An Overview of Fatigue Strength of Case-Hardening TRIP-Aided Martensitic Steels

Abstract

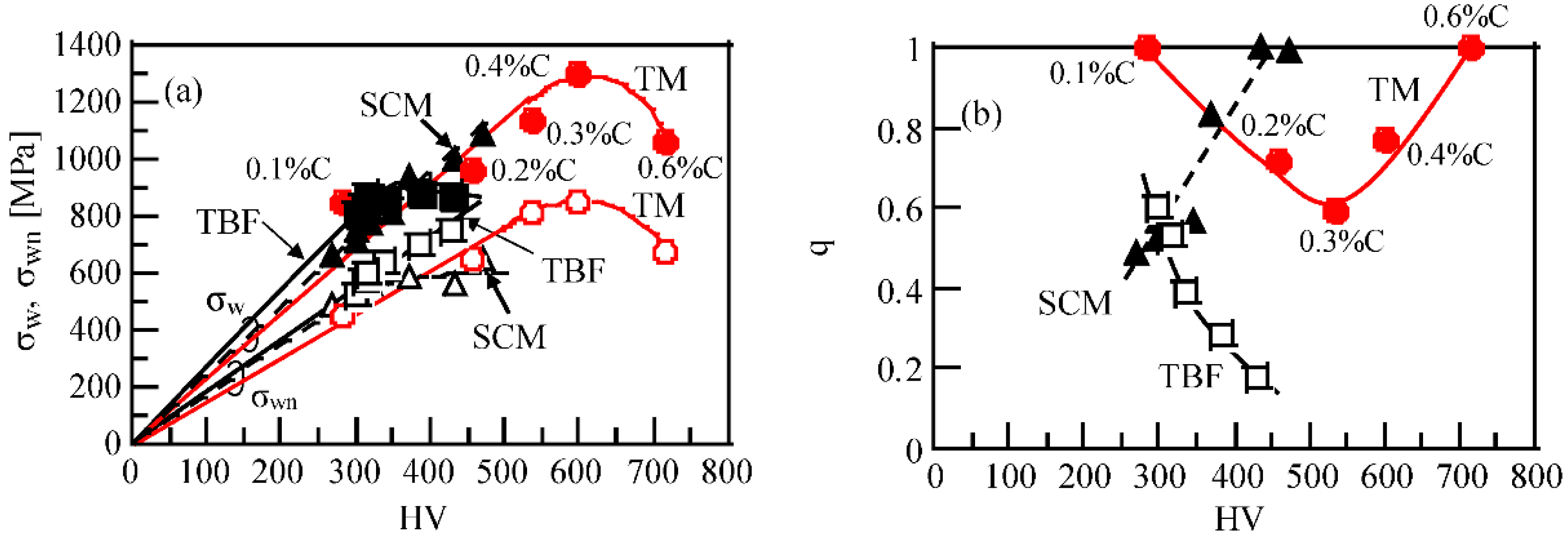

1. Introduction

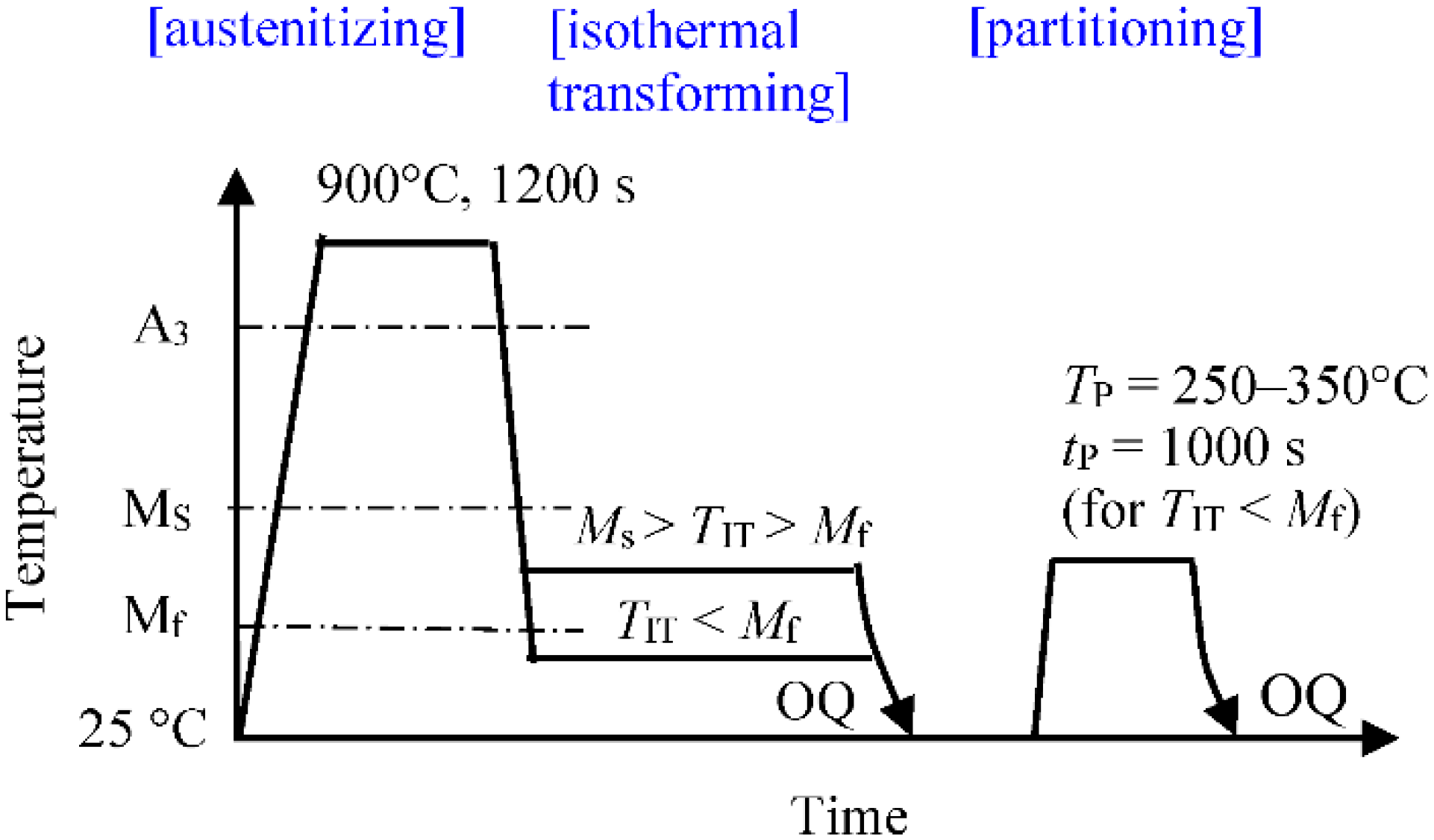

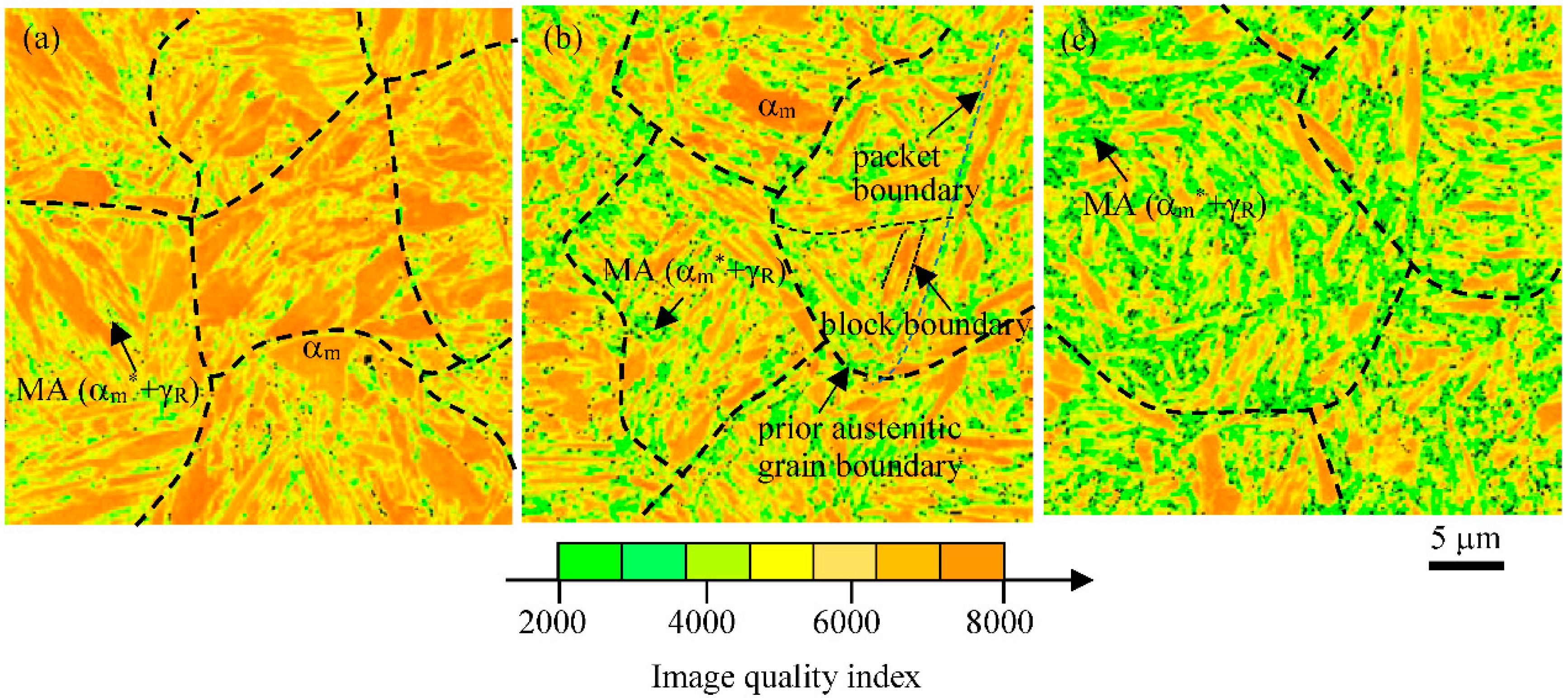

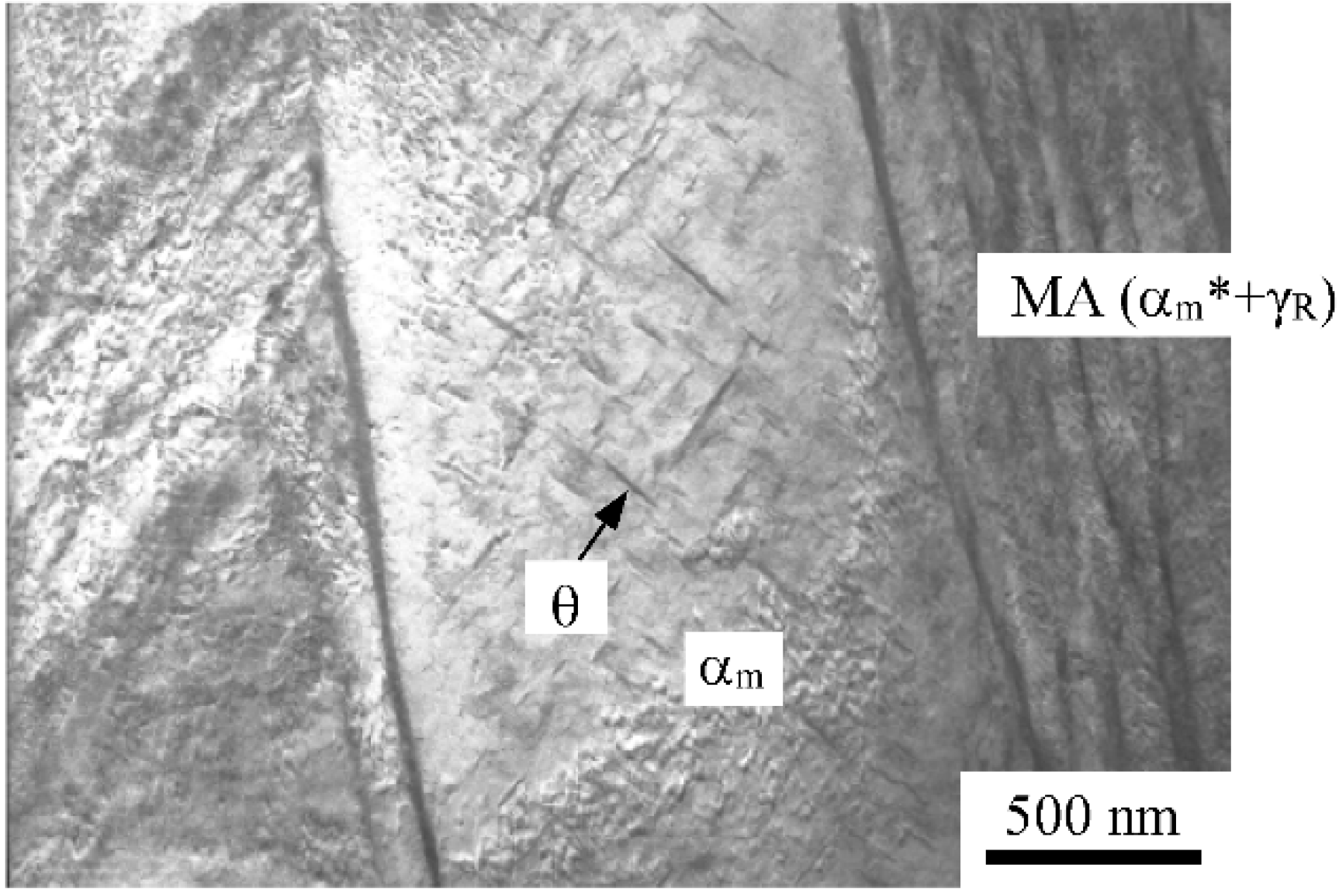

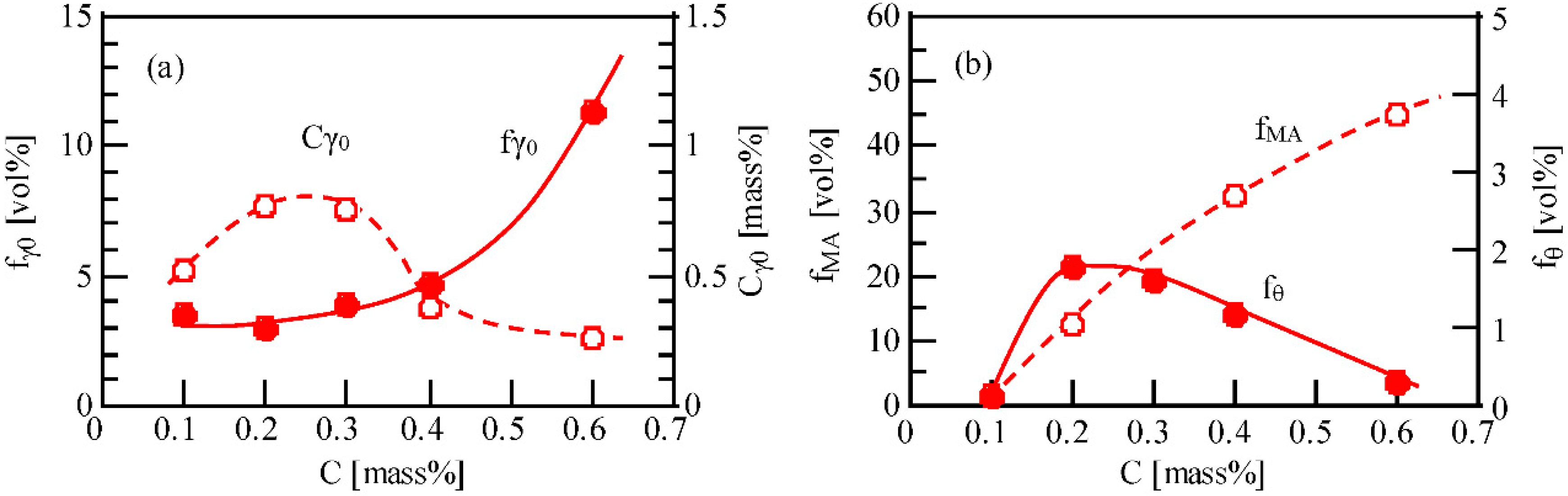

2. As-Heat-Treated TM Steels

2.1. Microstructure

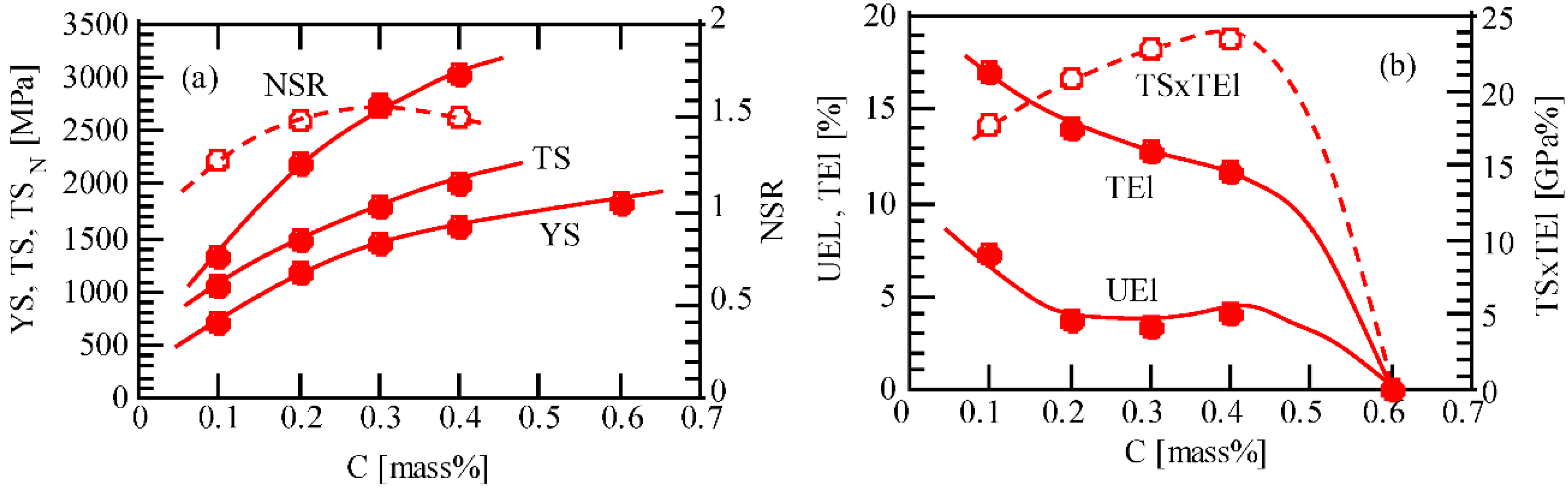

2.2. Tensile Properties

- (1)

- a soft wide lath-martensite matrix with only a little carbide and diluted carbon concentration which improves the ductility,

- (2)

- a large quantity of finely dispersed MA-like phase which produces a large mean internal stress resulting from a difference in flow stress between a soft wide-lath martensite and a hard MA-like phase,

- (3)

- a metastable retained austenite of 2–5 vol %, which increases hard strain-induced martensite fraction and plastically relaxes the localized stress concentration on strain-induced transformation.

