4.1. Softening Behavior

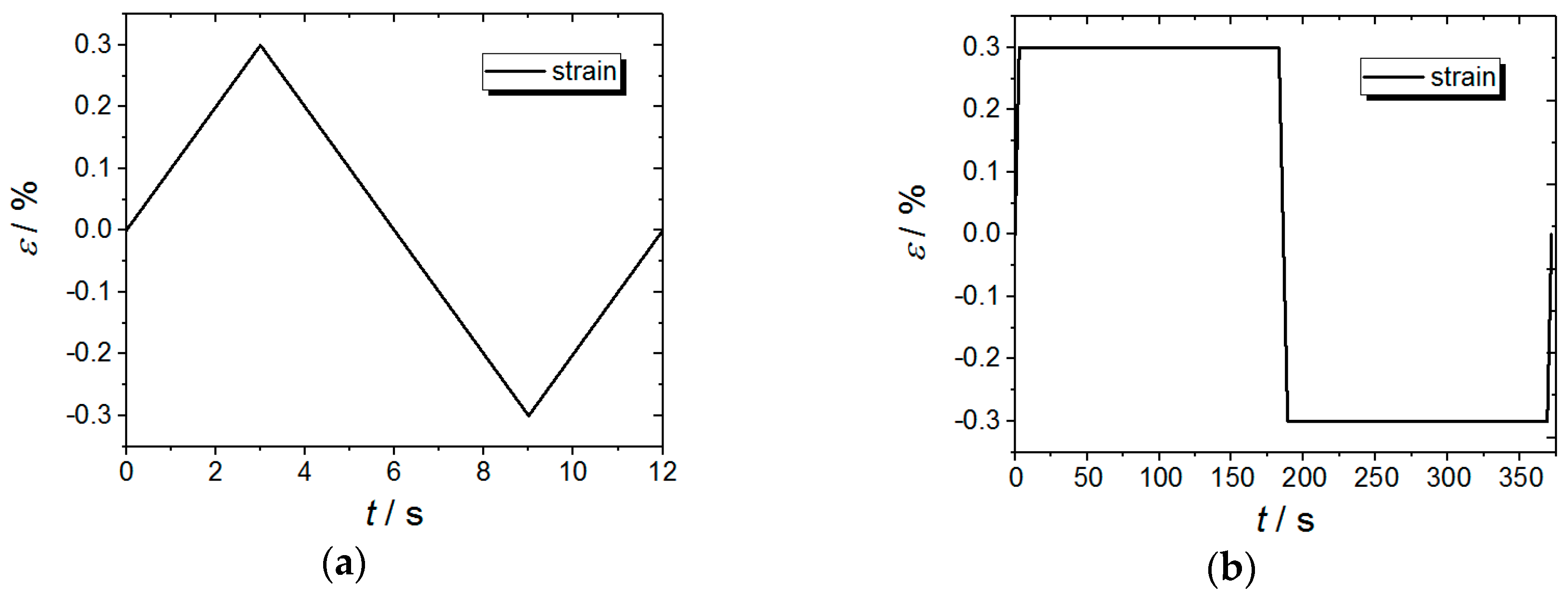

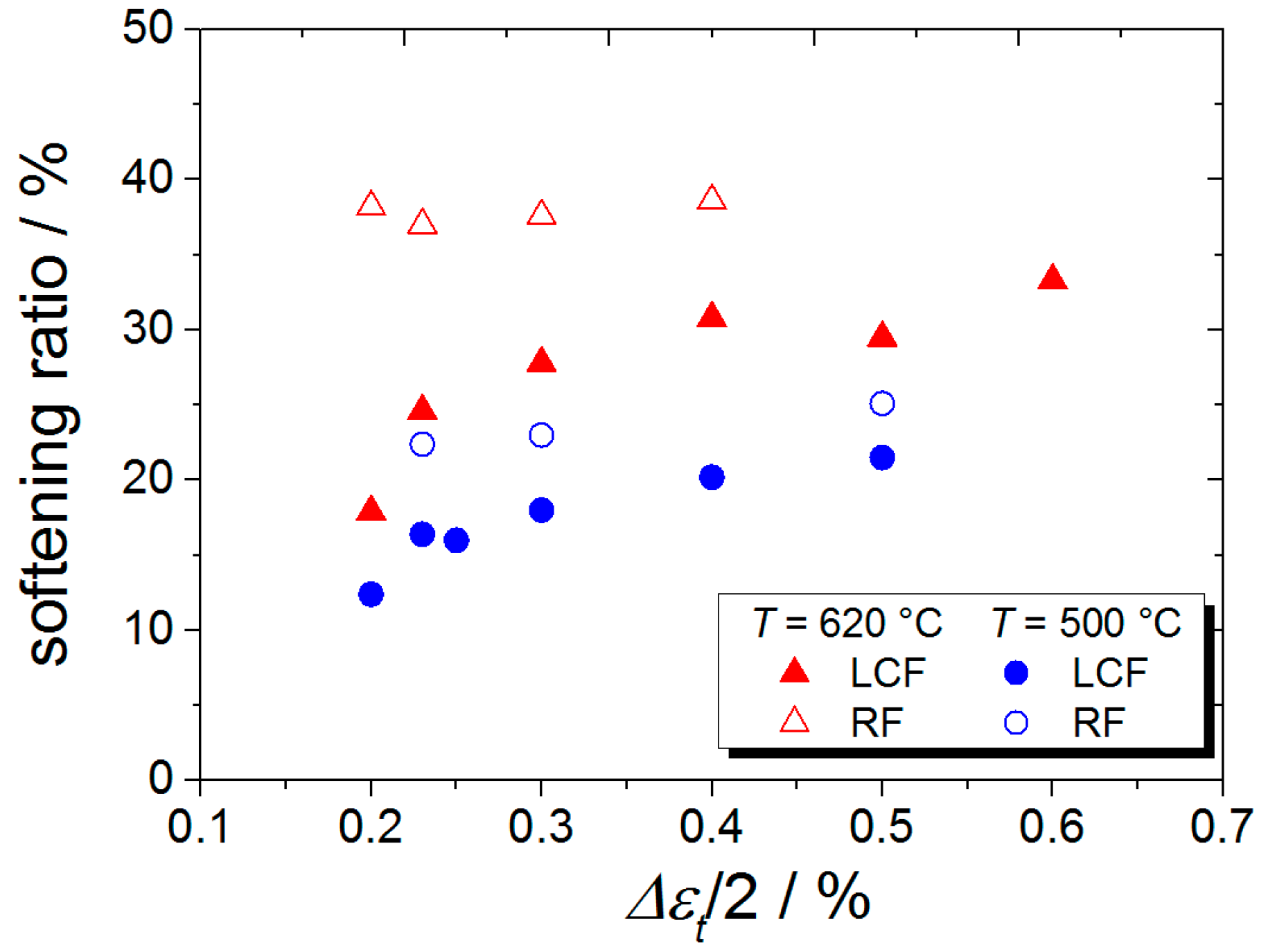

In

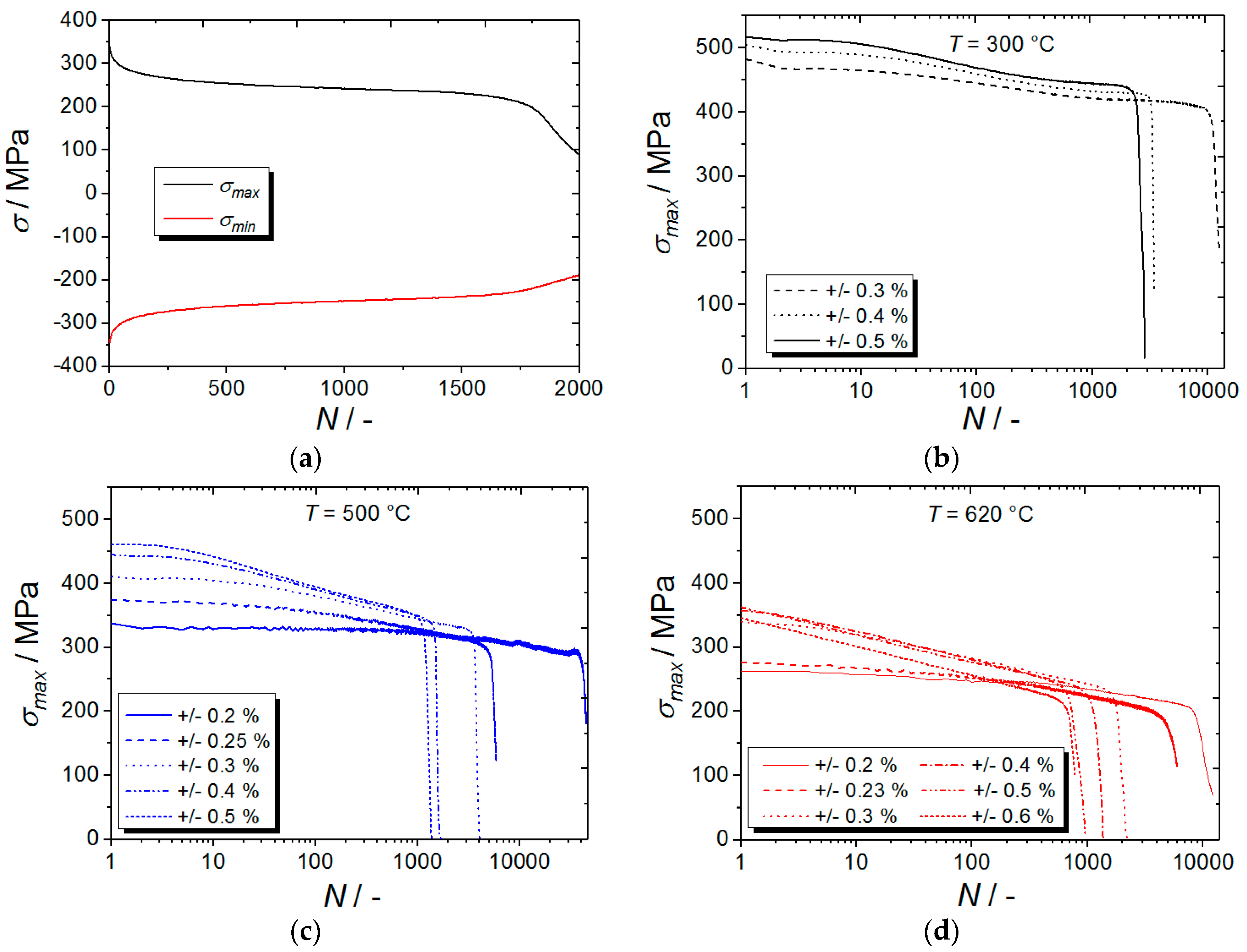

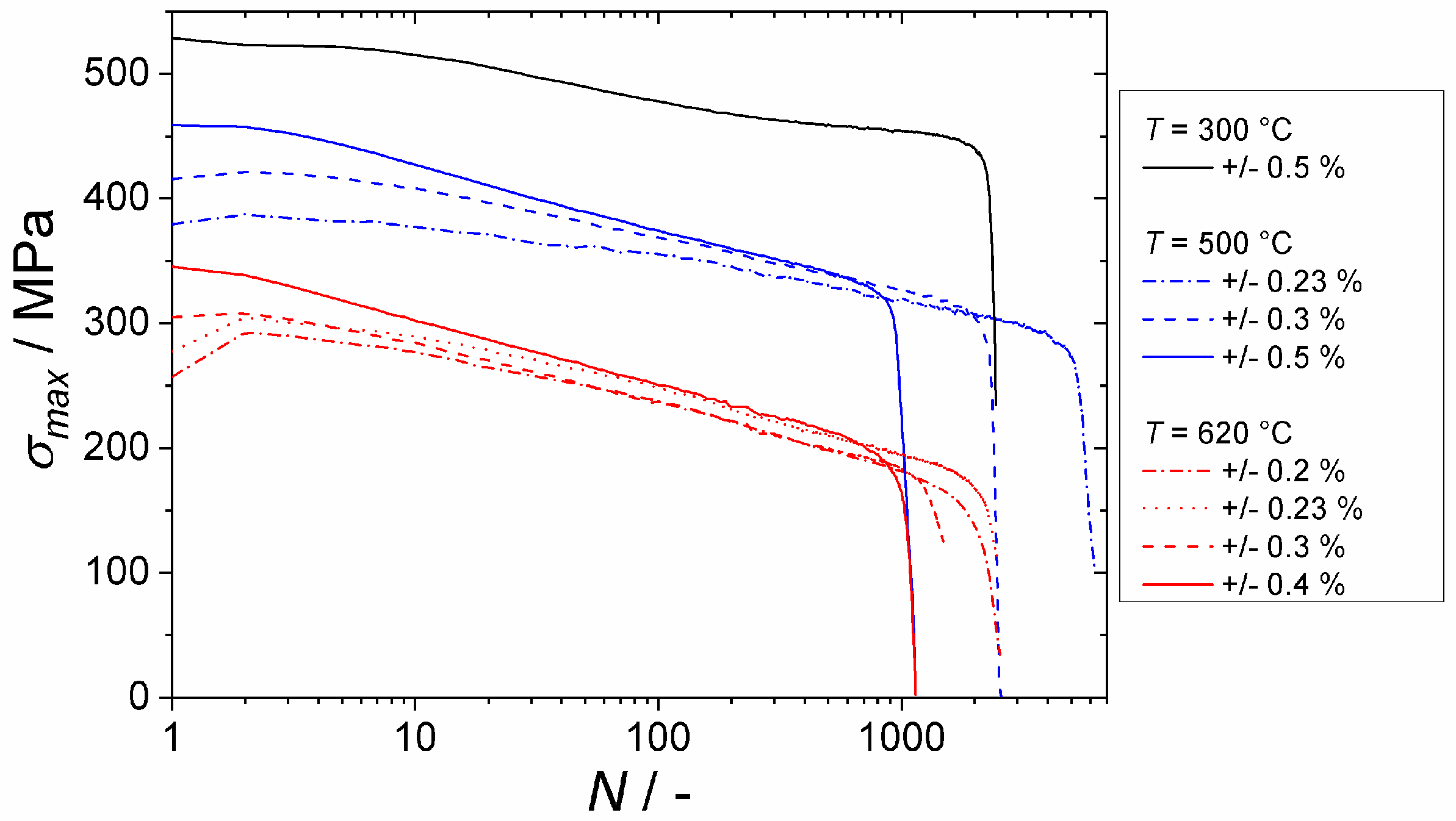

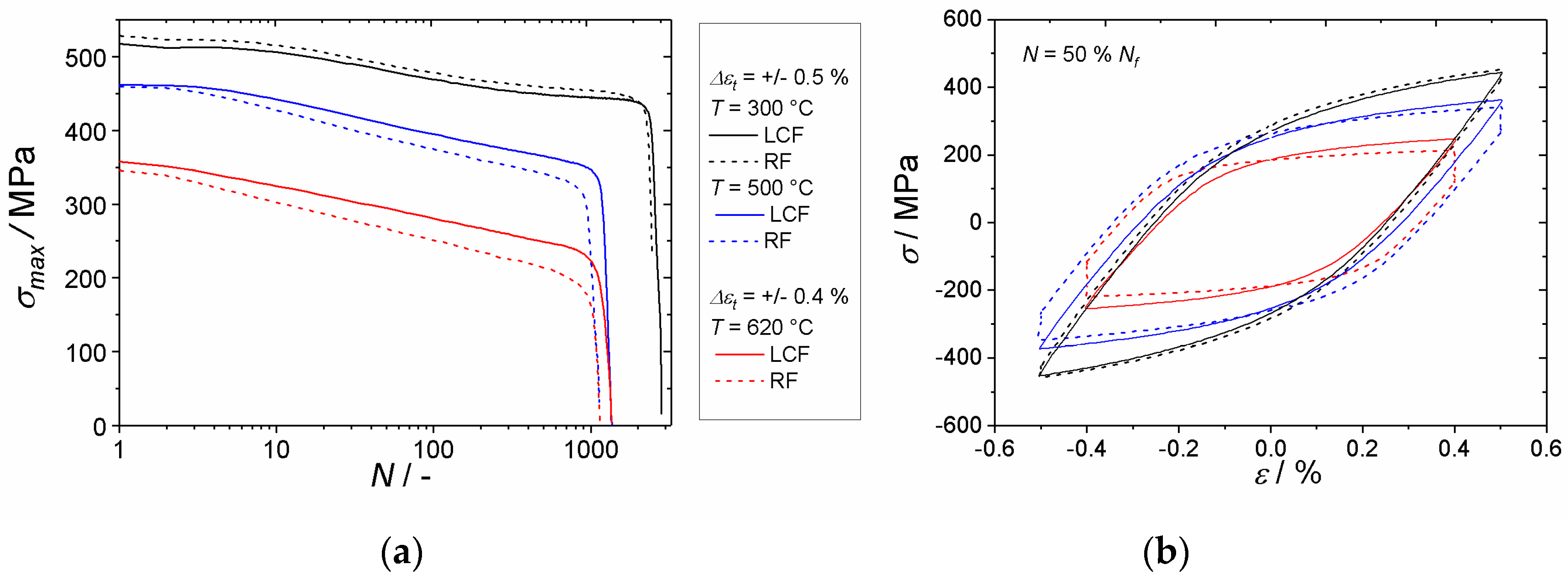

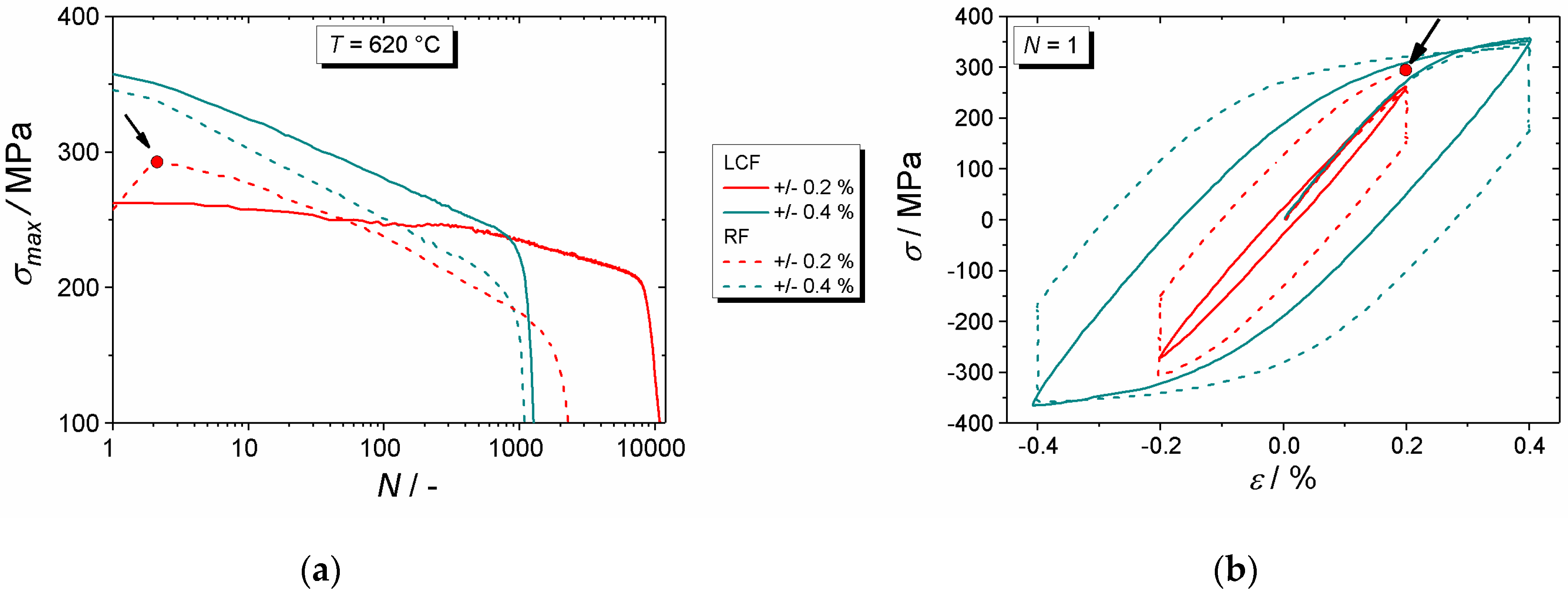

Figure 19, the softening ratio values (cf. Equation (8)) for all conducted LCF- and RF-tests at 500 °C and 620 °C have been plotted as a function of the applied strain amplitude. In the case of the LCF-tests (filled symbols), the softening ratio clearly increased with increasing strain amplitude, but with varying intensity. While a strong dependence was obvious at the lower applied strains, only a little further variation was obtained at the total strain amplitudes of 0.4% or higher, after reaching a softening ratio of about 20% (at 500 °C) and 30% (at 620 °C), respectively. As indicated by the cyclic stress response curves in

