Effects of Grain Boundary Microconstituents on Heat-Affected Zone Cracks in a Mar-M004 Weldment

Abstract

1. Introduction

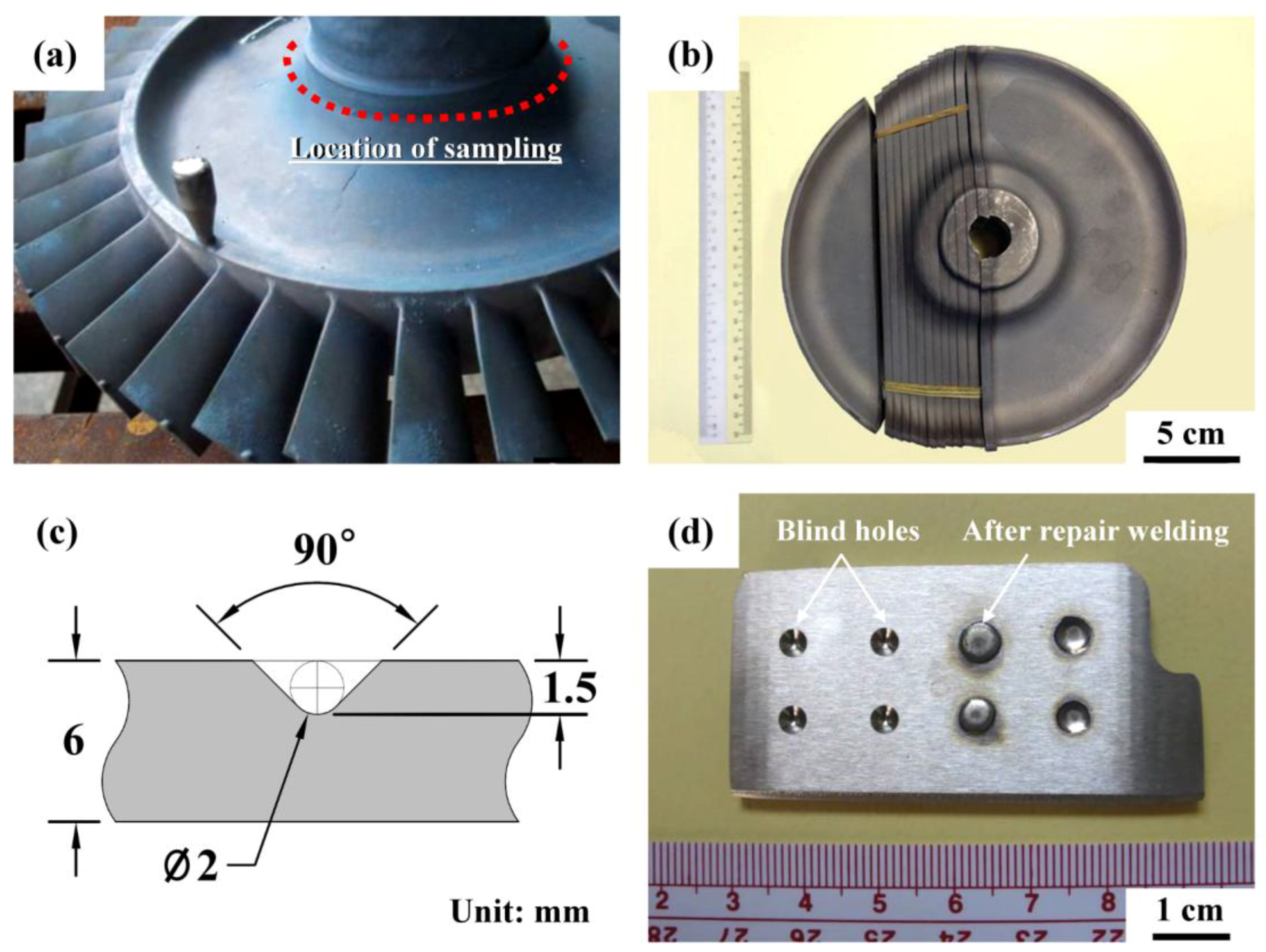

2. Materials and Experimental Procedures

3. Results and Discussion

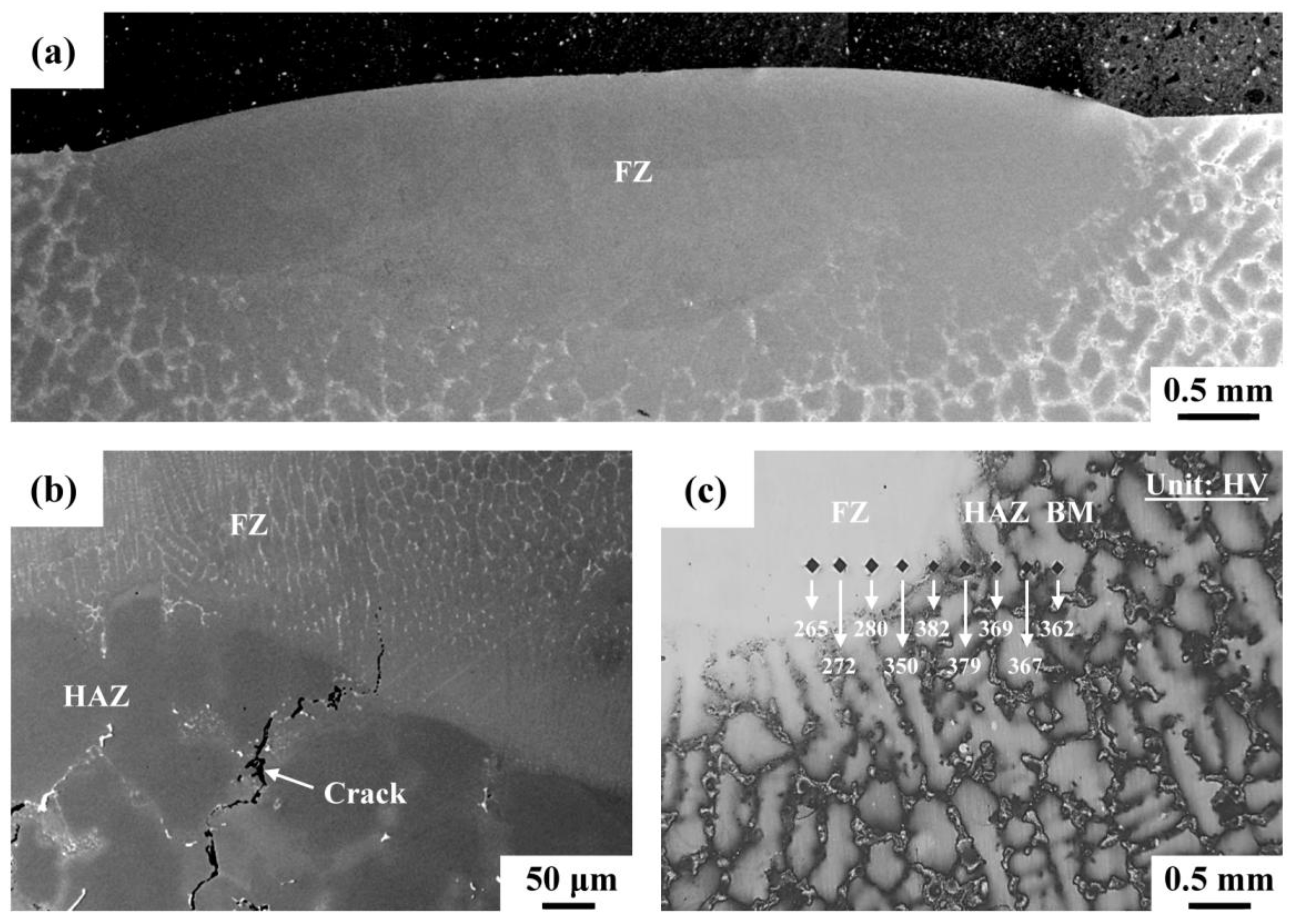

