Local Fatigue Strength Evaluation of Shot Peened 40Cr Notched Steel

Abstract

1. Introduction

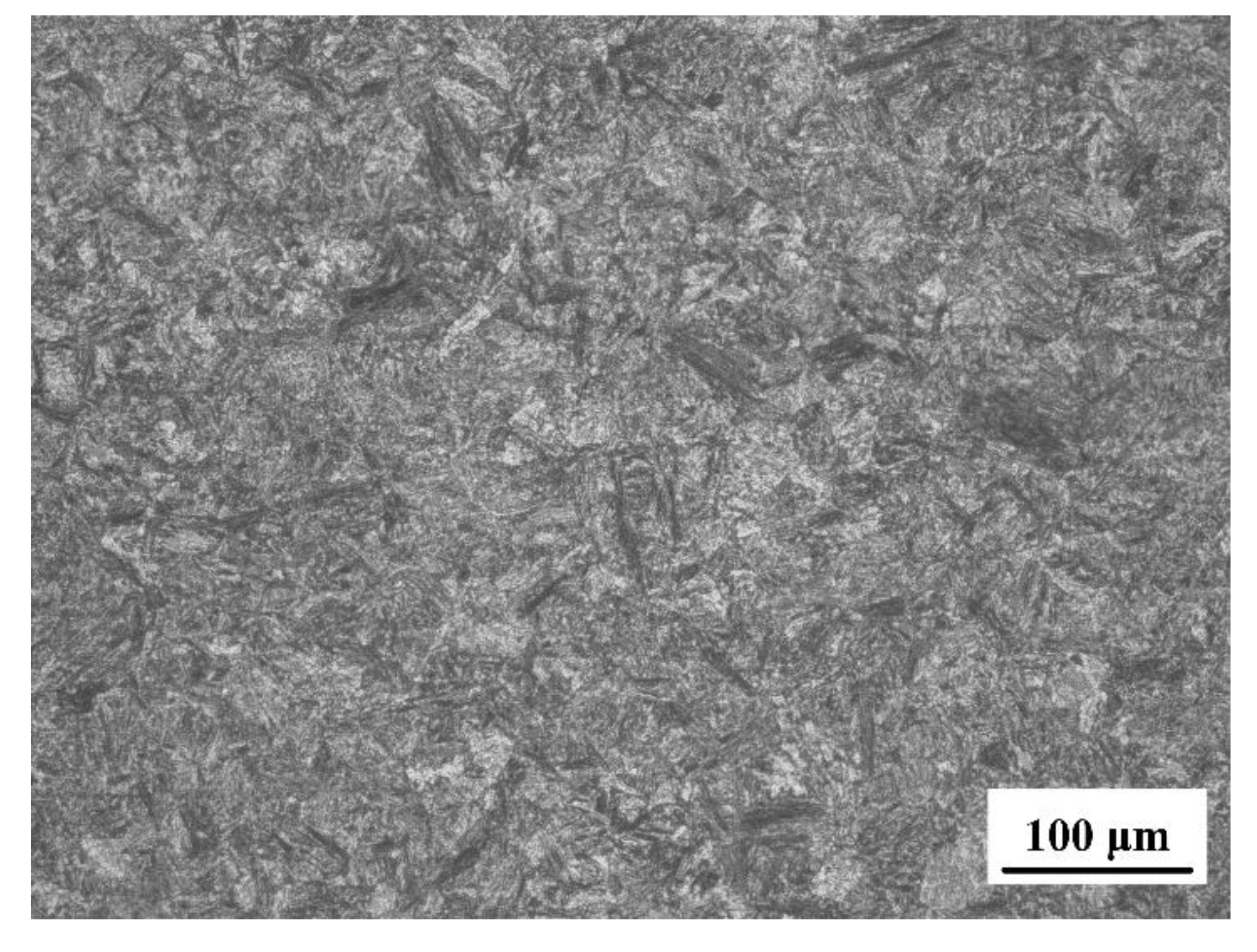

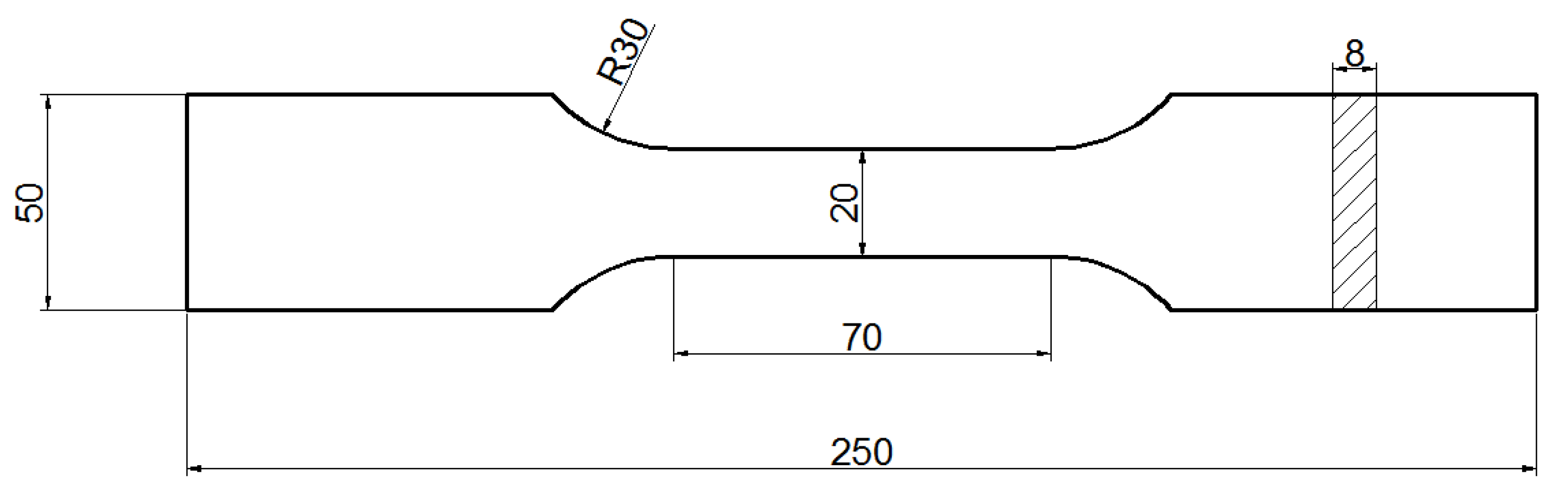

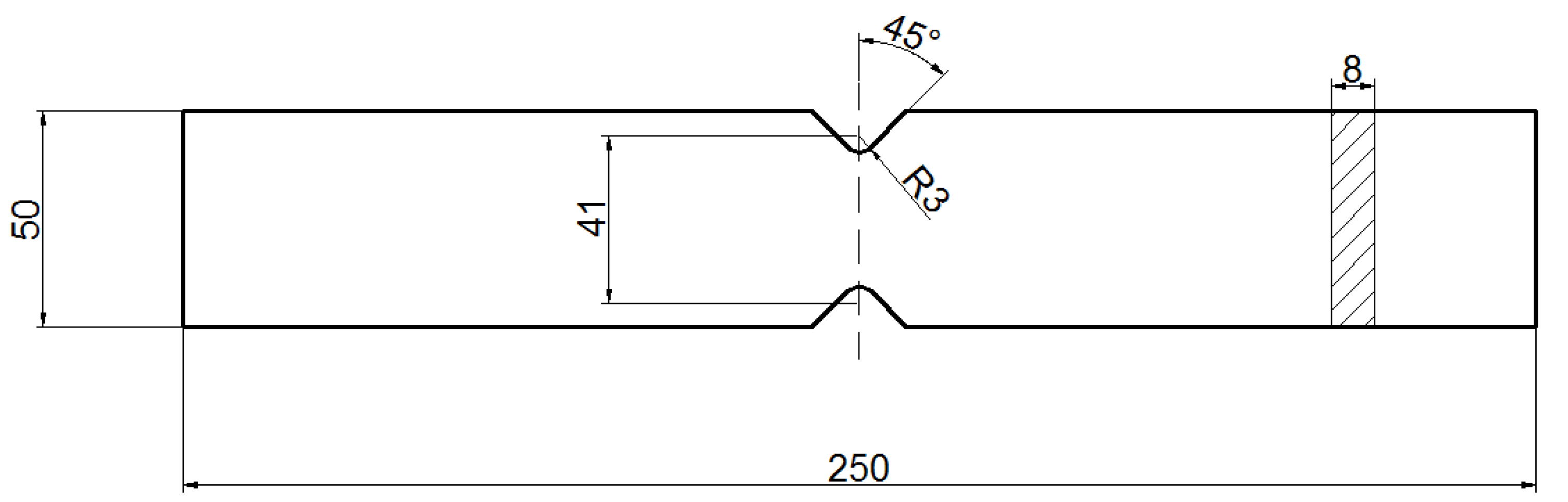

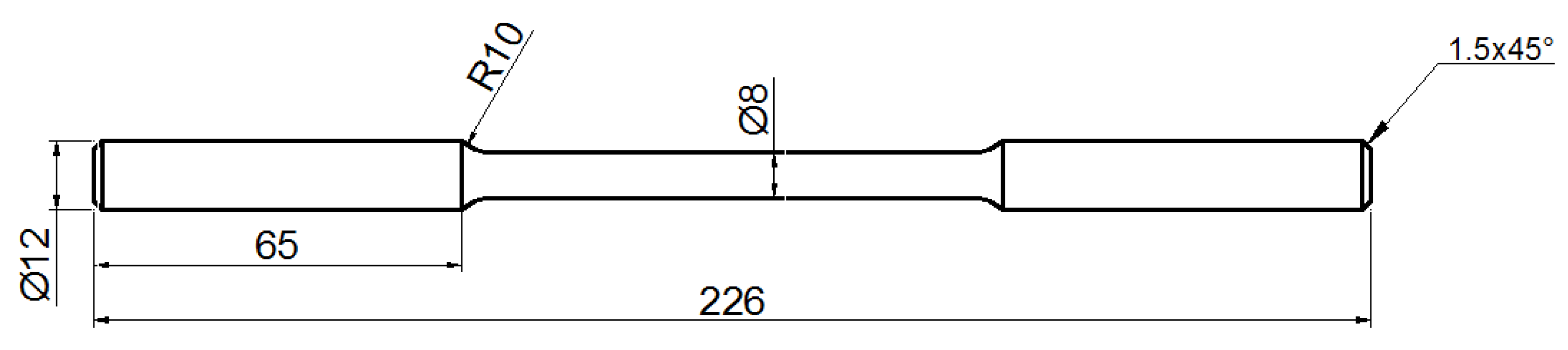

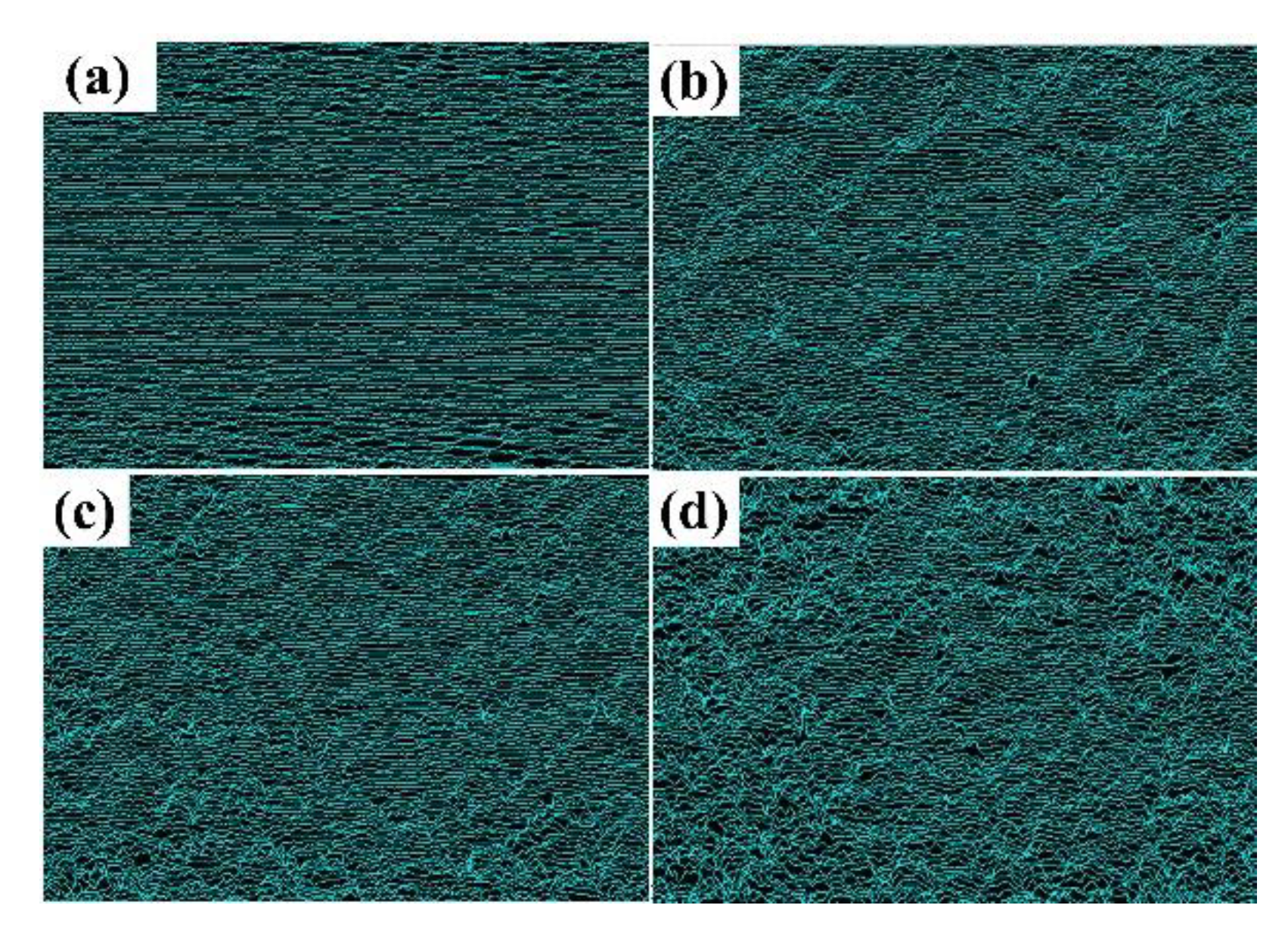

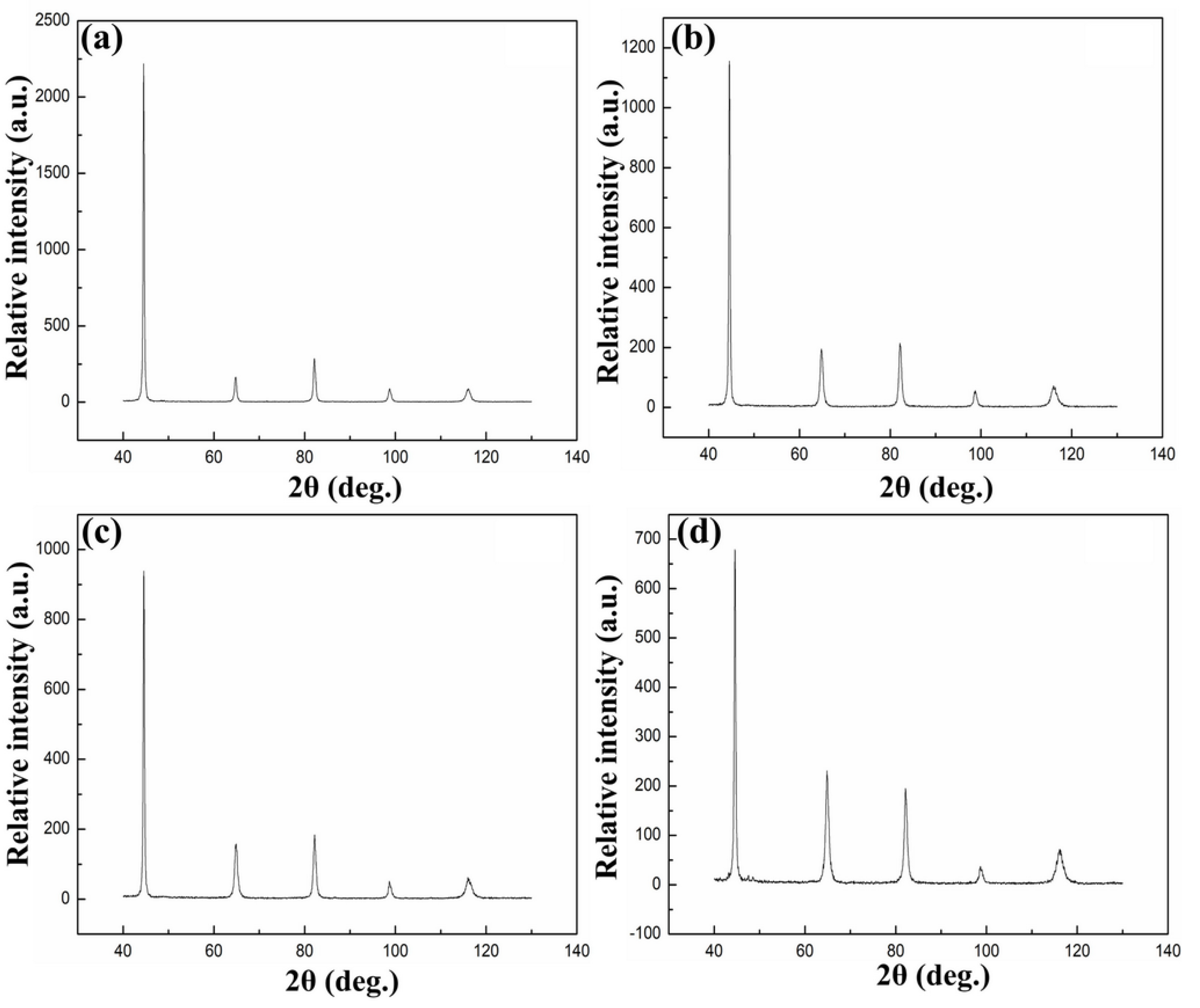

2. Experimental Procedures

3. Results and Discussion

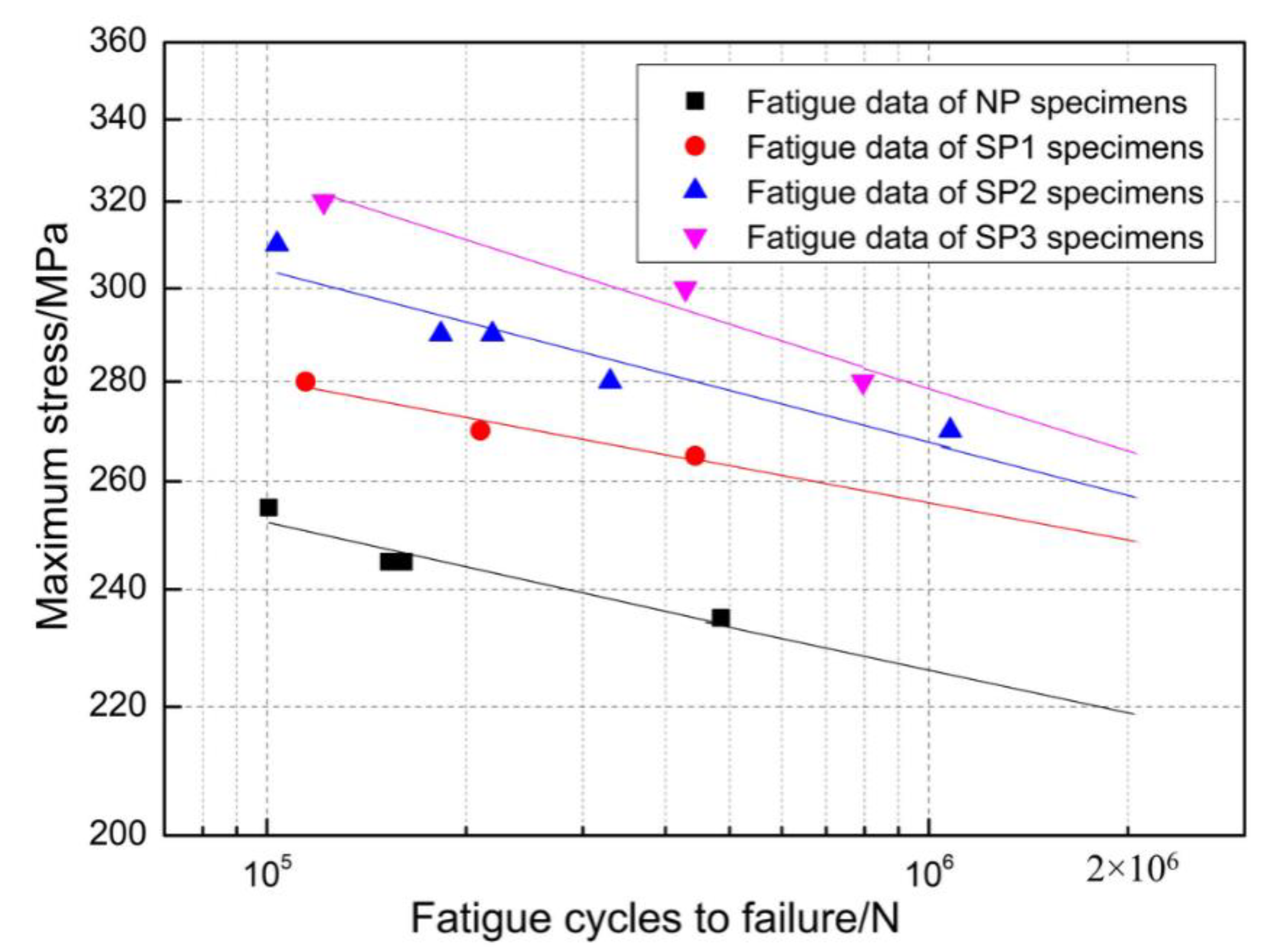

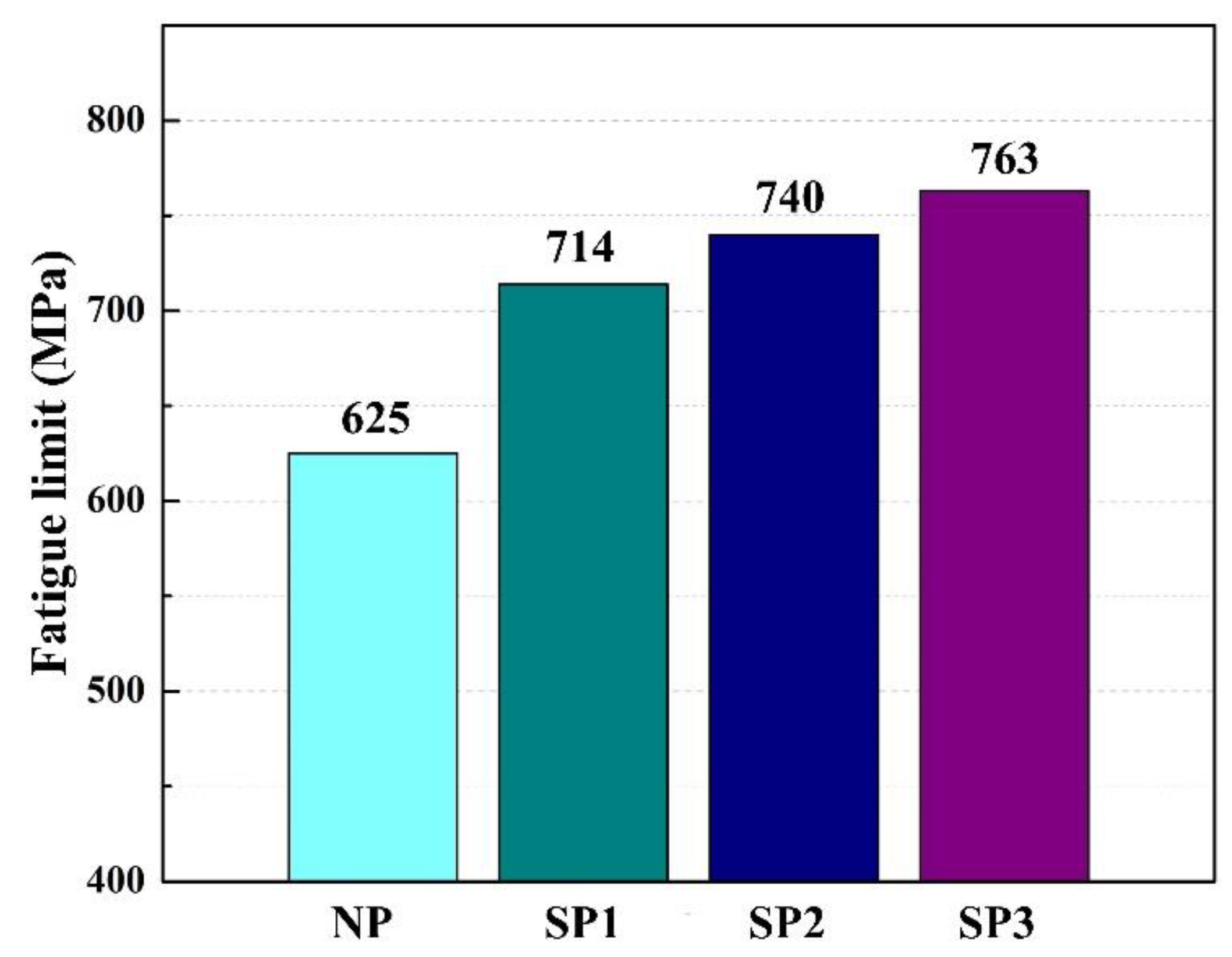

3.1. Fatigue Properties

3.1.1. Effect of Shot Peening on Fatigue Strength

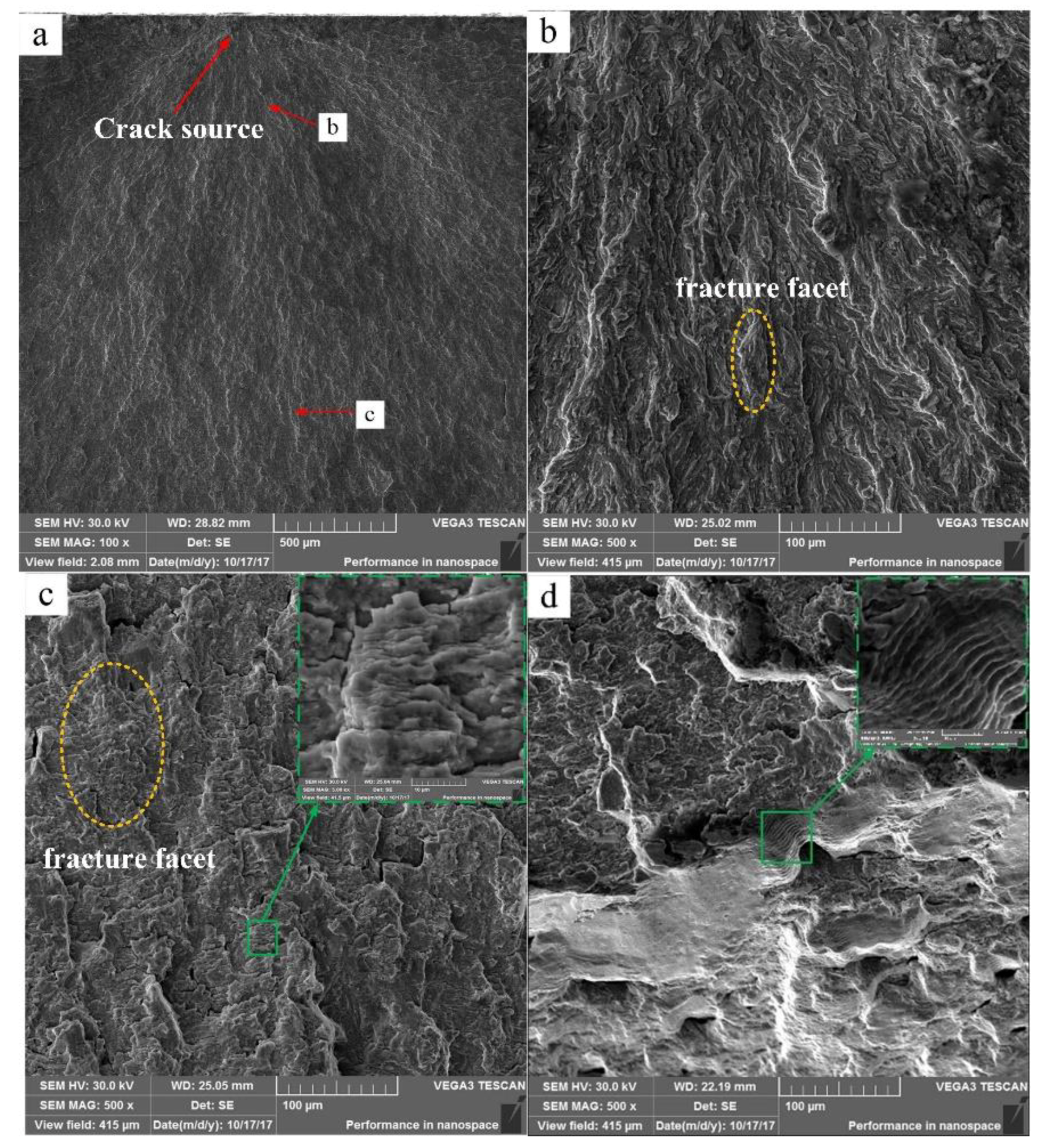

3.1.2. Fatigue Fracture Analysis

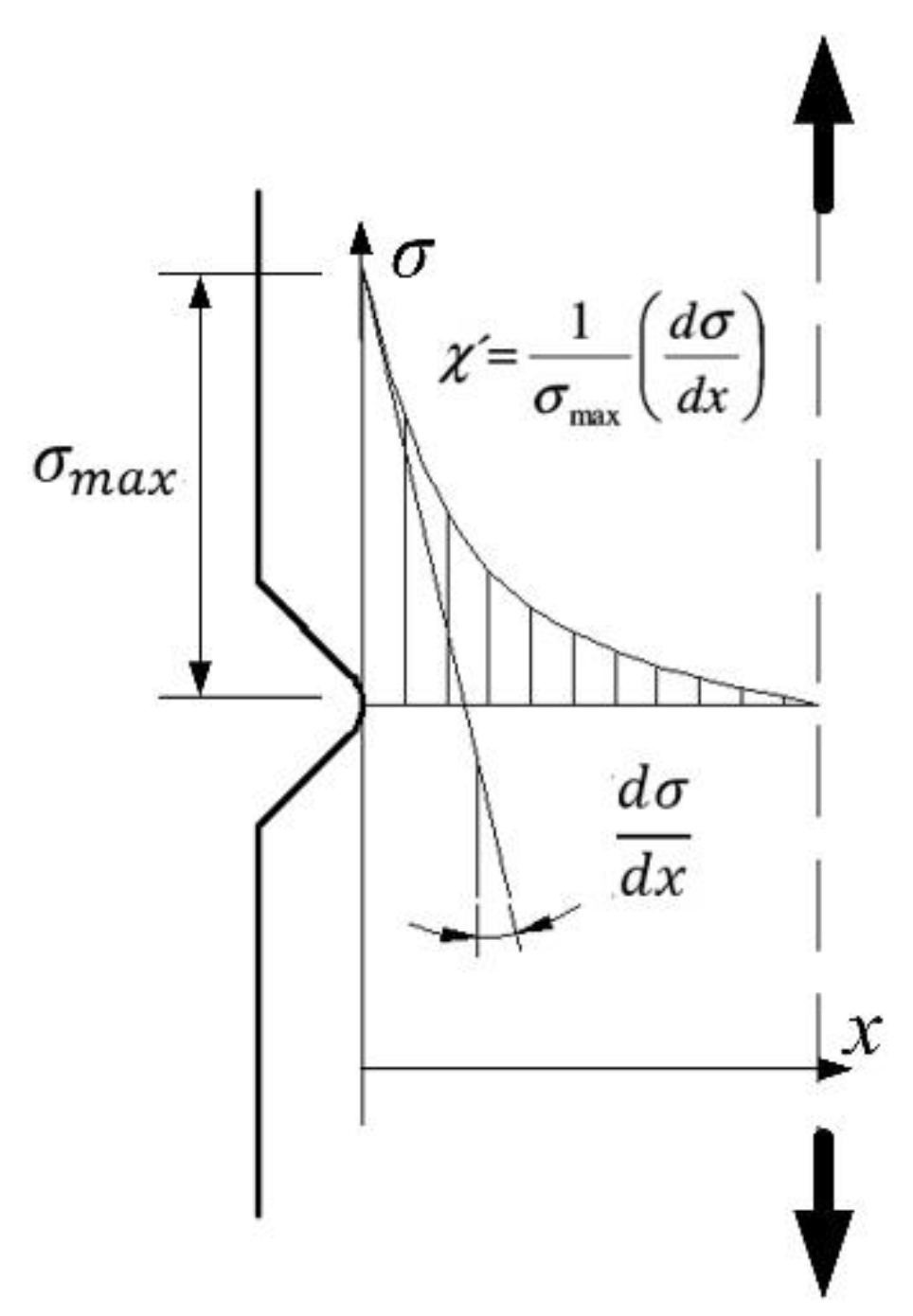

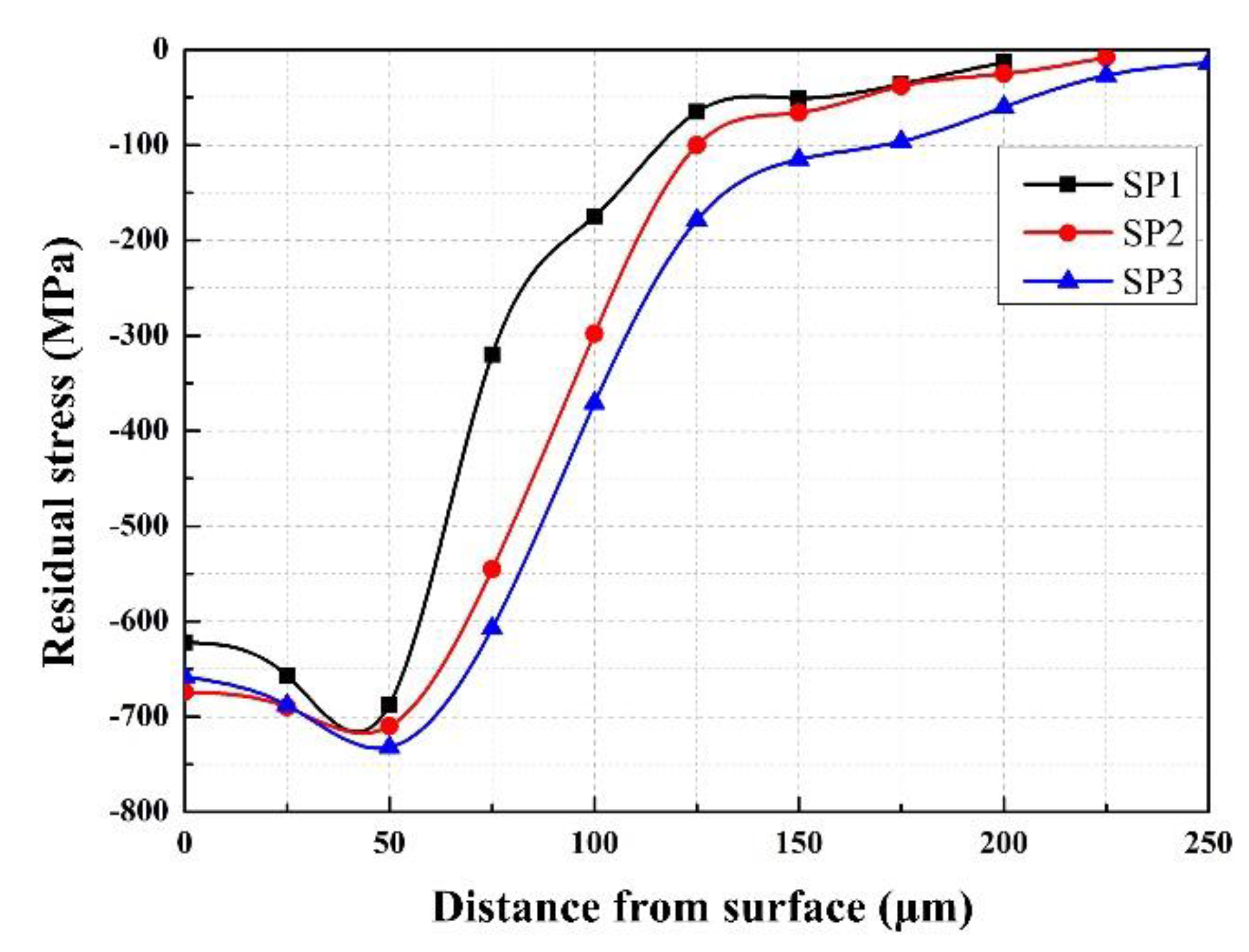