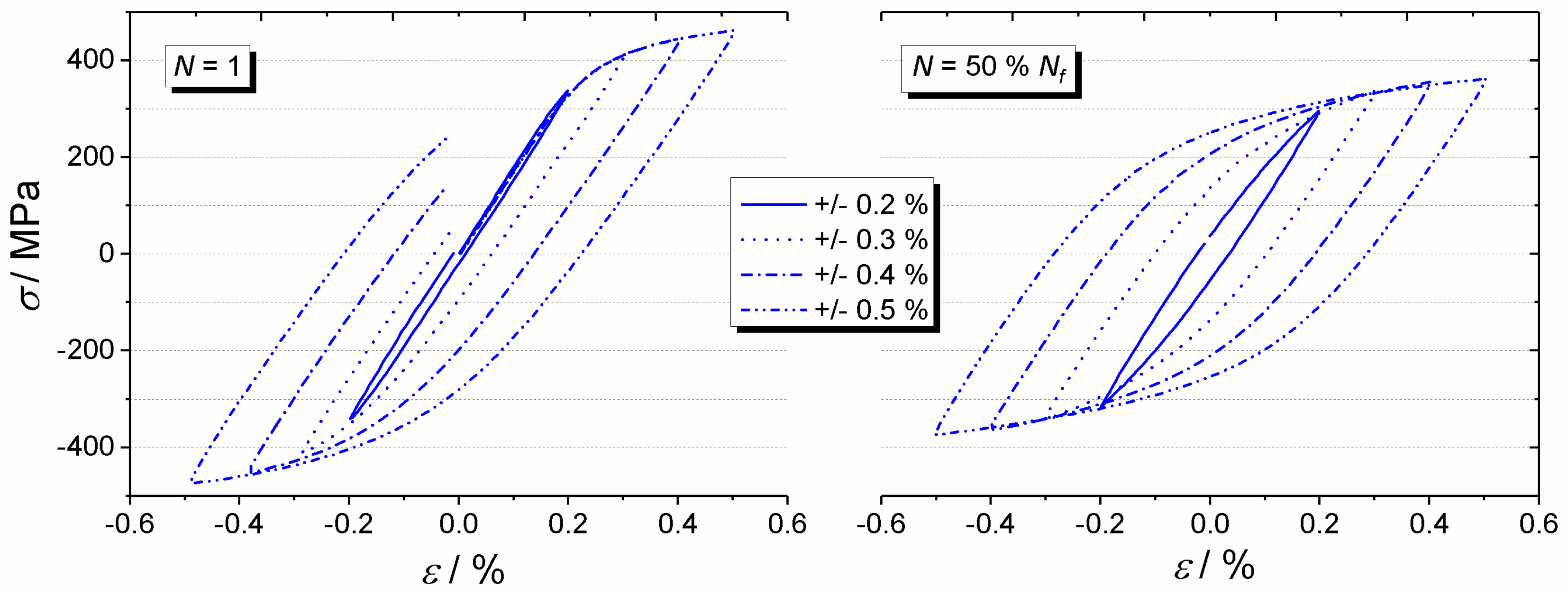

Figure 5c,d, the tests at this intermediate strain amplitude level were characterized by quite high initial stress levels. In fact, any further increase in strain amplitude led to little or no change of the observed initial maximum stress, suggesting a direct relation between this initial value and the subsequent stress evolution. This phenomenon of nearly similar maximum stresses at different (but rather high) strain amplitudes could be rationalized on the basis of the hysteresis loops plotted in

Figure 7. They show that higher amplitudes forced the specimens into plastic deformation, and that this plastic flow occurred at only moderately growing stresses.

