C.; Gilbon, D.; Pilvin, P. Investigation of neutron radiation effects on the mechanical behavior of recrystallized zirconium alloys. J. Nucl. Mater. 2006, 358, 176–189. [Google Scholar] [CrossRef]

- Marmy, P.; Leguey, T. Impact of irradiation on the tensile and fatigue properties of two titanium alloys. J. Nucl. Mater. 2001, 296, 155–164. [Google Scholar] [CrossRef]

- Li, M.; Byun, T.S.; Snead, L.L.; Zinkle, S.J. Low-temperature thermally-activated deformation and irradiation softening in neutron-irradiated molybdenum. J. Nucl. Mater. 2008, 377, 409–414. [Google Scholar] [CrossRef]

- Chopra, O.K.; Rao, A.S. A review of irradiation effects on LWR core internal materials—IASCC susceptibility and crack growth rates of austenitic stainless steels. J. Nucl. Mater. 2011, 409, 235–256. [Google Scholar] [CrossRef]

- Knaster, J.; Moeslang, A.; Muroga, T. Materials research for fusion. Nat. Phys. 2016, 12, 424–434. [Google Scholar] [CrossRef]

- Song, C. Irradiation effects on Zr-2.5Nb in power reactors. CNL Nucl. Rev. 2016, 5, 17–36. [Google Scholar] [CrossRef]

- Azevedo, C.R.F. A review on neutron-irradiation-induced hardening of metallic components. Eng. Fail. Anal. 2011, 18, 1921–1942. [Google Scholar] [CrossRef]

- Singh, B.N.; Foreman, A.J.E.; Trinkaus, H. Radiation hardening revisited: Role of intracascade clustering. J. Nucl. Mater. 1997, 249, 103–115. [Google Scholar] [CrossRef]

- Kuksenko, V.; Pareige, C.; Genevois, C.; Cuvilly, F.; Roussel, M.; Pareige, P. Effect of neutron-irradiation on the microstructure of a Fe-12at.%Cr alloy. J. Nucl. Mater. 2011, 415, 61–66. [Google Scholar] [CrossRef]

- Kuksenko, V.; Pareige, C.; Pareige, P. Cr precipitation in neutron irradiated industrial purity Fe-Cr model alloys. J. Nucl. Mater. 2013, 432, 160–165. [Google Scholar] [CrossRef]

- Byun, T.S.; Farrell, K.; Li, M. Deformation in metals after low-temperature irradiation: Part I—Mapping macroscopic deformation modes on true stress-dose plane. Acta Mater. 2008, 56, 1044–1055. [Google Scholar] [CrossRef]

- Byun, T.S.; Farrell, K.; Li, M. Deformation in metals after low-temperature irradiation: Part II—Irradiation hardening, strain hardening, and stress ratios. Acta Mater. 2008, 56, 1056–1064. [Google Scholar] [CrossRef]

- Chang, Y.; Zhang, J.; Li, X.; Guo, Q.; Wan, F.; Long, Y. Microstructure and nanoindentation of the CLAM steel with nanocrystalline grains under Xe irradiation. J. Nucl. Mater. 2014, 455, 624–629. [Google Scholar] [CrossRef]

- Dai, Y.; Henry, J.; Tong, Z.; Averty, X.; Malaplate, J.; Long, B. Neutron/proton irradiation and He effects on the microstructure and mechanical properties of ferritic/martensitic steels T91 and EM10. J. Nucl. Mater. 2011, 415, 306–310. [Google Scholar] [CrossRef]

- Suzudo, T.; Yamaguchi, M. Simulation of He embrittlement at grain boundaries in bcc transition metals. J. Nucl. Mater. 2015, 465, 695–701. [Google Scholar] [CrossRef]

- Yang, Y.; Ding, J.; Zhang, H.; Zhang, P.; Mei, X.; Huang, S.; Zhao, J. Atomistic understanding of helium behaviors at grain boundaries in vanadium. Comput. Mater. Sci. 2019, 158, 296–306. [Google Scholar] [CrossRef]

- Fan, H.; El-Awady, J.A.; Wang, Q. Towards further understanding of stacking fault tetrahedron absorption and defect-free channels—A molecular dynamics study. J. Nucl. Mater. 2015, 458, 176–186. [Google Scholar] [CrossRef]