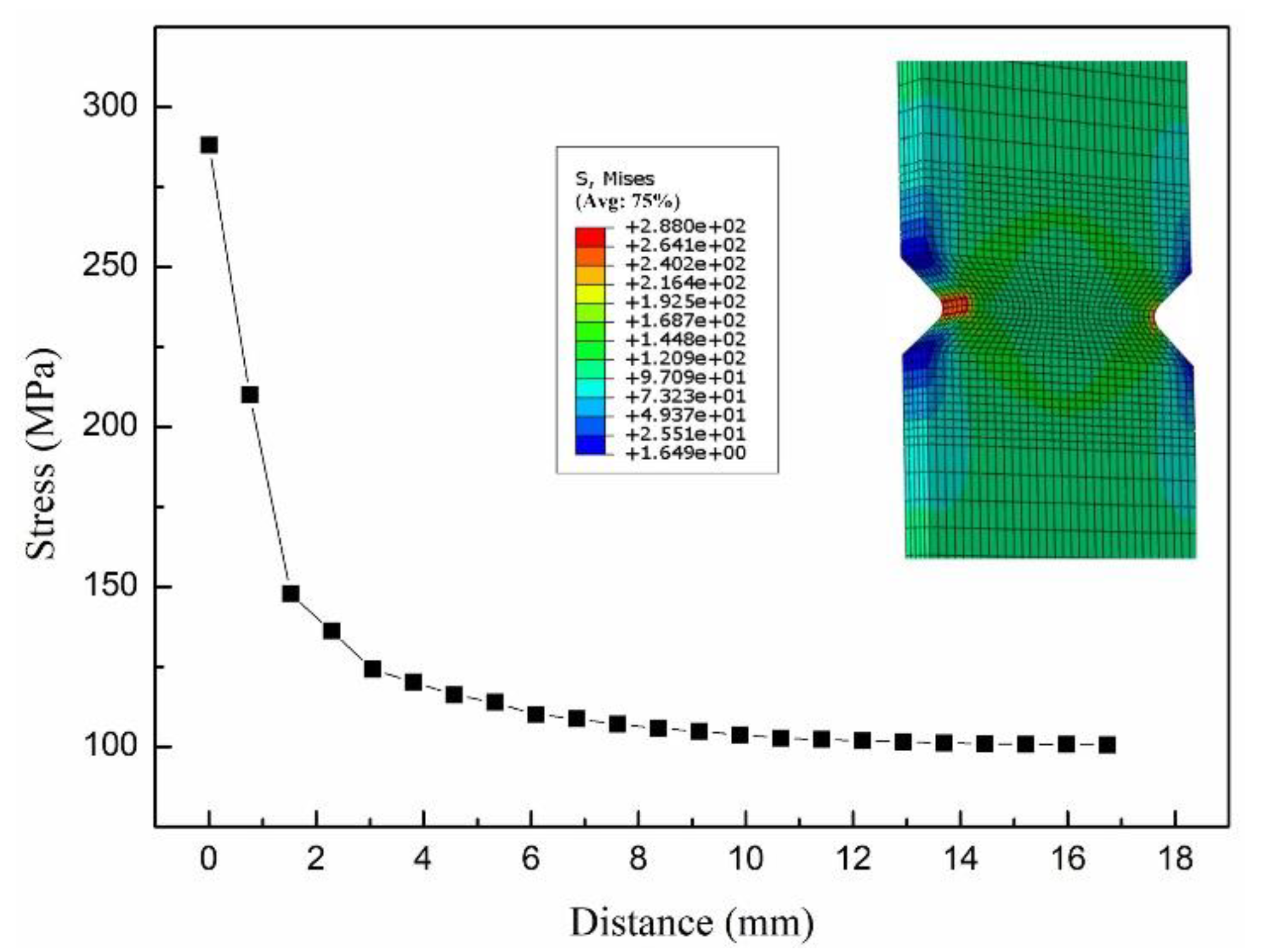

3.2. Local Fatigue Strength Evaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schulze, V. Modern Mechanical Surface Treatment, States, Stability, Effects; John Wiley & Sons: New York, NY, USA, 2006; pp. 247–319. [Google Scholar]

- Liu, G.; Wang, S.C.; Lou, X.F.; Lu, J.; Lu, K. Low carbon steel with nanostructured surface layer induced by high-energy shot peening. Scr. Mater. 2001, 44, 1791–1795. [Google Scholar] [CrossRef]

- Abrão, A.M.; Aspinwall, D.K. The surface integrity of turned and ground hardened bearing steel. Wear 1996, 196, 279–284. [Google Scholar] [CrossRef]