When adding a hold time (RF-tests), the softening was more pronounced, as was reflected in the softening ratio-values which were up to 20 percentage points higher than that in the continuous (LCF) tests. The RF results in

Figure 19 (open symbols) suggest that, within the range of strain amplitudes employed here, the softening ratio was nearly independent of the total strain. Especially in case of the tests at 620 °C, no clear dependence could be inferred from the data, anymore. However, it should not be overlooked that the phenomenon of initial hardening (as outlined in

Section 3.3.2) contributed to the softening ratio values of these tests, since the overall maximum stress was taken for the calculation of the ratio in all cases (Equation (8)). The magnitude and varying impact of the hardening effect at different strain amplitudes is best demonstrated in

Figure 11. At

N = 1 the maximum stress was very different for the RF-tests performed at the same temperature. At 620 °C, for example, it was 258 MPa for a total strain range of ±0.2% and 345 MPa for ±0.4%. Due to the initial hardening during the first cycle of the test performed at 620 °C and a total strain range of ±0.2%, the maximum stress level of the test was raised to 295 MPa and approached the stress level of the other RF-tests performed at higher total strain ranges. From there on, a nearly similar softening trend was apparent for all tests. In other studies on ferritic–martensitic steels, e.g., [

15,

23], the softening ratio was often calculated on the basis of the maximum stress of the first cycle, neglecting the possibility that the global maximum stress was reached in a later cycle. If the maximum stress of the first cycle is taken for calculation, the softening ratio, in the present work, would result in values of 29.9% (for the RF-test at 620 °C and ±0.2%) and 31.1% (at 620 °C and ±0.23%). Returning to

Figure 19, these values would represent a softening to strain amplitude dependence that would be more similar to the curves of the LCF-tests. The real material behavior under a combined static and cyclic loading, which is obviously a result of a competing hardening phenomenon,

Figure 11, and pronounced softening,

Figure 13a, would however, not have been recognized.

This leads to the question of why the initial hardening took place at smaller strain amplitudes. The hardening already occurred within the first cycle—after the first (tensile) hold time, a higher stress value in the compression was reached,

Figure 13b. A hardening also occurs during the first stage of a creep test on ferritic–martensitic steels [

30]. In these tests, the specimen was subjected to a constant stress and through solid solution hardening (W, Mo) and precipitation hardening (M

23C

6, MX, Laves-phase) the microstructure was stabilized [

31,

32]. Moreover, during the primary creep, an increase of the dislocation density due to deformation takes place, which results in a hardening. Similar mechanisms might also cause the short initial hardening in the RF-tests. The hold time resembles a creep deformation (elastic strains are substituted by creep strains, see discussion below) and, therefore, similar microstructural changes could take place. After the first tensile hold time, the strain at

σ = 0 was 0.1% for the RF-test with ±0.2%, at 620 °C. To compensate for this extension, the material underwent a stronger deformation when switching into compression. Consequently, a higher stress value was reached. In the RF-test with ±0.4%, the specimen also exhibited a remaining deformation (0.28%) when unloading to

σ = 0. In addition to that, at higher strain amplitudes (>0.3%) hardly no dependence of the maximum stress on the applied strain existed anymore (see

Figure 12b and

Figure 13b). Therefore, in

Figure 13b, despite the following strong deformation during the compression, plastic deformation occurred only at moderate growing stress. Consequently, the LCF- and RF-tests with ±0.4% reached the same minimum stress level, in contrast to the LCF- and RF-tests with ±0.2%.

