Mechanical Properties of In-Situ Synthesis of Ti-Ti3Al Metal Composite Prepared by Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Methods

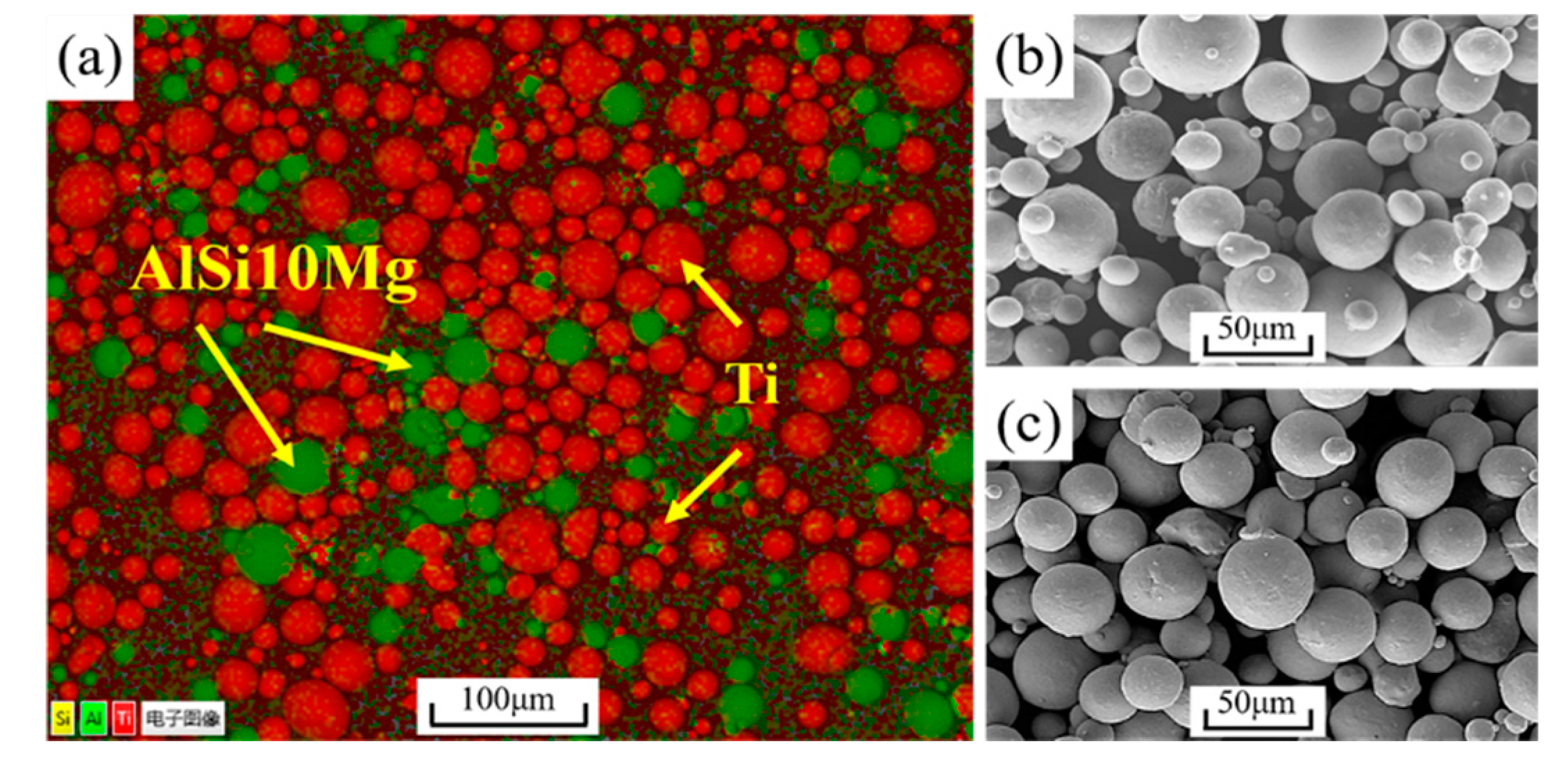

2.1. Materials

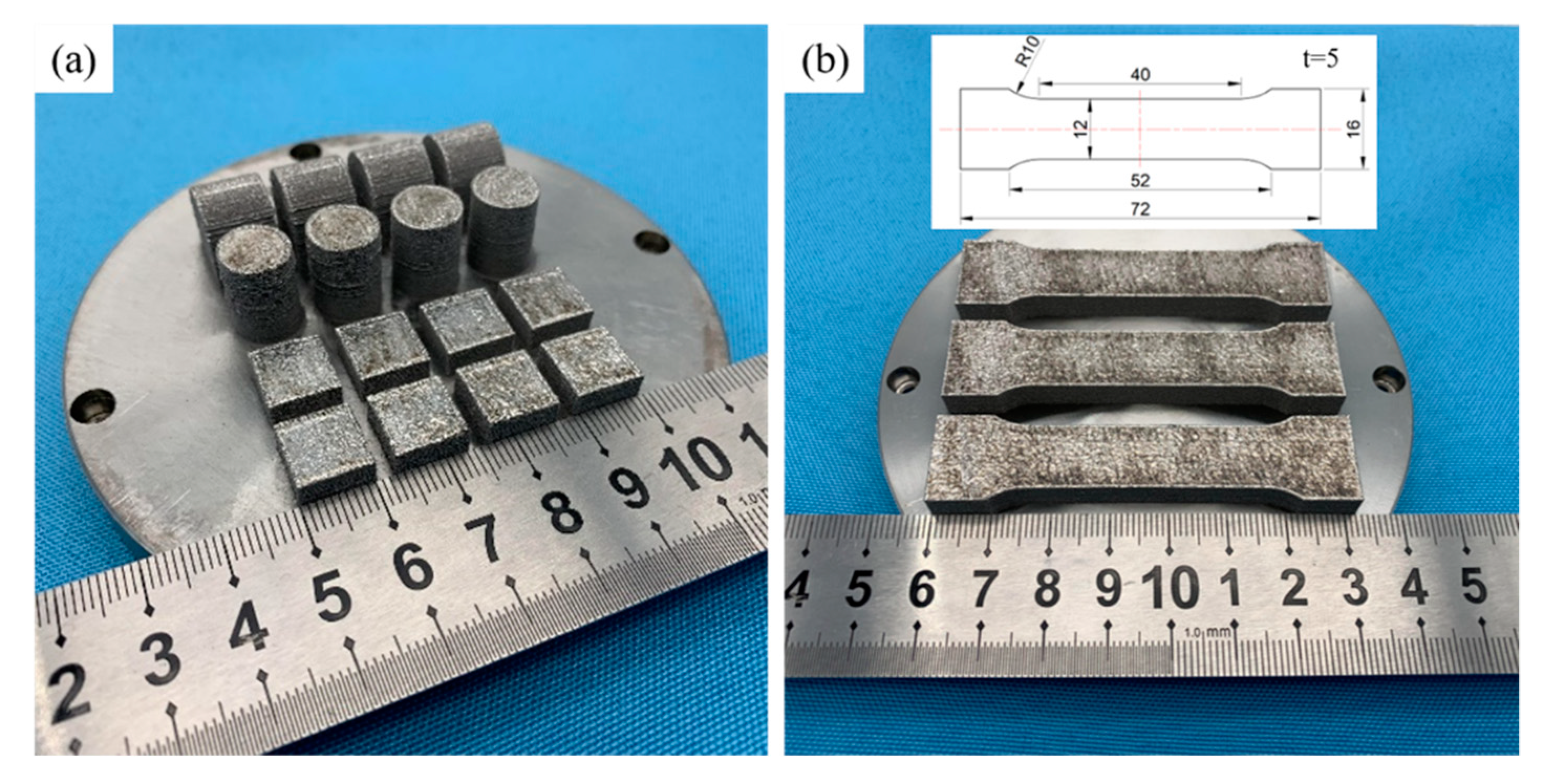

