Analyzing the Deformation and Fracture of Bioinert Titanium, Zirconium and Niobium Alloys in Different Structural States by the Use of Infrared Thermography

Abstract

1. Introduction

2. Specimens and Methods of Investigation

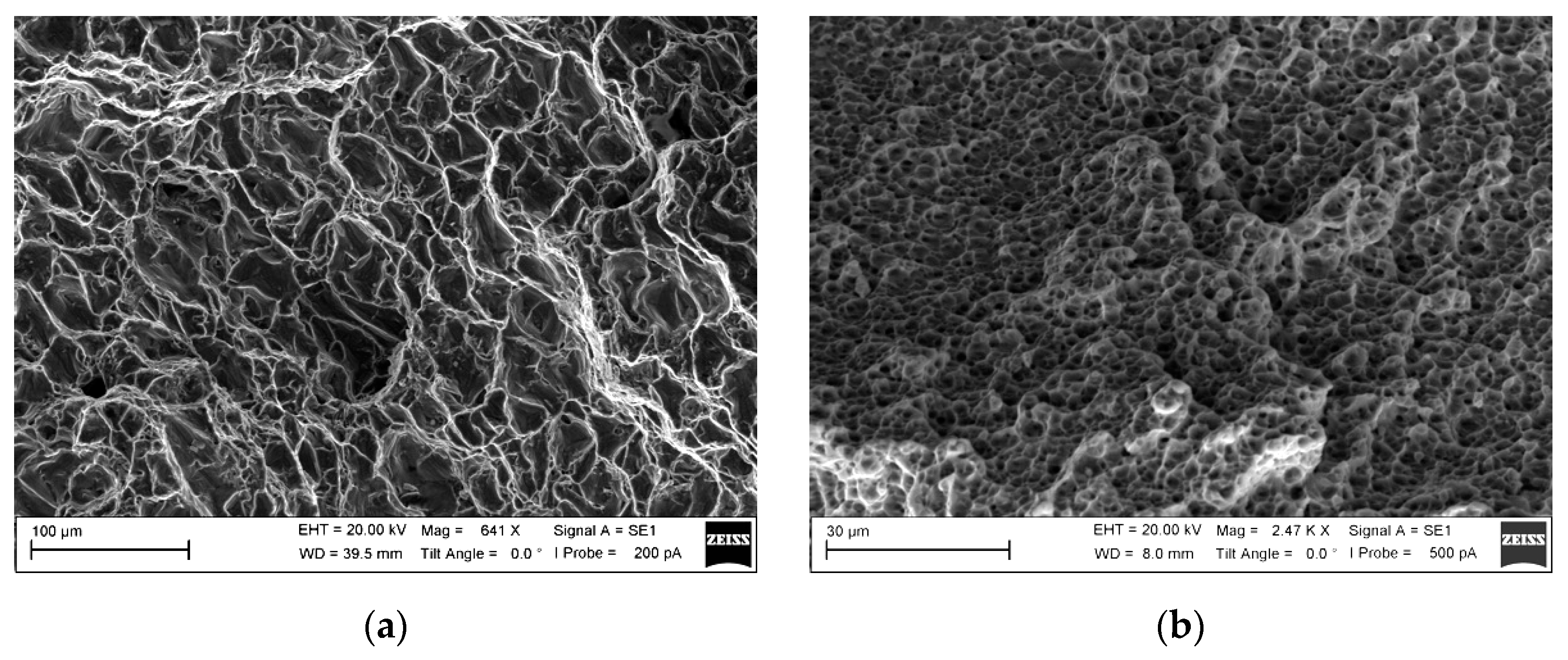

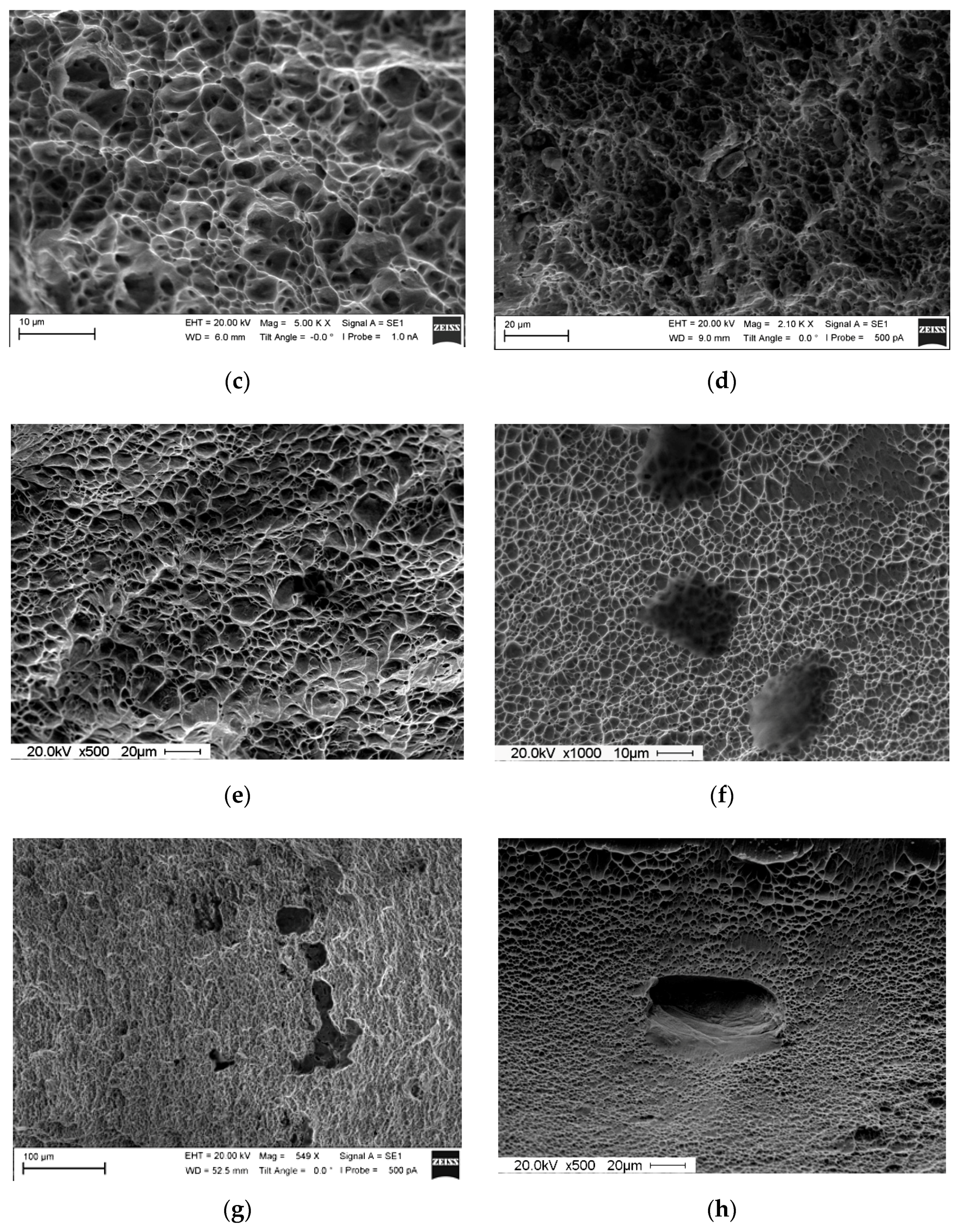

3. Results and Discussion

4. Conclusions

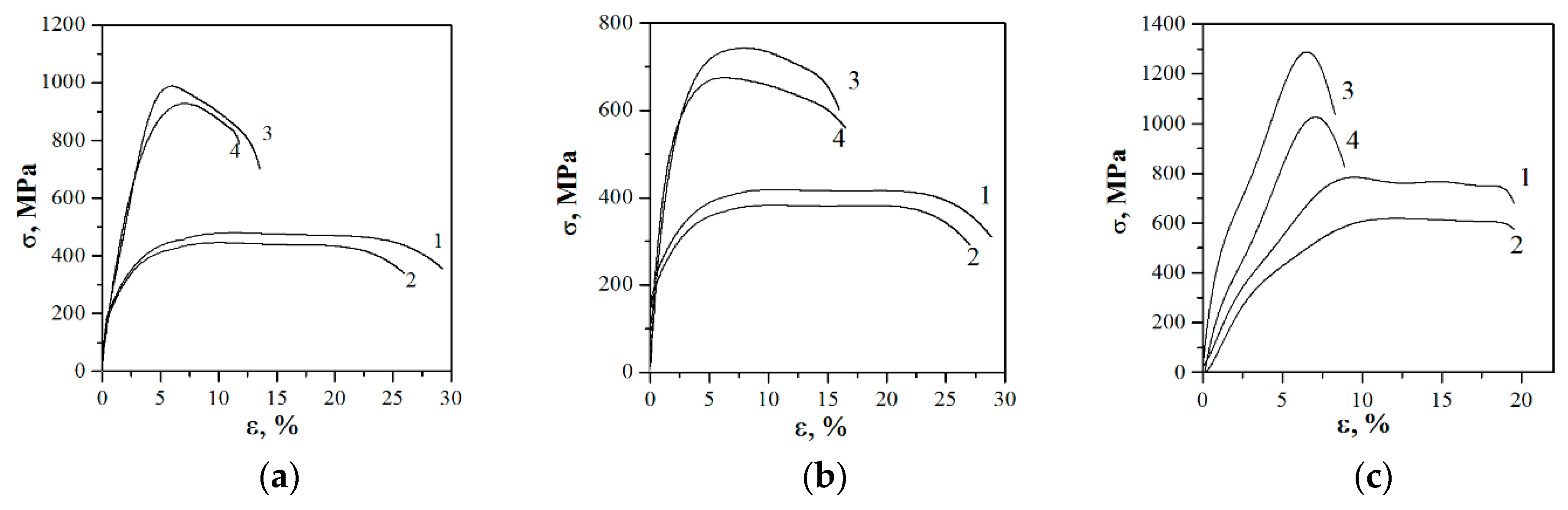

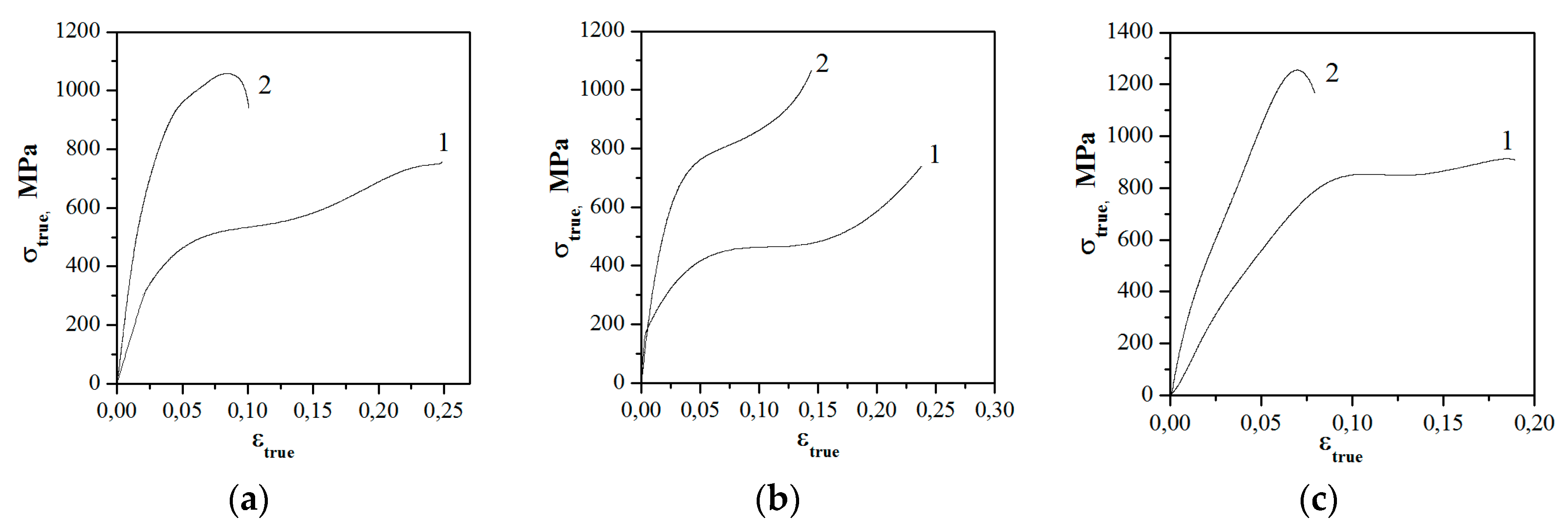

- A UFG state was created by the severe plastic deformation of the investigated alloys and this has improved their mechanical properties. The ultimate tensile strength of the VT1-0 titanium, Zr-1Nb and Ti-45Nb alloys in the UFG state is 200%, 176% and 163%, of those in the CG state respectively. The ultimate strain before fracture of alloys in the UFG state is lower than in the CG state. For titanium and Ti-45Nb alloys, the ultimate strain before fracture is 43% of CG and for Zr-1Nb alloy the strain is 55.5% of CG. The transition of alloys into the UFG state leads to a decrease in the strain energy during deformation. For titanium and Ti-45Nb alloys, the strain energy decreases to 80% and 50% of CG respectively, while for the Zr-1Nb alloy it remains practically unchanged.

