Investigation on the High-Temperature Oxidation Resistance of Ni-(3~10) Ta and Ni-(3~10) Y Alloys

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples Preparation

2.2. Oxidation and Characterization

3. Results and Discussions

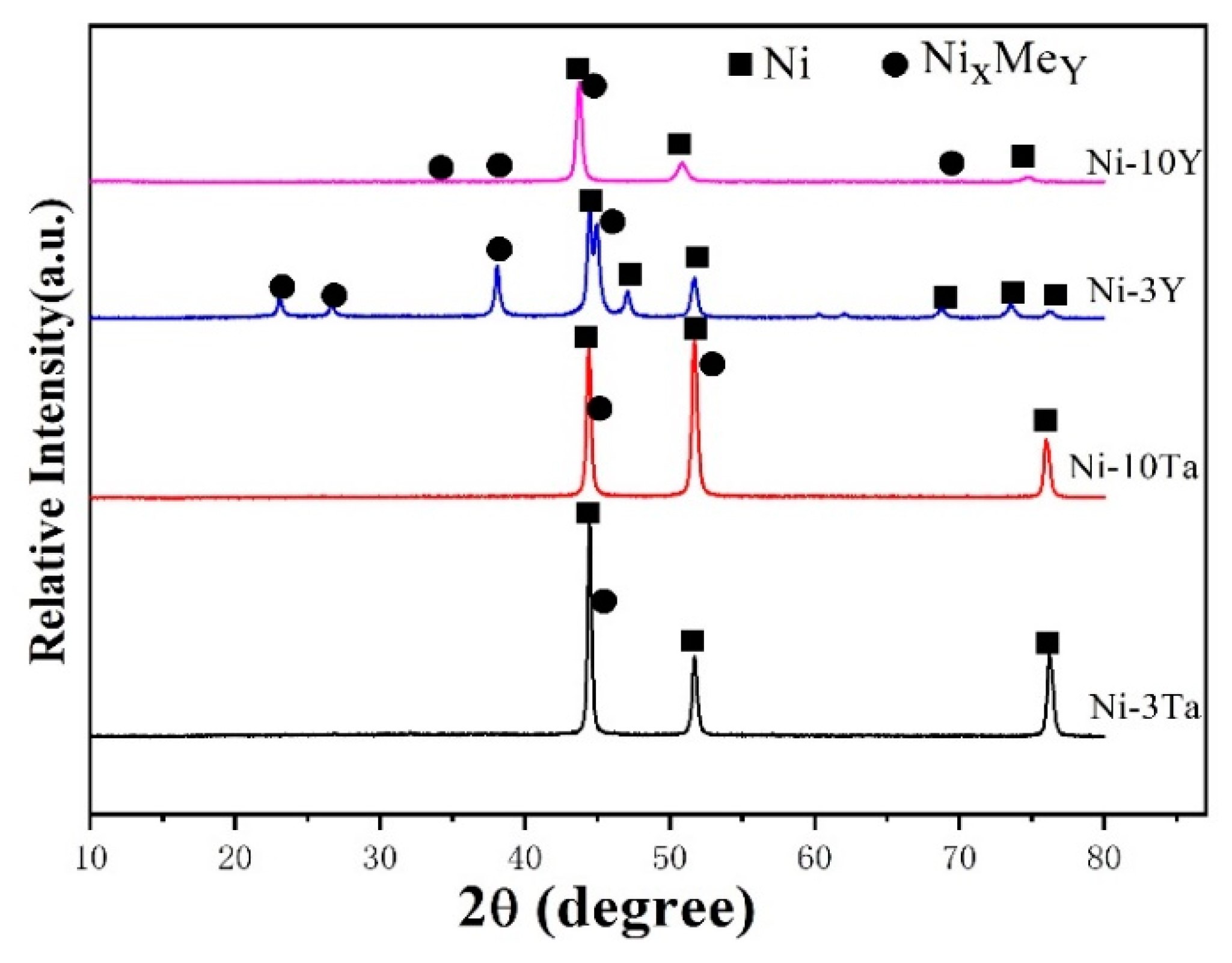

