Variation of Magnetic Memory Signals in Fatigue Crack Initiation and Propagation Behavior

Abstract

:1. Introduction

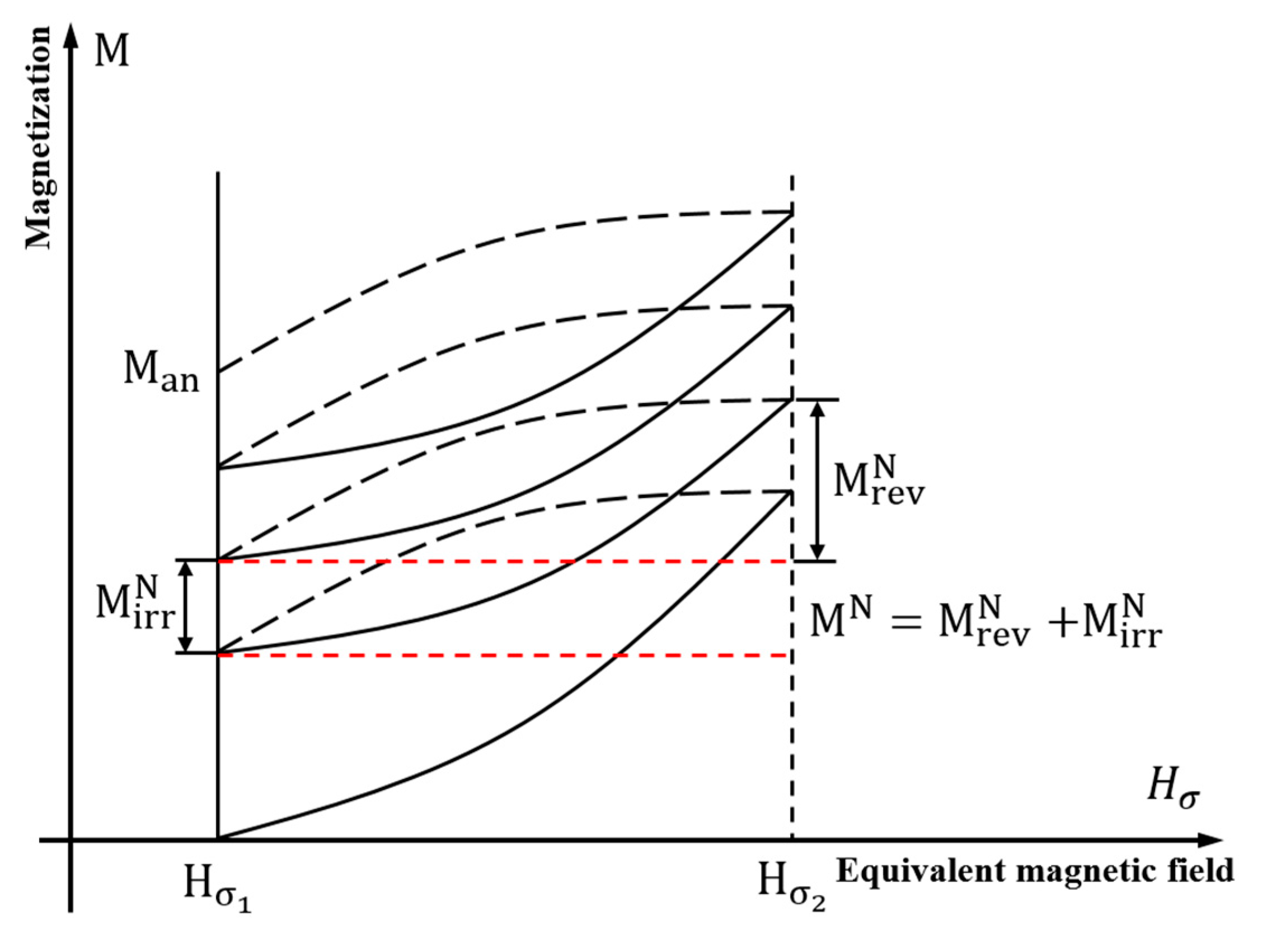

2. Theoretical Modeling

3. Experiment

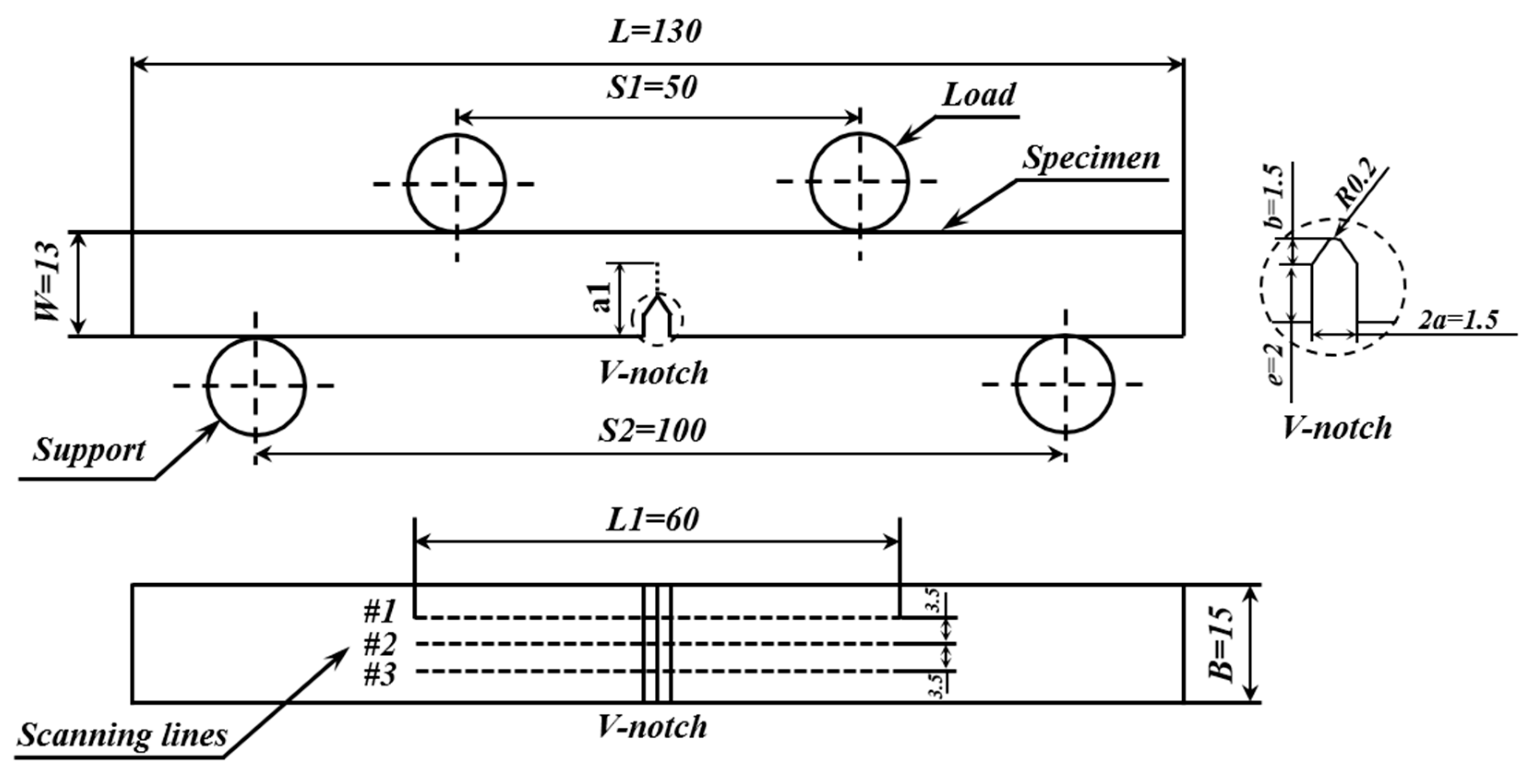

3.1. Specimen Preparation

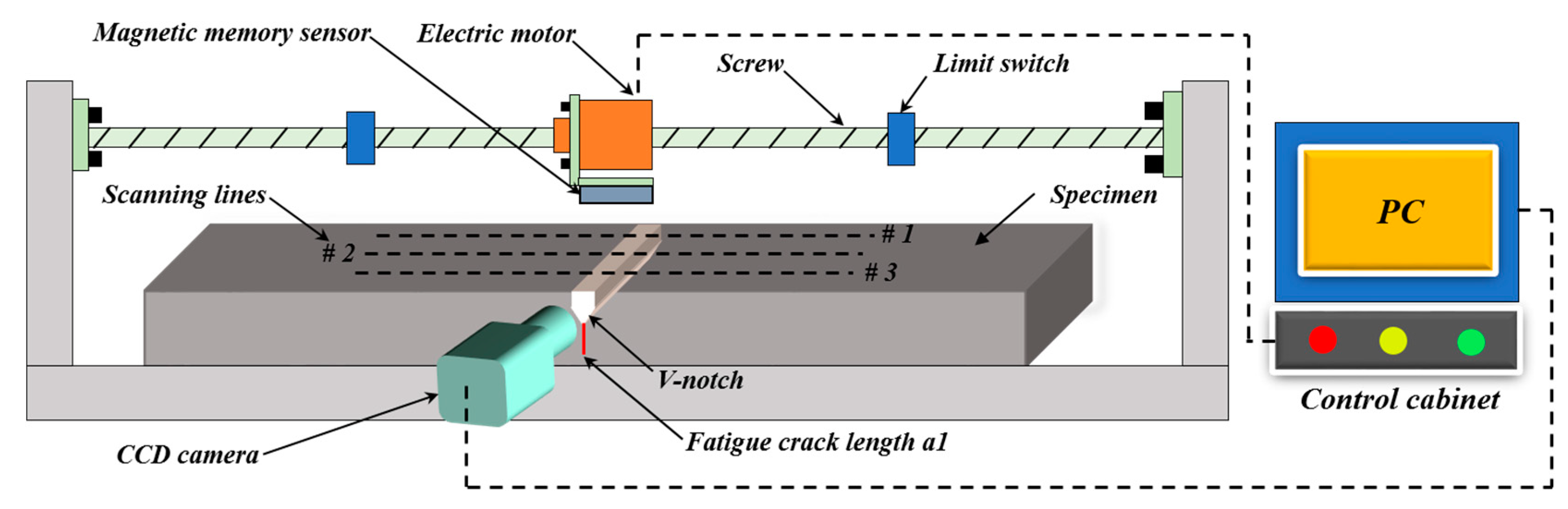

3.2. Instrument and Testing Method

