Bending and Torsion Fatigue-Testing Machine Developed for Multiaxial Non-Proportional Loading

Abstract

1. Introduction

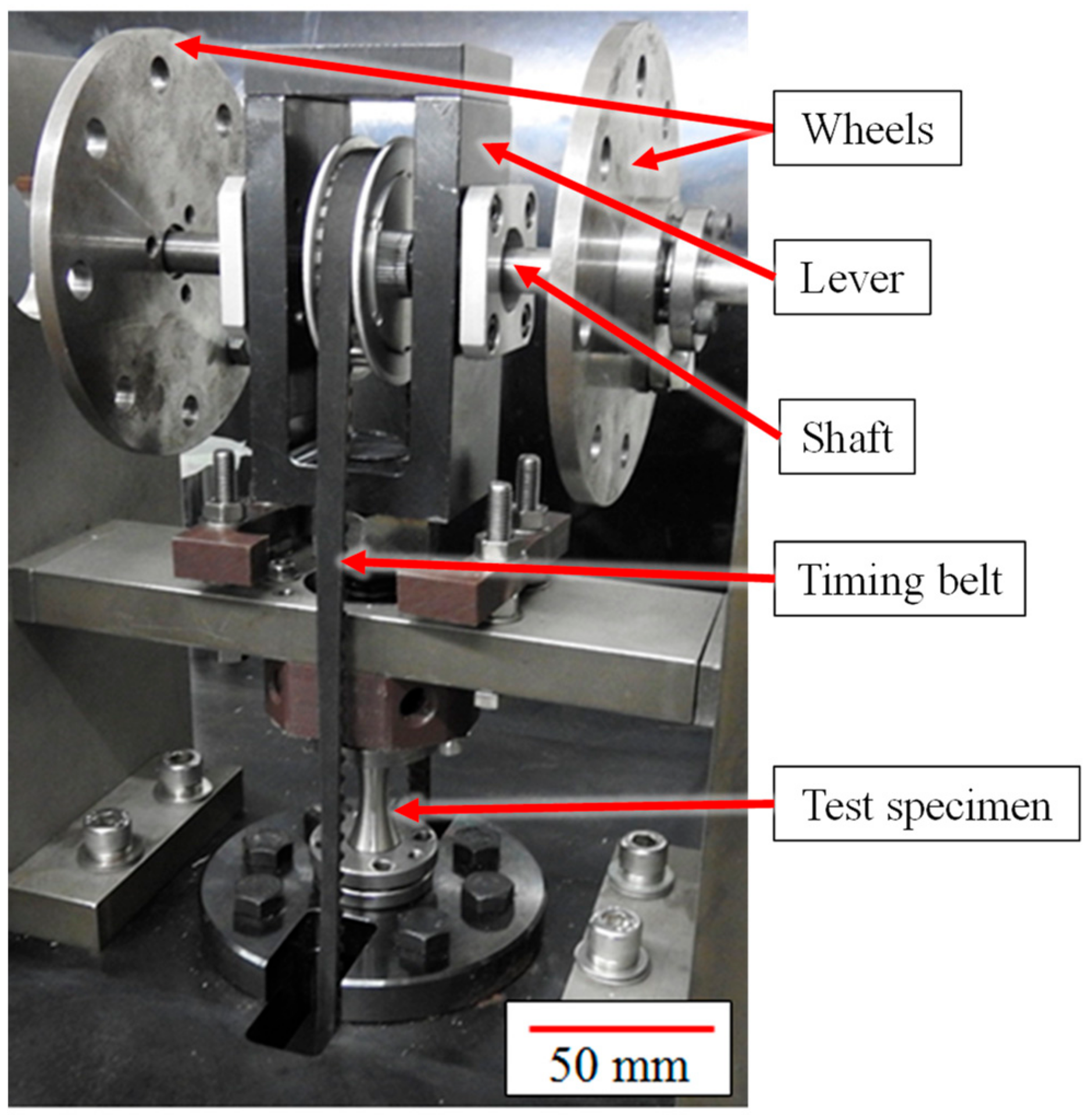

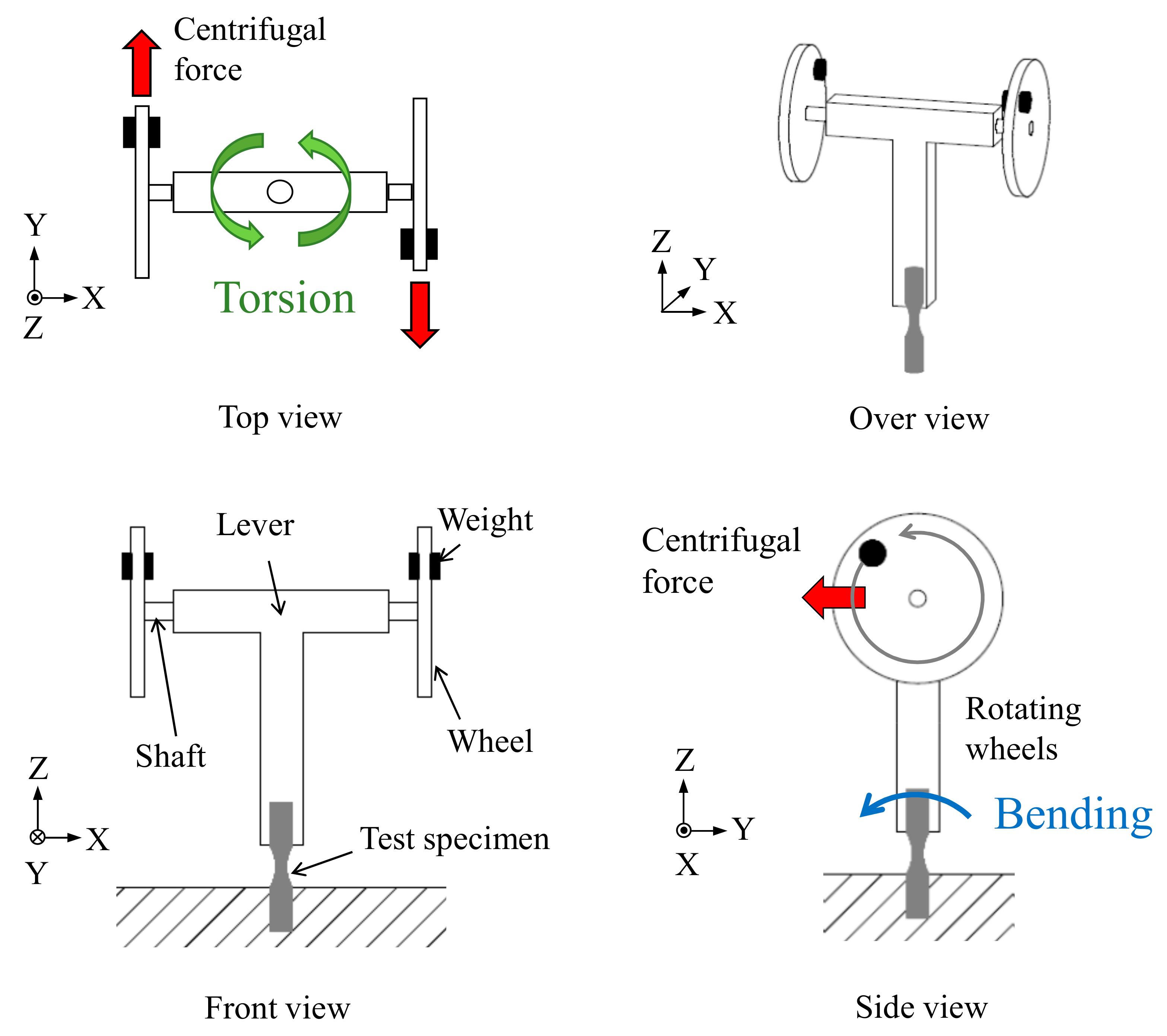

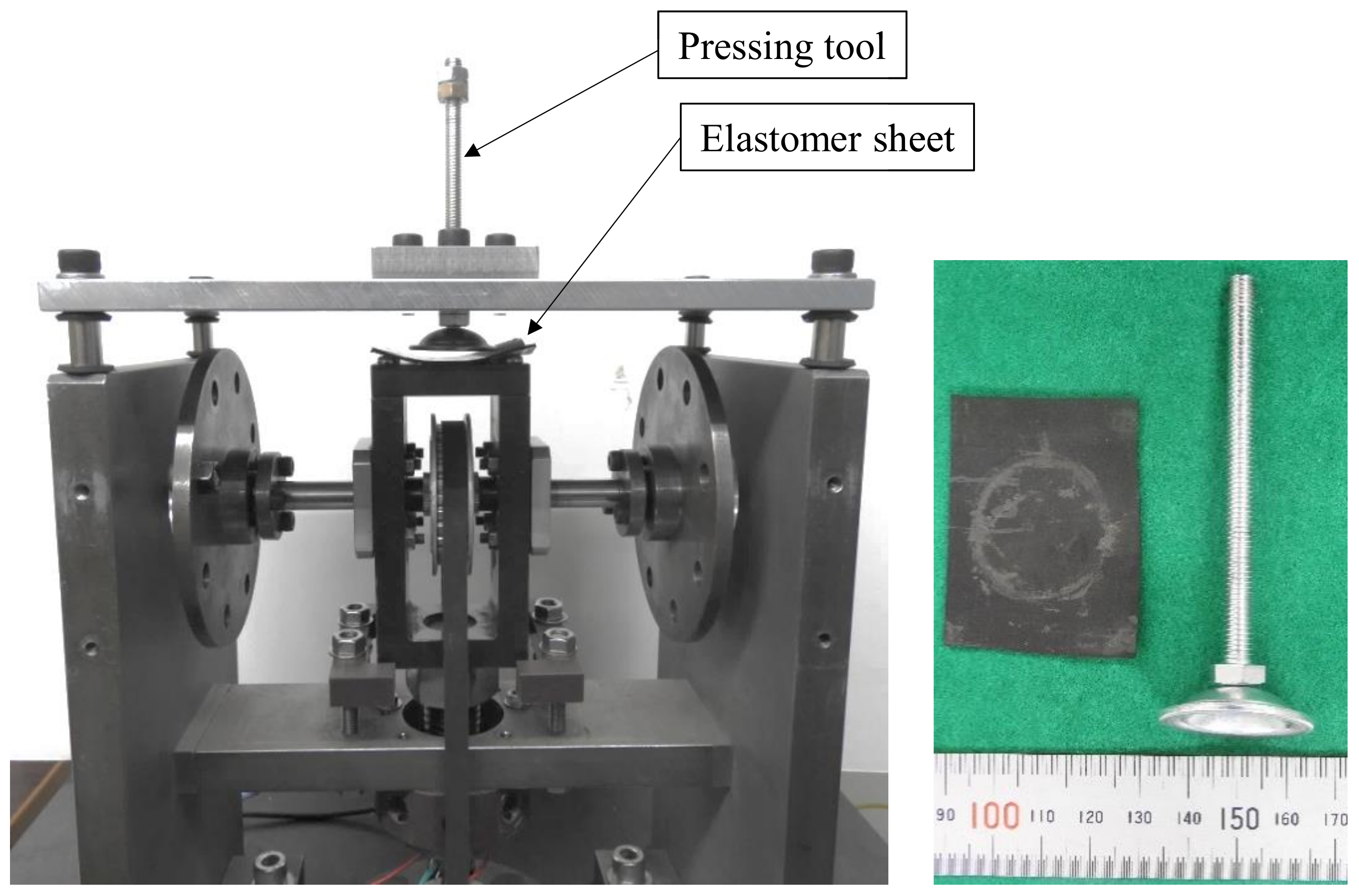

