Measurement of Molten Steel Velocity near the Surface and Modeling for Transient Fluid Flow in the Continuous Casting Mold

Abstract

1. Introduction

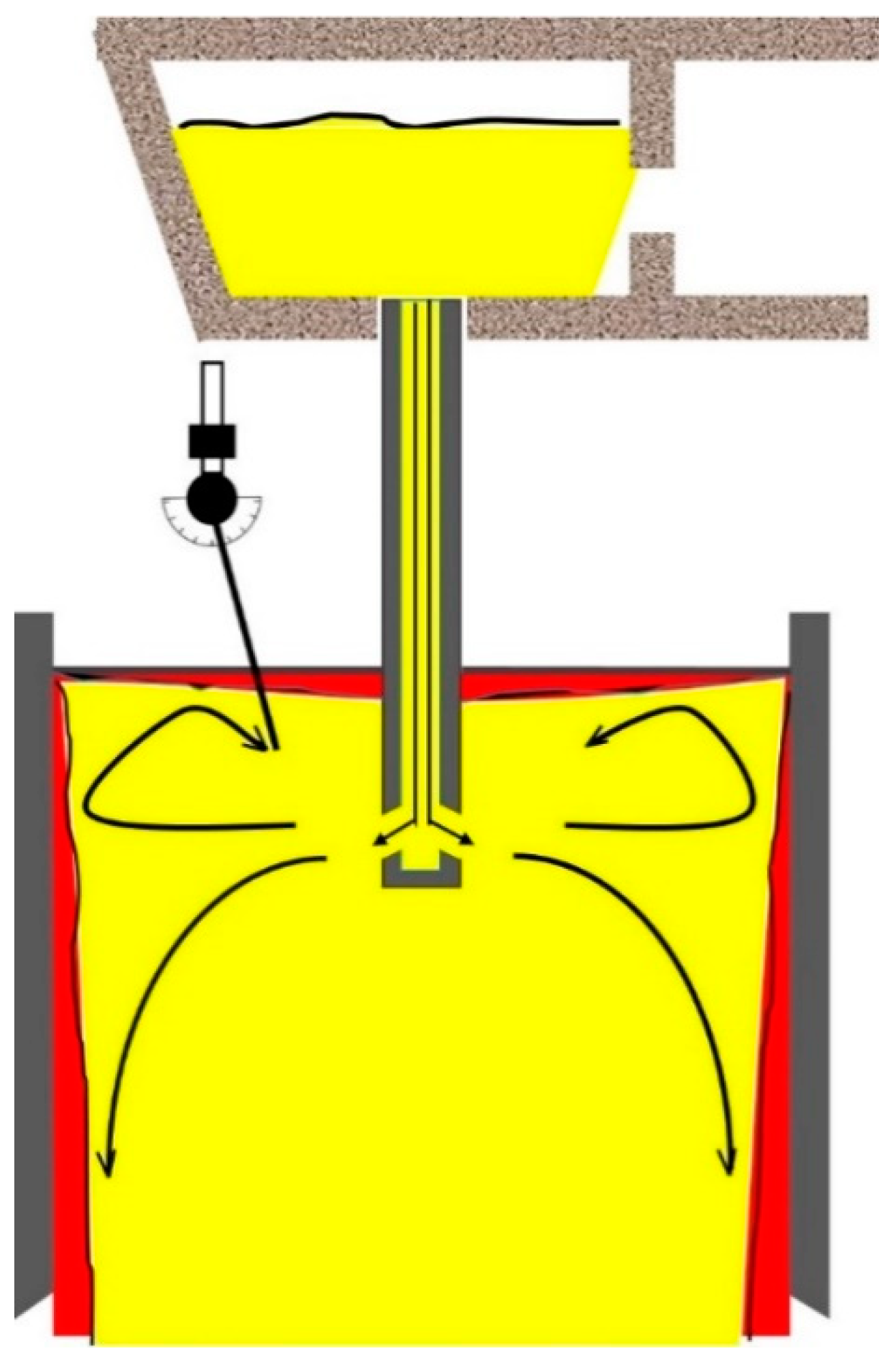

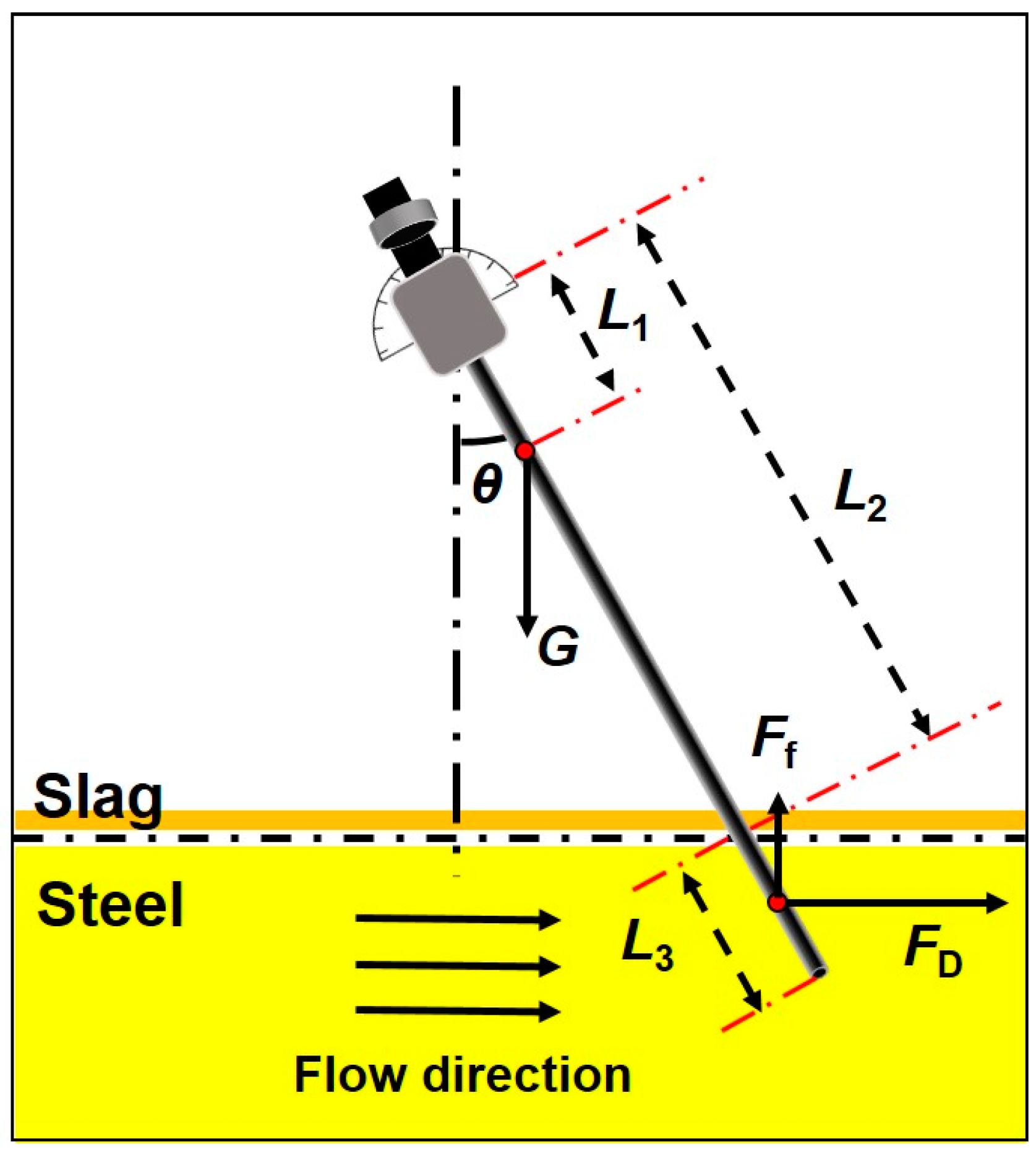

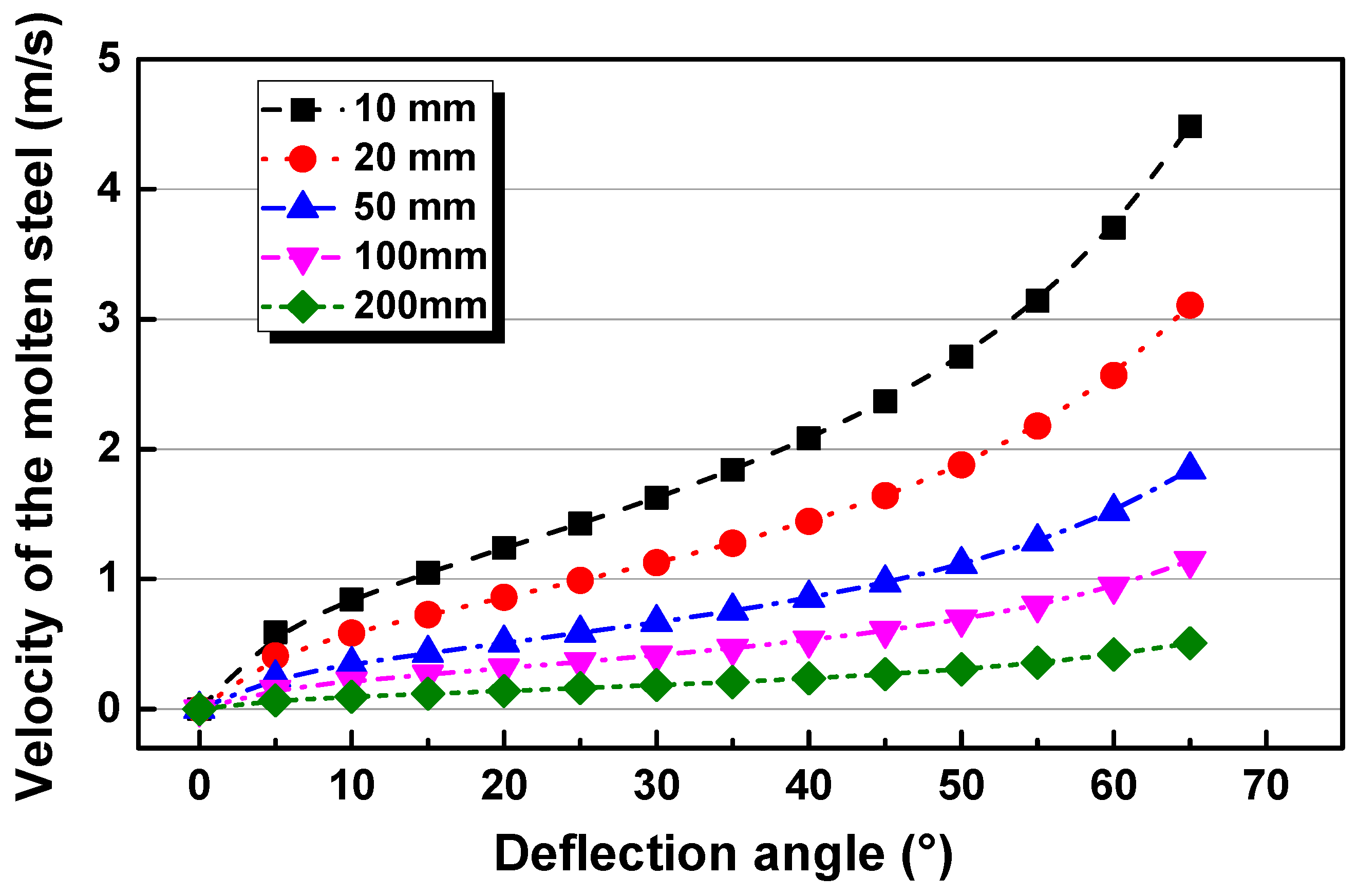

2. Experimental Apparatus and Method

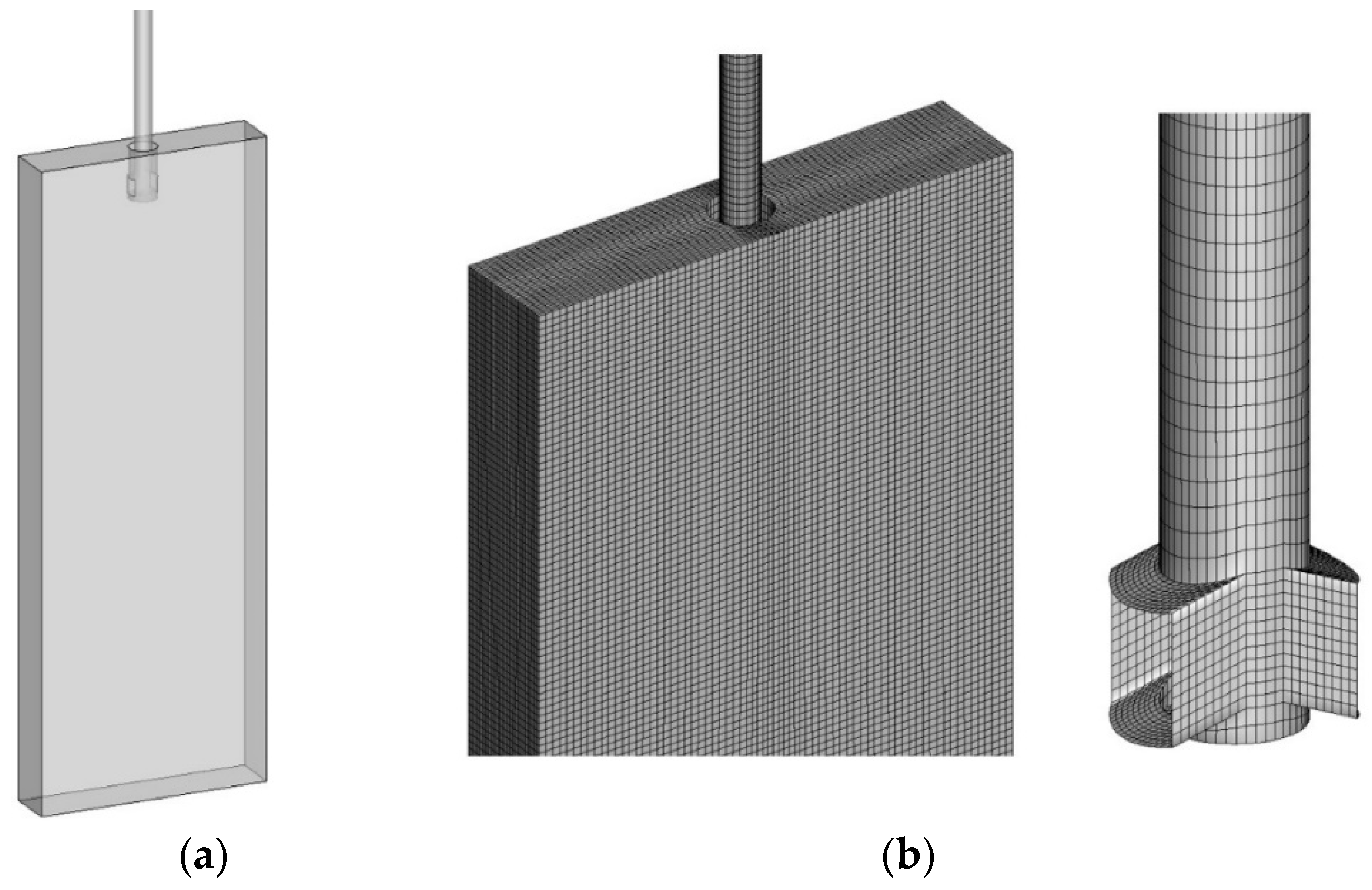

3. Numerical Simulation

- (1)

- The continuous phase is regarded as being an incompressible fluid;

- (2)

- The effect of the slag layer on the flow behavior of molten steel is ignored;

- (3)

- All bubbles are treated as the spherical shape and the effects of temperature and pressure on the bubble shape and size are ignored.