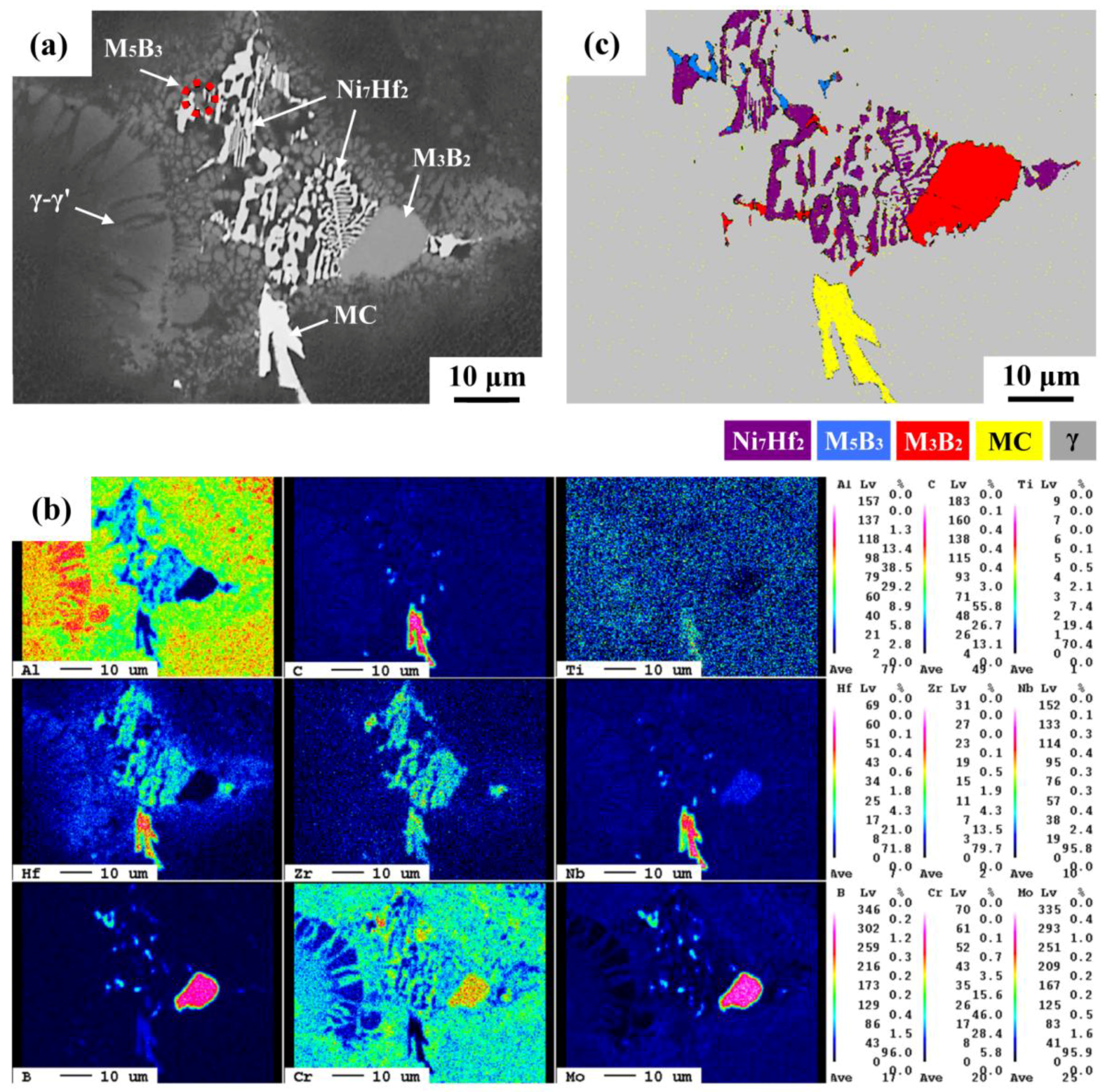

3.1. Metallographic Observations and EPMA Analyses

3.2. EBSD Crystallographic Analyses

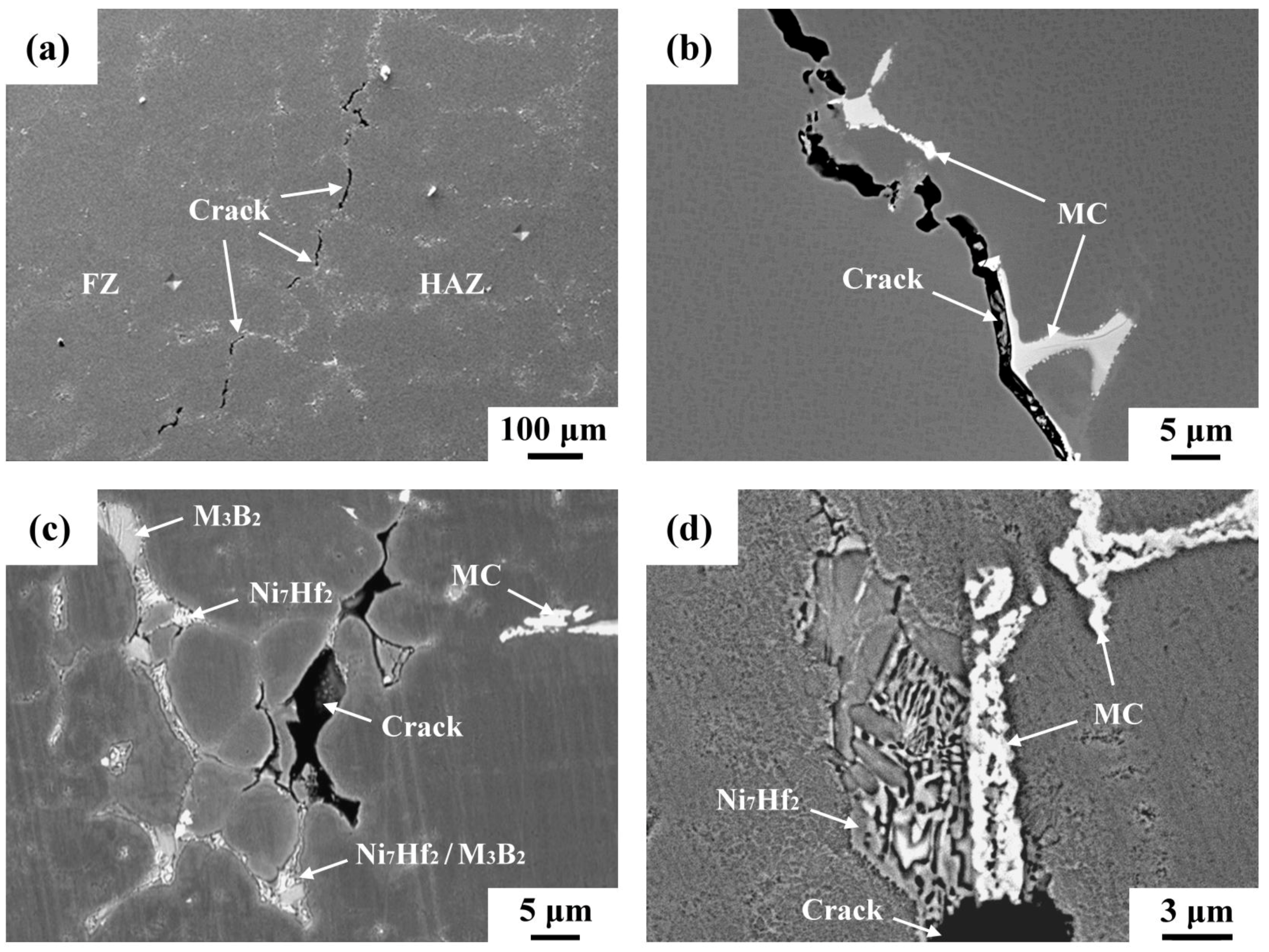

3.3. HAZ Microcracks

3.4. SEM Fractographs of Liquated Cracks in the HAZ

3.5. Pre-Weld Heat Treatment

4. Conclusions

- (1)