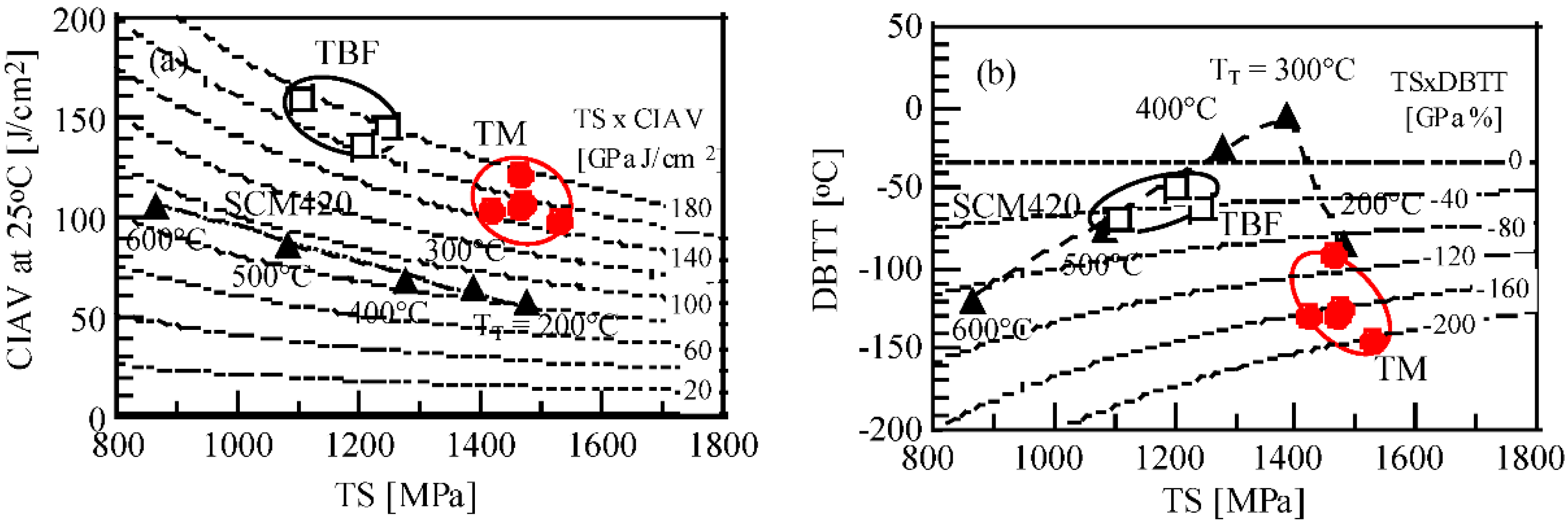

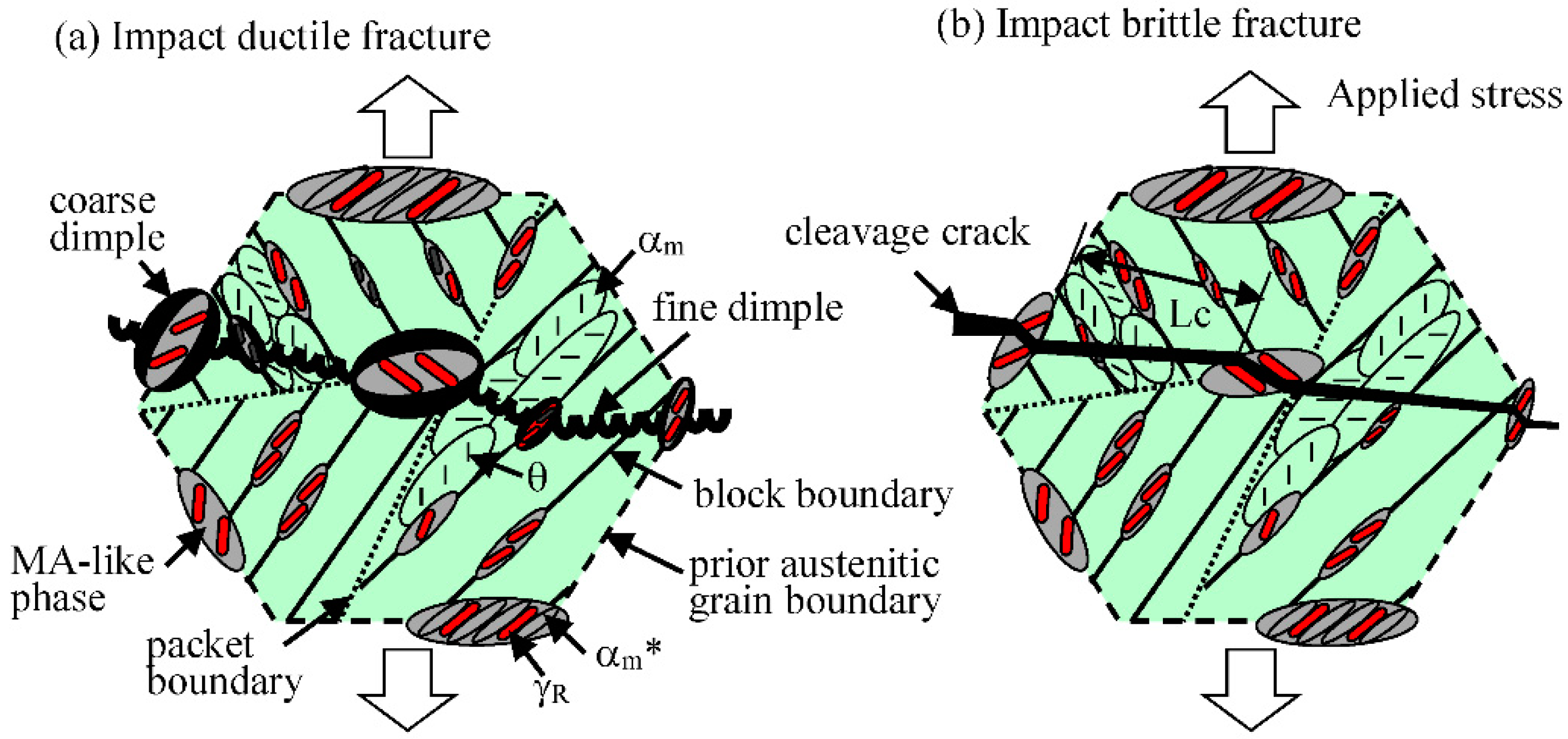

2.3. Impact Toughness

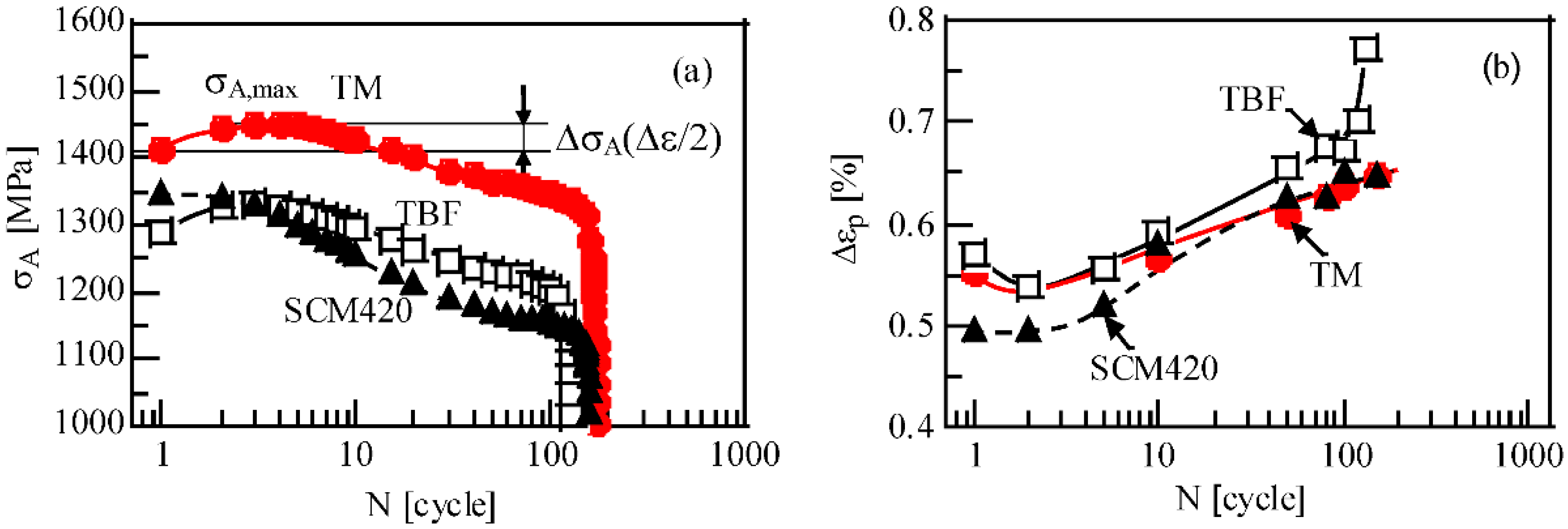

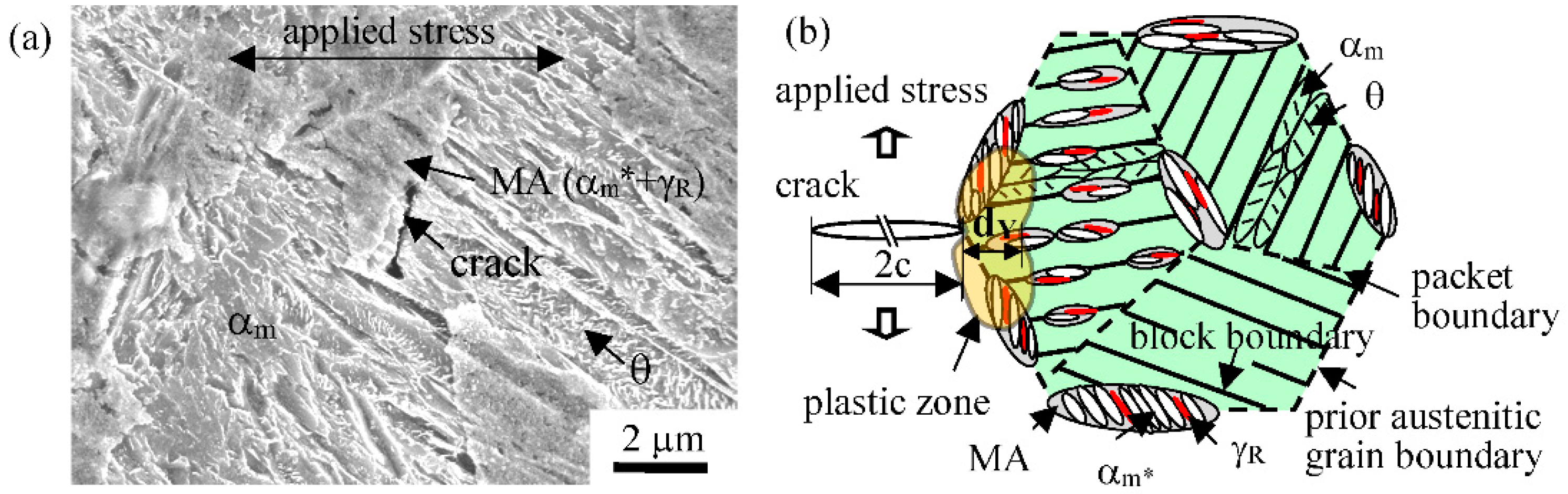

2.4. Fatigue Properties

3. Heat-Treated and Subsequently Fine-Particle Peened TM Steels

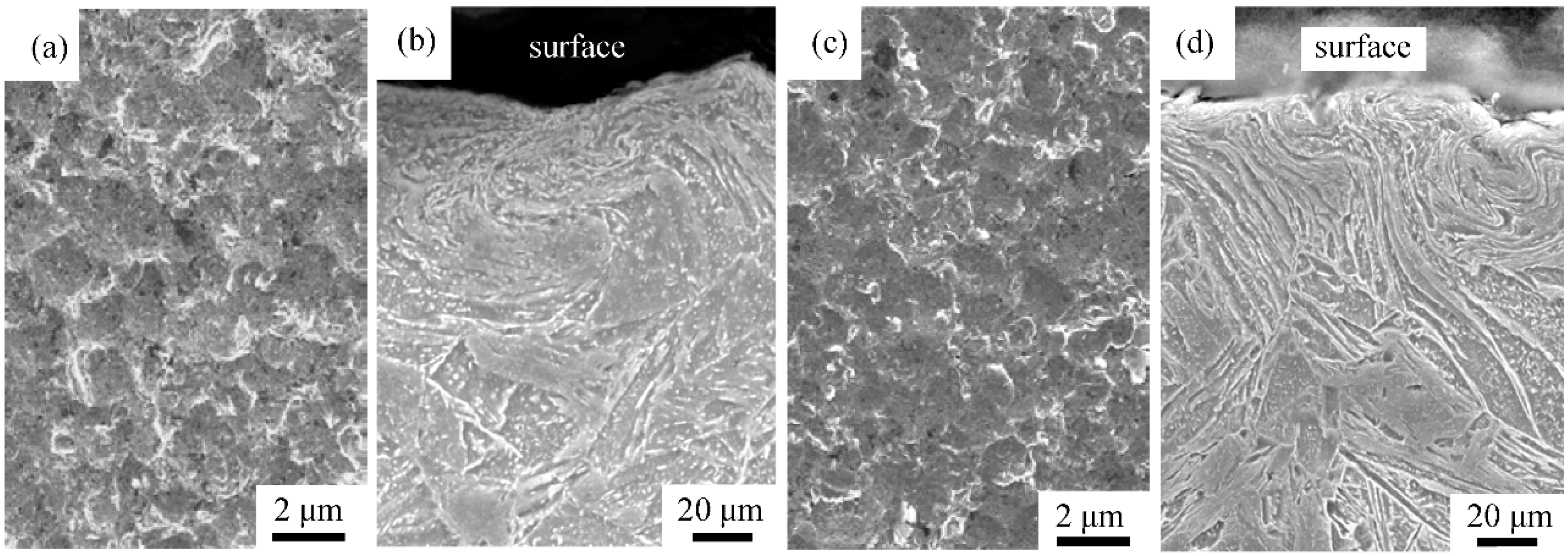

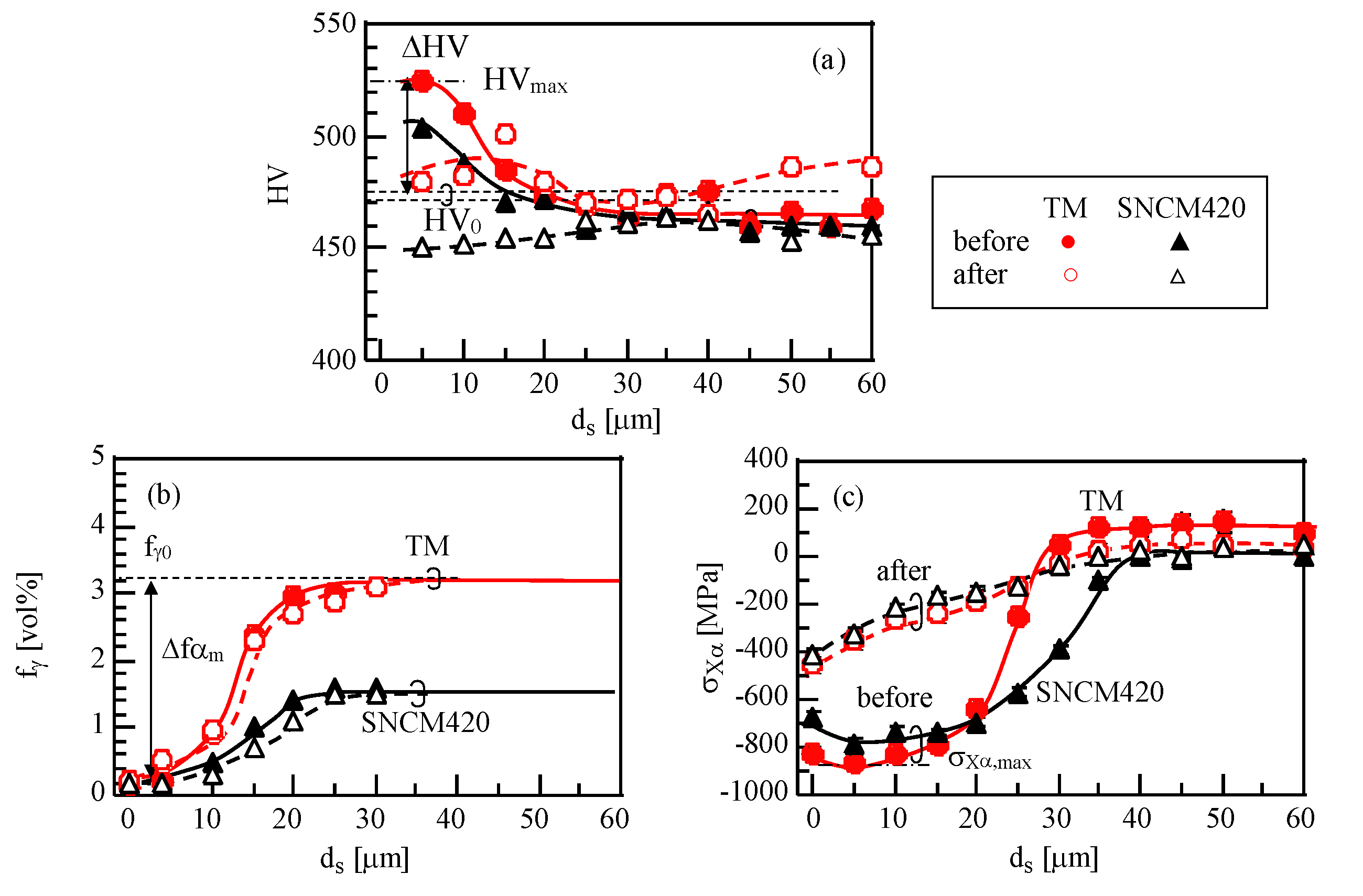

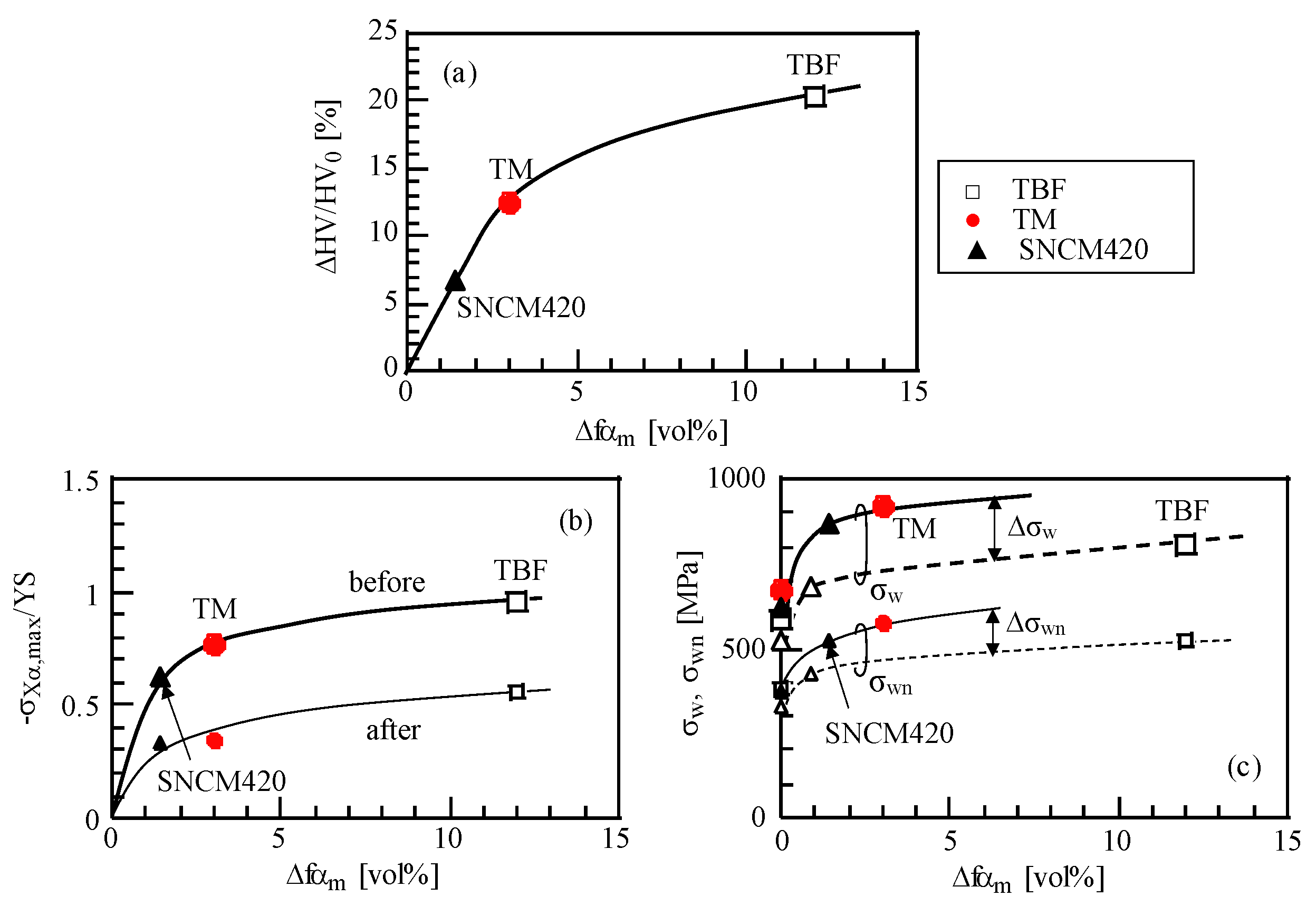

3.1. Surface-Hardened Layer Properties

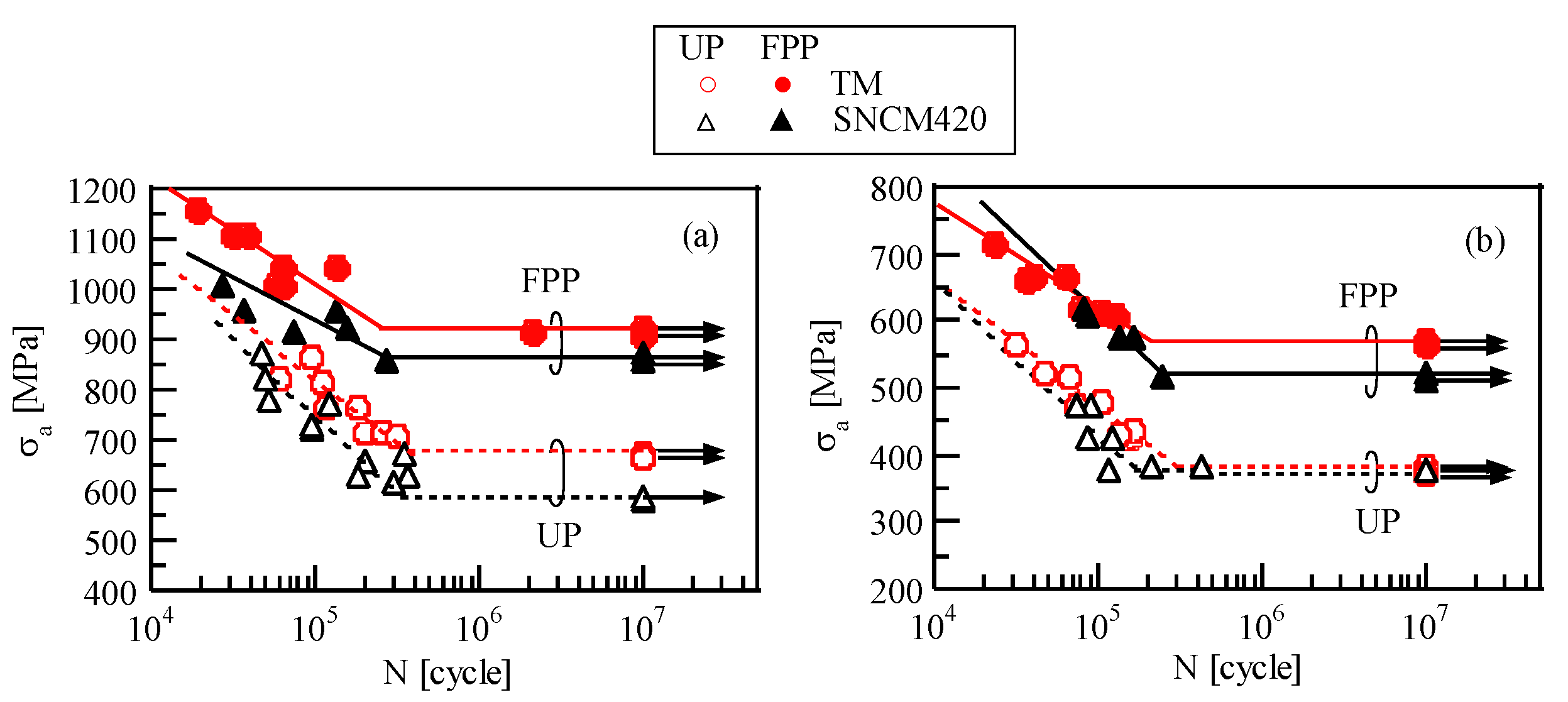

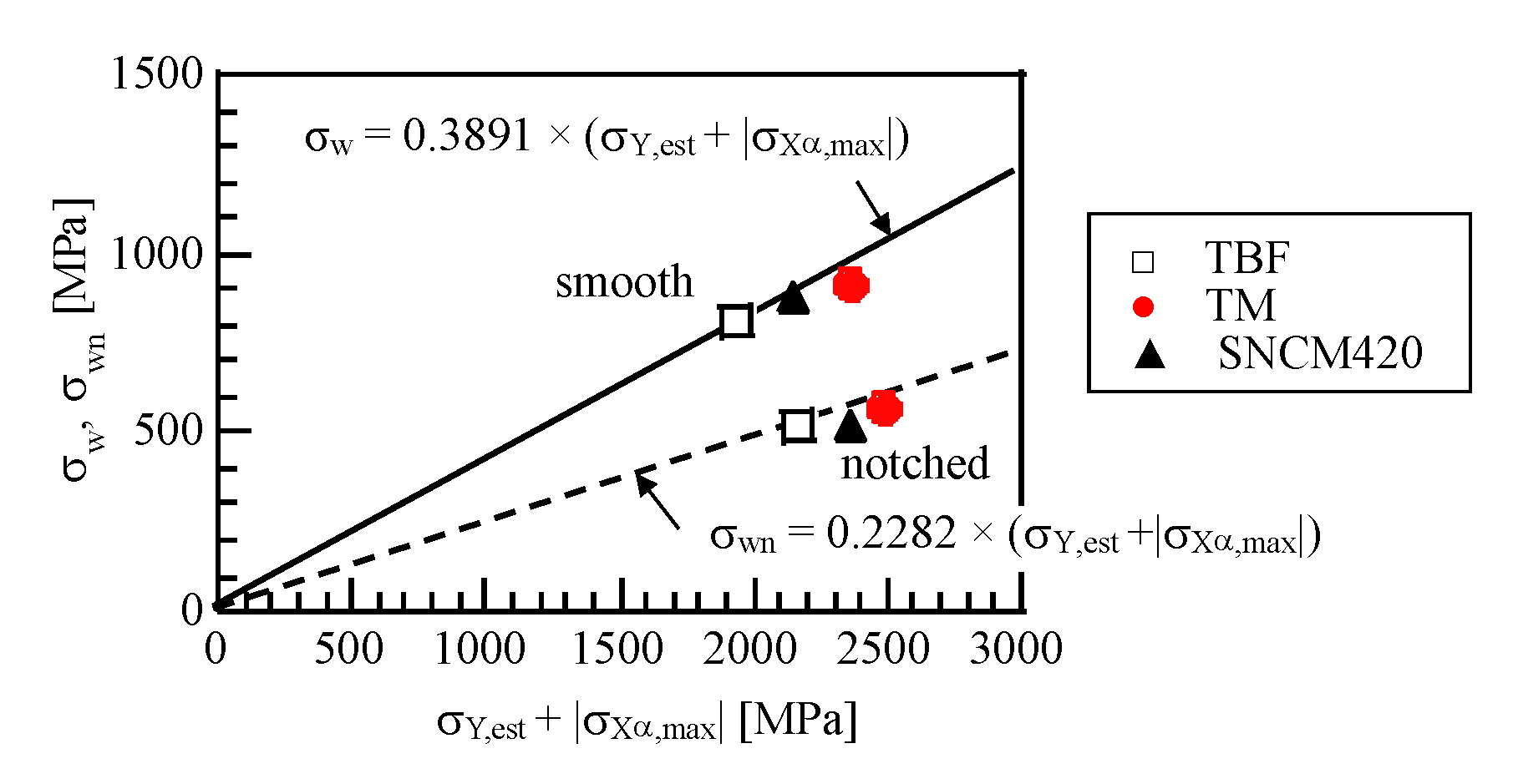

3.2. Fatigue Strength

4. Vacuum-Carburized and Subsequently Fine-Particle Peened TM Steels

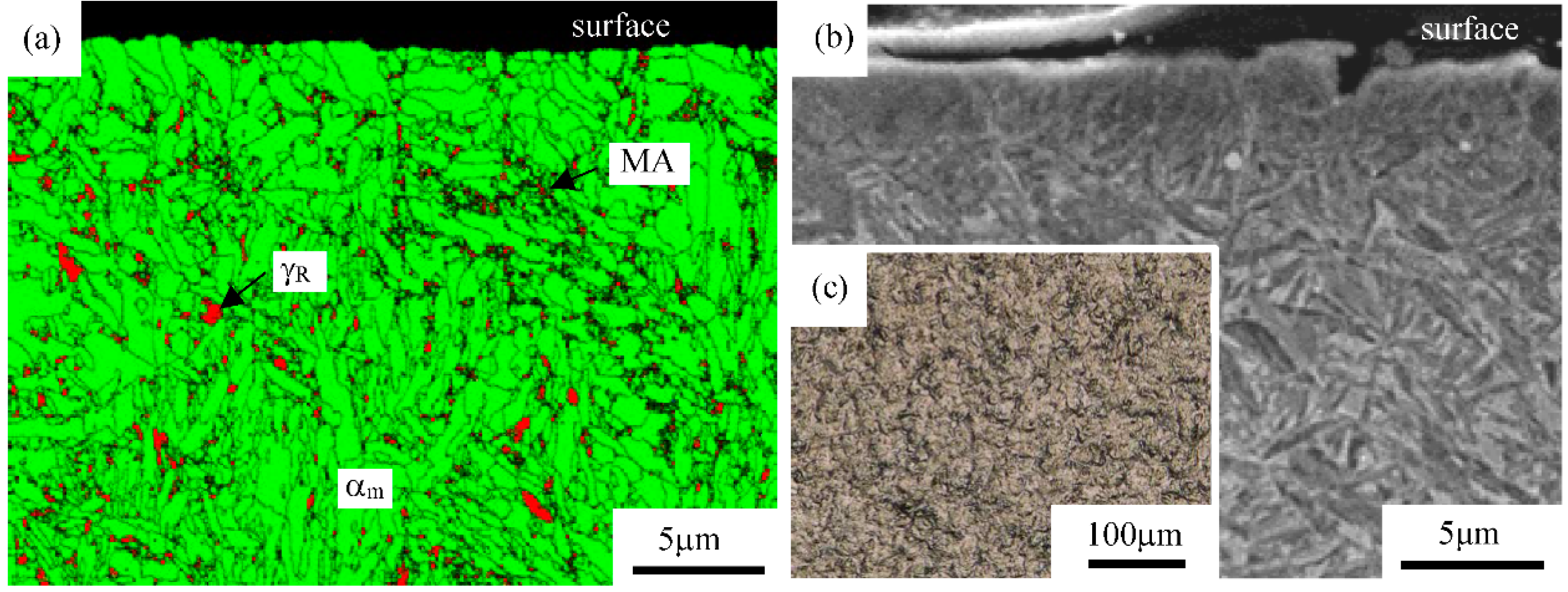

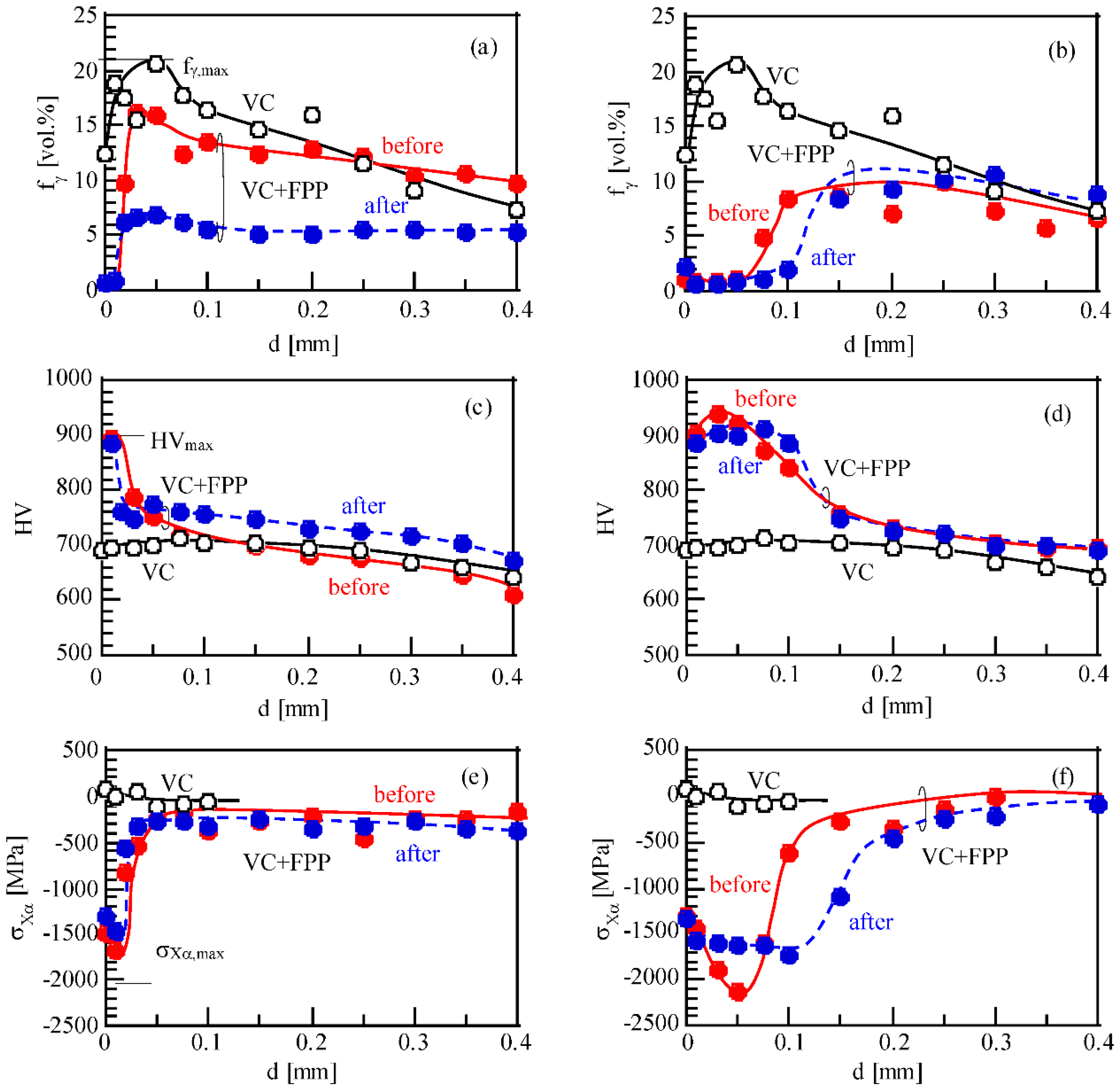

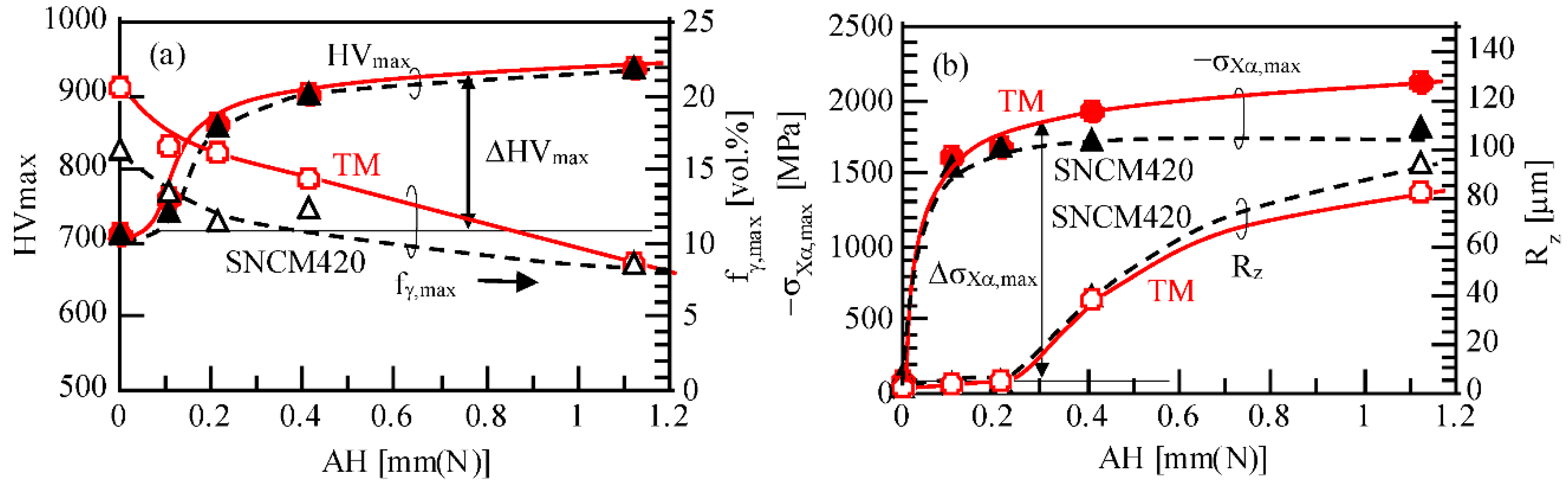

4.1. Surface-Hardened Layer Properties

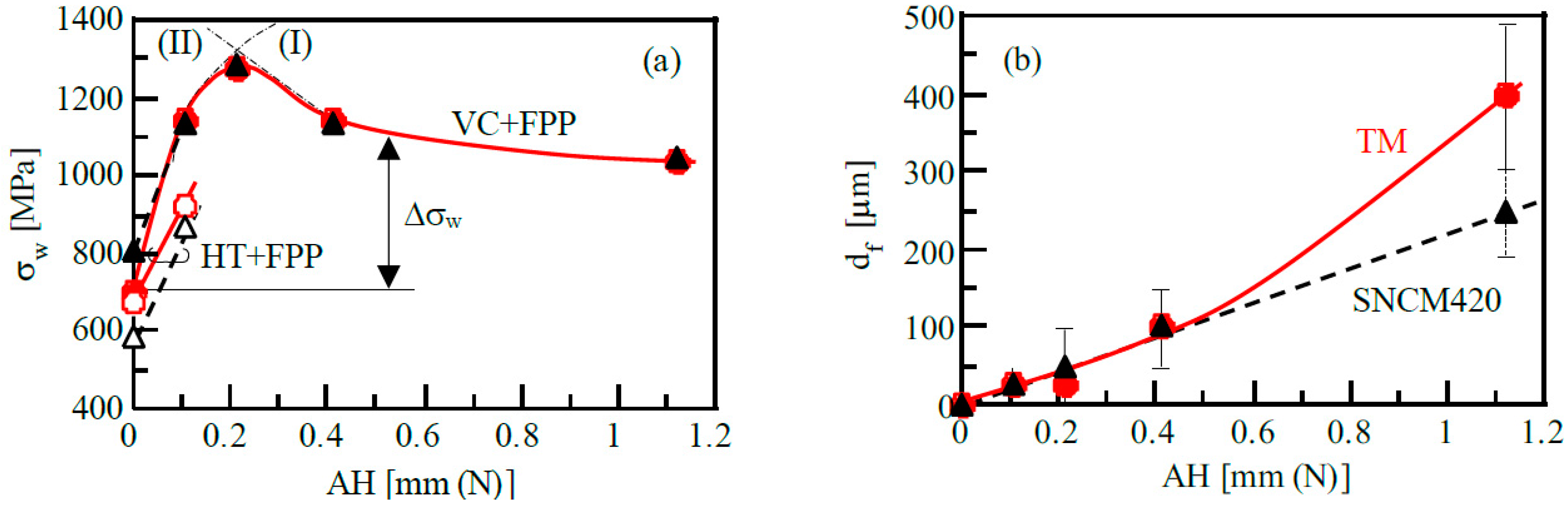

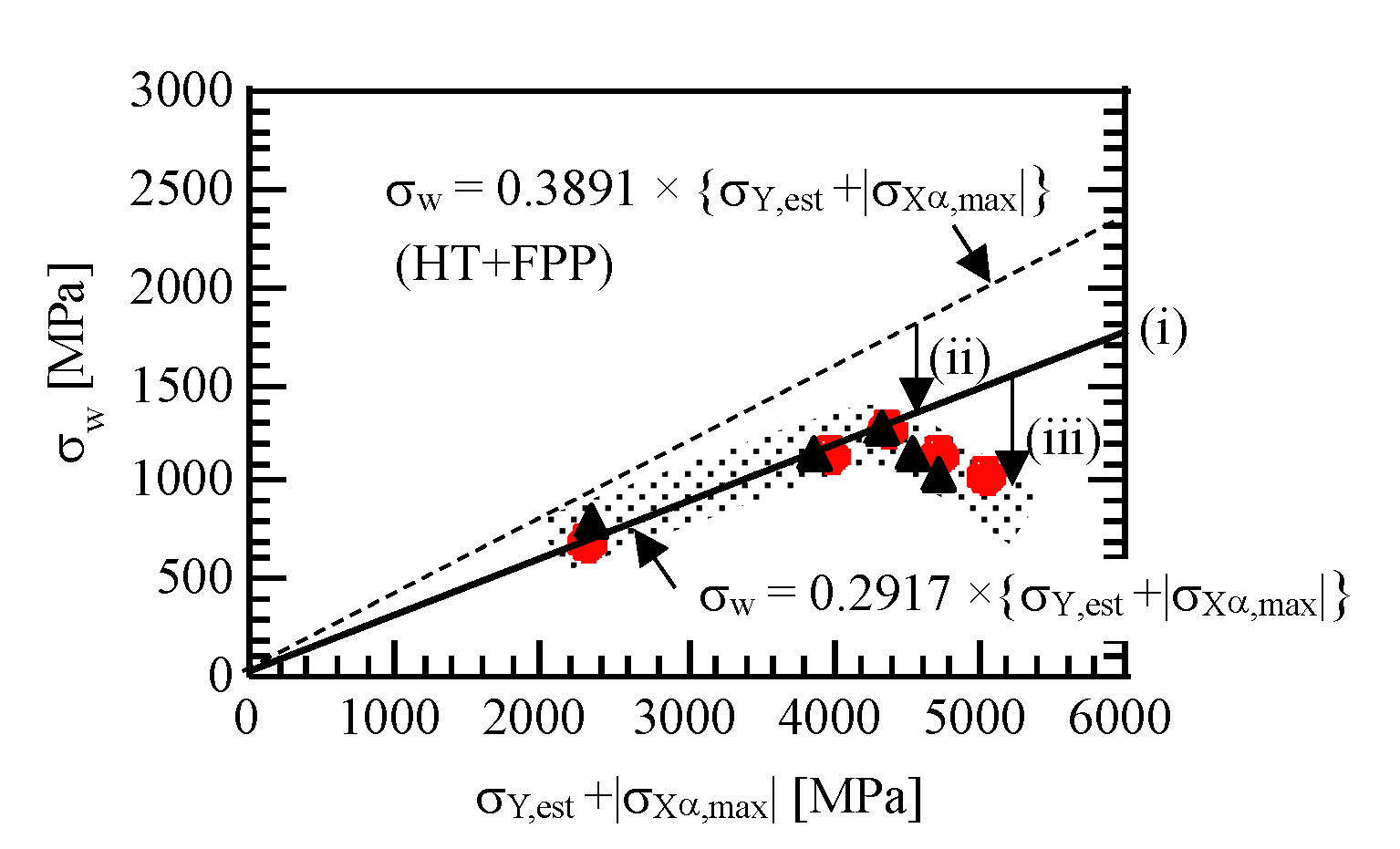

4.2. Fatigue Properties

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Sugimoto, K.; Kobayashi, M.; Inoue, K.; Sun, X.; Soshiroda, T. Fatigue strength of TRIP-aided bainitic sheet steels. Tetsu-to-Hagane 1998, 52, 559–565. [Google Scholar] [CrossRef][Green Version]

- Sugimoto, K.; Kobayashi, M.; Inoue, K.; Masuda, S. Fatigue-hardening behavior of TRIP-aided bainitic steels. Tetsu-to-Hagane 1999, 85, 856–862. [Google Scholar] [CrossRef][Green Version]

- Sugimoto, K.; Song, S.; Inoue, K.; Kobayashi, M.; Masuda, S. Effect of prestraining on low cycle fatigue properties of low alloy TRIP steels. J. Soc. Mater. Sci. Jpn. 2001, 50, 657–664. [Google Scholar] [CrossRef][Green Version]