- Fan, H.; Wang, Q.; Ouyang, C. Comprehensive molecular dynamics simulations of the stacking fault tetrahedron interacting with a mixed dislocation at elevated temperature. J. Nucl. Mater. 2015, 465, 245–253. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, Y.; Cheng, G.; Jian, W.; Millett, P.C.; Koch, C.C.; Mathaudhu, S.N.; Zhu, Y. In-situ atomic-scale observation of irradiation-induced void formation. Nat. Commun. 2013, 4, 2288. [Google Scholar] [CrossRef] [PubMed]

- Xiong, L.; Xu, S.; McDowell, D.L.; Chen, Y. Concurrent atomistic-continuum simulations of dislocation-void interactions in fcc crystals. Int. J. Plast. 2015, 65, 33–42. [Google Scholar] [CrossRef]

- Traiviratana, S.; Bringa, E.M.; Benson, D.J.; Meyers, M.A. Void growth in metals: Atomistic calculations. Acta Mater. 2008, 56, 3874–3886. [Google Scholar] [CrossRef]

- Cui, Y.; Po, G.; Ghoniem, N. Size-Tuned Plastic Flow Localization in Irradiated Materials at the Submicron Scale. Phys. Rev. Lett. 2018, 120, 215501. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Po, G.; Ghoniem, N. A Coupled Dislocation Dynamics-Continuum Barrier Field Model with Application to Irradiated Materials. Int. J. Plast. 2018, 104, 54–67. [Google Scholar] [CrossRef]

- Kumar, N.N.; Durgaprasad, P.V.; Dutta, B.K.; Dey, G.K. Modeling of radiation hardening in ferritic/martensitic steel using multi-scale approach. Comput. Mater. Sci. 2012, 53, 258–267. [Google Scholar] [CrossRef]

- Patra, A.; McDowell, D.L. A void nucleation and growth based damage framework to model failure initiation ahead of a sharp notch in irradiated bcc materials. J. Mech. Phys. Solids 2015, 74, 111–135. [Google Scholar] [CrossRef]

- Barton, N.R.; Arsenlis, A.; Marian, J. A polycrystal plasticity model of strain localization in irradiated iron. J. Mech. Phys. Solids 2013, 61, 341–351. [Google Scholar] [CrossRef]

- Xiao, X.; Yu, L. Cross-sectional nano-indentation of ion-irradiated steels: Finite element simulations based on the strain-gradient crystal plasticity theory. Int. J. Eng. Sci. 2019, 143, 56–72. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, L.; Yu, L.; Duan, H. Modelling nano-indentation of ion-irradiated FCC single crystals by strain-gradient crystal plasticity theory. Int. J. Plast. 2019, 111, 135–151. [Google Scholar] [CrossRef]

- Bacon, D.J.; Osetsky, Y.N. The atomic-scale modeling of dislocation-obstacle interactions in irradiated metals. JOM 2007, 59, 40–45. [Google Scholar] [CrossRef]

- Bacon, D.J.; Osetsky, Y.N. Dislocation-Obstacle Interactions at Atomic Level in Irradiated Metals. Math. Mech. Solids 2009, 14, 270–283. [Google Scholar] [CrossRef]

- Baudouin, J.B.; Nomoto, A.; Perez, M.; Monnet, G.; Domain, C. Molecular dynamics investigation of the interaction of an edge dislocation with Frank loops in Fe-Ni-10-Cr-20 alloy. J. Nucl. Mater. 2015, 465, 301–310. [Google Scholar] [CrossRef]

- Di, S.; Yao, Z.; Daymond, M.R.; Zu, X.; Peng, S.; Gao, F. Dislocation-accelerated void formation under irradiation in zirconium. Acta Mater. 2015, 82, 94–99. [Google Scholar] [CrossRef]

- Hayward, E.; Deo, C.; Uberuaga, B.P.; Tome, C.N. The interaction of a screw dislocation with point defects in bcc iron. Philos. Mag. 2012, 92, 2759–2778. [Google Scholar] [CrossRef]

- Liu, Q.; Deng, L.; Wang, X. Interactions between prismatic dislocation loop and coherent twin boundary under nanoindentation investigated by molecular dynamics. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2016, 676, 182–190. [Google Scholar] [CrossRef]

- Ma, L.; Xiao, S.; Deng, H.; Hu, W. Atomistic simulation of mechanical properties and crack propagation of irradiated nickel. Comput. Mater. Sci. 2016, 120, 21–28. [Google Scholar] [CrossRef]

