Effect of Temperature and Texture on Hall–Petch Strengthening by Grain and Annealing Twin Boundaries in the MnFeNi Medium-Entropy Alloy

Abstract

1. Introduction

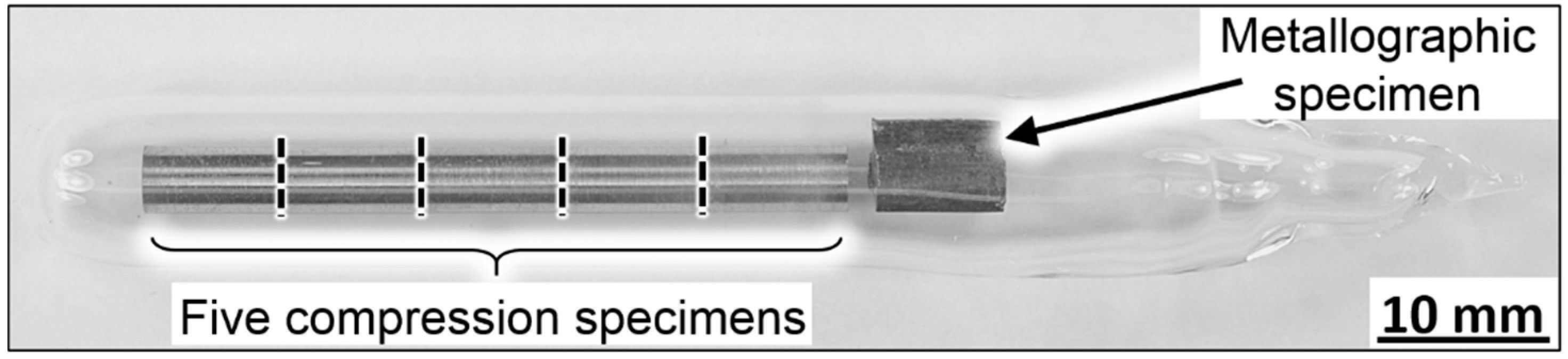

2. Experimental Methods

3. Results

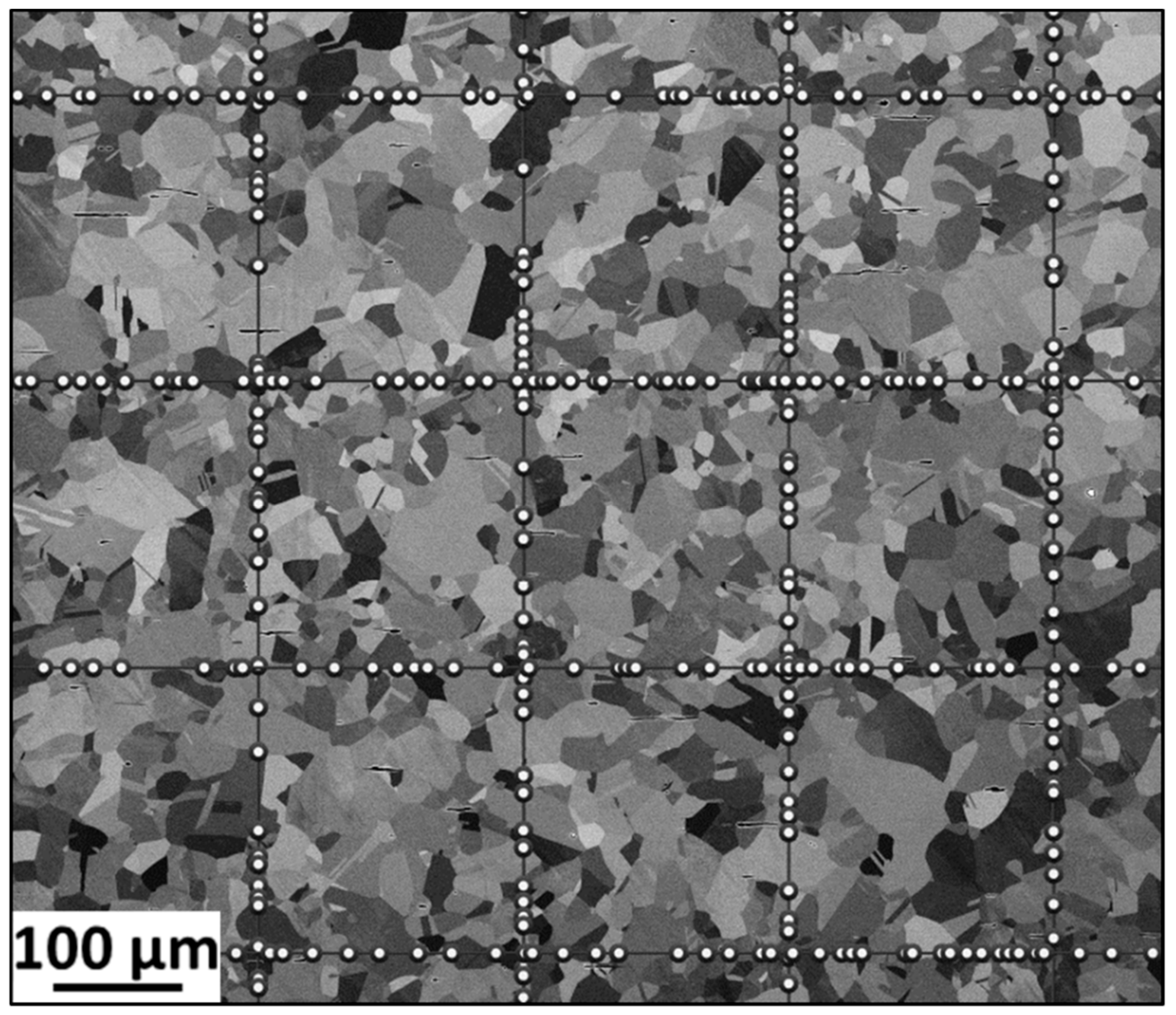

