Abstract

Porous titanium samples with a porosity of 1.34~15.54% were prepared by a spark plasma sintering (SPS) process at sintering temperatures of 800 °C, 850 °C and 900 °C, and a sintering pressure of 10 MPa. The microstructures and fracture morphology of the samples were investigated by scanning electron microscopy (SEM) and X-ray diffraction (XRD) analyses. The compressive strength and elastic modulus were likewise measured. The results showed that no new phase occurred after the samples were sintered, and the main phases were α phase of hcp structure. The porosity of the samples decreased significantly with the increase of sintering temperature. At 800 °C, the sample phase was dominated by equiaxed α. There were more irregular coarse pores in the samples. At 850 °C, the microstructure was mainly zigzag α, and the pores were finely and relatively uniform in distribution. At 900 °C, the sample’s structure transformed into a dense sheet-like α. The sample’s densities increased and the pores disappeared. The room temperature compression test showed that the porous titanium sintered by SPS had excellent compressive strength. The yield strength, compressive strength, compressive strain and elastic modulus were 81.85~122.36 MPa, 161.65~498.86 MPa, 36.75~59.97% and 2.79~4.22 GPa, respectively.

1. Introduction

Triton (T) and deuterium (D) are important thermonuclear fusion materials. The thermonuclear fusion reaction energy of T and D, and the safe storage of nuclear components of T storage are extremely important in the field of national defense security [1,2]. As a storage material of T- and D-based thermonuclear fusion reaction energy, helium produced by T decay gathers at the grain boundary. Concentrations exceeding the critical threshold eventually lead to material failure [3,4,5]. Therefore, developing new materials for the storage of T and H has important strategic significance and economic value. So far, pure titanium has the highest hydrogen-absorbing density among metal materials [6,7]. It has been used as a hydrogen storage material and storage target. Studies have shown that fine-grained materials have superior storage properties. For example, Pang H.C. [8] et al. found that nanocrystalline titanium films with a grain size of 10~20 nm have He/Ti atomic ratios of up to 35%~48% and fine-grained Ti materials have a storage capacity that is much higher than that of coarse-grained material. At the same time, due to the interfacial effect, the introduction of pores is expected to further improve the storage properties of H but the high porosity often degrades the mechanical properties of the material.

Spark plasma sintering (SPS) is a sintering process that integrates plasma activation, resistance heating and hot pressing; it is consistent with the traditional powder metallurgy process [9,10,11,12]. The sintering process is also divided into the initial stage of sintering, the middle stage and the final stage. First, the on–off DC pulse current in the initial stage of sintering forms a plasma between the particles. At this time, a spark discharge occurs on the surface of the particle, and the plasma activates the surface of the particle, accelerating the contact of the particle from the physical meshing to the metallurgical bonding process, the axial pressure will force the powder to be discharged and increase the contact area between the particles. The medium-term current will be shunted from the large contact area of the particles to the small contact area. Simultaneously, a large amount of Joule heat will be generated to promote the formation of the sintered neck and grow up. The final-term the plasma circuit is turned off, the sample is densified by the Joule heat and pressure generated by the direct current. At present, due to the SPS process has the advantages of rapid heating rate, low sintering temperature, short sintering time and short sintering cycle. Moreover, the sample prepared by SPS has a uniform microstructure, fine grain size, high density and excellent mechanical properties, and some scholars have already carried out the work of SPS to prepare titanium alloy [11,13,14,15]. Zhang L. et al. used ammonium bicarbonate (NH4HCO3) as a space-holder to mix with non-spherical titanium powder, prepared porous titanium with a porosity of 38~56% and a pore diameter of 50~500 μm by SPS [16]. Guo Y. et al. used the SPS technology to prepare a titanium-based tricalcium phosphate composite [17]. Miriyev A. et al. used SPS technology to study the combination of Ti-6Al-4V and low alloy steel (AISI4330) in the temperature range of 850~950 °C [18]. The SPS technology is expected to produce porous titanium with more fine grains, many grain boundaries, high specific surface area, and excellent mechanical properties. It presents a new idea for the preparation of porous titanium with an interfacial structure effect and raises the critical threshold of T and H material storage [19].

In this paper, spherical titanium powder (45~180 μm) prepared via plasma rotating electrode process (PREP) was used as raw material, and porous titanium with low porosity was prepared by SPS method at different sintering temperatures (800 °C, 850 °C and 900 °C). The phase composition, porosity, microstructure, compression properties and fractures morphology of the sintered product were evaluated.

2. Materials and Methods

2.1. Material

The experiment uses a spherical pure titanium powder (purity >99.76%, powder particle size 45~180 μm) prepared by PREP as raw material. According to the national standard GB/T1482-2010, the original powder apparent density and powder flowability were measured by Velocity Instrument FT-102 (Ningbo Rooko Instrument Co., Zhejiang, China), and the mean was taken after three tests. The contents of powder nitrogen (N), oxygen (O) and other impurity elements were detected by LECO RH600 Nitrogen/Oxygen determinator (Changsha Jingkai Instrument Equipment Co. Ltd, Changsha, China). The powder morphology and sphericity were observed by JSM-6460 scanning electron microscope (JEOL Co. Ltd, Beijing, China).