- Dai, C.; Balogh, L.; Yao, Z.; Daymond, M.R. Atomistic simulations of the formation of <c>-component dislocation loops in alpha-zirconium. J. Nucl. Mater. 2016, 478, 125–134. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, C.; Tieu, K.; Su, L.; Zhao, X.; Pei, L. Stacking fault tetrahedron induced plasticity in copper single crystal. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 680, 27–38. [Google Scholar] [CrossRef]

- Coppola, R.; Klimenkov, M. Dose Dependence of Micro-Voids Distributions in Low-Temperature Neutron Irradiated Eurofer97 Steel. Metals 2019, 9, 552. [Google Scholar] [CrossRef]

- Stergar, E.; Eremin, S.G.; Gavrilov, S.; Lambrecht, M.; Makarov, O.; Iakovlev, V. Influence of LBE long term exposure and simultaneous fast neutron irradiation on the mechanical properties of T91 and 316L. J. Nucl. Mater. 2016, 473, 28–34. [Google Scholar] [CrossRef]

- Fu, Z.Y.; Liu, P.P.; Wan, F.R.; Zhan, Q. Helium and hydrogen irradiation induced hardening in CLAM steel. Fusion Eng. Des. 2015, 91, 73–78. [Google Scholar] [CrossRef]

- Bai, X.M.; Voter, A.F.; Hoagland, R.G.; Nastasi, M.; Uberuaga, B.P. Efficient Annealing of Radiation Damage Near Grain Boundaries via Interstitial Emission. Science 2010, 327, 1631–1634. [Google Scholar] [CrossRef] [PubMed]

- Byun, T.S.; Hoelzer, D.T.; Kim, J.H.; Maloy, S.A. A comparative assessment of the fracture toughness behavior of ferritic-martensitic steels and nanostructured ferritic alloys. J. Nucl. Mater. 2017, 484, 157–167. [Google Scholar] [CrossRef]

- Nakai, R.; Yabuuchi, K.; Nogami, S.; Hasegawa, A. The effect of voids on the hardening of body-centered cubic Fe. J. Nucl. Mater. 2016, 471, 233–238. [Google Scholar] [CrossRef]

- Kudiiarov, V.N.; Larionov, V.V.; Tyurin, Y.I. Mechanical Property Testing of Hydrogenated Zirconium Irradiated with Electrons. Metals 2018, 8, 207. [Google Scholar] [CrossRef]

- Saleh, M.; Zaidi, Z.; Hurt, C.; Ionescu, M.; Munroe, P.; Bhattacharyya, D. Comparative Study of Two Nanoindentation Approaches for Assessing Mechanical Properties of Ion-Irradiated Stainless Steel 316. Metals 2018, 8, 719. [Google Scholar] [CrossRef]

- Ge, H.E.; Peng, L.; Dai, Y.; Huang, Q.Y.; Ye, M.Y. Tensile properties of CLAM steel irradiated up to 20.1 dpa in STIP-V. J. Nucl. Mater. 2016, 468, 240–245. [Google Scholar] [CrossRef]

- Huang, H.F.; Li, J.J.; Li, D.H.; Liu, R.D.; Lei, G.H.; Huang, Q.; Yan, L. TEM, XRD and nanoindentation characterization of Xenon ion irradiation damage in austenitic stainless steels. J. Nucl. Mater. 2014, 454, 168–172. [Google Scholar] [CrossRef]

- Victoria, M.; Baluc, N.; Bailat, C.; Dai, Y.; Luppo, M.I.; Schaublin, R.; Singh, B.N. The microstructure and associated tensile properties of irradiated fcc and bcc metals. J. Nucl. Mater. 2000, 276, 114–122. [Google Scholar] [CrossRef]

- Madjasevic, M.; Alrriazouzi, A. Effect of Cr on the mechanical properties and microstructure of Fe-Cr model alloys after n-irradiation. J. Nucl. Mater. 2008, 377, 147–154. [Google Scholar] [CrossRef]

- Robach, J.S.; Robertson, I.M.; Lee, H.J.; Wirth, B.D. Dynamic observations and atomistic simulations of dislocation-defect interactions in rapidly quenched copper and gold. Acta Mater. 2006, 54, 1679–1690. [Google Scholar] [CrossRef]