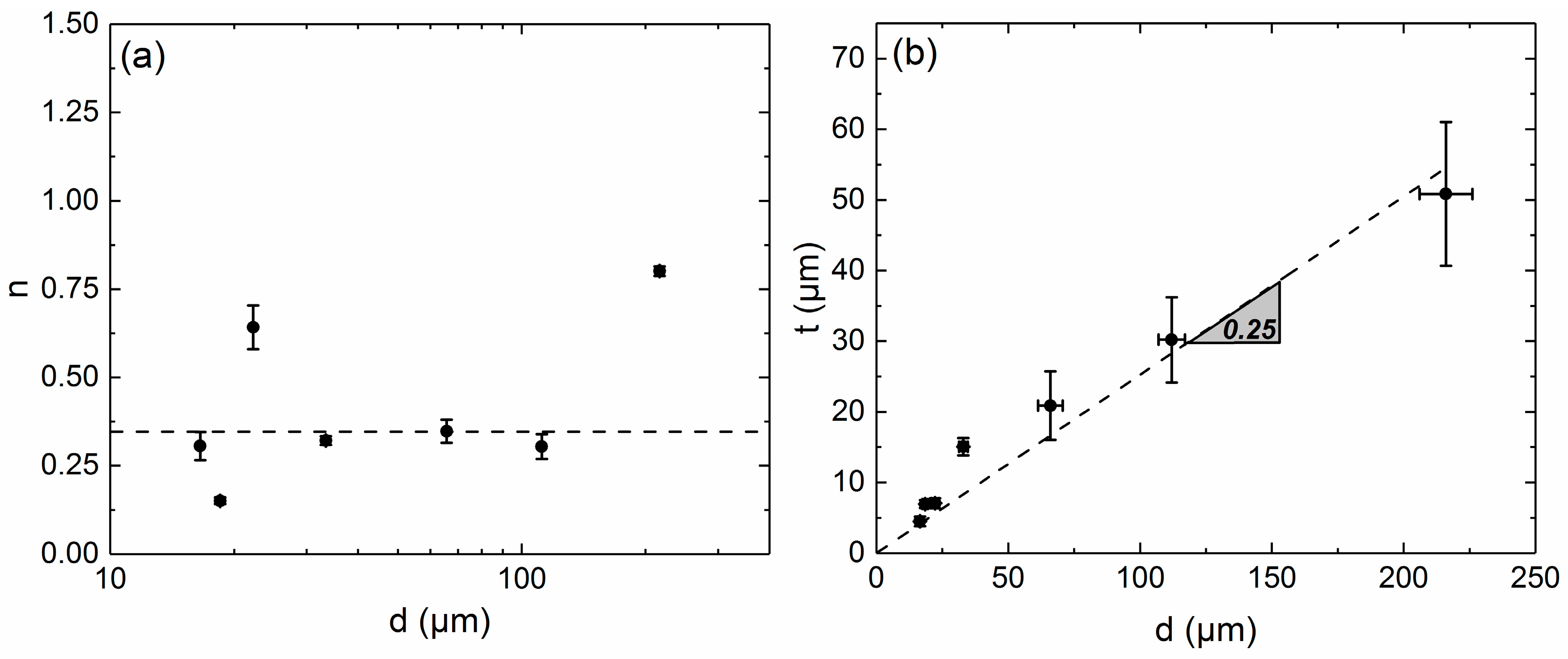

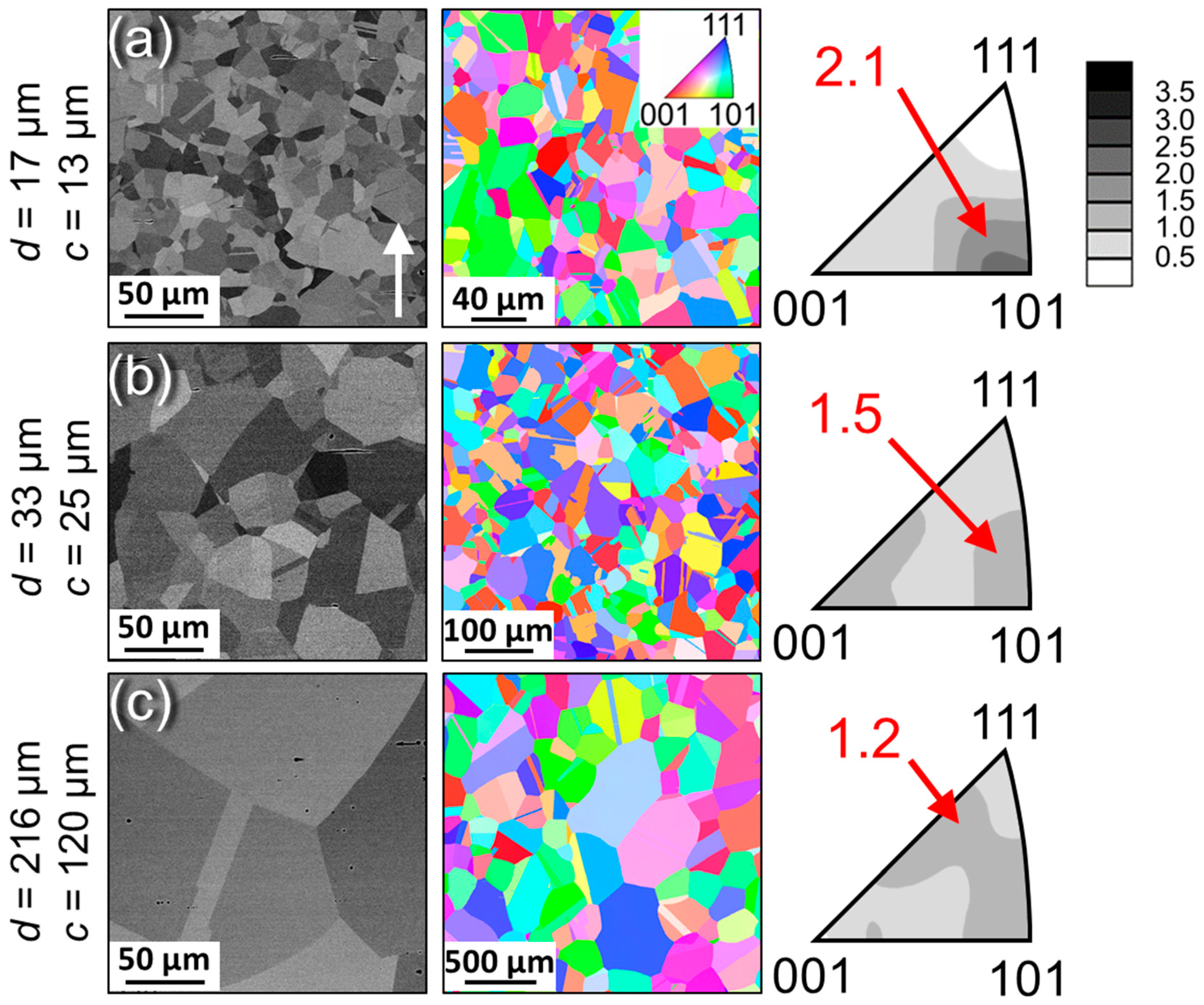

3.1. Grain and Crystallite Sizes

3.2. Texture

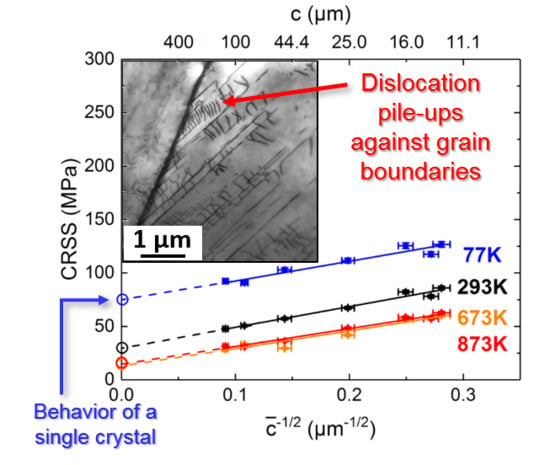

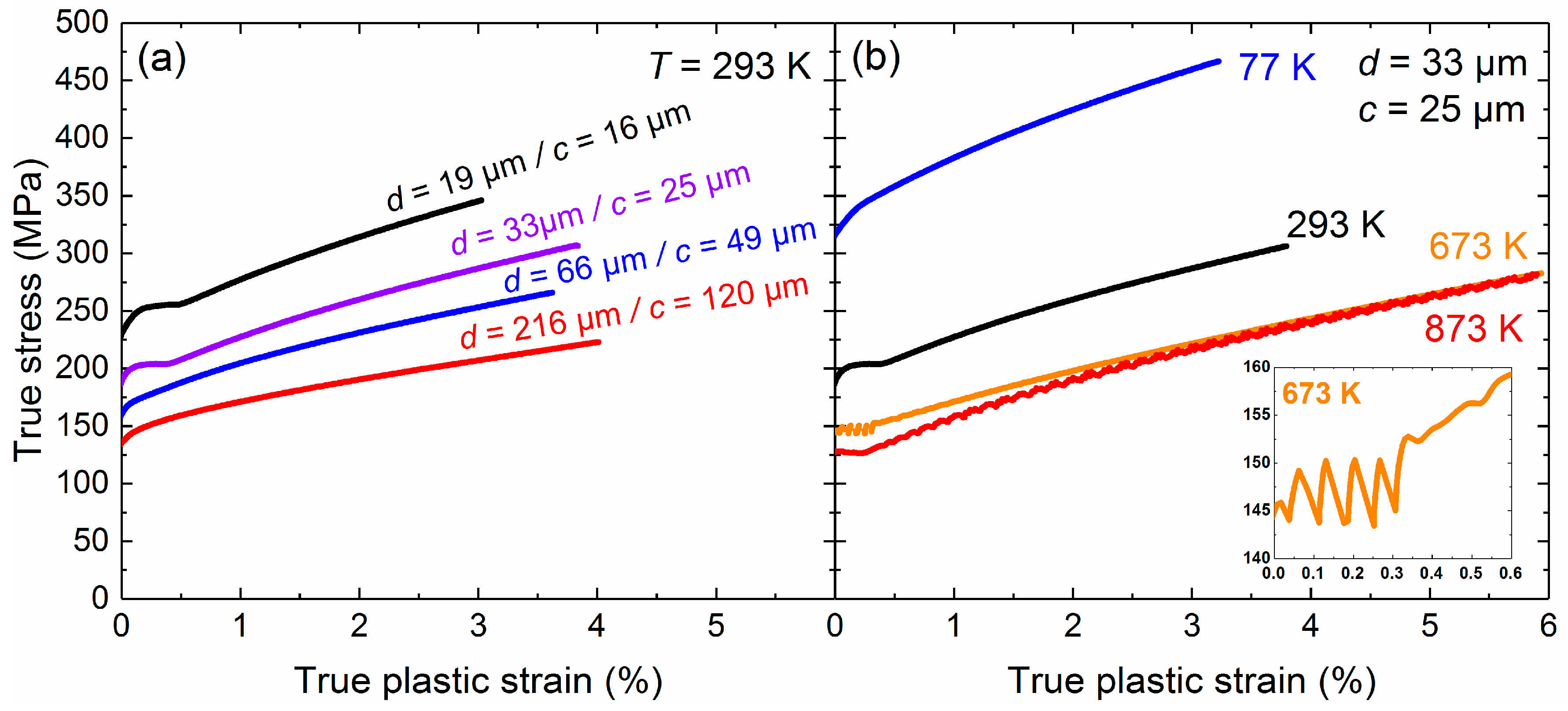

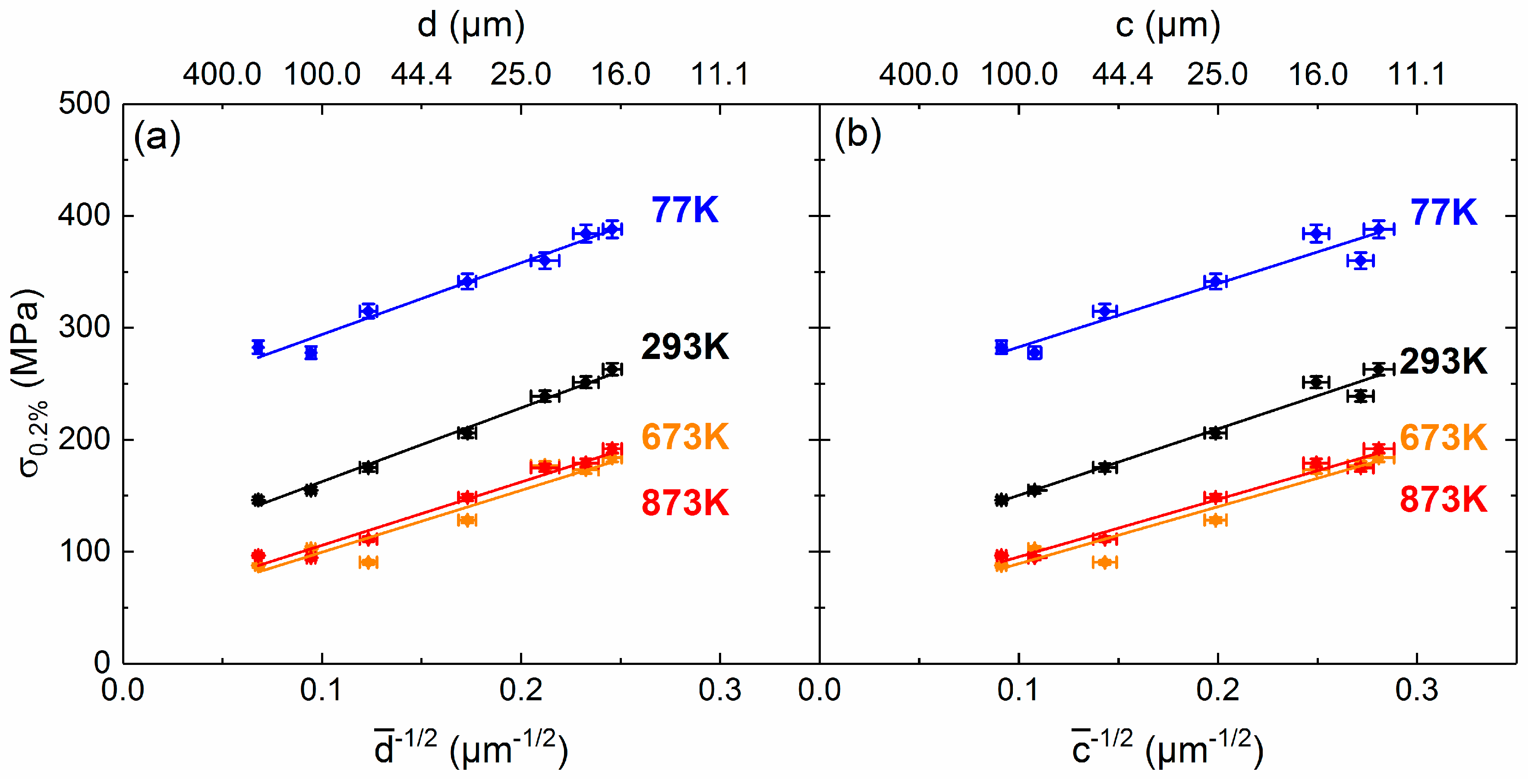

