Phase Field Simulations of Microstructure Evolution in IN718 Using a Surrogate Ni–Fe–Nb Alloy during Laser Powder Bed Fusion †

Abstract

1. Introduction

2. Computational Approach

2.1. Heat and Fluid Flow

2.2. Phase Field Theory

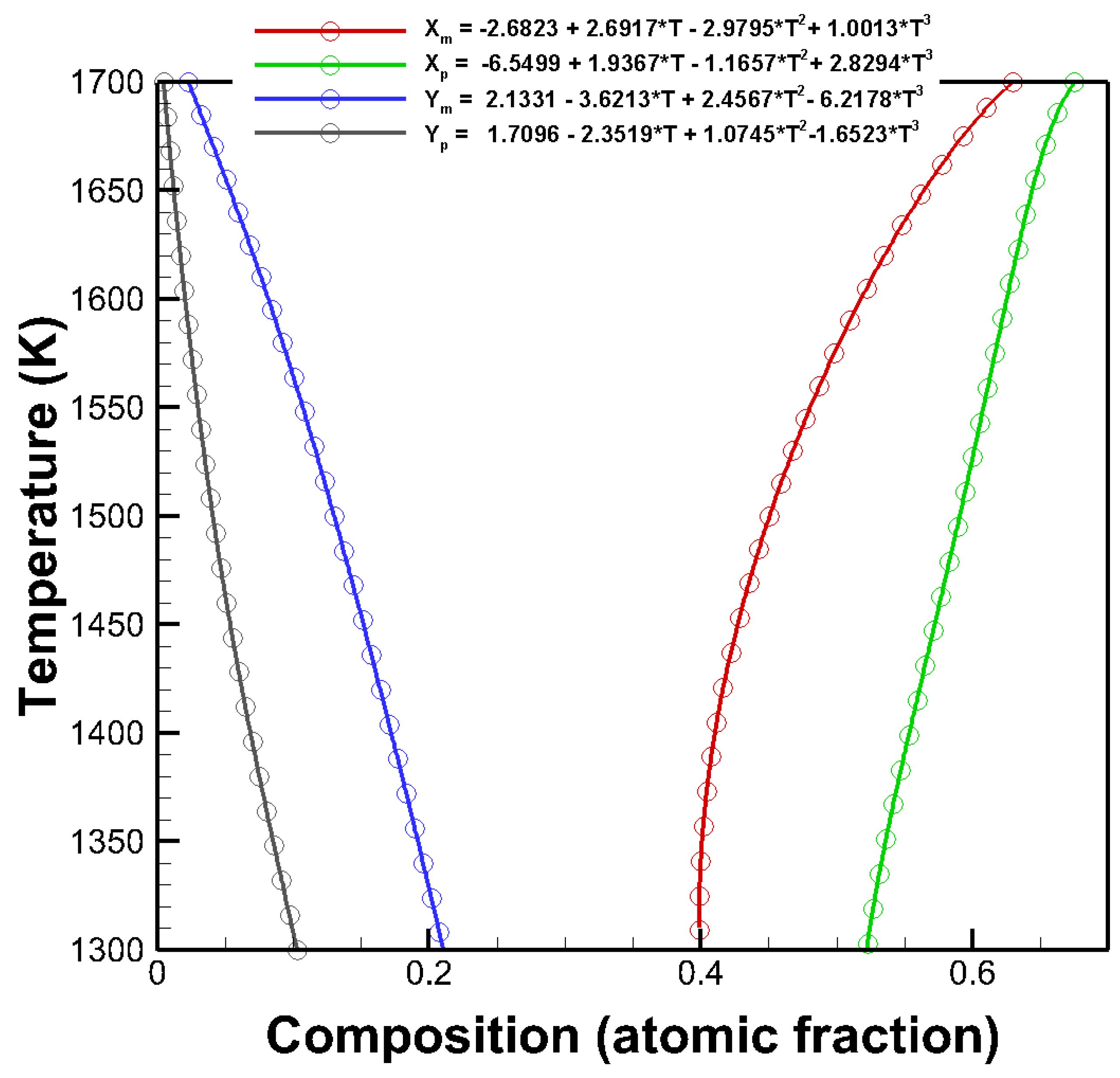

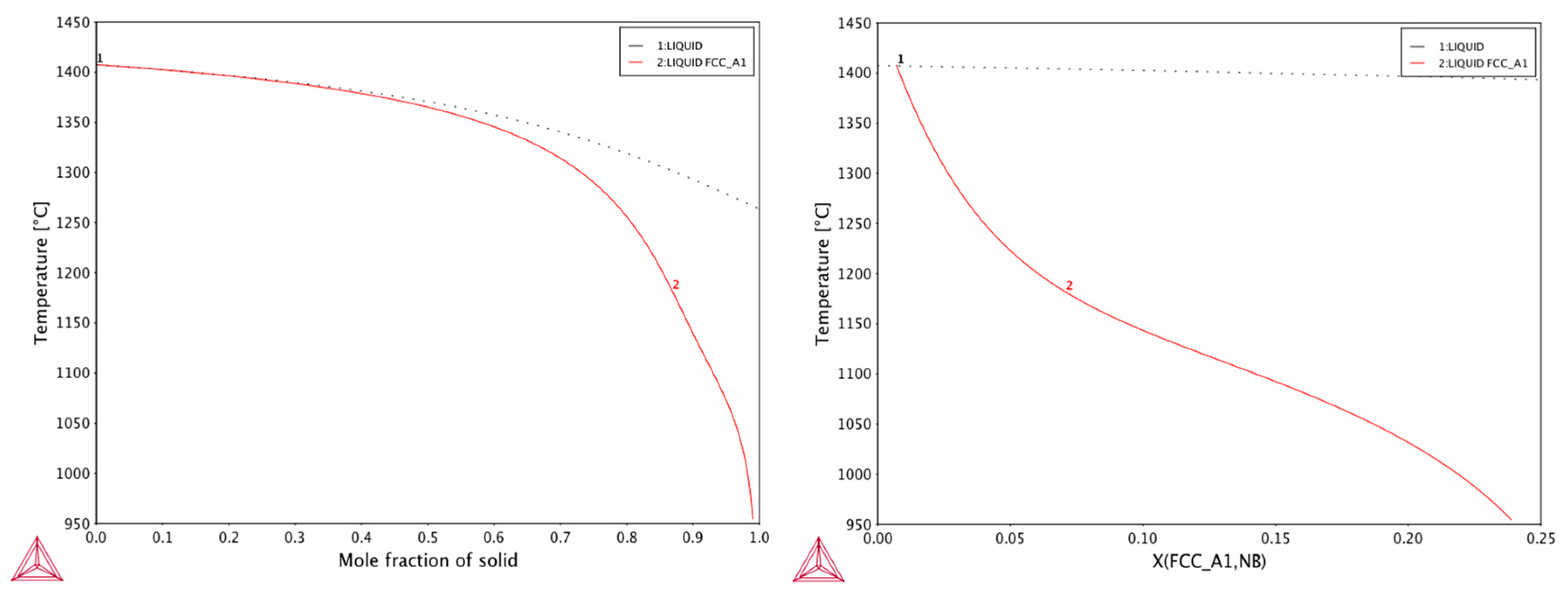

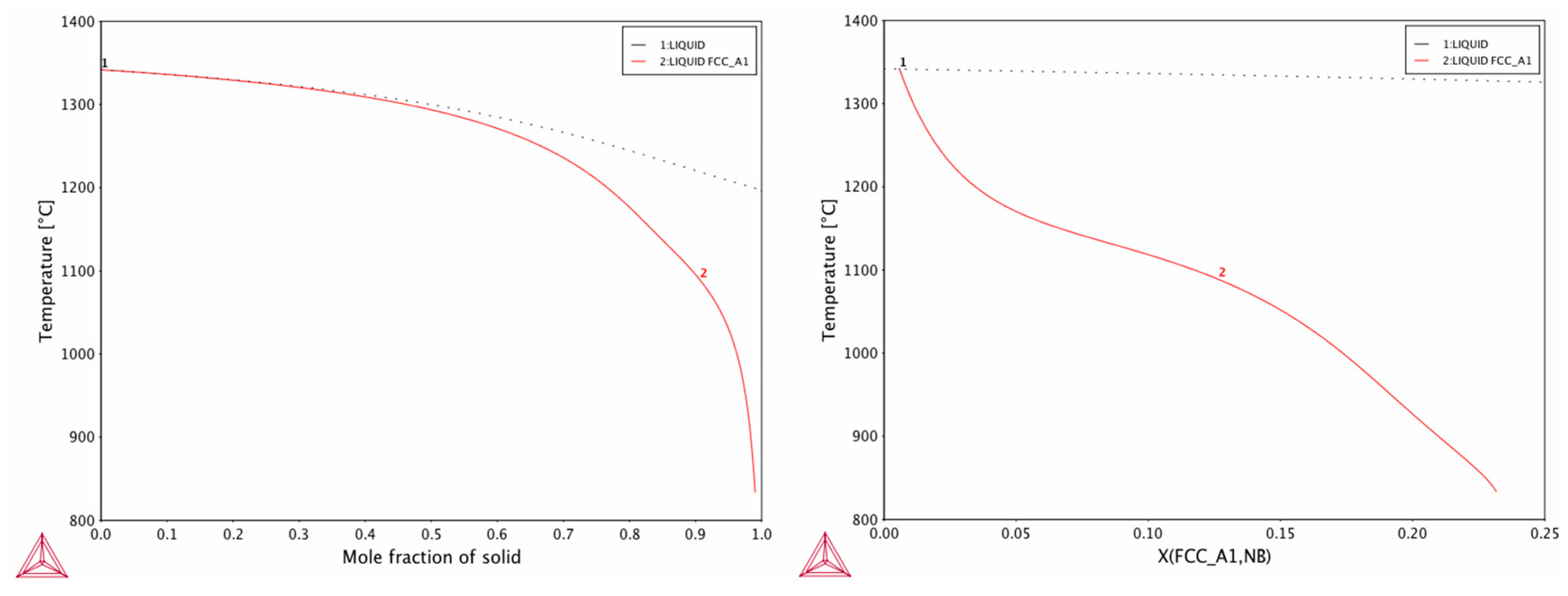

2.3. Surrogate Alloy and CALPHAD Integration

3. Experimental Approach

4. Numerical Results

4.1. Simulation Details