- Matsukawa, Y.; Zinkle, S.J. Dynamic observation of the collapse process of a stacking fault tetrahedron by moving dislocations. J. Nucl. Mater. 2004, 329, 919–923. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, Q.; Yang, H.; Duan, H.; Qu, J. A mechanistic model for depth-dependent hardness of ion irradiated metals. J. Nucl. Mater. 2017, 485, 80–89. [Google Scholar] [CrossRef]

- Sharma, G.; Sarkar, A.; Varshney, J.; Ramamurty, U.; Kumar, A.; Gupta, S.K.; Chakravartty, J.K. Effect of irradiation on the microstructure and mechanical behavior of nanocrystalline nickel. Scr. Mater. 2011, 65, 727–730. [Google Scholar] [CrossRef]

- Liu, W.B.; Ji, Y.Z.; Tan, P.K.; Zhang, C.; He, C.H.; Yang, Z.G. Microstructure evolution during helium irradiation and post-irradiation annealing in a nanostructured reduced activation steel. J. Nucl. Mater. 2016, 479, 323–330. [Google Scholar] [CrossRef]

- Chen, C.L.; Richter, A.; Koegler, R. The effect of dual Fe+/He+ ion beam irradiation on microstructural changes in FeCrAl ODS alloys. J. Alloy. Compd. 2014, 586, S173–S179. [Google Scholar] [CrossRef]

- Jin, S.; Guo, L.; Li, T.; Chen, J.; Yang, Z.; Luo, F.; Tang, R.; Qiao, Y.; Liu, F. Microstructural evolution of P92 ferritic/martensitic steel under Ar+ ion irradiation at elevated temperature. Mater. Charact. 2012, 68, 63–70. [Google Scholar] [CrossRef]

- Eldrup, M.; Singh, B.N.; Zinkle, S.J.; Byun, T.S.; Farrell, K. Dose dependence of defect accumulation in neutron irradiated copper and iron. J. Nucl. Mater. 2002, 307, 912–917. [Google Scholar] [CrossRef]

- Jin, S.X.; Guo, L.P.; Yang, Z.; Fu, D.J.; Liu, C.S.; Xiao, W.; Tang, R.; Liu, F.H.; Qiao, Y.X. Microstructural evolution in nickel alloy C-276 after Ar+ ion irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms 2011, 269, 209–215. [Google Scholar] [CrossRef]

- Hu, X.; Koyanagi, T.; Fukuda, M.; Katoh, Y.; Snead, L.L.; Wirth, B.D. Defect evolution in single crystalline tungsten following low temperature and low dose neutron irradiation. J. Nucl. Mater. 2016, 470, 278–289. [Google Scholar] [CrossRef]

- Schaublin, R.; Ramar, A.; Baluc, N.; de Castro, V.; Monge, M.A.; Leguey, T.; Schmid, N.; Bonjour, C. Microstructural development under irradiation in European ODS ferritic/martensitic steels. J. Nucl. Mater. 2006, 351, 247–260. [Google Scholar] [CrossRef]

- Materna-Morris, E.; Lindau, R.; Schneider, H.C.; Moeslang, A. Tensile behavior of EUROFER ODS steel after neutron irradiation up to 16.3 dpa between 250 and 450 degrees C. Fusion Eng. Des. 2015, 98-99, 2038–2041. [Google Scholar] [CrossRef]

- Tanigawa, H.; Sakasegawa, H.; Hashimoto, N.; Klueh, R.L.; Ando, M.; Sokolov, M.A. Irradiation effects on precipitation and its impact on the mechanical properties of reduced-activation ferritic/martensitic steels. J. Nucl. Mater. 2007, 367, 42–47. [Google Scholar] [CrossRef]

- Madjasevic, M.; Lucon, E.; Almazouzi, A. Behavior of ferritic/martensitic steels after n-irradiation at 200 and 300 degrees C. J. Nucl. Mater. 2008, 377, 101–108. [Google Scholar] [CrossRef]

- Klimenkov, M.; Materna-Morris, E.; Moeslang, A. Characterization of radiation induced defects in EUROFER 97 after neutron irradiation. J. Nucl. Mater. 2011, 417, 124–126. [Google Scholar] [CrossRef]

- Jin, H.H.; Shin, C.; Kim, D.H.; Oh, K.H.; Kwon, J.H. Irradiation induced dislocation loop and its influence on the hardening behavior of Fe-Cr alloys by an Fe ion irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms 2008, 266, 4845–4848. [Google Scholar] [CrossRef]