3.3. Effects of Grain Size and Temperature on Yield Stress

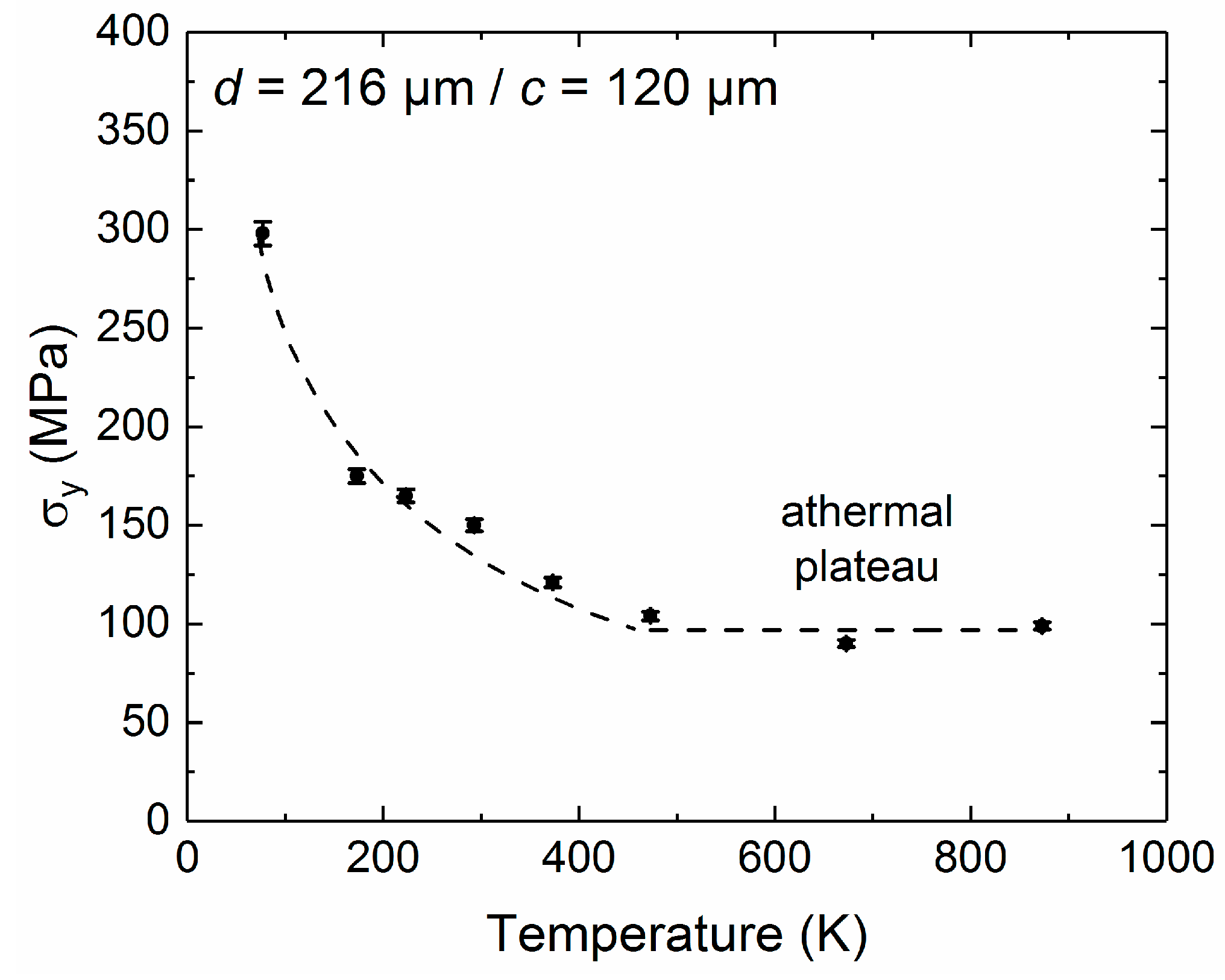

3.4. Temperature Dependence of the Yield Stress

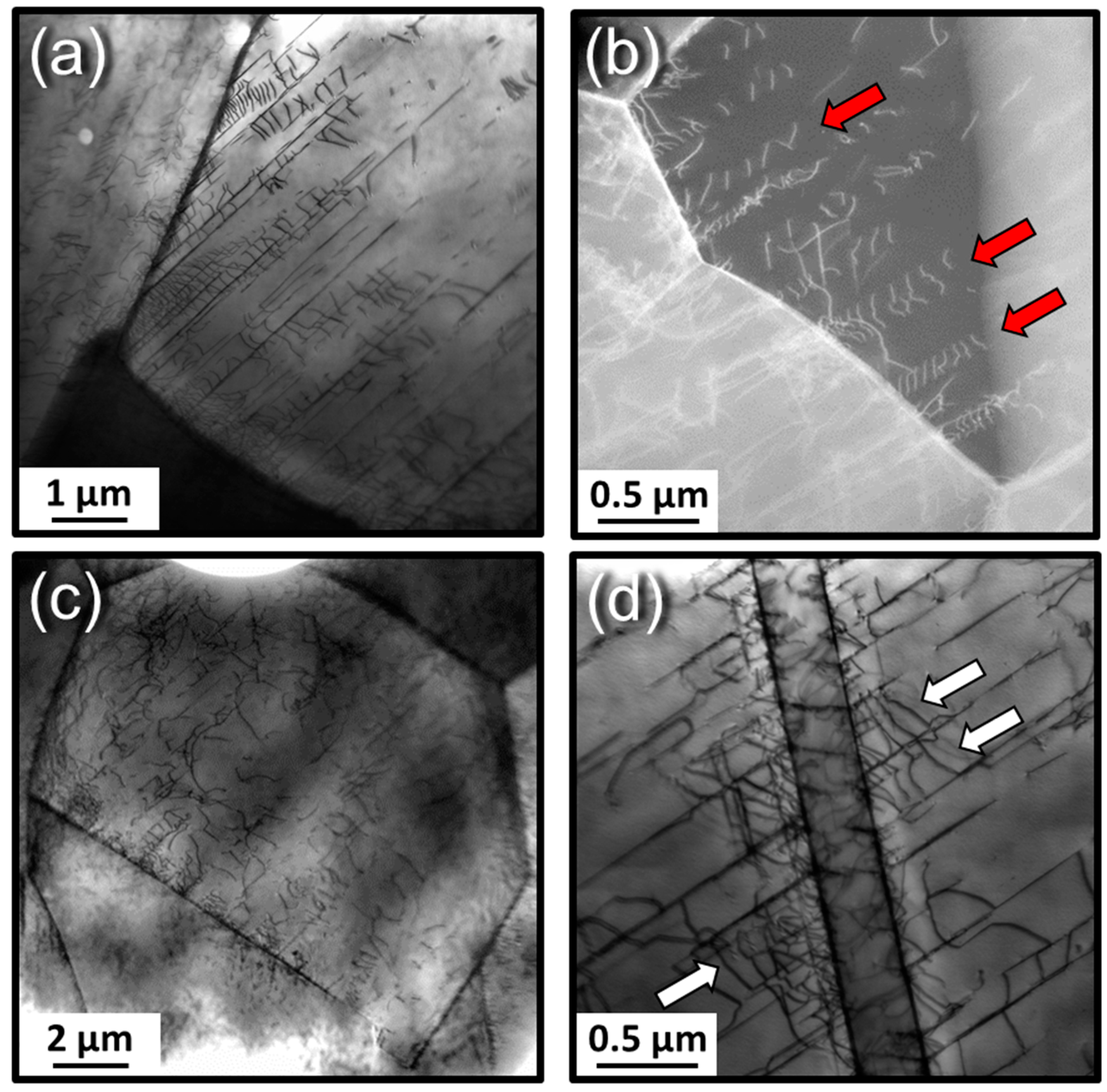

3.5. STEM Analyses of Grain and Annealing Twin Boundaries

4. Discussion

5. Conclusions

- For all investigated grain/crystallite sizes, it has been found that the average number of annealing twin boundaries per grain in MnFeNi is approximately 0.35 ± 0.1. This value is relatively low compared to other high- and medium-entropy alloys from the Cr-Mn-Fe-Co-Ni system.