- Song, S.; Sugimoto, K.; Kandaka, S.; Futamura, A.; Kobayashi, M.; Masuda, S. Effects of prestraining on high cycle fatigue strength of high strength low alloy TRIP steels. J. Soc. Mater. Sci. Jpn. 2001, 50, 1091–1097. [Google Scholar] [CrossRef][Green Version]

- Sugimoto, K. Fracture strength and toughness of ultrahigh-strength TRIP aided steels. Mater. Sci. Technol. 2009, 25, 1108–1117. [Google Scholar] [CrossRef]

- Sugimoto, K.; Yoshikawa, N. Advanced high-strength TRIP-aided steels for ultra high pressure DI-diesel engine common rail. In Proceedings of the 3rd International Conference on Stainless Steel in Cars and Trucks (SCT2011), Stuttgart, Germany, 5–9 June 2011; pp. 365–372. [Google Scholar]

- Yoshikawa, N.; Kobayashi, J.; Sugimoto, K. Notch fatigue properties of advanced TRIP-aided bainitic ferrite steels. Metall. Mater. Trans. A 2012, 43, 4129–4136. [Google Scholar] [CrossRef]

- Zhou, Q.; Qian, L.; Meng, J.; Zhao, L.; Zhang, F. Low-cycle fatigue behavior and microstructure evolution in a low carbon carbide-free bainitic steel. Mater. Des. 2015, 85, 487–496. [Google Scholar] [CrossRef]

- El-Din, H.N.; Showaib, E.A.; Zaafarani, N.; Refaiy, H. Structure-properties relationship in TRIP type bainitic ferrite steel austempered at different temperatures. Int. J. Mech. Mater. Eng. 2017, 12, 3. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T.; Kobayashi, J. Critical assessment of TRIP-aided bainitic ferrite steels. Mater. Sci. Technol. 2017, 33, 2005–2007. [Google Scholar] [CrossRef]

- Kobayashi, J.; Song, S.; Sugimoto, K. Microstructure and retained austenite characteristics of ultrahigh-strength TRIP-aided martensitic steels. ISIJ Int. 2012, 52, 1124–1129. [Google Scholar] [CrossRef]