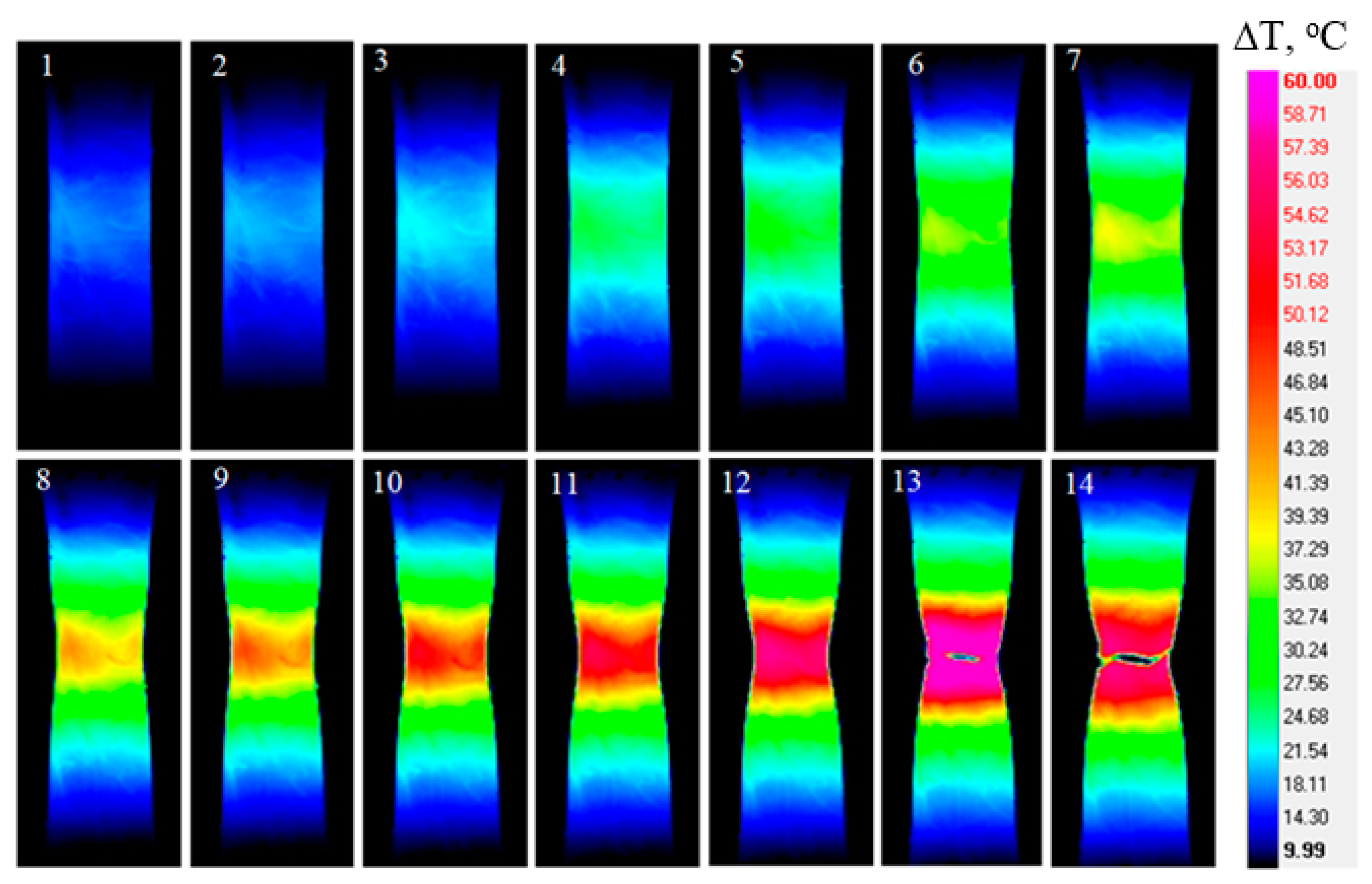

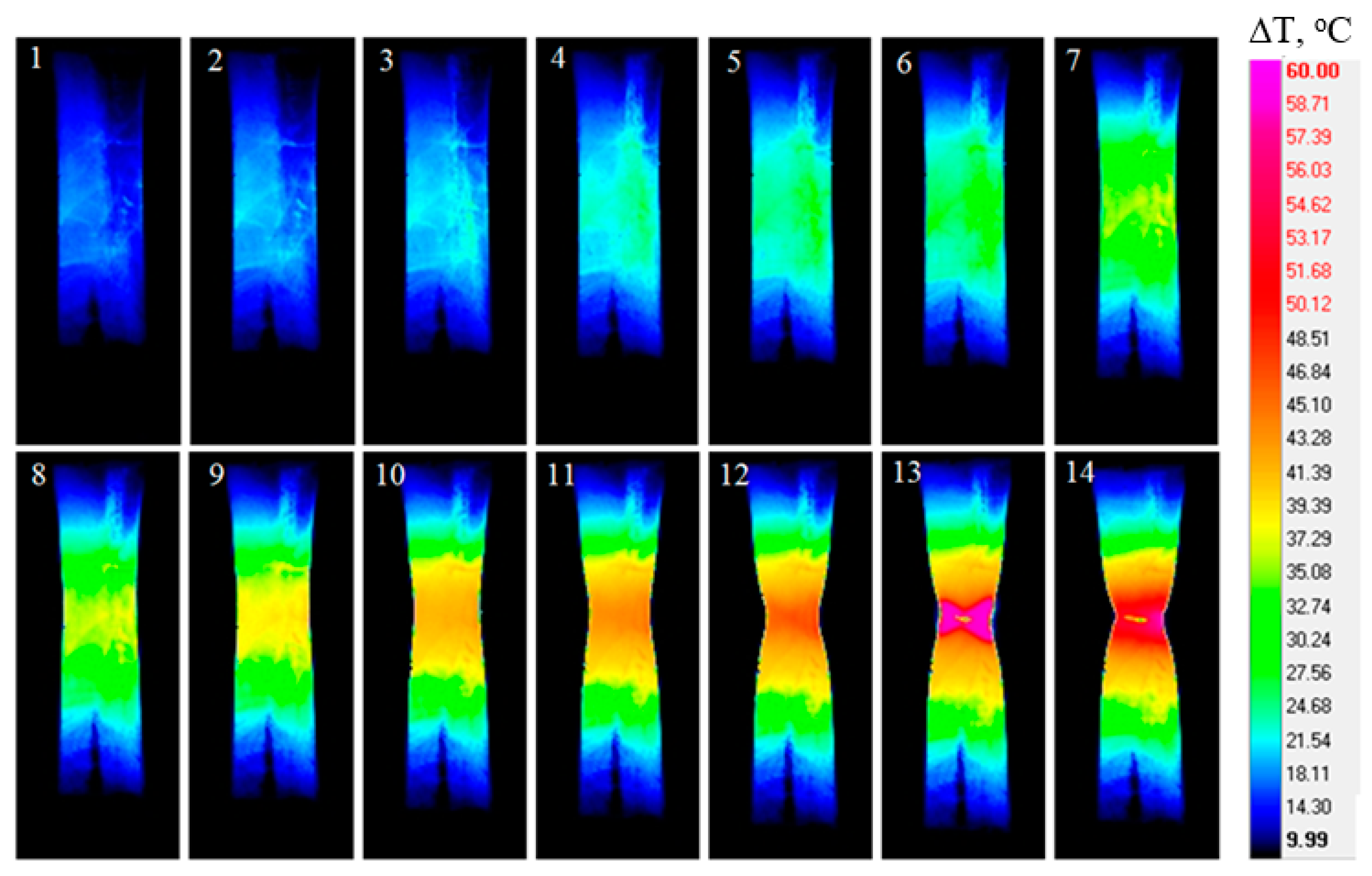

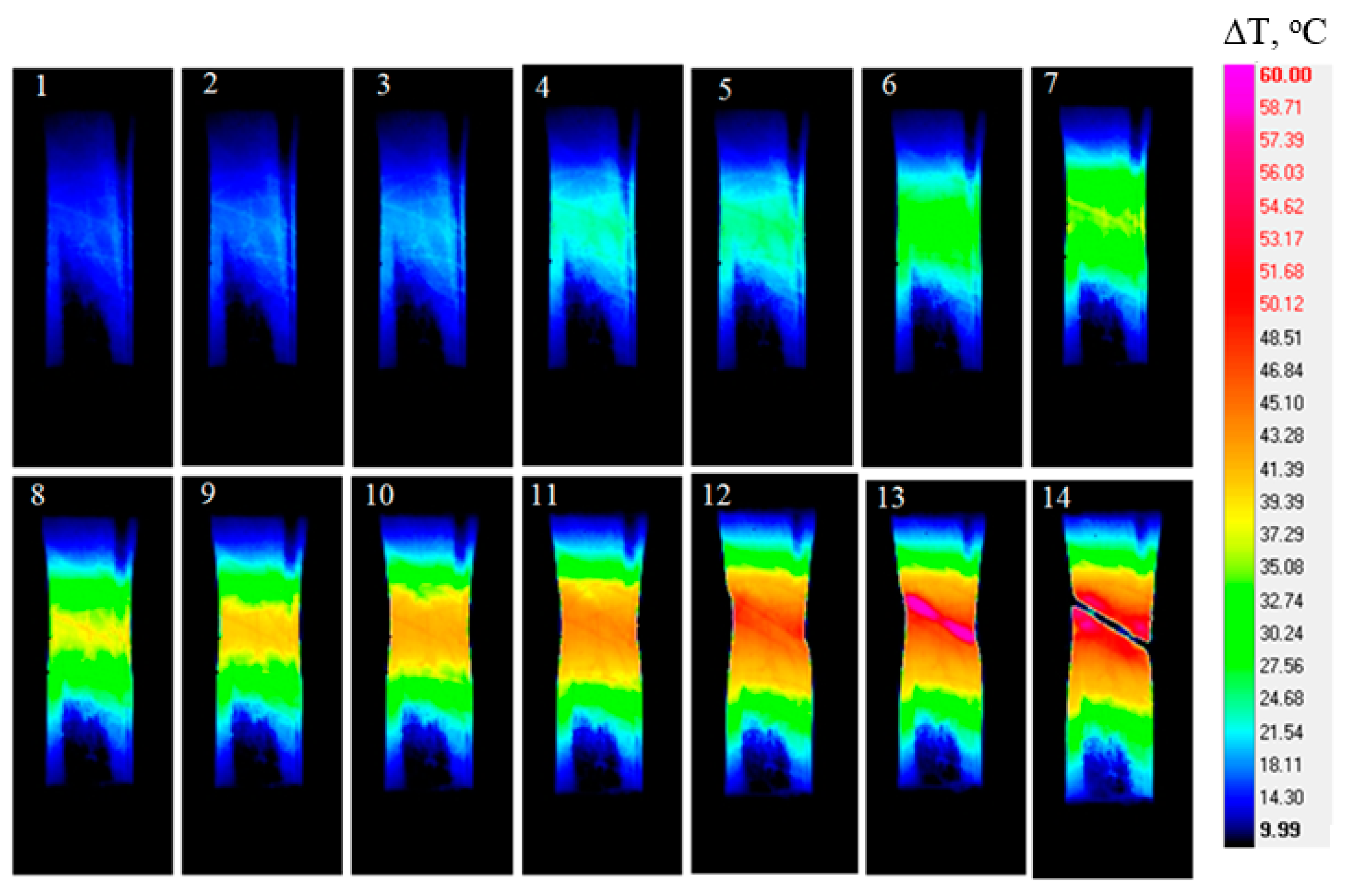

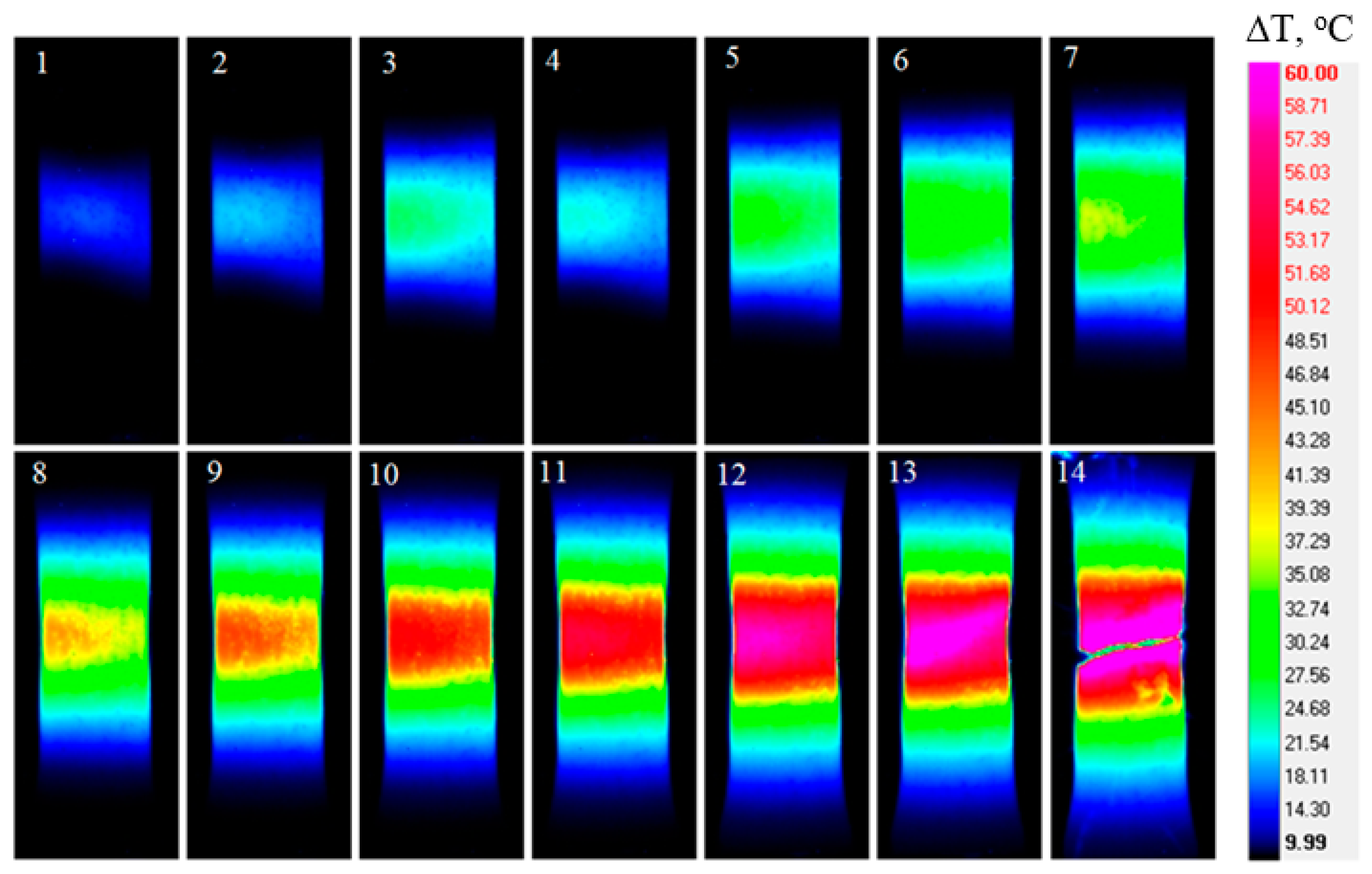

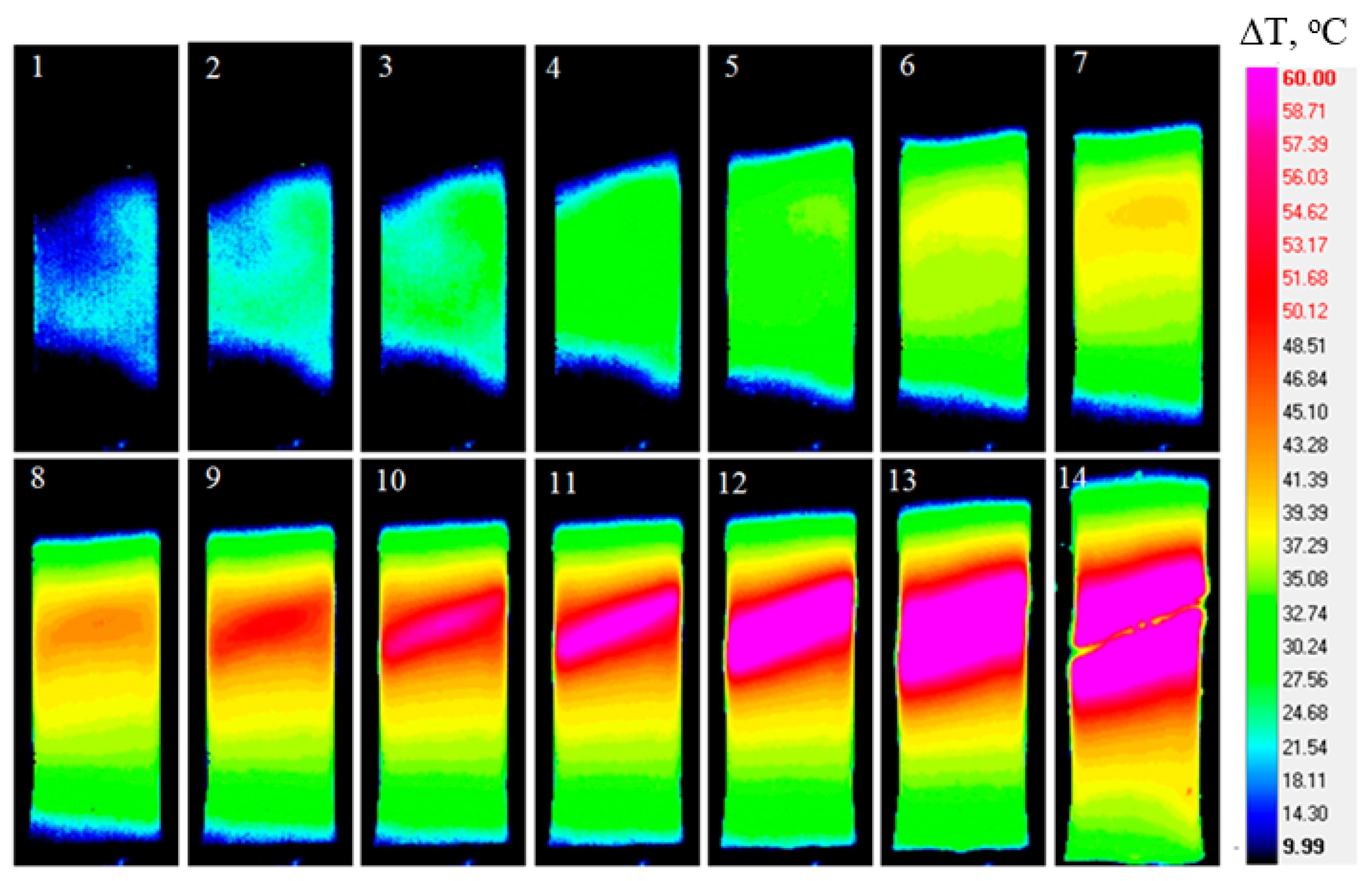

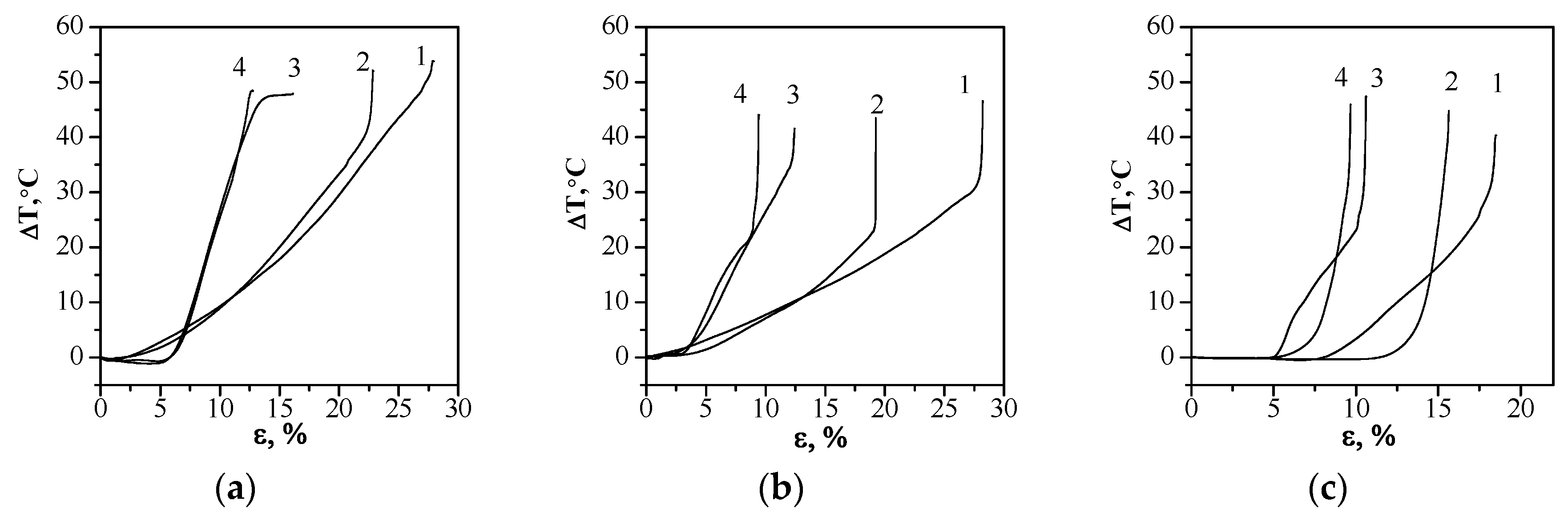

- The temperature distributions that appear during a tensile test are unique for each alloy. These distributions depend on the material structure, the mechanical and thermal properties and the presence of defects in material. When applying a tensile load to UFG titanium and UFG Zr-1Nb, deformation bands arise within the elastic region of the specimens and the direction of the deformation corresponds to the maximum shear stresses. In UFG alloys, flow stresses are higher than that in CG state, thus causing more intensive energy dissipation. Therefore, when the alloys change to the UFG state, the deformation processes and the related temperature changes develop much faster due to the highly-stressed state of the UFG