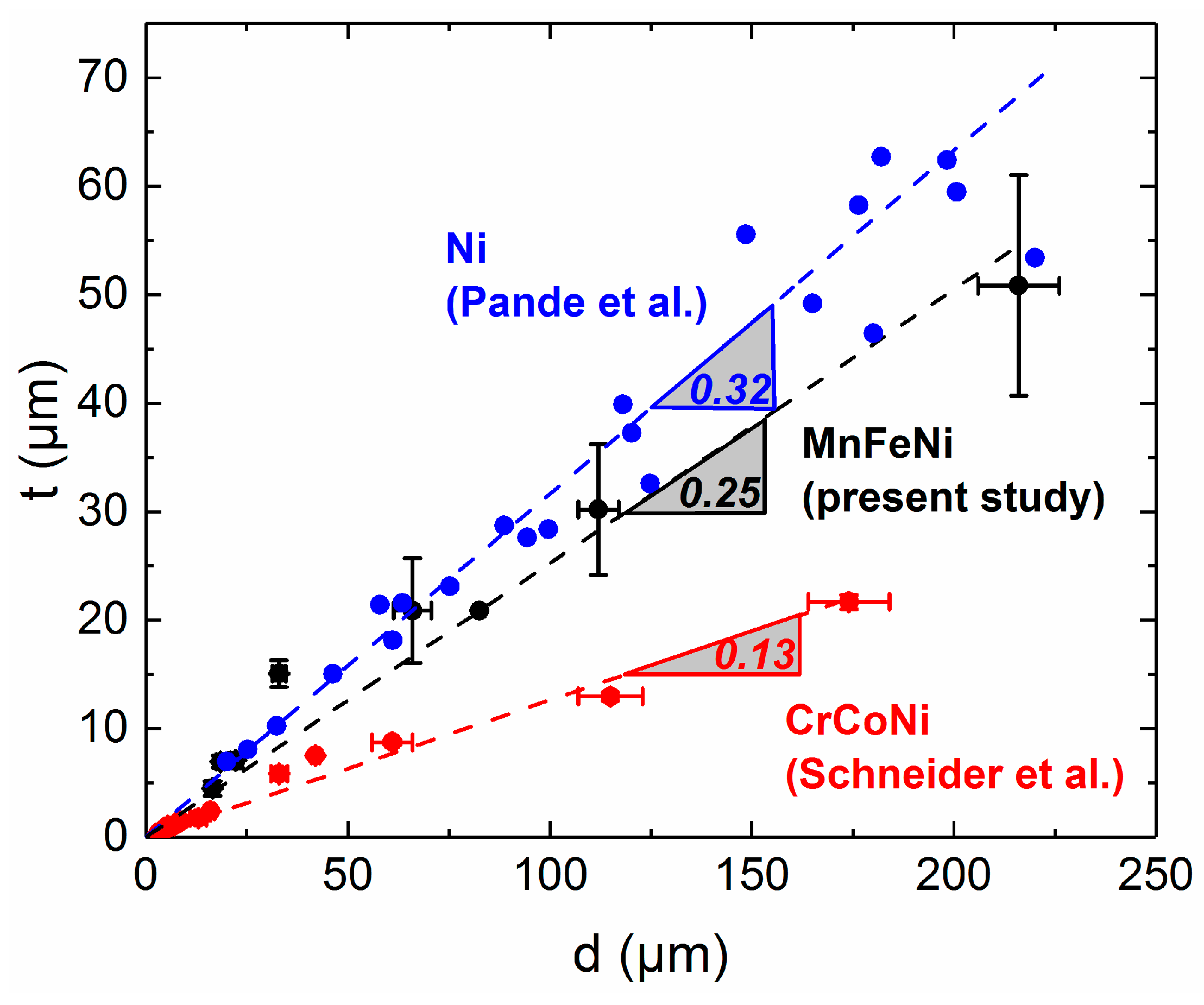

- When two twin boundaries forming an annealing twin are present in one grain, its average thickness is found to increase linearly with increasing grain size with a slope of 0.25 ± 0.2. Based on the model developed by Dash and Brown [43], we estimated a stacking fault energy of 80 ± 20 mJ/m2 for MnFeNi.