2.2. Experimental Equipment and Methods

2.3. Test Instruments

3. Results and Discussion

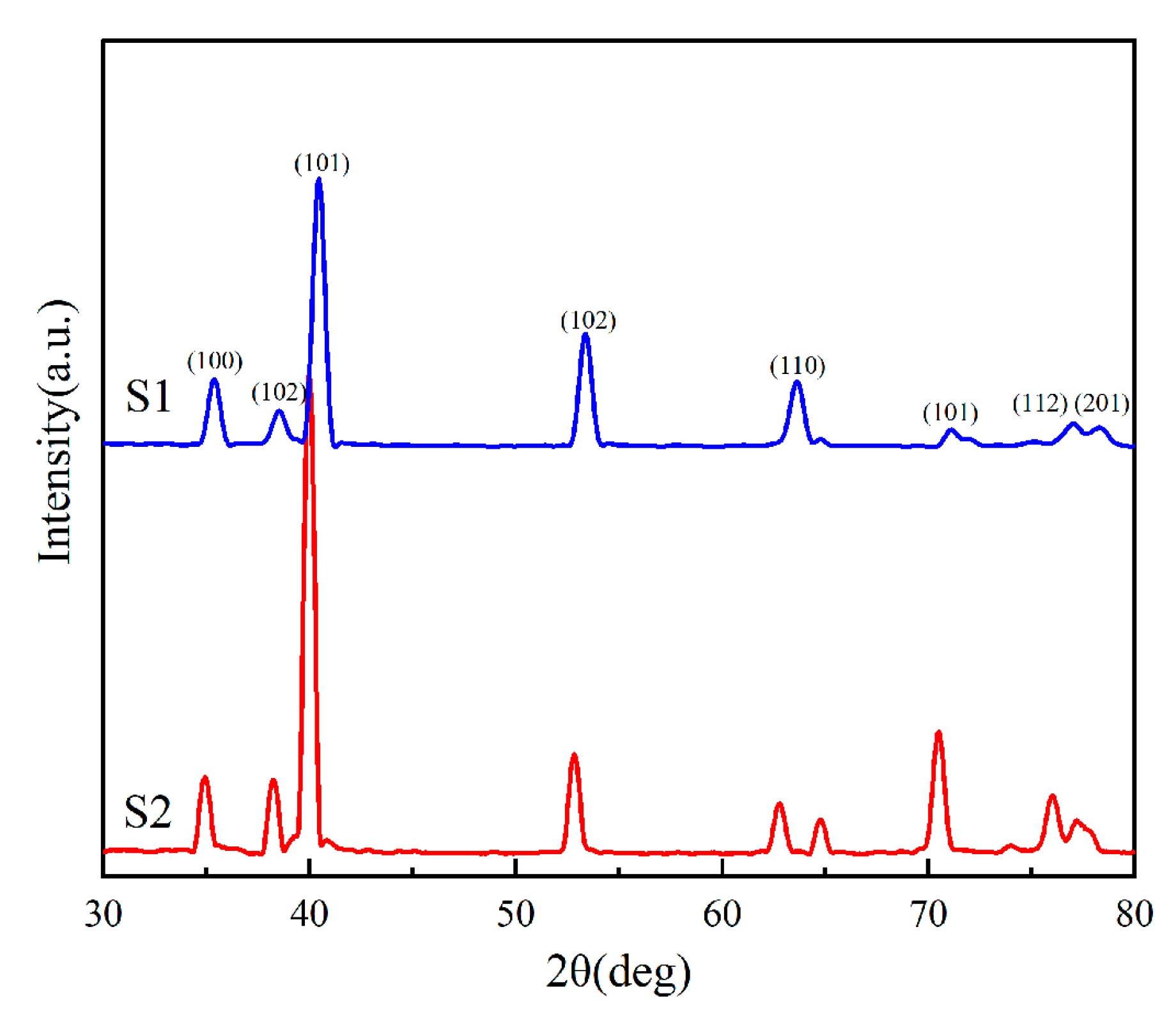

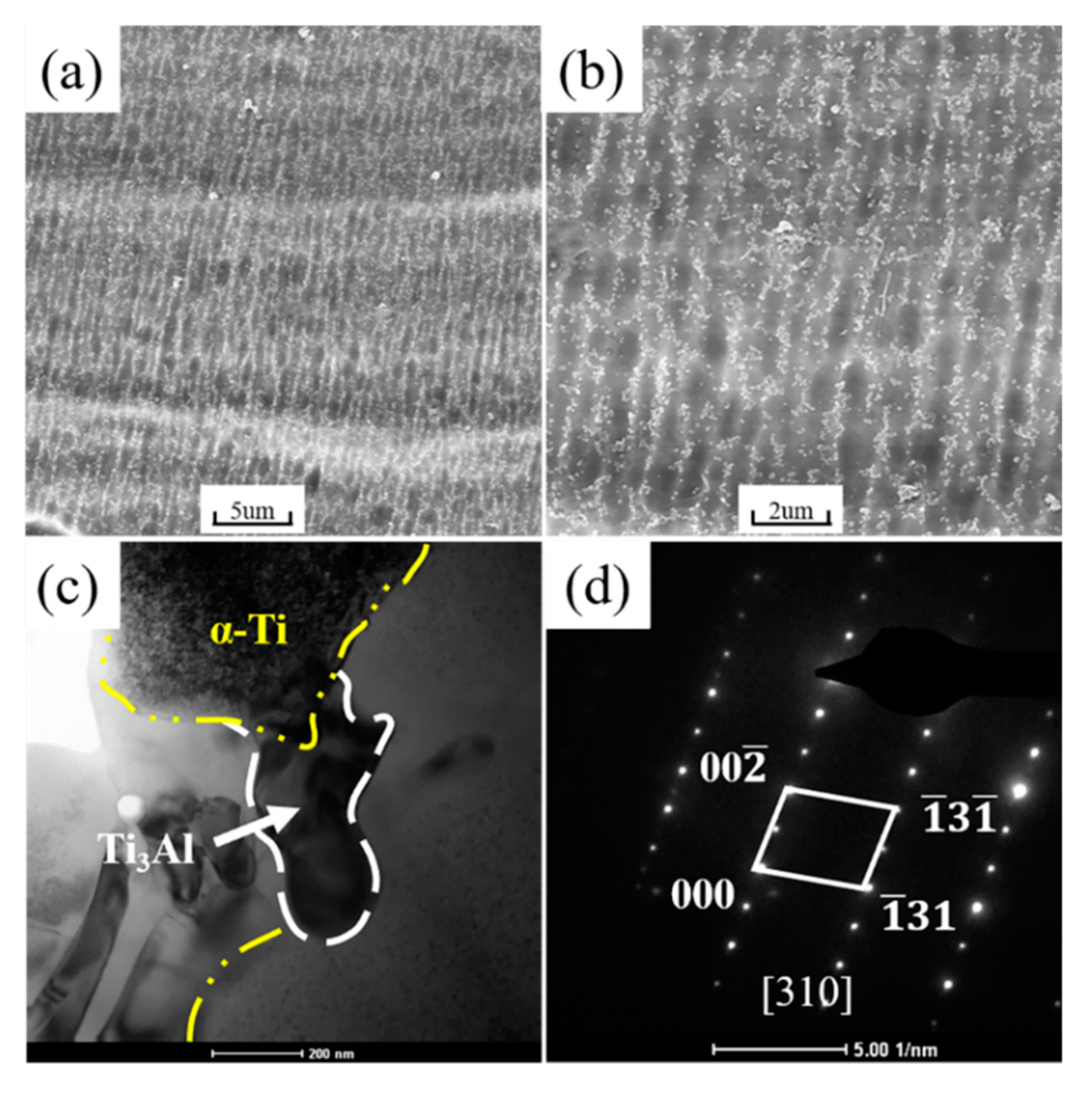

3.1. Phase Identification

3.2. Mechanical Characterization