- (4)

- The deformation of the solidified shell is ignored.

- (5)

- The surface oscillations are not considered.

3.1. Fluid Flow Model

3.2. Discrete Phase Model

3.3. Simulation Details

4. Results and Discussion

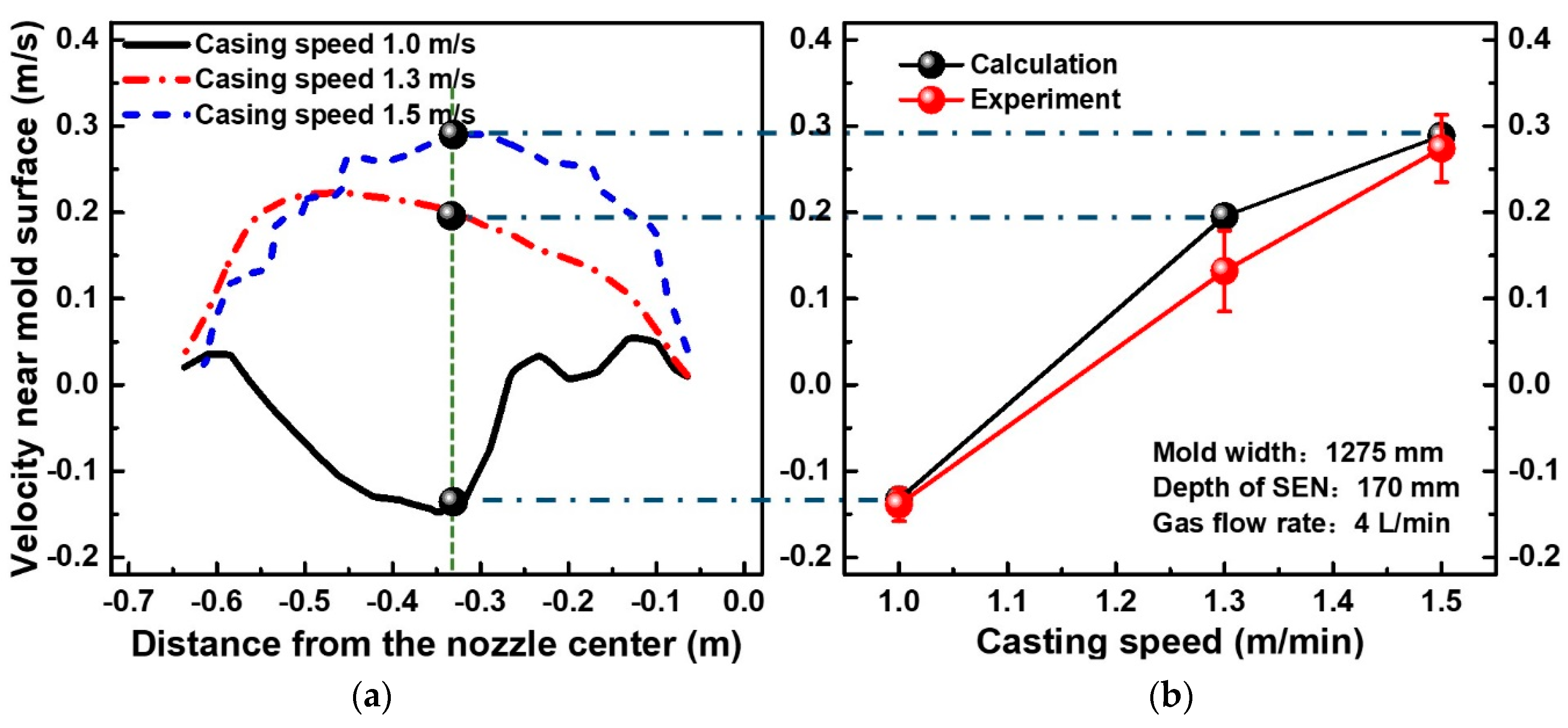