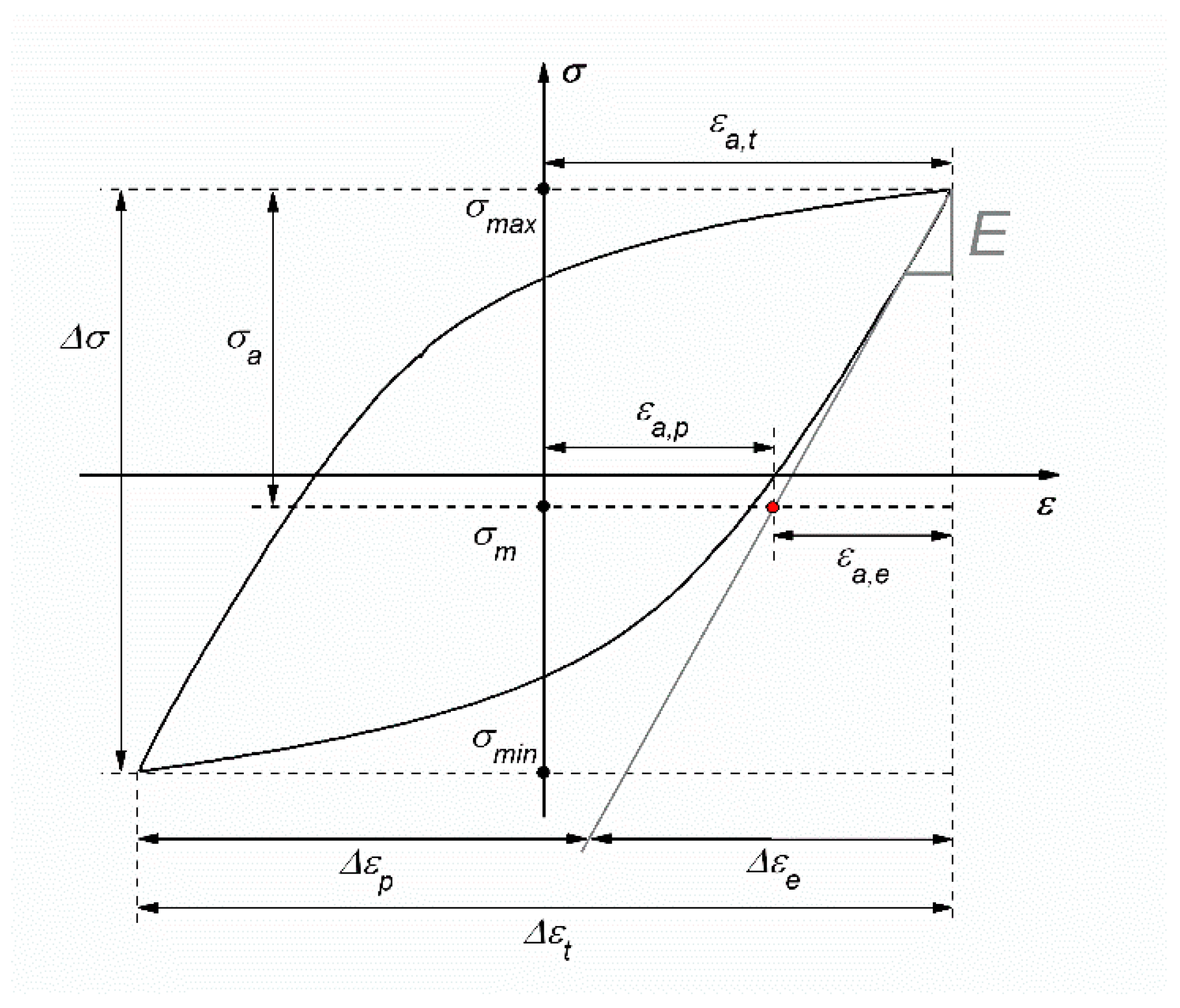

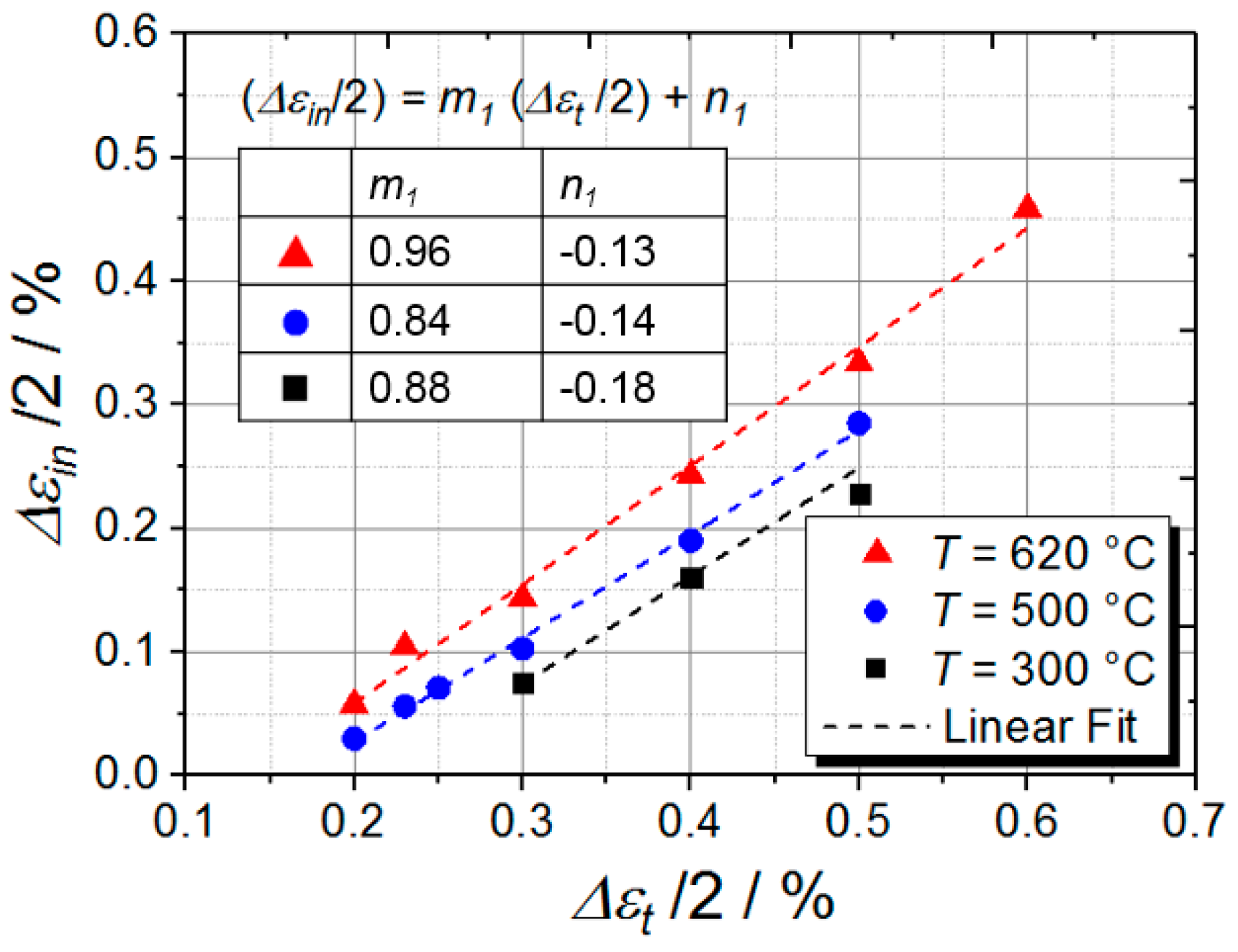

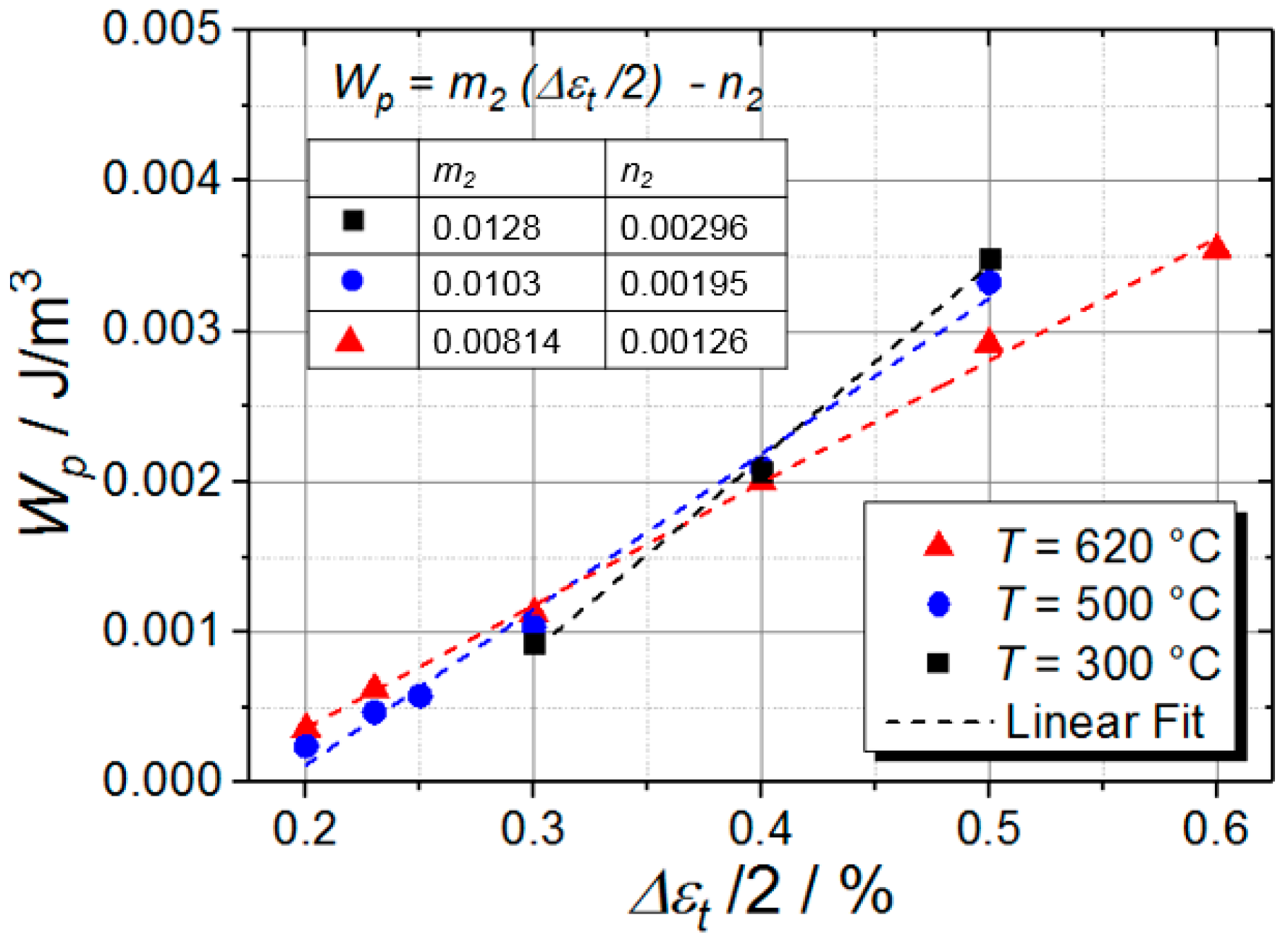

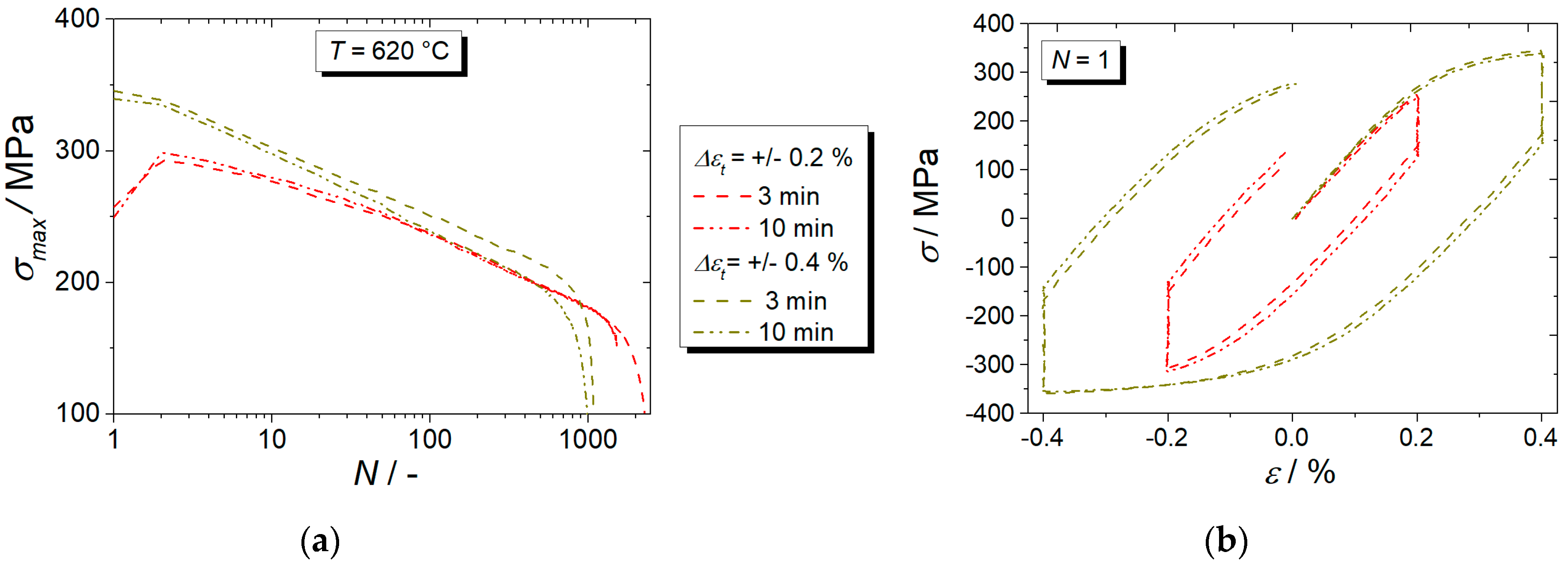

During the hold time of an RF-test, a stress relaxation occurs and elastic strains are substituted by creep strains. With the development of creep strains during the hold time, the inelastic strain, being the sum of plastic strain and creep strain (Equation (6)), also increases. This increase in inelastic strain has been illustrated in

Figure 20, where the inelastic strain amplitude for the first cycle (solid lines) and the cycle at 50% of lifetime (dashed lines) was plotted as a function of the total strain amplitude for all the LCF- and RF-tests, at 620 °C. Both in the LCF- (full symbols) and the RF-tests (open symbols) the inelastic strain amplitude increased between the first cycle and half-lifetime. The reason for this was the pronounced softening that occurred in both test types. When assuming constant elastic material properties in a first-order approximation, the continuously decreasing stresses resulted in similarly lower elastic strain contributions while the total strain limit was kept constant. The material, therefore, underwent more and more plastic deformation during a cyclic test. This also meant that the softening ratio and the increasing inelastic strain were closely linked, which could be shown by further evaluating the data in

Figure 20. For the LCF-tests, the increase of inelastic strain amplitude between the first cycle and the cycle at 50% lifetime was constant, with an absolute value of 0.07%, for a strain amplitude of 0.3% and higher, whereas, at the lower strain amplitudes of 0.23% and 0.2%, it was considerably smaller. The same applied for the values of the softening ratio (

Figure 19) as described in the previous paragraphs. For the RF-test, the increase of inelastic strain amplitude during the first half of lifetime was smaller than that of the LCF-test, although the inelastic strain level was generally higher. The increase was identical (0.03%-points) for all RF-tests, at different strain amplitudes, which was again in line with the constant softening ratios given in

Figure 19. No larger increase was obtained, since the initial inelastic strain amplitude for the first cycle of the RF-tests already included the increase of inelastic strain, which was created during the hold time. Between

N = 1 and

N = 50%

Nf, the composition of the inelastic strain changed for the RF-test. The creep strain which was accumulated during each hold period decreased (due to the generally lower stress level), while the plastic strain increased due to the softening process, as outlined before. Therefore, the inelastic strain did not increase as strongly as could be expected, due to the high softening ratio values of almost 40% (

Figure 19). In other words, the increase of plastic strain was compensated by the decrease of the creep strain.

The results regarding the lifetime, softening ratio, and maximum stresses of the LCF-tests were in a good agreement with the results obtained by Zhang et al. [

23] and Wang et al. [

15]. It should be mentioned that the tests results of the LCF-tests at 300 °C, in this work, were similar to those obtained at room temperature by Zhang et al., which showed in the values of the softening ratio and the constants of the Basquin Manson-Coffin relationship. Literature findings on the behavior of P92 under combined static and cyclic loading, and especially regarding the softening characteristics under these conditions, are rather scarce. Moreover, they appear to be partly in disagreement with the current findings. In fact, the cyclic softening results recently published by Gopinath et al. [

19] explicitly suggest similar softening behavior during the LCF- and RF-tests at 600 °C, while the present work showed that clear differences in the softening behavior could be identified, e.g., in

Figure 13a. However, the results of Gopinath et al. were obtained at only one rather high strain amplitude level (±0.6%). The results obtained at higher strain amplitudes, in this study, had also shown no dramatic influence of hold times on lifetime. Only when also considering small strain amplitudes, the influence on softening behavior can be studied in detail. Therefore, our results clearly demonstrate how important it is to consider small strains, and also because they are more realistic during the operation of a real power plant.