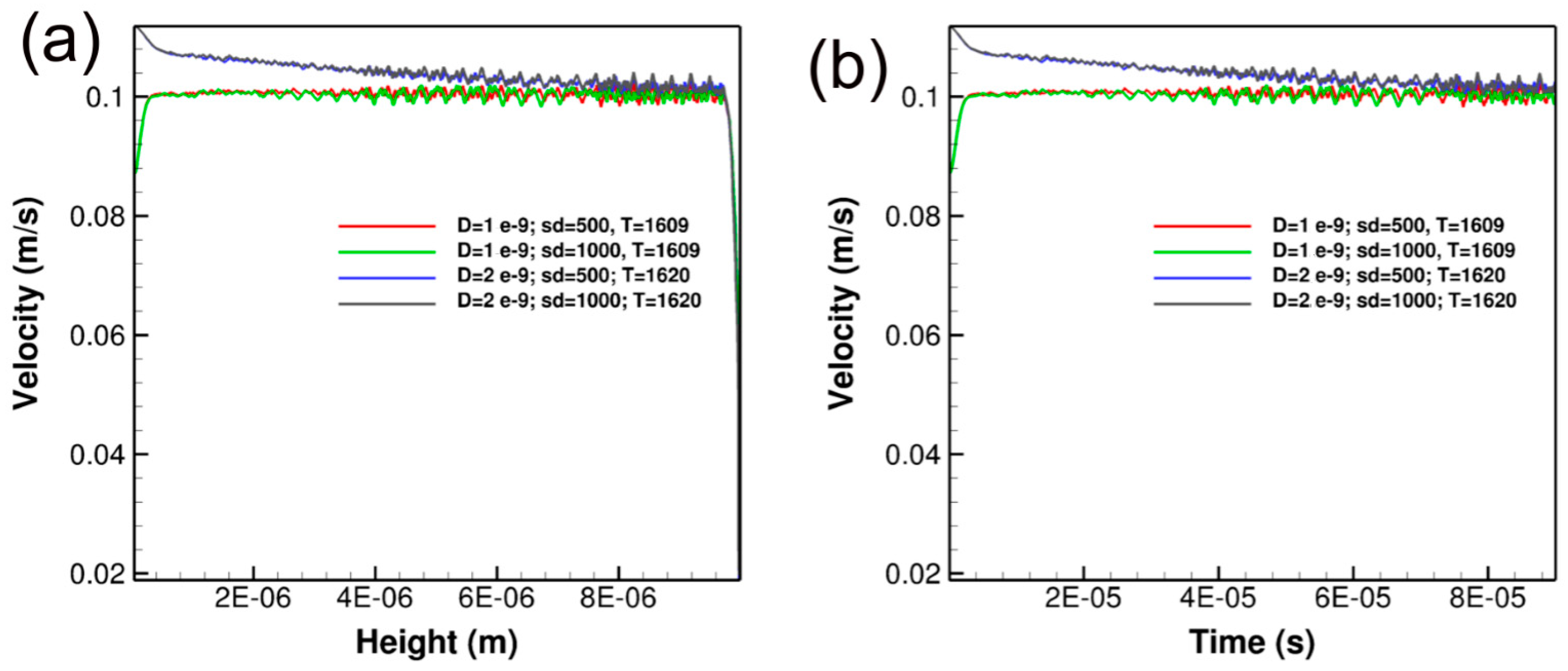

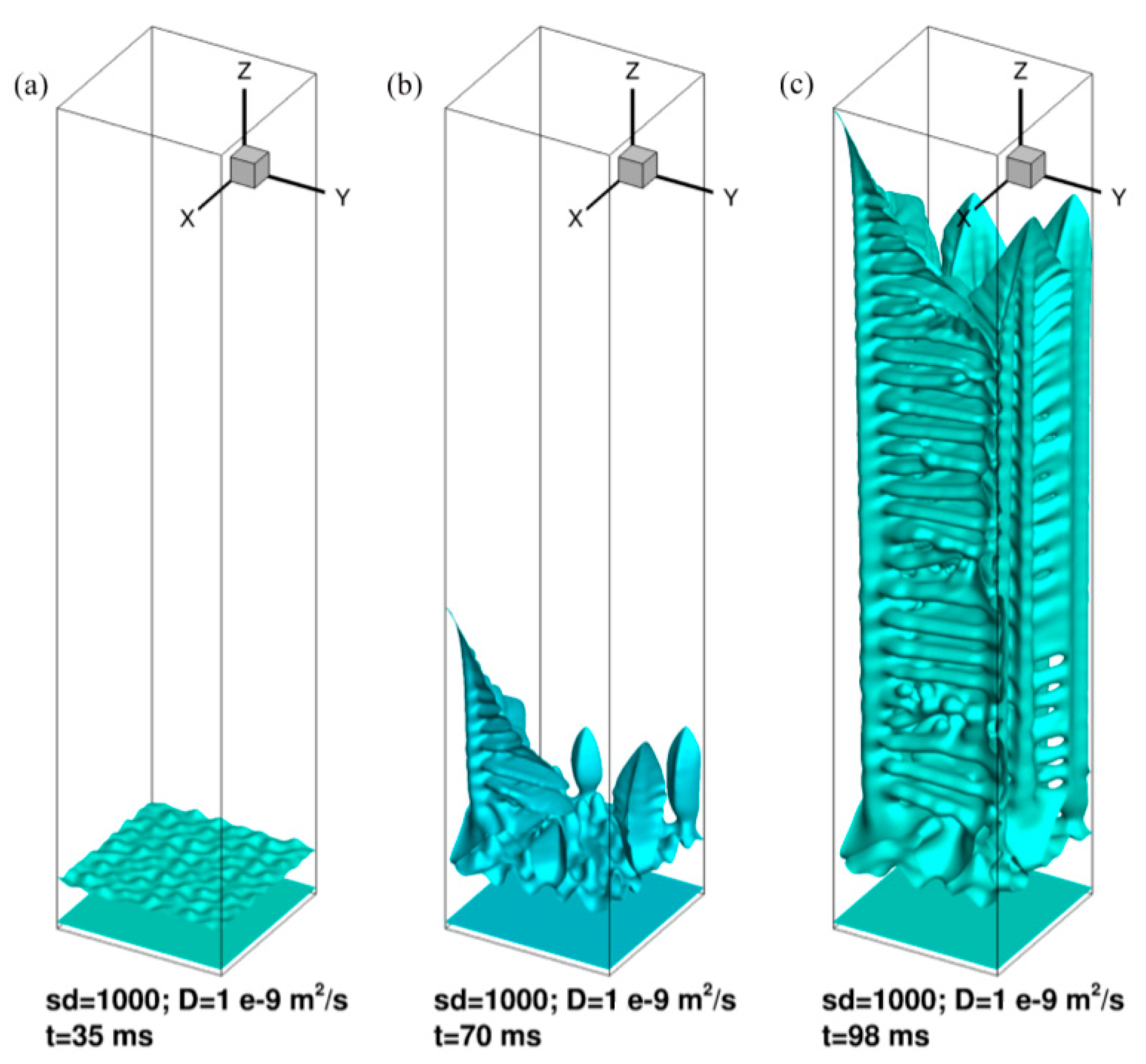

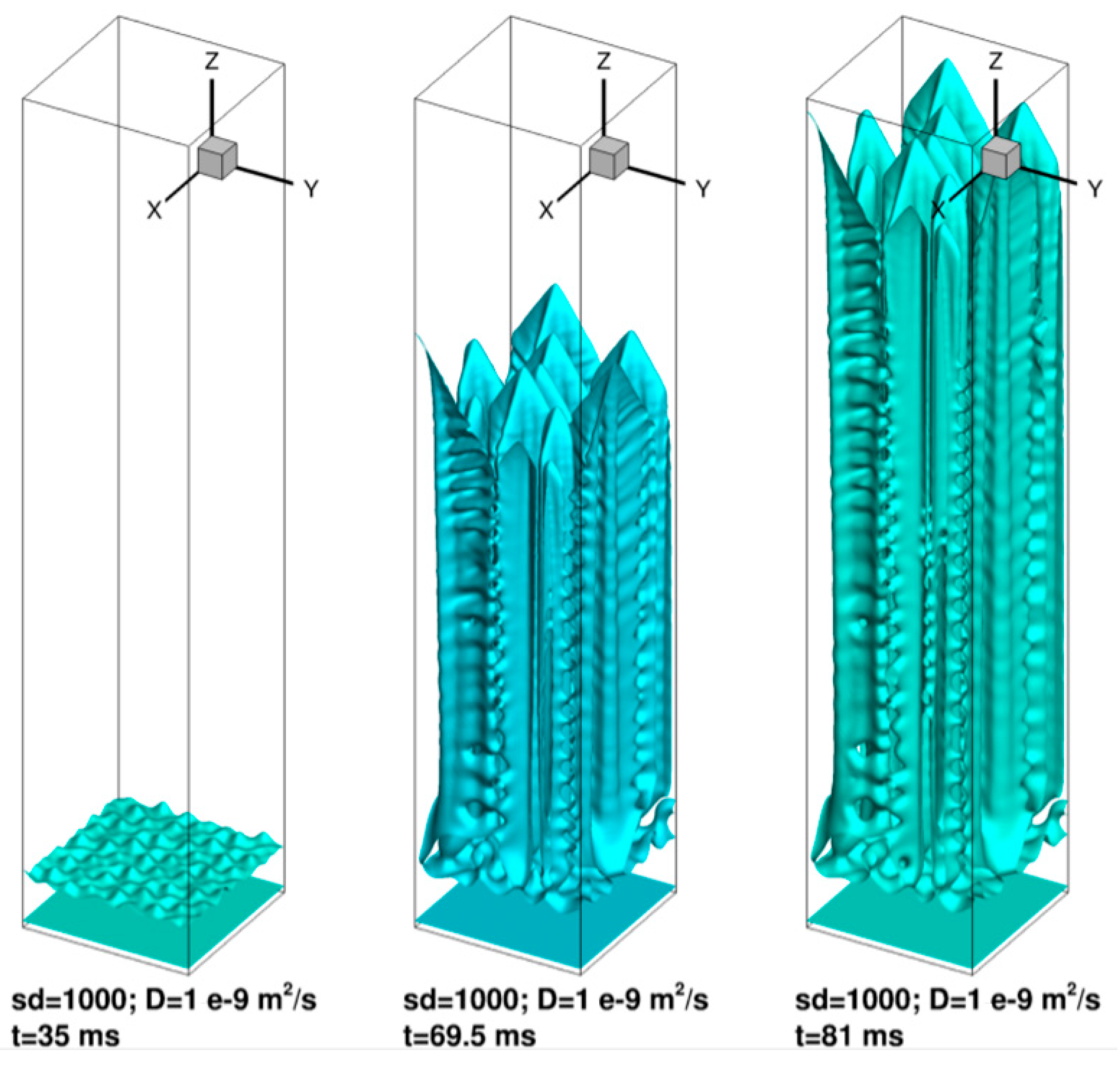

4.2. Effect of Superimposed Noise–Isothermal Solidification

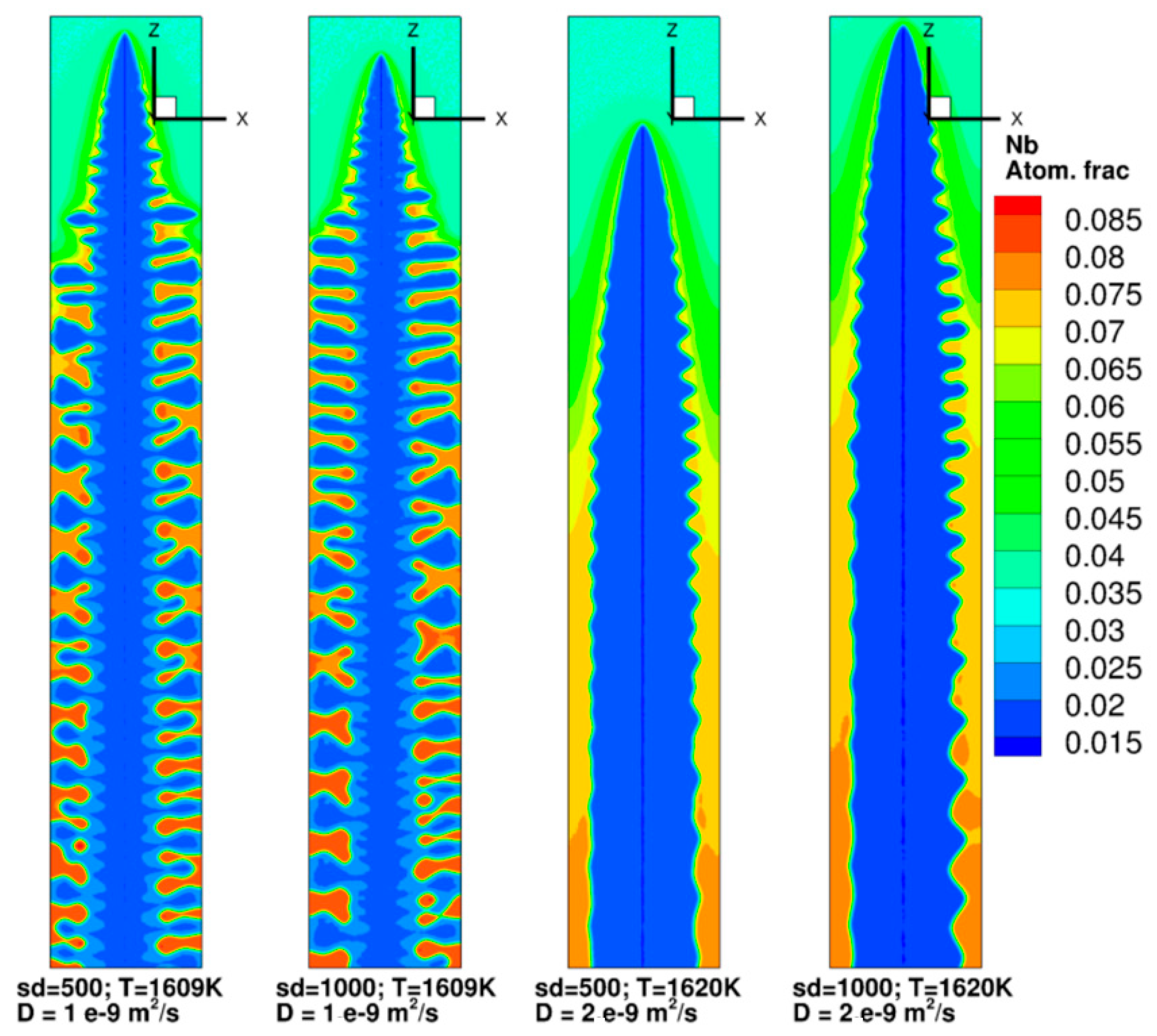

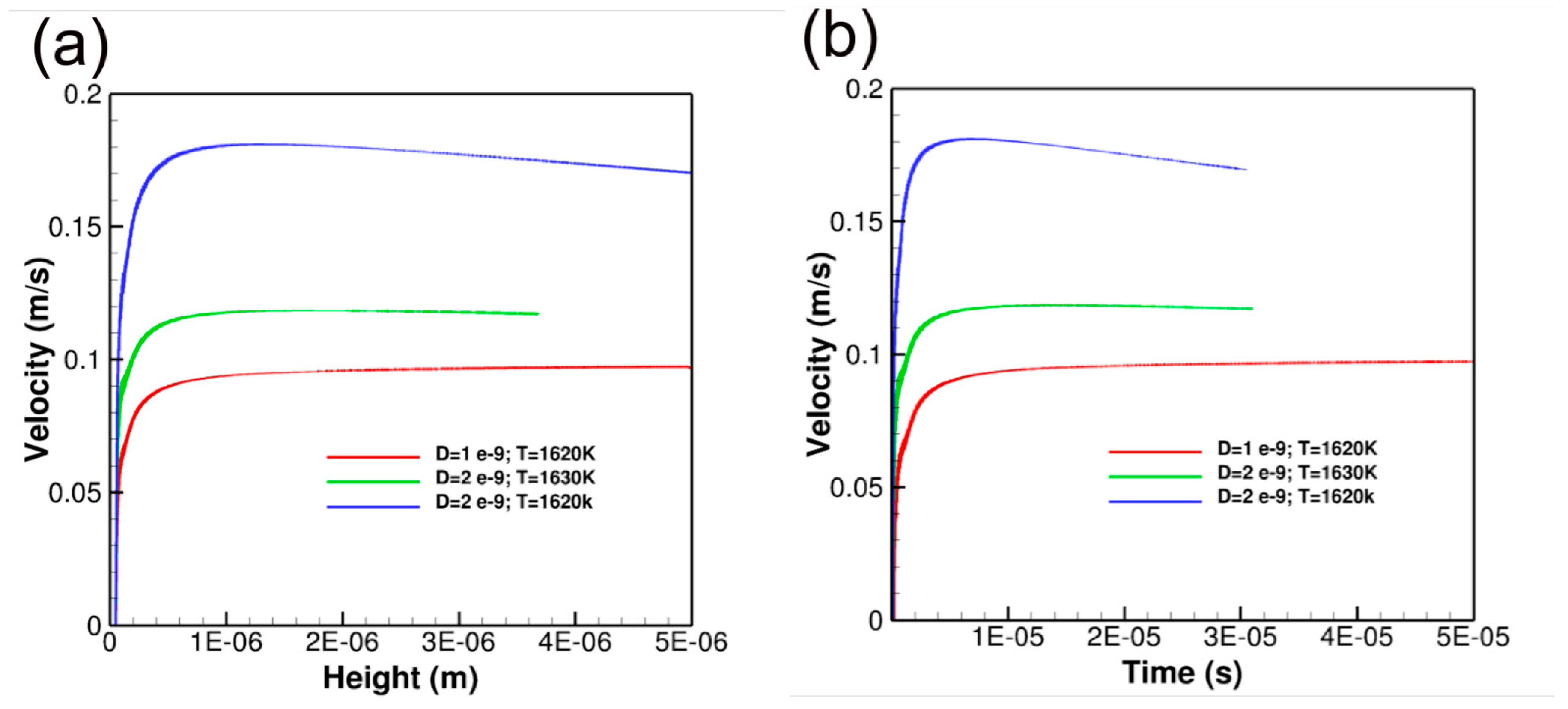

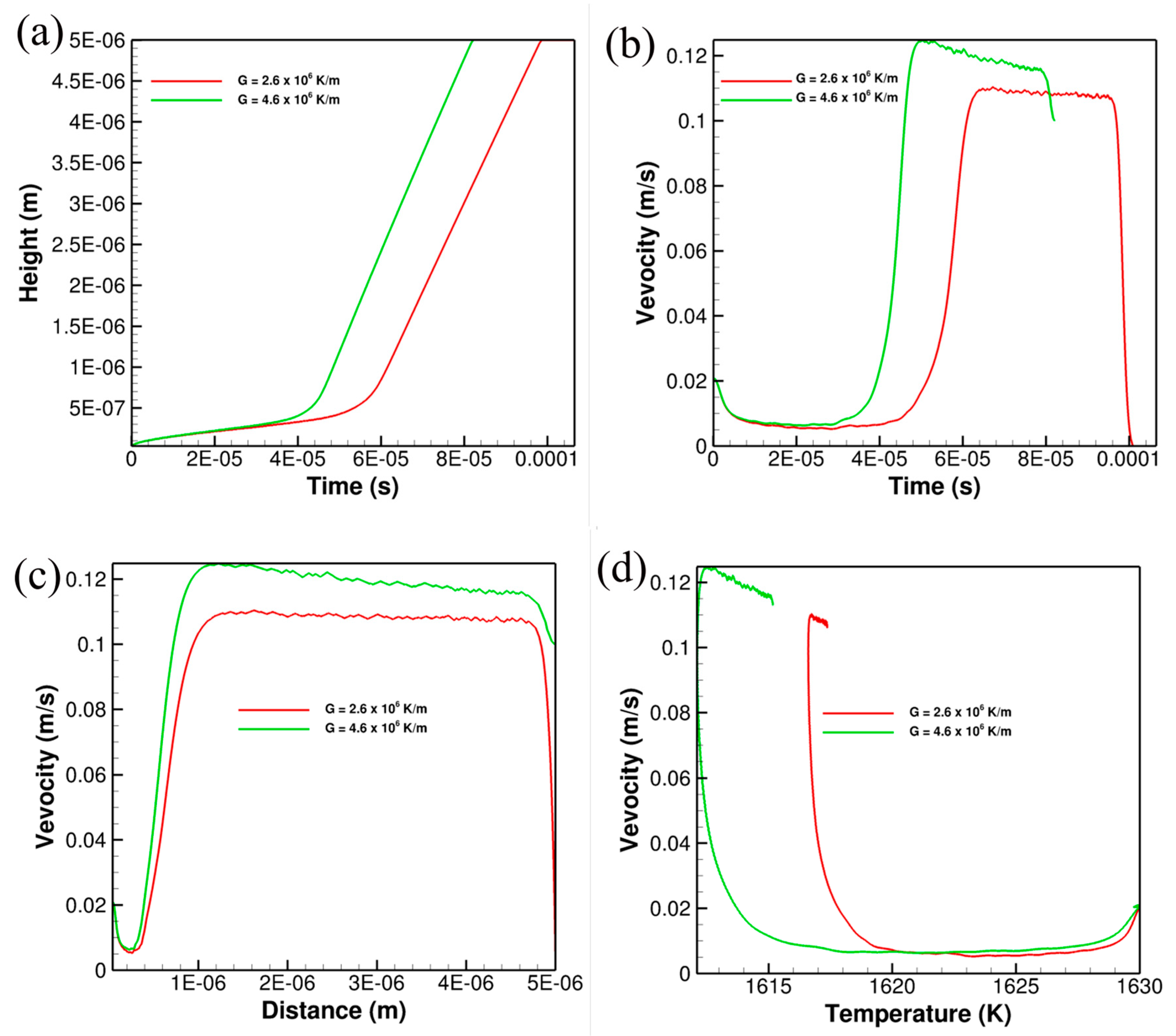

4.3. Directional Solidification–Steady State

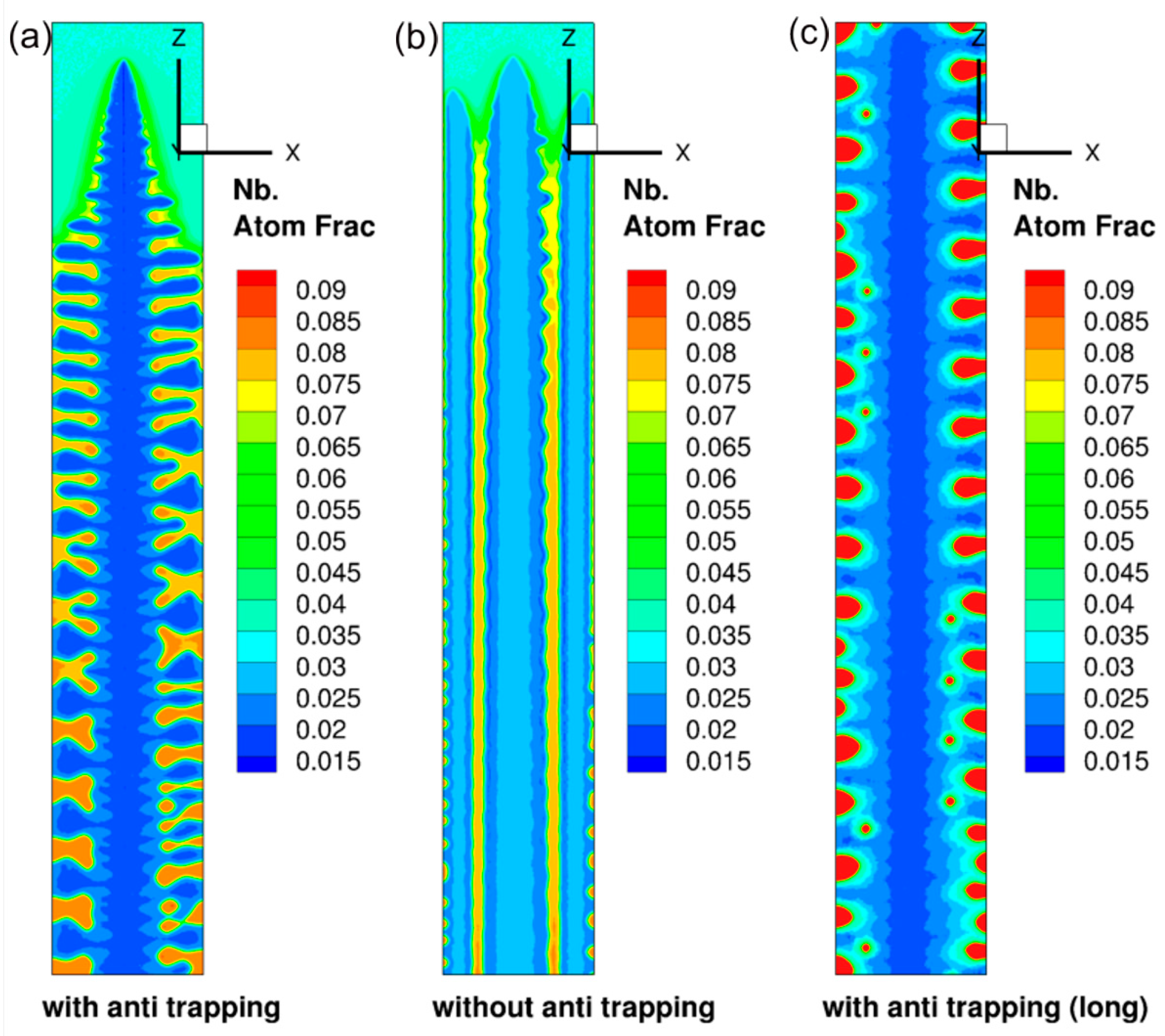

4.4. Effect of Anti-trapping Current