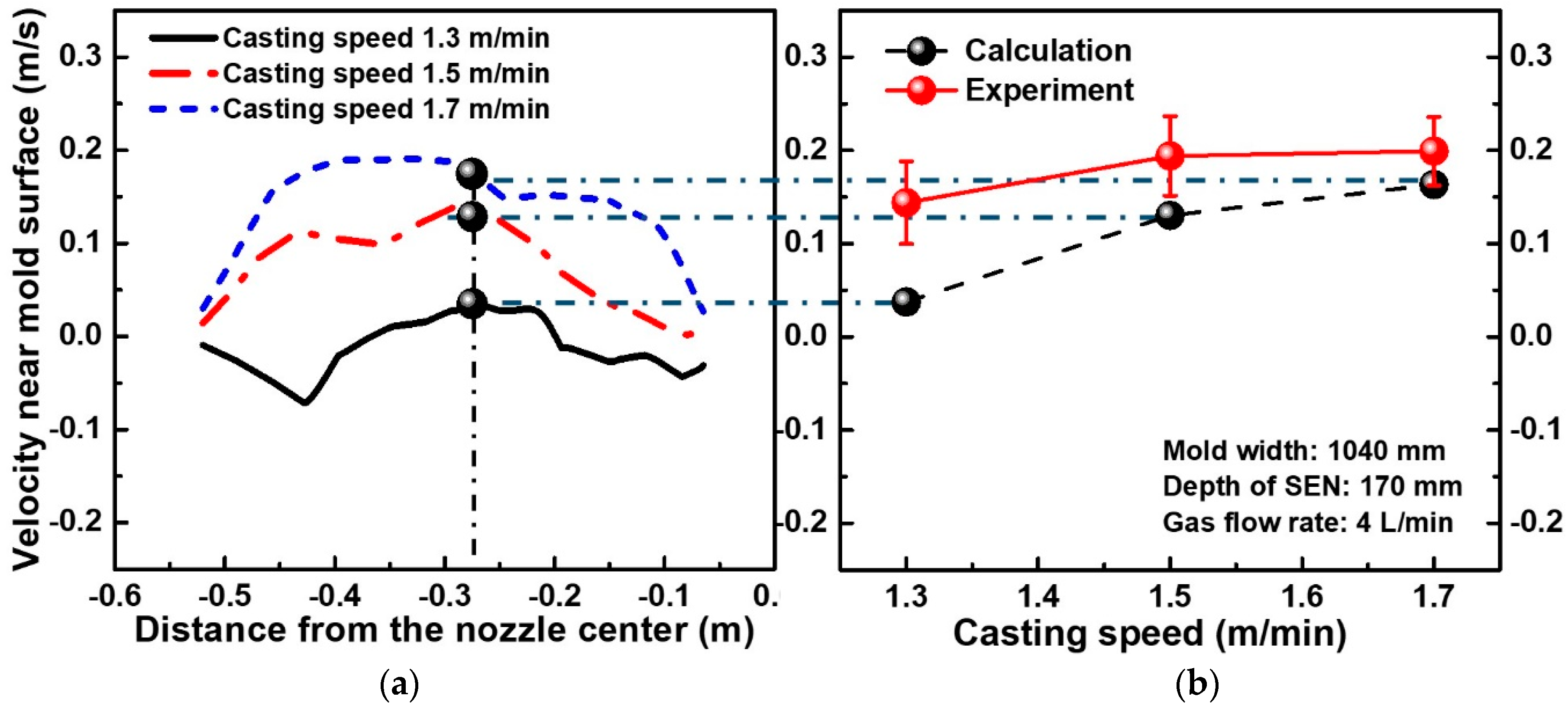

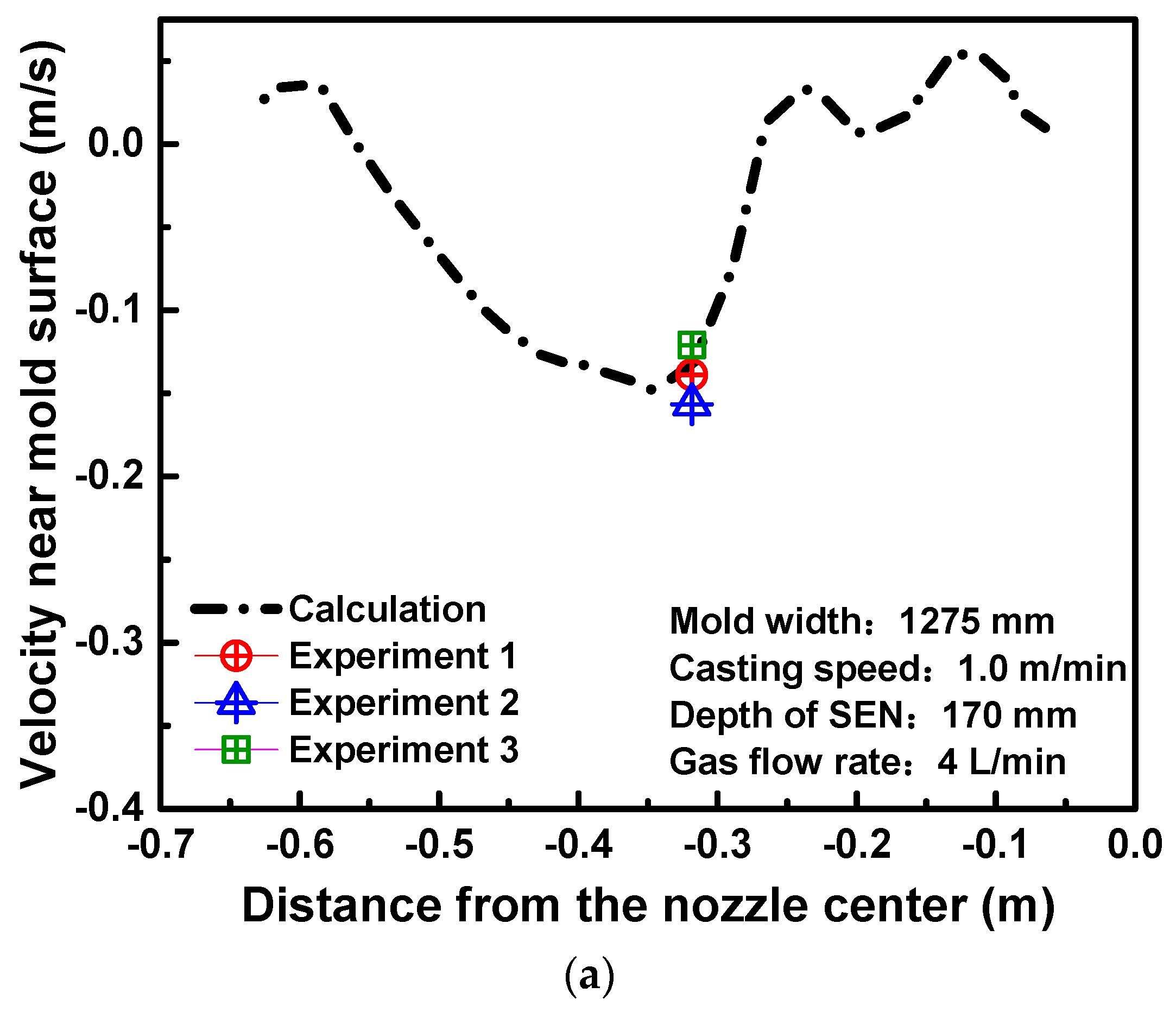

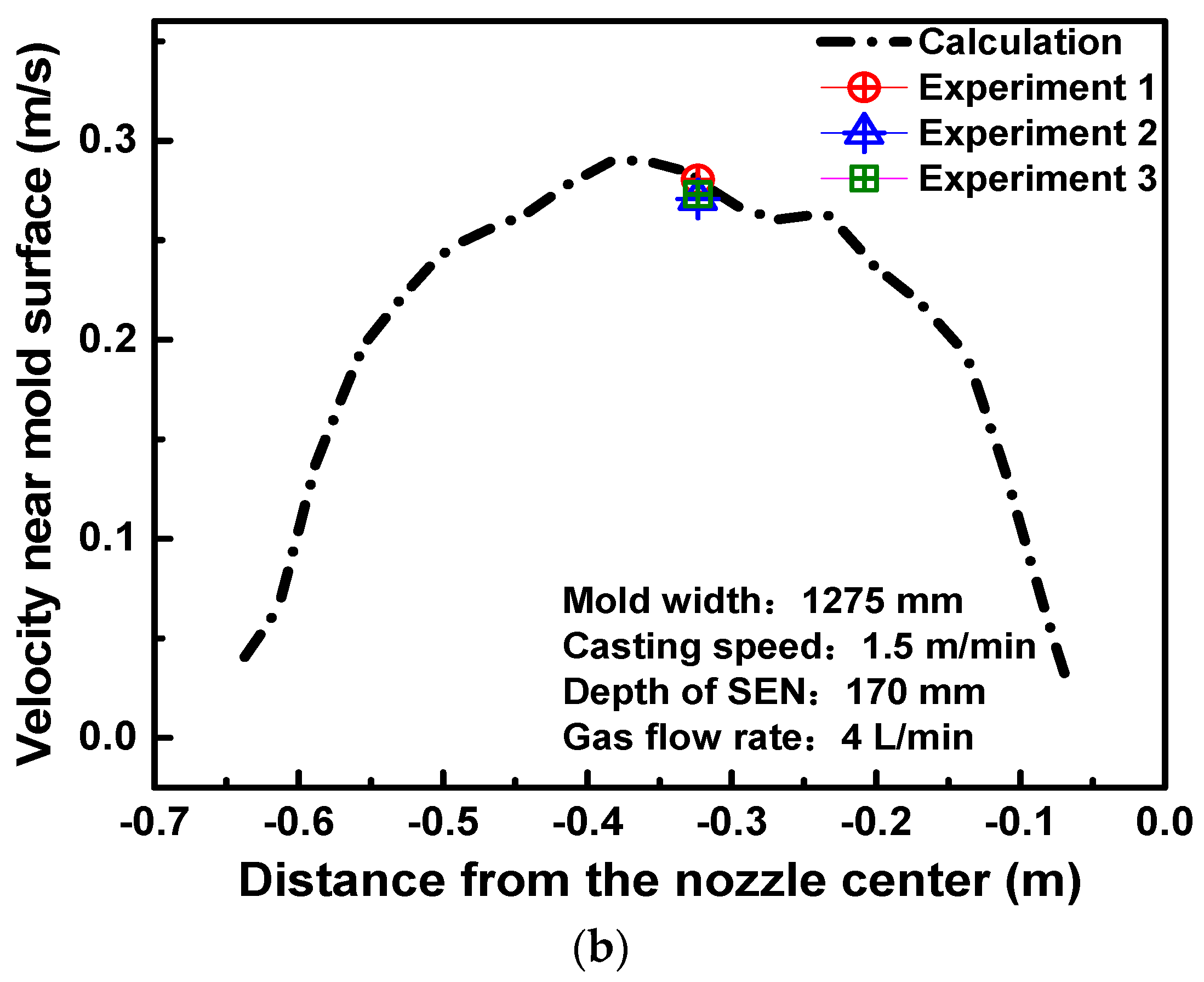

4.1. The Comparison between the Experimental and Calculated Results

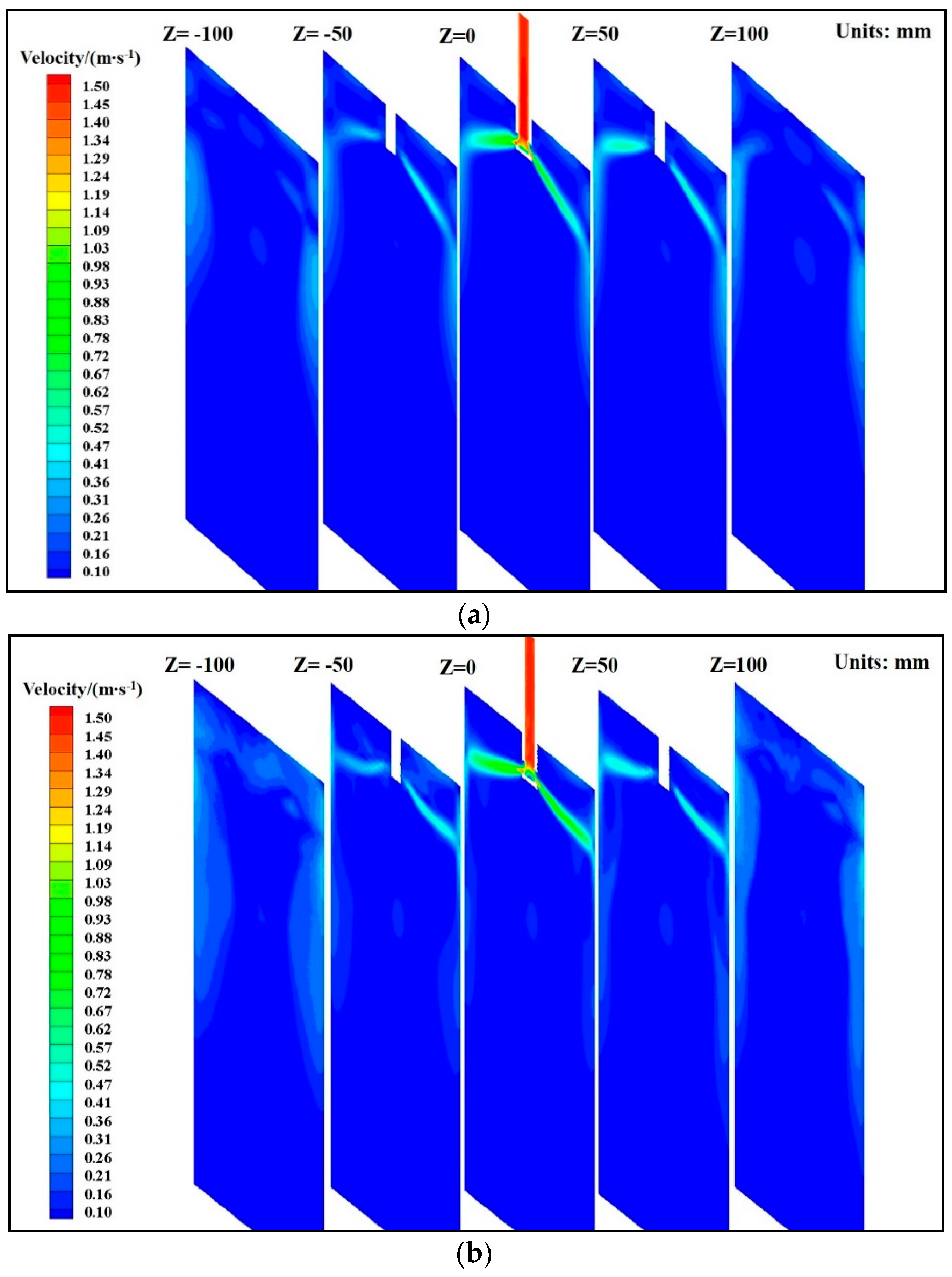

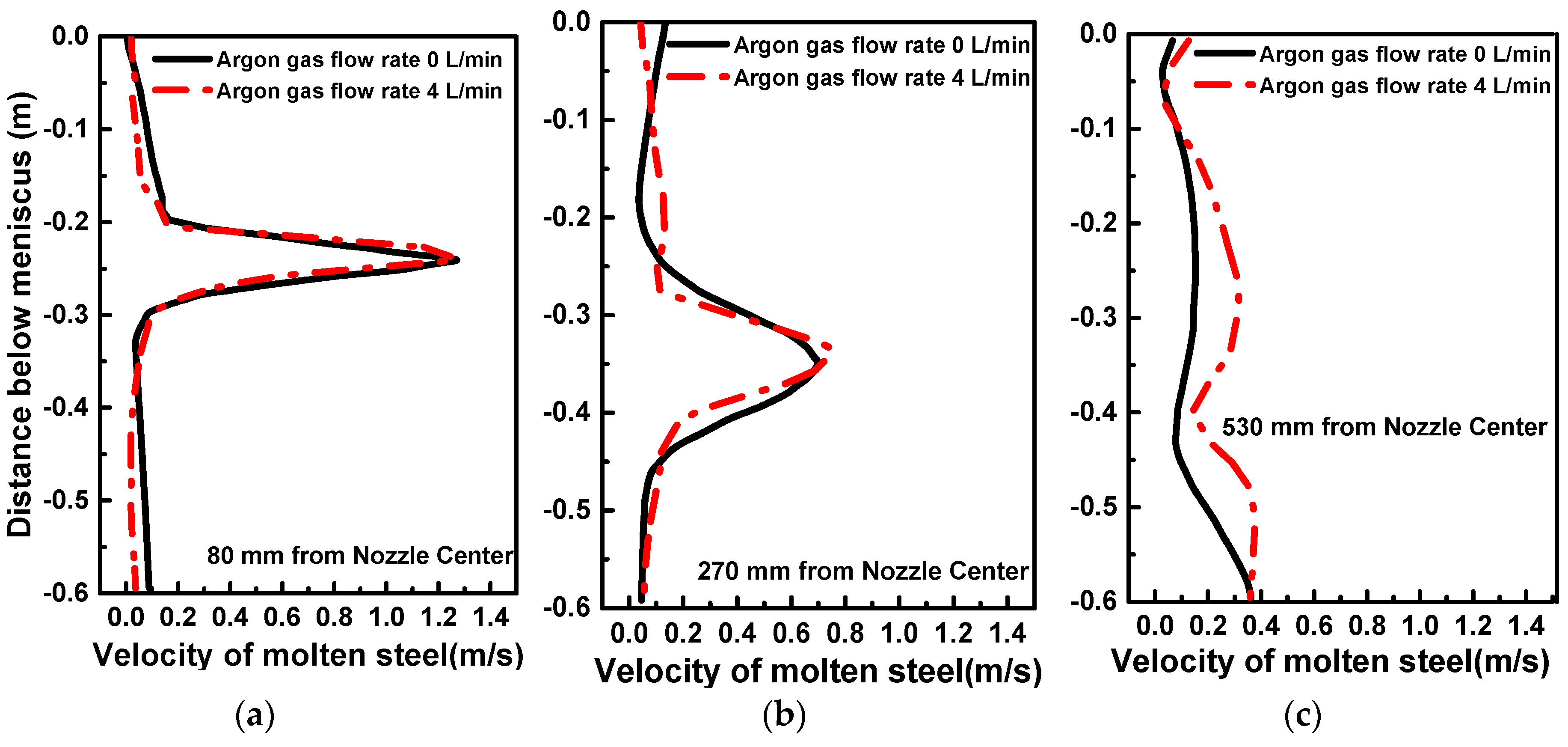

4.2. Flow Patterns in the Mold

5. Conclusions

- The rod deflection method is conducted to measure the flow velocity of molten steel near the surface of the mold in the industrial experiment. With this measurement, the flow velocity and direction can be obtained.