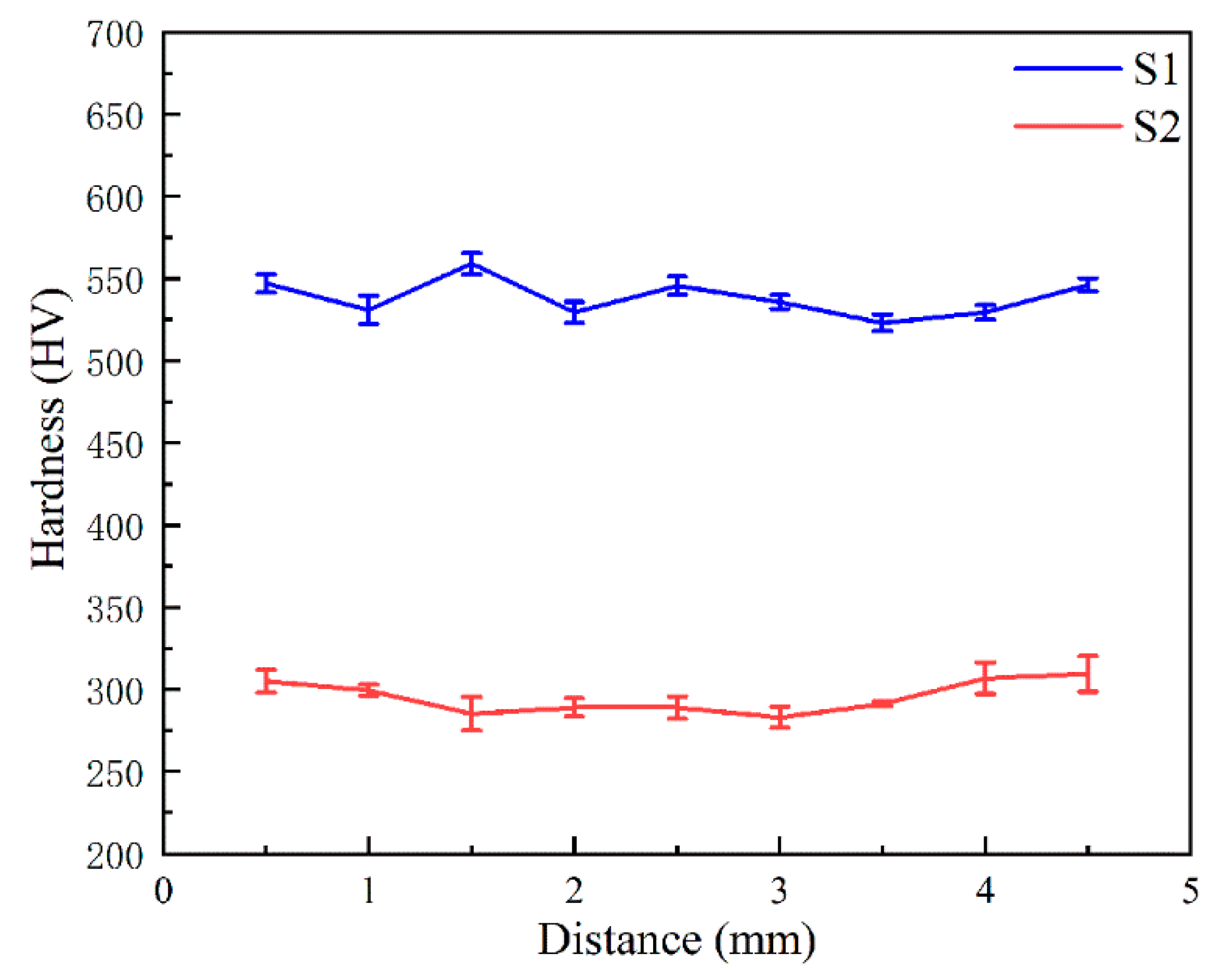

3.3. Hardness

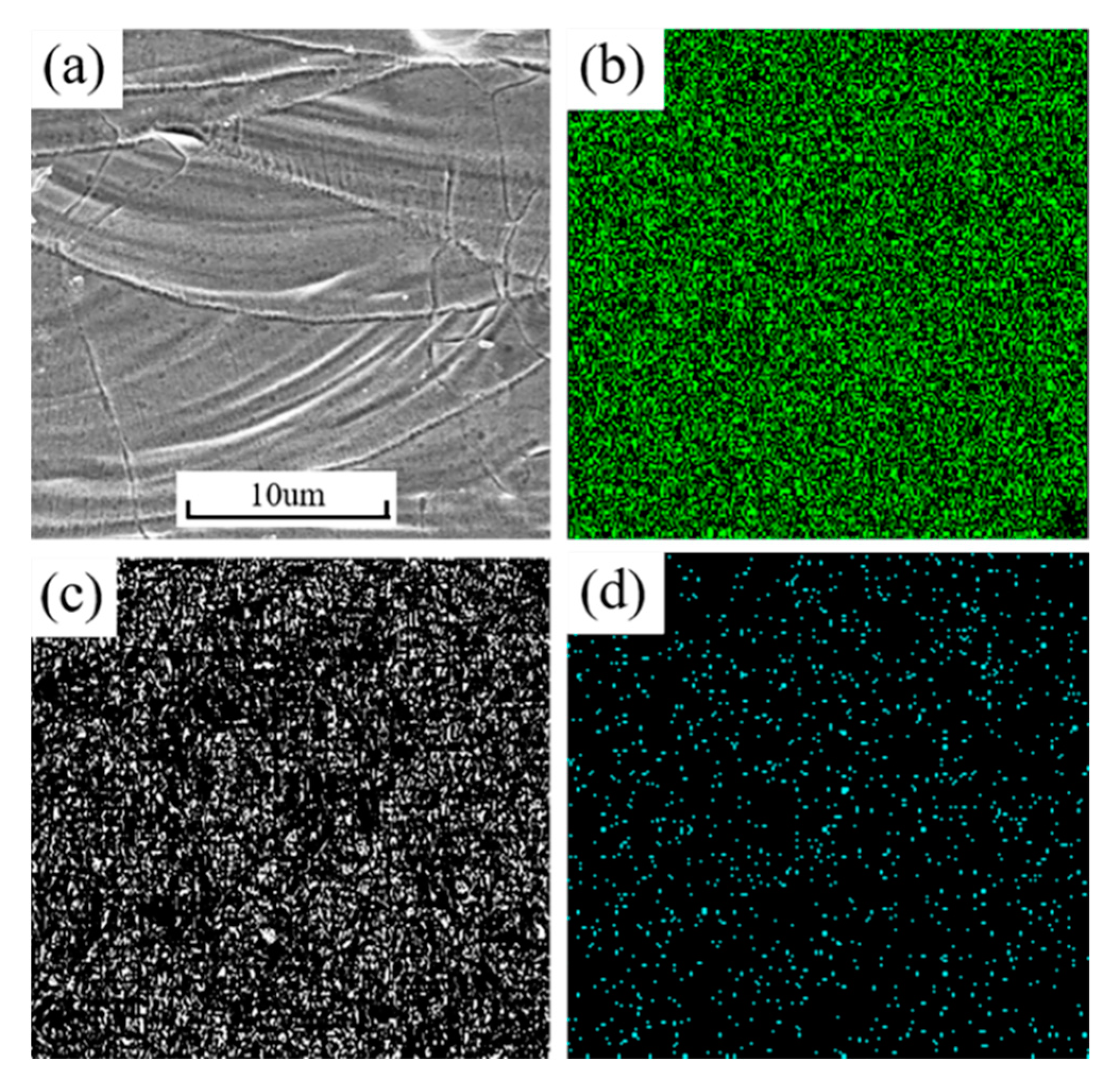

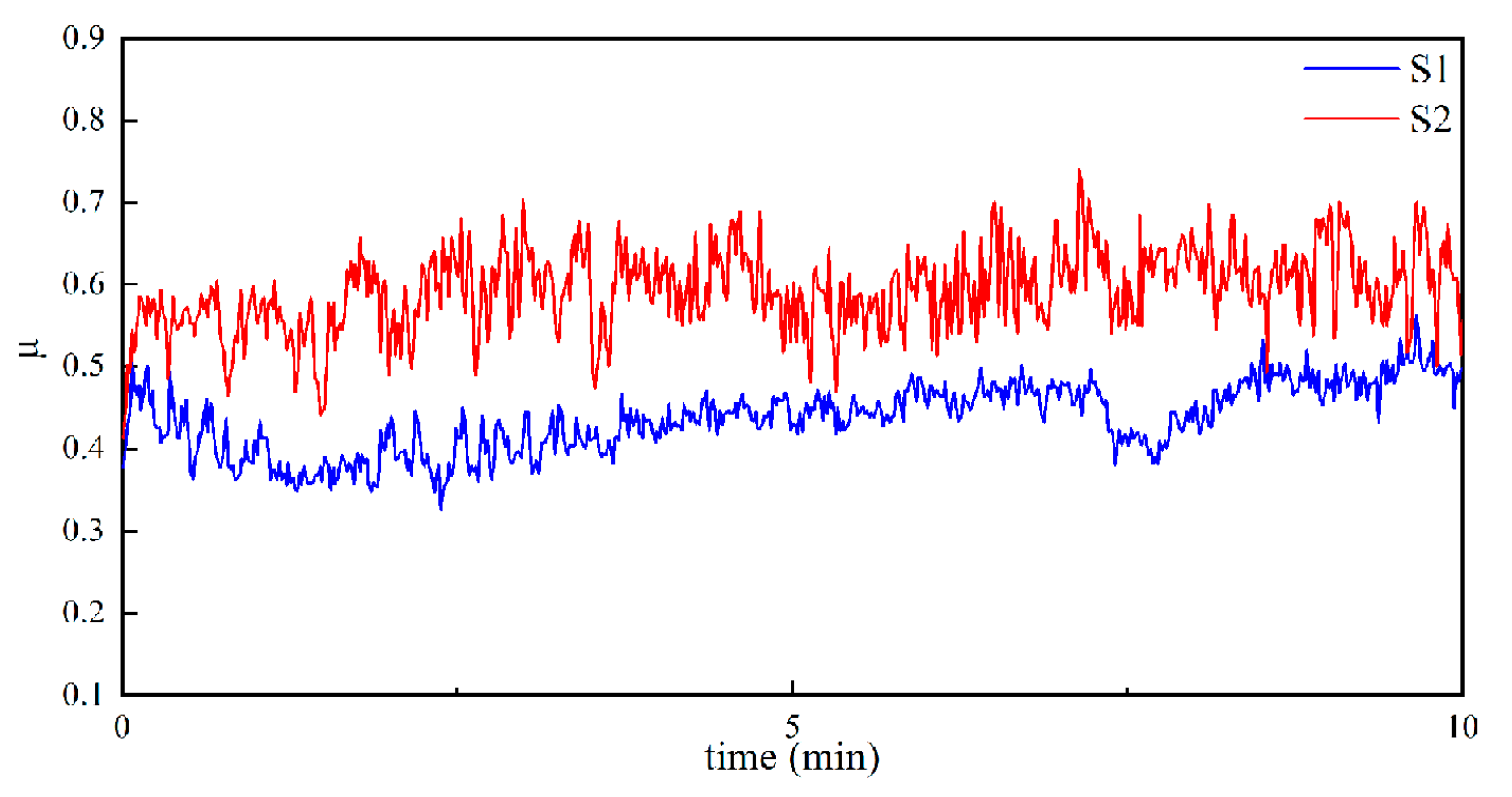

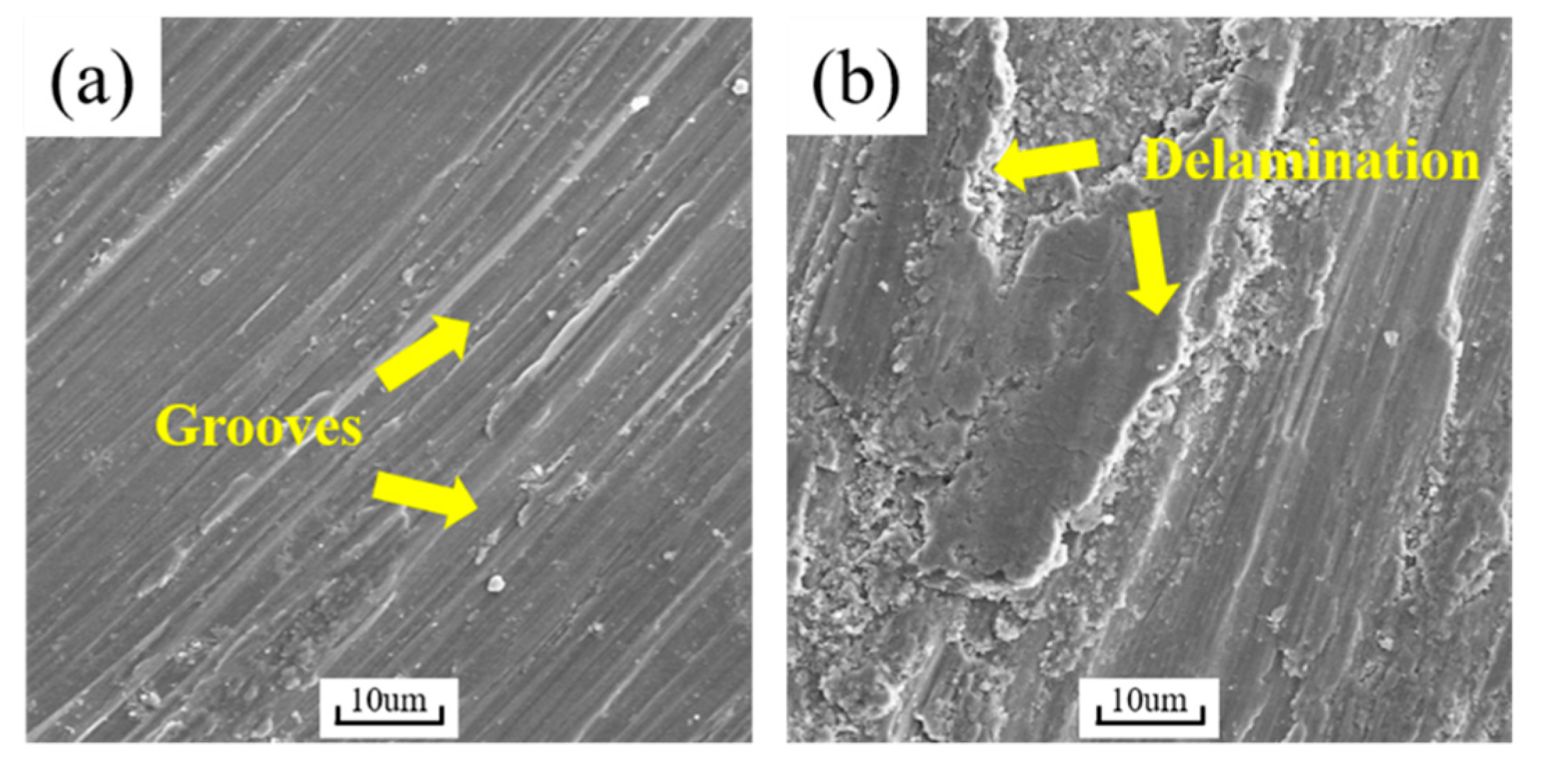

3.4. Wear Performance

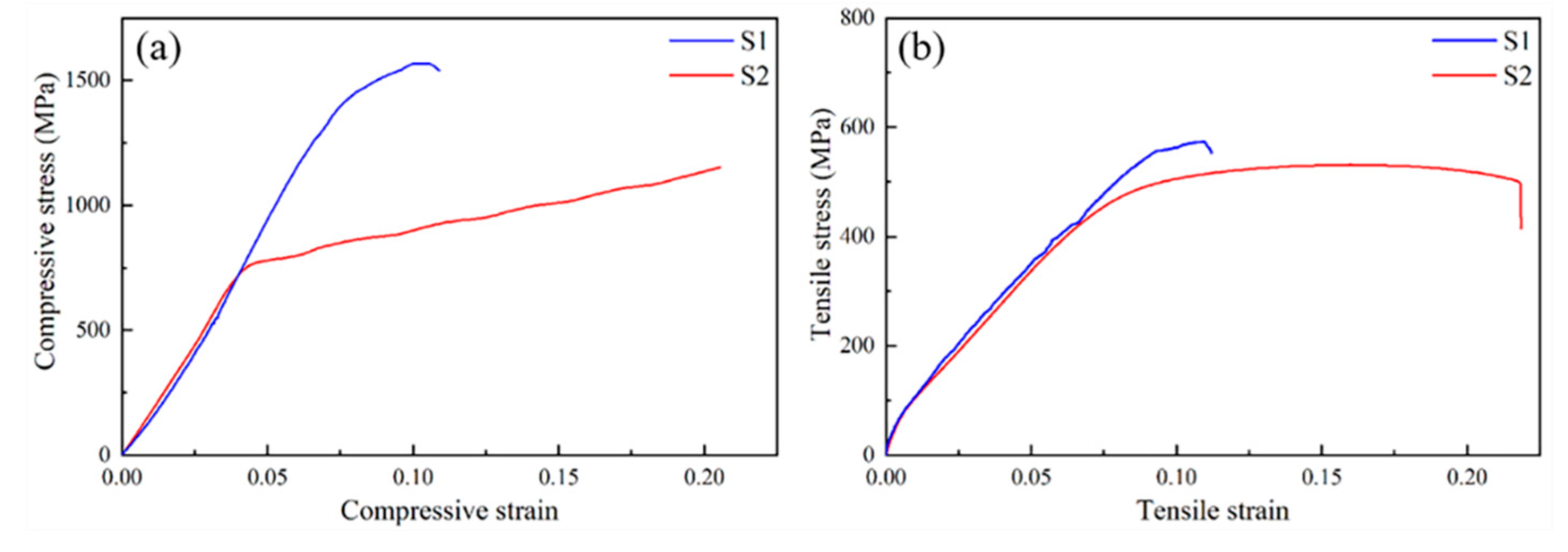

