Effect of the Number of CFRP Prepregs and Roughness at the Bonding Area on the Spring-Back and Flexural Strength of Hybrid Composites of CFRP Combined with CR980

Abstract

1. Introduction

2. Experiment Methods

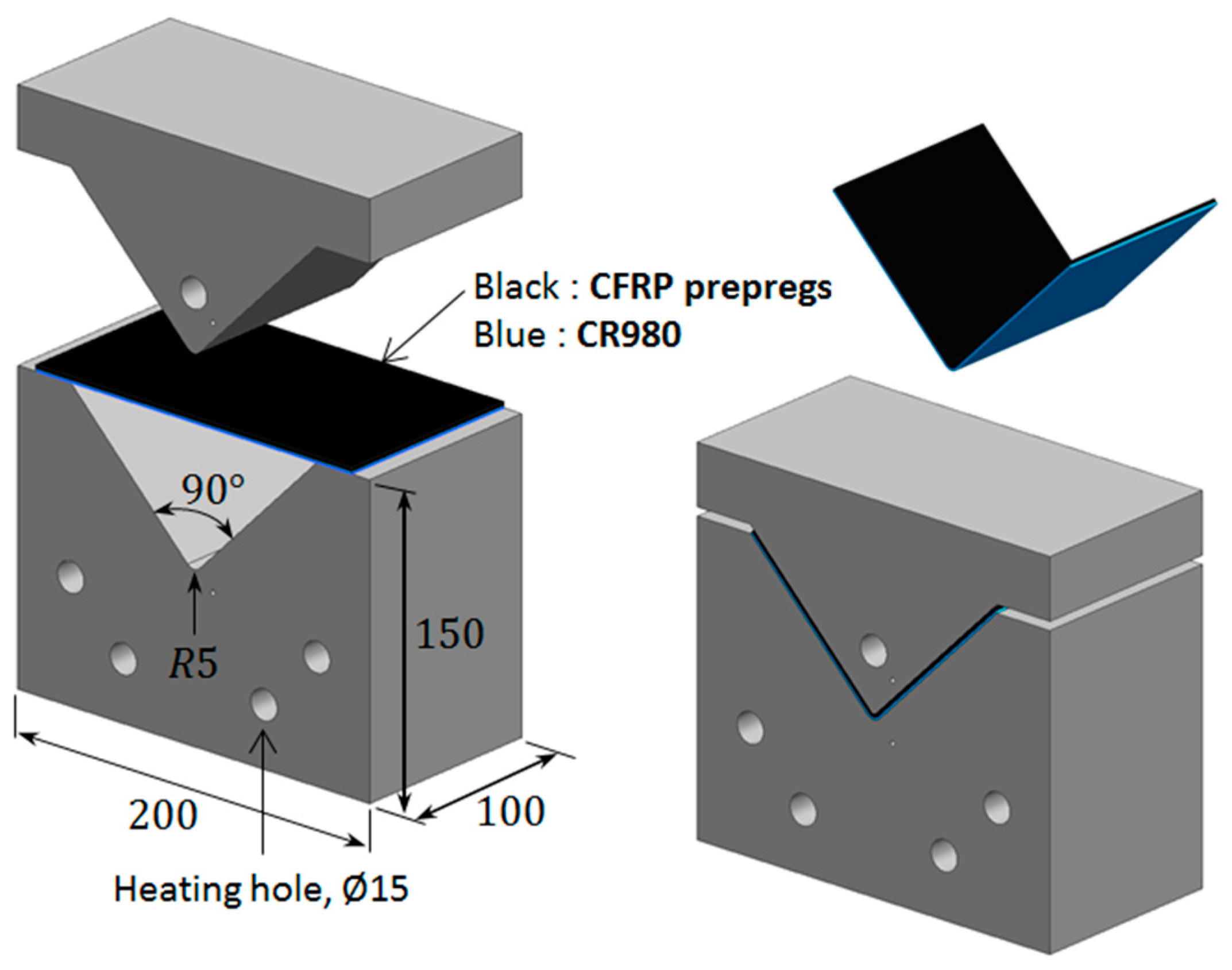

2.1. V-Bending Test of Hybrid Composites

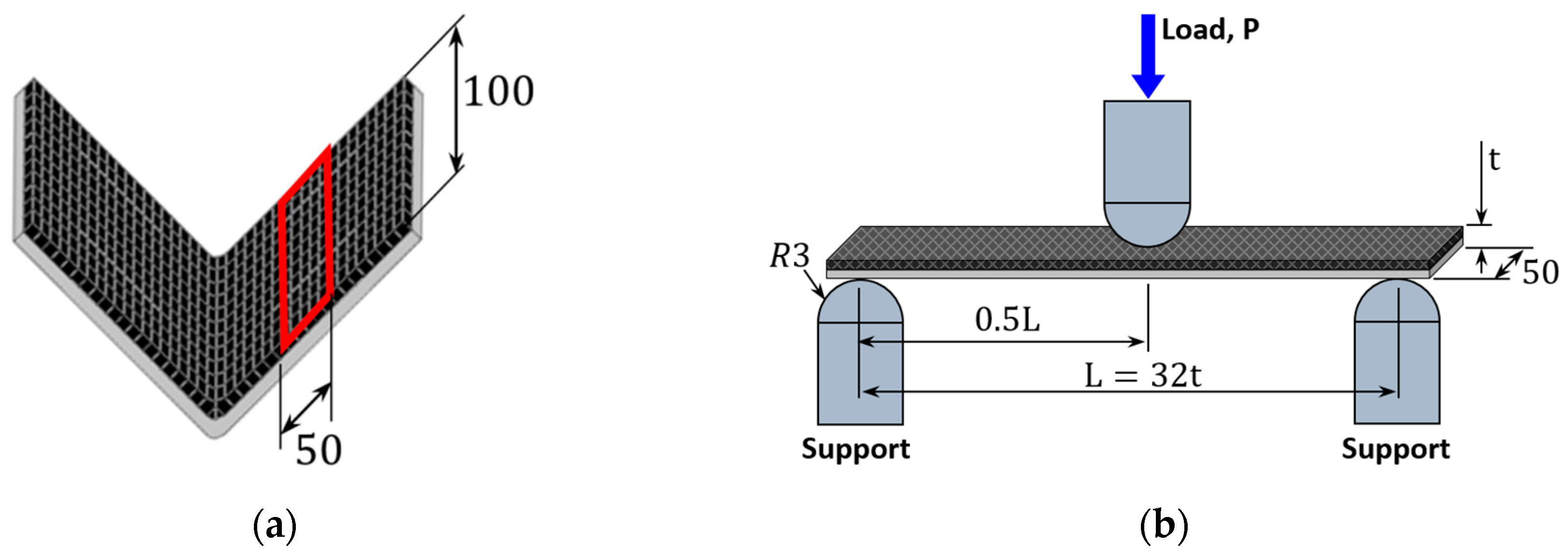

2.2. Three-Point Bending Test of Hybrid Composites