2. Development of the Testing Machine

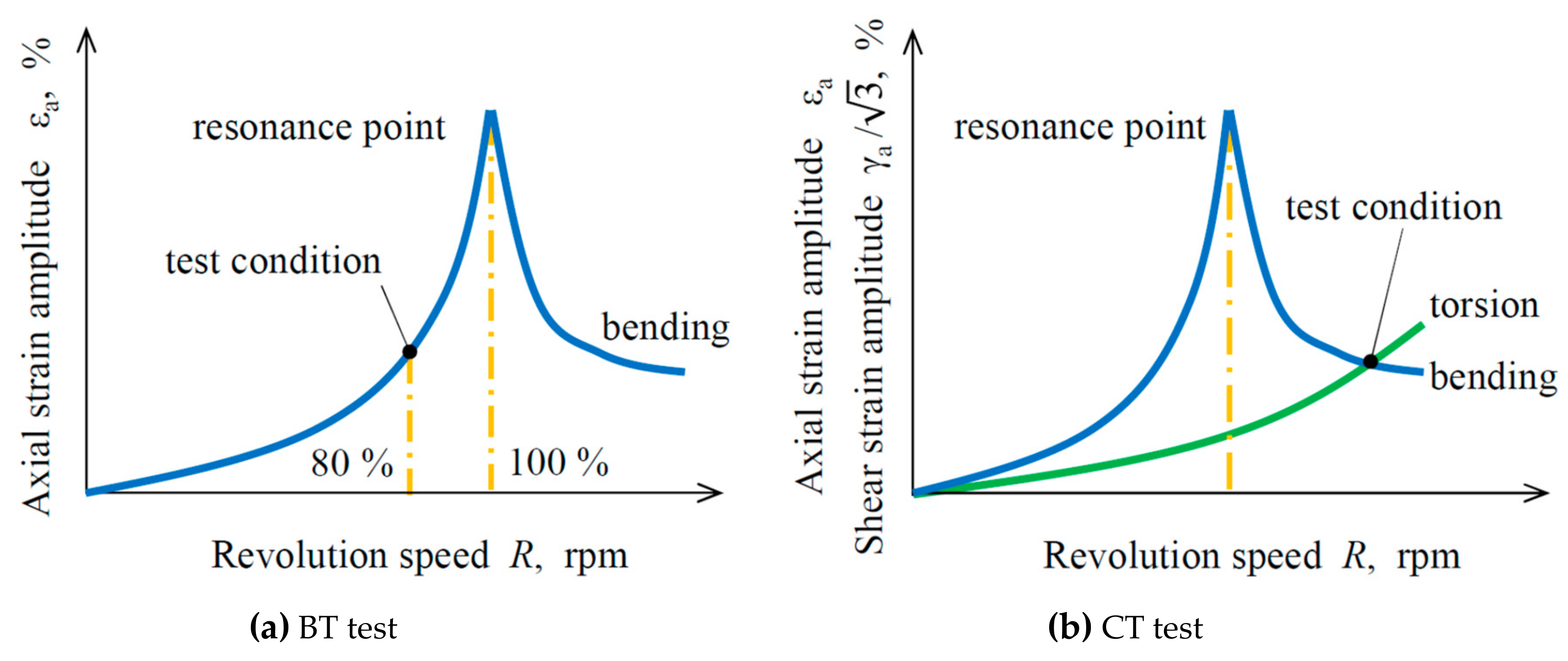

2.1. Basic Concept

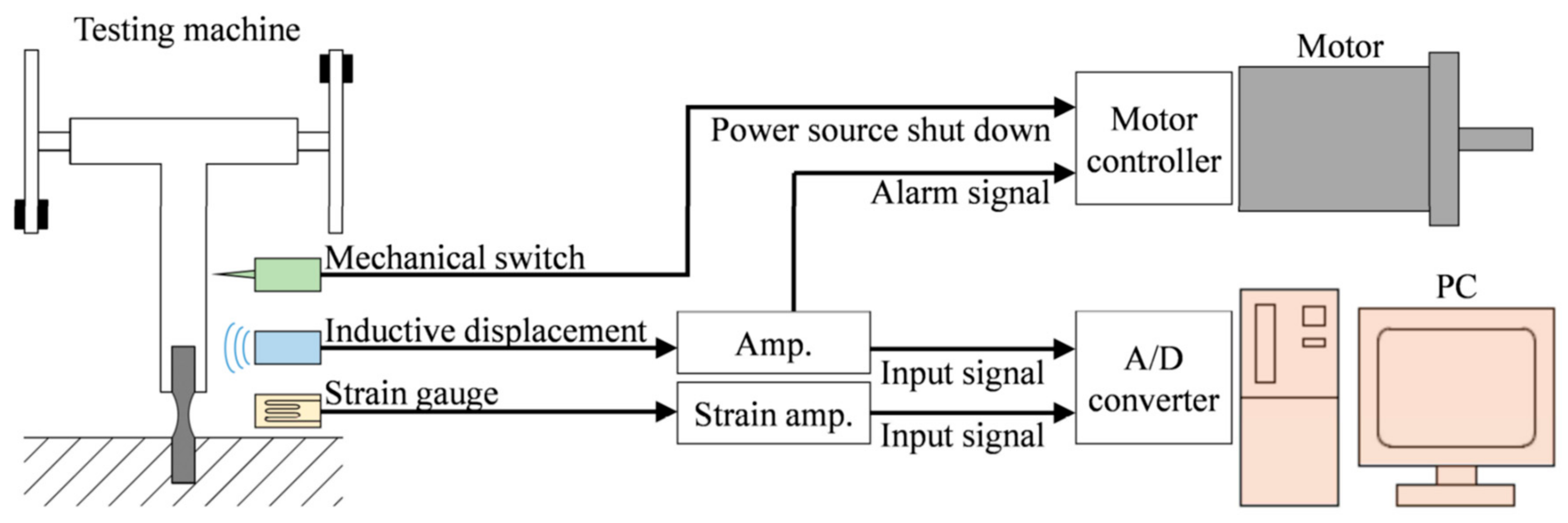

2.2. Measurement and Control System

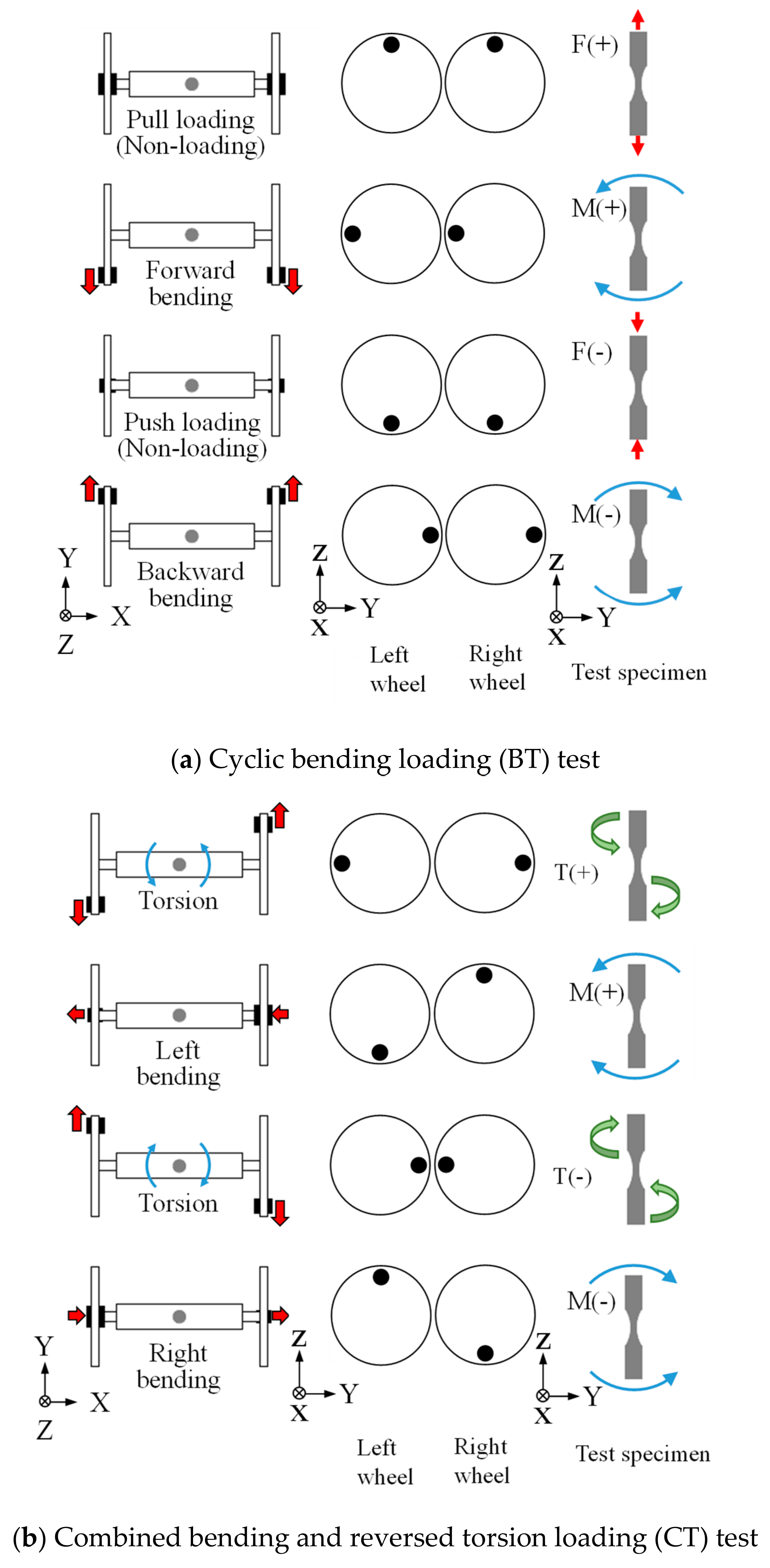