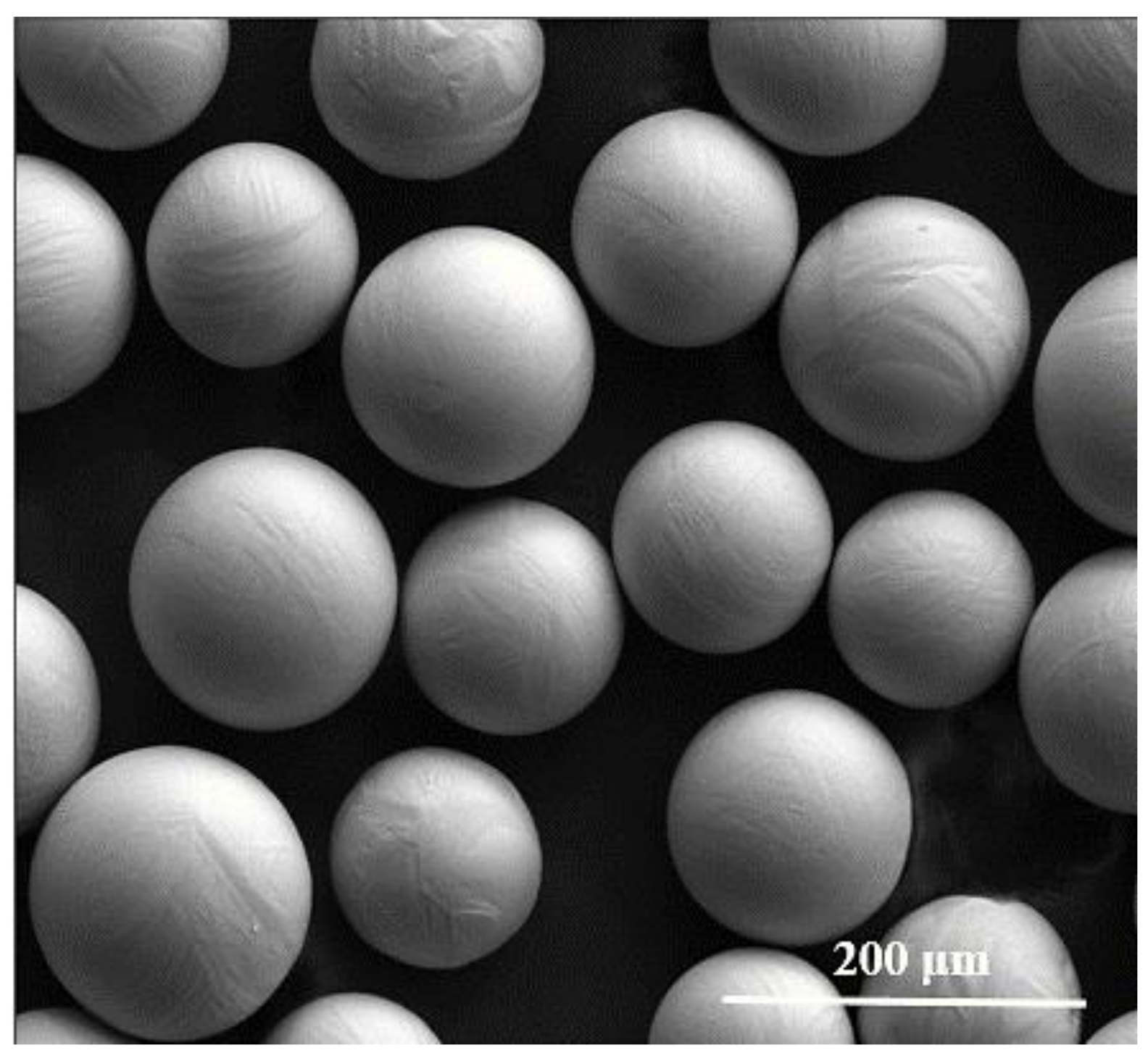

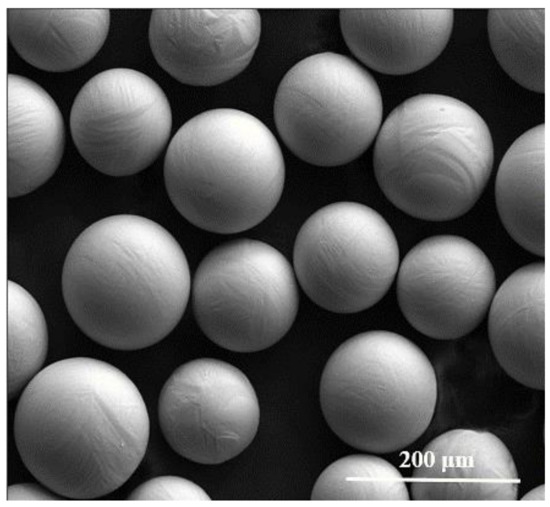

Figure 1 is the original titanium powder morphology, and Table 1 is the powder composition. Metal powder is the key raw material for powder metallurgy, and its quality largely determine the final moulding effect and comprehensive performance of powder metallurgy products [20]. The apparent density and flowability of the original Ti powder were tested by Hall flow-meter. The results show that the apparent density is 2.67 g/cm3, the flowability is 27.82 s/50 g and the sphericity of ≥98.87%. It can be seen from Figure 1 that the overall surface of the powder is smooth, the shape is regular, and the sphericity is high. No "satellite ball", flake powder and other shaped powders is found. Doubtlessly, it is related to the preparation process of the powder properties. The molten metal droplets are extracted by the centrifugal force and finally form a powder with a high sphericity under the surface tension. Simultaneously, acicular fine streaks observed on the surface of the particles are more pronounced on the surface of large-sized particles. This was because the β phase of the bcc structure undergoes a non-diffusion phase transformation to form the α phase of the hcp structure when the powder was rapidly cooled, and finally a metastable fine needle-like αʹ and αʹʹ martensite structure is formed [21,22].

Figure 1.

SEM of the starting powders: Ti powders (45~180 μm).

Table 1.

Chemical composition of Ti powder. (mass fraction/%).

2.2. Preparation of Samples

The experiment used HPD25-3 SPS sintering furnace (manufactured by FCT, Munich, Germany) and graphite die. Firstly, cleaned the graphite die with an inner diameter of Ф40 mm, then placed two layers of graphite paper on the bottom of the mold to prevent the powder from coming into contact with the die. Subsequently, weighted 50 g of pure titanium powder and placed it in the mold to shake the abrasive horizontally to keep the powder even. Finally, two layers of graphite paper were put on top of the powder, and the upper mold was simultaneously loaded. Place the filled die in the SPS furnace.

The experimental sintering process was as fllows. The sintering temperature (T) is 800 °C, 850 °C and 900 °C. The heating rates were: 150 °C/min from 0~(T-200) °C; 100 °C/min from (T-200) °C~(T-100) °C; 50 °C/min from (T-100) °C~(T-50) °C; and 25 °C/min from (T-50) °C~T °C. The holding time of high temperature is 5 min and a uniaxial pressure of 10 MPa was applied.