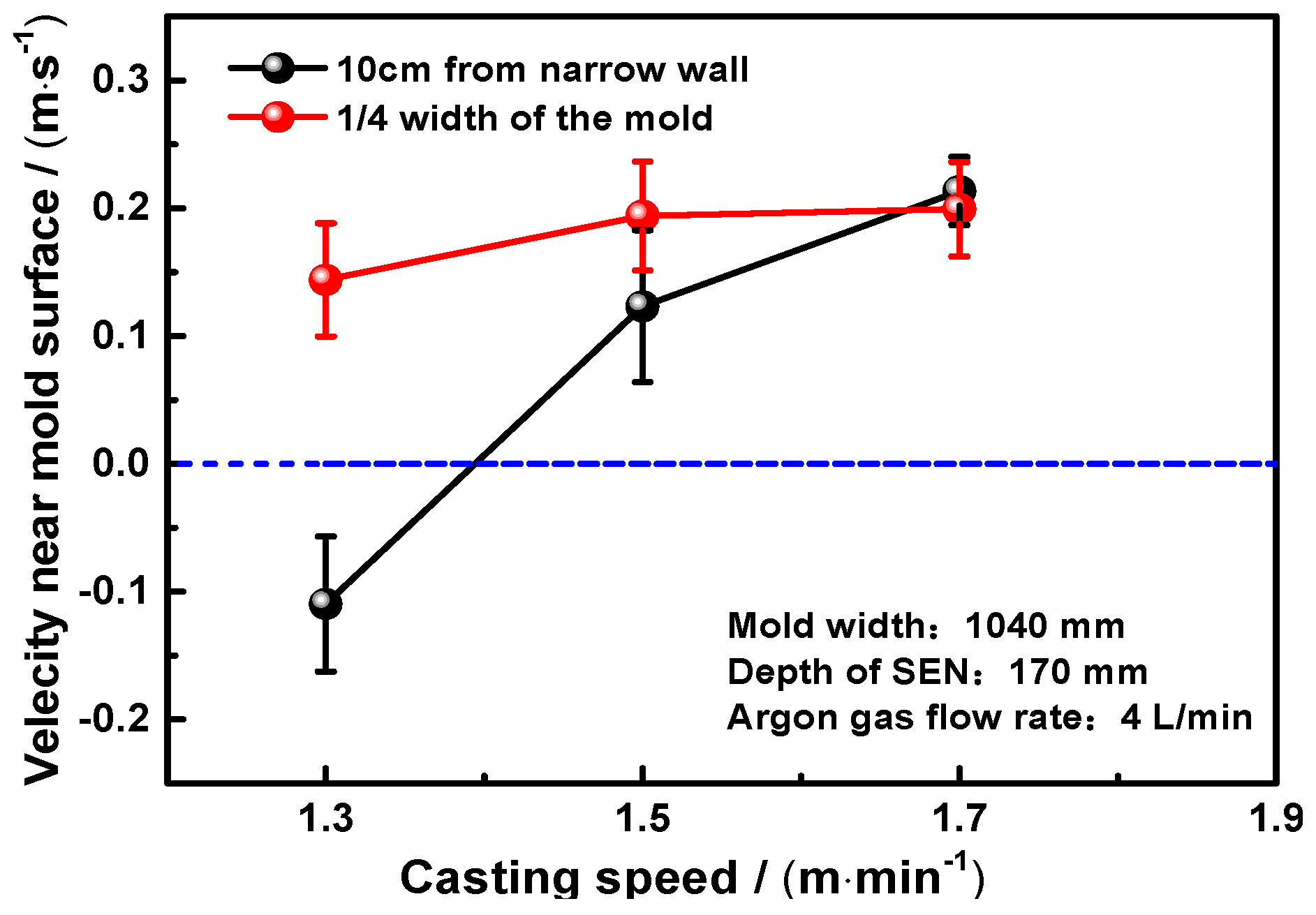

- Both experimental and calculated results show that the molten steel velocity near the mold surface increases with increasing casting speed. Furthermore, argon gas injection can slow down the molten steel velocity and uplift the jet zone, due to the buoyancy of bubbles.