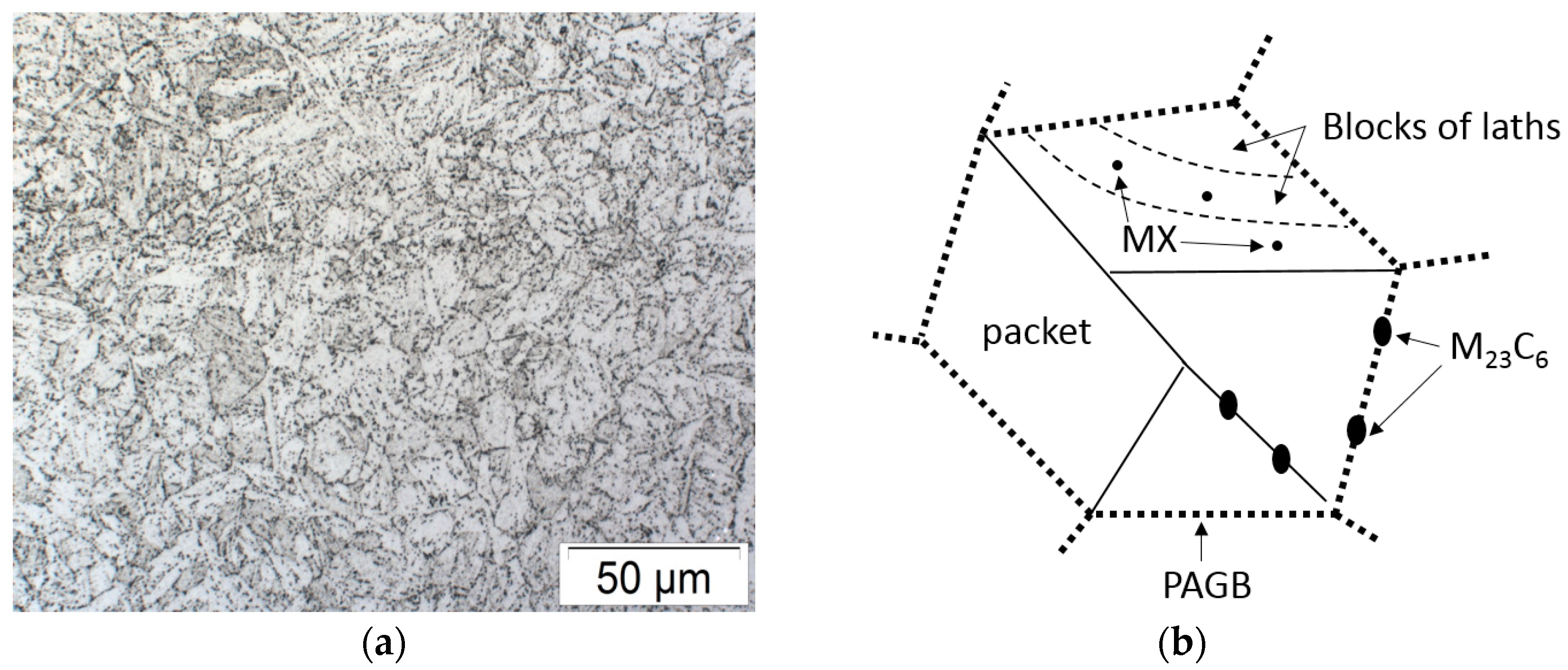

The cyclic softening of the ferritic–martensitic steels is attributed to the changes in the microstructure. After the initial heat treatment, a high dislocation density exists in the initial material condition. The rapid softening during the first loading cycles is, therefore, often attributed to a decrease of free dislocation density [

6,

17,

33]. Especially at high temperatures, a microstructural recovery due to thermally activated deformation mechanisms, such as dislocation climb, cross-slip, and thermal recovery, may be expected [

23]. The recovery results in the formation of a sub-grain structure, where the dislocations get arranged in cell walls [

34]. Consequently, the dislocation density inside the grains declines. Moreover, upon mechanical cycling, the low-angle boundaries might disappear and, therefore, the initial lath structure coarsens [

35]. However, this trend is partly counterbalanced by opposite effects—subgrains are typically not free of dislocations since they may get pinned by small and homogeneously distributed precipitates inside the subgrains [

19,

23]. Shankar et al. [

33] reported that the application of a hold time promotes the formation of subgrains. Moreover, hold time tests also promote coarsening and morphological changes of carbides. This subgrain and carbide modification underlines that a unique and fast microstructure evolution might be obtained in the case of RF-testing, thereby, justifying the present finding of different softening behaviors in the LCF and RF experiments.

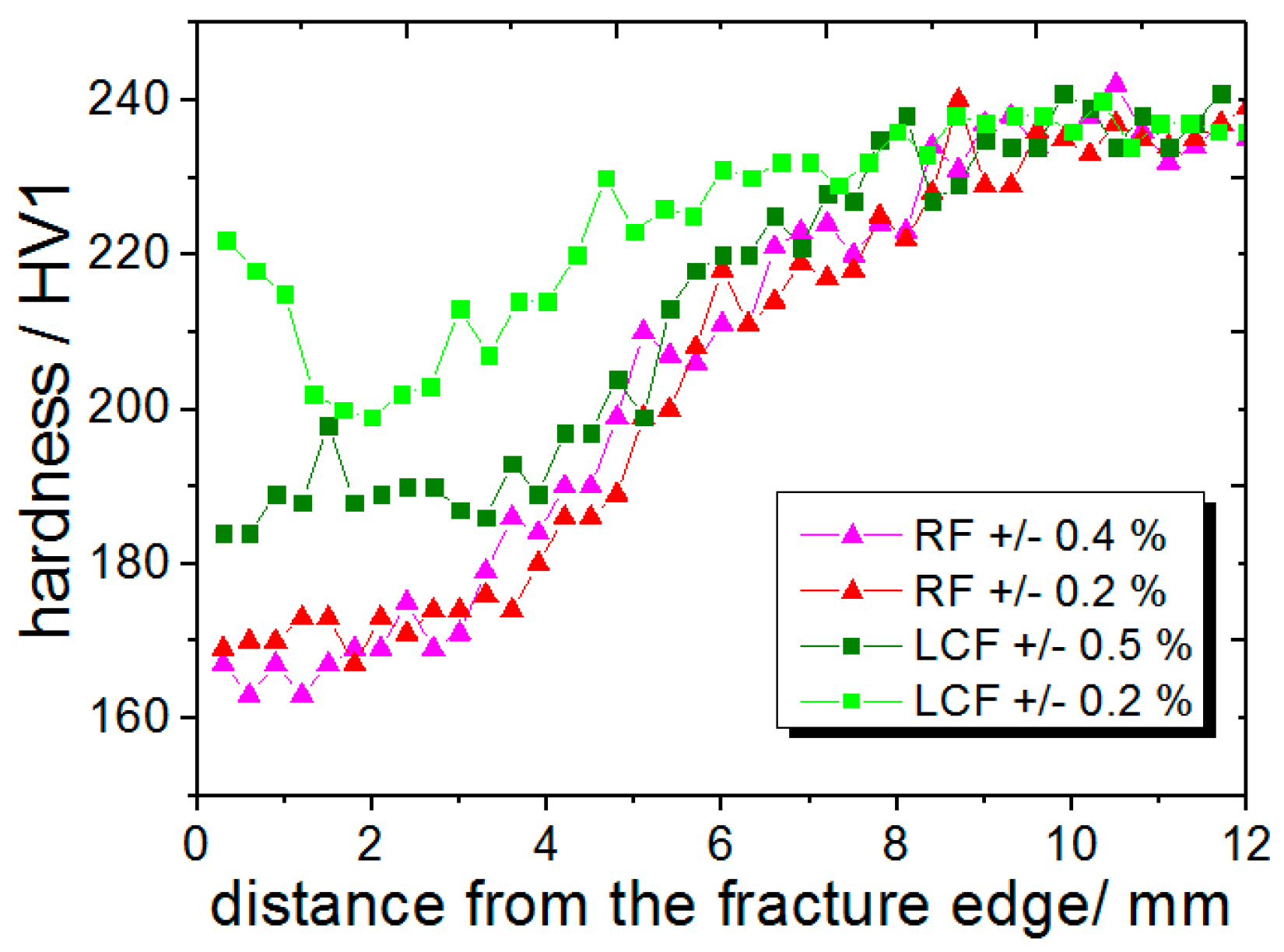

The microstructural changes which possibly represent the origin of the softening phenomenon might also be characterized by means of (micro) hardness measurements. The hardness was measured at the longitudinal sections of the failed specimens. In

Figure 21 the course of the hardness from the fracture surface of the fatigue specimen to the end of its gauge length has been plotted for the different LCF- and RF-tests. For the first 4–5 mm distance, the hardness values were constantly low, except for the LCF-specimen tested at ±0.2%. It is very likely that the largest softening had taken place in this region. Then, with an increasing distance from the fracture surface, the hardness increased, eventually reaching a common value which corresponded to the original hardness in all specimens, at a position close to the end of the gauge length, right before the onset of the transition zone to the specimen head. The general shape of the hardness profiles was probably related to the corresponding temperature profiles in the specimens. The temperature was controlled at the center of the specimen and up to ±5 mm distance from the middle. After 5 mm, i.e., outside the controlled region, the temperature continuously decreased, due to the heat flow into the applied water-cooled grips. With decreasing temperature, the softening also decreased, as might be assumed from the data in

Figure 19. The hardness level of the RF-tests was the lowest within the first 5 mm distance, which was consistent with the more pronounced softening in the tests with hold time. Additionally, for both RF-tests with higher and lower strain amplitudes, not only the hardness levels but also the softening ratio (

Figure 19) were similar. This indicated that in all RF-specimens of the present study the microstructure might have evolved towards a similar condition. Moreover, the lower hardness of the RF- vs. LCF-specimens indicated that a coarser microstructure with less subgrains might have been present in the RF-specimen, since the subgrain walls, which consisted of arranged dislocations, were one of the hardest regions of the microstructure and would reduce the plastic flow during the hardness testing. For the LCF-tests, the hardness values seemed to depend on the applied strain amplitudes, with a trend towards a softer material condition, at a higher applied strain. For the test with a total strain range of ± 0.2%, the hardness first decreased and then increased after passing the 4 mm position. To ensure validity of this particular result, the hardness profile measurements were repeated both at a different place on the same surface, as well as after re-polishing the cross-section’s surface. The same trend of hardness was obtained in all measurements, indicating that the microstructure softening might be rather inhomogeneous at the smaller strain amplitude. The need for a more detailed microstructure characterization to fully rationalize this finding was acknowledged.