2.3. Characterization

The sample density was measured by the Archimedes method, and then the sample porosity was determined by the mass volume method. The microstructure of the sample was characterized by OLMPUS-PMG3 optical microscope (OM, OLMPUS, Tokyo, Japan) and JSM-6700F scanning electron microscopy (SEM, JEOL, Tokyo, Japan). The grain size was measured by a mean linear intercept method. The polishing agent was configured with an aqueous solution of chromium trioxide and the pickling solution was HF:HNO3:H2O = 1:3:16 self-configured mixed solution, pickling time is 30 s. The phase composition of the sintered samples was characterized by D8 ADVANCE A25 ray diffractometer (XRD, Bruker, Karlsruhe, Germany) using Cu Kα irradiation at 40 KV from 30° to 90°, and the scanning step size is 0.02°. The compression of samples was characterized by INSTRON-3369 (INSTRON, Shanghai, China) material mechanics testing machine, the compressed sample size is Ф6 mm × 9 mm and the loading rate is 0.5 mm/min.

3. Results and Discussion

3.1. Phase Analysis

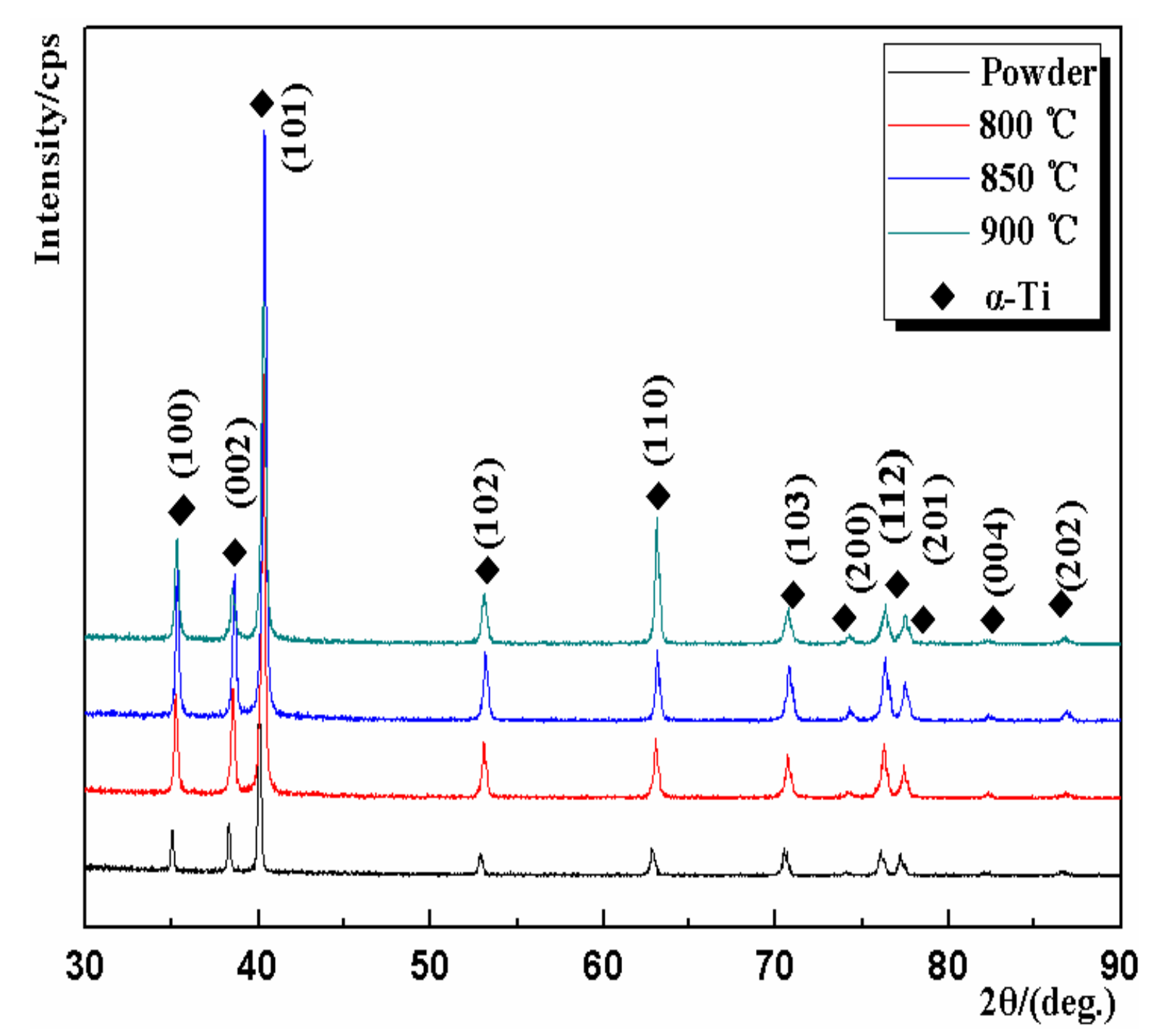

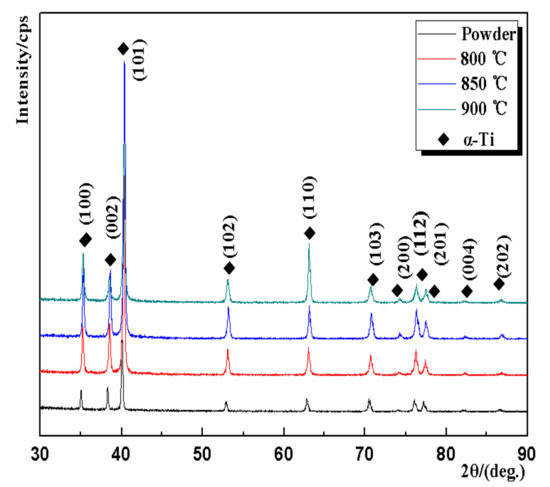

Figure 2 shows the XRD diffraction pattern of the sample prepared at different sintering temperatures. It can be seen that the phase composition of the sample under different sintering parameters consist of only a single hcp structure of the α-Ti phase, and no abnormal diffraction peak is observed. Comparing the diffraction peaks of the powders and sintered samples, it was found that the SPS sample had the same peak shape as that of the original powder, indicating that the powder was not contaminated after SPS sintering and there were no impurities or other alloy phases in the SPS process, however it is related to the detection accuracy of the XRD device. As the temperature rises, the intensity of the diffraction peaks slightly increases, but the difference is small. The diffraction peaks of (100), (002), (100), and (112) have a certain sharpening phenomenon. This is due to the sintering temperature. The atomic diffusion of Ti increased, and the grains grew as the sample became densified.