2.3. Weight Setting and Loading Conditions

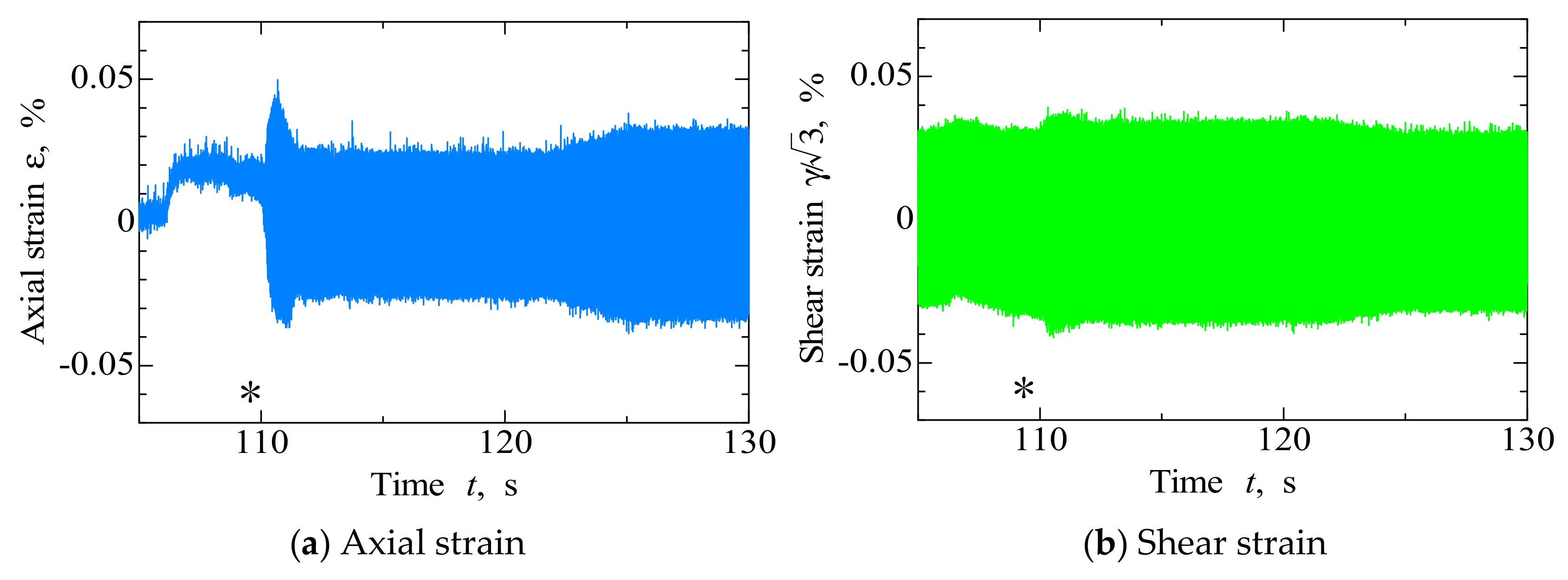

2.4. Control of the Testing Machine

3. Fatigue Tests

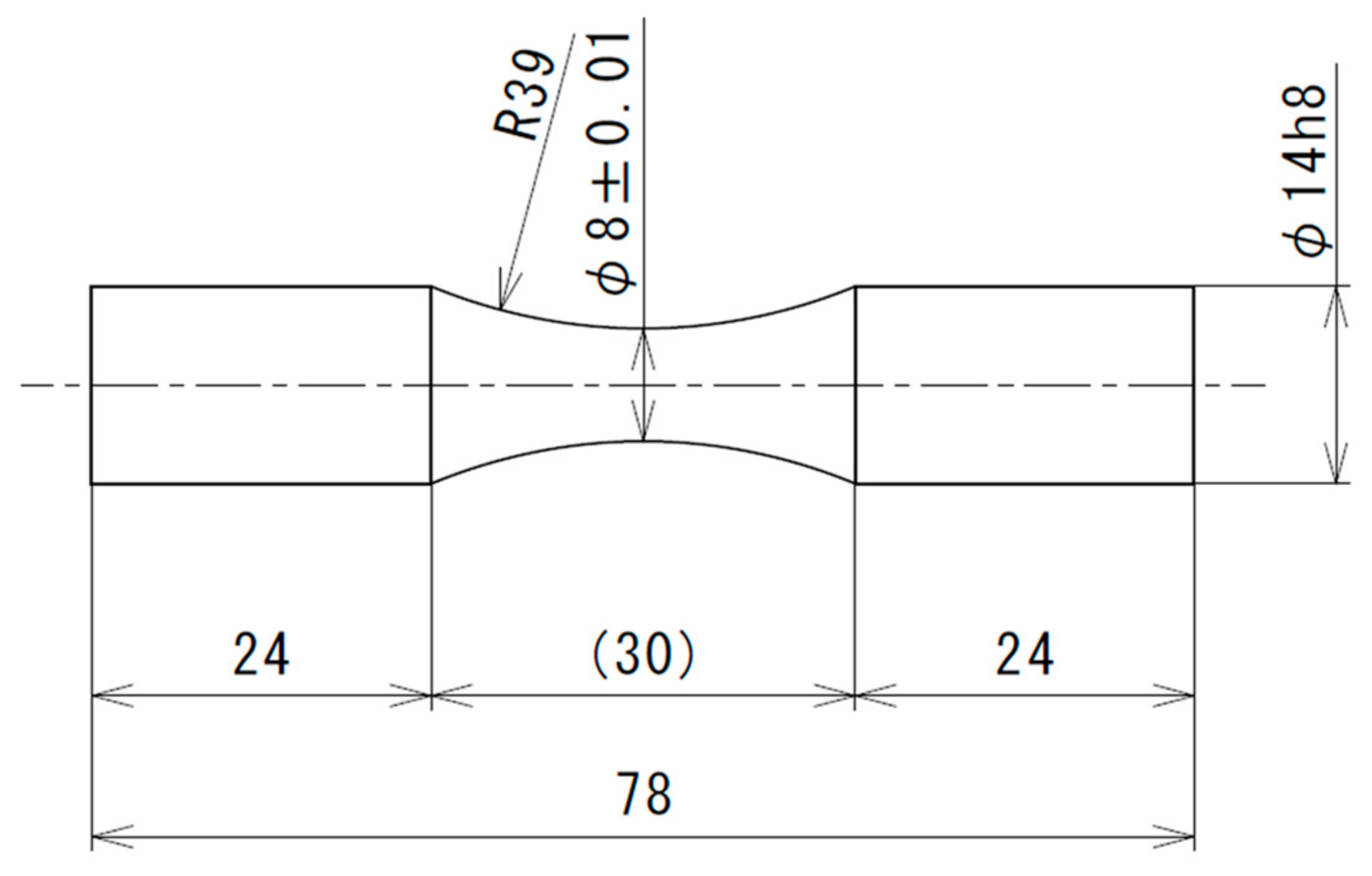

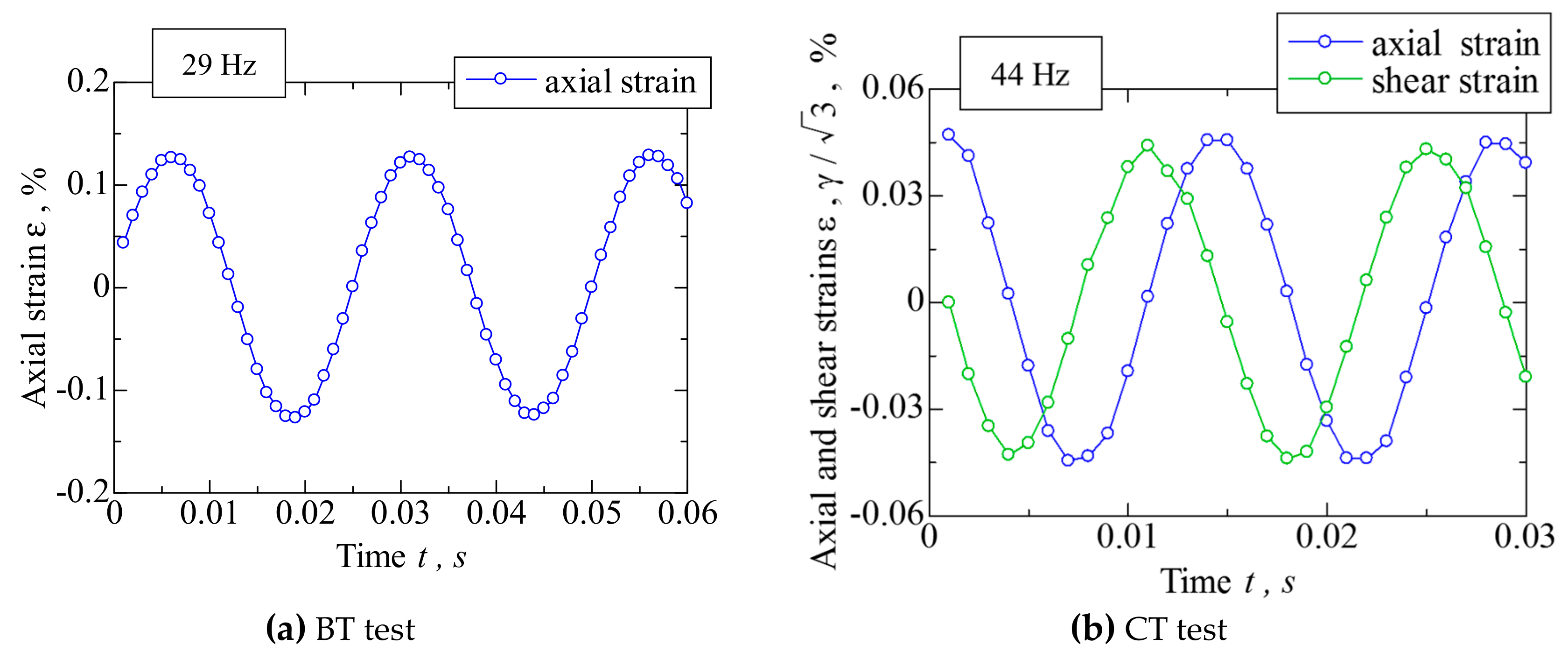

3.1. Specimens and Loading Paths