- Kobayashi, J.; Sugimoto, K.; Arai, G. Effects of hot-forging process on combination of strength and toughness in ultrahigh-strength TRIP-aided martensitic steels. Adv. Mater. Res. 2012, 409, 696–701. [Google Scholar] [CrossRef]

- Kobayashi, J.; Yoshikawa, N.; Sugimoto, K. Notch-fatigue strength of advanced TRIP-aided martensitic steels. ISIJ Int. 2013, 53, 1479–1486. [Google Scholar] [CrossRef]

- Kobayashi, J.; Ina, D.; Nakajima, Y.; Sugimot, K. Effects of microalloying on the impact toughness of ultrahigh-strength TRIP-aided martensitic steels. Metall. Mater. Trans. A 2013, 44, 5006–5017. [Google Scholar] [CrossRef]

- Sugimoto, K.; Kobayashi, J.; Hojo, T. Mechanical properties of TRIP-aided martensitic steels for hot-worked automotive drivetrain components. In Proceedings of the 4th International Conference on Steels in Cars and Trucks (SCT), Braunschweig, Germany, 15–19 June 2014; pp. 21–28. [Google Scholar]

- Kobayashi, J.; Ina, D.; Futamura, A.; Sugimoto, K. Fracture toughness of an advanced ultrahigh-strength TRIP-aided steels. ISIJ Int. 2014, 54, 955–962. [Google Scholar] [CrossRef]

- Pham, D.V.; Kobayashi, J.; Sugimoto, K. Effects of microalloying on stretch-flangeability of ultrahigh-strength TRIP-aided martensitic steel sheet. ISIJ Int. 2014, 54, 1943–1951. [Google Scholar] [CrossRef]

- Hojo, T.; Kobayashi, J.; Kochi, T.; Sugimoto, K. Effects of thermomechanical processing on microstructure and shear properties of 22SiMnCrMoB TRIP-aided martensitic steel. Iron Steel Technol. Mag. 2015, 12, 102–110. [Google Scholar]