Figure 2.

XRD patterns of raw powders and samples sintered at different temperatures.

3.2. Microstructure and Pore Characteristic

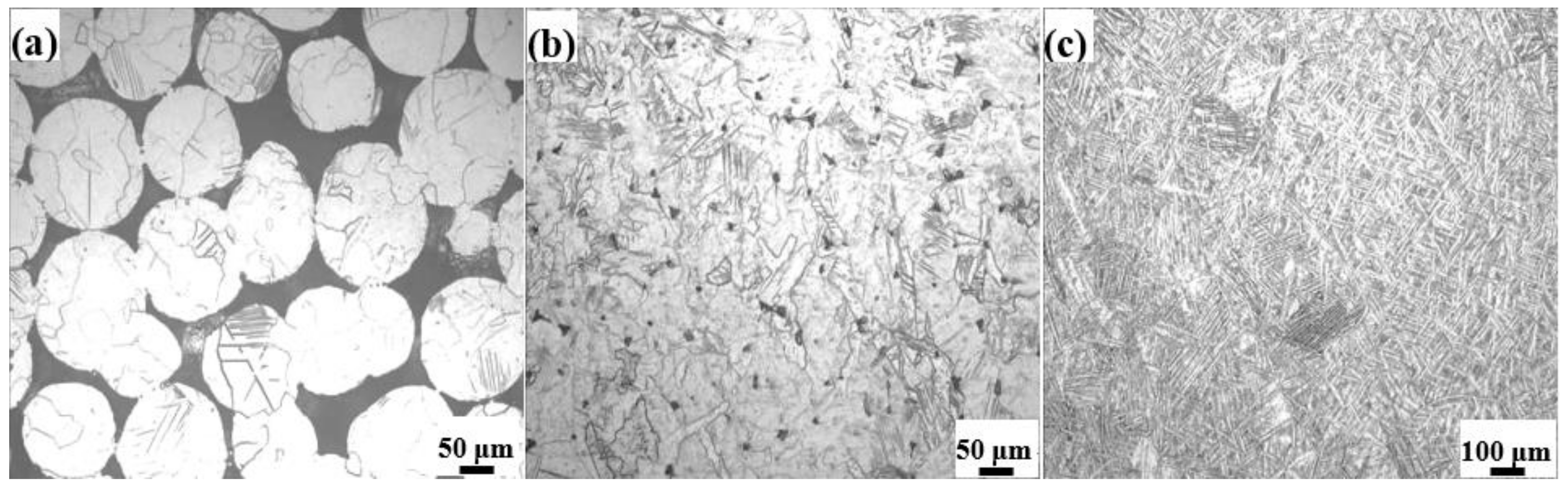

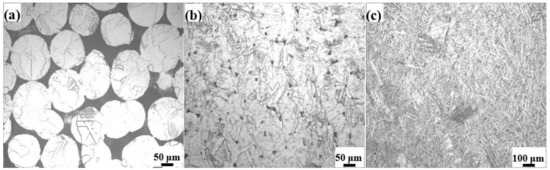

Figure 3 is the OM microstructure of the sample at different sintering temperatures, with a sintering pressure of 10 MPa and sintering temperatures of 800 °C (Figure 3a), 850 °C (Figure 3b) and 900 °C (Figure 3c). It can be seen that at the sintering temperature of 800 °C, SPS sintered powder is re-nucleated to form an equiaxed structure and the grain size is quite different. The coarse grain size is about 50~80 μm and the small equiaxed grain size is about 20 μm; fine acicular αʹ martensite can be observed inside some grains. The pore shape in the sample is irregular and the size is large. Most of the pores are interpenetrating and the sample densification is more difference. When the temperature rises to 850 °C, the microstructure in the sample consists of zigzag α-structure, acicular α-clusters and a small amount of acicular αʹ martensite, and some α-crystals exist in elongated α-structure. It can be seen from Figure 3b that there are a large number of pores on the surface of the sample. Compared with 800 °C (Figure 3a), the pores are mostly spherical or nearly spherical, and a dense sintered neck is formed between the powders, some of the original powder boundaries are clearly visible after diffusion. When the temperature is further increased to 900 °C, the coarse pore size in the sample has basically disappeared. The microstructure is a dense full-sheet α-structure and a small amount of intergranular β, which the α-sheet thickness is 3~10 μm and the length is 50~150 μm.

Figure 3.

The microstructures of the samples sintered at different temperature. (a) 800 °C; (b) 850 °C; (c) 900 °C.

Overall, the microstructure of the SPS samples was dominated by equiaxed and lamellar α structures, but the thickness and grain size of the samples varied with the sintering temperature. The higher the sintering temperature, the faster the atom migration in the powder, the easier the granules grow and the denser the sample. When the sintering temperature is lower, the atom diffusion is more difficult and the titanium powder particles are not completely sintered, so there is a large amount pores after sintering. As the sintering temperature increases, the diffusion capacity of Ti atoms increases, the grain growth is good, the shrinkage of the green body increases, and the pores disappear and shrink spheroidize. The microstructure of the sample is related to the alloy composition and the cooling rate after the SPS is completed. The sintering temperature in the sample reaches above β/α temperature and starts to cool, When the cooling rate is slow, only a small degree of subcooling is generated, and the crystal grains are nucleated at the original β grain boundary and grow into the crystal to form elongated α-shaped tissues which are oriented in the same direction and parallel to each other. When the speed is faster, the position of crystal nucleation increases, the orientation increases and the parallel α clusters become less widened, meanwhile the microstructures are interlaced with α bundles [23].