materials. This leads to a localization of plastic deformation in the strain zone and this subsequently leads to fracture. Unlike the CG state, the formation of a “neck” during the loading of all the UFG alloys is less evident and fracture predominantly occurs in a plane at an angle close to 45°. At low strain rates, the temperature distribution is caused not only by the effects of dissipation of mechanical energy but also by the ambient cooling of specimens. Hence, at low strain rates, the rate of temperature increase in the specimens is lower than at high strain rates.

- The presence of defects in the structure of the studied alloys, which are in the highly-stressed UFG state, apparently causes a decrease in their thermal diffusivity and this leads to faster deformation and heat diffusion and causes specimen fracture to quasi-static tensile testing may allow the identification of the material structural state of a material before fracture.

- Further research in the detection of thermal indications that precede deformation and fracture in bioinert alloys that are in different structural states and possess hidden structural macro-defects is related to a deeper study of the physics of formation of dissipative structures. This leads to a conclusion that changes in the temperature distributions are caused by microstructural features of alloys in different states.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zardiackas, L.D.; Kraay, M.J.; Freese, H.L. Titanium, Niobium, Zirconium, and Tantalum for Medical and Surgical Applications; ASTM Publ. STP 1471: Washington, WA, USA, 2006; p. 148. ISBN 0-8031-3497-5. [Google Scholar]

- Rechtin, J.; Torresani, E.; Ivanov, E.; Olevsky, E. Fabrication of titanium-niobium-zirconium-tantalium alloy (TNZT) bioimplant components with controllable porosity by spark plasma sintering. Materials 2018, 11, 181. [Google Scholar] [CrossRef] [PubMed]

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2014; p. 456. ISBN 9781118742679. [Google Scholar]

- Klevtsov, G.V.; Valiev, R.Z.; Klevtsova, N.A.; Zaripov, N.G.; Karavaeva, M.V. Strength and fracture mechanisms of nanostructured metallic materials under single kinds of loading. Met. Sci. Heat Treat. 2018, 59, 597–605. [Google Scholar] [CrossRef]

- Wu, H.; Jiang, J.; Liu, H.; Sun, J.; Gu, Y.; Tang, R.; Zhao, X.; Ma, A. Fabrication of an ultra-fine grained pure titanium with high strength and good ductility via ECAP plus cold rolling. Metals 2017, 7, 563. [Google Scholar] [CrossRef]

- Kwan, C.C.F.; Wang, Z. The cyclic deformation behavior of severe plastic deformation (SPD) metals and the influential factors. Metals 2012, 2, 41–55. [Google Scholar] [CrossRef]

- Jiang, Z.-H.; Li, N.; Zhang, H.-X.; Zhao, C.-Z. The effect of growth rate on the microstructure and tensile behavior of directionally solidified Ti-44Al-9Nb-1Cr-0.2W-0.2Y alloys. Metals 2018, 8, 535. [Google Scholar] [CrossRef]