- Sugimoto, K.; Srivastava, A.K. Microstructure and mechanical properties of a TRIP-aided martensitic steel. Metall. Microstr. Anal. 2015, 4, 344–354. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T. Fatigue hardening behavior of a 1.5 GPa Grade TRIP-aided martensitic steel. Metall. Mater. Trans. A 2016, 47, 5272–5279. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; Gao, G.; Hui, W.; Misra, R.D.K.; Bai, B.; Weng, Y. The potential significance of microalloying with niobium in governing very high cycle fatigue behavior of bainit/martensite multiphase steels. Mater. Sci. Eng. A 2016, 650, 438–444. [Google Scholar] [CrossRef]

- Speer, J.G.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Speer, J.G.; De Moor, E.; Findley, K.O.; Matlock, D.K.; De Cooman, B.C.; Edmonds, D.V. Analysis of microstructure evolution in quenching and partitioning automotive sheet steel. Metall. Mater. Trans. A 2011, 42, 3591–3601. [Google Scholar] [CrossRef]

- Cerny, I.; Mikulova, D.; Sis, J.; Masek, B.; Jirkova, H.; Malina, J. Fatigue properties of a low alloy 42SiCr steel heat treated by quenching and partitioning process. Proc. Eng. 2011, 10, 3310–3315. [Google Scholar] [CrossRef]

- Toji, Y.; Matsuda, H.; Herbig, M.; Choi, P.; Raabe, D. Atomic-scale analysis of carbon partitioning between martensite and austenite by atom probe tomography and correlative transmission electron microscopy. Acta Mater. 2014, 65, 215–228. [Google Scholar] [CrossRef]

- Wu, R.; Li, W.; Zhou, S.; Zhong, S.; Wang, L.; Jin, X. Effect of retained austenite on the fracture toughness of quenching and partitioning (Q&P)-treated sheet steels. Metall. Mater. Trans. A 2014, 45, 1892–1902. [Google Scholar]