3. Experimental Results

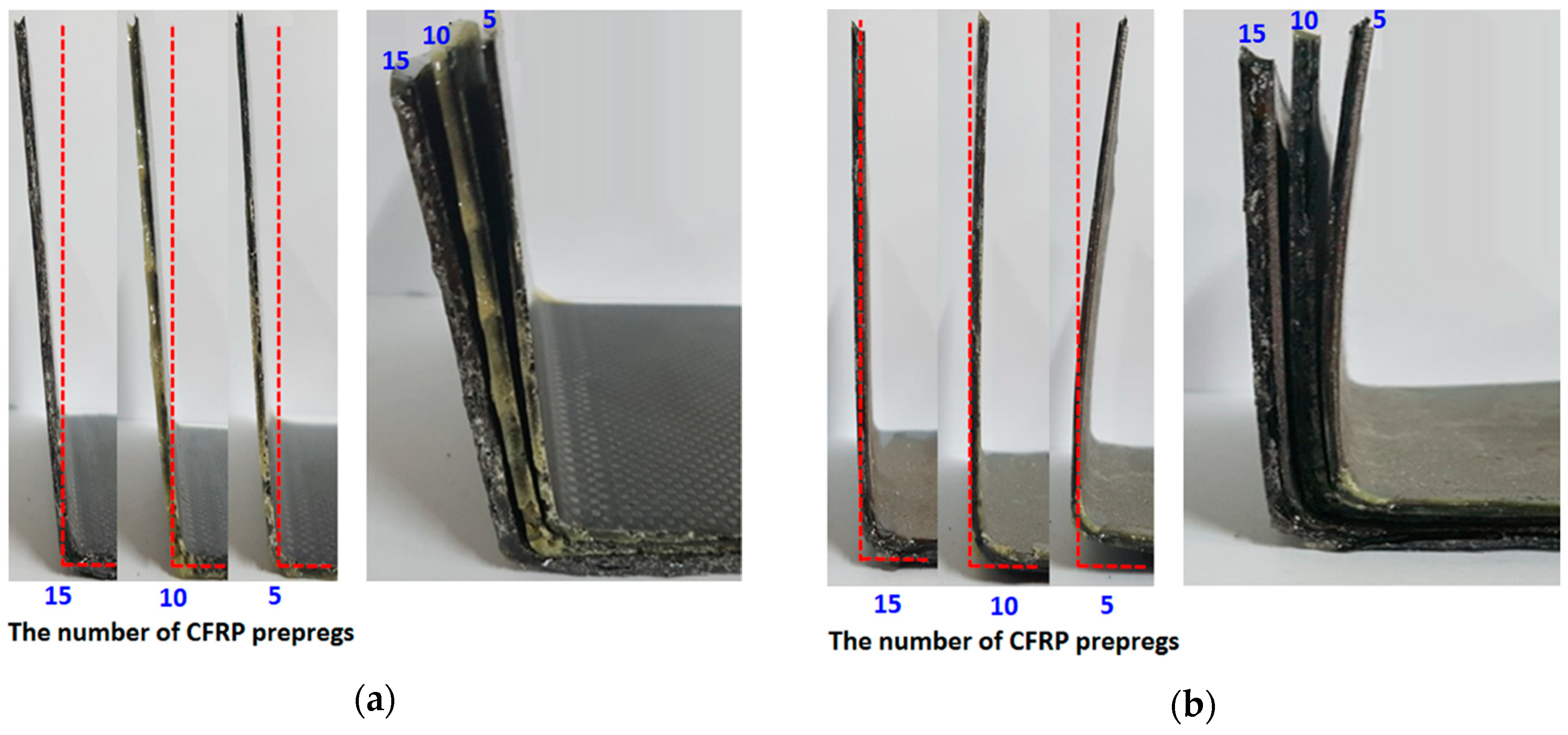

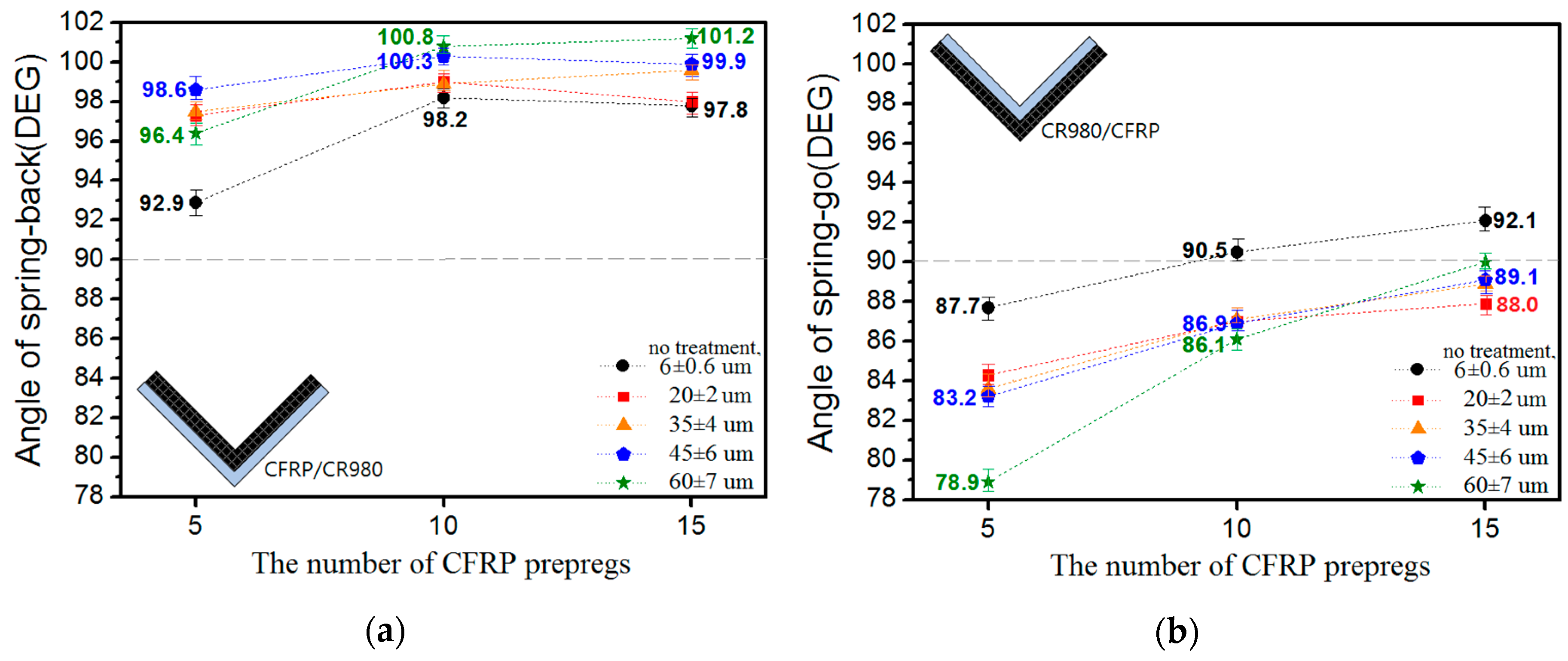

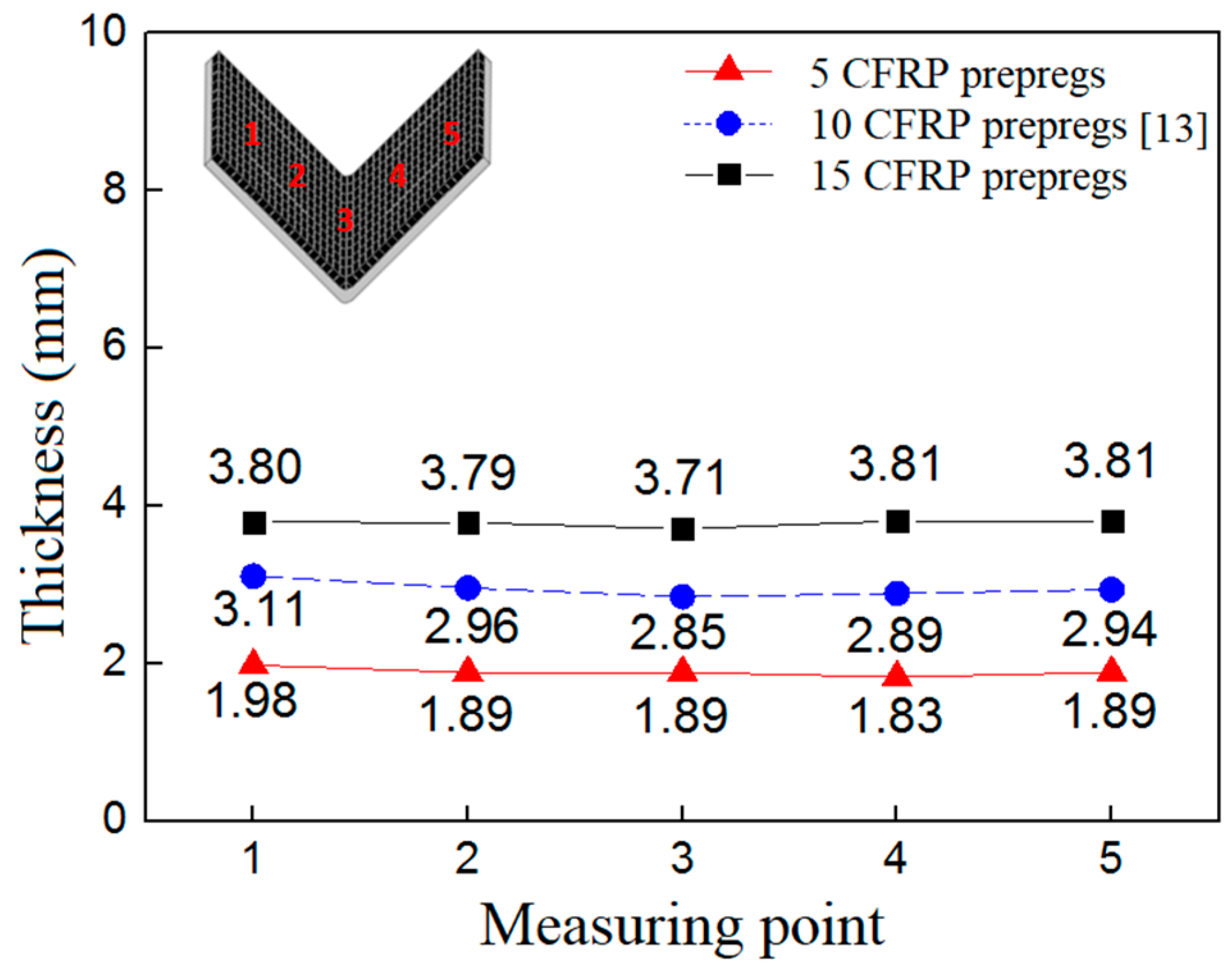