3.3. Mechanical Properties

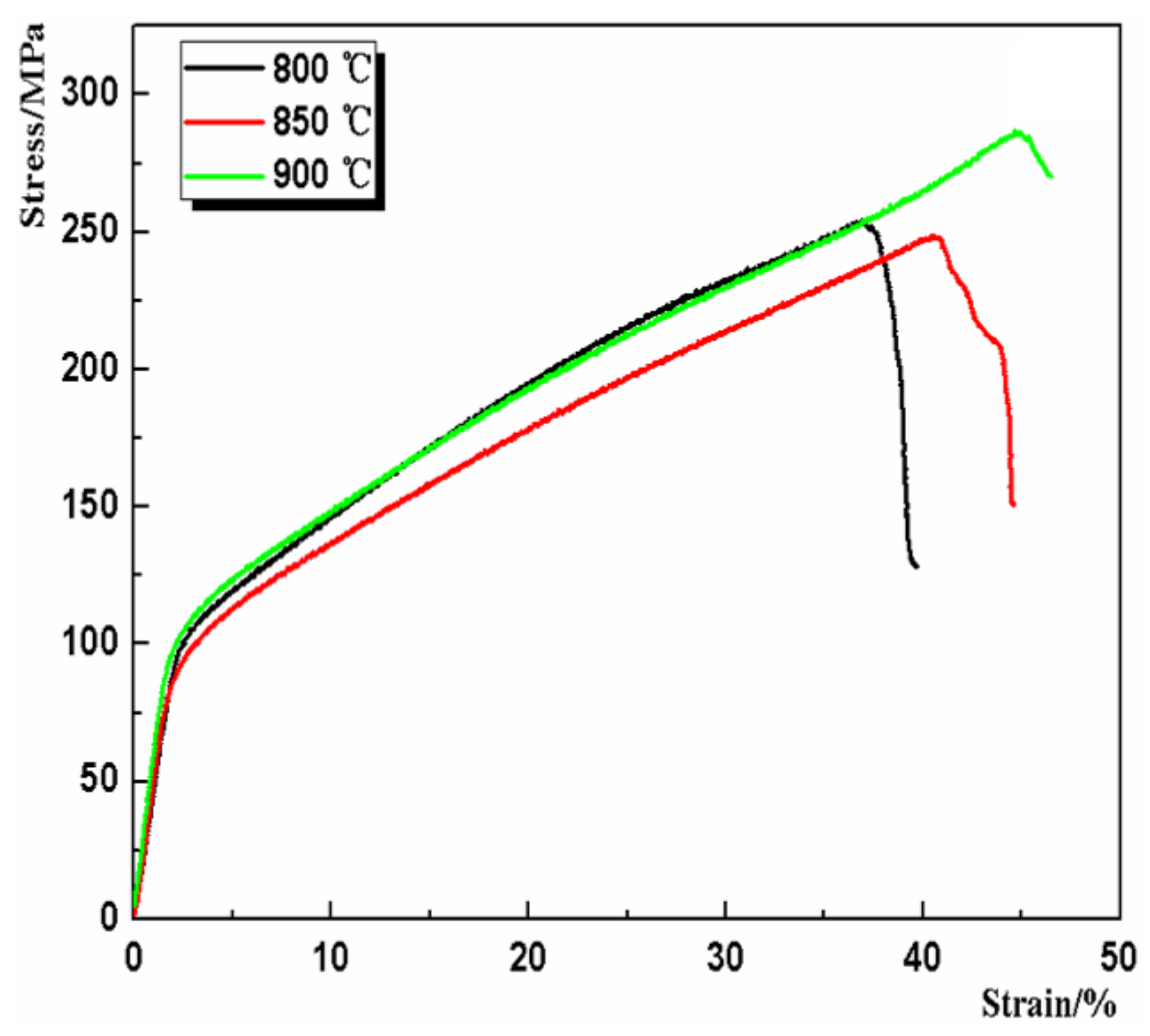

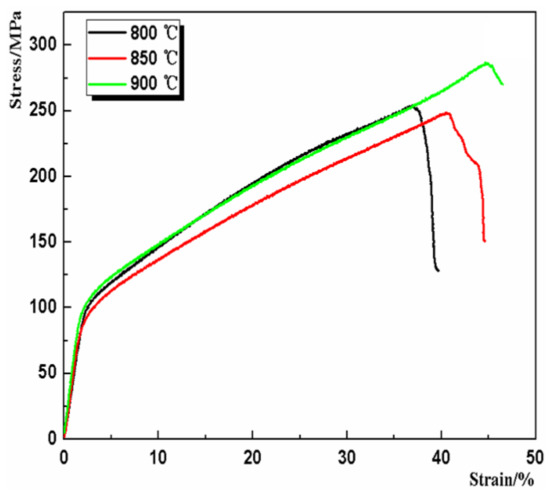

Figure 4 is a room temperature compressive stress-strain curve for a SPS porous titanium sample. It can be seen that the compressive stress-strain curve of the sample contain three distinct parts during the compression process. At the initial stage of compression, the sample is elastic deformation under the action of pressure. Corresponding to the elastic deformation stage in the line curve, the sample can still be restored to its original state after unloading. At this time, the deformation amount is relatively small, only about 2%. The second stage is a dense area. With the continuous action of compressive stress, obvious stress concentration will appear around the hole in the sample. After the hole is pressed, the hole wall will be deformed, gradually deviating from the initial position, and the sample as a whole exhibits strain hardening characteristics with relatively slow stress growth. The third stage is the failure zone. After the plastic deformation around the hole reaches a certain critical state, that is, after reaching and exceeding the maximum strength of the hole wall, the hole wall of the sample is plastically deformed until the pore collapses. As the strain continues to accumulate, the amount of sample compression increases, the sample compacts and enters the densification phase, and the stress continues to increase. At this point, the porous sample has completely failed [24].

Figure 4.

Stress–strain curves of samples prepared at different sintering temperatures (800 °C, 850 °C and 900 °C).

