Precipitation Strengthening in Ni–Cu Alloys Fabricated Using Wire Arc Additive Manufacturing Technology

Abstract

1. Introduction

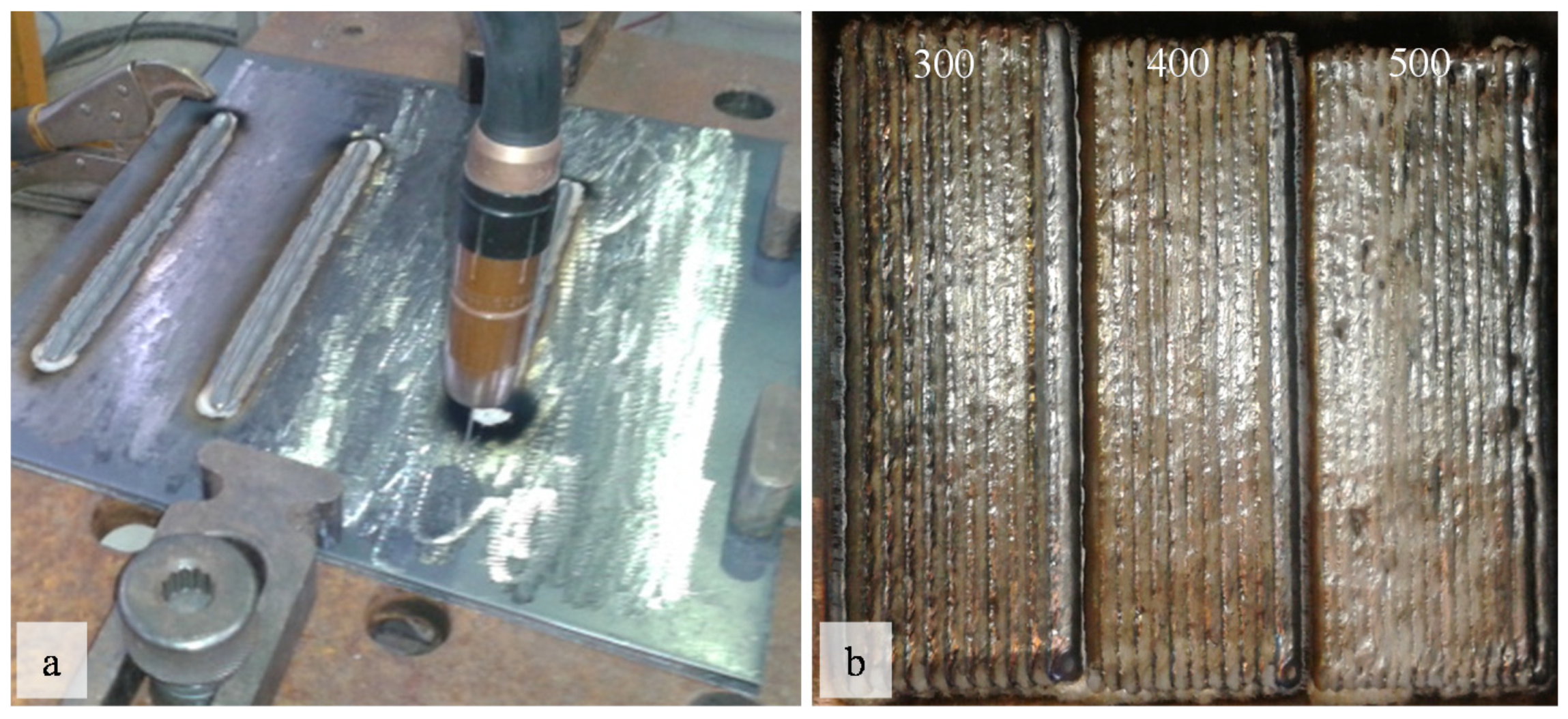

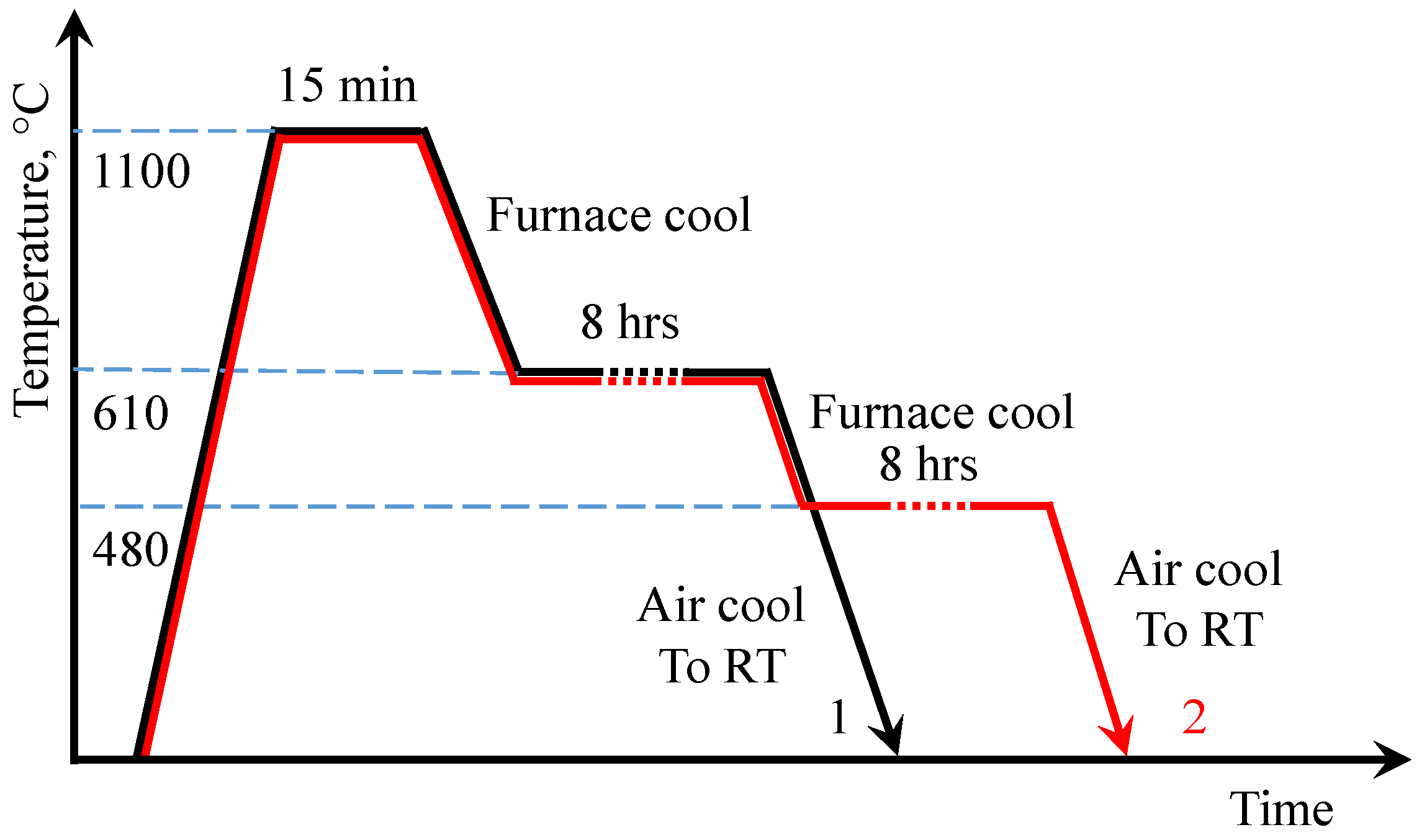

2. Materials and Experimental Techniques

3. Results

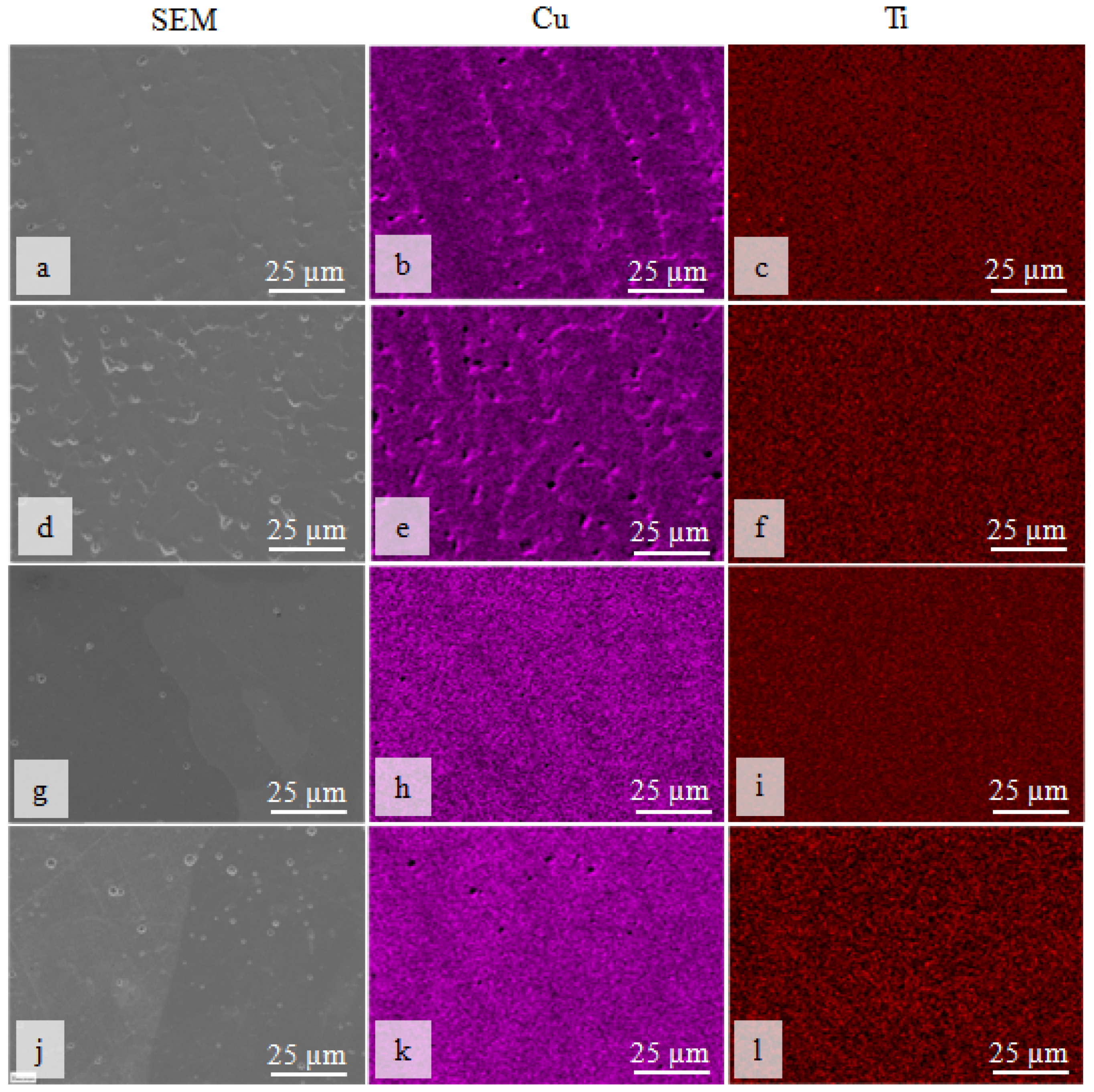

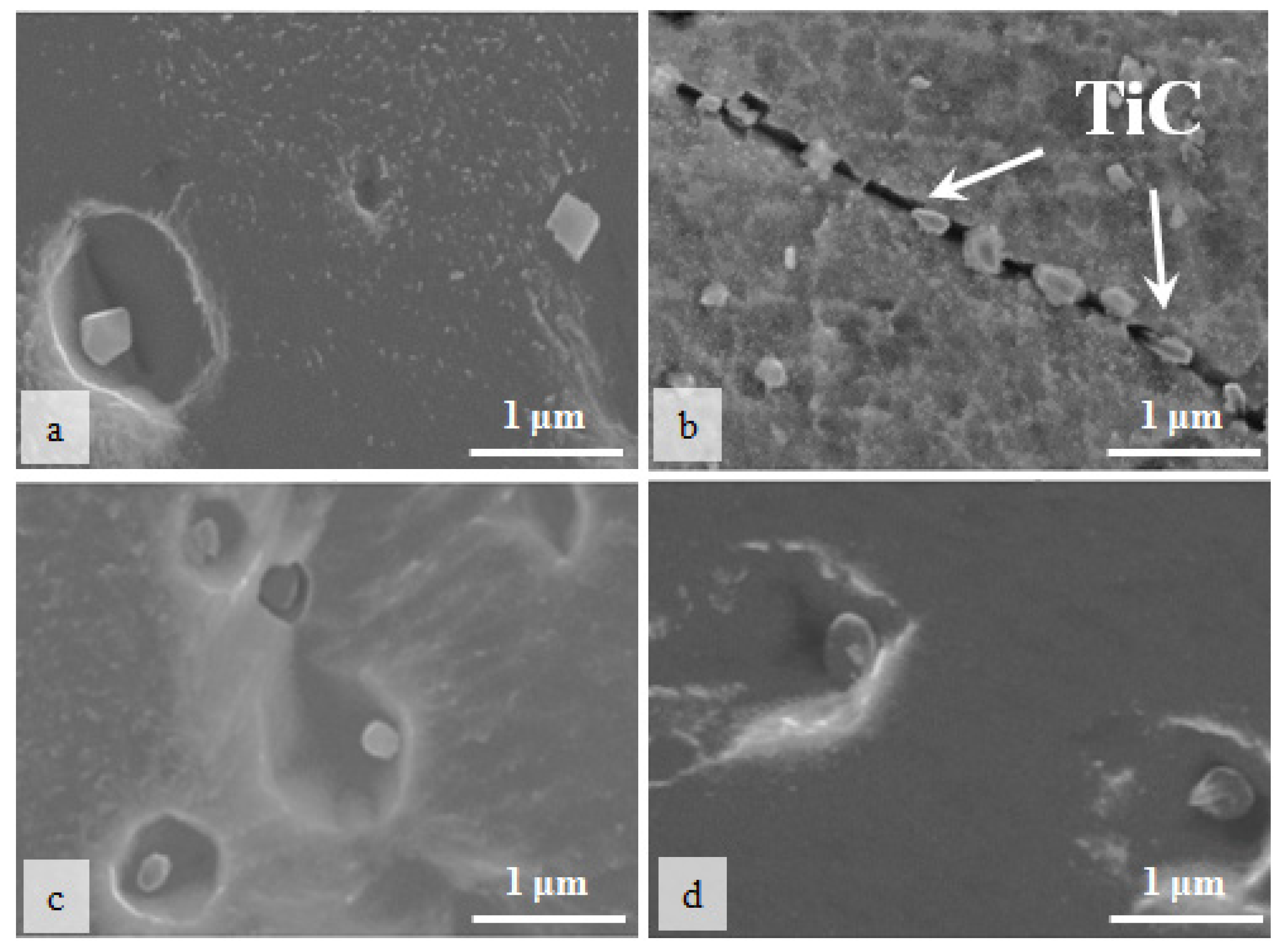

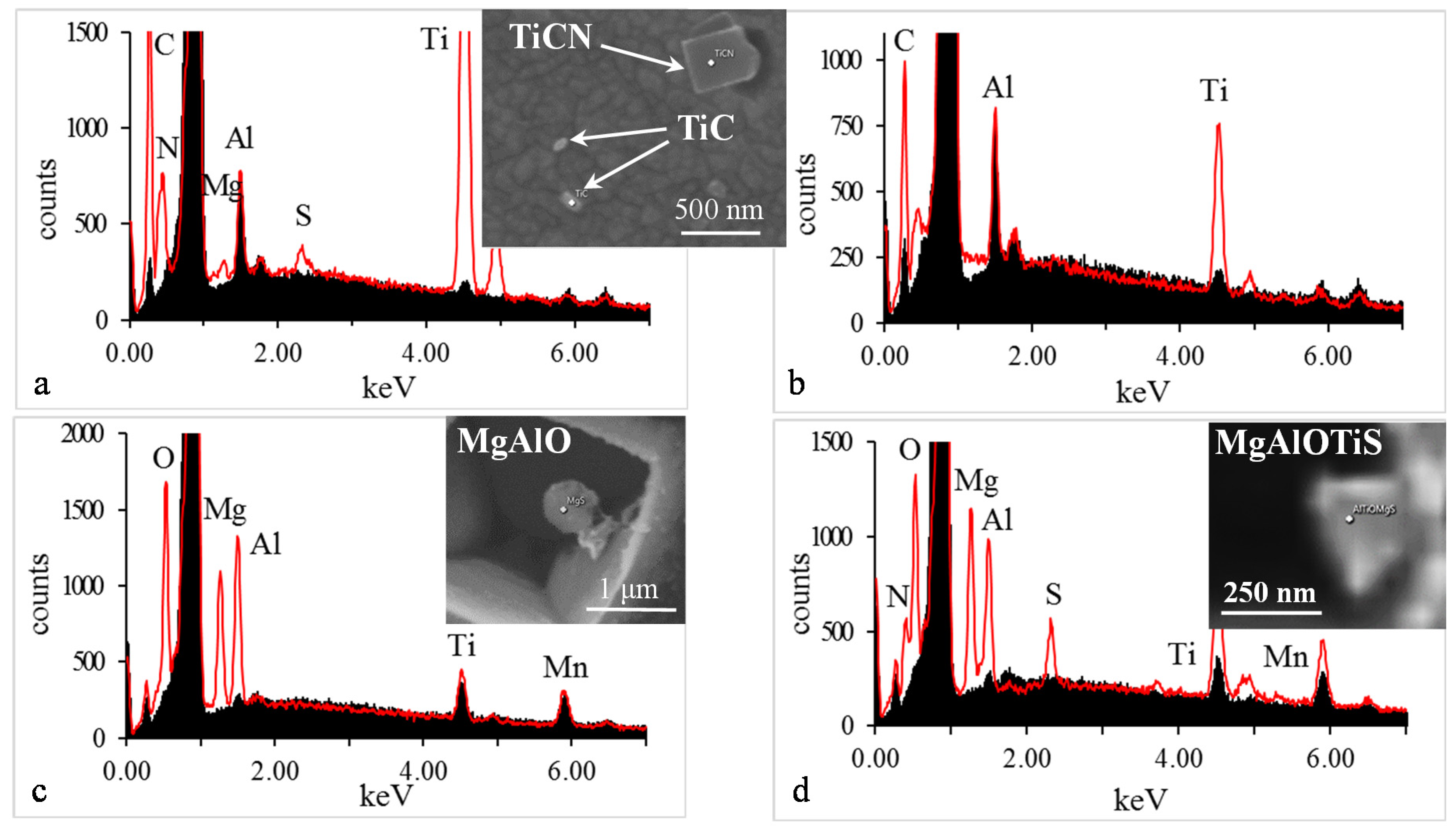

3.1. Microstructure Characterisation

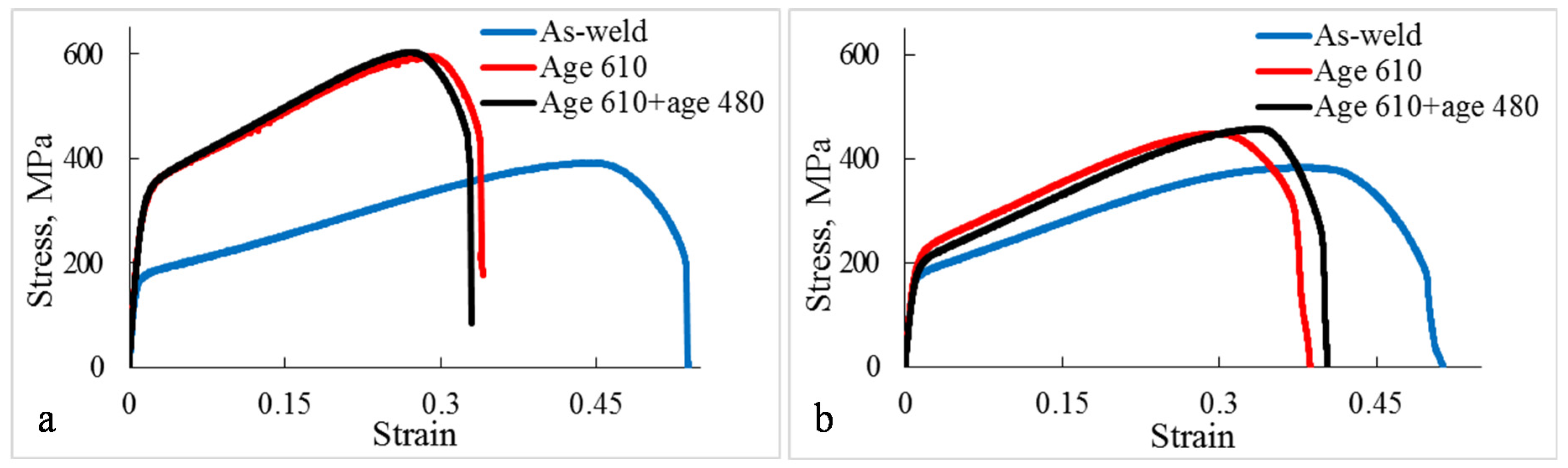

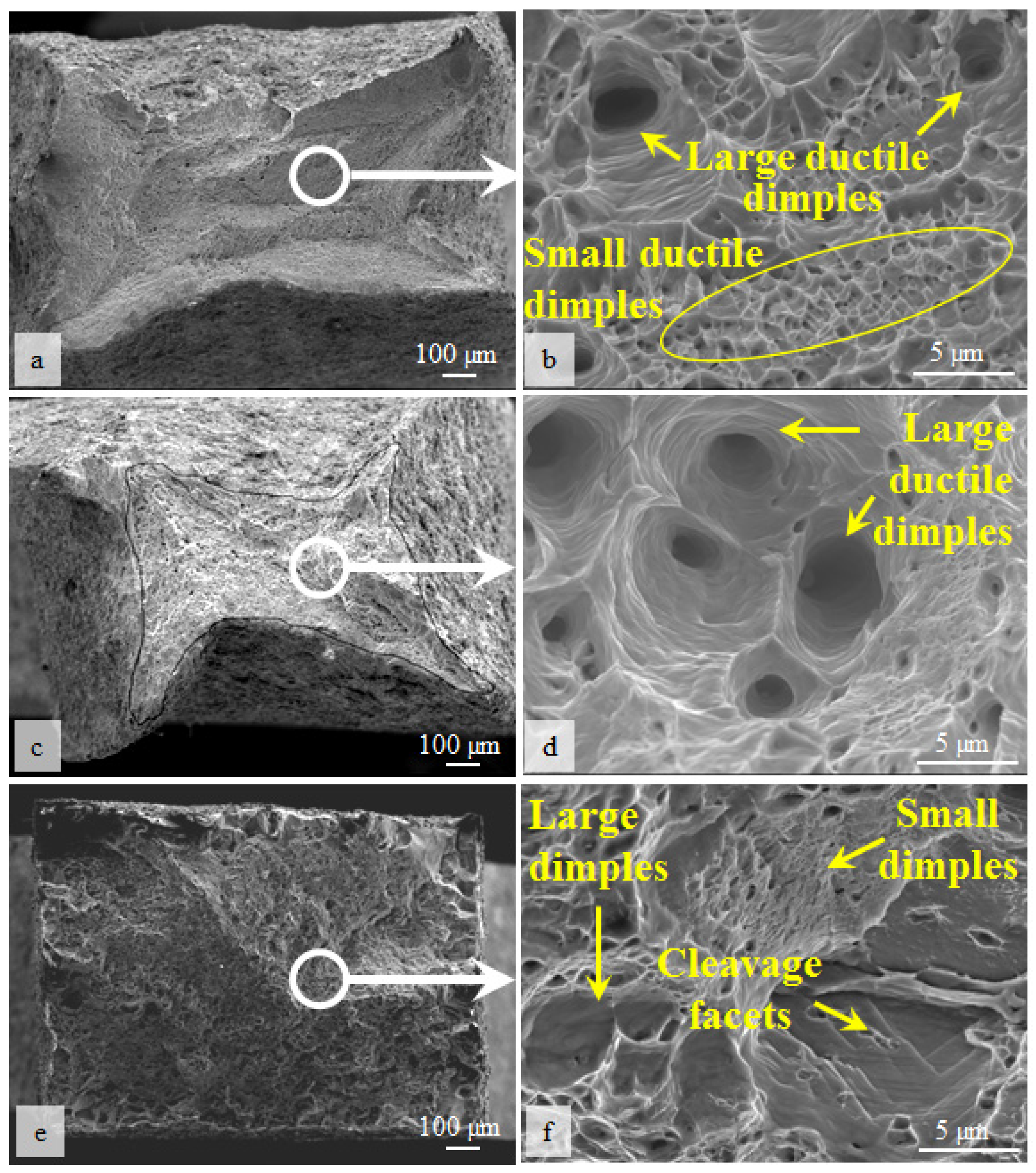

3.2. Tensile Properties

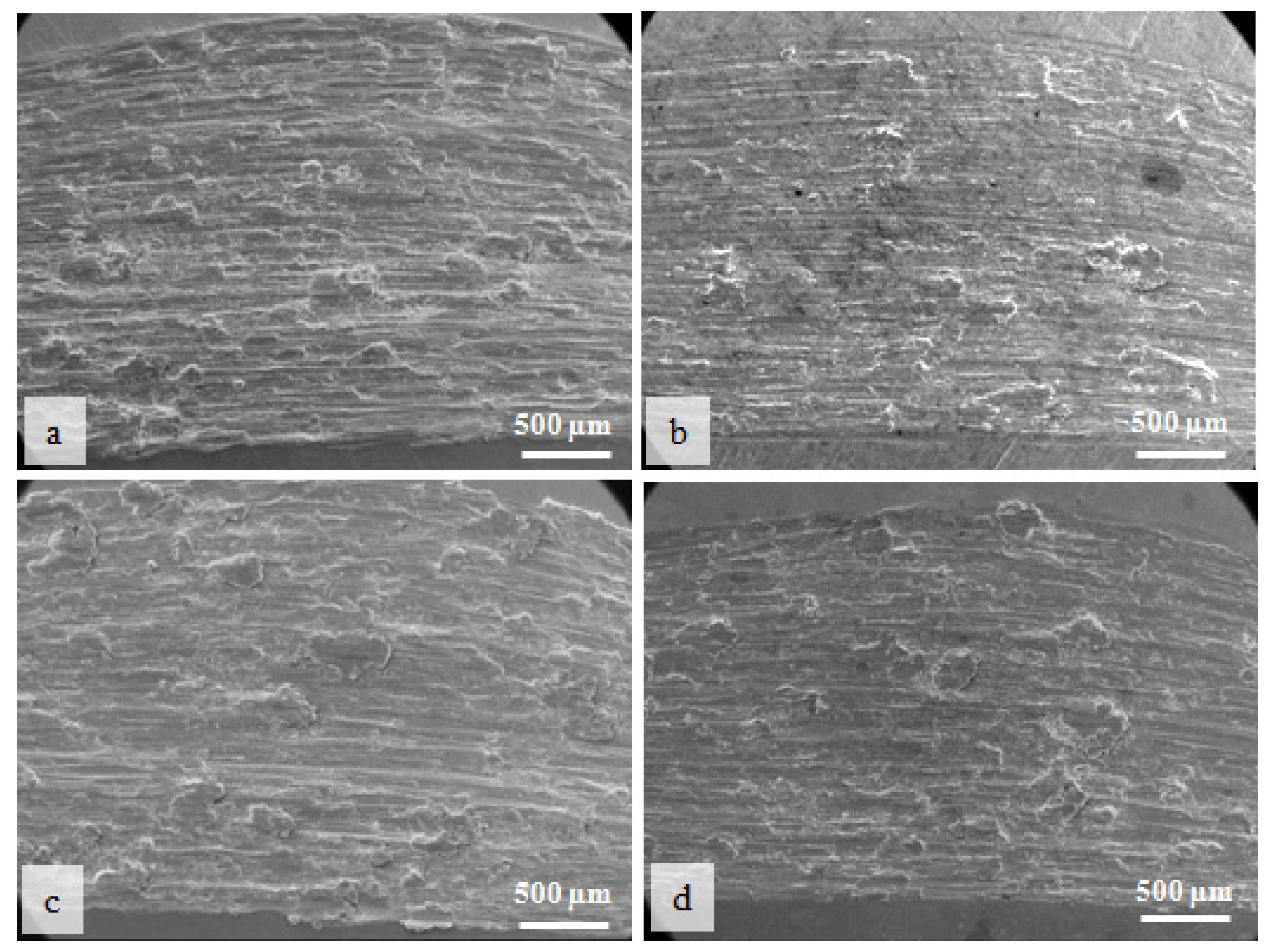

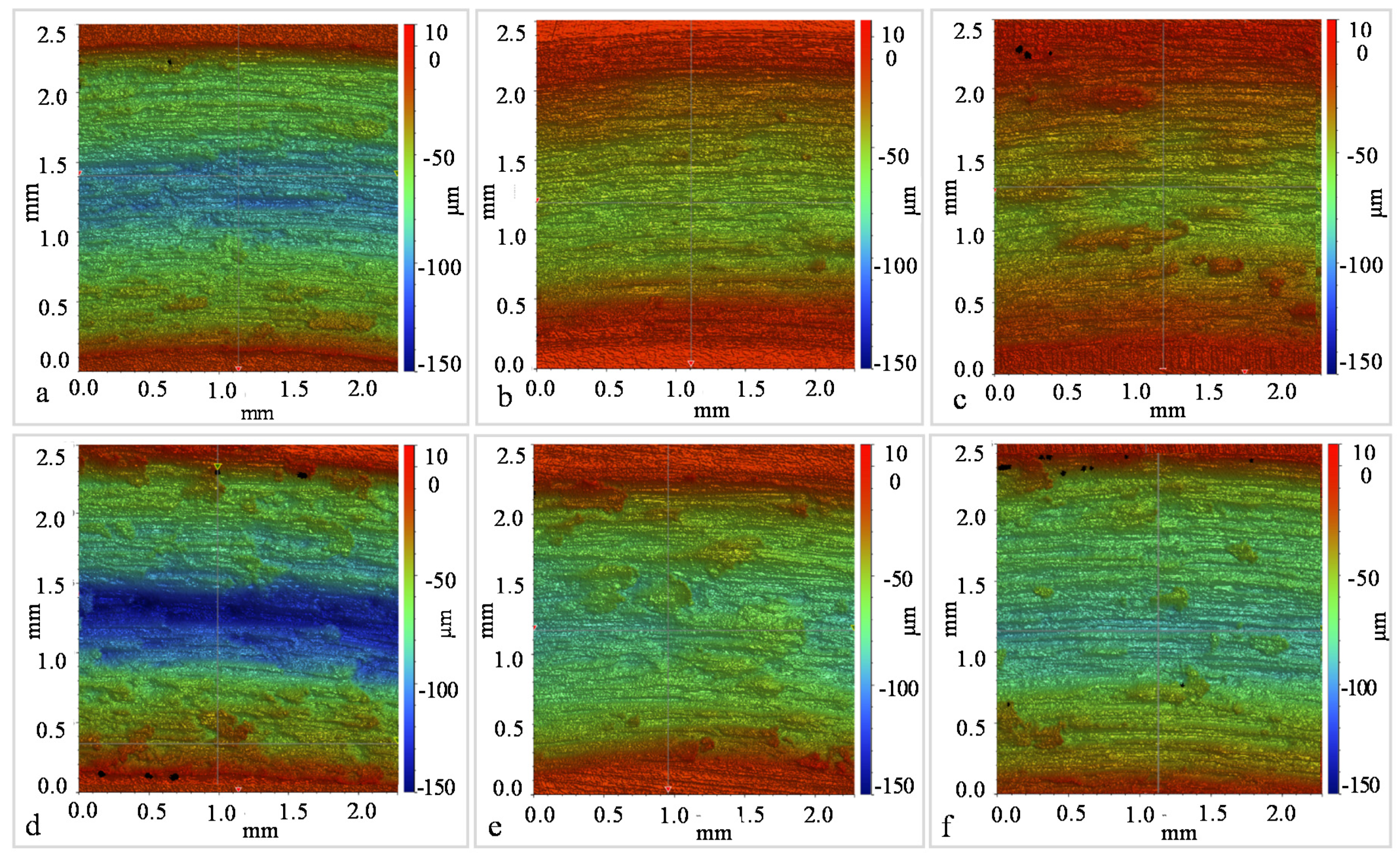

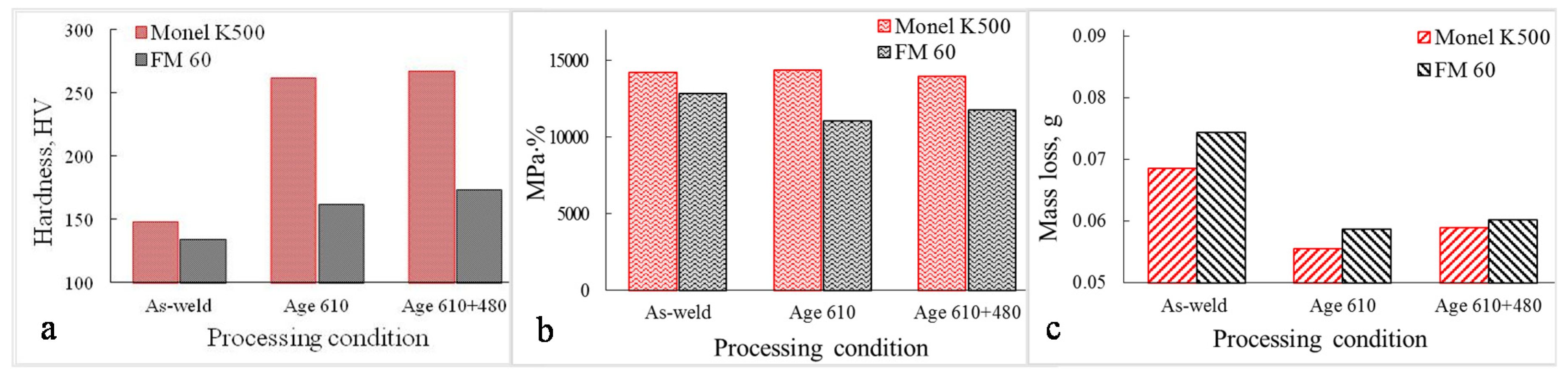

3.3. Hardness, Toughness and Wear Resistance

3.4. Mechanical Properties of Hot Rolled Monel K500 Plate

4. Discussion

4.1. Effect of Alloy Composition and Processing on Grain Structure and Particle Parameters

4.2. Effect Of Alloy Composition and Processing on Mechanical and Wear Properties