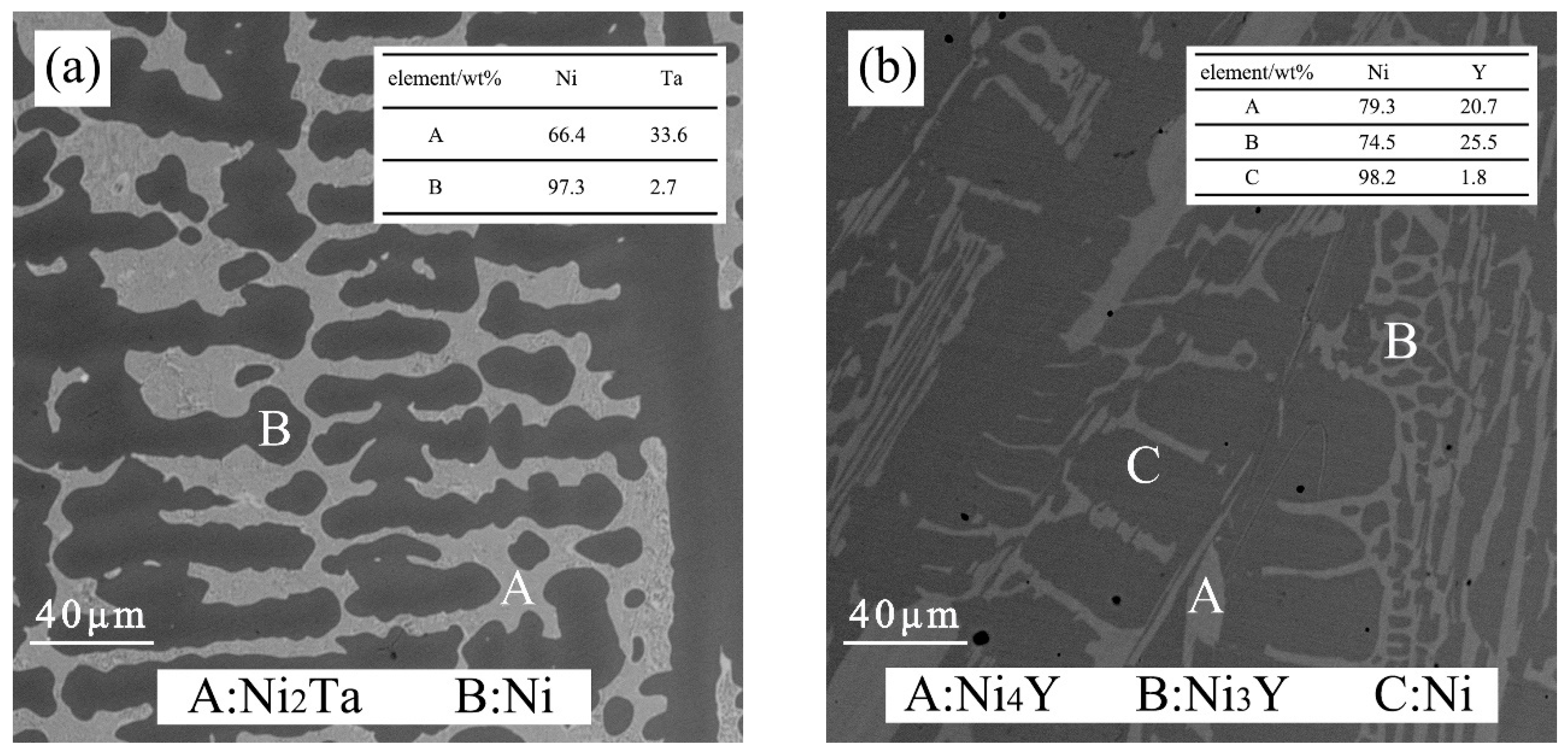

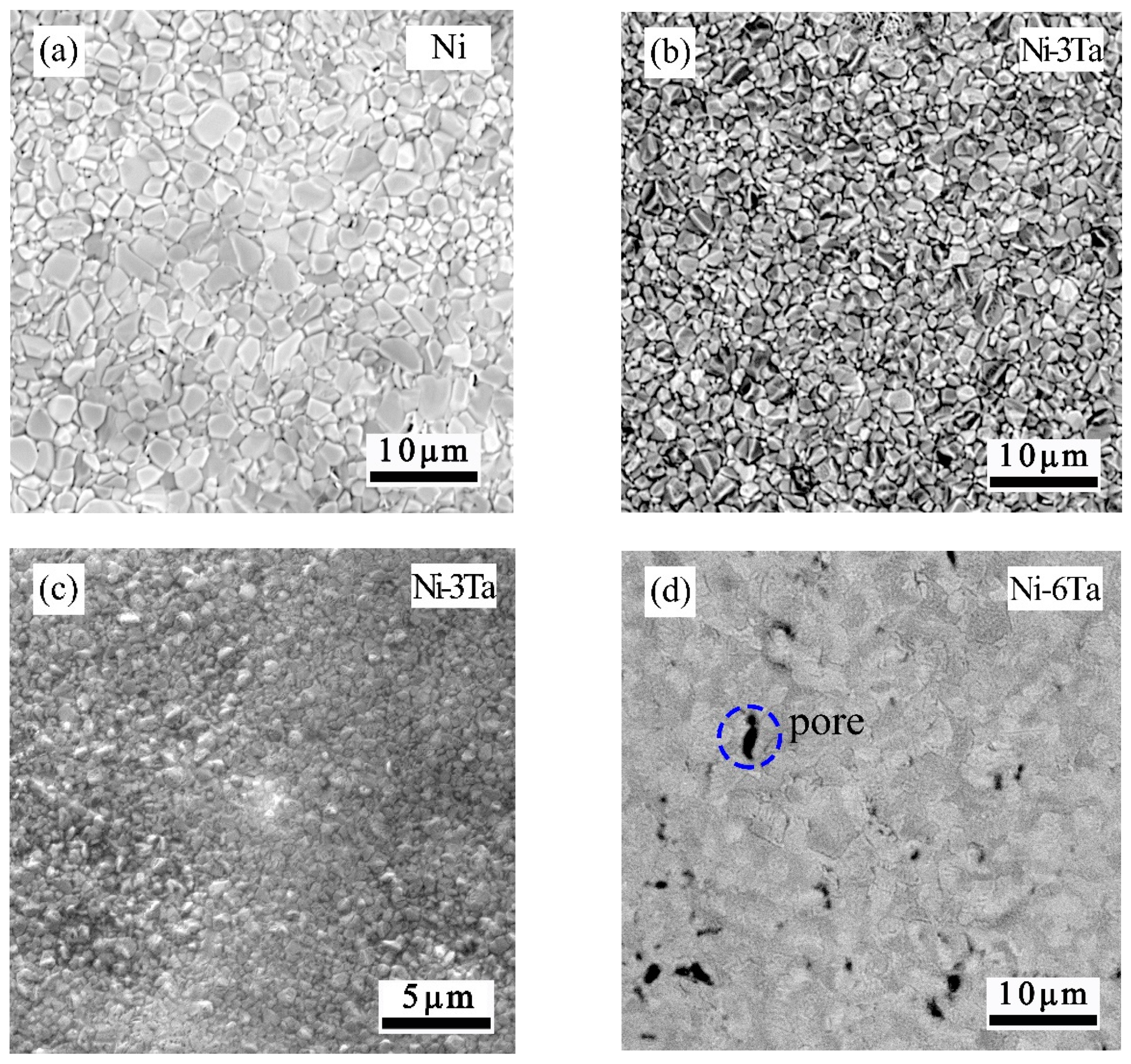

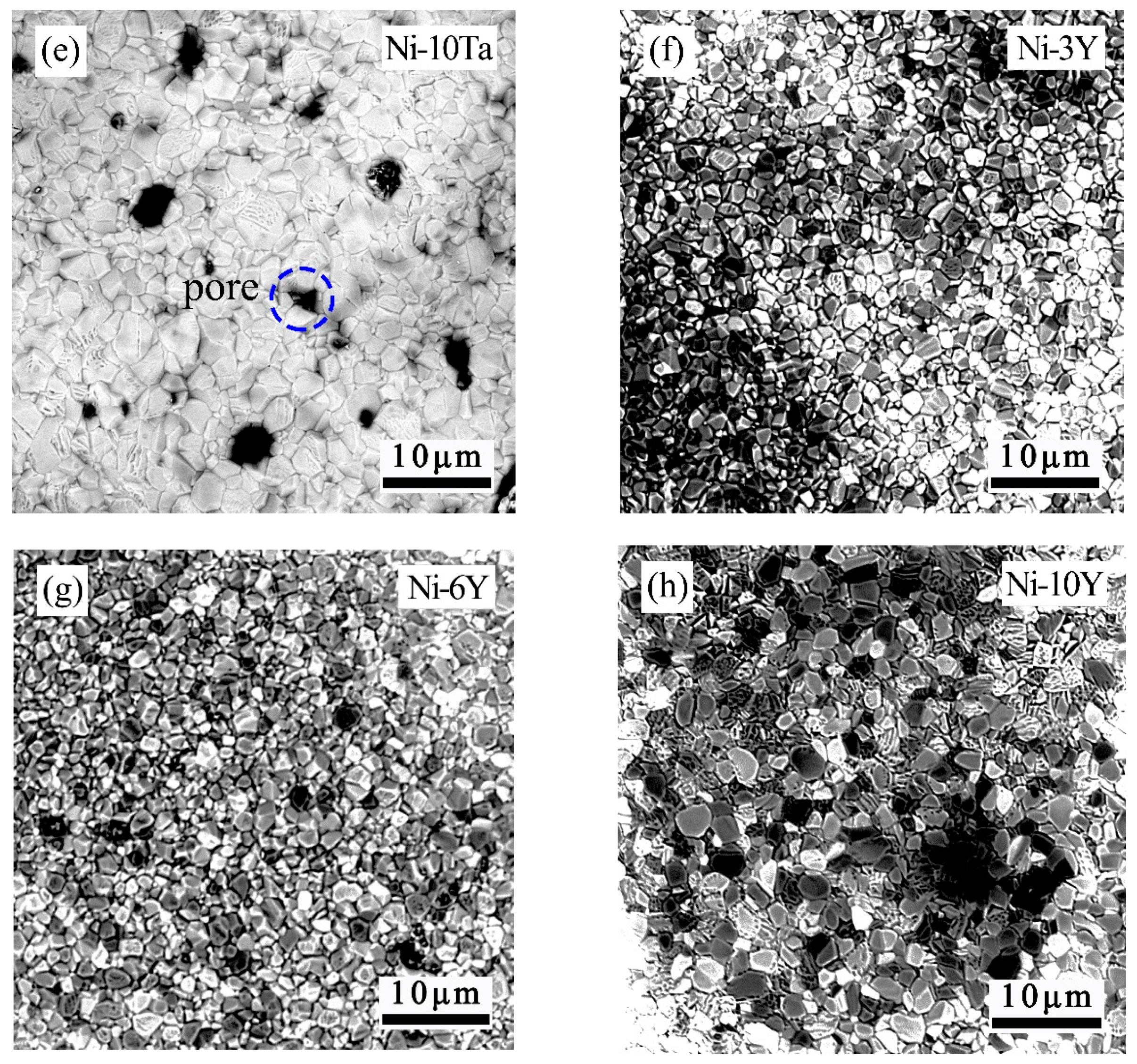

3.1. Properties of the Ni-Based Alloys

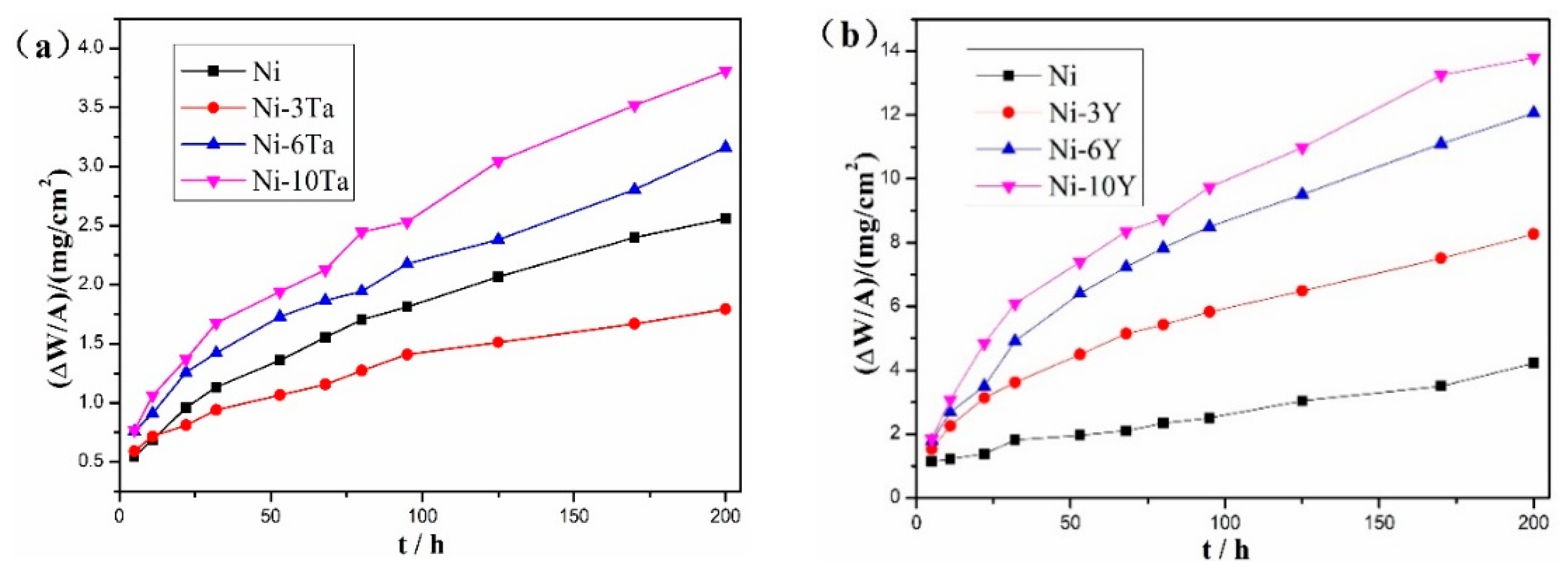

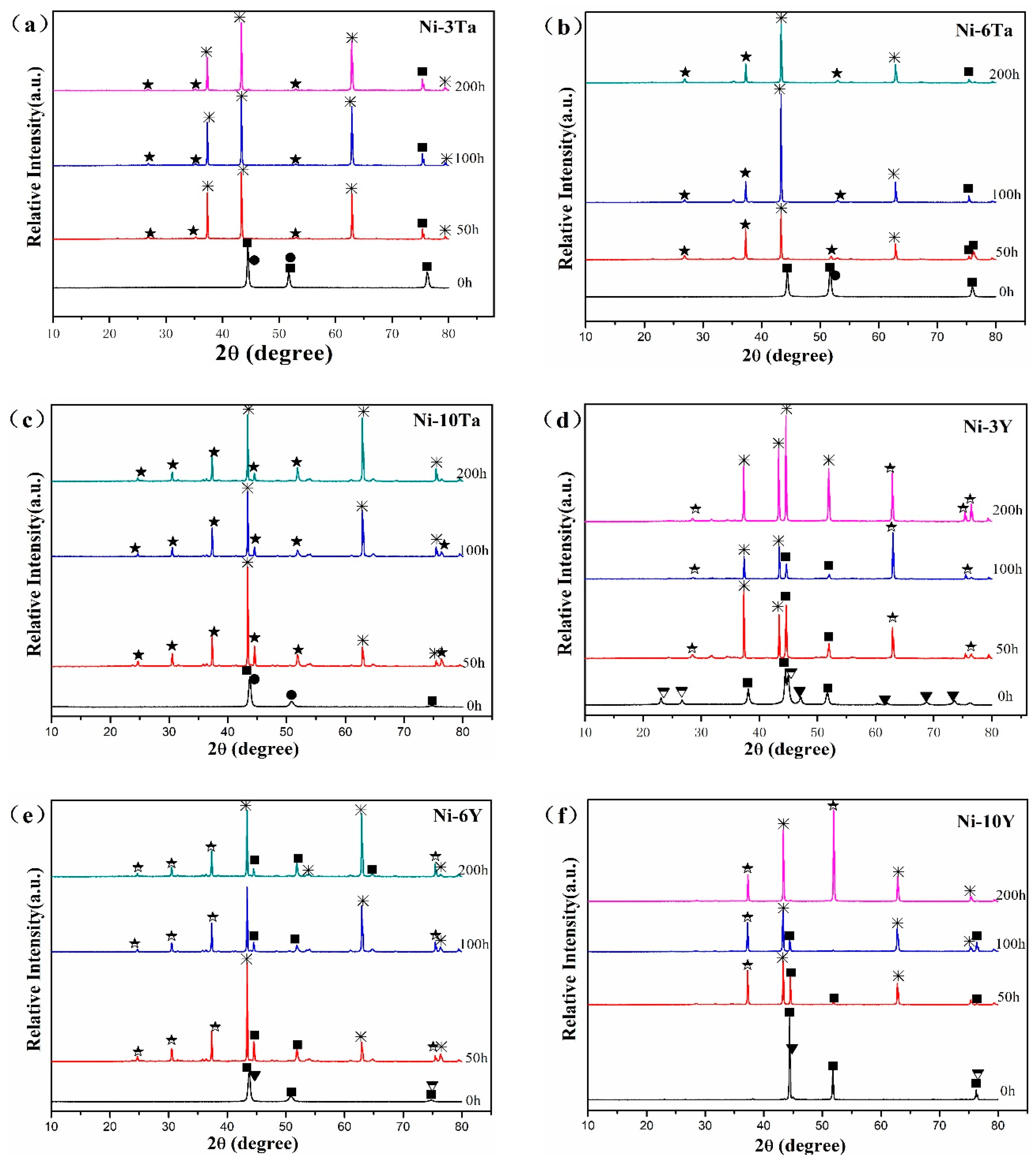

3.2. High-Temperature Oxidation Resistance of the Ni-Based Alloys