The strength and modulus of elasticity of porous titanium are related to the porosity of the sample, the shape and distribution of the pores. The elastic modulus and compression strength of the samples with different sintering temperature is shown in Table 2. It can be seen from Figure 4 and Table 2 that under constant sintering pressure, the strength of the compressed sample increases with increasing temperature. When sintering temperatures are 800 °C, 850 °C and 900 °C, the compressive strength of the sample is 253.21 MPa, 248.12 MPa and 286.00 MPa, respectively. During the SPS sintering process, the temperature rise is favorable for the sintering process. At this time, the pores in the sample are more uniform and smooth, the surface of the pore wall becomes smooth, the porosity and pore size decrease rapidly, and the degree of densification becomes high, which result in compressive strength raising. Assuming that the pore size factor is not considered, the Gibson–Ashby model is used to estimate the elastic modulus of the sample [25]. The porosity of the porous sample prepared by the experiment ranges from 1.05% to 16.14%. The Gibson-Ashby model is shown in the following Equations (1) and (2) [25]. The elastic modulus of the porous sample is estimated to be 0.12~4.16 GPa, which is in good agreement with the results of 2.79~4.22 GPa.

where E is the elastic modulus of the porous titanium sample, Eb is the dense titanium elastic modulus, θ is the sample porosity, ρ is the shape factor, and ρ and ρb are the porous sample density and the dense titanium density, respectively. Among them, dense titanium elastic modulus Eb was 116 GPa, and ρb was 4.51 g/cm3.

Table 2.

Compression mechanical properties of the samples with different sintering temperature.