3.1. Angle of Spring-Back or Spring-Go from the V-Bending Test of Hybrid Composites

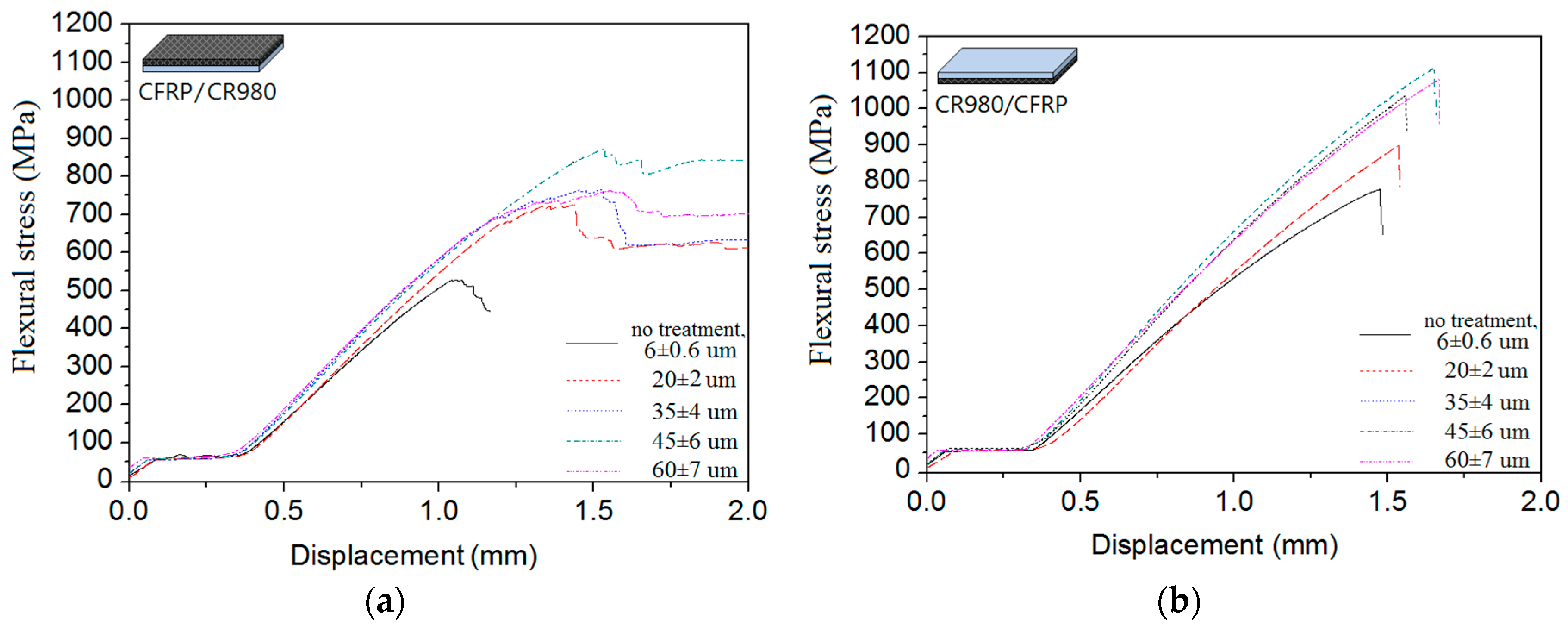

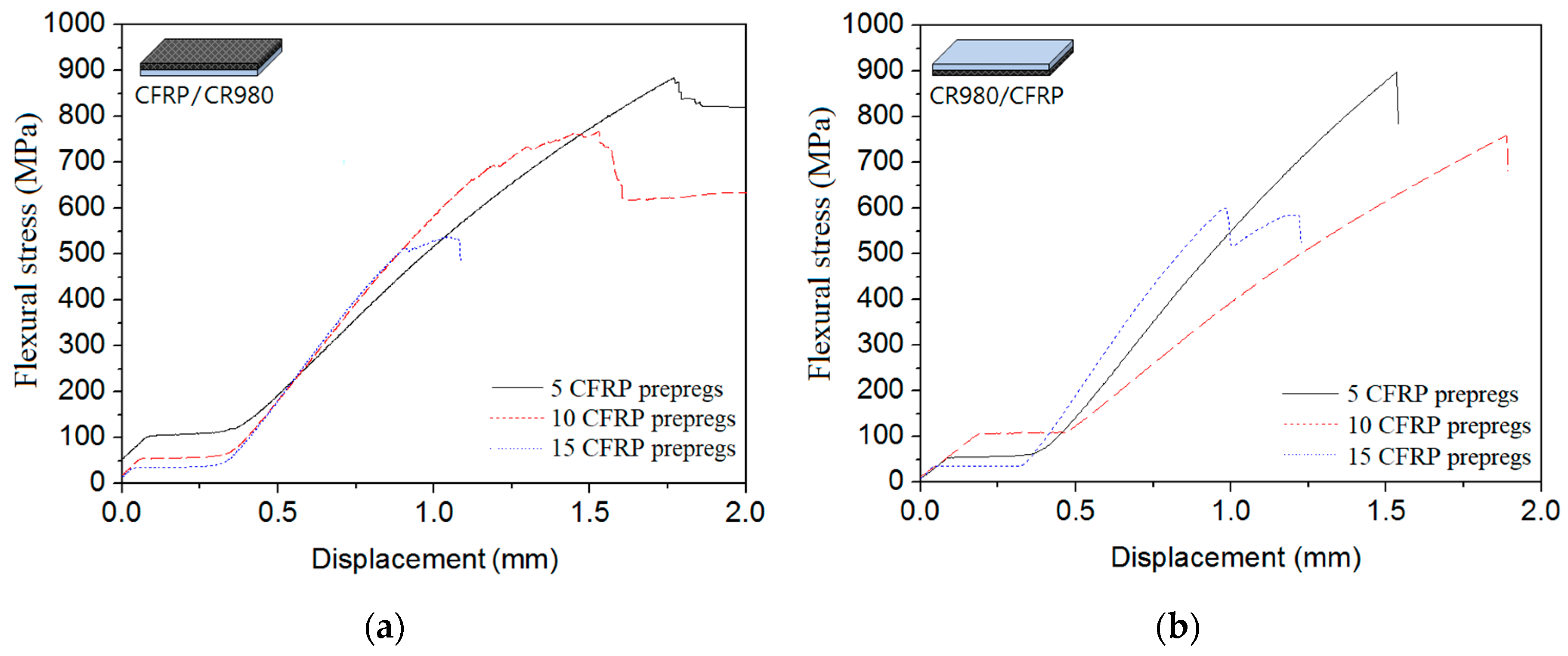

3.2. Flexural Strength from the Three-point Bending Test of Hybrid Composites

4. Conclusions

- (1)

- Spring-back was observed for CFRP/CR980 hybrid composites, and spring-go was observed for CR980/CFRP hybrid composites.

- (2)

