Temperature Dependence of the Microstructure and Mechanical Properties of a Twinning-Induced Plasticity Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results

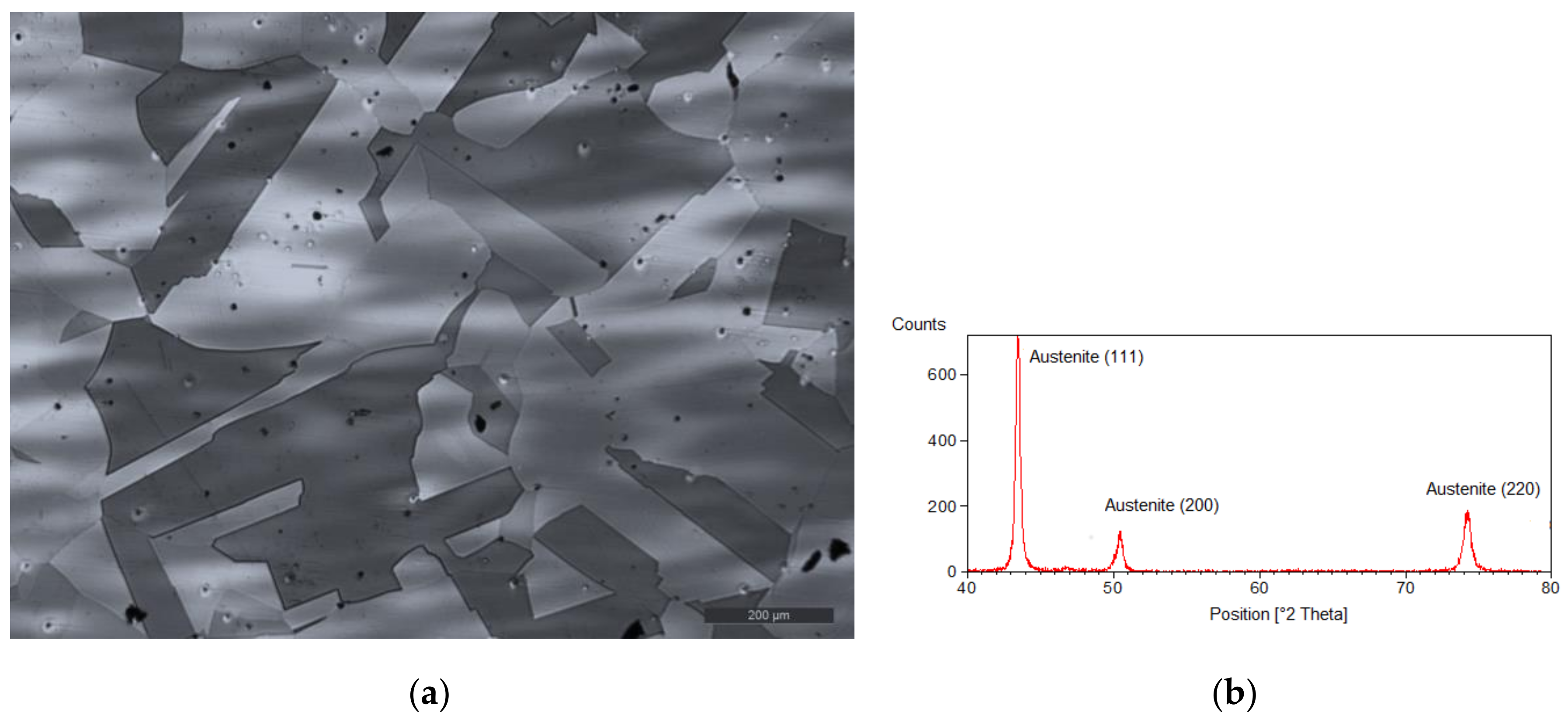

3.1. Initial Material

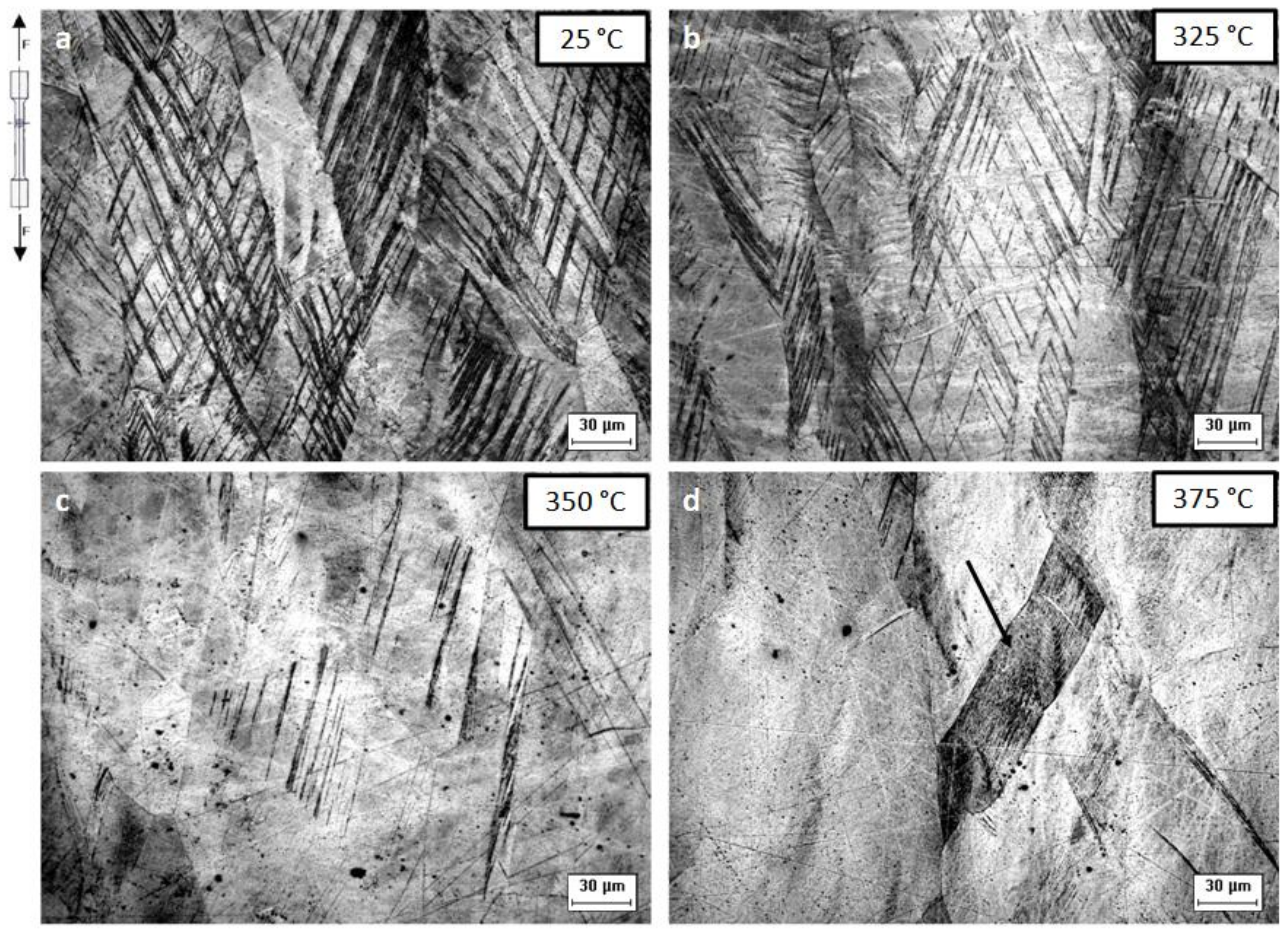

3.2. Microstructure after Tensile Tests

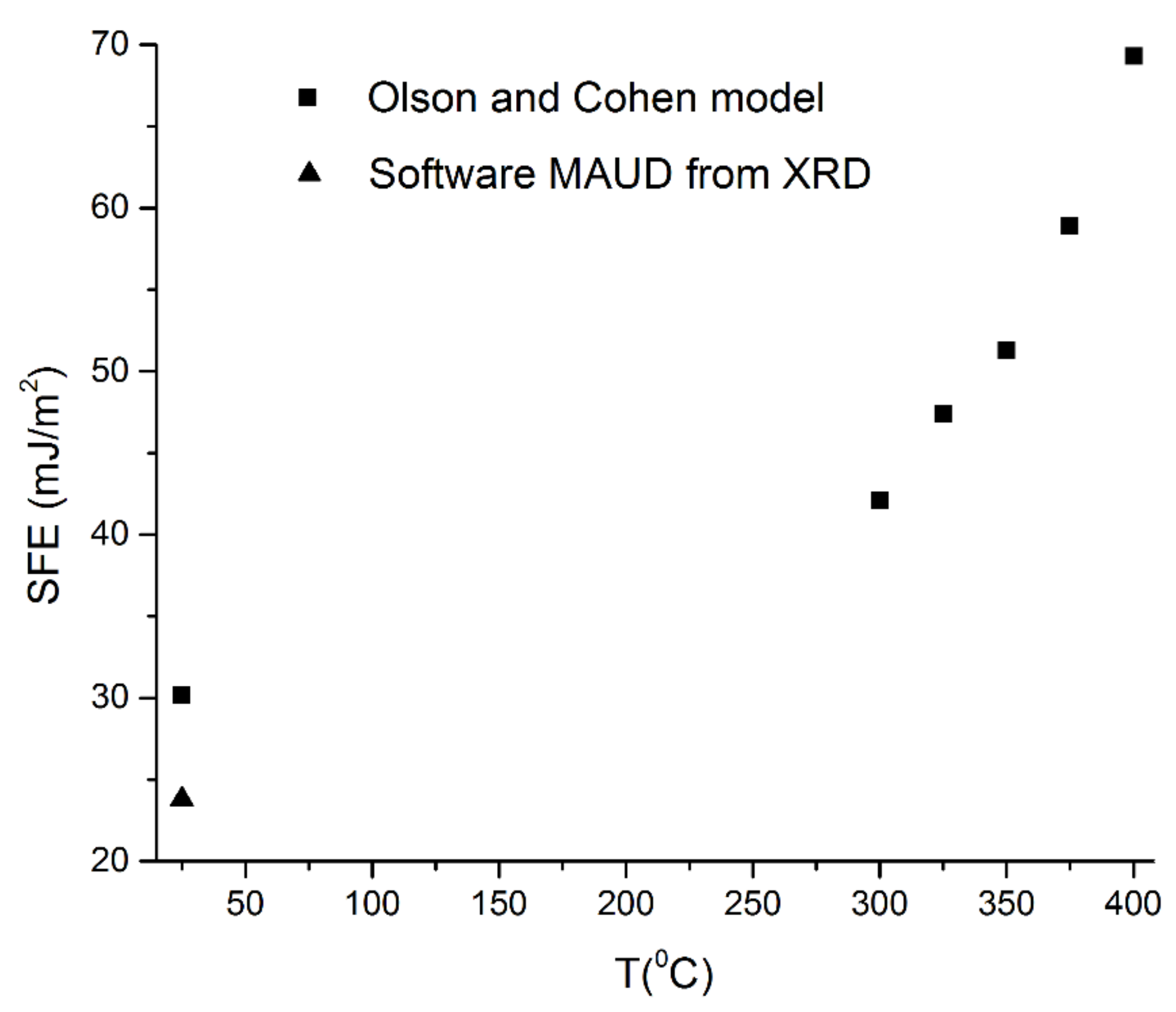