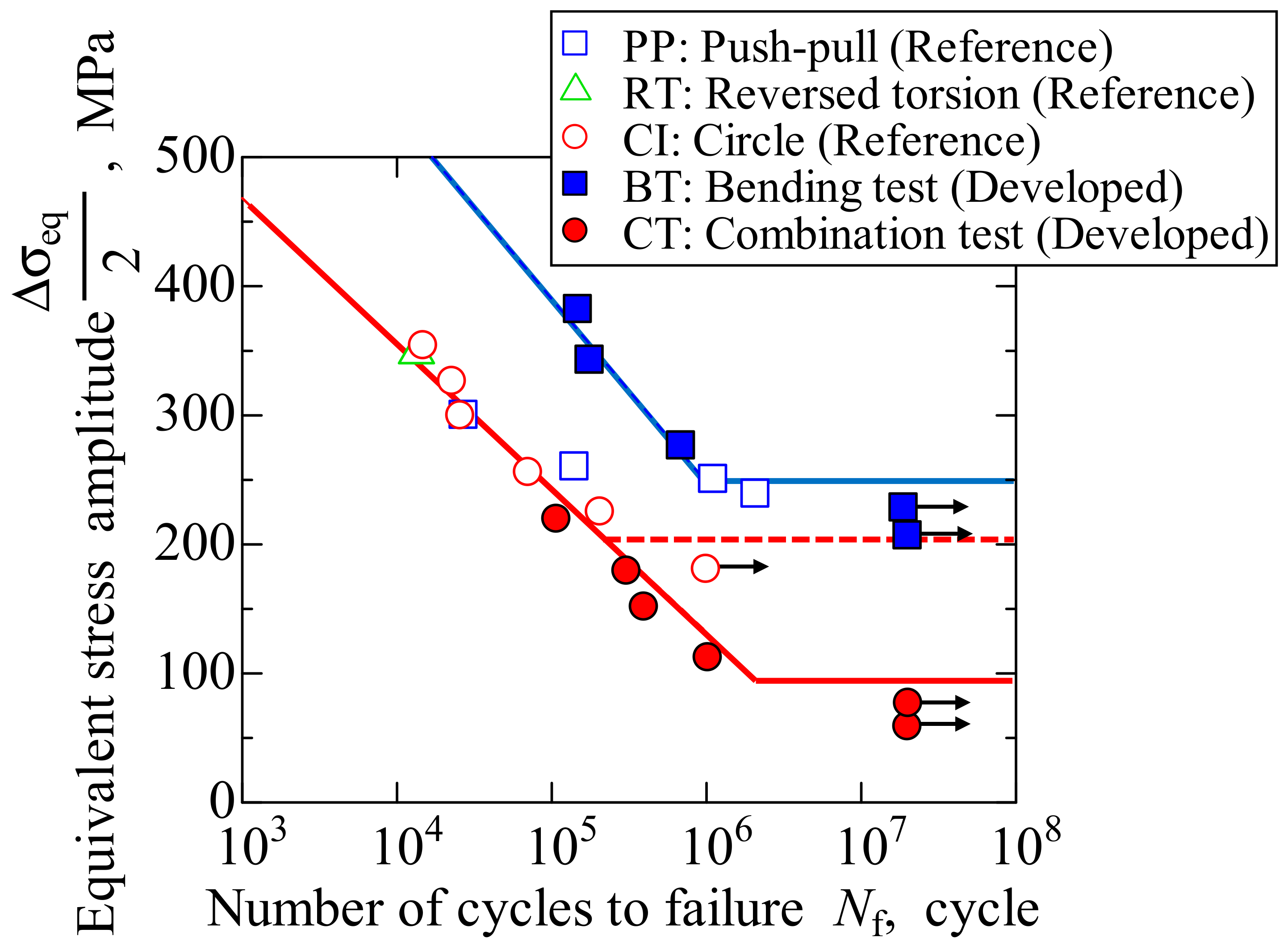

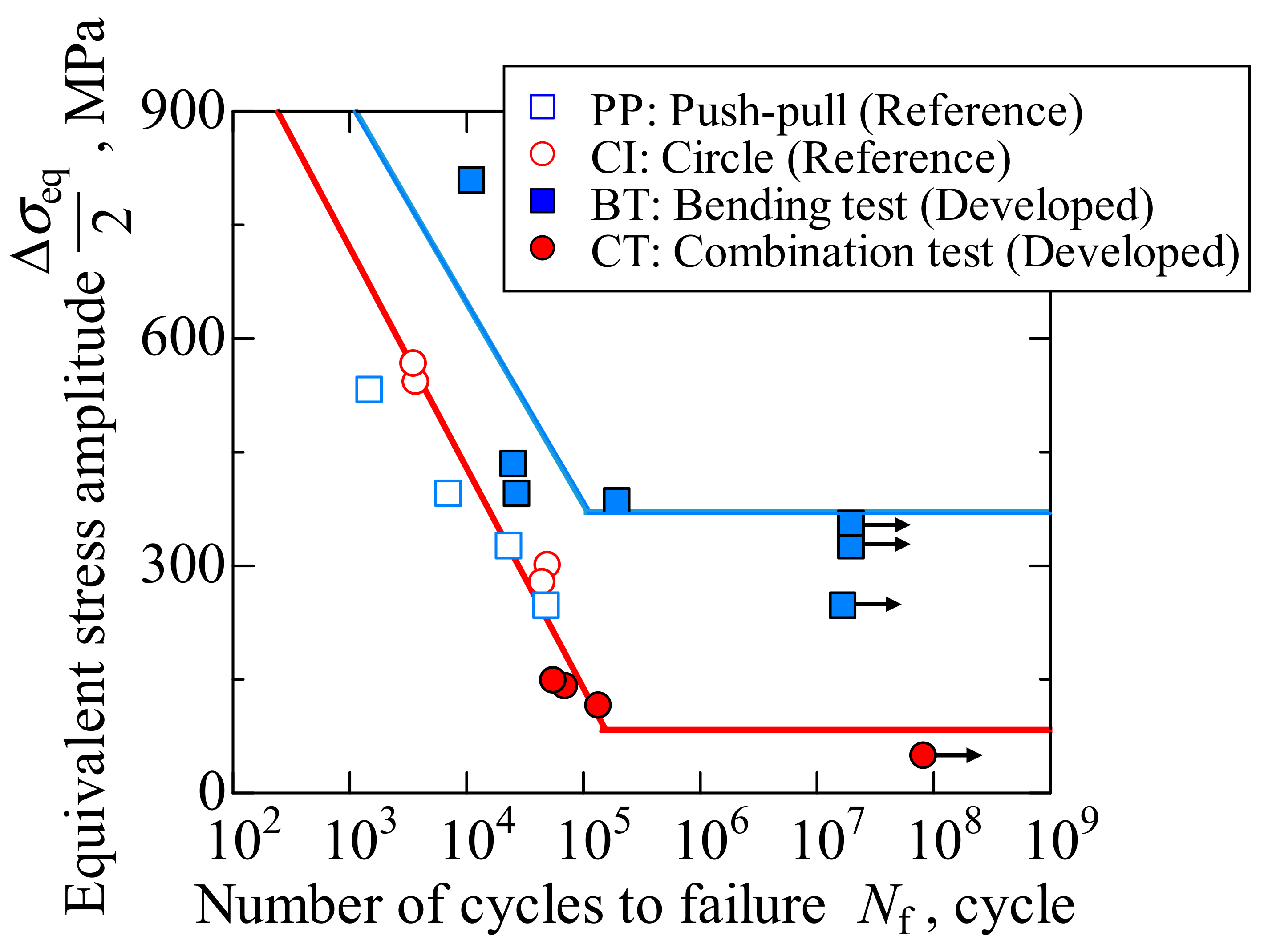

3.2. Test Results

4. Conclusions

- (1)

- Overload occurred when exceeding the resonance frequency. However, the effect of overload was negligible, and multiaxial fatigue tests could be performed at high frequency. Fatigue tests with 107 cycles could be performed over a period of 3 days.

- (2)

- The position of the weight determined the type of test. The same weight position led to bending loading, whereas a difference in the weight position (by 180°) led to bending and torsion combination loading. Non-proportional loading with a 90° phase difference in bending waveform and torsional waveform can be achieved.