- Guilhem, Y.; Basseville, S.; Curtit, F.; Stéphan, J.; Cailletaud, G. Numerical analysis of the effect of surface roughness on mechanical fields in polycrystalline aggregates. Model. Simul. Mater. Sc. 2018, 26, 045004. [Google Scholar] [CrossRef]

- Nascimento, M.P.; Souza, R.C.; Pigatin, W.L.; Voorwald, H.J.C. Effects of surface treatments on the fatigue strength of AISI 4340 aeronautical steel. Int. J. Fatigue 2001, 23, 607–618. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, D. Effect of shot peening on fretting fatigue of Ti811 alloy at elevated temperature. Int. J. Fatigue 2009, 31, 889–893. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, Y.; Wu, H.; Du, S.S.; Shen, G.; Wu, W.Y.; Lu, K.; Wei, J.; Readman, P.; Peñate, J.; et al. Fatigue tests on ITER PF6 Coil Helium Inlet at 77K. IEEE T. Appl. Supercon. 2018, 28, 1–7. [Google Scholar] [CrossRef]

- Eichlseder, W. Fatigue analysis by local stress concept based on finite element results. Comput. Struct. 2002, 80, 2109–2113. [Google Scholar] [CrossRef]

- Bagherifard, S.; Colombo, C.; Guagliano, M. Application of different fatigue strength criteria to shot peened notched components. Part 1: Fracture Mechanics based approaches. Appl. Surf. Sci. 2014, 289, 180–187. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Application of different fatigue strength criteria on shot peened notched parts. Part 2: Nominal and local stress approaches. Appl. Surf. Sci. 2014, 289, 173–179. [Google Scholar] [CrossRef]