3.3. SFE Calculations

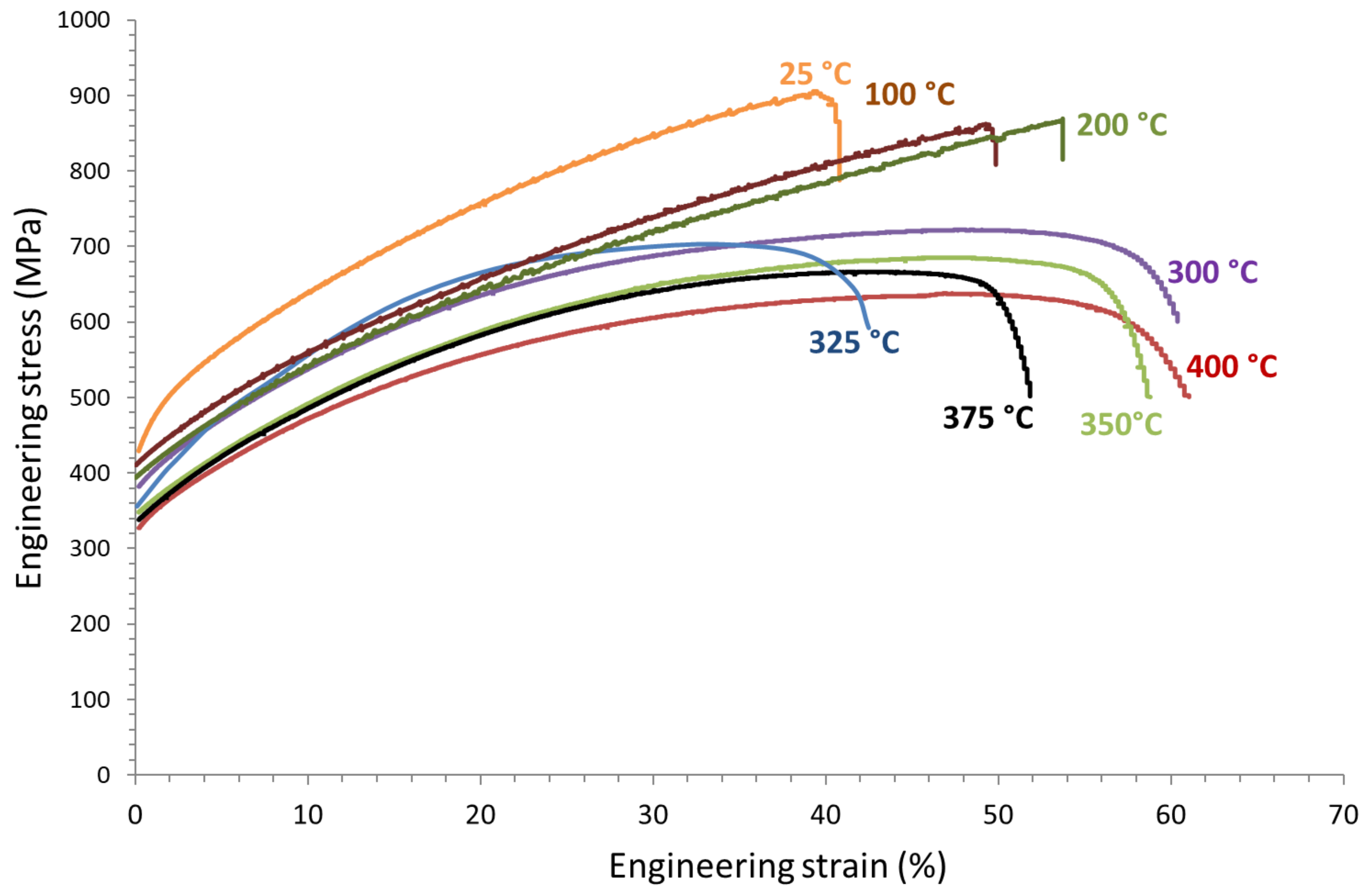

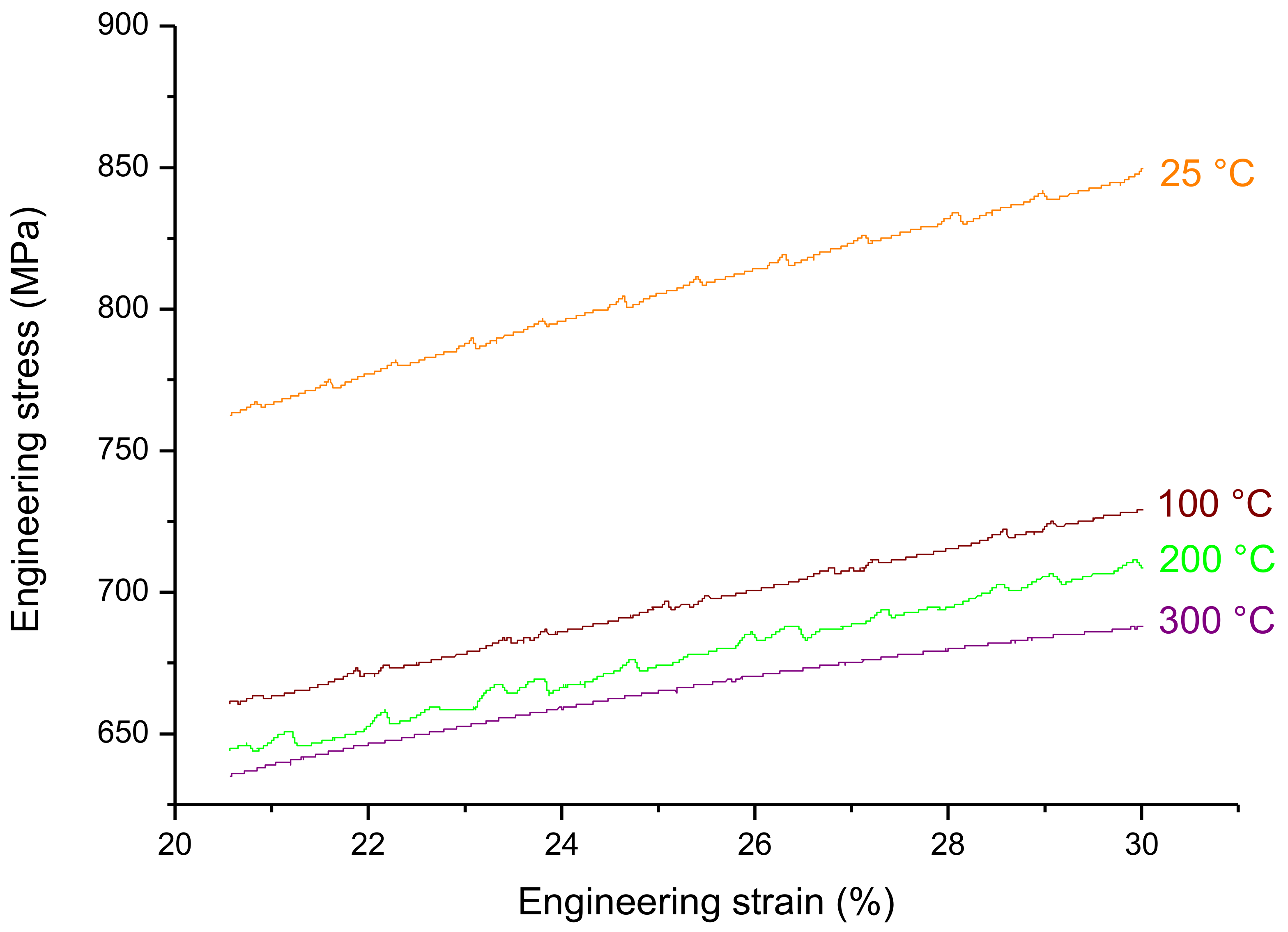

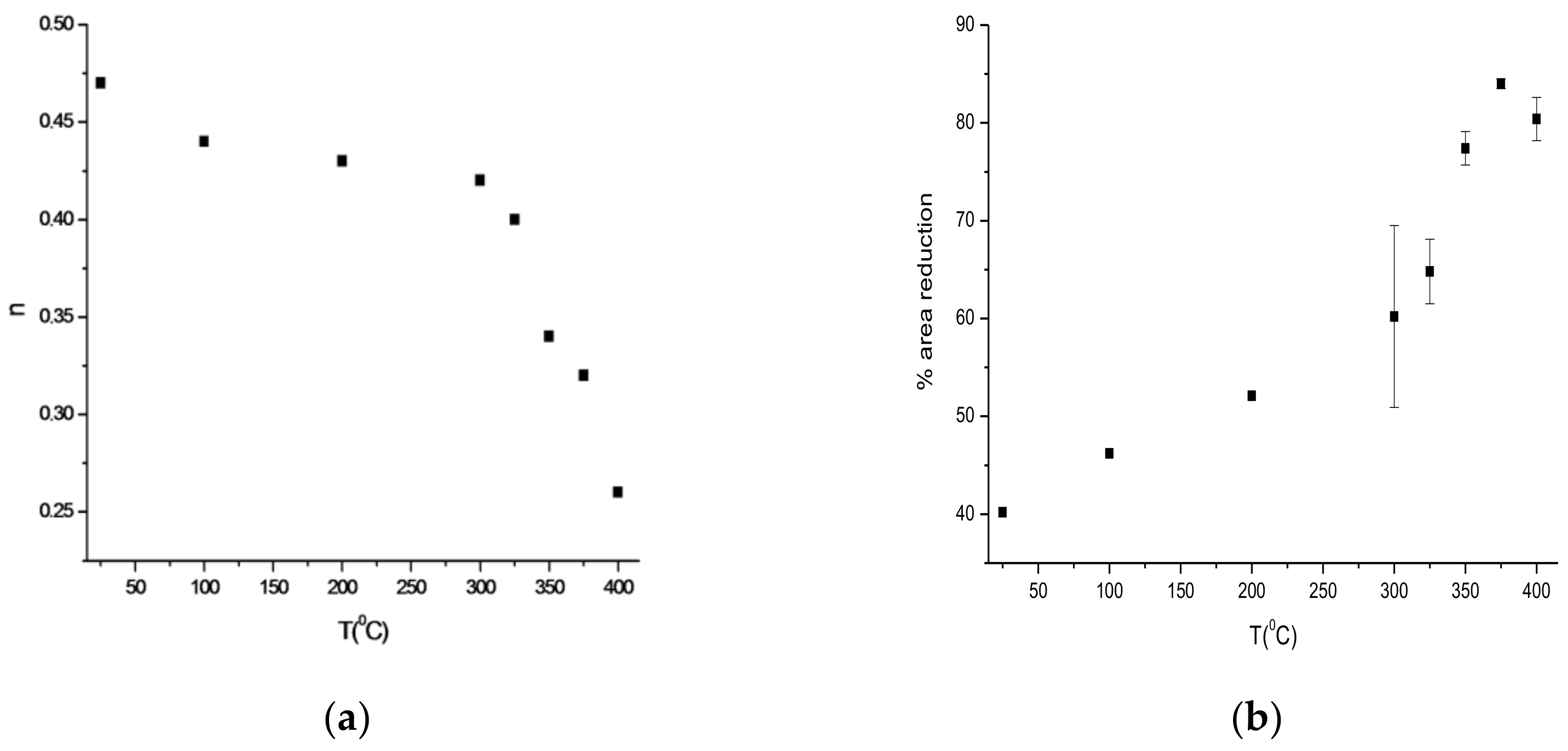

3.4. Tensile Tests

4. Discussion

4.1. Microstructure Evolution after High-Temperature Tensile Tests

4.2. Tensile Tests Analysis

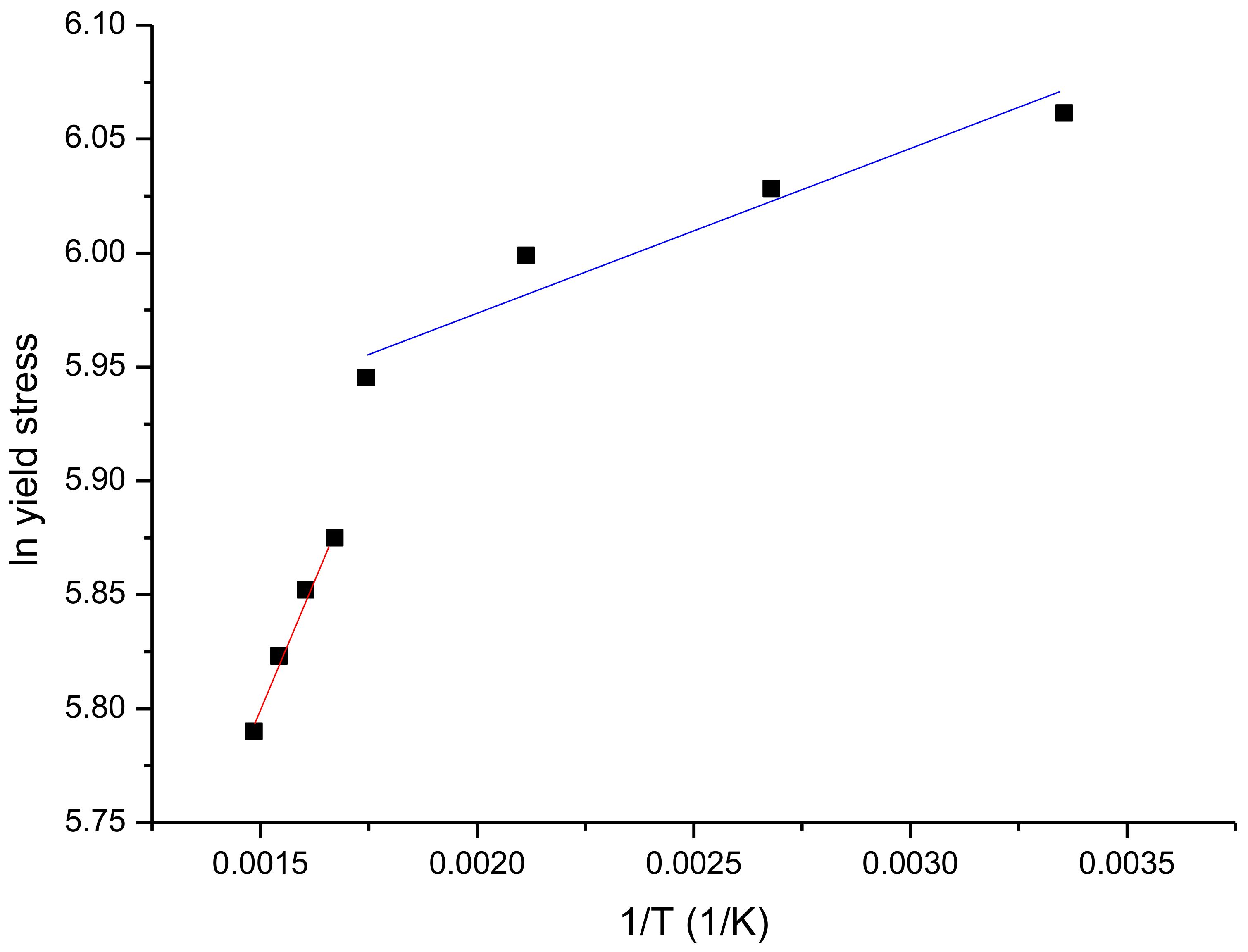