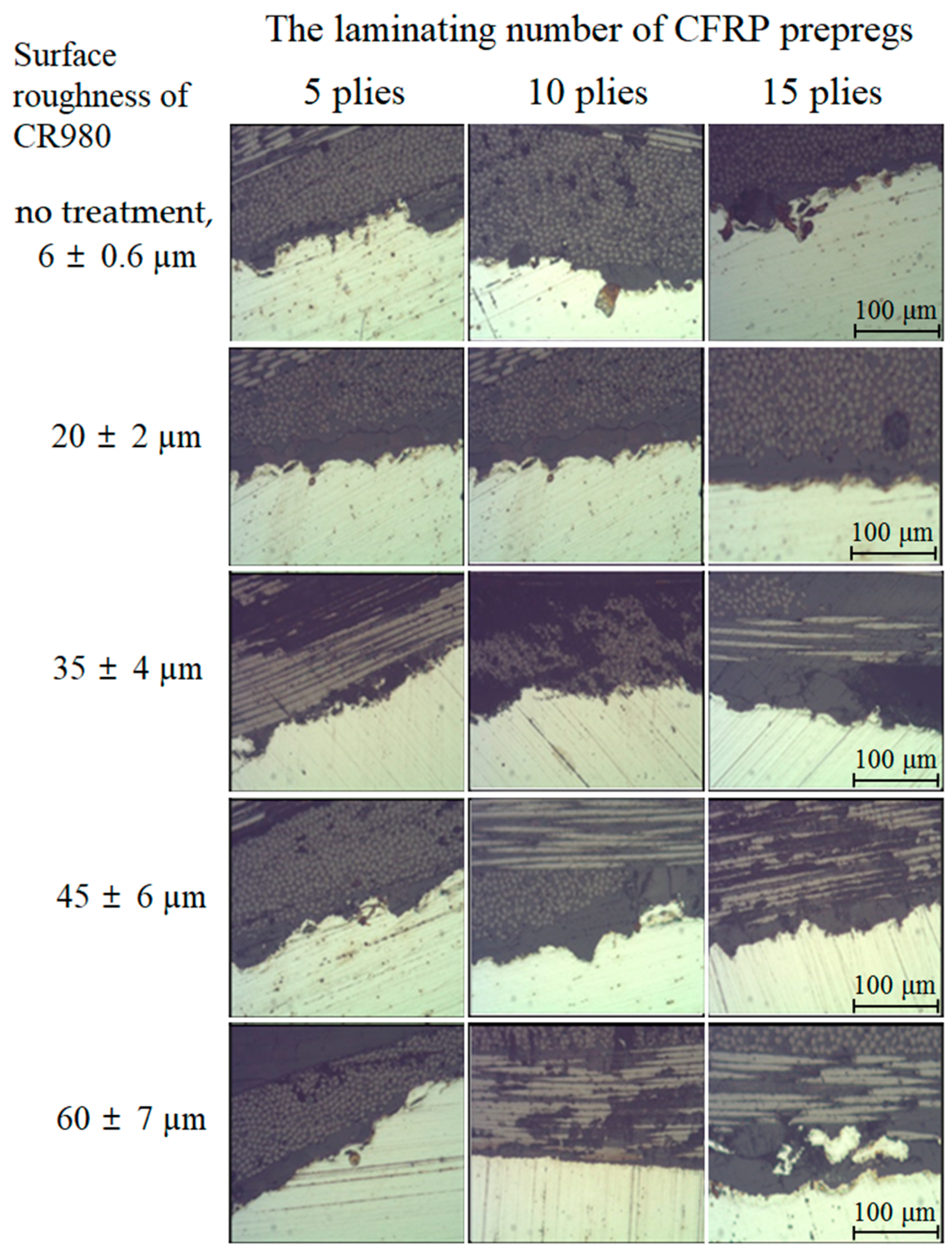

- There were no pores at the interfacial bonding area of V-curved surface through V-bending test.

- (3)

- As the roughness value at the bonding area of the CFRP/CR980 increased, the flexural stress became slightly increased.

- (4)

- CFRP/CR980 hybrid composites were more prone to deformation when CFRP received a compressive stress rather than a tensile stress.

- (5)

- The flexural strength and deformation values decreased for both the CFRP/CR980 hybrid composites and CR980/CFRP hybrid composites as the laminating number of the CFRP prepregs increased.

Author Contributions

Funding

Conflicts of Interest

References

- Lightweighting-Wikipedia. Available online: https://en.wikipedia.org/wiki/Lightweighting (accessed on 1 June 2019).

- Lightweight-Materials-Cars-and-Trucks/Department of Energy. Available online: https://www.energy.gov/eere/vehicles/lightweight-materials-cars-and-trucks (accessed on 1 June 2019).

- Al-Zubaidy, H.; Zhao, X.L.; Al-Mihaidi, R. Mechanical Behaviour of Normal Modulus Carbon Fibre Reinforced Polymer (CFRP) and Epoxy under Impact Tensile Loads. ICM 2011, 10, 2453–2458. [Google Scholar] [CrossRef]

- Van-Paepegem, W.; De-Geyter, K.; Vanhooymissen, P.; Degrieck, J. Effect of friction on the hysteresis loops from three-point bending fatigue tests of fibre-reinforced composites. Compos. Struct. 2006, 72, 212–217. [Google Scholar] [CrossRef]

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of Lightweight Components by Metal Forming. CIRP Ann. 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Fuwa, M.; Bunsell, A.R.; Harris, B. Tensile failure mechanisms in carbon fibre reinforced plastics. J. Mater. Sci. 1975, 10, 2062–2070. [Google Scholar] [CrossRef]