5. Conclusions

- In the as-weld condition, precipitation of TiC and TiCN particles was observed in Monel K500, the alloy with a higher C content, rather than in FM60, containing a higher Ti content. In FM60, the precipitation of Ti-rich oxides and MnS-core particles took place, which coincided with a higher Mn content in FM60.

- Annealing at 1100 °C followed by ageing at 610 °C resulted in an extensive precipitation of TiC particles in Monel K500 (a 240–290 times increase in the TiC number density compared to the as-weld condition). However, in FM60, the particle precipitation was relatively sluggish (up to a 70% increase in the number density). The second ageing at 410 °C has led to the particle coarsening, accompanied by a decrease in the particle number density, in both alloys.

- Due to the precipitation of TiC/TiCN particles and the smaller secondary dendrite arm spacing, Monel K500 exhibited higher hardness, yield stress and tensile strength than FM60 for all the studied conditions. In spite of the FM60 elongation being larger in annealed and aged conditions, the toughness of Monel K500 was higher due to higher strength. In accordance with higher hardness and toughness, the wear resistance of Monel K500 was higher in almost all conditions.

- In the as-weld condition, the lowest hardness, strength and wear resistance in both alloys were observed for the slowest deposition speed of 300 mm/min. These coincided with the highest particle number density in both alloys. In the annealed and aged conditions, the highest wear resistance (supported by either the highest hardness or strength) in both alloys was obtained at the highest deposition speed of 500 mm/min. These coincided with the low particle number density. In spite of a 240–290 times increase in the particle number density in Monel K500, after annealing and ageing at 610 °C, the wear resistance increased by only 16%, and only a 70% increase in the