4.2.1. Effect of Temperature on Strength

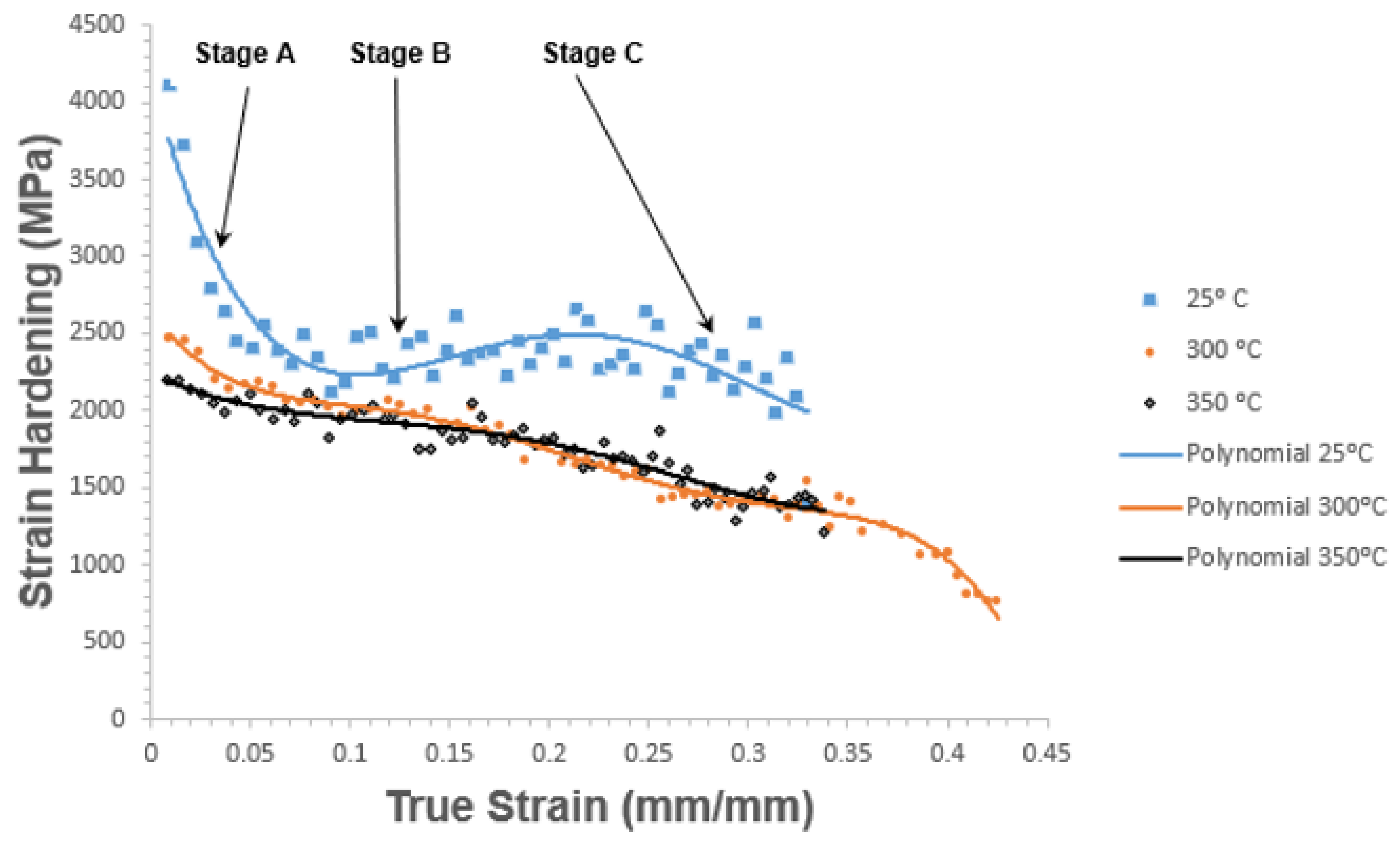

4.2.2. Effect of Temperature on Hardening Behavior

4.2.3. Other Structure–Property Relations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Frommeyer, G.; Brüx, U.; Neumann, P. Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Grässel, O.; Krüger, L.; Frommeyer, G.; Meyer, L.W. High