- Wu, J.; Lü, Z.; Zhang, C.; Han, J.; Zhang, H.; Zhang, S.; Hayat, M.; Cao, P. Investigation of the deformation mechanism of a near titanium alloy through isothermal compression. Metals 2017, 7, 498. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A review of metastable beta titanium alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Niinomi, M.; Liu, Y.; Nakai, M.; Liu, H.; Li, H. Biomedical titanium alloys with Young’s moduli close to that of cortical bone. Regener. Biomater. 2016, 3, 173–185. [Google Scholar] [CrossRef] [PubMed]

- Fedorova, M.; Bannikova, A.; Terekhina, O.; Plekhov, O. Heat dissipation energy under fatigue based on infrared data processing. Qual. Infrared Thermogr. J. 2014, 11, 2–9. [Google Scholar] [CrossRef]

- Naimark, O.B.; Bayandin, Y.V.; Leontiev, V.A.; Panteleev, I.A.; Plekhov, O.A. Structural-scaling transitions and thermodynamic and kinetic effects in submicro-(nano-)crystalline bulk materials. Phys. Mesomech. 2009, 12, 239–248. [Google Scholar] [CrossRef]

- Milovanović, B.; Banjad Pečur, I. Review of active IR thermography for detection and characterization of defects in reinforced concrete. J. Imaging 2016, 2, 11. [Google Scholar] [CrossRef]

- Brock, L.M. Effects of thermoelasticity and a Von Mises condition in rapid steady-state quasi-brittle fracture. Int. J. Struct. 1996, 33, 4131–4142. [Google Scholar] [CrossRef]

- Grinzato, E.; Vavilov, V.; Bison, P.G.; Marinetti, S. Methodology of Processing Experimental Data in Transient Thermal NDT. In Proceedings of the Thermosense XVII: An International Conference on Thermal Sensing and Imaging Diagnostic Applications, Orlando, FL, USA, 19–21 April 1995; pp. 62–65. [Google Scholar]

- Moyseychik, E.A. Heat generation and fracture initiation in stretched steel plate with a process-induced structural defect. J. Appl. Mech. Tech. Phys. 2013, 54, 116–123. [Google Scholar] [CrossRef]

- Moyseychik, E.A.; Vavilov, V.P. Analyzing patterns of heat generated by the tensile loading of steel rods containing discontinuity-like defects. Int. J. Damage Mech. 2018, 27, 950–960. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Vavilov, V.P.; Belyavskaya, O.A.; Skripnyak, V.A.; Nesteruk, D.A.; Kozulin, A.A.; Kim, V.M. Analyzing deformation and damage of VT1-0 titanium in different structural states by using infrared thermography. J. Nondestruct. Eval. 2016, 35, 42–47. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Vavilov, V.P.; Skripnyak, V.A.; Klimenov, V.A.; Belyavskaya, O.A.; Nesteruk, D.A.; Kozulin, A.A.; Tolmachev, A.I. Evolution of the temperature field during deformation and fracture of specimens of coarse-grained and ultrafine-grained titanium. Russ. J. Nondestruct. Test. 2011, 47, 701–706. [Google Scholar] [CrossRef]

- Weichert, R.; Schönert, K. Heat generation at the tip of a moving crack. J. Mech. Phys. Solid 1978, 26, 151–161. [Google Scholar] [CrossRef]

- Pieczyska, E.A.; Maj, M.; Golasiński, K.; Staszczak, M.; Furuta, T.; Kuramoto, S. Thermomechanical studies of yielding and strain localization phenomena of gum metal under tension. Materials 2018, 11, 567. [Google Scholar] [CrossRef] [PubMed]

- Muc, A.; Chwał, M.; Romanowicz, P.; Stawiarski, A. Fatigue-damage evolution of notched composite multilayered structures under tensile loads. J. Compos. Sci. 2018, 2, 27. [Google Scholar] [CrossRef]

- Eroshenko, A.Y; Mairambekova, A.M.; Sharkeev, Y.P.; Kovalevskaya, Z.G.; Khimich, M.A.; Uvarkin, P.V. Structure, phase composition and mechanical properties in bioinert zirconium-based alloy after severe plastic deformation. Lett. Mater. 2017, 7, 469–472. [Google Scholar] [CrossRef]

- Davis, J.R. Introduction to tensile testing. In Tensile Testing, 2nd ed.; ASM International: Almere, The Netherlands, 2004; p. 283. ISBN 978-0-87170-806-9. [Google Scholar]

- Brandon, D.; Kaplan, W.D. Microstructural Characterization of Materials; John Wiley and Sons Ltd.: Haifa, Israel, 1999; p. 424. ISBN 0471 985015. [Google Scholar]

- Glezer, A.M.; Kozlov, E.V.; Koneva, N.A.; Popova, N.A.; Kurzina, I.A. Fundamentals of Plastic Deformation of Nanostructured Materials; FIZMATLIT: Moscow, Russia, 2016; p. 304. ISBN 978-5-9221-1689-3. (In Russian) [Google Scholar]

- Vu, Q.H.; Halm, D.; Nadot, Y. High cycle fatigue of 1045 steel under complex loading: Mechanisms map and damage modelling. Int. J. Damage Mech. 2014, 23, 377–410. [Google Scholar] [CrossRef]

- Lin, M.-R.; Wagoner, R.H. An experimental investigation of deformation induced heating during tensile testing. Metall. Mater. Trans. A 1987, 18, 1035–1042. [Google Scholar] [CrossRef]

- Robinson, A.F.; Dulieu-Barton, J.M.; Quinn, S.; Burguete, R.L. Paint coating characterization for thermoelastic stress analysis of metallic materials. Meas. Sci. Technol. 2010, 21, 085502. [Google Scholar] [CrossRef]

- Panin, V.E. Foundations of physical mesomechanics. Phys. Mesomech. 1998, 1, 5–20. [Google Scholar]

- Mroz, Z.; Oliferuk, W. Energy balance and identification of hardening moduli in plastic deformation processes. Int. J. Plast. 2002, 18, 379–397. [Google Scholar] [CrossRef]

- Farren, W.S.; Taylor, G.I. The heat developed during plastic extension of metals. Proc. R. Soc. Lond. 1925, 107, 422–451. [Google Scholar] [CrossRef]

- Amiri, M.; Naderi, M.; Khonsari, M.M. An experimental approach to evaluate the critical damage. Int. J. Damage Mech. 2011, 20, 89–112. [Google Scholar] [CrossRef]