- Paiva, J.M.F.; Mayer, S.; Rezende, M.C. Comparison of Tensile Strength of Different Carbon Fabric Reinforced Epoxy Composites. Mater. Res. IBERO Am. J. 2006, 9, 83–89. [Google Scholar] [CrossRef]

- Yu, T.; Fernando, D.; Teng, J.G.; Zhao, X.L. Experimental study on CFRP-to-steel bonded interfaces. Compos. Part B-Eng. 2012, 43, 2279–2289. [Google Scholar] [CrossRef]

- High Performance Carbon Fibers-National Historic Chemical Landmark. Available online: https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/carbonfibers.html (accessed on 1 June 2019).

- Fan, L.-T.; Gharpuray, M.M.; Lee, Y.H. Nature of Cellulosic Material. Cellul. Hydrolys. 1987, 3, 5–20. [Google Scholar]

- Via, B.K.; So, C.L.; Shupe, T.F.; Groom, L.H.; Wikaira, J. Mechanical response of longleaf pine to variation in microfibril angle, chemistry associated wavelengths, density, and radial position. Compos. Part A Appl. Sci. Manuf. 2009, 40, 60–66. [Google Scholar] [CrossRef]

- Wei, P.; Rao, X.; Yang, J.; Guo, Y.; Chen, H.; Zhang, Y.; Wang, Z. Hot pressing of wood-based composites: A review. For. Prod. J. 2016, 66, 419–427. [Google Scholar] [CrossRef]

- Hwang, J.H.; Jin, C.K.; Lee, M.S.; Choi, S.W.; Kang, C.G. Effect of Surface Roughness on the Bonding Strength and Spring-Back of CFRP/CR980 Hybrid Composite. Metals 2018, 8, 716. [Google Scholar] [CrossRef]

- Toray. Available online: https://www.toray.com/products/prod_001.html (accessed on 1 June 2019).

- Hyundai Steel. Available online: https://www.hyundai-steel.com/kr/products-technology/products/hotrolledsteel.hds (accessed on 1 June 2019).