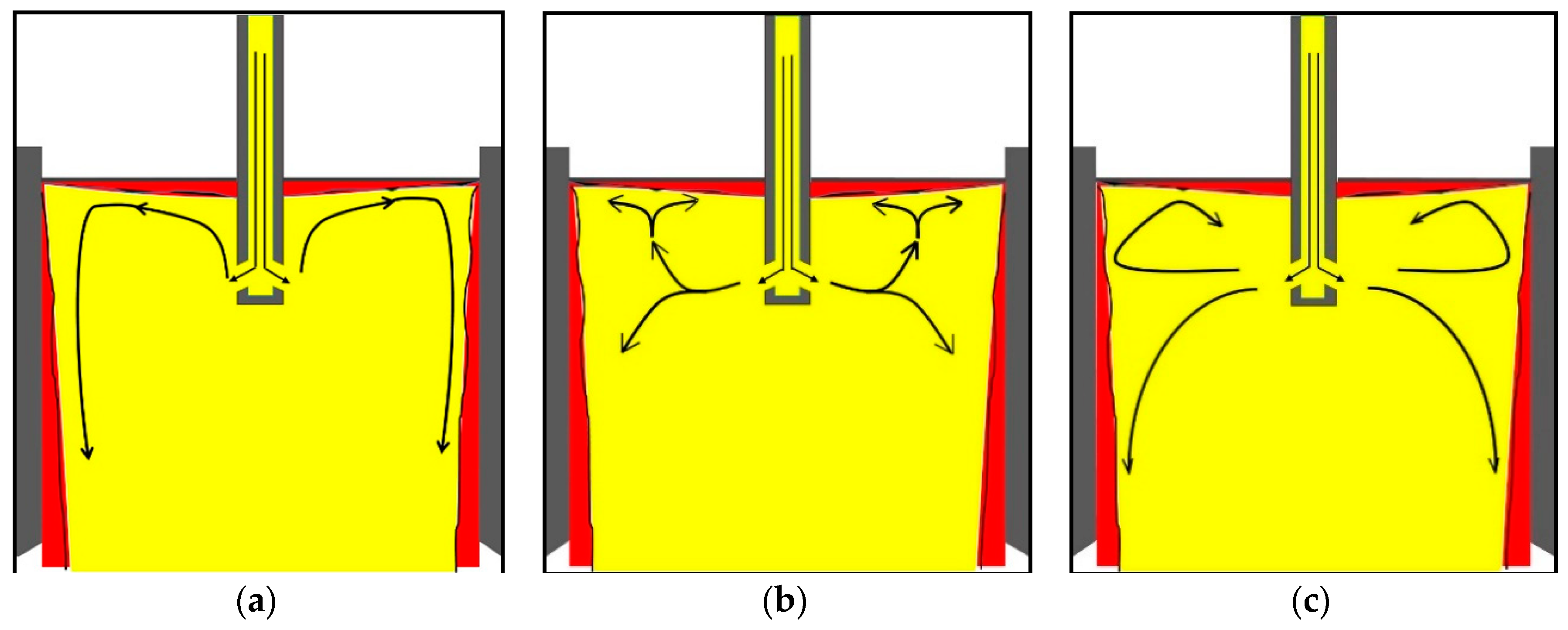

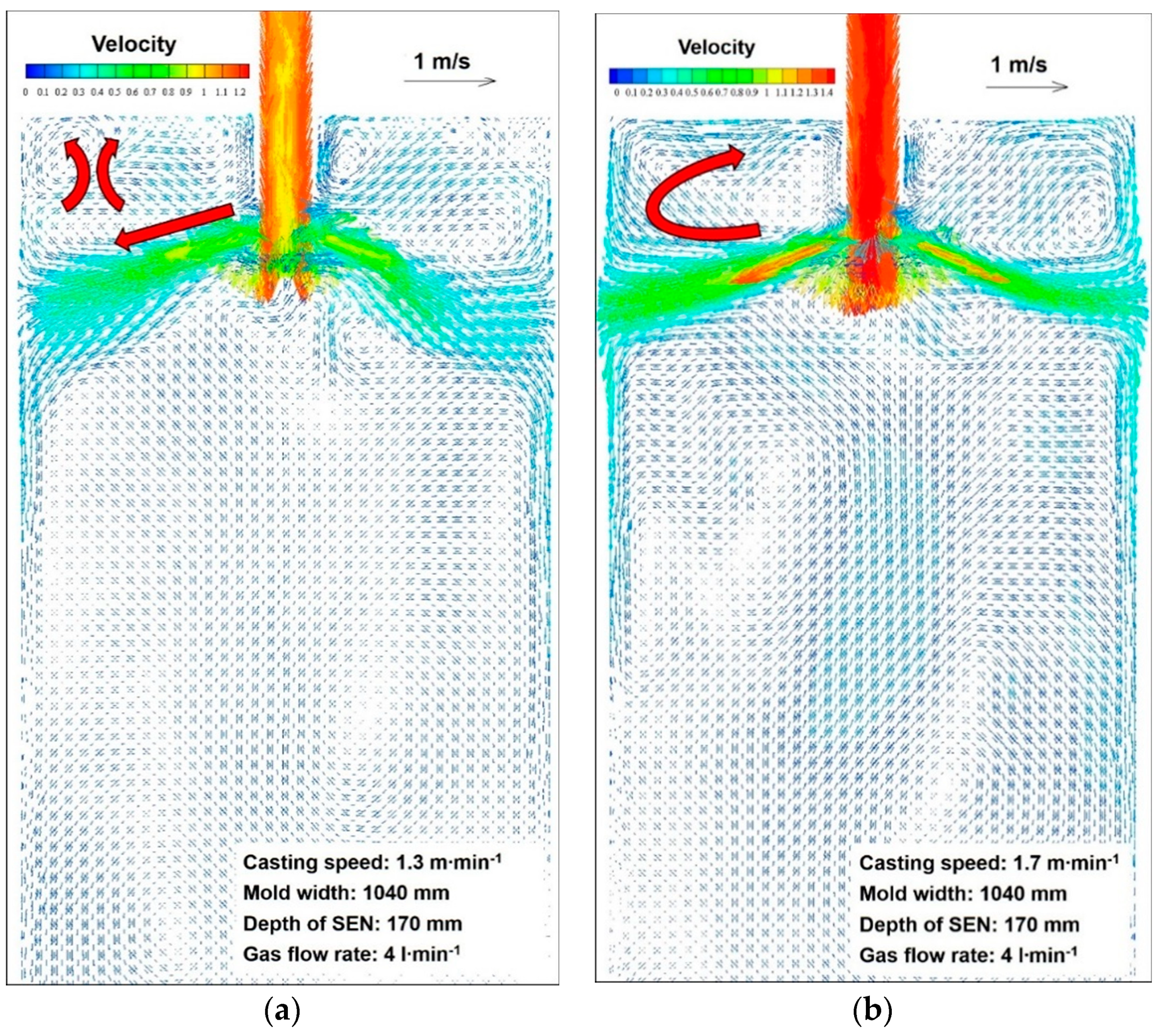

- Three different types of flow patterns of molten steel in the CC mold can be obtained from the present calculation and measurement results. The pattern A is the single-roll-flow (SRF) and the pattern C is the double-roll-flow (DRF). The pattern B is a transition state between DRF and SRF, which is neither cause the vortices nor excessive surface velocity on the meniscus, so the slag entrainment rarely occurs.

- It is found both from the measurement results and calculated results of the molten steel velocity near the mold surface that the casting speed can change the flow pattern in the mold. When the argon flow rate is 4 l/min and the casting speed is 1.0 m/min, the SRF will be formed. However, the flow pattern becomes the DRF with increasing the casting speed to larger than 1.3 m/min.

- Good and reasonable agreements have been obtained between the calculated and measured results. Combination of the measurement and calculation results is an effective tool to investigate the transient flow behavior in the CC mold and optimize the actual operation parameters of continuous casting to avoid the surface defects of the automobile outer panel.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.H. Non-metallic inclusion control technology for high quality cold rolled steel sheets. Iron Steel 2013, 48, 1–7. [Google Scholar]

- Zeze, M.; Tanaka, A.; Tsujino, R. Formation Mechanism of Sliver-type Surface Defects with Oxide Scale on Sheet and Coil. Tetsu-to-Hagane 2001, 87, 15–22. [Google Scholar] [CrossRef]

- Yang, J.; Zhi, J.J.; Wang, R.Z.; Zhu, K. Analysis of involved mold powders and inclusions for the surface defects on car body panels. In Proceedings of the 17th Chinese Steelmaking Conference, Hangzhou, China, 16 May 2013; pp. 809–814. [Google Scholar]

- Wang, X.H. Possibility of producing high quality cold rolled coils with thin slab casting production route. Iron Steel 2004, 39, 18–25. [Google Scholar]

- Yuan, F.M.; Wang, X.H.; Liu, X.M. Research of surface inclusive slag defects in interstitial-free steel slab. Contin. Cast. 2004, 6, 32–35. [Google Scholar]

- Bai, H.; Thomas, B.G. Turbulent flow of liquid steel and argon bubbles in slide-gate tundish nozzles: Part I. Model development and validation. Metall. Mater. Trans. B 2001, 32, 253–267. [Google Scholar] [CrossRef]

- Thomas, B.G. Review on modeling and simulation of continuous casting. Steel Res. Int. 2017, 89, 1700312. [Google Scholar] [CrossRef]

- Zhang, T.; Luo, Z.G.; Liu, C.L.; Zhou, H.; Zou, Z.S. A mathematical model considering the interaction of bubbles in continuous casting mold of steel. Powder Technol. 2015, 273, 154–164. [Google Scholar] [CrossRef]

- Zhu, M.Y.; Cai, Z.Z.; Yu, H.Q. Multiphase flow and thermo-mechanical behaviors of solidifying shell in continuous casting mold. J. Iron Steel Res. Int. 2013, 20, 6–17. [Google Scholar] [CrossRef]

- Liu, Z.; Li, B.; Jiang, M. Transient asymmetric flow and bubble transport inside a slab continuous-casting mold. Metall. Mater. Trans. B 2013, 45, 675–697. [Google Scholar] [CrossRef]

- Thomas, B.G.; Zhang, L. Mathematical modeling of fluid flow in continuous casting. ISIJ Int. 2001, 41, 1181–1193. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhao, B.; Vanka, S.P.; Thomas, B.G. Study of computational issues in simulation of transient flow in continuous casting. Steel Res. Int. 2005, 76, 33–43. [Google Scholar] [CrossRef]

- Chaudhary, R.; Ji, C.; Thomas, B.G.; Vanka, S.P. Transient turbulent flow in a liquid-metal model of continuous casting, including comparison of six different methods. Metall. Mater. Trans. B 2011, 42, 987–1007. [Google Scholar] [CrossRef]