- Plekhov, O.A.; Panteleev, I.A.; Naimark, O.B. Energy accumulation and dissipation in metals as a result of structural-scaling transitions in a mesodefect ensemble. Phys. Mesomech. 2007, 10, 294–301. [Google Scholar] [CrossRef]

- Hilarov, V.L.; Slutsker, A.I. Description of the thermoelastic effect in solids in a wide temperature range. Phys. Solid State 2014, 56, 2493–2495. [Google Scholar] [CrossRef]

- Sirinakorn, T.; Uthaisangsuk, V. Investigation of damage initiation in high-strength dual-phase steels using cohesive zone model. Int. J. Damage Mech. 2016, 27, 409–438. [Google Scholar] [CrossRef]

- Larikov, L.N.; Yurchenko, Y.F. Thermal Properties of Metals and Alloys. Handbook; Naukova Dumka: Kiev, Russia, 1985; p. 438. (In Russian) [Google Scholar]

- Kirillov, P.L.; Terentyeva, M.I.; Deniskina, N.B. Thermophysical properties of materials for nuclear engineering. In A Tutorial and Collection of Data; The IAEA: Vienna, Austria, 2008; p. 200. ISBN 978-92-0-106508-7. [Google Scholar]

- Kolmogorov, G.L.; Snigireva, M.V. Elastic and thermophysical properties of transversely isotropic superconducting composite materials. In Scientific Research and Innovations; Perm State Technical University: City of Perm, Russia, 2007; Volume 3, pp. 31–40. (In Russian) [Google Scholar]

- Gorbatov, V.I.; Polev, V.F.; Pilugin, V.P.; Korshunov, L.G.; Smirnov, A.L.; Talutz, S.G.; Brytkov, D.A. Thermal diffusivity of submicro- and nanocrystalline niobium, titanium, and zirconium at high temperatures. High Temp. 2013, 51, 482–485. [Google Scholar] [CrossRef]

| Material | Yield Stress σ02, MPa Mean ± SD */Min/Max (N **) | Ultimate Tensile Strength σuts, MPa Mean ± SD/Min/Max (N) | Plastic Deformation εp, % Mean ± SD/Min/Max (N) |

|---|---|---|---|

| VT1-0, CG | 337 ± 10/320/350 (8) | 476 ± 12/450/495 (8) | 24 ± 0.9/23/25 (8) |

| VT1-0, UFG | 728 ± 47/650/800 (9) | 974 ± 18/940/1000 (9) | 10 ± 0.6/9/11 (9) |

| Zr-1Nb, CG | 262 ± 8/255/275 (8) | 410 ± 10/390/425 (8) | 26.5 ± 0.8/25/27 (8) |

| Zr-1Nb, UFG | 503 ± 8/490/515 (9) | 714 ± 20/680/750 (9) | 15.5 ± 0.6/14,5/16 (9) |

| Ti-45Nb, CG | 345 ± 13/320/360 (11) | 707 ± 60/620/790 (11) | 14.5 ± 0.5/14/15 (11) |

| Ti-45Nb, UFG | 415 ± 58/300/500 (10) | 1155 ± 83/1020/1280 (10) | 6.5 ± 0.3/6/7 (10) |

| Material | Specific Work of Strain for Samples with High Mechanical Properties, MJ/m3 | Specific Work of Strain for Samples with Low Mechanical Properties, MJ/m3 |

|---|---|---|

| VT1-0, CG | 135 | 109 |

| VT1-0, UFG | 111 | 83 |

| Zr-1Nb, CG | 112 | 108 |

| Zr-1Nb, UFG | 111 | 107 |

| Ti-45Nb, CG | 129 | 100 |

| Ti-45Nb, UFG | 64 | 60 |

| Metal/Alloy | Density, kg/m3 | Melting Temperature, °C | Heat Capacity Cp, J/(kg·K) at 300 K | Thermal Conductivity λ, W/(mK) at 300 K | Thermal Diffusivity at 300 K, 10−6 m2/s |

|---|---|---|---|---|---|

| Ti | 4510 | 1671 | 522 | 20.0 | 8.5 * |

| Zr | 6510 | 1850 | 276 | 21.4 | 11.9 * |

| Nb | 8580 | 2500 | 268 | 53.0 | 23.0 * |

| Titanium VT1-0 | 4500 | 1725 | 520 | 19.3 | 8.3 * |

| Zr-1Nb | 6550 | 1837 | 320 | 18.0 | 8.6 * (10.3) ** |

| Ti-45Nb | 6336 *** | - | 406 *** | 44.5 *** | 17.4 *** |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharkeev, Y.; Vavilov, V.; Skripnyak, V.A.; Belyavskaya, O.; Legostaeva, E.; Kozulin, A.; Chulkov, A.; Sorokoletov, A.; Skripnyak, V.V.; Eroshenko, A.; et al. Analyzing the Deformation and Fracture of Bioinert Titanium, Zirconium and Niobium Alloys in Different Structural States by the Use of Infrared Thermography. Metals 2018, 8, 703. https://doi.org/10.3390/met8090703

Sharkeev Y, Vavilov V, Skripnyak VA, Belyavskaya O, Legostaeva E, Kozulin A, Chulkov A, Sorokoletov A, Skripnyak VV, Eroshenko A, et al. Analyzing the Deformation and Fracture of Bioinert Titanium, Zirconium and Niobium Alloys in Different Structural States by the Use of Infrared Thermography. Metals. 2018; 8(9):703. https://doi.org/10.3390/met8090703

Chicago/Turabian StyleSharkeev, Yurii, Vladimir Vavilov, Vladimir A. Skripnyak, Olga Belyavskaya, Elena Legostaeva, Alexander Kozulin, Arsenii Chulkov, Alexey Sorokoletov, Vladimir V. Skripnyak, Anna Eroshenko, and et al. 2018. "Analyzing the Deformation and Fracture of Bioinert Titanium, Zirconium and Niobium Alloys in Different Structural States by the Use of Infrared Thermography" Metals 8, no. 9: 703. https://doi.org/10.3390/met8090703

APA StyleSharkeev, Y., Vavilov, V., Skripnyak, V. A., Belyavskaya, O., Legostaeva, E., Kozulin, A., Chulkov, A., Sorokoletov, A., Skripnyak, V. V., Eroshenko, A., & Kuimova, M. (2018). Analyzing the Deformation and Fracture of Bioinert Titanium, Zirconium and Niobium Alloys in Different Structural States by the Use of Infrared Thermography. Metals, 8(9), 703. https://doi.org/10.3390/met8090703