- Olmi, G.; Comandini, M.; Freddi, A. Fatigue on Shot-Peened Gears: Experimentation, Simulation and Sensitivity Analyses. Strain 2010, 46, 382–395. [Google Scholar] [CrossRef]

- Olmi, G.; Freddi, A. A new method for modelling the support effect under rotating bending fatigue: Application to Ti-6Al-4V alloy, with and without shot peening. Fatigue Fract. Eng. Mater. 2013, 36, 981–993. [Google Scholar] [CrossRef]

- Zhao, L.H.; Feng, J.Z.; Zheng, S.L. Effect of Cyclic Stresses Below the Endurance Limit on the Fatigue Life of 40Cr Steel. Strength Mater. 2018, 50, 2–10. [Google Scholar] [CrossRef]

- Zhao, X.H.; Zhao, B.; Liu, Y.; Cai, Y.; Hu, C.H. Research on friction and wear behavior of gradient nano-structured 40Cr steel induced by high frequency impacting and rolling. Eng. Fail. Anal. 2017, 83, 167–177. [Google Scholar] [CrossRef]

- Wu, G.C.; Li, Y.F.; Pan, X.D; Wang, G.L. Numerical simulation of fatigue damage and shape instability behavior of steel 40Cr by the damage-coupled crystal plastic model. Strength Mater. 2017, 49, 118–124. [Google Scholar] [CrossRef]

- Gao, Y.K. Fatigue limit of chemical heat treated specimens and effect of shot peening. Surf. Eng. 2013, 24, 322–326. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.; Wang, D. Effective FE model to predict surface layer characteristics of ultrasonic surface rolling with experimental validation. Mater. Sci. Technol. 2014, 30, 627–636. [Google Scholar] [CrossRef]

- Fathallah, R.; Laamouri, A.; Sidhom, H.; Braham, C. High cycle fatigue behavior prediction of shot-peened parts. Int. J. Fatigue 2004, 26, 1053–1067. [Google Scholar] [CrossRef]

- Song, P.S.; Wen, C.C. Crack closure and crack growth behaviour in shot peened fatigued specimen. Eng. Fract. Mech. 1999, 63, 295–304. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Horstmann, M.; Chupakhin, S.; Riekehr, S.; Falck, R.; Maawad, E.; Staron, P.; Schell, N.; Huber, N. Effects of laser shock peening on the microstructure and fatigue crack propagation behaviour of thin AA2024 specimens. Int. J. Fatigue 2017, 98, 223–233. [Google Scholar] [CrossRef]