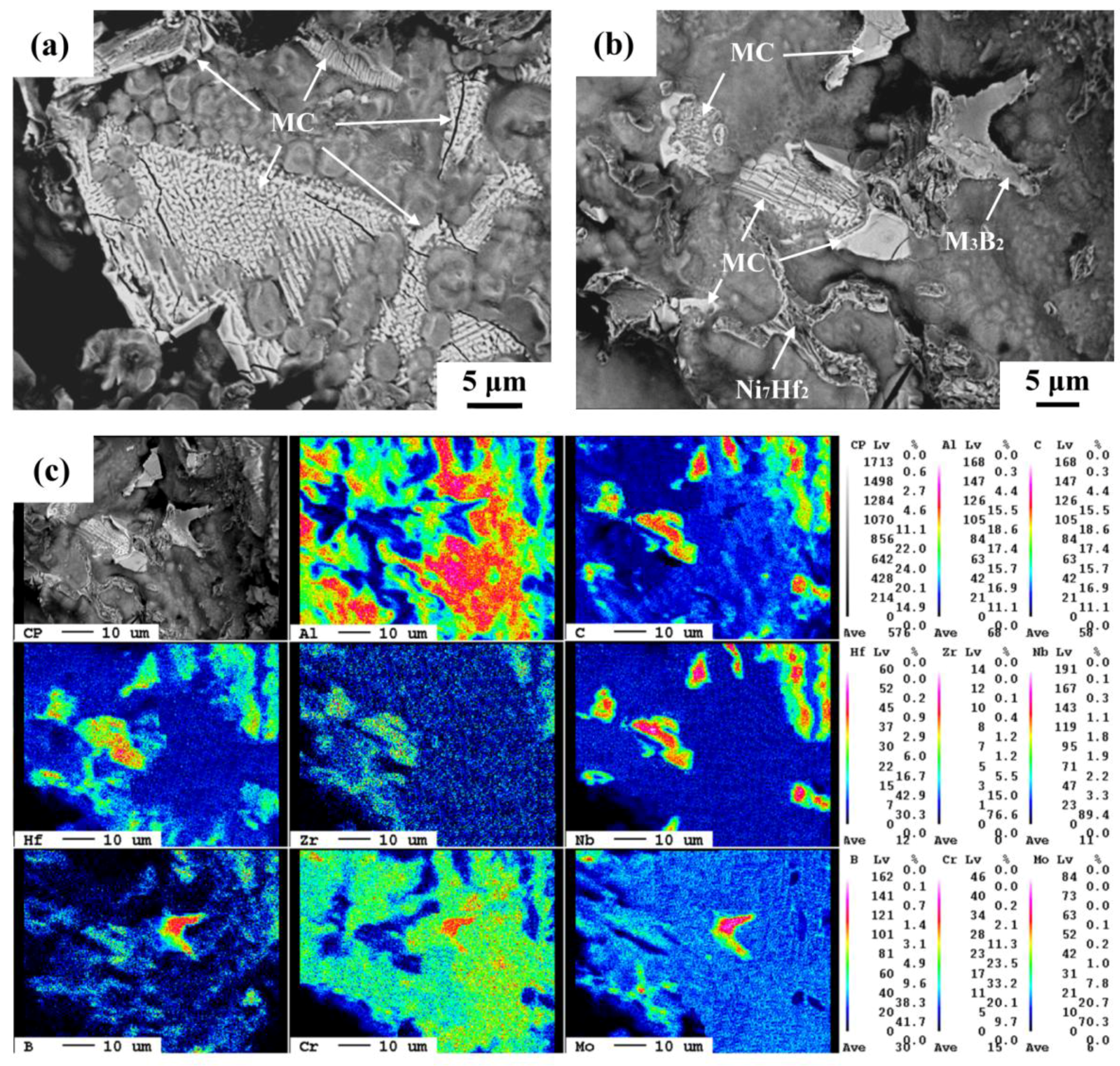

- Liquation cracks in the HAZ of a repaired Mar-M004 weld resulted from low-melting constituents along solidification boundaries. Premature melting of final solidification products, such as γ-γ′ eutectic colonies, MC carbides, Cr-Mo borides, and Ni-Hf intermetallic compounds at the dendrite boundaries, were responsible for the HAZ liquation cracking of the weld.

- (2)

- Cracks were more likely to propagate along the interface between γ and MC carbides because the MC carbides were the major second phase of the cast Mar-M004 superalloy. Moreover, the borides and lamellar intermetallics formed ahead of γ-γ′ colonies were melted preferentially at a much lower temperature during welding.