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, C.T.; Ma, J.; Sun, X.F.; Zhao, P.C. Mechanism of the oxidation and degradation of the aluminide coating on the nickel-base single-crystal superalloy DD32M. Surf. Coat. Technol. 2010, 204, 3641–3646. [Google Scholar] [CrossRef]

- Li, J.; Pu, J.; Xiao, J.; Qian, X. Oxidation of Haynes 230 alloy in reduced temperature solid oxide fuel cell environments. J. Power Sources 2005, 139, 182–187. [Google Scholar]

- Bogner, S.; Ivanova, E.; Müller, M.; Wang, F.; Ma, D.; Bührig-Polaczek, A. Investigation of the undercoolability of Ni-based alloys using high temperature thermal analysis. Metals 2015, 5, 1971–1983. [Google Scholar] [CrossRef]

- Huang, K.; Hou, P.Y.; Goodenough, J.B. Characterization of iron-based alloy interconnects for reduced temperature solid oxide fuel cells. Solid State Ion. 2000, 129, 237–250. [Google Scholar] [CrossRef]

- Guo, P.; Lai, Y.; Shao, Y.; Zhang, Y.; Wang, Y. Thermal growth Cu1.2Mn1.8O4 spinel coatings on metal interconnects for solid oxide fuel cell applications. Metals 2017, 7, 522. [Google Scholar] [CrossRef]