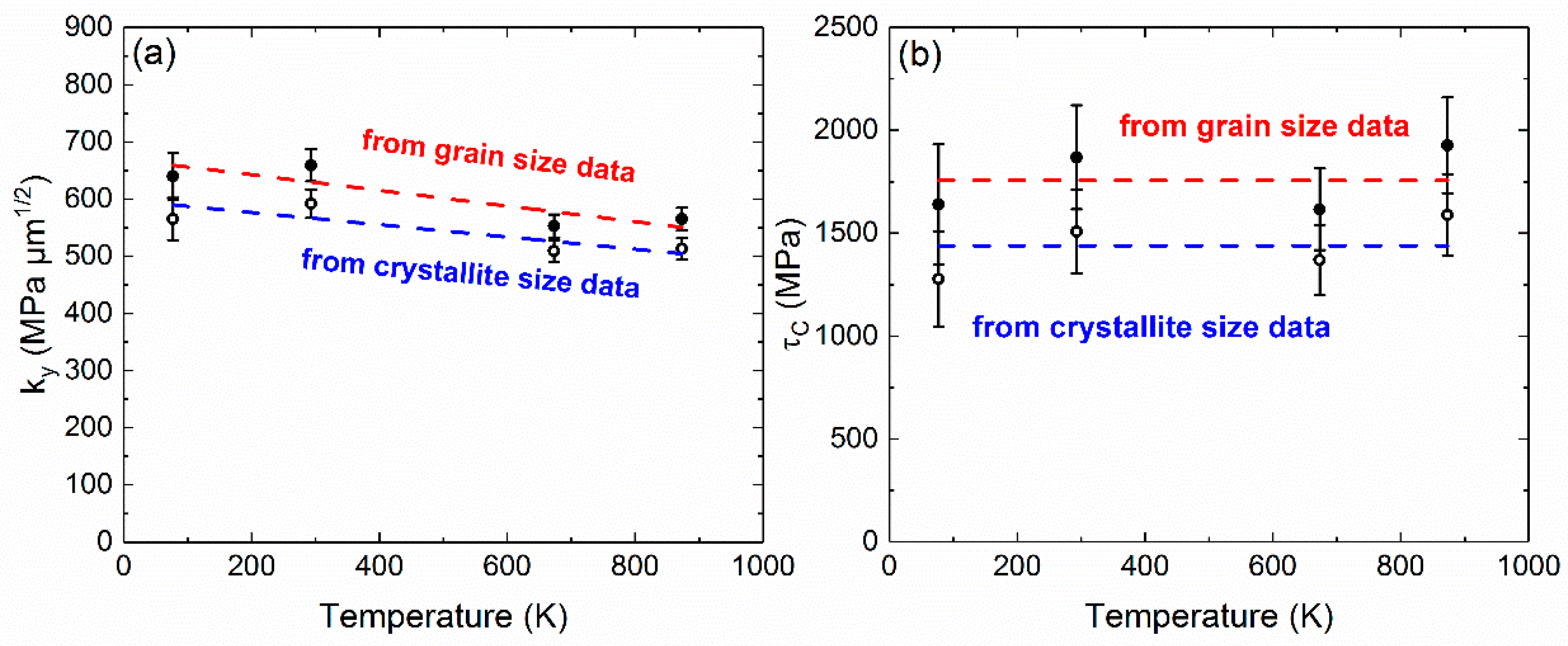

- The strength of the MnFeNi alloy follows the well-known Hall–Petch relationship for both grain and crystallite sizes, i.e., it increases with decreasing grain/crystallite sizes. Regarding the effect of temperature on the slope of the Hall–Petch lines, it was found that it slightly decreases (~15%) with increasing temperature in the range between 77 and 873 K.