- (3)

- Fractographs of liquation cracks displayed solidified droplets and eutectic constituents. The smooth fractured surface was enriched in Al but lean in other alloying elements, which was associated with γ-γ′ colonies. Nb/Hf combined with C to form blocky MC carbides or assist the γ/MC eutectic reactions. Without the participation of C, co-segregation of Hf and Zr enhanced the formation of Ni-(Hf,Zr) intermetallics in lamellar form. In addition to the formation of Cr-Mo borides, the fractured surface contained a certain amount of B, which implied a strong tendency of B segregation to the final solidification products.

- (4)

- Pre-weld heat treatment of the cast superalloy at 1180 °C/4 h resulted in melting of borides (M3B2 and M5B3) and lamellar intermetallics (Ni7Hf2) ahead of γ-γ′ colonies. In contrast, MC carbides were more resistant to melting during the pre-weld heat treatment.

- (5)

- To achieve a crack-free weld, a proper pre-weld heat treatment for such a cast superalloy should be customized on the first priority if refurbishment of the turbine is required.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Balikci, E.; Raman, A.; Mirshams, R.A. Influence of various heat treatments on the microstructure of polycrystalline IN738LC. Metall. Mater. Trans. A 1997, 28, 1993–2003. [Google Scholar] [CrossRef]

- Balikci, E.; Raman, A. Characteristics of the γ′ precipitates at high temperatures in Ni-base polycrystalline superalloy IN738LC. J. Mater. Sci. 2000, 35, 3593–3597. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Nategh, S.; Guthrie, R.I.L. Study of microstructure and mechanical properties of high performance Ni-base superalloy GTD-111. Mater. Sci. Eng. A 2002, 325, 484–489. [Google Scholar] [CrossRef]

- Monajati, H.; Jahazi, M.; Bahrami, R.; Yue, S. The influence of heat treatment conditions on γ′ characteristics in Udimet® 720. Mater. Sci. Eng. A 2004, 373, 286–293. [Google Scholar] [CrossRef]

- Wongbunyakul, P.; Visuttipitukkul, P.; Wangyao, P.; Lothongkum, G.; Sricharoenchai, P. Effect of reheat treatment on microstructural refurbishment and hardness of the as-cast Inconel 738. High Temp. Mater. Process. 2014, 33, 453–461. [Google Scholar] [CrossRef]

- Kotval, P.S.; Venables, J.D.; Calder, R.W. The role of hafnium in modifying the microstructure of cast nickel-base superalloys. Metall. Mater. Trans. B 1972, 3, 457–462. [Google Scholar] [CrossRef]

- Balikci, E.; Mirshams, R.A.; Raman, A. Fracture behavior of superalloy IN738LC with various precipitate microstructures. Mater. Sci. Eng. A 1999, 265, 50–62. [Google Scholar] [CrossRef]

- Zupanič, F.; Bončina, T.; Križman, A.; Tichelaar, F.D. Structure of continuously cast Ni-based superalloy Inconel 713C. J. Alloys Compd. 2001, 329, 290–297. [Google Scholar] [CrossRef]

- El-Bagoury, N.; Nofal, A. Microstructure of an experimental Ni base superalloy under various casting conditions. Mater. Sci. Eng. A 2010, 527, 7793–7800. [Google Scholar] [CrossRef]

- Zhang, H.R.; Ojo, O.A.; Chaturvedi, M.C. Nanosize boride particles in heat-treated nickel base superalloys. Scr. Mater. 2008, 58, 167–170. [Google Scholar] [CrossRef]

- Du, B.; Shi, Z.; Yang, J.; Chu, Z.; Cui, C.; Sun, X.; Sheng, L.; Zheng, Y. M5B3 boride at the grain boundary of a nickel-based superalloy. J. Mater. Sci. Technol. 2016, 32, 265–270. [Google Scholar] [CrossRef]

- Jahangiri, M.R.; Arabi, H.; Boutorabi, S.M.A. Investigation on the dissolution of η phase in a cast Ni-based superalloy. Int. J. Miner. Metall. Mater. 2013, 20, 42–48. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy. Scr. Mater. 2004, 50, 641–646. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Microstructural study of weld fusion zone of TIG welded IN 738LC nickel-based superalloy. Scr. Mater. 2004, 51, 683–688. [Google Scholar] [CrossRef]