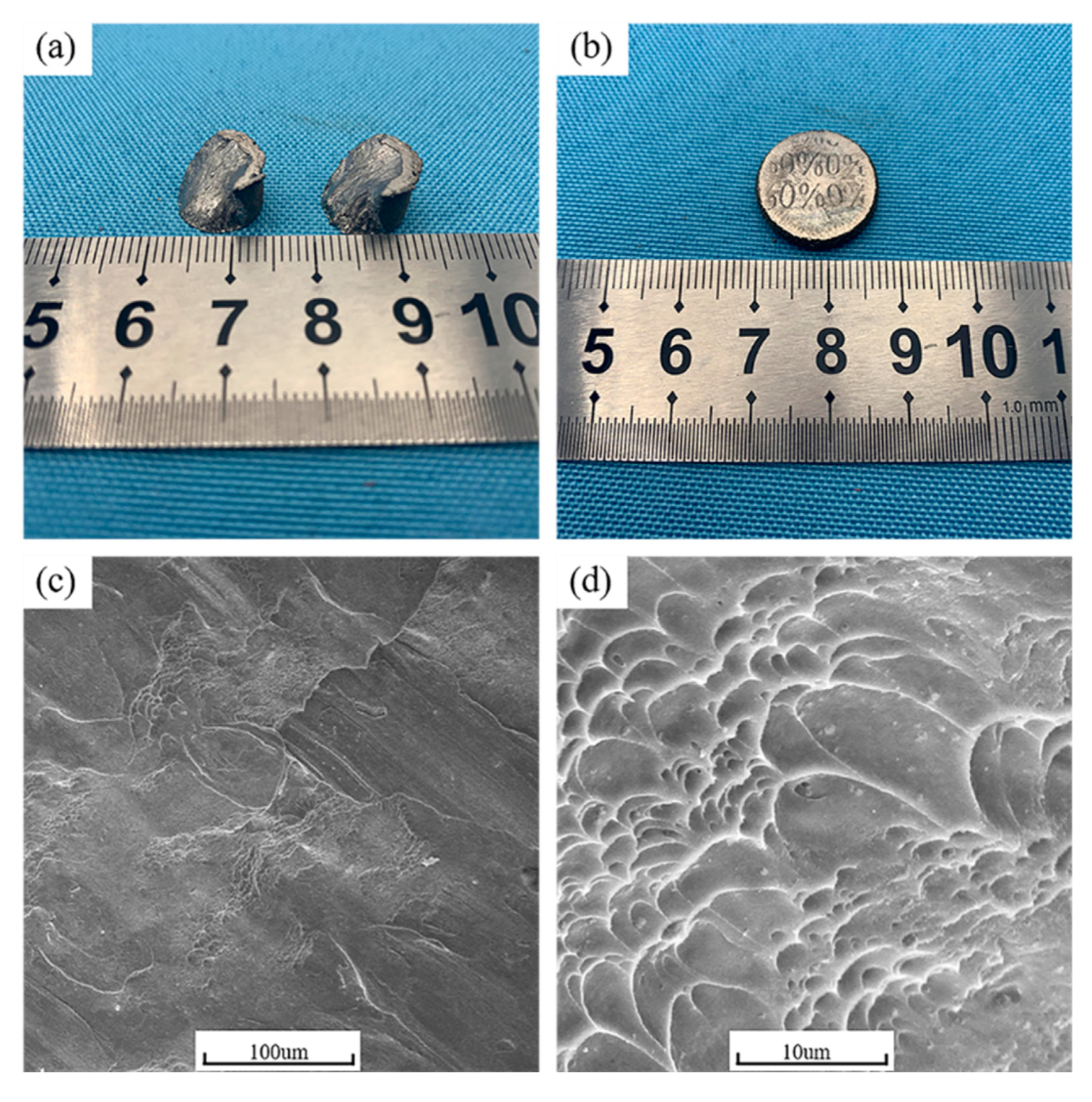

3.5. Tensile and Compression Test

4. Conclusions

- (1)

- Nano Ti3Al particles were precipitated out of the formed workpiece, with the technological parameters used in the work. The α phase in the titanium matrix was transformed into a supersaturated α phase.

- (2)

- Due to the dispersion strengthening of Ti3Al particles and the solid solution strengthening of the Al element in Ti crystal, the microhardness of Ti-based composites treated by SLM was significantly improved. With parameters of 300 W and 720 mm/s, the microhardness of the workpiece with Al was 538.56 HV, almost twice that of the Cp-Ti workpiece (218.10 HV).

- (3)

- Compared with the Cp–Ti sample, the wear resistance, tensile resistance and compression resistance of the sample were improved after adding aluminum. The wear and deformation of the sample were prevented by the interaction of the precipitated Ti3Al particles and the supersaturated α-Ti.