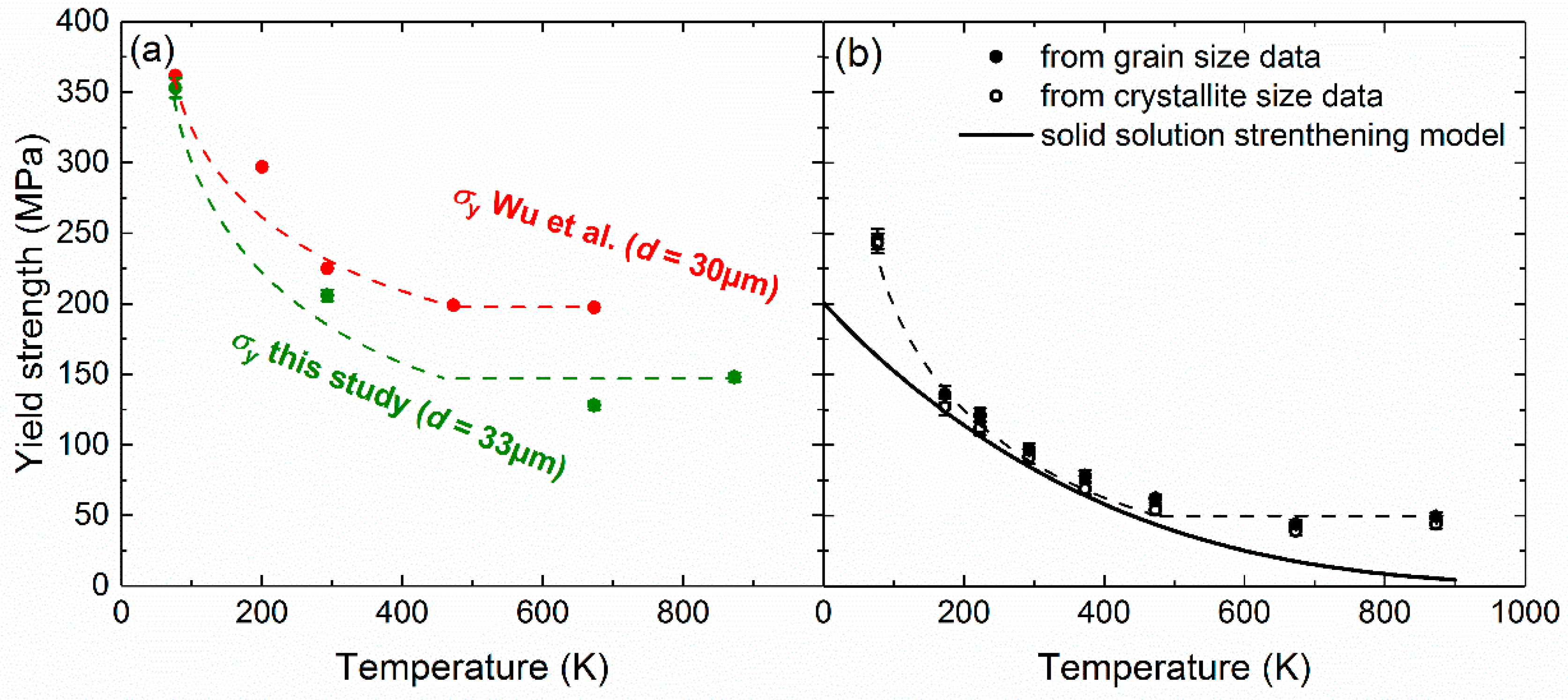

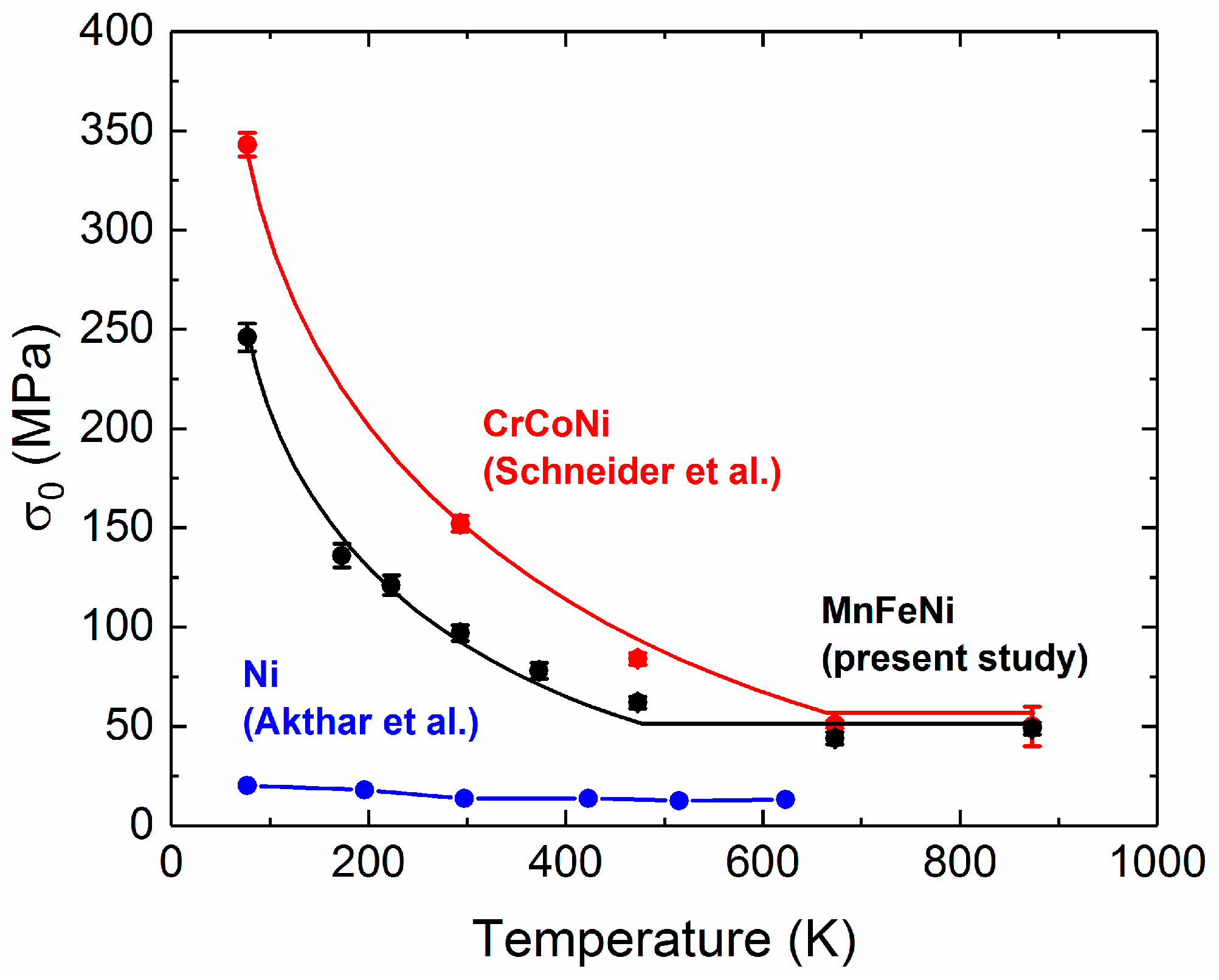

- The yield strength of a polycrystal with an infinite grain size (~ single crystal behavior) strongly decreases with increasing temperature. This temperature dependence can be rationalized in the frame of a solid solution strengthening model reported in the literature [47] for 173 K < T < 473 K. Above 473 K, an athermal plateau is reached.

- STEM analyses reveal that pile-ups form at both grain and annealing twin boundaries. However, pile-ups against annealing twins seems to be shorter than against grain boundaries which may indicate that annealing twins are less resistant than grain boundaries against dislocation motion.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, Y.-L.; Lin, S.-J.; Chen, S.-K. High-entropy Alloys—A New Era of Exploitation. Mater. Sci. Forum 2007, 560, 1–9. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Laurent-Brocq, M.; Akhatova, A.; Perrière, L.; Chebini, S.; Sauvage, X.; Leroy, E.; Champion, Y. Insights into the phase diagram of the CrMnFeCoNi high entropy alloy. Acta Mater. 2015, 88, 355–365. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Couzinié, J.P.; Dirras, G.; Perrière, L.; Chauveau, T.; Leroy, E.; Champion, Y.; Guillot, I. Microstructure of a near-equimolar refractory high-entropy alloy. Mater. Lett. 2014, 126, 285–287. [Google Scholar] [CrossRef]

- Dobbelstein, H.; Gurevich, E.L.; George, E.P.; Ostendorf, A.; Laplanche, G. Laser metal deposition of a refractory TiZrNbHfTa high-entropy alloy. Addit. Manuf. 2018, 24, 386–390. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Thurston, K.V.S.; Gludovatz, B.; Hohenwarter, A.; Laplanche, G.; George, E.P.; Ritchie, R.O. Effect of temperature on the fatigue-crack growth behavior of the high-entropy alloy CrMnFeCoNi. Intermetallics 2017, 88, 65–72. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Laplanche, G.; Gadaud, P.; Bärsch, C.; Demtröder, K.; Reinhart, C.; Schreuer, J.; George, E.P. Elastic moduli and thermal expansion coefficients of medium-entropy subsystems of the CrMnFeCoNi high-entropy alloy. J. Alloys Compd. 2018, 746, 244–255. [Google Scholar] [CrossRef]

- Shiga, M. Invar alloys. Curr. Opin. Solid State Mater. Sci. 1996, 1, 340–348. [Google Scholar] [CrossRef]

- Hausch, G. Thermal expansion of anti-invar alloys up to high temperatures. J. Magn. Magn. Mater. 2007, 310, 1859–1860. [Google Scholar] [CrossRef]

- Liu, W.H.; Wu, Y.; He, J.Y.; Nieh, T.G.; Lu, Z.P. Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Sun, S.J.; Tian, Y.Z.; Lin, H.R.; Dong, X.G.; Wang, Y.H.; Zhang, Z.J.; Zhang, Z.F. Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure. Mater. Des. 2017, 133, 122–127. [Google Scholar] [CrossRef]

- Yoshida, S.; Bhattacharjee, T.; Bai, Y.; Tsuji, N. Friction stress and Hall-Petch relationship in CoCrNi equiatomic medium entropy alloy processed by severe plastic deformation and subsequent annealing. Scr. Mater. 2017, 134, 33–36. [Google Scholar] [CrossRef]

- Schneider, M.; George, E.P.; Manescau, T.J.; Záležák, T.; Hunfeld, J.; Dlouhý, A.; Eggeler, G.; Laplanche, G. Hall-Petch strengthening of the CrCoNi medium-entropy alloy by grain boundaries and annealing twin boundaries. manuscript in preparation.

- Klimova, M.; Stepanov, N.; Shaysultanov, D.; Chernichenko, R.; Yurchenko, N.; Sanin, V.; Salishchev, G. Microstructure and Mechanical Properties Evolution of the Al, C-Containing CoCrFeNiMn-Type High-Entropy Alloy during Cold Rolling. Materials 2018, 11, 53. [Google Scholar] [CrossRef] [PubMed]

- Stepanov, N.; Tikhonovsky, M.; Yurchenko, N.; Zyabkin, D.; Klimova, M.; Zherebtsov, S.; Efimov, A.; Salishchev, G. Effect of cryo-deformation on structure and properties of CoCrFeNiMn high-entropy alloy. Intermetallics 2015, 59, 8–17. [Google Scholar] [CrossRef]

- Holcomb, G.; Tylczak, J.; Carney, C. Oxidation of CoCrFeMnNi High Entropy Alloys. JOM 2015, 67, 2326–2339. [Google Scholar] [CrossRef]

- Laplanche, G.; Volkert, U.F.; Eggeler, G.; George, E.P. Oxidation Behavior of the CrMnFeCoNi High-Entropy Alloy. Oxid. Met. 2016, 85, 629–645. [Google Scholar] [CrossRef]

- Adomako, N.K.; Kim, J.H.; Hyun, Y.T. High-temperature oxidation behaviour of low-entropy alloy to medium- and high-entropy alloys. J. Therm. Anal. Calorim. 2018, 133, 13–16. [Google Scholar] [CrossRef]

- Dieter, G.E.; Bacon, D.J. Strengthening Mechanisms. Mechanical Metallurgy, 3rd ed.; McGraw-Hill: London, UK, 1989; ISBN 0-07-100406-8. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM E112-10: Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Nakanishi, K.; Suzuki, H. Analysis of the Grain Size Dependence of the Yield Stress in Copper-Aluminum and Copper-Nickel Alloys. J. Jpn. Inst. Met. 1974, 15, 435–440. [Google Scholar] [CrossRef][Green Version]