3.4. Compression Fracture Analysis

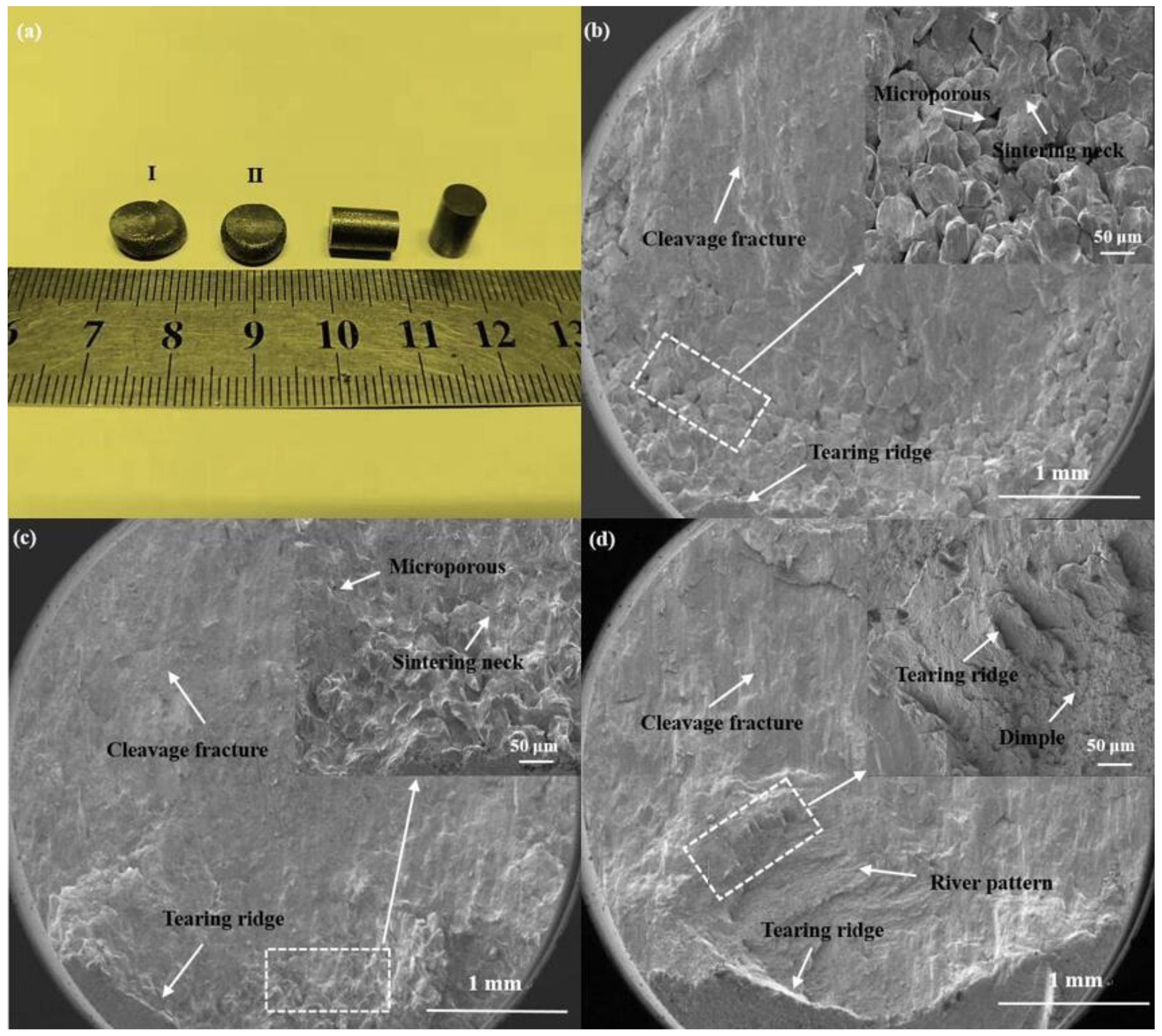

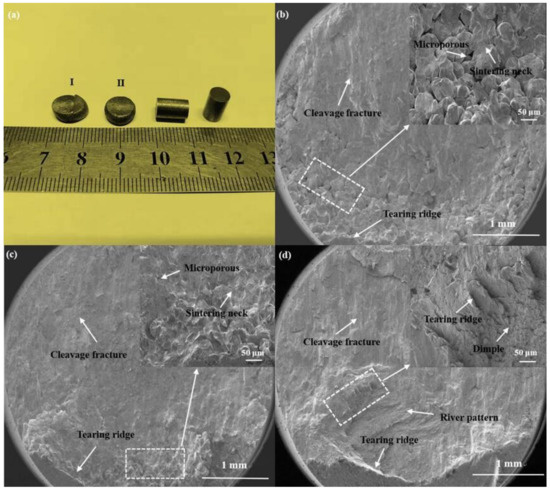

Figure 5 is a photograph of the axial compression fracture morphology of the sample. As shown in Figure 5a, most of the samples with a sintering temperature of 800 °C and a small portion of the sample with a sintering temperature of 850 °C have a shear crack on the surface that is inclined at 45° to the direction of the compressive stress after axial compression (Figure 5aІ). However, most of the samples with a sintering temperature of 900 °C produced a large strain under compressive stress, showing good plasticity, and the macroscopic morphology appeared as a densified "drum-like" with no obvious crack on the sample surface (Figure 5aII). In the Griffith microcrack theory: the fracture of porous titanium can be considered as the process of crack formation, expansion and separation [26]. On the one hand, when an external force acts, the stress caused by the tip of the pore concentrates to form a microcrack, and once the crack is generated, the stress concentration will be more intense, causing the crack to expand rapidly, causing the material to break. On the other hand, the increase of porosity, the increase of pore irregularity and the decrease of radius of curvature of the pores are all the pore factors that cause the stress concentration and strength of the sample to decrease, and the spheroidization of the pores can reduce the stress concentration [27].

Figure 5.

Compression fracture morphology of samples with different sintering temperatures. (a) is compressed sample photo; (b), (c) and (d) are the fracture morphology of sintered samples with sintering temperatures of 800 °C, 900 °C and 1000 °C, respectively.

Figure 5b shows the macroscopic fracture morphology of the sample at a sintering temperature of 800 °C and a sintering pressure of 10 MPa. It can be seen that there is a large difference between the center and the edge of the sample; the center is smooth, the density is high and the edge is opposite. In addition, the original grain boundary of the spherical titanium powder and the sintered neck formed after sintering are obviously observed through the high power lens, and there are many micropores. At this time, the fracture is almost entirely spread from the contact portion of the particle, and there are a small amount of fine cleavage steps and tearing ridges. This is mainly due to the sintering temperature gradient. Figure 5c is a fracture morphology of the sample at a sintering temperature of 850 °C and a sintering pressure of 10 MPa. It can be seen from Figure 5c that the density of the sample increases and the surface is smooth, and the cleavage step and the tearing ridge appear, and the atom diffusion between the powders is sufficient. However, the difference between the center and the edge of the sample can still be observed through a high power lens. The original powder boundary and the sintered neck can still be observed at the edge of the fracture, but the number of pores has been greatly reduced. Figure 5d is a fracture morphology of the sample at a sintering temperature of 900 °C and a sintering pressure of 10 MPa. It can be seen that the sample has completely densified with the increase of sintering temperature, and the center and edge parts cannot be clearly distinguished. No obvious pores are observed on the surface, the sample fracture is undulating, and there are more river patterns, cleavage steps and tearing ridges, this indicates that the plasticity of the sample is better. Through partial enlargement, the deeper dimples and the tearing ridges left by the stress can be observed, and the tearing ridge has a certain directional distribution, which is related to the preferred orientation of the crystal.

4. Conclusions

(1) Porous titanium samples with low porosity of 1.34~15.54% were prepared by SPS using spherical titanium powder as raw material, the porosity of the sample is significantly reduced with the increase of sintering temperature.

(2) The XRD analysis showed that the main phase of porous titanium was hcp-α phase, and the sintering temperature had little effect on the phase structure.

(3) When sintering at 800 °C, the sample microstructure is equiaxed with α grains and a small amount of needle and sheet α. At 850 °C, the medium-axis grain size of the sample becomes smaller, the α-sheet becomes tighter and finer. At 900 °C, the sample is a full α sheet structure, and a certain coarsening phenomenon occurs.

(4) The room temperature compressive stress-strain curve has no obvious yield point, and contains three distinct stages; namely, elastic deformation zone, dense zone and failure zone. The compressive strength was 161.65~498.86 MPa, and the elastic modulus was 2.79~4.22 GPa.

Author Contributions

S.L. and X.Y. designed the experiments, and preparation the raw materials; A.L. and M.S. performed the experiments and analyzed the results; S.L. and X.Y. help analyzed date and gave some suggestions about how to write this manuscript; M.S. and G.Z. wrote the manuscript; G.Z. revised the manuscript; all authors read and approved the final manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No.51671152, No.51874225 and No.51504191), the Natural Science Foundation of Shaanxi Educational Committee (14JK512), the Industrialization Project of Shaanxi Education Department (Z20180440) and the Science & Technology Bureau of Xi’an (CXYZKD001).

Acknowledgments

The authors are grateful to the other members of their research team for their help in the experimental process.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Prem, M.; Krexner, G.; Pleschiutschnig, J. Helium damage in long-aged metal–tritium systems. J. Alloys Compd. 2003, 356–357, 683–687. [Google Scholar] [CrossRef]

- Wang, P.; Song, J. Helium in Materials and the Permeation of Tritium; National Defense Industry Press: Beijing, China, 2002. [Google Scholar]

- Walters, R.T.; Nobile, A., Jr.; Mosley, W.C. Helium dynamics in metal tritides II. The significance of microstructure in the observed helium behavior for La Ni Al tritides. J. Less Common Met. 1991, 170, 63–74. [Google Scholar] [CrossRef]

- Shen, H.H.; Peng, S.M.; Long, X.G.; Xiang, X.; Zhou, X.S.; Yang, L.; Zu, X.T. Microstructure changes of erbium and erbium deuteride films induced by helium implantation. Mater. Lett. 2012, 80, 17–19. [Google Scholar] [CrossRef]

- Hirooka, Y.; Miyake, M.; Sano, T. A study of hydrogen absorption and desorption by titanium. J. Nucl. Mater. 1981, 96, 227–232. [Google Scholar] [CrossRef]

- Wu, Y.X.; Yang, R.; Zheng, H.; Wang, Y.M. First-principles study of alloying effect of transition metals on He in titanium ditritide. J. Nucl. Mater. 2006, 354, 36–48. [Google Scholar] [CrossRef]