particle number density in FM60 resulted in a 24% increase in the wear resistance. Obviously, fine (<20 nm) particles, not visible in SEM and not studied here, played their role in properties development. This requires further investigation.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- High-Performance Alloys for Resistance to Aqueous corrosion, Special Metals Corporation, Publication number SMC-026. 2000. Available online: https://www.scribd.com/document/55871734/Nickel-Base (accessed on 12 December 2017).

- Davis, J.R. Nickel, Cobalt, and Their Alloys; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Bassford, T.H.; Hosier, J. Nickel and its Alloys. In Handbook of Materials Selection; Kutz, M., Ed.; Wiley: New York, NY, USA, 2002. [Google Scholar]

- Lippold, J.C.; DuPont, J.N.; Kiser, S.D. Welding Metallurgy and Weldability of Nickel-Base Alloys; Wiley: New York, NY, USA, 2009. [Google Scholar]

- Hibner, E.; Lemk, T.F. History of Monel Alloy K-500, Special Metals Corporation. 2002. Available online: https://www.corrosionmaterials.com/k500-nickel-copper-alloy (accessed on 12 December 2017).

- Wu, B.; Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Han, J.; Fei, Z. Effects of heat accumulation on the arc characteristics and metal transfer behavior in Wire Arc Additive Manufacturing of Ti6Al4V. J. Mater. Process. Technol. 2017, 250, 304–312. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Rush, M. Morphology investigation on direct current pulsed gas tungsten arc welded additive layer manufactured Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2011, 57, 597–603. [Google Scholar] [CrossRef]

- Haden, C.; Zeng, G.; Carter, F.; Ruhl, C.; Krick, B.; Harlow, D. Wire and arc additive manufactured steel: tensile and wear properties. Addit. Manuf. 2017, 16, 115–123. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Ding, D.; Li, H. Influences of deposition current and interpass temperature to the Fe3Al-based iron aluminide fabricated using wire-arc additive manufacturing process. Int. J. Adv. Manuf. Technol. 2018, 88, 2009–2018. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Van Duin, S.; Li, H.; Shen, C. Fabricating superior NiAl Bronze components through wire arc additive manufacturing. Materials 2016, 9, 652. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Lv, Y.; Xu, B.; Liu, Y.; Shu, F.; He, P. Effect of deposition strategy on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by pulsed plasma arc deposition. Mater. Des. 2013, 45, 446–455. [Google Scholar] [CrossRef]

- Baufeld, B. Mechanical properties of Inconel 718 parts manufactured by shaped metal deposition (SMD). J. Mater. Eng. Perform. 2012, 21, 1416–1421. [Google Scholar] [CrossRef]

- Lim, Y.S.; Kim, H.P.; Jung, M.K.; Kim, J.S. Phase analysis of the precipitates in an Alloy 600/182 weld. Solid State Phenom. 2007, 119, 111–114. [Google Scholar] [CrossRef]