- Etienne, A.; Hernandez-Mayoral, M.; Genevois, C.; Radiguet, B.; Pareige, P. Dislocation loop evolution under ion irradiation in austenitic stainless steels. J. Nucl. Mater. 2010, 400, 56–63. [Google Scholar] [CrossRef]

- Yao, B.; Edwards, D.J.; Kurtz, R.J. TEM characterization of dislocation loops in irradiated bcc Fe-based steels. J. Nucl. Mater. 2013, 434, 402–410. [Google Scholar] [CrossRef]

- Kai, J.J.; Kulcinski, G.L. 14 Mev nickel-ion irradiated HT-9 ferritic steel with and without helium preimplantation. J. Nucl. Mater. 1990, 175, 227–236. [Google Scholar] [CrossRef]

- Wang, K.; Dai, Y.; Spaetig, P. Microstructure and fracture behavior of F82H steel under different irradiation and tensile test conditions. J. Nucl. Mater. 2016, 468, 246–254. [Google Scholar] [CrossRef]

- Li, M.; Eldrup, M.; Byun, T.S.; Hashimo, N.; Snead, L.L.; Zinkle, S.J. Low temperature neutron irradiation effects on microstructure and tensile properties of molybdenum. J. Nucl. Mater. 2008, 376, 11–28. [Google Scholar] [CrossRef]

- Yamashita, S.; Tachi, Y.; Akasaka, N.; Nishinoiri, K.; Takahashi, H. Effect of neutron irradiation on the microstructure of modified SUS316 stainless steels. J. Nucl. Mater. 2011, 417, 953–957. [Google Scholar] [CrossRef]

- Fukuda, M.; Hasegawa, A.; Nogami, S.; Yabuuchi, K. Microstructure development of dispersion-strengthened tungsten due to neutron irradiation. J. Nucl. Mater. 2014, 449, 213–218. [Google Scholar] [CrossRef]

- Zhang, T.; Vieh, C.; Wang, K.; Dai, Y. Irradiation-induced evolution of mechanical properties and microstructure of Eurofer 97. J. Nucl. Mater. 2014, 450, 48–53. [Google Scholar] [CrossRef]

- Getto, E.; Jiao, Z.; Monterrosa, A.M.; Sun, K.; Was, G.S. Effect of irradiation mode on the microstructure of self-ion irradiated ferritic-martensitic alloys. J. Nucl. Mater. 2015, 465, 116–126. [Google Scholar] [CrossRef]

- Kolluri, M.; Edmondson, P.D.; Luzginova, N.V.; Vander Berg, F.A. Influence of irradiation temperature on microstructure of EU batch of ODS Eurofer97 steel irradiated with neutrons. Mater. Sci. Technol. 2014, 30, 1697–1703. [Google Scholar] [CrossRef]

- Klimenkov, M.; Moeslang, A.; Materna-Morris, E. Helium influence on the microstructure and swelling of 9%Cr ferritic steel after neutron irradiation to 16.3 dpa. J. Nucl. Mater. 2014, 453, 54–59. [Google Scholar] [CrossRef]

- Cockeram, B.V.; Smith, R.W.; Hashimoto, N.; Snead, L.L. The swelling, microstructure, and hardening of wrought LCAC, TZM, and ODS molybdenum following neutron irradiation. J. Nucl. Mater. 2011, 418, 121–136. [Google Scholar] [CrossRef]

- Heintze, C.; Bergner, F.; Akhmadaliev, S.; Altstadt, E. Ion irradiation combined with nanoindentation as a screening test procedure for irradiation hardening. J. Nucl. Mater. 2016, 472, 196–205. [Google Scholar] [CrossRef]

- Kasada, R.; Konishi, S.; Yabuuchi, K.; Nogami, S.; Ando, M.; Hamaguchi, D.; Tanigawa, H. Depth-dependent nanoindentation hardness of reduced-activation ferritic steels after MeV Fe-ion irradiation. Fusion Eng. Des. 2014, 89, 1637–1641. [Google Scholar] [CrossRef]

- Dunn, A.; Dingreville, R.; Martinez, E.; Capolungo, L. Identification of dominant damage accumulation processes at grain boundaries during irradiation in nanocrystalline alpha-Fe: A statistical study. Acta Mater. 2016, 110, 306–323. [Google Scholar] [CrossRef]