- Rush, M.T.; Colegrove, P.A.; Zhang, Z.; Broad, D. Liquation and post-weld heat treatment cracking in Rene 80 laser repair welds. J. Mater. Process. Technol. 2012, 212, 188–197. [Google Scholar] [CrossRef]

- Montazeri, M.; Ghaini, F.M. The liquation cracking behavior of IN738LC superalloy during low power Nd:YAG pulsed laser welding. Mater. Charact. 2012, 67, 65–73. [Google Scholar] [CrossRef]

- Osoba, L.O.; Ding, R.G.; Ojo, O.A. Microstructural analysis of laser weld fusion zone in Haynes 282 superalloy. Mater. Charact. 2012, 65, 93–99. [Google Scholar] [CrossRef]

- Angella, G.; Barbieri, G.; Donnini, R.; Montanari, R.; Richetta, M.; Varone, A. Electron beam welding of IN792 DS: Effects of pass speed and PWHT on microstructure and hardness. Materials 2017, 10, 1033. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Lippold, J.C.; Li, J.; Rohklin, S.R.; Vollbrecht, J.; Grylls, R. Laser engineered net shape (LENS) technology for the repair of Ni-base superalloy turbine components. Metall. Mater. Trans. A 2014, 45, 4454–4469. [Google Scholar] [CrossRef]

- Ding, R.G.; Huang, Z.W.; Li, H.Y.; Mitchell, I.; Baxter, G.; Bowen, P. Electron microscopy study of direct laser deposited IN718. Mater. Charact. 2015, 106, 324–337. [Google Scholar] [CrossRef]

- Jalilvand, V.; Omidvar, H.; Shakeri, H.R.; Rahimipour, M.R. Microstructural evolution during transient liquid phase bonding of Inconel 738LC using AMS 4777 filler alloy. Mater. Charact. 2013, 75, 20–28. [Google Scholar] [CrossRef]

- Henderson, M.B.; Arrell, D.; Larsson, R.; Heobel, M.; Marchant, G. Nickel based superalloy welding practices for industrial gas turbine applications. Sci. Technol. Weld. Join. 2004, 9, 13–21. [Google Scholar] [CrossRef]

- Li, Q.; Lin, X.; Wang, X.; Yang, H.; Song, M.; Huang, W. Research on the grain boundary liquation mechanism in heat affected zones of laser forming repaired K465 nickel-based superalloy. Metals 2016, 6, 64. [Google Scholar] [CrossRef]

- Lachowicz, M.; Dudziński, W.; Podrez-Radziszewska, M. TEM observation of the heat-affected zone in electron beam welded superalloy Inconel 713C. Mater. Charact. 2008, 59, 560–566. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Study of the fusion zone and heat-affected zone microstructures in tungsten inert gas-welded INCONEL 738LC superalloy. Metall. Mater. Trans. A 2006, 37, 421–433. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. On incipient melting during high temperature heat treatment of cast Inconel 738 superalloy. J. Mater. Sci. 2004, 39, 7401–7404. [Google Scholar] [CrossRef]

- Shahsavari, H.A.; Kokabi, A.H.; Nategh, S. Effect of preweld microstructure on HAZ liquation cracking of Rene 80 superalloy. Mater. Sci. Technol. 2007, 23, 547–555. [Google Scholar] [CrossRef]

- Wang, W.; Li, C.; Jiang, L.; Ye, X.-X.; Yu, K.; Chen, S.; Li, Z.; Zhou, X. Evolution of carbide precipitates in Hastelloy N joints during welding and post weld heat treatment. Mater. Charact. 2018, 135, 311–316. [Google Scholar] [CrossRef]

- Xu, H.; Liu, W.; Lu, F.; Wang, P.; Ding, Y. Evolution of carbides and its characterization in HAZ during NG-TIG welding of Alloy 617B. Mater. Charact. 2017, 130, 270–277. [Google Scholar] [CrossRef]

- Xu, J.; Lin, X.; Guo, P.; Hu, Y.; Wen, X.; Xue, L.; Liu, J.; Huang, W. The effect of preheating on microstructure and mechanical properties of laser solid forming IN-738LC alloy. Mater. Sci. Eng. A 2017, 691, 71–80. [Google Scholar] [CrossRef]