- De Diego-Calderon, I.; Rodriguez-Calvillo, A.; Lara, A.; Molina-Aldareguia, J.M.; Petrov, R.H.; De Knijf, D.; Sabirov, I. Effect of microstructure on fatigue behavior of advanced high strength steels produced by quenching and partitioning and the role of retained austenite. Mater. Sci. Eng. A 2015, 641, 215–224. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, B.; Cheng, C.; Misra, R.D.K.; Gao, G.; Bai, B.; Weng, Y. The significance of ultrafine film-like retained austenite in governing very high cycle fatigue behavior in an ultrahigh-strength MN–SI–Cr–C steel. Mater. Sci. Eng. A 2015, 645, 116–121. [Google Scholar] [CrossRef]

- Speer, J.G.; De Moor, E.; Clarke, A.J. Critical assessment 7: Quenching and partitioning. Mater. Sci. Technol. 2015, 31, 3–9. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; Estrin, Y.; De Cooman, B.C. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar]

- Gao, G.; An, B.; Zhang, H.; Guo, H.; Gui, X.; Bai, B. Concurrent enhancement of ductility and toughness in an ultrahigh strength lean alloy steel treated by bainite-based quenching-partitioning-tempering process. Mater. Sci. Eng. A 2017, 702, 104–112. [Google Scholar] [CrossRef]

- Miller, R.L. Ultrafine-grained microstructures and mechanical properties of alloy steels. Metall. Trans. 1972, 3, 905–912. [Google Scholar] [CrossRef]

- Furukawa, T. Dependence of strength-ductility characteristics on thermal history in low carbon 5 wt-%Mn steels. Mater. Sci. Technol. 1989, 5, 465–470. [Google Scholar] [CrossRef]