Author Contributions

Funding

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Wennerberg, A.; Albrektsson, T. Effects of titanium surface topography on bone integration: A systematic review. Clin. Oral Implant. Res. 2009, 20, 172–184. [Google Scholar] [CrossRef] [PubMed]

- Chan, K.S.; Leverant, G.R.; Perocchi, L. Constitutive properties of hard-alpha titanium. Metall. Mater. Trans. A 2000, 31, 3029–3040. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Lee, D.G.; Lee, S. Effects of nano-sized α2 (Ti3Al) particles on quasi-static and dynamic deformation behavior of Ti-6Al-4V alloy with bimodal microstructure. J. Mater. Sci. 2005, 40, 4077–4084. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2010. [Google Scholar]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Shuai, C.; Cheng, Y.; Yang, Y.; Peng, S.; Yang, W.; Qi, F. Laser additive manufacturing of Zn-2Al part for bone repair: Formability, microstructure and properties. J. Alloys Compd. 2019, 798, 606–615. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y.; Lu, Z. Preparation of TiN-Ti5Si3 in-situ composites by selective laser melting. Mater. Lett. 2009, 63, 1577–1579. [Google Scholar] [CrossRef]

- Sahoo, P.; Koczak, M.J. Microstructure-property relationships of in situ reacted TiC/Al Cu metal matrix composites. Mater. Sci. Eng. A 1991, 131, 69–76. [Google Scholar] [CrossRef]

- Chrysanthou, A.; Erbaccio, G. Production of copper-matrix composites by in situ processing. J. Mater. Sci. 1995, 30, 6339–6344. [Google Scholar] [CrossRef]

- Wang, L.; Arsenault, R.J. Interfaces in XD processed TiB 2 /NiAl composites. Metall. Trans. A 1991, 22, 3013–3018. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, F.; Gao, C.; Feng, P.; Xue, L.; He, S.; Shuai, C. A combined strategy to enhance the properties of Zn by laser rapid solidification and laser alloying. J. Mech. Behav. Biomed. Mater. 2018, 82, 51–60. [Google Scholar] [CrossRef] [PubMed]

- Jangg, G.; Kutner, F.; Korb, G. Dispersion hardening of aluminium with Al 4C 3. Powder Metall. 1977, 9, 24–26. [Google Scholar]

- Ma, Z.Y.; Li, J.H.; Li, S.X.; Ning, X.G.; Lu, Y.X.; Bi, J. Property-microstructure correlation in in situ formed Al2O3, TiB2 and Al3Ti mixture-reinforced aluminium composites. J. Mater. Sci. 1996, 31, 741–747. [Google Scholar] [CrossRef]

- Li, Y.; Shen, Y.; Leu, M.C.; Tsai, H.-L. Building Zr-based metallic glass part on Ti-6Al-4V substrate by laser-foil-printing additive manufacturing. Acta Mater. 2018, 144, 810–821. [Google Scholar] [CrossRef]

- Lu, L.; Lai, M.O.; Wang, H.Y. Synthesis of titanium diboride TiB2 and Ti-Al-B metal matrix composites. J. Mater. Sci. 2000, 35, 241–248. [Google Scholar] [CrossRef]

- Wu, H.; Fan, G.; Geng, L.; Cui, X.; Huang, M. Nanoscale origins of the oriented precipitation of Ti 3 Al in Ti Al systems. Scr. Mater. 2016, 125, 34–38. [Google Scholar] [CrossRef]

- Gu, D.; Meng, G.; Li, C.; Meiners, W.; Poprawe, R. Selective laser melting of TiC/Ti bulk nanocomposites: Influence of nanoscale reinforcement. Scr. Mater. 2012, 67, 185–188. [Google Scholar] [CrossRef]

- Zhang, L.C.; Das, J.; Lu, H.B.; Duhamel, C.; Calin, M.; Eckert, J. High strength Ti-Fe-Sn ultrafine composites with large plasticity. Scr. Mater. 2007, 57, 101–104. [Google Scholar] [CrossRef]

- Kang, Y.C.; Chan, S.L.I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- He, G.; Löser, W.; Eckert, J. In situ formed Ti-Cu-Ni-Sn-Ta nanostructure-dendrite composite with large plasticity. Acta Mater. 2003, 51, 5223–5234. [Google Scholar] [CrossRef]

- Trojanová, Z.; Gärtnerová, V.; Jäger, A.; Námešný, A.; Chalupová, M.; Palček, P.; Lukáč, P. Mechanical and fracture properties of an AZ91 Magnesium alloy reinforced by Si and SiC particles. Compos. Sci. Technol. 2009, 69, 2256–2264. [Google Scholar] [CrossRef]

| Ti | C | Fe | N | O | H |

|---|---|---|---|---|---|

| Balance | 0.012 | 0.023 | 0.010 | 0.058 | 0.001 |

| Al | Cu | Mg | Fe | Si | Mn | Zn |

|---|---|---|---|---|---|---|

| Balance | 0.05 | 0.623 | 0.010 | 9.624 | 0.01 | 0.03 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liang, H.; Tian, Z.; Yang, Y.; Xie, D.; Zhu, L.; Shen, L.; Wang, C. Mechanical Properties of In-Situ Synthesis of Ti-Ti3Al Metal Composite Prepared by Selective Laser Melting. Metals 2019, 9, 1121. https://doi.org/10.3390/met9101121

Li Y, Liang H, Tian Z, Yang Y, Xie D, Zhu L, Shen L, Wang C. Mechanical Properties of In-Situ Synthesis of Ti-Ti3Al Metal Composite Prepared by Selective Laser Melting. Metals. 2019; 9(10):1121. https://doi.org/10.3390/met9101121

Chicago/Turabian StyleLi, Yize, Huixin Liang, Zongjun Tian, Youwen Yang, Deqiao Xie, Lei Zhu, Lida Shen, and Changjiang Wang. 2019. "Mechanical Properties of In-Situ Synthesis of Ti-Ti3Al Metal Composite Prepared by Selective Laser Melting" Metals 9, no. 10: 1121. https://doi.org/10.3390/met9101121

APA StyleLi, Y., Liang, H., Tian, Z., Yang, Y., Xie, D., Zhu, L., Shen, L., & Wang, C. (2019). Mechanical Properties of In-Situ Synthesis of Ti-Ti3Al Metal Composite Prepared by Selective Laser Melting. Metals, 9(10), 1121. https://doi.org/10.3390/met9101121