- Danis, Y.; Arvieu, C.; Lacoste, E.; Larrouy, T.; Quenisset, J.-M. An investigation on thermal, metallurgical and mechanical states in weld cracking of Inconel 738LC superalloy. Mater. Des. 2010, 31, 402–416. [Google Scholar] [CrossRef]

- Sidhu, R.K.; Richards, N.L.; Chaturvedi, M.C. Effect of filler alloy composition on post-weld heat treatment cracking in GTA welded cast Inconel 738LC superalloy. Mater. Sci. Technol. 2008, 24, 529–539. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Chen, J.T.; Shiue, R.K.; Tsay, L.W. The Evolution of Cast Microstructures on the HAZ Liquation Cracking of Mar-M004 Weld. Metals 2018, 8, 35. [Google Scholar] [CrossRef]

- González, M.A.; Martínez, D.I.; Pérez, A.; Guajardo, H.; Garza, A. Microstructural response to heat affected zone cracking of prewelding heat-treated Inconel 939 superalloy. Mater. Charact. 2011, 62, 1116–1123. [Google Scholar] [CrossRef]

- Gonzalez, H.; Calleja, A.; Pereira, O.; Ortega, N.; de Lacalle, L.N.L.; Barton, M. Super abrasive machining of integral rotary components using grinding flank tools. Metals 2018, 8, 24. [Google Scholar] [CrossRef]

- Calleja, A.; Fernandez, A.; Rodriguez, A.; de Lacalle, L.N.L.; Lamikiz, A. Turn-milling of blades in turning centres and multitasking machines controlling tool tilt angle. J. Eng. Manuf. 2015, 229, 1324–1336. [Google Scholar] [CrossRef]

| Alloy/Element | Al | B | C | Cr | Hf | Mo | Nb | Ti | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Mar-M004 | 5.95 | 0.015 | 0.05 | 12.0 | 1.3 | 4.5 | 2.0 | 0.6 | 0.05 | Bal |

| Location/Element | Al | B | C | Cr | Hf | Mo | Nb | Ti | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Site 1 | 1.20 | — | 44.52 | 0.57 | 5.06 | 4.23 | 29.10 | 5.96 | 0.41 | Bal |

| Site 2 | 0.27 | 3.37 | 44.85 | 1.29 | 3.86 | 6.54 | 27.93 | 7.38 | 0.20 | Bal |

| Site 3 | 1.57 | — | 8.26 | 4.57 | 7.40 | 2.11 | 1.81 | 0.80 | 3.79 | Bal |

| Site 4 | 0.54 | 40.93 | 0.01 | 21.47 | 0.26 | 27.21 | 2.24 | 0.18 | 0.08 | Bal |

| Phase/Element | Al | B | C | Cr | Hf | Mo | Nb | Ti | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| MC | 0.03 | — | 44.34 | 0.77 | 18.74 | 3.69 | 23.37 | 3.52 | 1.70 | Bal |

| M3B2 | 0.02 | 25.43 | 1.03 | 31.81 | 0.09 | 33.85 | 2.38 | 0.30 | — | Bal |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.-C.; Cheng, Y.-H.; Tsay, L.-W.; Shiue, R.-K. Effects of Grain Boundary Microconstituents on Heat-Affected Zone Cracks in a Mar-M004 Weldment. Metals 2018, 8, 201. https://doi.org/10.3390/met8040201

Chen T-C, Cheng Y-H, Tsay L-W, Shiue R-K. Effects of Grain Boundary Microconstituents on Heat-Affected Zone Cracks in a Mar-M004 Weldment. Metals. 2018; 8(4):201. https://doi.org/10.3390/met8040201

Chicago/Turabian StyleChen, Tai-Cheng, Yi-Hsin Cheng, Leu-Wen Tsay, and Ren-Kae Shiue. 2018. "Effects of Grain Boundary Microconstituents on Heat-Affected Zone Cracks in a Mar-M004 Weldment" Metals 8, no. 4: 201. https://doi.org/10.3390/met8040201

APA StyleChen, T.-C., Cheng, Y.-H., Tsay, L.-W., & Shiue, R.-K. (2018). Effects of Grain Boundary Microconstituents on Heat-Affected Zone Cracks in a Mar-M004 Weldment. Metals, 8(4), 201. https://doi.org/10.3390/met8040201