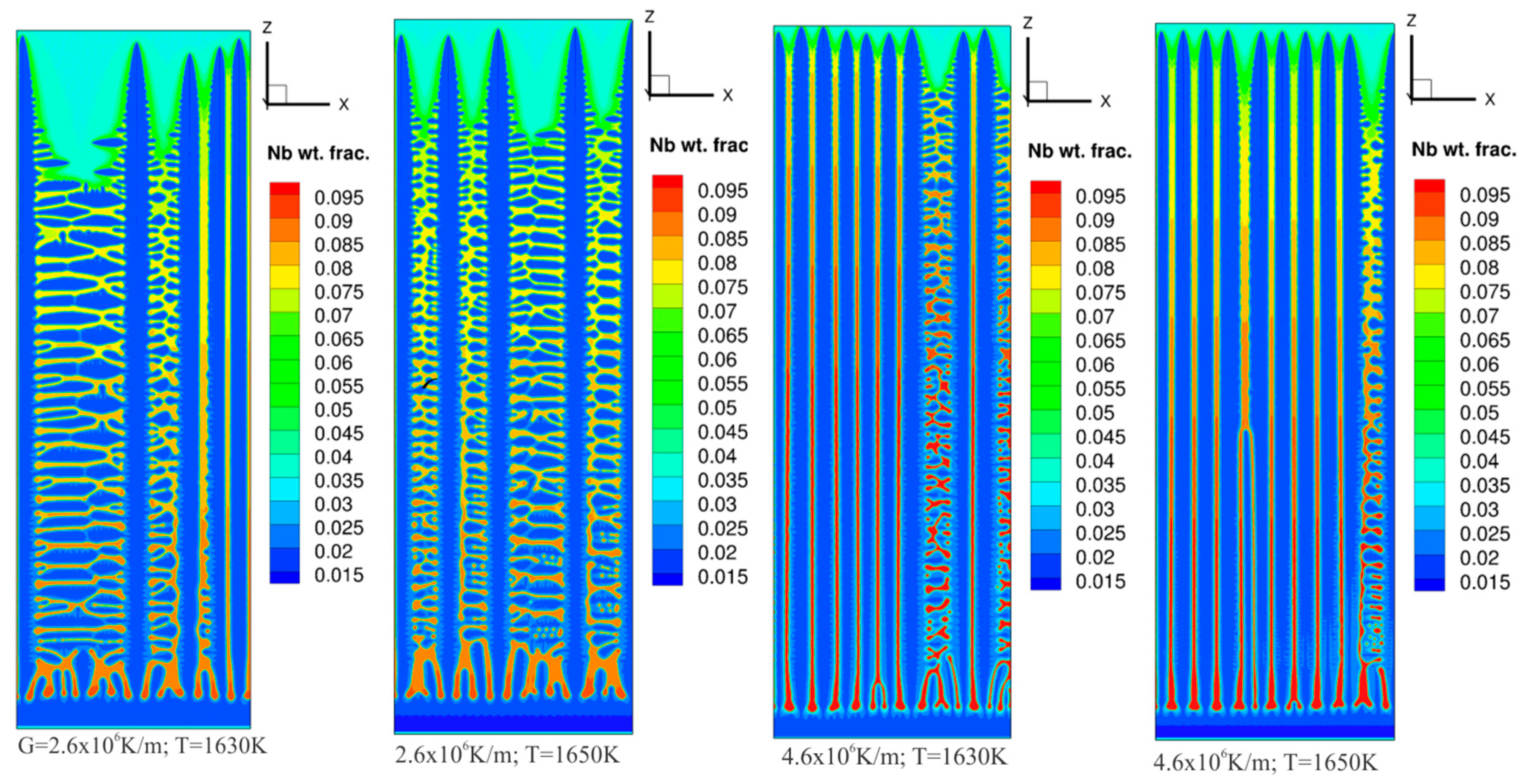

Nb Enrichment in Re-Solidified Interdendritic Areas

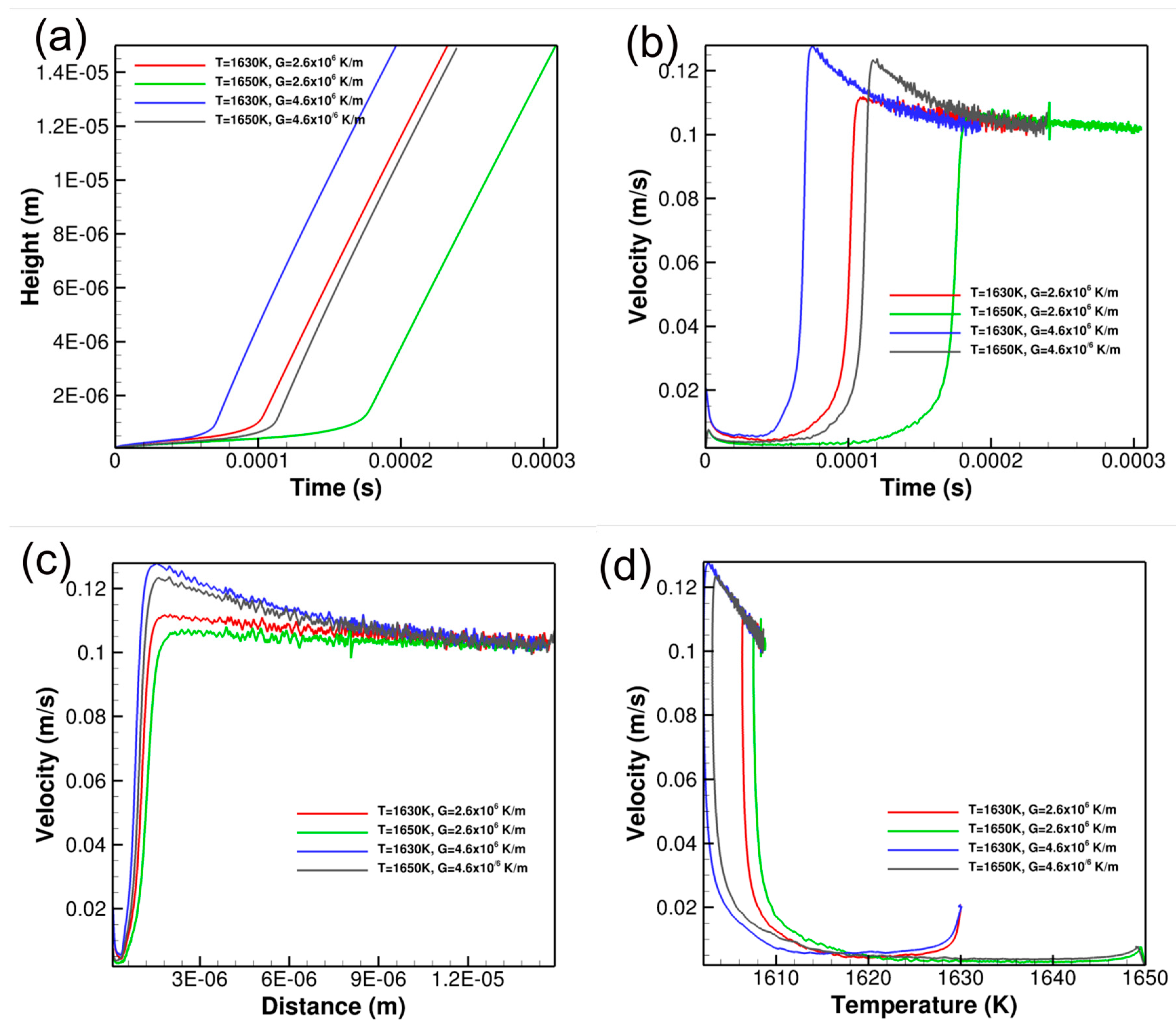

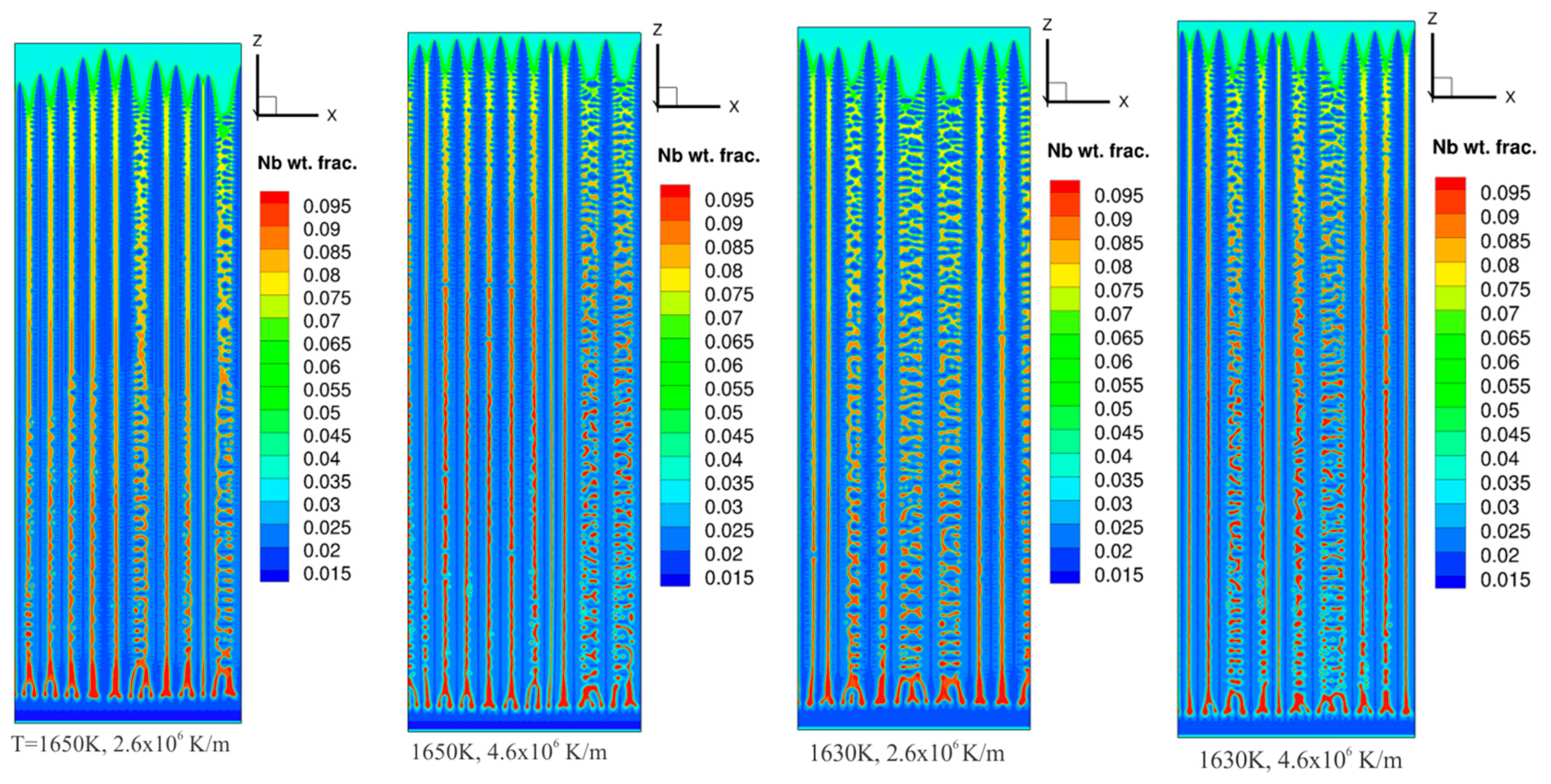

4.5. Directional Solidification Unsteady State Conditions

5. Discussion

5.1. Impact of Anti-Trapping Term

5.2. Effect of Superimposed Noise

5.3. Columnar to Dendritic Transition

5.4. Primary Dendrite Arm Spacing (PDAS)

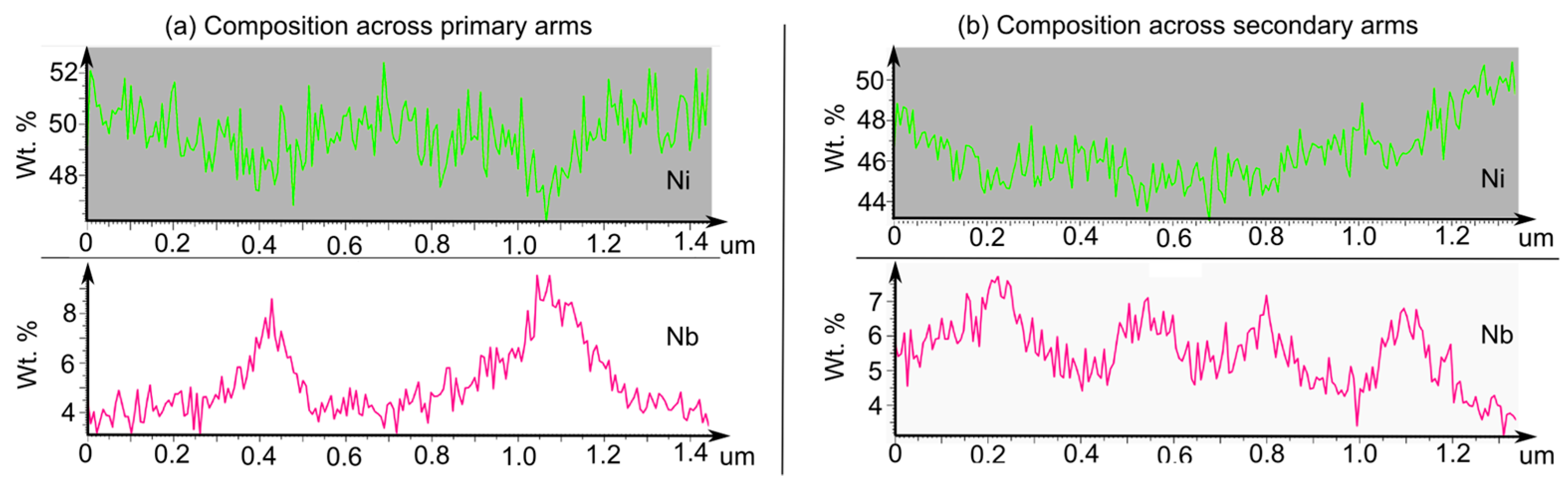

5.5. Secondary Dendrite Arm Spacing (SDAS)