- Brett, D.J.; Atkinson, A.; Brandon, N.P.; Skinner, S.J. Intermediate temperature solid oxide fuel cells. Chem. Soc. Rev. 2008, 37, 1568–1578. [Google Scholar] [CrossRef] [PubMed]

- Brylewski, T.; Nanko, M.; Maruyama, T.; Przybylski, K. Application of Fe-16Cr ferritic alloy to interconnector for a solid oxide fuel cell. Solid State Ion. 2001, 143, 131–150. [Google Scholar] [CrossRef]

- Safikhani, A.; Esmailian, M.; Salmani, M.R.; Aminfard, M. Effect of Ni-Mo addition on cyclic and isothermal oxidation resistance and electrical behavior of ferritic stainless steel for SOFCs interconnect. Int. J. Hydrogen Energy 2014, 39, 11210–11223. [Google Scholar] [CrossRef]

- Gai, L.; Liu, Y.; Xin, X.; Zeng, Z.; Qi, Q.; Huang, J.; Liu, X. Promising cermets of TiN-Ni for intermediate temperature solid oxide fuel cell interconnects application. J. Power Sources 2017, 359, 166–172. [Google Scholar] [CrossRef]

- Sato, A.; Chiu, Y.-L.; Reed, R. Oxidation of nickel-based single-crystal superalloys for industrial gas turbine applications. Acta Mater. 2011, 59, 225–240. [Google Scholar] [CrossRef]

- Park, S.-J.; Seo, S.-M.; Yoo, Y.-S.; Jeong, H.-W.; Jang, H. Statistical study of the effects of the composition on the oxidation resistance of Ni-based superalloys. J. Nanomater. 2015, 16, 256. [Google Scholar] [CrossRef]

- Kim, H.-S.; Park, S.-J.; Seo, S.-M.; Yoo, Y.-S.; Jeong, H.-W.; Jang, H. High temperature oxidation resistance of Ni-(5∼13) Co-(10∼16) Cr-(5∼9) W-5Al-(1∼1.5) Ti-(3∼6) Ta alloys. Met. Mater. Int. 2016, 22, 789–796. [Google Scholar] [CrossRef]

- Jalowicka, A.; Nowak, W.; Naumenko, D.; Singheiser, L.; Quadakkers, W. Effect of nickel base superalloy composition on oxidation resistance in SO2 containing, high pO2 environments. Mater. Corros. 2014, 65, 178–187. [Google Scholar] [CrossRef]

- Klein, L.; Bauer, A.; Neumeier, S.; Göken, M.; Virtanen, S. High temperature oxidation of γ/γ′-strengthened Co-base superalloys. Corros. Sci. 2011, 53, 2027–2034. [Google Scholar] [CrossRef]

- Elliott, P.; Hampton, A. The influence of ternary additions of W, Mo, Ti, Ta, and Nb on the isothermal and cyclic oxidation of Ni-10Cr alloy. Oxid. Met. 1980, 14, 449–468. [Google Scholar] [CrossRef]

- Chicardi, E.; Gotor, F.; Córdoba, J. Enhanced oxidation resistance of Ti (C, N)-based cermets containing Ta. Corros. Sci. 2014, 84, 11–20. [Google Scholar] [CrossRef]

- Chicardi, E.; Córdoba, J.; Gotor, F.J. High temperature oxidation resistance of (Ti, Ta)(C, N)-based cermets. Corros. Sci. 2016, 102, 125–136. [Google Scholar] [CrossRef]

- Chuprina, V.; Shalya, I. Oxidation processes of alloys of the Ni-Ta system. II. Oxidation of the intermetallic compound NiTa. Powder Metall. Met. Ceram. 1999, 38, 278–283. [Google Scholar] [CrossRef]

- Wu, Y.; Hagihara, K.; Umakoshi, Y. Improvement of cyclic oxidation resistance of Y-containing TiAl-based alloys with equiaxial gamma microstructures. Intermetallics 2005, 13, 879–884. [Google Scholar] [CrossRef]