- Dashevskii, V.Y.; Aleksandrov, A.; Kanevskii, A.G.; Makarov, M.A. Deoxidation Equilibrium of Titanium in the Iron–Nickel Melts. ISIJ Int. 2010, 50, 44–52. [Google Scholar] [CrossRef]

- Karasev, A.V.; Suito, H. Nitride precipitation on particles in Fe–10mass%Ni alloy deoxidized with Ti, M (M_Mg, Zr and Ce) and Ti/M. ISIJ Int. 2009, 49, 229–238. [Google Scholar] [CrossRef]

- Soto, R.; Saikaly, W.; Bano, X.; Issartel, C.; Rigaut, G.; Charai, A. Statistical and theoretical analysis of precipitates in dual-phase steels microalloyed with titanium and their effect on mechanical properties. Acta Mater. 1999, 47, 3475–3481. [Google Scholar] [CrossRef]

- Strid, J.; Easterling, K.E. On the chemistry and stability of complex carbides and nitrides in microalloyed steels. Acta Metall. 1985, 33, 2057–2074. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zhao, A. Precipitation of AlN and MnS in low carbon aluminium killed steel. J. Iron Steel Res. Int. 2012, 19, 51–56. [Google Scholar] [CrossRef]

- Garbarz, B.; Marcisz, J.; Wojtas, J. TEM analysis of fine sulphides dissolution and precipitation in steel. Mater. Chem. Phys. 2003, 81, 486–489. [Google Scholar] [CrossRef]

- Akben, M.; Chandra, T.; Plassiard, P.; Jonas, J. Dynamic precipitation and solute hardening in a titanium microalloyed steel containing three levels of manganese. Acta Metall. 1984, 32, 591–601. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, X.; Yang, Z.; Yong, Q.; Zhang, C.; Li, Z.; Weng, Y. Effect of Mn concentration on the kinetics of strain induced precipitation in Ti microalloyed steels. Mater. Sci. Eng. A 2013, 561, 212–219. [Google Scholar] [CrossRef]

- Angella, G.; Donnini, R.; Ripamonti, D.; Maldini, M. The role of particle ripening on the creep acceleration of Nimonic 263 superalloy. MATEC Web Conf. 2014, 14, 14001. [Google Scholar] [CrossRef]

- Baldan, A. Review: Progress in Ostwald ripening theories and their applications to the γ’-precipitates in nickel-base superalloys, Part II Nickel-base superalloys. J. Mater. Sci. 2002, 37, 2379–2405. [Google Scholar] [CrossRef]

| Alloy | Ni | Mn | Fe | Si | Al | Ti | C | S | P | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| Monel K500 | 68.3 | 0.8 | 1.29 | 0.17 | 3.0 | 0.5 | 0.088 | 0.003 | 0.003 | bal. |

| FM60 | 67.2 | 3.2 | 0.08 | 0.07 | 0.2 | 1.5 | 0.004 | 0.014 | 0.003 | bal. |

| Heat Treatment Condition | Particles (SEM Size Range) | Mechanical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ND * × 10−3 µm−2 | Size, nm | Chemistry, % | HV | YS, MPa | UTS, MPa | El, % | MPa·% | Wear Mass Loss, g | Wear Track | |||

| Width, mm | Max. Depth, μm | |||||||||||

| As-weld | 300 | 3.6 | 437 ± 150 | 72 Ti-rich 28 Mn-rich | 144 | 170 ± 5 | 430 ± 15 | 47 ± 2 | 14,100 | 0.0896 | 2.101 | 106 |

| 400 | 3.1 | 448 ± 140 | 69 Ti-rich 31 Mn-rich | 141 | 165 ± 10 | 410 ± 10 | 51 ± 3 | 14,662 | 0.0662 | 2.124 | 100 | |

| 500 | 2.6 | 331 ± 160 | 64 Ti-rich 36 Mn-rich | 148 | 160 ± 5 | 408 ± 15 | 50 ± 1 | 14,200 | 0.0685 | 2.160 | 75 | |

| Age at 610 | 300 | 865 | 90 ± 50 | 100 Ti-rich | 256 | 250 ± 4 | 522 ± 25 | 39 ± 1 | 15,054 | 0.0758 | 1.923 | 106 |

| 400 | 898 | 75 ± 45 | 100 Ti-rich | 255 | 300 ± 3 | 615 ± 20 | 37 ± 1 | 16,928 | 0.0601 | 2.057 | 90 | |

| 500 | 692 | 85 ± 47 | 100 Ti-rich | 262 | 290 ± 4 | 609 ± 15 | 32 ± 1 | 14,384 | 0.0556 | 2.190 | 47 | |

| Age at 610 + 480 | 300 | 448 | 160 ± 74 | 100 Ti-rich | 259 | 320 ± 3 | 536 ± 5 | 12 ± 1 | 5,136 | 0.0748 | 2.020 | 82 |

| 400 | 667 | 90 ± 50 | 100 Ti-rich | 236 | 250 ± 5 | 563 ± 5 | 34 ± 4 | 13,821 | 0.0625 | 2.105 | 48 | |

| 500 | 641 | 95 ± 45 | 100 Ti-rich | 265 | 280 ± 3 | 622 ± 20 | 31 ± 1 | 13,981 | 0.0589 | 2.270 | 43 | |

| Heat Treatment Condition | Particles (SEM Size Range) | Mechanical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ND × 10−3 µm−2 | Size, nm | Chemistry, % | HV | YS, MPa | UTS, MPa | El, % | MPa·% | Wear Mass Loss, g | Wear track | |||

| Width, mm | Max. Depth, µm | |||||||||||

| As-weld | 300 | 11.4 | 311 ± 170 | 67Mn-rich 33TiAl-rich | 131 | 146 ± 3 | 356 ± 10 | 48 ± 3 | 12,048 | 0.0902 | 2.234 | 132 |

| 400 | 7.2 | 392 ± 150 | 66Mn-rich 34TiAl-rich | 132 | 149 ± 5 | 361 ± 20 | 47 ± 1 | 11,985 | 0.0722 | 2.240 | 124 | |

| 500 | 4.7 | 388 ± 160 | 80Mn-rich 20TiAl-rich | 134 | 160 ± 4 | 375 ± 5 | 48 ± 2 | 12,840 | 0.0744 | 2.379 | 95 | |

| Age at 610 | 300 | 12.7 | 278 ± 90 | 52Mn-rich 48TiAl-rich | 163 | 160 ± 3 | 397 ± 5 | 41 ± 1 | 10,804 | 0.0689 | 1.730 | 107 |

| 400 | 8.5 | 274 ± 110 | 50Mn-rich 50TiAl-rich | 164 | 155 ± 5 | 410 ± 10 | 43 ± 1 | 11,718 | 0.0639 | 2.085 | 85 | |