- Korea Carbon. Available online: https://www.hcarbon.com/product/overview.asp (accessed on 1 June 2019).

- Lee, M.S.; Kim, S.J.; Lim, O.D.; Kang, C.G. A study on mechanical properties of Al5052/CFRP/Al5052 composite through three-point bending tests and shear lap tests according to surface roughness. J. Compos. Mater. 2016, 10, 1–11. [Google Scholar] [CrossRef]

- Choi, S.W.; Lee, M.S.; Kang, C.G. Effect of process parameters and laminating methods on spring-back in V-bending of CFRP/CR340 hybrid composites. Int. J. Precis. Eng. Manuf. 2016, 17, 395–400. [Google Scholar] [CrossRef]

- Standard Guide for Testing Polymer Matrix Composite Materials; ASTM D4762-16; ASTM International: West Conshohocken, PA, USA, 2011.

- Methods of Making Samples of Carbon Fiber Reinforced Plastics; KS M 3713:2012; Korean Agency for Technology and Standards (KATS): Maeng dong-myeon, Korea, 2012.

- Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials; D 7264/D 7264M–07; ASTM International: West Conshohocken, PA, USA, 2011.

| Type | Weight of Carbon Fiber | Weight of Resin | Resin Content | Total Weight | Fabric Thickness |

|---|---|---|---|---|---|

| Plain | 205 g/m2 | 150 g/m2 | 42% ± 2% | 352 g/m2 | 0.27 ± 0.05 mm |

| Specimen No. | The Number of CFRP Prepregs | Surface Roughness of CR980 | Lamination Sequence | Specimen No. | The Number of CFRP Prepregs | Surface Roughness of CR980 | Lamination Sequence |

|---|---|---|---|---|---|---|---|

| 1 | 5 plies | 6 ± 0.6 µm | CFRP/CR980 | 16 | 5 plies | 6 ± 0.6 µm | CR980/CFRP |

| 2 | 20 ± 2 µm | 17 | 20 ± 2 µm | ||||

| 3 | 35 ± 4 µm | 18 | 35 ± 4 µm | ||||

| 4 | 45 ± 6 µm | 19 | 45 ± 6 µm | ||||

| 5 | 60 ± 7 µm | 20 | 60 ± 7 µm | ||||

| 6 | 10 plies | 6 ± 0.6 µm | 21 | 10 plies | 6 ± 0.6 µm | ||

| 7 | 20 ± 2 µm | 22 | 20 ± 2 µm | ||||

| 8 | 35 ± 4 µm | 23 | 35 ± 4 µm | ||||

| 9 | 45 ± 6 µm | 24 | 45 ± 6 µm | ||||

| 10 | 60 ± 7 µm | 25 | 60 ± 7 µm | ||||

| 11 | 15 plies | 6 ± 0.6 µm | 26 | 15 plies | 6 ± 0.6 µm | ||

| 12 | 20 ± 2 µm | 27 | 20 ± 2 µm | ||||

| 13 | 35 ± 4 µm | 28 | 35 ± 4 µm | ||||

| 14 | 45 ± 6 µm | 29 | 45 ± 6 µm | ||||

| 15 | 60 ± 7 µm | 30 | 60 ± 7 µm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, J.H.; Jin, C.K.; Seo, H.Y.; Kang, C.G. Effect of the Number of CFRP Prepregs and Roughness at the Bonding Area on the Spring-Back and Flexural Strength of Hybrid Composites of CFRP Combined with CR980. Metals 2019, 9, 1054. https://doi.org/10.3390/met9101054

Hwang JH, Jin CK, Seo HY, Kang CG. Effect of the Number of CFRP Prepregs and Roughness at the Bonding Area on the Spring-Back and Flexural Strength of Hybrid Composites of CFRP Combined with CR980. Metals. 2019; 9(10):1054. https://doi.org/10.3390/met9101054

Chicago/Turabian StyleHwang, Ji Hoon, Chul Kyu Jin, Hyung Yoon Seo, and Chung Gil Kang. 2019. "Effect of the Number of CFRP Prepregs and Roughness at the Bonding Area on the Spring-Back and Flexural Strength of Hybrid Composites of CFRP Combined with CR980" Metals 9, no. 10: 1054. https://doi.org/10.3390/met9101054

APA StyleHwang, J. H., Jin, C. K., Seo, H. Y., & Kang, C. G. (2019). Effect of the Number of CFRP Prepregs and Roughness at the Bonding Area on the Spring-Back and Flexural Strength of Hybrid Composites of CFRP Combined with CR980. Metals, 9(10), 1054. https://doi.org/10.3390/met9101054