- Furukawa, T.; Huang, H.; Matsumura, O. Effects of carbon content on mechanical properties of 5% Mn steels exhibiting transformation induced plasticity. Mater. Sci. Technol. 1994, 10, 964–969. [Google Scholar] [CrossRef]

- Nakada, N.; Tsuchiyama, T.; Takaki, S.; Miyano, N. Temperature dependence of austenite nucleation behavior from lath martensite. ISIJ Int. 2011, 51, 299–304. [Google Scholar] [CrossRef]

- Sugimoto, K.; Tanino, H.; Kobayashi, J. Impact toughness of medium Mn transformation-induced plasticity-aided steels. Steel Res. Int. 2015, 86, 1151–1160. [Google Scholar] [CrossRef]

- Rana, R.; Gibbs, P.J.; De Moor, E.; Speer, J.G.; Matlock, D.K. A composite modeling analysis of the deformation behavior of medium manganese steels. Steel Res. Int. 2015, 86, 1139–1150. [Google Scholar] [CrossRef]

- Tsuchiyama, T.; Inoue, T.; Tobata, J.; Akama, D.; Takaki, S. Microstructure and mechanical properties of a medium manganese steel treated with interrupted quenching and intercritical annealing. Scr. Mater. 2016, 122, 36–39. [Google Scholar] [CrossRef]

- Qi, X.Y.; Du, L.X.; Hu, J.; Misra, R.D.K. High-cycle fatigue behavior of low-C medium-Mn high strength steel with austenite-martensite submicron-sized lath-like structure. Mater. Sci. Eng. A 2018, 718, 477–482. [Google Scholar] [CrossRef]

- Raedt, H.W.; Wilke, F.; Ernst, C.S. Light weight forging initiative phase II: Lightweight design potential for a light commercial vehicle. ATZ 2015, 118, 48–52. [Google Scholar]

- Tomita, Y.; Kijima, F.; Morioka, K. Modified austempering effect on bending fatigue properties of Fe-0.6C-1.5Si-0.8Mn steel. Z. Metallkd. 2000, 91, 43–46. [Google Scholar]

- Bhadeshia, H.K.D.H. Nanostructure bainite. Proc. R. Soc. Lond. A 2010, 466, 3–18. [Google Scholar] [CrossRef]

- Yang, J.; Wang, T.S.; Zhang, B.; Zhang, F.C. High-cycle bending fatigue behavior of nanostructured bainitic steel. Scr. Mater. 2012, 66, 363–366. [Google Scholar] [CrossRef]

- Sourmail, T.; Caballero, F.G.; Garcia-Mateo, C.; Smanio, V.; Ziegler, C.; Kunts, M. Evaluation of potential of high Si high C steel nanostructured bainite for wear and fatigue applications. Mater. Sci. Technol. 2013, 29, 1166–1173. [Google Scholar] [CrossRef]

- Shendy, B.R.; Yoozbashi, M.N.; Avishan, B.; Yazdani, S. An investigation on rotating bending fatigue behavior of nanostructured low-temperature bainitic steel. Acta Metall. Sin. 2014, 27, 233–238. [Google Scholar] [CrossRef]

- Rementeria, R.; Morales-Rivas, L.; Kuntz, M.; Garcia-Mateo, C.; Kerscher, E.; Sourmail, T.; Caballero, F.G. On the role of microstructure in governing the fatigue behavior of nanostructured banitic steels. Mater. Sci. Eng. A 2015, 630, 71–77. [Google Scholar] [CrossRef]

- Müller, I.; Rementeria, R.; Caballero, F.G.; Kuntz, M.; Sourmail, T.; Kerscher, E. A constitutive relationship between fatigue limit and microstructure in nanostructured bainitic steels. Materials 2016, 9, 831–849. [Google Scholar] [CrossRef] [PubMed]

- Müller, I.; Rementeria, R.; Caballero, F.G.; Kuntz, M.; Kerscher, E. Correlation of fatigue limit and crack growth threshold value to the nanobainite microstructure. Solid State Phenom. 2016, 258, 314–317. [Google Scholar] [CrossRef]

- Egami, N.; Kagaya, C.; Inoue, N.; Takeshita, H.; Mizutani, H. Hybrid surface modification of SCM415 material by vacuum carburizing and fine particle peening. Jpn. Soc. Mech. Eng. A 2000, 66, 1936–1942. [Google Scholar] [CrossRef][Green Version]

- Torres, M.A.S.; Voorwald, H.J.C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

- Shaw, B.A.; Aylott, C.; O’Hara, P.; Brimble, K. The role of residual stress on the fatigue strength of high performance gearing. Int. J. Fatigue 2003, 25, 1279–1283. [Google Scholar] [CrossRef]

- Eto, H.; Matsui, K.; Jin, Y.; Ando, K. Influence of retained austenite, strain-induced martensite and pre-loaded stress upon compressive residual stress with shot peening method. Jpn. Soc. Mech. Eng. A 2003, 69, 733–740. [Google Scholar] [CrossRef][Green Version]

- Kato, M.; Matsumura, Y.; Ishikawa, R.; Kobayashi, Y.; Ujihashi, S. Influence of shot peening condition on the fatigue strength of the carburizing steel. Electr. Furn. Steel 2008, 79, 69–76. [Google Scholar] [CrossRef]

- Koshimune, M.; Matsui, K.; Takahashi, K.; Nakano, W.; Ando, K. Influence of hardness and residual stress on fatigue limit for high strength steel. Trans. Jpn. Soc. Spring Eng. 2009, 54, 19–26. [Google Scholar] [CrossRef]

- Matsui, K.; Koshimune, M.; Takahashi, K.; Ando, K. Influence of shot peening method on rotating bending fatigue limit for high strength steel. Trans. Jpn. Soc. Spring Eng. 2010, 55, 7–12. [Google Scholar] [CrossRef]

- Davies, D.P.; Jenkins, S.L. Influence of stress and environment on the fatigue strength and failure characteristics of case carburized low alloy steels for aerospace applications. Int. J. Fatigue 2012, 44, 234–244. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Fatigue behavior of a low-alloy steel with nanostructured surface obtained by severe shot peening. Eng. Fract. Mech. 2012, 81, 56–68. [Google Scholar] [CrossRef]

- Dalaei, K.; Karlsson, B. Influence of shot peening on fatigue durability of normalized steel subjected to variable amplitude loading. Int. J. Fatigue 2012, 38, 75–83. [Google Scholar] [CrossRef]

- Bagherifard, S.; Fernandez-Pariente, I.; Ghelichi, R.; Guagliano, M. Fatigue behavior of notched steel specimens with nonaocrystallized surface obtained by severe shot peening. Mater. Des. 2013, 46, 497–503. [Google Scholar] [CrossRef]

- Natori, M.; Song, S.; Sugimoto, K. The effects of fine particle peening on surface residual stress of a TRIP-aided bainitic ferrite steel. J. Soc. Mater. Sci. Jpn. 2014, 63, 662–668. [Google Scholar] [CrossRef]

- Natori, M.; Mizuno, Y.; Song, S.; Sugimoto, K. Effects of fine particle peening on fatigue strength of TRIP-aided bainitic ferrite steel. J. Soc. Mater. Sci. Jpn. 2015, 64, 620–627. [Google Scholar] [CrossRef][Green Version]

- Sugimoto, K.; Mizuno, Y.; Natori, M.; Hojo, T. Effects of fine particle peening on fatigue strength of a TRIP-aided martensitic steel. Int. J. Fatigue 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T.; Mizuno, Y. Surface-hardened layer properties of newly developed case-hardening steel. ISIJ Int. 2018, 58, 727–733. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T.; Mizuno, Y. Effects of fine particle peening conditions on the rotational bending fatigue strength of a vacuum-carburized transformation-induced plasticity-aided martensitic steel. Metall. Mater. Trans. A 2018, 49, 1552–1560. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T.; Mizuno, Y. Effects of vacuum-carburizing conditions on the fatigue strength of a transformation-induced plasticity-aided martensitic steel. Mater. Sci. Technol. 2018, 34, 743–750. [Google Scholar] [CrossRef]

- Koistinen, D.P.; Marburger, R.E. A general equation describing the extent of the austenite-martensite transformation in pure iron carbon alloys and plain carbon steel. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy (SI Metric Edition); McGraw-Hill: Singapore, 1988; p. 403. [Google Scholar]

- Knott, J.F. Fundamentals of Fracture Mechanics; Baifukan: Tokyo, Japan, 1977; p. 138. [Google Scholar]

- Umemoto, M. Nanocrystallization of steels by severe plastic deformation. Mater. Trans. 2003, 44, 1900–1911. [Google Scholar] [CrossRef]

- Sakaki, T.; Sugimoto, K.; Fukuzato, T. Role of internal stress for continuous yielding of dual-phase steels. Acta Metall. 1983, 31, 1737–1746. [Google Scholar] [CrossRef]

- Sugimoto, K.; Sato, S.; Arai, G. Hot forging of ultra high-strength TRIP-aided steel. Mater. Sci. Forum 2010, 638–642, 3074–3079. [Google Scholar] [CrossRef]

- Sugimoto, K.; Kobayashi, J.; Arai, G. Development of low alloy TRIP-aided steel for hot-forging parts with excellent toughness. Steel Res. Int. 2010, 81, 254–257. [Google Scholar]

- Bleck, W.; Prahl, U.; Hirt, G.; Bambach, M. Designing new forging steels by ICMPE. In Advanced in Production Technology; Brecher, C., Ed.; Springer International Publishing AG: Cham, Switzerland, 2015; pp. 85–98. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sugimoto, K.-i.; Hojo, T.; Srivastava, A.K. An Overview of Fatigue Strength of Case-Hardening TRIP-Aided Martensitic Steels. Metals 2018, 8, 355. https://doi.org/10.3390/met8050355

Sugimoto K-i, Hojo T, Srivastava AK. An Overview of Fatigue Strength of Case-Hardening TRIP-Aided Martensitic Steels. Metals. 2018; 8(5):355. https://doi.org/10.3390/met8050355

Chicago/Turabian StyleSugimoto, Koh-ichi, Tomohiko Hojo, and Ashok Kumar Srivastava. 2018. "An Overview of Fatigue Strength of Case-Hardening TRIP-Aided Martensitic Steels" Metals 8, no. 5: 355. https://doi.org/10.3390/met8050355

APA StyleSugimoto, K.-i., Hojo, T., & Srivastava, A. K. (2018). An Overview of Fatigue Strength of Case-Hardening TRIP-Aided Martensitic Steels. Metals, 8(5), 355. https://doi.org/10.3390/met8050355