- Ueji, R.; Tsuchida, N.; Fujii, H.; Kondo, D.; Kunishige, K. Effect of Grain Size on Tensile Properties of TWIP Steel. J. Jpn. Inst. Met. 2007, 71, 815–821. [Google Scholar] [CrossRef][Green Version]

- Okamoto, N.L.; Fujimoto, S.; Kambra, Y.; Kawamura, M.; Chen, Z.M.T.; Matsunoshita, H.; Tanaka, K.; Inui, H.; George, E.P. Size effect, critical resolved shear, stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. Sci. Rep. 2016, 6, 1–10. [Google Scholar] [CrossRef]

- Köster, W.; Speidel, M.O. Der Einfluß der Temperatur und der Korngröße auf die ausgeprägte Streckgrenze von Kupferlegierungen. Zeitschrift für Metallkunde 1965, 56, 585–595. (In German) [Google Scholar]

- Tabata, T.; Takagi, K.; Fujita, H. The Effect of Grain Size and Deformation Sub-structure on Mechanical Properties of Polycrystalline Copper and Cu-Al Alloys. J. Jpn. Inst. Met. 1975, 16, 569–579. [Google Scholar] [CrossRef]

- Priester, L. “Dislocation-interface” interaction—Stress accommodation processes at interfaces. Mater. Sci. Eng. A 2001, 309–310, 430–439. [Google Scholar] [CrossRef]

- Pande, C.S.; Rath, B.B.; Imam, M.A. Effect of annealing twins on Hall-Petch relation in polycrystalline materials. Mater. Sci. Eng. A 2004, 367, 171–175. [Google Scholar] [CrossRef]

- De las Cuevas, F.; Reis, M.; Ferraiuolo, A.; Pratolongo, G.; Karjalainen, L.P.; Alkorta, J.; Sevillani, J.G. Hall-Petch relationship of a TWIP steel. Key Eng. Mater. 2010, 423, 147–152. [Google Scholar] [CrossRef]

- Kacher, J.; Eftink, B.P.; Cui, B.; Robertson, I.M. Dislocation interactions with grain boundaries. Curr. Opin. Solid State Mater. Sci. 2017, 18, 227–243. [Google Scholar] [CrossRef]

- Suzuki, H. Chemical Interaction of Solute Atoms with Dislocations. Sci. Rep. Res. Inst. Tohoku Univ. 1952, 4, 455–463. [Google Scholar]

- Cottrell, A.H.; Bilby, B.A. Dislocation theory of yielding and strain ageing of iron. Proc. Phys. Soc. Lond. Sect. A 1949, 62, 49–62. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Pande, C.S.; Imam, M.A.; Rath, B.B. Study of Annealing Twins in FCC Metals and Alloys. Metall. Trans. A 1990, 21, 2891–2896. [Google Scholar] [CrossRef]

- Dash, S.; Brown, N. An investigation of the origin and growth of annealing twins. Acta Mater. 1963, 11, 1067–1075. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Carter, C.B.; Holmes, S.M. The stacking-fault energy of nickel. Philos. Mag. J. Theor. Exp. Appl. Phys. 1977, 35, 1161–1172. [Google Scholar] [CrossRef]

- Eshelby, J.D.; Frank, F.C.; Nabarro, F.R.N. XLI. The equilibrium of linear arrays of dislocations. Lond. Edinburgh Dublin Philos. Mag. J. Sci. 1951, 42, 351–364. [Google Scholar] [CrossRef]

- Varvenne, C.; Luque, A.; Curtin, W.A. Theory of strengthening in fcc high entropy alloys. Acta Mater. 2016, 118, 164–176. [Google Scholar] [CrossRef]

- Laplanche, G.; Bonneville, J.; Varvenne, C.; Curtin, W.A.; George, E.P. Thermal activation parameters of plastic flow reveal deformation mechanisms in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2018, 143, 257–264. [Google Scholar] [CrossRef]

- Varvenne, C.; Curtin, W.A. Predicting yield strengths of noble metal high entropy alloys. Scr. Mater. 2018, 142, 92–95. [Google Scholar] [CrossRef]

- Akhtar, A.; Teghtsoonian, E. Plastic deformation of Ni-Cr single crystals. Metall. Trans. 1971, 2, 2757–2763. [Google Scholar] [CrossRef]

| T (K) | Time (min) | d (µm) | c (µm) | n (-) | t (µm) | Magnification |

|---|---|---|---|---|---|---|

| 1073 | 45 | 17 ± 1 | 13 ± 1 | 0.3 | 4.5 | 250 |

| 1073 | 60 | 19 ± 1 | 16 ± 1 | 0.1 | 7.0 | 150 |

| 1073 | 120 | 22 ± 2 | 14 ± 1 | 0.6 | 7.0 | 200 |

| 1173 | 60 | 33 ± 2 | 25 ± 1 | 0.3 | 15 | 100 |

| 1273 | 60 | 66 ± 2 | 49 ± 4 | 0.3 | 21 | 75 |

| 1373 | 30 | 112 ± 5 | 86 ± 6 | 0.3 | 30 | 75 |

| 1473 | 60 | 216 ± 10 | 120 ± 8 | 0.8 | 51 | 70 |

| Grain/Crystallite Sizes | T (K) | σ0 (MPa) | ky (MPa µm1/2) |

|---|---|---|---|

| d | 77 | 230 ± 7 | 640 ± 40 |

| 293 | 97 ± 4 | 660 ± 30 | |

| 673 | 44 ± 3 | 550 ± 20 | |

| 873 | 49 ± 3 | 570 ± 20 | |

| c | 77 | 226 ± 7 | 570 ± 40 |

| 293 | 91 ± 4 | 590 ± 25 | |

| 673 | 38 ± 3 | 510 ± 20 | |

| 873 | 44 ± 3 | 515 ± 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schneider, M.; Werner, F.; Langenkämper, D.; Reinhart, C.; Laplanche, G. Effect of Temperature and Texture on Hall–Petch Strengthening by Grain and Annealing Twin Boundaries in the MnFeNi Medium-Entropy Alloy. Metals 2019, 9, 84. https://doi.org/10.3390/met9010084

Schneider M, Werner F, Langenkämper D, Reinhart C, Laplanche G. Effect of Temperature and Texture on Hall–Petch Strengthening by Grain and Annealing Twin Boundaries in the MnFeNi Medium-Entropy Alloy. Metals. 2019; 9(1):84. https://doi.org/10.3390/met9010084

Chicago/Turabian StyleSchneider, Mike, Felicitas Werner, Dennis Langenkämper, Christian Reinhart, and Guillaume Laplanche. 2019. "Effect of Temperature and Texture on Hall–Petch Strengthening by Grain and Annealing Twin Boundaries in the MnFeNi Medium-Entropy Alloy" Metals 9, no. 1: 84. https://doi.org/10.3390/met9010084

APA StyleSchneider, M., Werner, F., Langenkämper, D., Reinhart, C., & Laplanche, G. (2019). Effect of Temperature and Texture on Hall–Petch Strengthening by Grain and Annealing Twin Boundaries in the MnFeNi Medium-Entropy Alloy. Metals, 9(1), 84. https://doi.org/10.3390/met9010084