- Kratzsch, C.; Timmel, K.; Eckert, S.; Schwarze, R. Urans simulation of continuous casting mold flow: Assessment of revised turbulence models. Steel Res. Int. 2015, 86, 400–410. [Google Scholar] [CrossRef]

- Liu, C.L.; Luo, Z.G.; Zhang, T.; Deng, S.; Wang, N.; Zou, Z.S. Mathematical modeling of multi-sized argon gas bubbles motion and its impact on melt flow in continuous casting mold of steel. J. Iron Steel Res. Int. 2014, 21, 403–407. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhang, L.F. Transient fluid flow phenomena during continuous casting: Part 1—cast start. ISIJ Int. 2010, 50, 1777–1782. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhang, L.F. Transient fluid flow phenomena during continuous casting: Part 2—cast speed change, temperature fluctuation, and steel grade mixing. ISIJ Int. 2010, 50, 1783–1791. [Google Scholar] [CrossRef]

- Thomas, B.G.; Yuan, Q.; Mahmood, S.; Liu, R.; Chaudhary, R. Transport and entrapment of particles in steel continuous casting. Metall. Mater. Trans. B 2014, 45, 22–35. [Google Scholar] [CrossRef]

- Singh, R.; Thomas, B.G.; Vanka, S.P. Effects of a magnetic field on turbulent flow in the mold region of a steel caster. Metall. Mater. Trans. B 2013, 44, 1201–1221. [Google Scholar] [CrossRef]

- Liu, Z.; Li, B.; Zhang, L.; Xu, G. Analysis of transient transport and entrapment of particle in continuous casting mold. ISIJ Int. 2014, 54, 2324–2333. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Li, L.; Li, B.; Jiang, M. Large eddy simulation of transient flow, solidification, and particle transport processes in continuous-casting mold. JOM 2014, 66, 1184–1196. [Google Scholar] [CrossRef]

- Singh, R.; Thomas, B.G.; Vanka, S.P. Large Eddy Simulations of Double-Ruler Electromagnetic Field Effect on Transient Flow During Continuous Casting. Mater. Trans. B 2014, 45, 1098–1115. [Google Scholar] [CrossRef]

- Miki, Y.; Takeuchi, S. Internal defects of continuous casting slabs caused by asymmetric unbalanced steel flow in mold. ISIJ Int. 2003, 43, 1548–1555. [Google Scholar] [CrossRef]

- Chaudhary, R.; Lee, G.G.; Thomas, B.G.; Cho, S.M.; Kim, S.-H.; Kwon, O.D. Effect of stopper-rod misalignment on fluid flow in continuous casting of steel. Metall. Mater. Trans. B 2011, 42, 300–315. [Google Scholar] [CrossRef]

- Yuan, Q.; Thomas, B.G.; Vanka, S.P. Study of transient flow and particle transport in continuous steel caster molds: Part I. Fluid flow. Metall. Mater. Trans. B 2004, 35, 685–702. [Google Scholar] [CrossRef]

- Shen, B.; Shen, H.; Liu, B. Instability of fluid flow and level fluctuation in continuous thin slab casting mould. ISIJ Int. 2007, 47, 427–432. [Google Scholar] [CrossRef]

- Thomas, B.G.; Yuan, Q.; Sivaramakrishnan, S.; Shi, T.; Vanka, S.P.; Assar, M.B. Comparison of four methods to evaluate fluid velocities in a continuous slab casting mold. ISIJ Int. 2001, 41, 1262–1271. [Google Scholar] [CrossRef]

- Sanchez-Perez, R.; Morales, R.D.; Diaz-Cruz, M. A physical model for the two-phase flow in a continuous casting mold. ISIJ Int. 2003, 43, 637–646. [Google Scholar] [CrossRef]

- Kubota, J.; Kubo, N.; Ishii, T. Steel flow control in continuous slab caster mold by traveling magnetic field. NKK Tech. Rev. 2001, 85, 1. [Google Scholar]

- Liu, R.; Thomas, B.G.; Sengupta, J.; Chung, S.D.; Trinh, M. Measurements of molten steel surface velocity and effect of stopper-rod movement on transient multiphase fluid flow in continuous casting. ISIJ Int. 2014, 54, 2314–2323. [Google Scholar] [CrossRef]

- Assar, M.B.; Dauby, P.H.; Lawson, G.D. The 83rd Steelmaking Conference; Iron and Steel Society: Pittsburgh, PA, USA, 2000. [Google Scholar]

- Iguchi, M.; Kawabata, H.; Demoto, Y.; Morita, Z. Cold model experiments for developing a new velocimeter applicable to molten metal. ISIJ Int. 1994, 34, 461–467. [Google Scholar] [CrossRef]

- Iguchi, M.; Terauchi, Y. Karman vortex probe for the detection of molten metal surface flow in low velocity range. ISIJ Int. 2002, 42, 939–943. [Google Scholar] [CrossRef]

- Jones, W.P.; Launder, B.E. The prediction of laminarization with a two-equation model of turbulence. Int. J. Heat Mass Transf. 1972, 15, 301–314. [Google Scholar] [CrossRef]

- Xu, Y.; Ersson, M.; Jönsson, P.G. A numerical study about the influence of a bubble wake flow on the removal of inclusions. ISIJ Int. 2016, 56, 1982–1988. [Google Scholar] [CrossRef]

- Thomas, B.G.; Huang, X.; Sussman, R.C. Simulation of argon gas flow effects in a continuous slab caster. Metall. Mater. Trans. B 1994, 25B, 527. [Google Scholar] [CrossRef]

- Zhang, T.; Luo, Z.; Zhou, H.; Ni, B.; Zou, Z. Analysis of two-phase flow and bubbles behavior in a continuous casting mold using a mathematical model considering the interaction of bubbles. ISIJ Int. 2016, 56, 116–125. [Google Scholar] [CrossRef]

- Deng, X.; Ji, C.; Cui, Y.; Li, L.; Yin, X.; Yang, Y.; McLean, A. Flow pattern control in continuous slab casting moulds: Physical modelling and plant trials. Ironmak. Steelmak. 2016, 44, 461–471. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Slab width (mm) | 1040, 1080, 1275 | Fluid density (kg/m3) | 7020 |

| Slab thickness (mm) | 230 | Gravity acceleration (m/s2) | 9.81 |

| Slab length (mm) | 3000 | Gas density (kg/m3) | 0.27 |

| SEN submerged depth (mm) | 170 | Gas bubble radius (mm) | 0.5 |

| Casting speed (m/min) | 1.0, 1.3, 1.5, 1.7 | Gas volume flow (l/min) | 0, 4, 7 |

| Fluid dynamic viscosity(N·s/m2) | 0.0056 | SEN port angle (°) | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Yang, J.; Jiang, P. Measurement of Molten Steel Velocity near the Surface and Modeling for Transient Fluid Flow in the Continuous Casting Mold. Metals 2019, 9, 36. https://doi.org/10.3390/met9010036

Zhang T, Yang J, Jiang P. Measurement of Molten Steel Velocity near the Surface and Modeling for Transient Fluid Flow in the Continuous Casting Mold. Metals. 2019; 9(1):36. https://doi.org/10.3390/met9010036

Chicago/Turabian StyleZhang, Tao, Jian Yang, and Peng Jiang. 2019. "Measurement of Molten Steel Velocity near the Surface and Modeling for Transient Fluid Flow in the Continuous Casting Mold" Metals 9, no. 1: 36. https://doi.org/10.3390/met9010036

APA StyleZhang, T., Yang, J., & Jiang, P. (2019). Measurement of Molten Steel Velocity near the Surface and Modeling for Transient Fluid Flow in the Continuous Casting Mold. Metals, 9(1), 36. https://doi.org/10.3390/met9010036