4. Results and Discussion

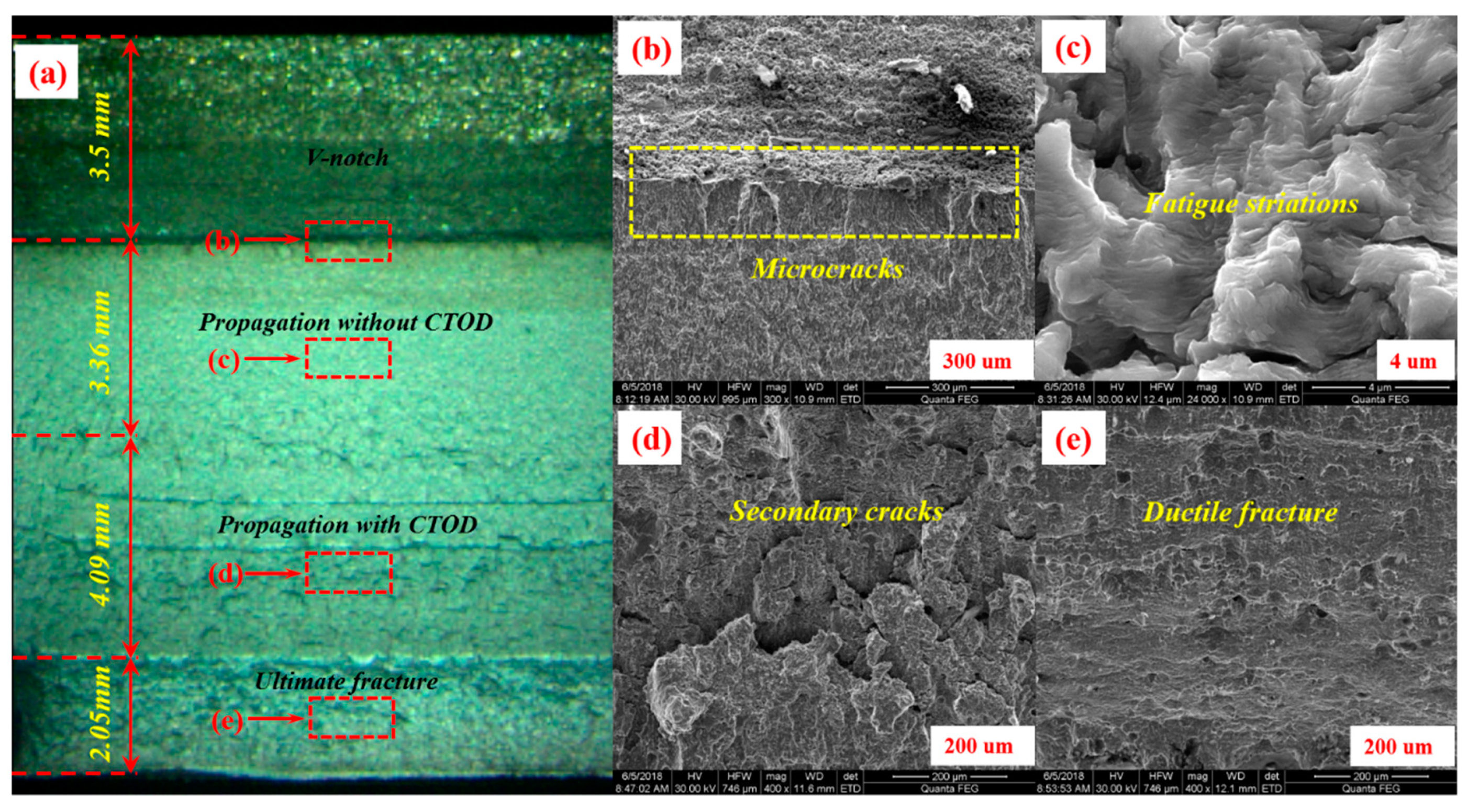

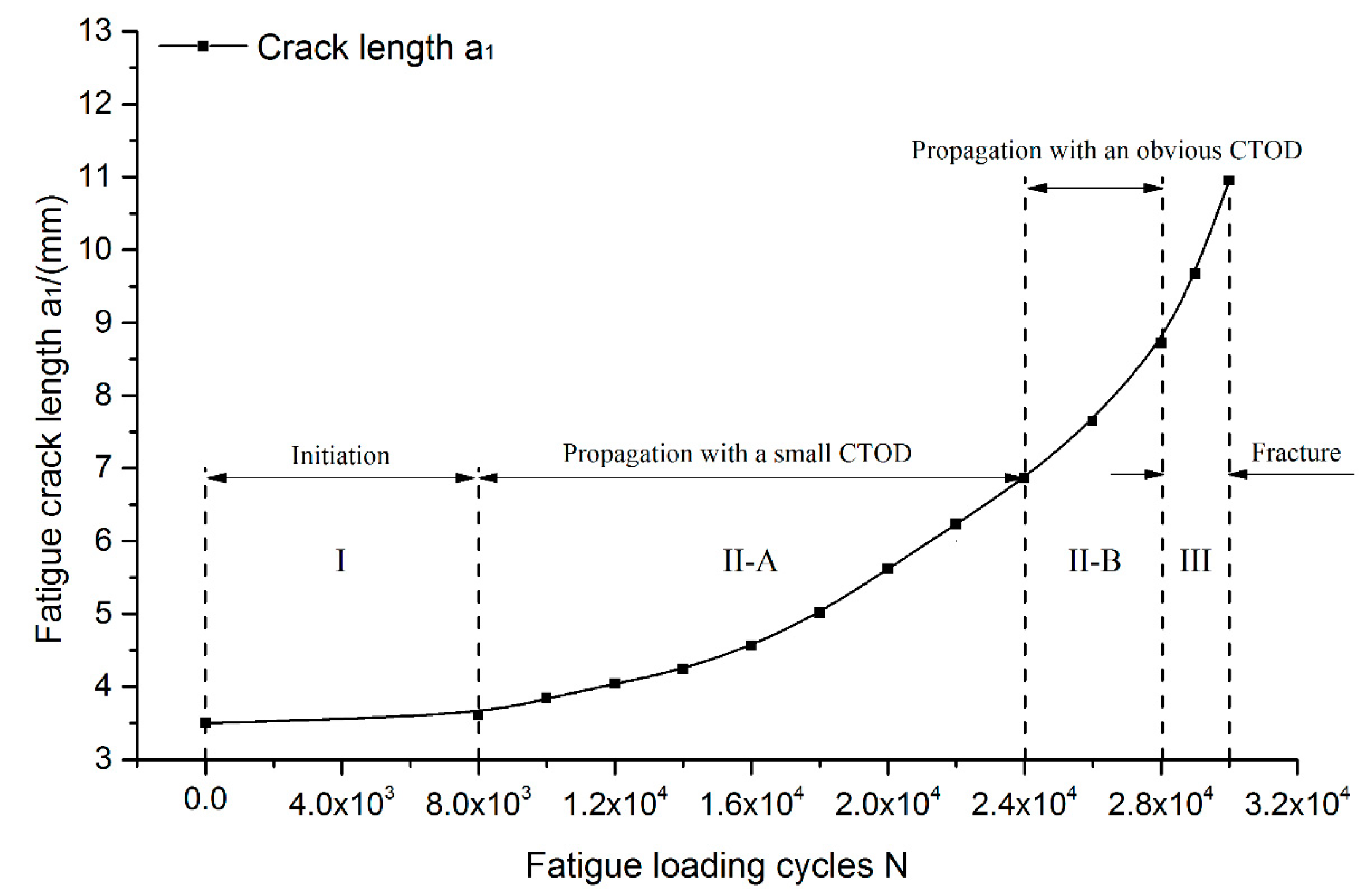

4.1. Four-Point Fatigue Bending Test

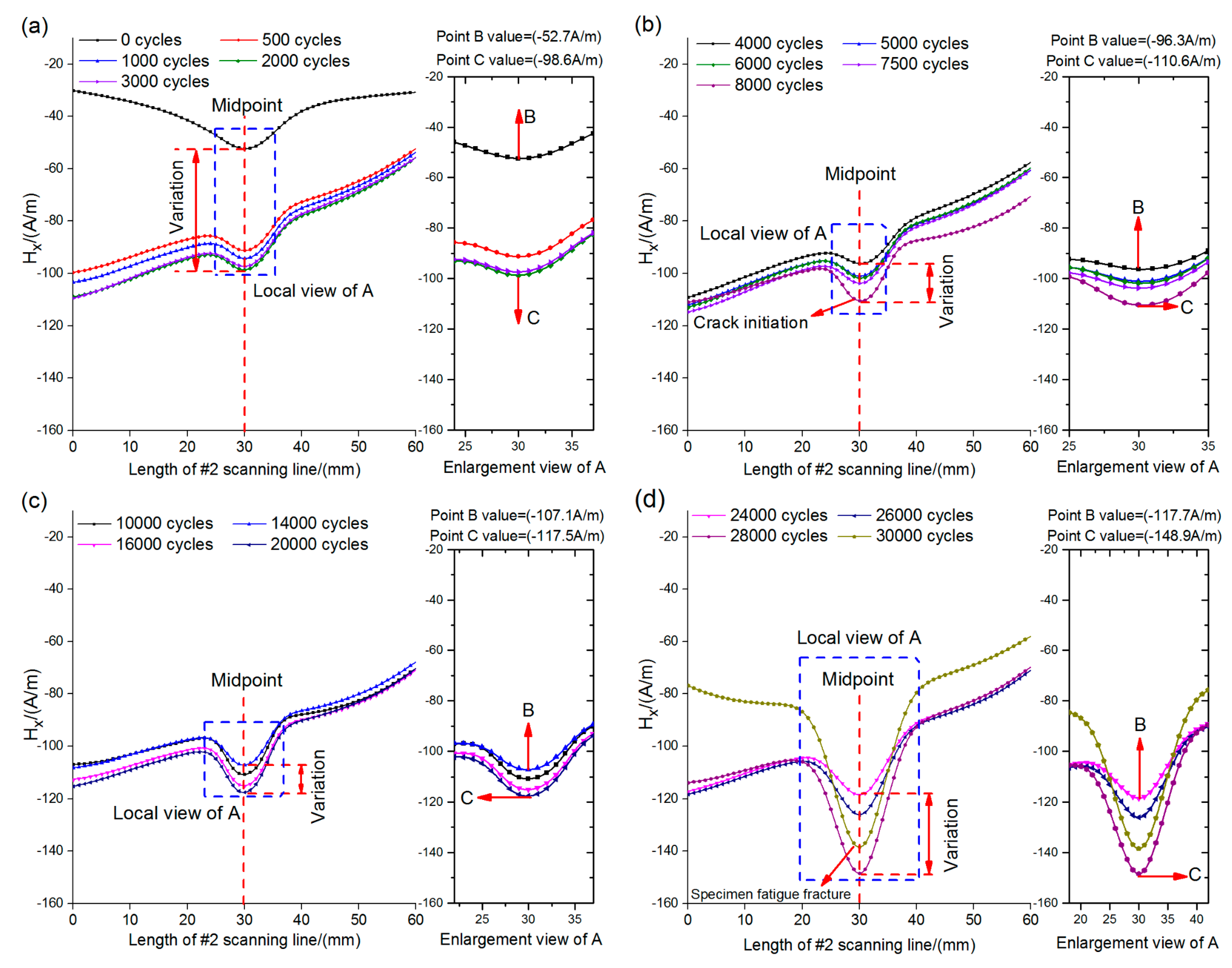

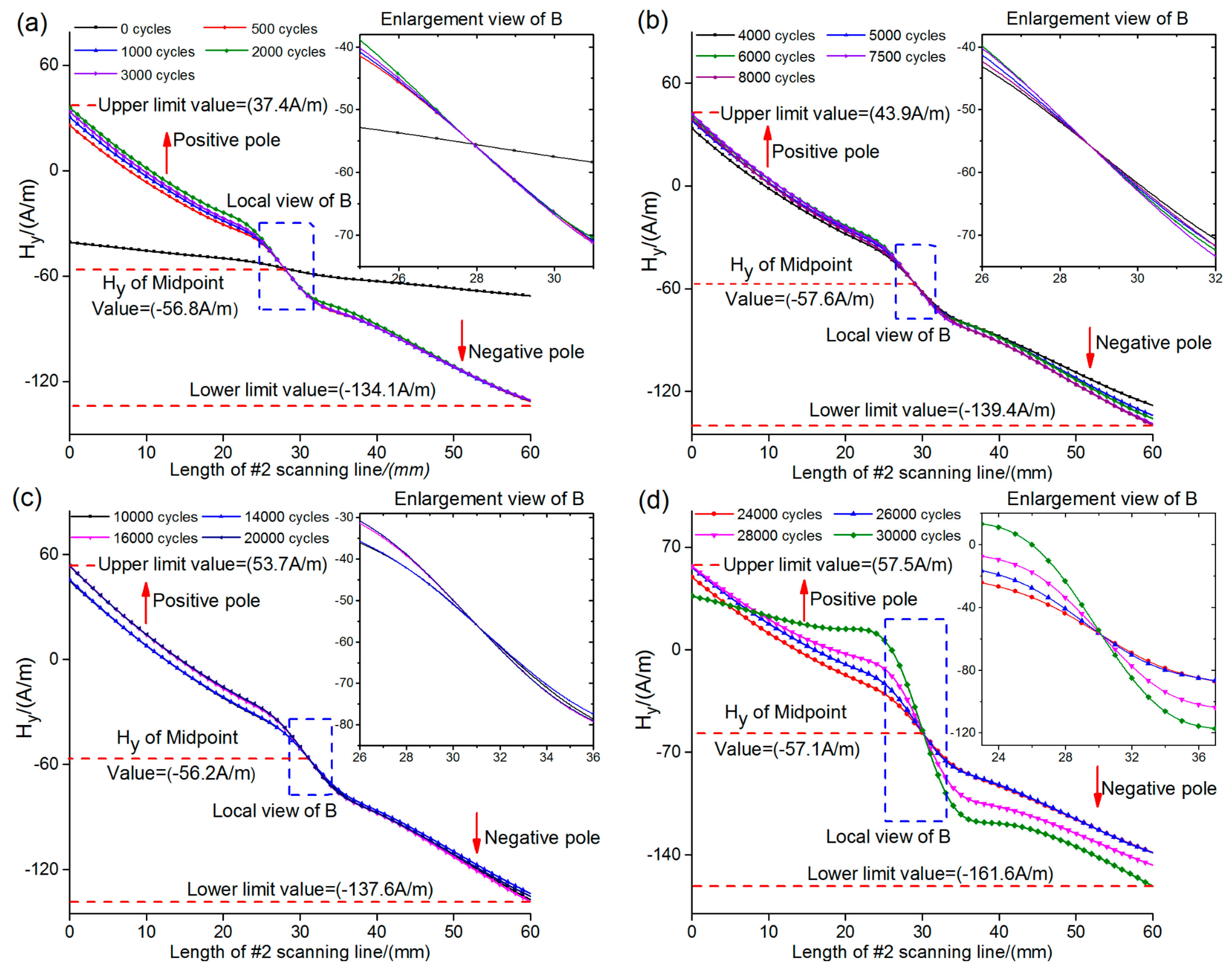

4.2. Relationship between Magnetic Memory Signals and Fatigue Loading Cycles

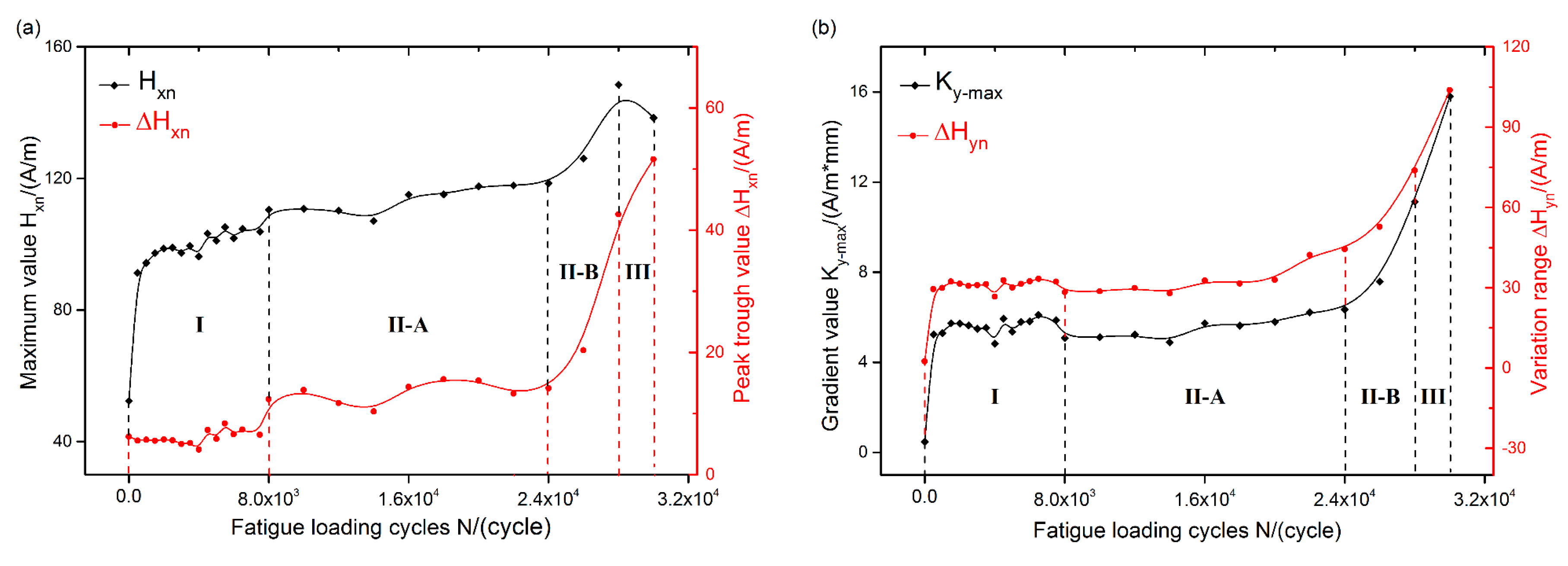