4.2. Lifetime Behavior

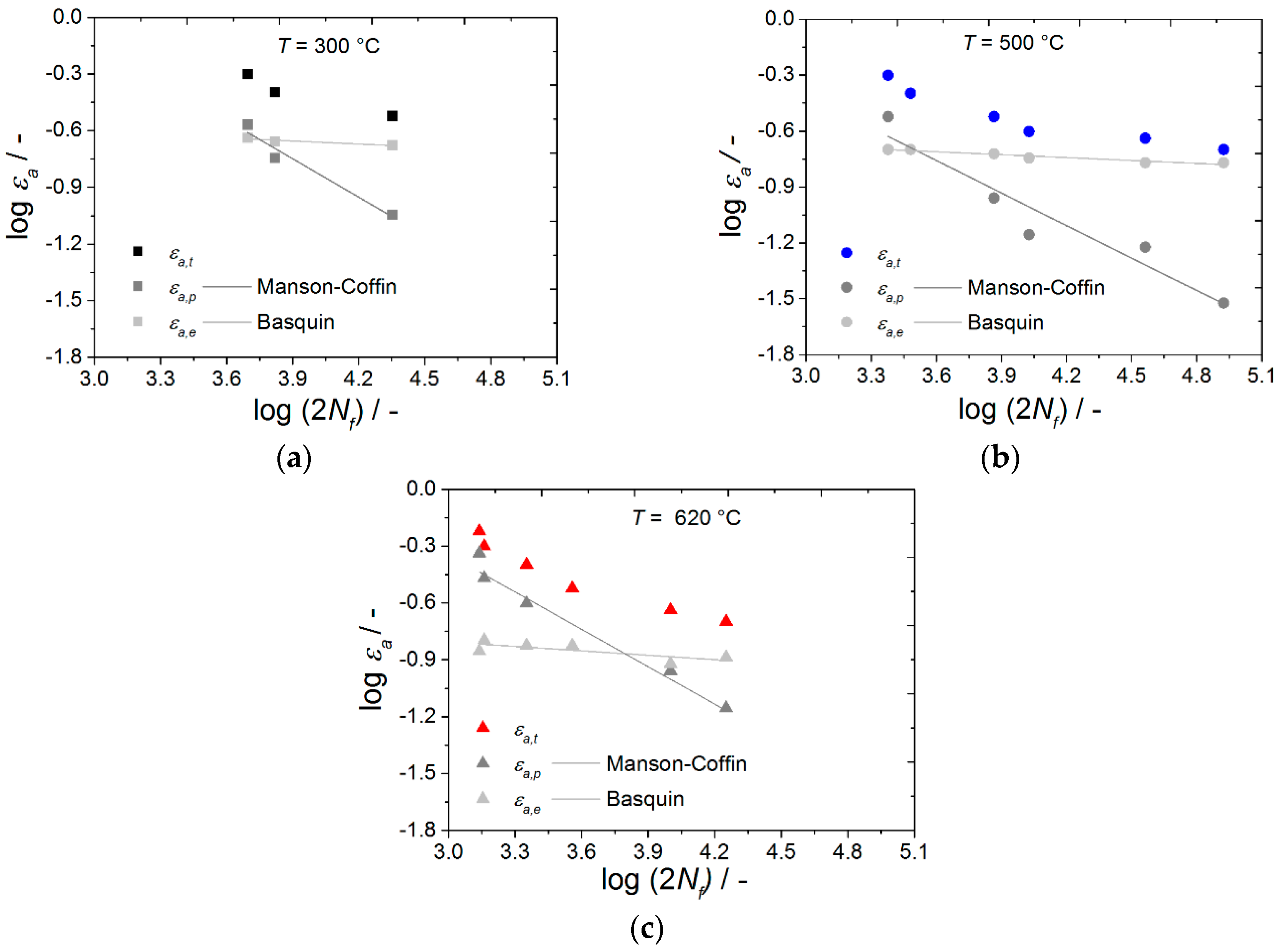

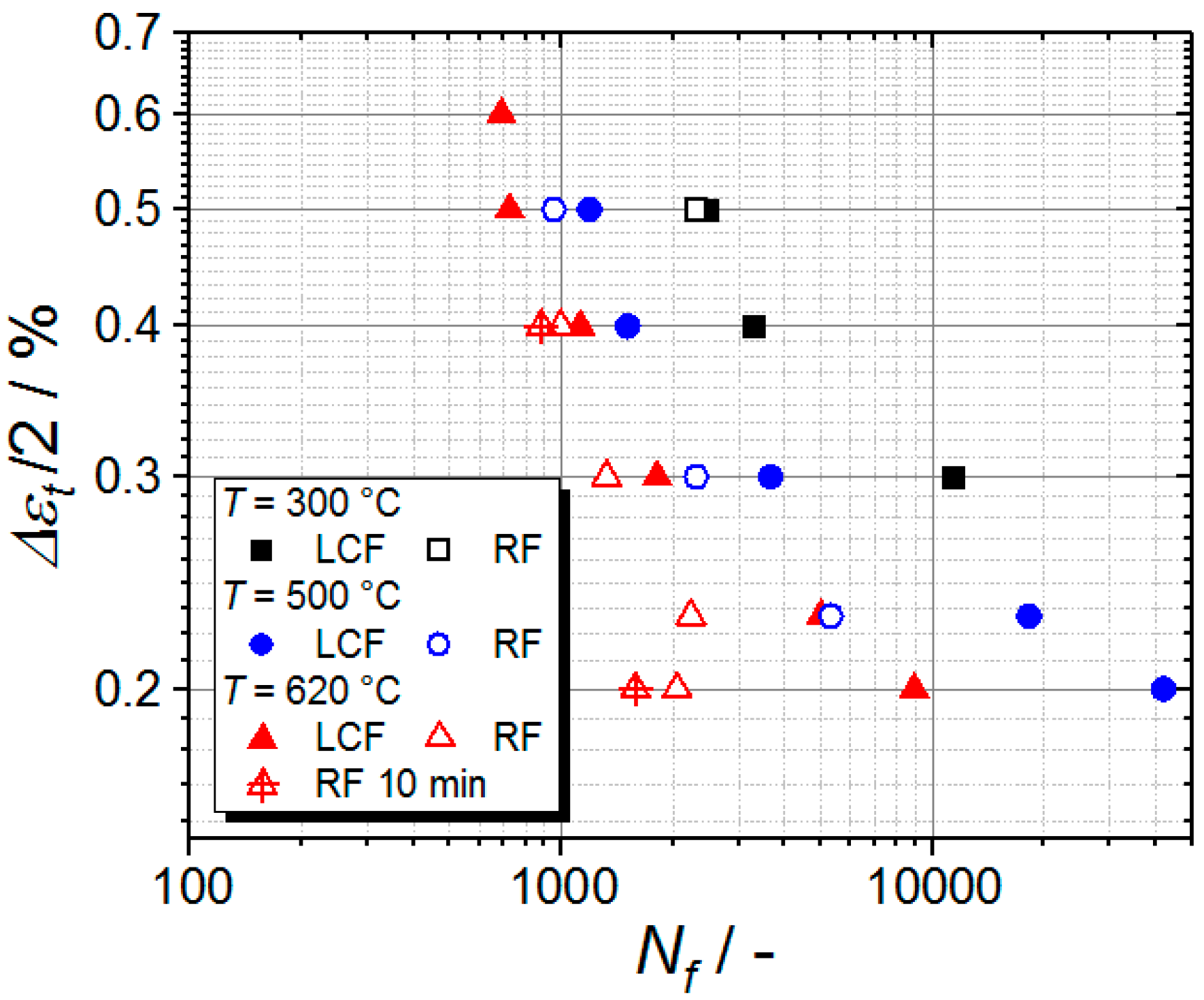

In

Figure 22, the lifetimes of all conducted tests were plotted as a function of the applied strain amplitude. Like generally known, lifetime decreased with increasing strain range and temperature. The addition of a hold time might reduce the lifetime drastically. The reduction of lifetime, firstly, depends on the temperature. According to the rule of Tammann, a transition from time-independent to time-dependent processes takes place at a temperature of

T > 0.4 ·

Tm (

Tm = melting temperature in K) [

36]. At 300 °C, no lifetime reduction due to holds could be identified, based on the limited available data. Additionally, nearly no stress relaxation occurred during the hold time,

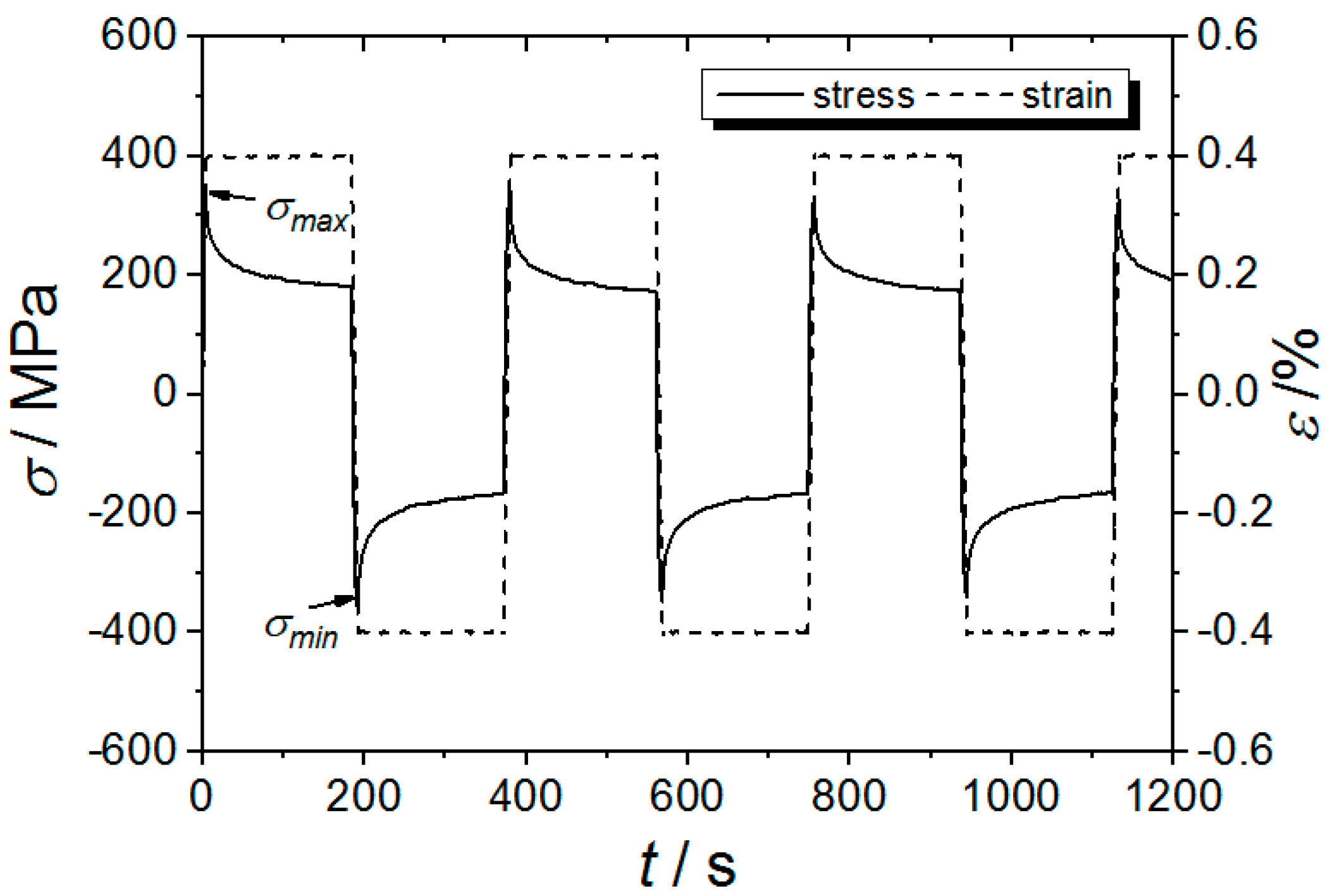

Figure 12b, which meant that nearly no additional inelastic strain, in the form of creep strain, developed. In contrast, at 500 °C and 620 °C, a stress relaxation associated with the development of creep strains was detected. Interestingly, there was only a slight lifetime reduction due to hold periods for tests at higher total strains. This observation suggests that the development of creep strains did not cause a reduction in lifetime under all loading conditions. An extension of the hold time from 3 minutes to 10 minutes only led to a small but further reduction in lifetime.

The stronger reduction of lifetime at small strain amplitudes was possibly related to the more pronounced softening, as described in the previous chapter. At small strain amplitudes (620 °C), the softening ratio increased the most, compared to the LCF-tests (cf.