- Wang, H.F.; Peng, S.M.; Zhou, X.S.; Cheng, G.J.; Wang, W.D.; Long, X.G.; Yang, B.F. Primarily Study on Thermodesorption From Titanium Tritide Films. At. Energy Sci. Technol. 2008, 42, 49–52. [Google Scholar]

- Hong-Chao, P.; Shun-Zhong, L.; Xing-Gui, L.; An, Z.; Ning, L.; Yan-Min, D.; Xing-Chun, W.; Ben-Fu, Y.; Pei-Lu, W.; Si-Xiao, Z. Effects of Substrate Temperature on Helium Content and Microstructure of Nanocrystalline Titanium Films. Chin. Phys. Lett. 2006, 23, 3238. [Google Scholar] [CrossRef]

- Chen, W.; Anselmi-Tamburini, U.; Garay, J.E.; Groza, J.R.; Munir, Z.A. Fundamental investigations on the spark plasma sintering/synthesis process: I. Effect of dc pulsing on reactivity. Mater. Sci. Eng. A 2005, 394, 139–148. [Google Scholar] [CrossRef]

- Liu, W.; An, R.; Wang, C.; Zheng, Z.; Tian, Y.; Xu, R.; Wang, Z. Recent Progress in Rapid Sintering of Nanosilver for Electronics Applications. Micromachines 2018, 9, 346. [Google Scholar] [CrossRef]

- Prasad, K.S.; Rao, A.; Bhardwaj, R.; Johri, K.K.; Chang, C.C.; Kuo, Y.K. Spark plasma sintering technique: An alternative method to enhance ZT values of Sb doped Cu2 SnSe3. J. Mater. Sci. Mater. Electron. 2018, 29, 13200–13208. [Google Scholar] [CrossRef]

- Shi, M.; Liu, S.; Wang, Q.; Yang, X.; Zhang, G. Preparation and Properties of Titanium Obtained by Spark Plasma Sintering of a Ti Powder–Fiber Mixture. Materials 2018, 11, 2510. [Google Scholar] [CrossRef] [PubMed]

- Shon, J.H.; Song, I.B.; Cho, K.S.; Park, Y.I.; Hong, J.K.; Park, N.K.; Oh, M.H. Effect of particle size distribution on microstructure and mechanical properties of spark-plasma-sintered titanium from CP-Ti powders. Int. J. Precis. Eng. Manuf. 2014, 15, 643–647. [Google Scholar] [CrossRef]

- Kozlík, J.; Becker, H.; Harcuba, P.; Stráský, J.; Janeček, M. Cryomilled and spark plasma sintered titanium: The evolution of microstructure. IOP Conf. Ser. Mater. Sci. Eng. 2017, 194, 012023. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, S.; You, M.; Tan, H.; Xiong, W. Fabrication of nanocomposite Ti(C,N)-based cermet by spark plasma sintering. Mater. Chem. Phys. 2005, 92, 64–70. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.Q.; Jiang, Y.H.; Zhou, R. Mechanical behaviors of porous Ti with high porosity and large pore size prepared by one-step spark plasma sintering technique. Vacuum 2015, 122, 187–194. [Google Scholar] [CrossRef]

- Guo, Y.; Tan, Y.; Liu, Y.; Liu, S.; Zhou, R.; Tang, H. Low modulus and bioactive Ti/α-TCP/Ti-mesh composite prepared by spark plasma sintering. Mater. Sci. Eng. C 2017, 80, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Miriyev, A.; Stern, A.; Tuval, E.; Kalabukhov, S.; Hooper, Z.; Frage, N. Titanium to steel joining by spark plasma sintering (SPS) technology. J. Mater. Process. Technol. 2013, 213, 161–166. [Google Scholar] [CrossRef]

- Nobuki, T.; Moriya, T.; Hatate, M.; Crivello, J.-C.; Cuevas, F.; Joubert, J.-M. Synthesis of TiFe Hydrogen Absorbing Alloys Prepared by Mechanical Alloying and SPS Treatment. Metals 2018, 8, 264. [Google Scholar] [CrossRef]

- Hidalgo, A.A.; Frykholm, R.; Ebel, T.; Pyczak, F. Powder Metallurgy Strategies to Improve Properties and Processing of Titanium Alloys: A Review. Adv. Eng. Mater. 2017, 19, 1600743. [Google Scholar] [CrossRef]

- Liu, N.; Li, Z.; Yuan, H.; Xu, W.; Zhang, Y.; Zhang, G. Fabrication and characterization of gas atomized TiAl alloy powder. J. Iron Steel Res. (Int.) 2011, s2, 537–540. [Google Scholar]

- Zhao, S.; Chen, G.; Tan, P.; Wang, J.; Liu, X. Characterization of spherical TC4 powders by gas atomization and its interstitial elemental control. Chin. J. Nonferrous Met. 2016, 26, 980–987. [Google Scholar]

- Popov, A.A.; Illarionov, A.G.; Stepanov, S.I.; Elkina, O.A.; Ivasishin, O.M. Effect of quenching temperature on structure and properties of titanium alloy: Structure and phase composition. Phys. Met. Metallogr. 2014, 115, 507–516. [Google Scholar] [CrossRef]

- Hernández-Nava, E.; Smith, C.J.; Derguti, F.; Tammas-Williams, S.; Leonard, F.; Withers, P.J.; Todd, I.; Goodall, R. The effect of defects on the mechanical response of Ti-6Al-4V cubic lattice structures fabricated by electron beam melting. Acta Mater. 2016, 108, 279–292. [Google Scholar] [CrossRef]

- Andrews, E.W.; Gibson, L.J.; Ashby, M.F. The creep of cellular solids. Acta Mater. 1999, 47, 2853–2863. [Google Scholar] [CrossRef]

- Griffith, A.A. The Phenomena of Rupture and Flow in Solids. Philos. Trans. R. Soc. Lond. 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Peiyun, H. Principle of Powder Metallurgy; Metallurgical Industry Press: Beijing, China, 1982; pp. 1–390. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).