- Pariente, I.F.; Guagliano, M. About the role of residual stresses and surface work hardening on fatigue ΔKth of a nitrided and shot peened low-alloy steel. Surf. Coat. Technol. 2008, 202, 3072–3080. [Google Scholar] [CrossRef]

- Buch, A. Fatigue Strength Calculation; Transtech Publications: Zürich, Switzerland, 1988; pp. 51–54. [Google Scholar]

| C | Si | Mn | Cr | Ni | P | S |

|---|---|---|---|---|---|---|

| 0.37~0.44 | 0.17~0.37 | 0.5~0.8 | 0.8~1.1 | ≤0.030 | ≤0.035 | ≤0.035 |

| Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation Rate (%) | HV |

|---|---|---|---|

| 750 | 880 | 9.7 | 260 |

| Treatment | Shot Type | Almen Intensity (mmA) | Coverage (%) |

|---|---|---|---|

| SP1 | S110 | 0.2 | 100 |

| SP2 | S110 | 0.3 | 100 |

| SP3 | S110 | 0.4 | 100 |

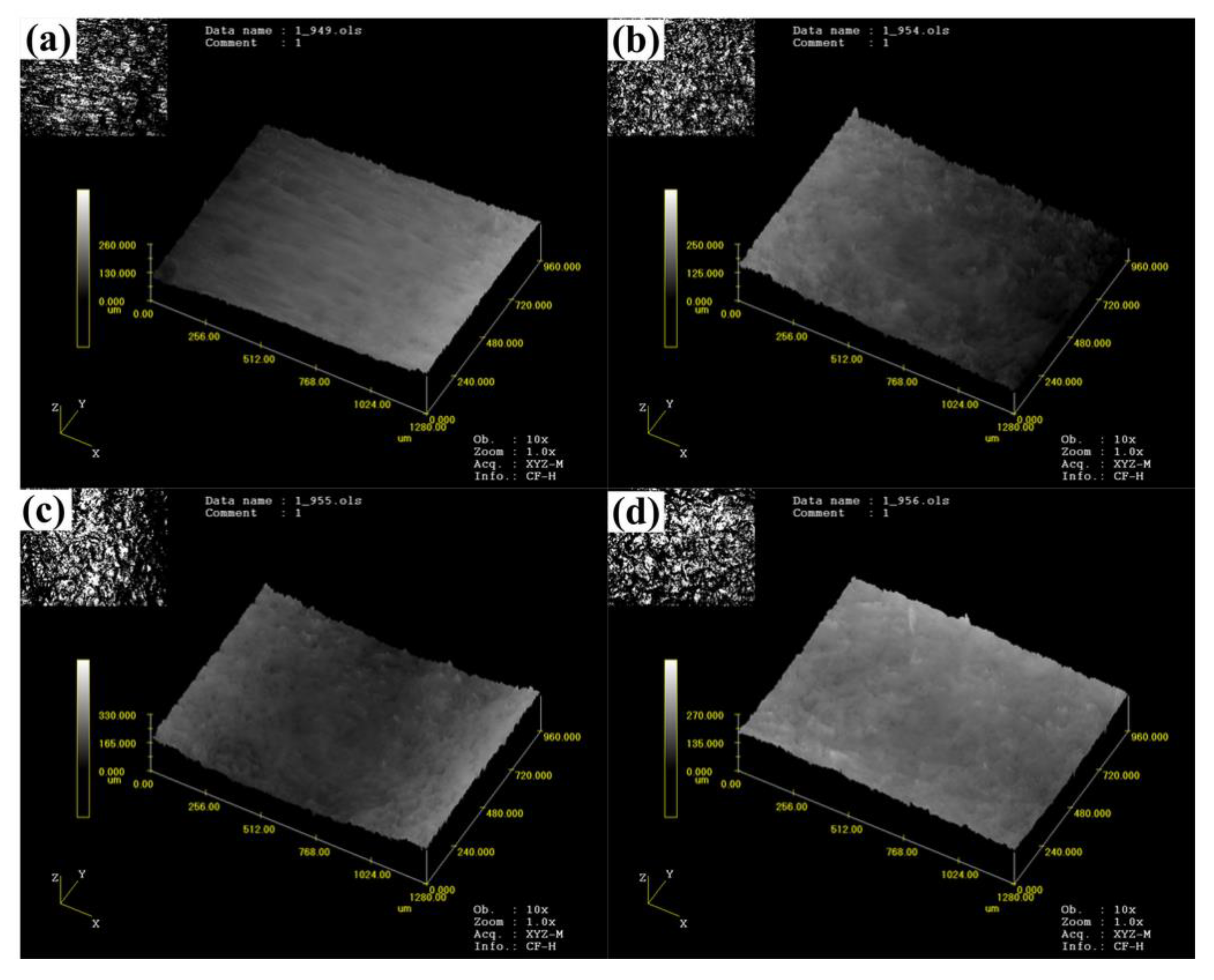

| Specimen | Ra | Rz | Rq |

|---|---|---|---|

| NP | 1.887 | 60.021 | 2.451 |

| SP1 | 2.747 | 98.082 | 3.746 |

| SP2 | 2.911 | 100.216 | 4.013 |

| SP3 | 3.133 | 117.381 | 4.335 |

| Specimen | Calculated Fatigue Limit (MPa) | Experimental Data (MPa) | Error% |

|---|---|---|---|

| SP1 | 703 | 714 | −1.5 |

| SP2 | 726 | 740 | −1.9 |

| SP3 | 738 | 763 | −3.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Sun, Z.; Xu, D.; Liu, Y. Local Fatigue Strength Evaluation of Shot Peened 40Cr Notched Steel. Metals 2018, 8, 681. https://doi.org/10.3390/met8090681

Zhao X, Sun Z, Xu D, Liu Y. Local Fatigue Strength Evaluation of Shot Peened 40Cr Notched Steel. Metals. 2018; 8(9):681. https://doi.org/10.3390/met8090681

Chicago/Turabian StyleZhao, Xiaohui, Zhaoyi Sun, Desheng Xu, and Yu Liu. 2018. "Local Fatigue Strength Evaluation of Shot Peened 40Cr Notched Steel" Metals 8, no. 9: 681. https://doi.org/10.3390/met8090681

APA StyleZhao, X., Sun, Z., Xu, D., & Liu, Y. (2018). Local Fatigue Strength Evaluation of Shot Peened 40Cr Notched Steel. Metals, 8(9), 681. https://doi.org/10.3390/met8090681