- Wu, Y.; Hagihara, K.; Umakoshi, Y. Influence of Y-addition on the oxidation behavior of Al-rich γ-TiAl alloys. Intermetallics 2004, 12, 519–532. [Google Scholar] [CrossRef]

- Moosa, A.; Rothman, S. Effect of yttrium additions on the oxidation of nickel. Oxid. Met. 1985, 24, 133–148. [Google Scholar] [CrossRef]

- Zhao, L.; Li, G.; Zhang, L.; Lin, J.; Song, X.; Ye, F.; Chen, G. Influence of Y addition on the long time oxidation behaviors of high Nb containing TiAl alloys at 900 °C. Intermetallics 2010, 18, 1586–1596. [Google Scholar] [CrossRef]

- Jo, K.H.; Kim, J.H.; Kim, K.M.; Lee, I.-S.; Kim, S.-J. Development of a new cost effective Fe-Cr ferritic stainless steel for SOFC interconnect. Int. J. Hydrogen Energy 2015, 40, 9523–9529. [Google Scholar] [CrossRef]

- Haugsrud, R. On the high-temperature oxidation of nickel. Corros. Sci. 2003, 45, 211–235. [Google Scholar] [CrossRef]

) Ni3Y; (★) Ta2O5; (

) Ni3Y; (★) Ta2O5; (  ) Y2O3; (

) Y2O3; (  ) NiO.

) NiO.

) Ni3Y; (★) Ta2O5; (

) Ni3Y; (★) Ta2O5; (  ) Y2O3; (

) Y2O3; (  ) NiO.

) NiO.

| Alloys | Ni | Ta | Y |

|---|---|---|---|

| Pure Ni | Bal. | - | - |

| Ni-3Ta | Bal. | 3 | - |

| Ni-6Ta | Bal. | 6 | - |

| Ni-10Ta | Bal. | 10 | - |

| Ni-3Y | Bal. | - | 3 |

| Ni-6Y | Bal. | - | 6 |

| Ni-10Y | Bal. | - | 10 |

| Alloys | Mass Gain (mg·cm−2) | K (mg2·cm−4·s−1) | r |

|---|---|---|---|

| Pure Ni | 2.9 | 1.17 × 10−5 | 0.998 |

| Ni-3Ta | 1.7 | 4.01 × 10−6 | 0.999 |

| Ni-6Ta | 3.2 | 1.42 × 10−5 | 0.994 |

| Ni-10Ta | 3.8 | 2.01 × 10−5 | 0.996 |

| Ni-3Y | 7.7 | 8.24 × 10−5 | 0.989 |

| Ni-6Y | 12.2 | 2.06 × 10−4 | 0.998 |

| Ni-10Y | 13.8 | 2.65 × 10−4 | 0.998 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, H.; Liu, Y.; Lin, T.; Zhang, H.; Huang, Z. Investigation on the High-Temperature Oxidation Resistance of Ni-(3~10) Ta and Ni-(3~10) Y Alloys. Metals 2019, 9, 97. https://doi.org/10.3390/met9010097

Duan H, Liu Y, Lin T, Zhang H, Huang Z. Investigation on the High-Temperature Oxidation Resistance of Ni-(3~10) Ta and Ni-(3~10) Y Alloys. Metals. 2019; 9(1):97. https://doi.org/10.3390/met9010097

Chicago/Turabian StyleDuan, Hang, Yan Liu, Tiesong Lin, Hui Zhang, and Zhengren Huang. 2019. "Investigation on the High-Temperature Oxidation Resistance of Ni-(3~10) Ta and Ni-(3~10) Y Alloys" Metals 9, no. 1: 97. https://doi.org/10.3390/met9010097

APA StyleDuan, H., Liu, Y., Lin, T., Zhang, H., & Huang, Z. (2019). Investigation on the High-Temperature Oxidation Resistance of Ni-(3~10) Ta and Ni-(3~10) Y Alloys. Metals, 9(1), 97. https://doi.org/10.3390/met9010097