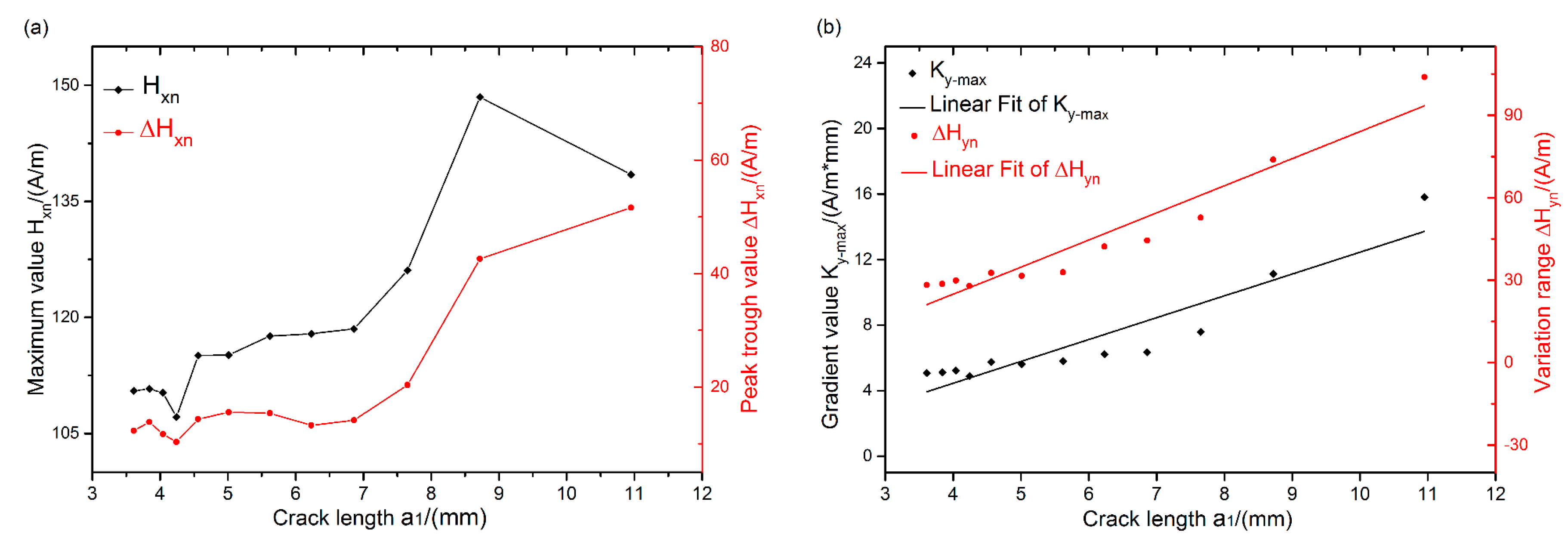

4.3. Relationship between Characteristic Parameters and Fatigue Loading Cycles, Fatigue Crack Length

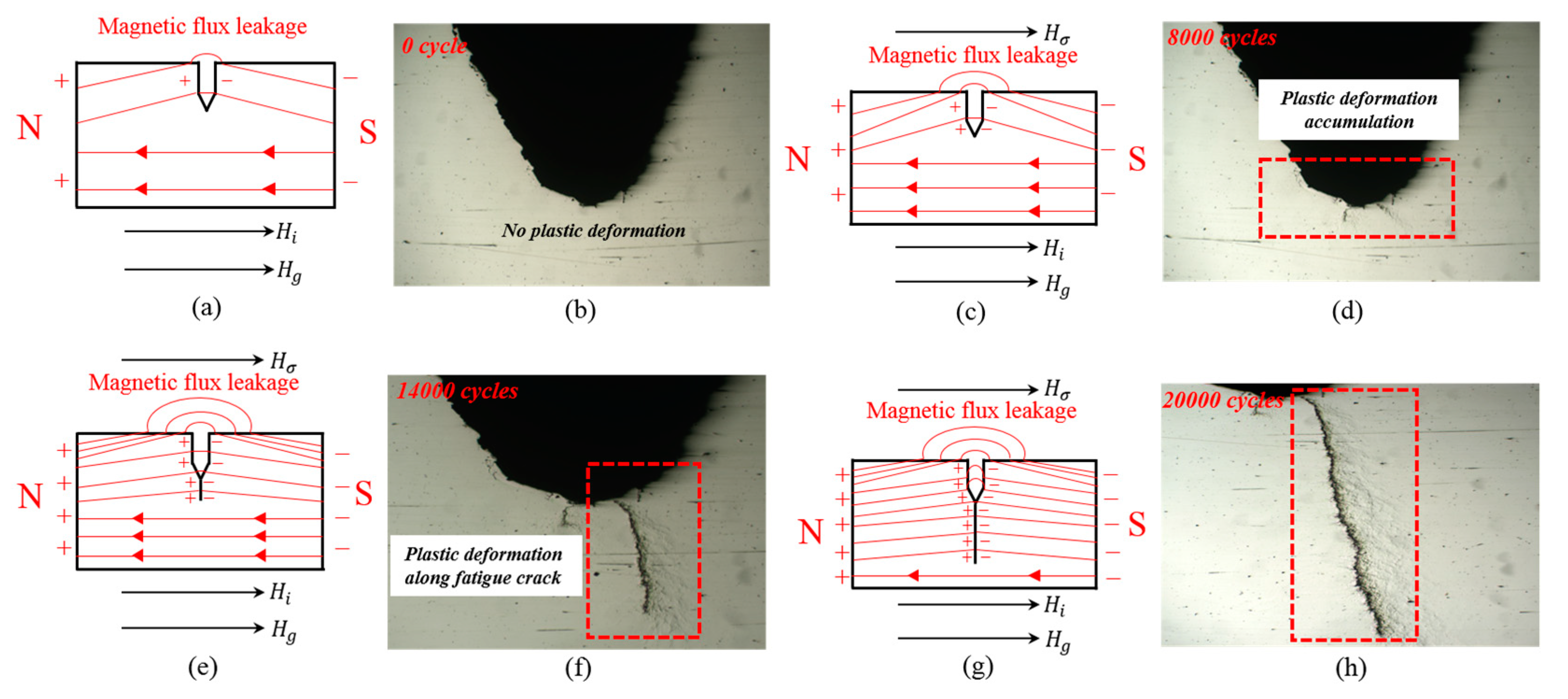

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schneider, B.; Beber, V.C. An experimental investigation of the fatigue damage behaviour of adhesively bonded