- Chen, Y.; Li, N.; Bufford, D.C.; Li, J.; Hattar, K.; Wang, H.; Zhang, X. In situ study of heavy ion irradiation response of immiscible Cu/Fe multilayers. J. Nucl. Mater. 2016, 475, 274–279. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Yu, K.Y.; Wang, H.; Kirk, M.A.; Li, M.; Zhang, X. In situ studies on radiation tolerance of nanotwinned Cu. Acta Mater. 2016, 111, 148–156. [Google Scholar] [CrossRef]

- Yu, K.Y.; Bufford, D.; Sun, C.; Liu, Y.; Wang, H.; Kirk, M.A.; Li, M.; Zhang, X. Removal of stacking-fault tetrahedra by twin boundaries in nanotwinned metals. Nat. Commun. 2013, 4, 1377. [Google Scholar] [CrossRef]

- Liu, W.; Ji, Y.; Tan, P.; Zang, H.; He, C.; Yun, D.; Zhang, C.; Yang, Z. Irradiation Induced Microstructure Evolution in Nanostructured Materials: A Review. Materials 2016, 9, 105. [Google Scholar] [CrossRef]

- Singh, B.N.; Edwards, D.J.; Toft, P. Effects of neutron irradiation on mechanical properties and microstructures of dispersion and precipitation hardened copper alloys. J. Nucl. Mater. 1996, 238, 244–259. [Google Scholar] [CrossRef]

- Shi, X.J.; Dupuy, L.; Devincre, B.; Terentyev, D.; Vincent, L. Interaction of <100> dislocation loops with dislocations studied by dislocation dynamics in alpha-iron. J. Nucl. Mater. 2015, 460, 37–43. [Google Scholar] [CrossRef]

- Bachhav, M.; Yao, L.; Odette, G.R.; Marquis, E.A. Microstructural changes in a neutron-irradiated Fe-6 at.%Cr alloy. J. Nucl. Mater. 2014, 453, 334–339. [Google Scholar] [CrossRef]

- Kuksenko, V.; Pareige, C.; Pareige, P. Intra granular precipitation and grain boundary segregation under neutron irradiation in a low purity Fe-Cr based alloy. J. Nucl. Mater. 2012, 425, 125–129. [Google Scholar] [CrossRef]

- Jiao, Z.; Was, G.S. Novel features of radiation-induced segregation and radiation-induced precipitation in austenitic stainless steels. Acta Mater. 2011, 59, 1220–1238. [Google Scholar] [CrossRef]

- Parish, C.M.; White, R.M.; LeBeau, J.M.; Miller, M.K. Response of nanostructured ferritic alloys to high-dose heavy ion irradiation. J. Nucl. Mater. 2014, 445, 251–260. [Google Scholar] [CrossRef]

- Sauzay, M.; Vor, K. Influence of plastic slip localization on grain boundary stress fields and microcrack nucleation. Eng. Fract. Mech. 2013, 110, 330–349. [Google Scholar] [CrossRef]

- Osetsky, Y.N.; Serra, A.; Priego, V. Interactions between mobile dislocation loops in Cu and alpha-Fe. J. Nucl. Mater. 2000, 276, 202–212. [Google Scholar] [CrossRef]

- Osetsky, Y.N.; Bacon, D.J.; Serra, A.; Singh, B.N.; Golubov, S.I. One-dimensional atomic transport by clusters of self-interstitial atoms in iron and copper. Philos. Mag. 2003, 83, 61–91. [Google Scholar] [CrossRef]

- Xiao, X.; Song, D.; Xue, J.; Chu, H.; Duan, H. A size-dependent tensorial plasticity model for FCC singlecrystal with irradiation. Int. J. Plast. 2015, 65, 152–167. [Google Scholar] [CrossRef]

- Xiao, X.; Song, D.; Xue, J.; Chu, H.; Duana, H. A self-consistent plasticity theory for modeling the thermo-mechanical properties of irradiated FCC metallic polycrystals. J. Mech. Phys. Solids 2015, 78, 1–16. [Google Scholar] [CrossRef]

- Yang, S.; Yang, Z.; Wang, H.; Watanabe, S.; Shibayama, T. Effect of laser and/or electron beam irradiation on void swelling in SUS316L austenitic stainless steel. J. Nucl. Mater. 2017, 488, 215–221. [Google Scholar] [CrossRef][Green Version]

- Fabritsiev, S.A.; Pokrovsky, A.S. Effect of irradiation temperature and dose on radiation hardening of some pure metals. J. Nucl. Mater. 2011, 417, 940–943. [Google Scholar] [CrossRef]