| 500 | 8.1 | 236 ± 95 | 55Mn-rich 45TiAl-rich | 162 | 205 ± 3 | 428 ± 20 | 36 ± 3 | 11,034 | 0.0587 | 2.105 | 65 | |

| Age at 610 + 480 | 300 | 9.2 | 285 ± 100 | 61Mn-rich 39TiAl-rich | 139 | 115 ± 4 | 358 ± 10 | 48 ± 2 | 11,160 | 0.0734 | 2.200 | 94 |

| 400 | 8.9 | 288 ± 97 | 70Mn-rich 30TiAl-rich | 192 | 170 ± 3 | 490 ± 20 | 39 ± 1 | 12,870 | 0.0680 | 2.208 | 86 | |

| 500 | 7.7 | 261 ± 95 | 62Mn-rich 38TiAl-rich | 173 | 190 ± 5 | 428 ± 20 | 40 ± 2 | 11,760 | 0.0602 | 2.220 | 79 | |

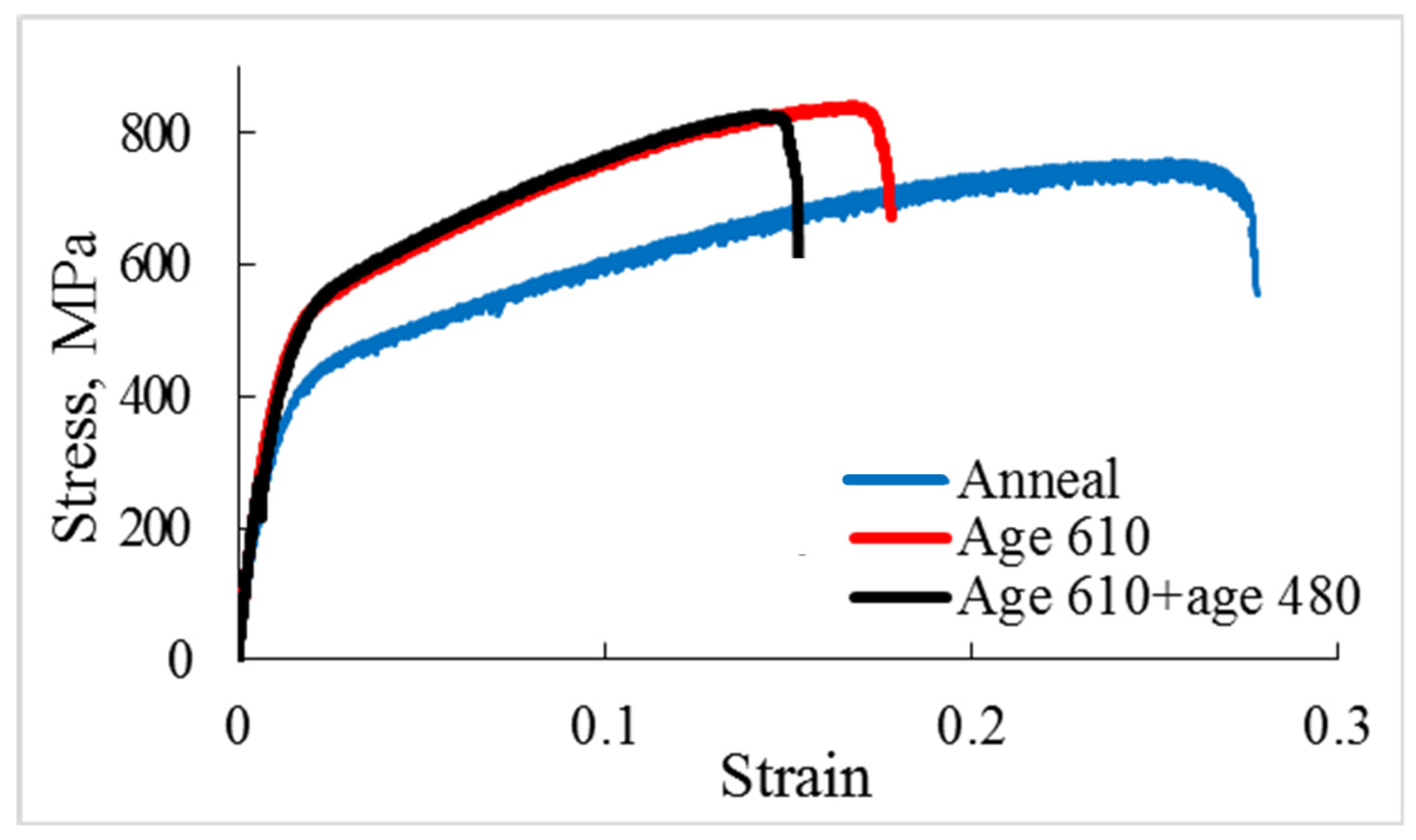

| Heat Treatment Condition | HV | YS, MPa | UTS, MPa | El, % | MPa·% | Mass Loss, g |

|---|---|---|---|---|---|---|

| Anneal | 155 | 368 | 724 ± 20 | 25 ± 1 | 13,650 | 0.1821 |

| Age at 610 | 250 | 515 | 833 ± 5 | 15 ± 1 | 10,110 | 0.1392 |

| Age at 610 + 480 | 270 | 518 | 815 ± 10 | 12 ± 1 | 7998 | 0.1380 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marenych, O.; Kostryzhev, A.; Shen, C.; Pan, Z.; Li, H.; van Duin, S. Precipitation Strengthening in Ni–Cu Alloys Fabricated Using Wire Arc Additive Manufacturing Technology. Metals 2019, 9, 105. https://doi.org/10.3390/met9010105

Marenych O, Kostryzhev A, Shen C, Pan Z, Li H, van Duin S. Precipitation Strengthening in Ni–Cu Alloys Fabricated Using Wire Arc Additive Manufacturing Technology. Metals. 2019; 9(1):105. https://doi.org/10.3390/met9010105

Chicago/Turabian StyleMarenych, Olexandra, Andrii Kostryzhev, Chen Shen, Zengxi Pan, Huijun Li, and Stephen van Duin. 2019. "Precipitation Strengthening in Ni–Cu Alloys Fabricated Using Wire Arc Additive Manufacturing Technology" Metals 9, no. 1: 105. https://doi.org/10.3390/met9010105

APA StyleMarenych, O., Kostryzhev, A., Shen, C., Pan, Z., Li, H., & van Duin, S. (2019). Precipitation Strengthening in Ni–Cu Alloys Fabricated Using Wire Arc Additive Manufacturing Technology. Metals, 9(1), 105. https://doi.org/10.3390/met9010105