5.6. Nb Enrichment in the Interdendritic Regions

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| 0 |

References

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Beese, A.M.; Wilson-Heid, A.; Elmer, J.W.; Milewski, J.O.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Raghavan, A.; Wei, H.L.; Palmer, T.A.; DebRoy, T. Heat Transfer and Fluid Flow in Additive Manufacturing. J. Laser Appl. 2013, 25, 052006. [Google Scholar] [CrossRef]

- Raghavan, N.; Dehoff, R.; Pannala, S.; Simunovic, S.; Kirka, M.; Turner, J.; Carlson, N.; Babu, S. Numerical modeling of heat transfer and the influence of process parameters on tailoring the grain morphology of IN718 in electron beam additive manufacturing. Acta Mater. 2016, 112, 303–314. [Google Scholar] [CrossRef]

- Keller, T.; Lindwall, G.; Ghosh, S.; Ma, L.; Lane, B.M.; Zhang, F.; Kattner, U.; Lass, E.; Heigel, J.; Idell, Y. Application of finite-element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys. Acta Mater. 2017, 139, 244–253. [Google Scholar] [CrossRef] [PubMed]

- Acharya, R.; Sharon, J.A.; Staroselsky, A. Prediction of microstructure in laser powder bed fusion process. Acta Mater. 2017, 124, 360–371. [Google Scholar] [CrossRef]

- Dehoff, R.; Kirka, M.; Sames, W.; Bilheux, H.; Tremsin, A.; Lowe, L.; Babu, S. Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater. Sci. Technol. 2015, 32, 931–938. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, J. Phase Field Simulation of Dendritic Solidification of Ti-6Al-4V During Additive Manufacturing Process. JOM 2018, 70, 2392–2399. [Google Scholar] [CrossRef]

- Roehling, J.D.; Perron, A.; Fattebert, J.L.; Haxhimali, T.; Guss, G.; Li, T.T.; Bober, D.; Stokes, A.W.; Clarke, A.J.; Turchi, P.E.; et al. Rapid Solidification in Bulk Ti-Nb Alloys by Single-Track Laser Melting. JOM 2018, 70, 1589–1597. [Google Scholar] [CrossRef]