Figure 19) and, similarly, the greatest influence on lifetime was obtained at ±0.2%, in

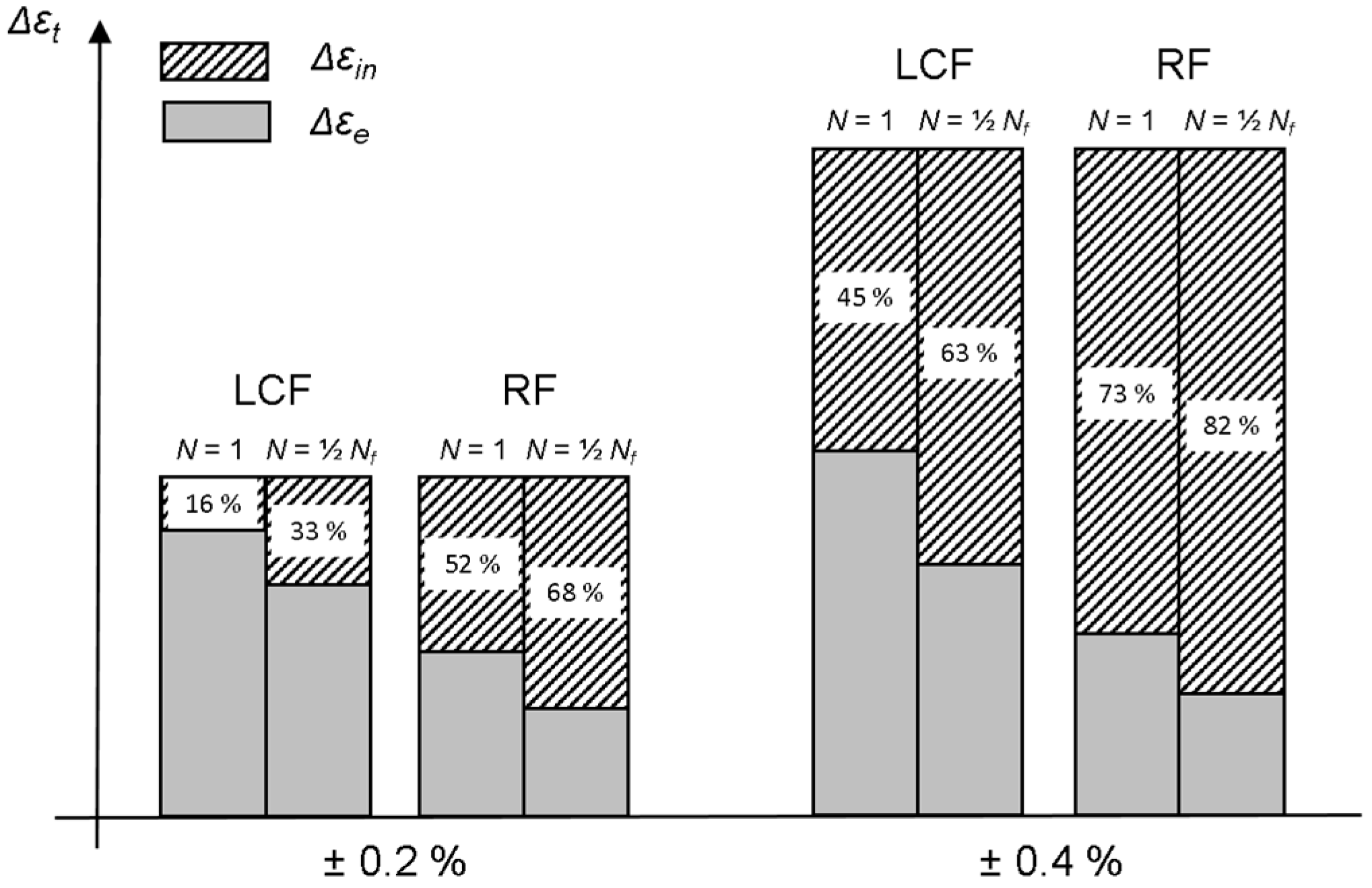

Figure 19. The following considerations might explain the high hold-time-related reduction of lifetime at low strain amplitudes. In

Figure 23. the composition of strain amplitude has been illustrated for the first cycle and the stabilized cycle (which is at half-lifetime), for the LCF- and RF-tests, at a small and a large strain amplitude. As a consequence of the hold time, all RF-tests exhibited a higher inelastic strain fraction than the corresponding LCF-test. Without a hold time at a total strain range of ±0.2%, there was a fraction of 16% of inelastic strain at

N = 1, whereas, the fraction was 52% in the RF-test with hold time. This means that due to the hold time, the inelastic strain was 3.25 times higher in the RF-test than in the LCF-test. For the total strain range of ±0.4%, the inelastic strain fraction for the LCF-test was 45%, in the first cycle, significantly greater than that for ±0.2%. The hold time resulted in a 1.6 times higher inelastic strain for the RF-test in the first cycle—which was a much lower variation—than that for ±0.2%. This more prominent increase of the fraction of inelastic strain at small strain amplitudes could be a reason for the strong lifetime reduction due to hold time, at low strain amplitudes. Since inelastic strain is directly related to microstructural recovery (as discussed above), hold times at small amplitudes result in a more pronounced/accelerated microstructure modification. The respective values obtained at 50%

Nf suggest that the higher level of inelastic strain in the RF-tests was indeed maintained throughout the tests, until fracture. The share of the inelastic strain grew with cycle number in the four experiments displayed in

Figure 23. Nevertheless, the inelastic strains of the LCF-tests at 50%

Nf did not even reach the level of the first RF cycle, despite their much higher number of accomplished reversals at half-lifetime.