strength Fe-Mn-(Al, Si) TRIP/TWIP steels development—Properties—Application. Int. J. Plast. 2000, 16, 1391–1409. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Mahajan, S.; Williams, D.F. Deformation Twinning in Metals and Alloys. Int. Metall. Rev. 1973, 18, 43–61. [Google Scholar]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Jung, I.-C.; de Cooman, B.C. Temperature dependence of the flow stress of Fe–18Mn–0.6C–xAl twinning-induced plasticity steel. Acta Mater. 2013, 61, 6724–6735. [Google Scholar]

- Lee, E.H.; Byun, T.S.; Hunn, J.D.; Yoo, M.H.; Farrell, K.; Mansur, L.K. On the origin of deformation microstructures in austenitic stainless steel: Part I—Microstructures. Acta Mater. 2001, 49, 3269–3276. [Google Scholar] [CrossRef]

- Lee, E.H.; Byun, T.S.; Hunn, J.D.; Yoo, M.H.; Farrell, K.; Mansur, L.K. On the origin of deformation microstructures in austenitic stainless steel: Part II—Mechanisms. Acta Mater. 2001, 49, 3277–3287. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Chen, L.; Kim, H.S.; Estrin, Y.; Kim, S.K.; Voswinckel, H. State-of-the-Science of High Manganese TWIP Steels for Automotive Applications. In Microstructure and Texture in Steels and Other Materials; Haldar, A., Suwas, S., Bhattacharjee, D., Eds.; Springer: Jamshedpur, India, 2009; pp. 165–182. [Google Scholar]