- (3)

- A bending loading test and combination loading test were performed using hourglass-shaped specimens made of type 490A hot-rolled steel and type 316 stainless steel. Fatigue life obtained using the bending test was slightly longer than in the case of using the conventional electric servohydraulic multiaxial fatigue-testing machine. The fatigue life in the combination test, obtained using the developed testing machine, coincided with that obtained using the conventional testing machine, regardless of the reduction in fatigue limit stress value. This was due to the difference in bending torsion and push–pull torsion waveforms and the definition assigned to “fatigue life.”

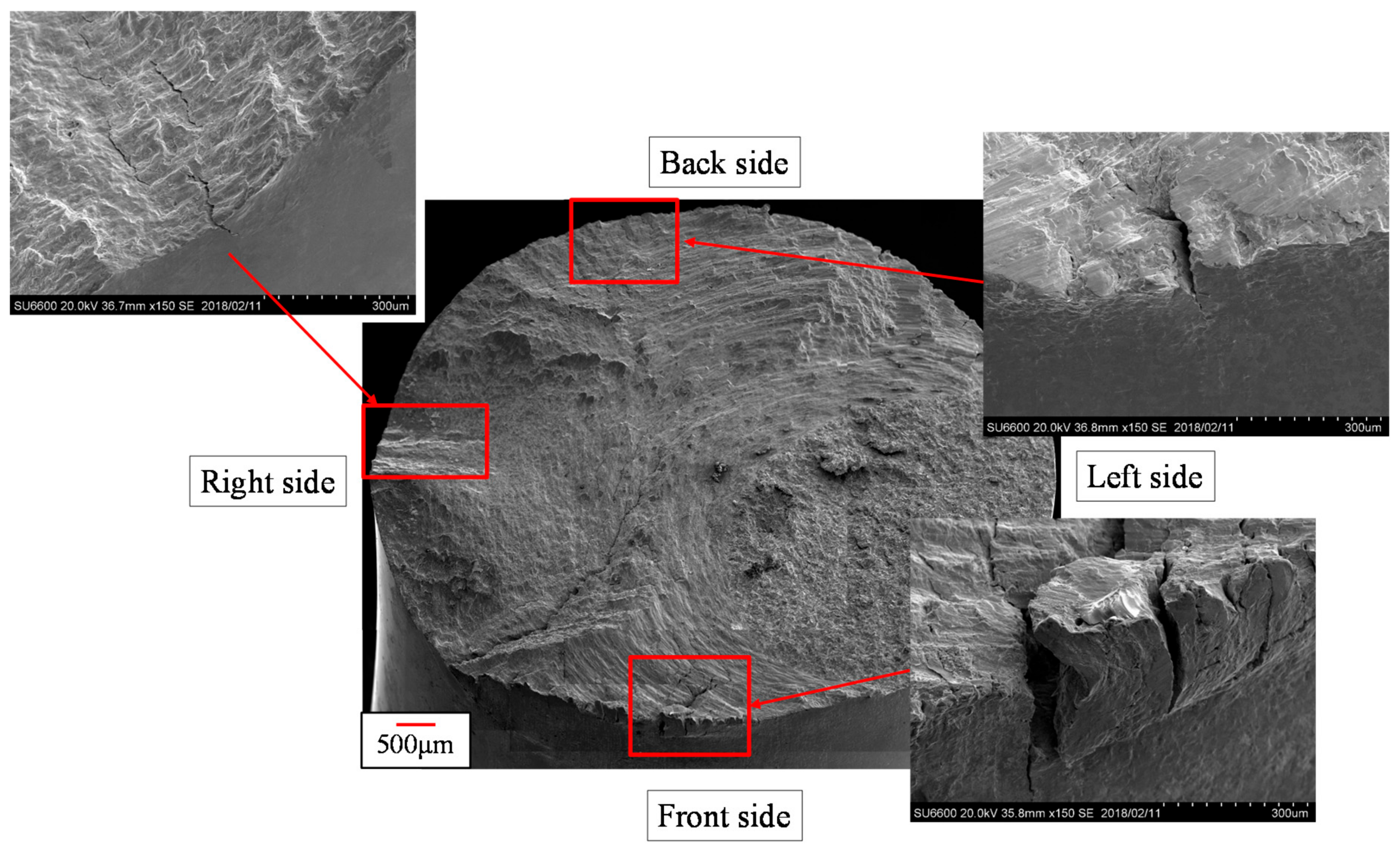

- (4)