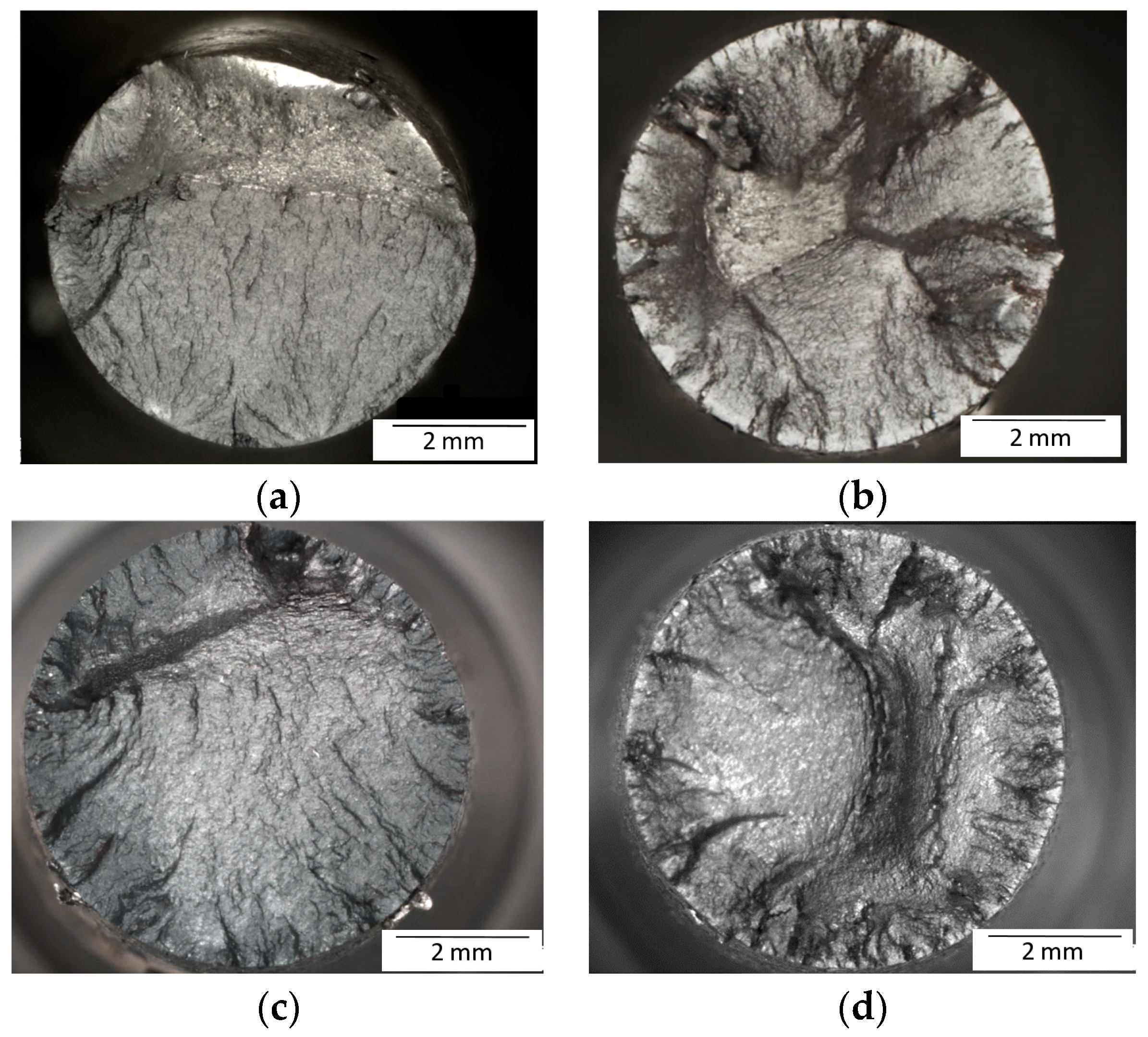

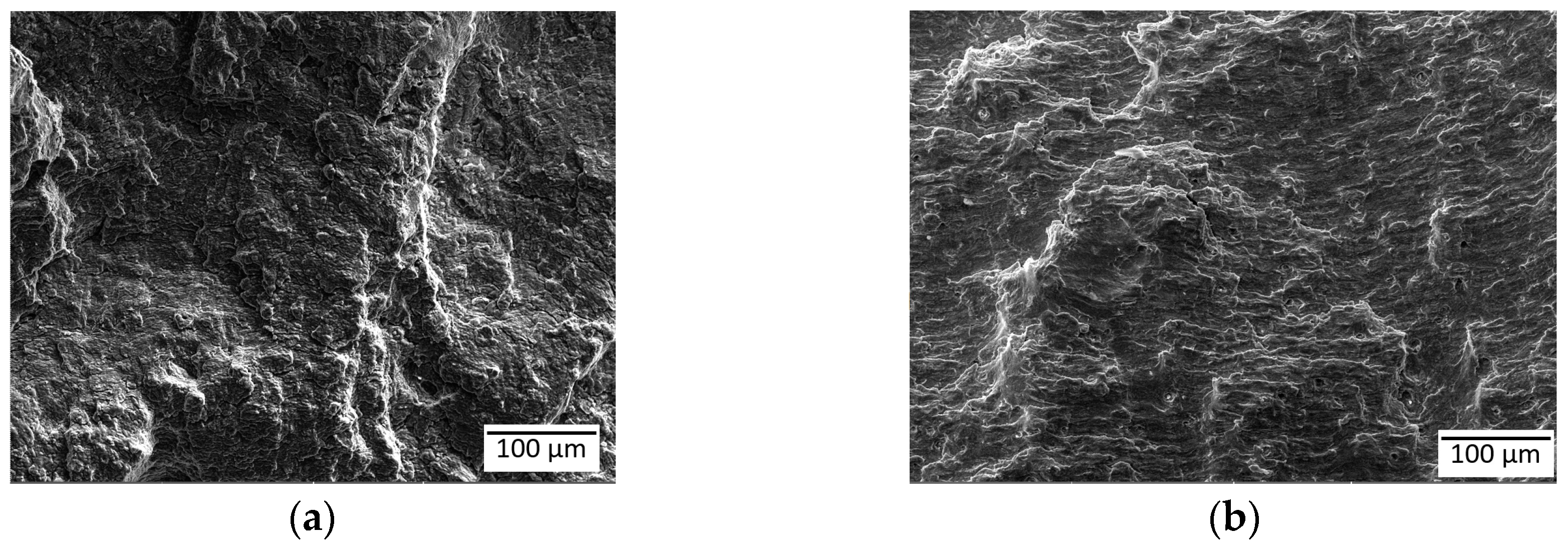

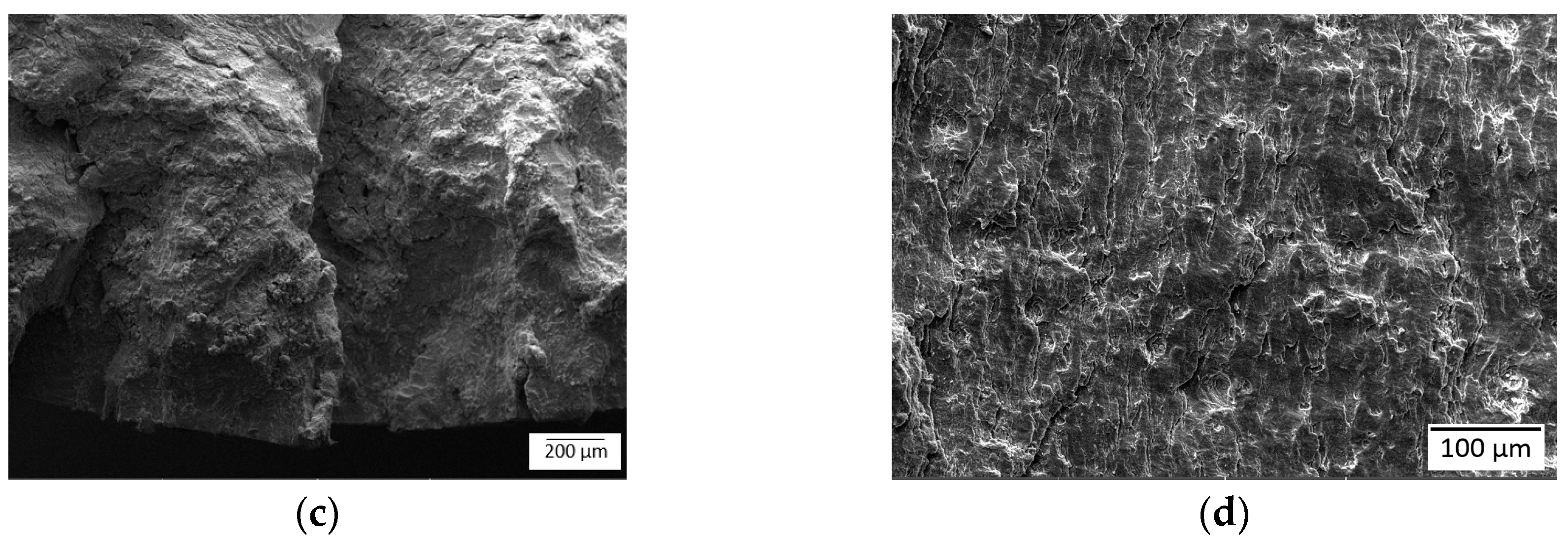

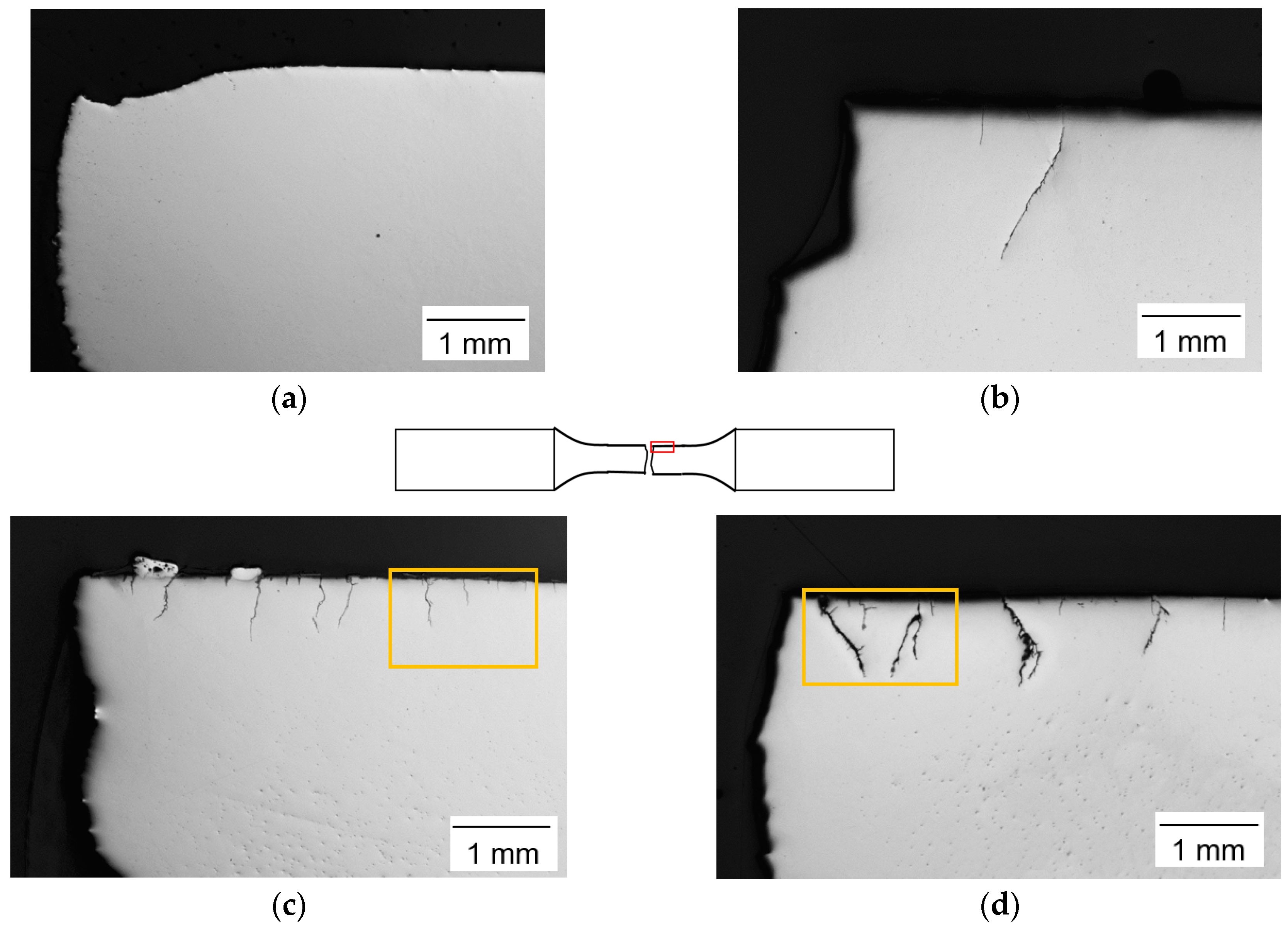

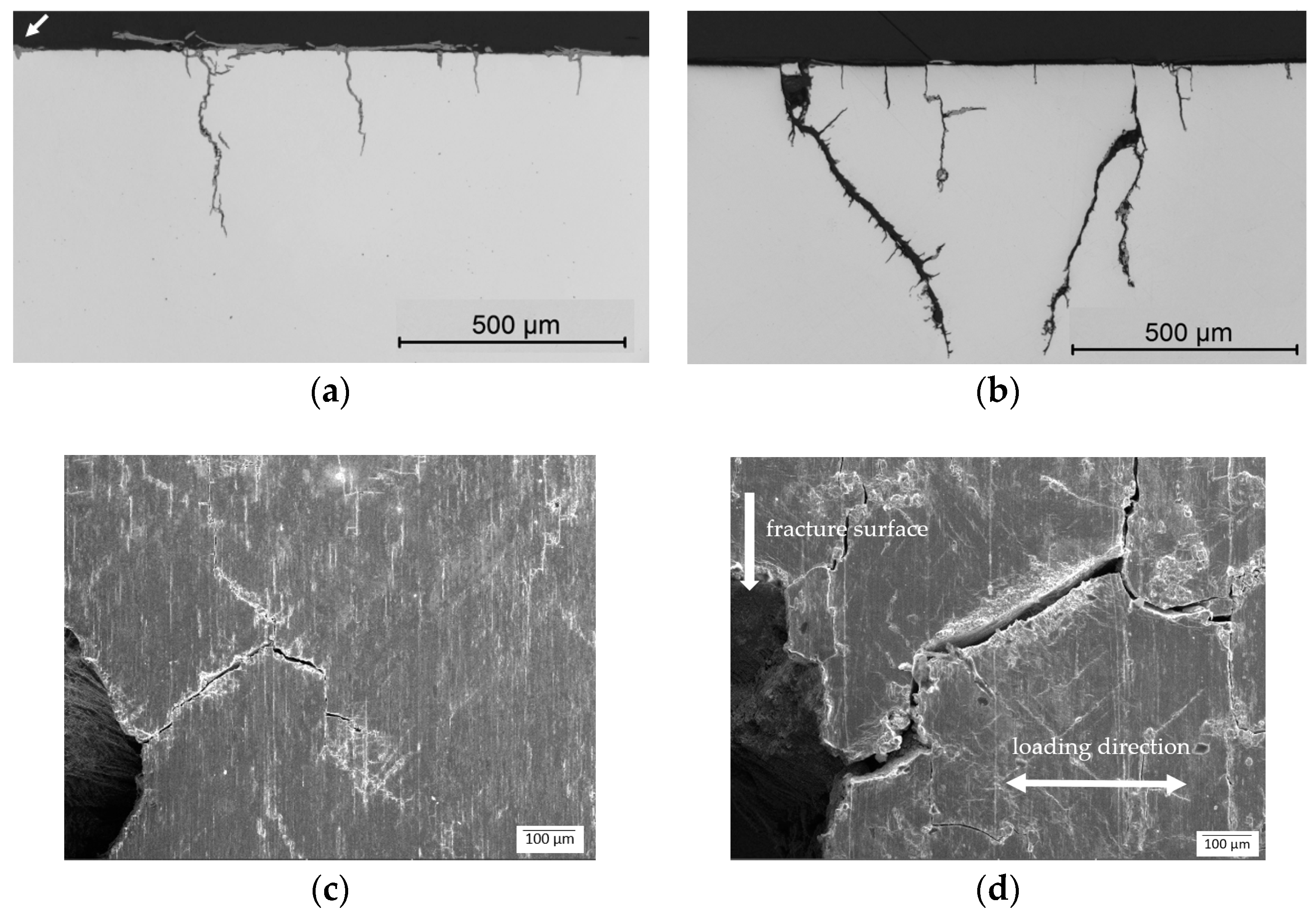

The fracture surfaces of the specimen did not show any evidence for a creep damage, such as intergranular crack growth or the formation of pores. Additionally, no mix of transgranular (fatigue damage) and intergranular (creep damage) crack growth was found. A possible explanation is that the strain rate of the conducted tests was too high. According to Skelton et al. [

37], only at small enough strain rates, creep damage might become predominant. However, a significantly higher number of cracks was found in the RF-specimens which were exposed to static loading phases. With more cracks, it might be expected that the RF-specimens would already fail earlier at a higher stress level than the LCF-specimens. This did not agree with the observation that in RF-tests, the transition from gradual lowering of the maximum stress to a sudden decrease at the end of the cyclic softening curves (

Figure 13) occurred at a lower stress level than that in the LCF-tests. Therefore, it is tempting to assume that the more pronounced softening is a direct mechanical consequence of more cracks that developed during the RF-tests which reduce the load-carrying cross section of the specimen.

On the other hand, there are some facts that seem to disagree with this interpretation, First, the micrographs of

Figure 17 indicate that more cracks developed during the RF-tests at higher strain amplitudes, but since the softening ratio of all RF-tests at 620 °C (

Figure 19) was the same, the number of cracks should be similar. Second, the hardness profiles in

Figure 21 suggest a lower hardness for the RF-specimen. This lower hardness could not result from cracking, since an unaffected central cross-section (not the outer shell) was investigated. Third, if more cracks would reduce the load-carrying cross-section of the specimen, an asymmetry in tension and compression (when the cracks were closed) would be the result, which was not the case. Therefore, the lower hardness at the RF-tests was apparently related to microstructure modification and not to the formation of multiple cracks.

In conclusion, the more pronounced softening under the RF conditions can mainly be attributed to changes in the microstructure. The dislocations are rearranged in a lower energy configuration, such as cells and subgrains [

38]. It is important to consider that the test duration of the RF-tests was longer, although lifetime in terms of number of cycles was less than that in the LCF-tests,

Table 3. During these far longer tests (e.g.,

T = 620 °C, ±0.2%: LCF = 19.8 h, RF = 209.6 h), the enhanced (time-dependent) dislocation rearrangement result in a more pronounced softening. Considerable mechanical stress is, however, a second prerequisite to allow for this microstructure evolution in the ferritic–martensitic steels, since it acts as the primary driving force. The finding that 10 min hold times did not considerably change the material reaction, compared to the tests with only 3 min hold times (

Figure 14), indicates that the remaining stresses after 3 min were already insufficient to stimulate further short-term microstructure evolutions even though they still exceed the 150 MPa level,

Figure 14b.