joints under the combined effect of variable amplitude stress and temperature variation. Int. J. Adhes. Adhes. 2018, 83, 41–49. [Google Scholar] [CrossRef]

- Xu, L.Y.; Zhao, L. A novel creep-fatigue interaction damage model with the stress effect to simulate the creep-fatigue crack growth behavior. Int. J. Mech. Sci. 2017, 130, 143–153. [Google Scholar] [CrossRef]

- Devaney, R.J.; O’Donoghue, P.E. Experimental characterisation and computational modelling for cyclic elastic-plastic constitutive behaviour and fatigue damage of X100Q for steel catenary risers. Int. J. Fatigue 2018, 116, 366–378. [Google Scholar] [CrossRef]

- Holt, J.; Goddard, D.J. Methods of measurement and assessment of acoustic emission activity from the deformation of low alloy steels. Ndt E Int. 1981, 14, 49–58. [Google Scholar] [CrossRef]

- Wang, Y.J.; Liu, X.C. Dipole modeling of stress-dependent magnetic flux leakage. Ndt E Int. 2018, 95, 1–8. [Google Scholar] [CrossRef]

- Dubov, A.A. A study of metal properties using the method of magnetic memory. Metal Sci. Heat Treat. 1997, 39, 401–405. [Google Scholar] [CrossRef]

- Dubov, A.; Dubov, A. Application of the metal magnetic memory method for detection of defects at the initial stage of their development for prevention of failures of power engineering welded steel structures and steam turbine parts. Weld. World 2014, 58, 225–236. [Google Scholar] [CrossRef]