- Brimbal, D.; Decamps, B.; Barbu, A.; Meslin, E.; Henry, J. Dual-beam irradiation of alpha-iron: Heterogeneous bubble formation on dislocation loops. J. Nucl. Mater. 2011, 418, 313–315. [Google Scholar] [CrossRef]

- Briceno, M.; Kacher, J.; Robertson, I.M. Dynamics of dislocation interactions with stacking-fault tetrahedra at high temperature. J. Nucl. Mater. 2013, 433, 390–396. [Google Scholar] [CrossRef]

- Matsukawa, Y.; Osetsky, Y.N.; Stoller, R.E.; Zinkle, S.J. Mechanisms of stacking fault tetrahedra destruction by gliding dislocations in quenched gold. Philos. Mag. 2008, 88, 581–597. [Google Scholar] [CrossRef]

- Rodney, D. Atomic-scale modeling of clear band formation in FCC metals. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms 2005, 228, 100–110. [Google Scholar] [CrossRef]

- Matsukawa, Y.; Osetsky, Y.N.; Stoller, R.E.; Zinkle, S.J. Destruction processes of large stacking fault tetrahedra induced by direct interaction with gliding dislocations. J. Nucl. Mater. 2006, 351, 285–294. [Google Scholar] [CrossRef]

- Matsukawa, Y.; Osetsky, Y.N.; Stoller, R.E.; Zinkle, S.J. The collapse of stacking-fault tetrahedra by interaction with gliding dislocations. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2005, 400, 366–369. [Google Scholar] [CrossRef]

- Osetsky, Y.N.; Rodney, D.; Bacon, D.J. Atomic-scale study of dislocation-stacking fault tetrahedron interactions. Part I: Mechanisms. Philos. Mag. 2006, 86, 2295–2313. [Google Scholar] [CrossRef]

- Kacher, J.; Cui, B.; Robertson, I.M. In situ and tomographic characterization of damage and dislocation processes in irradiated metallic alloys by transmission electron microscopy. J. Mater. Res. 2015, 30, 1202–1213. [Google Scholar] [CrossRef]

- Byun, T.S.; Hashimoto, N.; Farrell, K.; Lee, E.H. Characteristics of microscopic strain localization in irradiated 316 stainless steels and pure vanadium. J. Nucl. Mater. 2006, 349, 251–264. [Google Scholar] [CrossRef]

- Edwards, D.J.; Singh, B.N.; Bilde-Sorensen, J.B. Initiation and propagation of cleared channels in neutron-irradiated pure copper and a precipitation hardened CuCrZr alloy. J. Nucl. Mater. 2005, 342, 164–178. [Google Scholar] [CrossRef]

- Nogami, S.; Sato, Y.; Hasegawa, A. Fatigue Crack Initiation in Proton-Irradiated Austenitic Stainless Steel. J. Nucl. Sci. Technol. 2011, 48, 1265–1271. [Google Scholar] [CrossRef][Green Version]

- Jiao, Z.; Was, G.S. Impact of localized deformation on IASCC in austenitic stainless steels. J. Nucl. Mater. 2011, 408, 246–256. [Google Scholar] [CrossRef]

- Onimus, F.; Monnet, I.; Bechade, J.L.; Prioul, C.; Pilvin, P. A statistical TEM investigation of dislocation channeling mechanism in neutron irradiated zirconium alloys. J. Nucl. Mater. 2004, 328, 165–179. [Google Scholar] [CrossRef]

- Mahajan, S.; Eyre, B.L. Formation of dislocation channels in neutron irradiated molybdenum. Acta Mater. 2017, 122, 259–265. [Google Scholar] [CrossRef]

- Patra, A.; McDowell, D.L. Crystal plasticity investigation of the microstructural factors influencing dislocation channeling in a model irradiated bcc material. Acta Mater. 2016, 110, 364–376. [Google Scholar] [CrossRef]

- Robertson, I.M.; Beaudoin, A.; Al-Fadhalah, K.; Chun-Ming, L.; Robach, J.; Wirth, B.D.; Arsenlis, A.; Ahn, D.; Sofronis, P. Dislocation-obstacle interactions: Dynamic experiments to continuum modeling. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2005, 400, 245–250. [Google Scholar] [CrossRef]