- Rahman, K.M.; Jones, N.G.; Dye, D. Micromechanics of twinning in a TWIP steel. Mater. Sci. Eng. A 2015, 635, 133–142. [Google Scholar] [CrossRef]

- Saleh, A.; Gazder, A. A re-evaluation of “The micromechanics of twinning in a TWIP steel”. Mater. Sci. Eng. A 2016, 649, 184–189. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. Understanding martensite and twin formation in austenitic steels: A model describing TRIP and TWIP effects. Acta Mater. 2017. [Google Scholar] [CrossRef]

- Wong, S.L.; Madivala, M.; Prahl, U.; Roters, F.; Raabe, D. A crystal plasticity model for twinning- and transformation-induced plasticity. Acta Mater. 2016, 118, 140–151. [Google Scholar] [CrossRef]

- Materials Analysis Using Diffraction (MAUD). Available online: http://maud.radiographema.com (accessed on 22 May 2012).

- Dumay, A.; Chateau, J.-P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe–Mn–C steel. Mater. Sci. Eng. A 2008, 483–484, 184–187. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.-T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC → HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar]

- Curtze, S.; Kuokkala, V.-T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Monsalve, A.; de Barbieri, F.; Gómez, M.; Artigas, A.; Carvajal, L.; Sipos, K.; Bustos, O.; Pérez-Ipiña, J. Mechanical Behavior of a Twip Steel (Twinning Induced Plasticity). Matéria 2015, 20, 653–658. [Google Scholar] [CrossRef]

- Dastur, Y.N.; Leslie, W.C. Mechanism of work hardening in Hadfield manganese steel. Metall. Trans. A 1981, 12, 749–759. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Kwon, O.; Chin, K.-G. State-of-the-knowledge on TWIP steel. Mater. Sci. Technol. 2012, 28, 513–527. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | P | S |

|---|---|---|---|---|---|

| 0.65 | 22.14 | 0.16 | 0.28 | 0.060 | 0.007 |

| Temperature (°C) | σys (MPa) | UTS (MPa) | δ% | ϕ% | n |

|---|---|---|---|---|---|

| 25 | 429 ± 8.6 | 905 ± 0.7 | 40.8 | 40.2 | 0.47 |

| 100 | 415 ± 2.5 | 841 ± 1.5 | 50.01 | 46.22 | 0.44 |

| 200 | 403 ± 12.2 | 842 ± 3.3 | 53.8 | 52.1 | 0.43 |

| 300 | 382 ± 24 | 722 ± 4.9 | 60.4 ± 0.9 | 60.2 ± 9.3 | 0.42 |

| 325 | 356 ± 4.6 | 701 ± 9.8 | 42.6 ± 1.7 | 64.8 ± 3.3 | 0.40 |

| 350 | 348 ± 9.4 | 688 ± 30.7 | 58.8 ± 1.8 | 77.4 ± 1.7 | 0.34 |

| 375 | 338 ± 4.0 | 664 ± 0.7 | 51.8 ± 4.0 | 84.0 ± 0.5 | 0.32 |

| 400 | 327 ± 5.0 | 638 ± 2.1 | 61.0 ± 1.6 | 80.4 ± 1.5 | 0.26 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Barbieri, F.; Castro Cerda, F.; Pérez-Ipiña, J.; Artigas, A.; Monsalve, A. Temperature Dependence of the Microstructure and Mechanical Properties of a Twinning-Induced Plasticity Steel. Metals 2018, 8, 262. https://doi.org/10.3390/met8040262

De Barbieri F, Castro Cerda F, Pérez-Ipiña J, Artigas A, Monsalve A. Temperature Dependence of the Microstructure and Mechanical Properties of a Twinning-Induced Plasticity Steel. Metals. 2018; 8(4):262. https://doi.org/10.3390/met8040262

Chicago/Turabian StyleDe Barbieri, Flavio, Felipe Castro Cerda, Juan Pérez-Ipiña, Alfredo Artigas, and Alberto Monsalve. 2018. "Temperature Dependence of the Microstructure and Mechanical Properties of a Twinning-Induced Plasticity Steel" Metals 8, no. 4: 262. https://doi.org/10.3390/met8040262

APA StyleDe Barbieri, F., Castro Cerda, F., Pérez-Ipiña, J., Artigas, A., & Monsalve, A. (2018). Temperature Dependence of the Microstructure and Mechanical Properties of a Twinning-Induced Plasticity Steel. Metals, 8(4), 262. https://doi.org/10.3390/met8040262