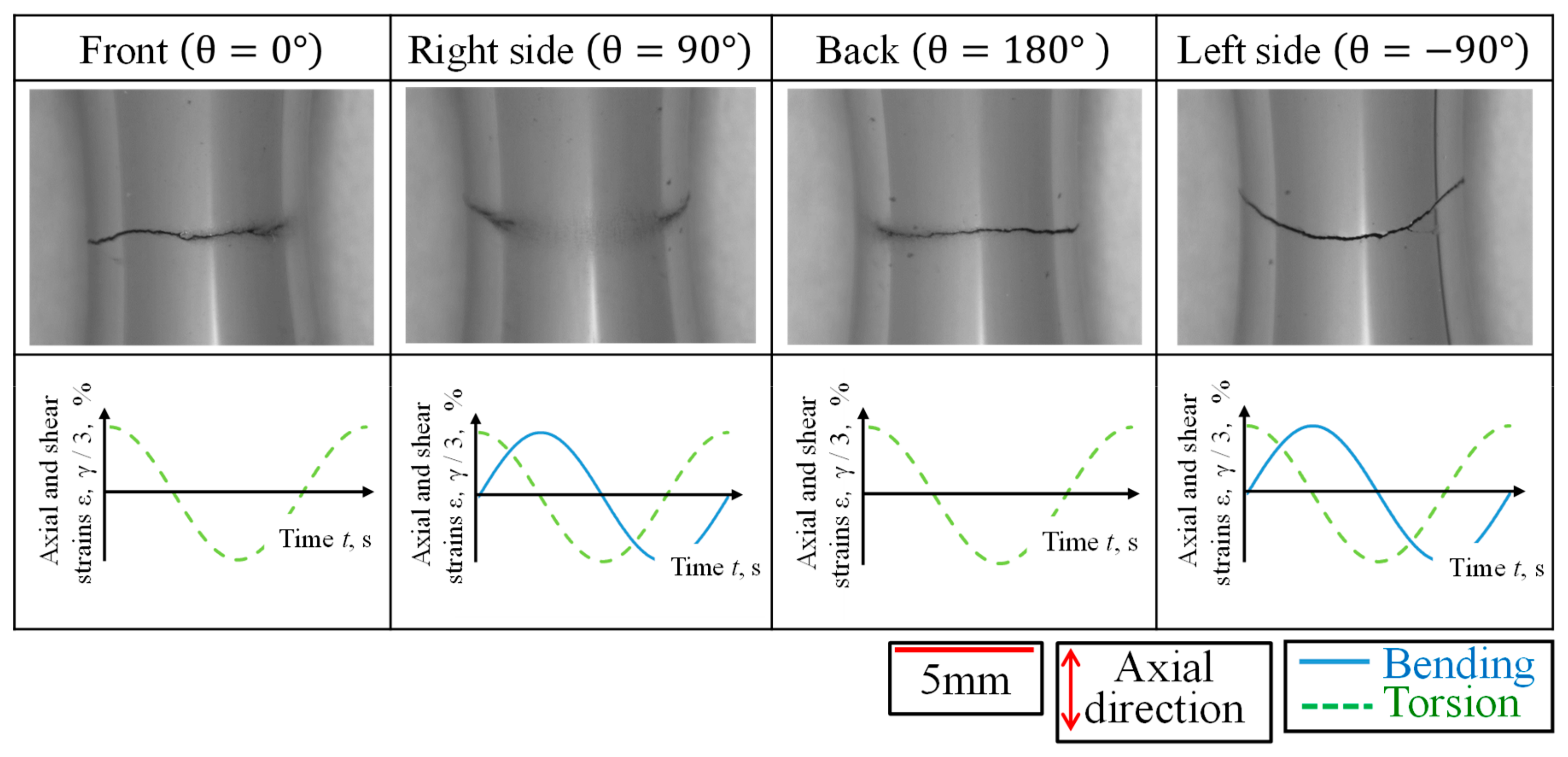

- Surface fractures were observed. Crack initiation at the site of the combination of bending and torsion occurred, and then it propagated to the sites in which torsion dominated. This coincided with the typical fracture pattern under non-proportional multiaxial loading. The validity and effectiveness of multiaxial fatigue tests were confirmed.

Author Contributions

Funding

Conflicts of Interest

References

- McDowell, F.L. On the path dependence of transient hardening and softening to stable states under complex biaxial cyclic loading. In Proceedings of the International Conference on Constitutive Laws for Engineering Materials, Tucson, AZ, USA, 10–14 January 1983; pp. 125–135. [Google Scholar]

- Socie, D.F. Multiaxial fatigue damage models. J. Eng. Mater. Technol. 1987, 109, 293–298. [Google Scholar] [CrossRef]

- Doong, S.H.; Socie, D.F.; Robertson, I.M. Dislocation substructures and nonproportional hardening. J. Eng. Mater. Technol. 1987, 112, 456–465. [Google Scholar] [CrossRef]

- Fatemi, A.; Socie, D.F. A critical plane approach to multiaxial fatigue damage including out-of-phase loading. Fatigue Eng. Mater. Struct. 1988, 11, 149–165. [Google Scholar] [CrossRef]

- Itoh, T.; Sakane, M.; Ohnami, M.; Socie, D.F. Non-proportional low cycle fatigue criterion for type 304 stainless steel. Trans. Am. Soc. Mech. Eng. J. Eng. Mater. Technol. 1995, 117, 285–292. [Google Scholar] [CrossRef]

- Itoh, T.; Nakata, D.F.; Socie, M.; Ohnami, M. Non-proportional low cycle fatigue of 6061 aluminum alloy under 14 strain path. Eur. Struct. Integrity Soc. 1999, 25, 41–54. [Google Scholar]

- Itoh, T.; Yang, T. Material dependence of multiaxial low cycle fatigue lives under non-proportional loading. Int. J. Fatigue 2011, 33, 1025–1031. [Google Scholar] [CrossRef]

- Morishita, T.; Takaoka, T.; Itoh, T. Fatigue strength of SS400 steel under non-proportional loading. Fract. Struct. Integrity 2016, 10, 289–295. [Google Scholar] [CrossRef]

- Nelson, D.V.; Rostami, A. Biaxial Fatigue of A533B Pressure Vessel Steel. J. Pres. Ves. Technol. 1997, 119, 325–331. [Google Scholar] [CrossRef]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering, 2nd ed.; Wiley Interscience: Hoboken, NJ, USA, 2000; pp. 1–18. [Google Scholar]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2008; pp. 1–36. [Google Scholar]

- Bathias, C.; Pineau, A. Fatigue of Materials and Structures: Fundamental; Wiley Interscience: Hoboken, NJ, USA, 2013; pp. 1–19. [Google Scholar]

- Frost, N.E.; Marsh, K.J.; Pook, L.P. Metal Fatigue; Dover Publications: Mineola, NY, USA, 2011; pp. 1–5. [Google Scholar]

- Dowling, N.E. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1998; pp. 19–39. [Google Scholar]

- Koe, S.; Nakamura, H.; Tsunenari, T.; Okada, T. Relation between bending and direct stress fatigue strengths of steels. J. Jpn. Soc. Mater. Sci. 1982, 356, 522–526. [Google Scholar]

| Name of Sensor | Role of Sensor |

|---|---|

| Mechanical switch | Detection of overload |

| Inductive displacement sensor | Measurement of vibration |

| Strain gauge | Measurement of strains on the surface of the specimen |

| Fatigue Life | Cycles | Fatigue Damage Based on LCD |

|---|---|---|

| 362,787 (with no overload) | 107,687 | 0.2968 |

| 196,271 (overload) | 100 | 0.00051 |

| Material | Chemical Composition (wt, %) | ||||

|---|---|---|---|---|---|

| Mn | Si | C | P | S | |

| SM490A | 1.45 | 0.29 | 0.15 | 0.02 | 0.0039 |

| Material | Chemical Composition (wt, %) | |||||

|---|---|---|---|---|---|---|

| Mn | Si | C | P | S | Cr | |

| SUS304 | 2.00 | 1.00 | 0.08 | 0.045 | 0.03 | 18.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogawa, F.; Shimizu, Y.; Bressan, S.; Morishita, T.; Itoh, T. Bending and Torsion Fatigue-Testing Machine Developed for Multiaxial Non-Proportional Loading. Metals 2019, 9, 1115. https://doi.org/10.3390/met9101115

Ogawa F, Shimizu Y, Bressan S, Morishita T, Itoh T. Bending and Torsion Fatigue-Testing Machine Developed for Multiaxial Non-Proportional Loading. Metals. 2019; 9(10):1115. https://doi.org/10.3390/met9101115

Chicago/Turabian StyleOgawa, Fumio, Yusuke Shimizu, Stefano Bressan, Takahiro Morishita, and Takamoto Itoh. 2019. "Bending and Torsion Fatigue-Testing Machine Developed for Multiaxial Non-Proportional Loading" Metals 9, no. 10: 1115. https://doi.org/10.3390/met9101115

APA StyleOgawa, F., Shimizu, Y., Bressan, S., Morishita, T., & Itoh, T. (2019). Bending and Torsion Fatigue-Testing Machine Developed for Multiaxial Non-Proportional Loading. Metals, 9(10), 1115. https://doi.org/10.3390/met9101115