- De la Rubia, T.D.; Zbib, H.M.; Khraishi, T.A.; Wirth, B.D.; Victoria, M.; Caturla, M.J. Multiscale modelling of plastic flow localization in irradiated materials. Nature 2000, 406, 871–874. [Google Scholar] [CrossRef] [PubMed]

- Kacher, J.; Liu, G.S.; Robertson, I.M. In situ and tomographic observations of defect free channel formation in ion irradiated stainless steels. Micron 2012, 43, 1099–1107. [Google Scholar] [CrossRef]

- McMurtrey, M.D.; Was, G.S.; Patrick, L.; Farkas, D. Relationship between localized strain and irradiation assisted stress corrosion cracking in an austenitic alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2011, 528, 3730–3740. [Google Scholar] [CrossRef]

- McMurtrey, M.D.; Cui, B.; Robertson, I.; Farkas, D.; Was, G.S. Mechanism of dislocation channel-induced irradiation assisted stress corrosion crack initiation in austenitic stainless steel. Curr. Opin. Solid State Mater. Sci. 2015, 19, 305–314. [Google Scholar] [CrossRef]

- Chaouadi, R. Effect of irradiation-induced plastic flow localization on ductile crack resistance behavior of a 9%Cr tempered martensitic steel. J. Nucl. Mater. 2008, 372, 379–390. [Google Scholar] [CrossRef]

| Materials | Dominant Defects | Irradiation Conditions |

|---|---|---|

| Copper [69] | SFTs | 0.8 dpa and 343 K with neutrons |

| Copper [7] | DLs and SFTs | 0.001-0.1 dpa and 353-423 K with neutrons |

| Nickel alloy [70] | DLs | Up to 82.5 dpa and 293 K with 115 KeV argon ions |

| Nanocrystalline Ni [8] | DLs | Up to 2.3 and 293 K with 12 MeV He ions |

| Iron [10] | DLs | 0.8 dpa and 343 K with neutrons |

| Iron [9] | DLs | 0.375 dpa and 523 K with neutrons |

| Tungsten [11] | Voids, bubbles and DLs | 0.15–0.47 dpa and 804–1073 K with neutrons |

| Tungsten [71] | DLs | 0.006–0.03 dpa and 363 K with neutrons |

| Palladium [60] | DLs | 0.12 dpa and 320 K with 590 MeV protons |

| ODS steels [72] | DLs | 1 dpa and 623 K with 590 MeV protons |

| EUROFER ODS steels [73] | DLs | 16.3 dpa and 298–723 K with neutrons |

| Reduced-activation steels [74] | Precipitates | 5 dpa and 623 K with neutrons |

| T91 steels [75] | DLs | 0.06 dpa and 573 K with neutrons |

| EUROFER97 steels [75] | DLs | 1.5 dpa and 573 K with neutrons |

| EUROFER97 steels [76] | DLs, voids and helium bubbles | 16.3 dpa and 523–723 K with neutrons |

| Fe-Cr alloys [61] | DLs and solute rich clusters | 0.06–1.5 dpa and 433–573 K with neutrons |

| Fe-Cr alloys [77] | DLs | 8 MeV and 293 K with Fe ions |

| 304 and 316 austenitic stainless steels [78] | DLs | 0.36–5 dpa and 623 K with 160 KeV Fe ions |

| RAFM steels [79] | DLs | He 23 appm/dpa and 673 K |

| HT-9 steels [80] | DLs | 8 and 573–773 K with 14 MeV nickel ions |

| F82H steels [81] | DLs and Helium bubbles | 10.7–19.6 dpa and 438–578 K with He |

| CLAM steels [52] | DLs | 3 and 773 K with He ions |

| Molybdenum [82] | DLs | 0.28 dpa and 353 K with neutrons |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, X. Fundamental Mechanisms for Irradiation-Hardening and Embrittlement: A Review. Metals 2019, 9, 1132. https://doi.org/10.3390/met9101132

Xiao X. Fundamental Mechanisms for Irradiation-Hardening and Embrittlement: A Review. Metals. 2019; 9(10):1132. https://doi.org/10.3390/met9101132

Chicago/Turabian StyleXiao, Xiazi. 2019. "Fundamental Mechanisms for Irradiation-Hardening and Embrittlement: A Review" Metals 9, no. 10: 1132. https://doi.org/10.3390/met9101132

APA StyleXiao, X. (2019). Fundamental Mechanisms for Irradiation-Hardening and Embrittlement: A Review. Metals, 9(10), 1132. https://doi.org/10.3390/met9101132