- Huang, H.H.; Jiang, S.L. Investigation of magnetic memory signals induced by dynamic bending load in fatigue crack propagation process of structural steel. J. Nondestruct. Eval. 2014, 43, 407–412. [Google Scholar] [CrossRef]

- Langman, R. The effect of stress on the magnetization of mild steel at moderate field strengths. IEEE Trans. Magn. 1985, 21, 1314–1320. [Google Scholar] [CrossRef]

- Hauser, H. Energetic model of ferromagnetic hysteresis Isotropic magnetization. J. Appl. Phys. 2004, 96, 2753–2767. [Google Scholar] [CrossRef]

- Misra, A.; Prasad, R.C. A theoretical model for the electromagnetic radiation emission during plastic deformation and crack propagation in metallic materials. Int. J. Fract. 2007, 145, 99–121. [Google Scholar] [CrossRef]

- Shi, C.L.; Dong, S.Y. Stress concentration degree affects spontaneous magnetic signals of ferromagnetic steel under dynamic tension load. Ndt E Int. 2010, 43, 8–12. [Google Scholar]

- Leng, J.C.; Xu, M.Q. Magnetic field variation induced by cyclic bending stress. Ndt E Int. 2009, 42, 410–414. [Google Scholar] [CrossRef]

- Huang, H.H.; Jiang, S.L. Characterization of spontaneous magnetic signals induced by cyclic tensile stress in crack propagation stage. J. Magn. Magn. Mater. 2014, 365, 70–75. [Google Scholar] [CrossRef]

- Li, C.C.; Dong, L.H. Metal magnetic memory technique used to predict the fatigue crack propagation behavior of 0.45%C steel. J. Magn. Magn. Mater. 2016, 405, 150–157. [Google Scholar]

- Chowdhury, P.; Sehitoglu, H. Mechanisms of fatigue crack growth—A critical digest of theoretical developments. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 652–674. [Google Scholar] [CrossRef]

- Hu, Z.; Fan, J. Characteristics of Metal Magnetic Memory Testing of 35CrMo Steel during Fatigue Loading. Metals 2018, 8, 119. [Google Scholar] [CrossRef]

- Jiles, D.C. The effect of compressive plastic deformation on the magnetic properties of AISI 4130 steels with various microstructures. J. Phys. D Appl. Phys. 1988, 21, 1196–1204. [Google Scholar] [CrossRef]

- Jiles, D.C.; Atherton, D.L. Theory of ferromagnetic hysteresis. J. Magn. Magn. Mater. 1986, 61, 48–60. [Google Scholar] [CrossRef]

- Jiles, D.C. Theory of the magneto mechanical effect. J. Phys. D Appl. Phys. 1995, 28, 1537–1546. [Google Scholar] [CrossRef]

- Mandache, C.; Clapham, L. A model for magnetic flux leakage signal predictions. J. Phys. D Appl. Phys. 2003, 36, 2427–2431. [Google Scholar] [CrossRef]

- Liu, B.; Ma, Z.Y. Quantitative study on the propagation characteristics of MMM signal for stress internal detection of long distance oil and gas pipeline. Ndt E Int. 2018, 100, 40–47. [Google Scholar] [CrossRef]

- Le, M.; Lee, J. Hall sensor array based validation of estimation of crack size in metals using magnetic dipole models. Ndt E Int. 2013, 53, 18–25. [Google Scholar] [CrossRef]

- Dutta, S.M.; Ghorbel, F.H. Dipole modeling of magnetic flux leakage. IEEE Trans. Magn. 2009, 45, 1959–1965. [Google Scholar] [CrossRef]

- Lo, C.C.H.; Tang, F. Effects of fatigue-induced changes in microstructure and stress on domain structure and magnetic properties of Fe–C alloys. J. Appl. Phys. 2000, 87, 6520–6522. [Google Scholar] [CrossRef]

- Panda, A.K.; Das, S.K. Evaluation of deformation behavior of HSLA-100 steel using magnetic hysteresis techniques. IEEE Trans. Magn. 2006, 42, 3264–3266. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Mo | Ni | Cr | Cu | Nb | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.07 | 1.39 | 0.21 | 0.011 | 0.002 | 0.003 | 0.255 | 0.223 | 0.129 | 0.082 | 0.015 | 0.035 |

| Steel | σ0.2 (MPa) | σb (MPa) | ψ | σ0.2/σb |

|---|---|---|---|---|

| API 5L X80 | 650.9 | 694.8 | 71% | 0.94 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Fan, J.; Ni, J.; Liu, S. Variation of Magnetic Memory Signals in Fatigue Crack Initiation and Propagation Behavior. Metals 2019, 9, 89. https://doi.org/10.3390/met9010089

Zhou W, Fan J, Ni J, Liu S. Variation of Magnetic Memory Signals in Fatigue Crack Initiation and Propagation Behavior. Metals. 2019; 9(1):89. https://doi.org/10.3390/met9010089

Chicago/Turabian StyleZhou, Wei, Jianchun Fan, Jinlu Ni, and Shujie Liu. 2019. "Variation of Magnetic Memory Signals in Fatigue Crack Initiation and Propagation Behavior" Metals 9, no. 1: 89. https://doi.org/10.3390/met9010089

APA StyleZhou, W., Fan, J., Ni, J., & Liu, S. (2019). Variation of Magnetic Memory Signals in Fatigue Crack Initiation and Propagation Behavior. Metals, 9(1), 89. https://doi.org/10.3390/met9010089