- Kim, S.G.; Kim, W.T.; Suzuki, T. Phase-field model for binary alloys. Phys. Rev. E 1999, 60, 7186–7197. [Google Scholar] [CrossRef]

- Bottger, B.; Apel, M.; Schaffnit, P.; Steinbach, I. Phase-Field Simulation of Solidification and Solid-State Transformations in Multicomponent Steels. Steel Res. Int. 2008, 79, 608–616. [Google Scholar] [CrossRef]

- Boettinger, W.J.; Warren, J.A.; Beckermann, C.; Karma, A. Phase-field simulation of solidification. Annu. Rev. Mater. Res. 2002, 32, 163–194. [Google Scholar] [CrossRef]

- Moelans, N.; Blanpain, B.; Wollants, P. An introduction to phase-field modeling of microstructure evolution. Comput. Coupling Phase Diagr. Thermochem. 2008, 32, 268–294. [Google Scholar] [CrossRef]

- Steinbach, I. Phase-field models in materials science. Model. Simul. Mater. Sci. Eng. 2009, 17, 073001. [Google Scholar] [CrossRef]

- Wang, X.C.; Kruth, J.P. Finite element analysis of thermal process in direct selective laser sintering. In Proceedings of the 1st International Seminar on Progress in Innovative Manufacturing Engineering, Genoa, Italy, 20–22 June 2001; pp. 205–210. [Google Scholar]

- Kim, S.G. A phase field model with antitrapping current for multicomponent alloys with arbitrary thermodynamic properties. Acta Mater. 2003, 55, 4391–4399. [Google Scholar] [CrossRef]

- Radhakrishnan, B.; Gorti, S.B.; Babu, S.S. Phase Field Simulations of Autocatalytic Formation of Alpha Lamellar Colonies in Ti-6Al-4V. Metall. Mater. Trans. A 2016, 47, 6577–6592. [Google Scholar] [CrossRef]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Kattner, U.R. The CALPHAD method and its role in material and process development. Tecnol. Met. Mater. Mineracao 2016, 13, 3–15. [Google Scholar] [CrossRef] [PubMed]

- Kundin, J.; Mushongera, L.; Emmerich, H. Phase-field modeling of microstructure formation during rapid solidification in Inconel 718 superalloy. Acta Mater. 2015, 95, 343–356. [Google Scholar] [CrossRef]

- Aziz, M.A.; Kaplan, T. Continuous Growth Model for Interface Motion during Alloy Solidification. Acta Metall. 1988, 36, 2335–2347. [Google Scholar] [CrossRef]

- Karma, A.; Rappel, W.J. Phase-field model of dendritic sidebrancing with thermal noise. Phys. Rev. E 1999, 60, 3614–3625. [Google Scholar] [CrossRef]

- Tourret, D.; Karma, A. Growth competition of columnar dendrite grains: A phase-field study. Acta Mater. 2015, 82, 64–83. [Google Scholar] [CrossRef]

- Mullis, A.M. Spontaneous deterministic side-branching behavior in phase field simulations of equiaxed dendritic growth. J. Appl. Phys. 2015, 117, 114305. [Google Scholar] [CrossRef]

- Wu, J.; Guo, Z.; Luo, C. Development of a parallel adaptive multigrid algorithm for solving the multi-scale thermal-solute 3D phase-field problems. Comput. Mater. Sci. 2018, 142, 89–98. [Google Scholar] [CrossRef]

- Fattebert, J.L.; (Oak Ridge National Laboratory, Oak Ridge, TN, USA). Personal communication, 2018.

- Trivedi, R.; Shen, Y.; Liu, S. Cellular-to-dendritic transition during the directional solidification of binary alloys. Metall. Mater. Trans. A 2003, 34, 395–401. [Google Scholar] [CrossRef]

- Rocha, O.L.; Siqueira, C.A.; Garcia, A. Cellular/dendritic transition during unsteady-state unidirectional solidification of Sn–Pb alloys. Mater. Sci. Eng. A 2003, 347, 59–69. [Google Scholar] [CrossRef]

- Rosa, D.M.; Spinelli, J.E.; Ferreira, I.L.; Garcia, A. Cellular/dendritic transition and microstructure evolution during transient directional solidification of Pb-Sb alloys. Metall. Mater. Trans. A 2008, 39, 2161–2174. [Google Scholar] [CrossRef]

| Power (W) | Scan Speed (m/s) | G (K/m) | Solidification period (sec) | Cooling rate (K/s) | Mean solidification velocity (m/s) |

|---|---|---|---|---|---|

| 285 | 0.96 | 2.6 × 106 | 0.00054 | 248816 | 0.096 |

| 180 | 0.6 | 4.6 × 106 | 0.00025 | 536000 | 0.117 |

| Sample number | Power, W | Speed, m/s | PDAS, nm (stdev) | SDAS, nm (stdev) |

|---|---|---|---|---|

| 1 | 285 | 0.96 | 631.0 (197.7) | 216.5 (22.8) |

| 2 | 180 | 0.60 | 486.3 (70.0) | 182.5 (11.0) |

| Parameter | Value |

|---|---|

| Mesh resolution | 5 × 10−9 m |

| Alloy Composition (atom. fraction) | Ni–0.60Fe–0.035Nb |

| Liquidus Temperature (K) | 1680.0 (calculated using Thermocalc) |

| Solidus Temperature (K) | 1537.0 (calculated using Thermocalc) |

| Grain Boundary Energy (J/m2) | 0.16 [17] |

| Energy Anisotropy factor | 0.05 [17] |

| Temperature gradient (K/m) | 2.6 ×106 or 4.6 ×106 |

| Diffusion coefficient of Nb and Fe in solid ( m2/s) | 0.0 |

| Diffusion coefficient of Nb and Fe in liquid ( m2/s) | 1.0 × 10−9 or 2.0 × 10−9 [17] |

| Steady-state velocity (m/s) | 0.1 |

| Phase field mobility (m3/Js) | Calculated for each site during simulation using Kim model [15] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radhakrishnan, B.; Gorti, S.B.; Turner, J.A.; Acharya, R.; Sharon, J.A.; Staroselsky, A.; El-Wardany, T. Phase Field Simulations of Microstructure Evolution in IN718 Using a Surrogate Ni–Fe–Nb Alloy during Laser Powder Bed Fusion. Metals 2019, 9, 14. https://doi.org/10.3390/met9010014

Radhakrishnan B, Gorti SB, Turner JA, Acharya R, Sharon JA, Staroselsky A, El-Wardany T. Phase Field Simulations of Microstructure Evolution in IN718 Using a Surrogate Ni–Fe–Nb Alloy during Laser Powder Bed Fusion. Metals. 2019; 9(1):14. https://doi.org/10.3390/met9010014

Chicago/Turabian StyleRadhakrishnan, Balasubramaniam, Sarma B. Gorti, John A. Turner, Ranadip Acharya, John A. Sharon, Alexander Staroselsky, and Tahany El-Wardany. 2019. "Phase Field Simulations of Microstructure Evolution in IN718 Using a Surrogate Ni–Fe–Nb Alloy during Laser Powder Bed Fusion" Metals 9, no. 1: 14. https://doi.org/10.3390/met9010014

APA StyleRadhakrishnan, B., Gorti, S. B., Turner, J. A., Acharya, R., Sharon, J. A., Staroselsky, A., & El-Wardany, T. (2019). Phase Field Simulations of Microstructure Evolution in IN718 Using a Surrogate Ni–Fe–Nb Alloy during Laser Powder Bed Fusion. Metals, 9(1), 14. https://doi.org/10.3390/met9010014