Characterization on the Microstructure Evolution and Toughness of TIG Weld Metal of 25Cr2Ni2MoV Steel after Post Weld Heat Treatment

Abstract

:1. Introduction

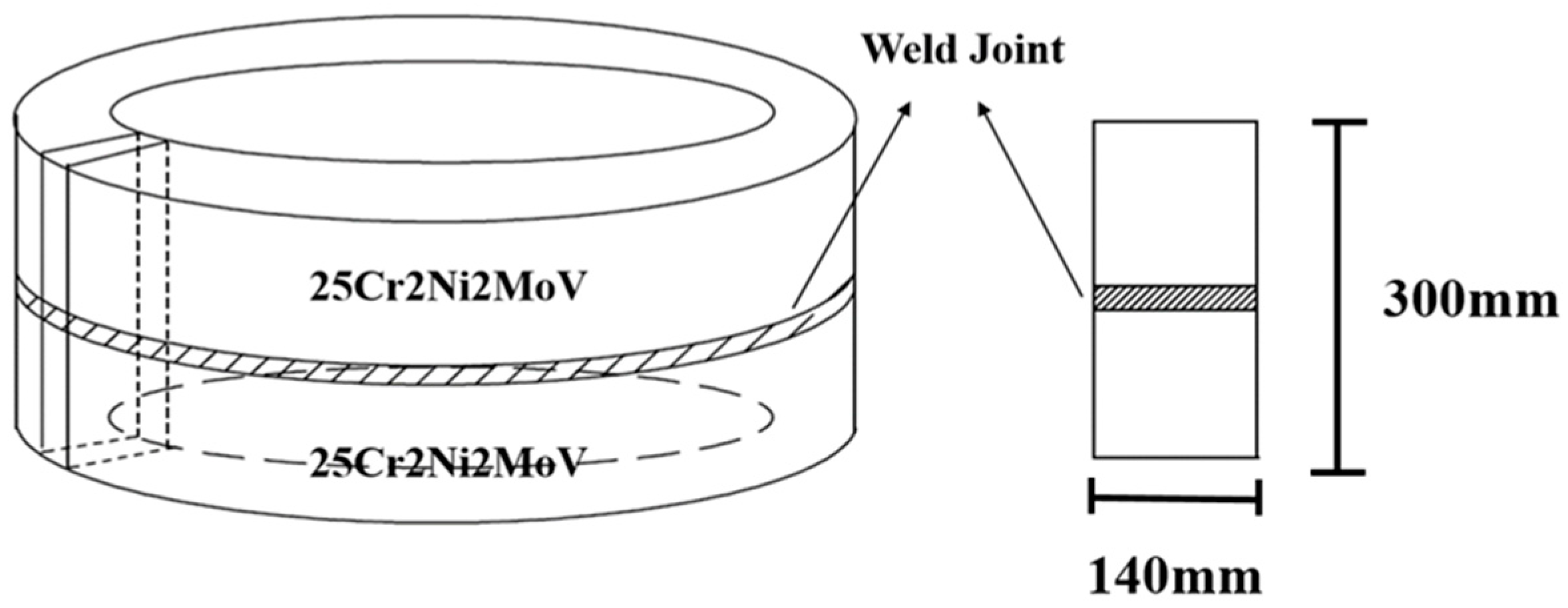

2. Materials and Methods

3. Results and Discussion

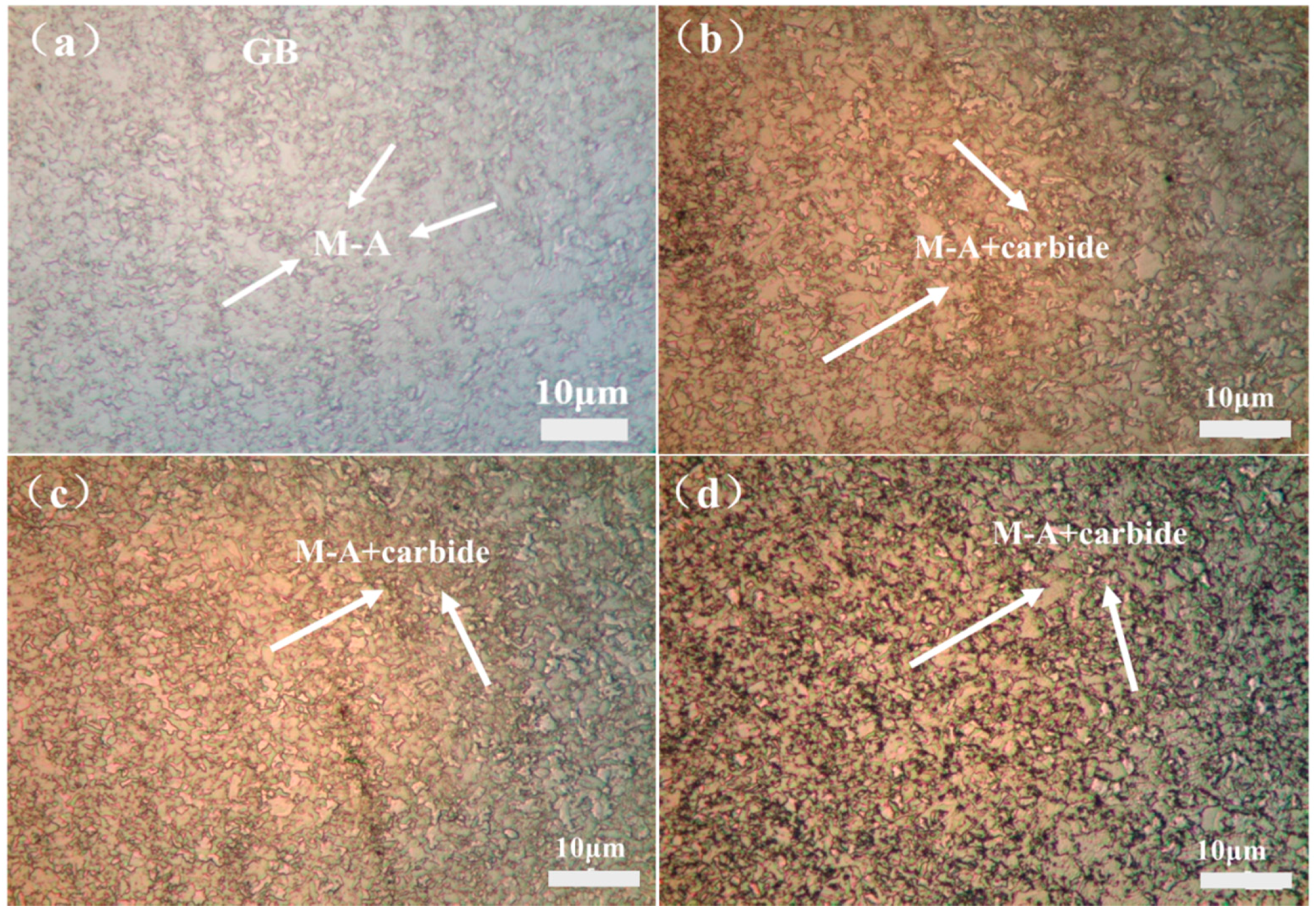

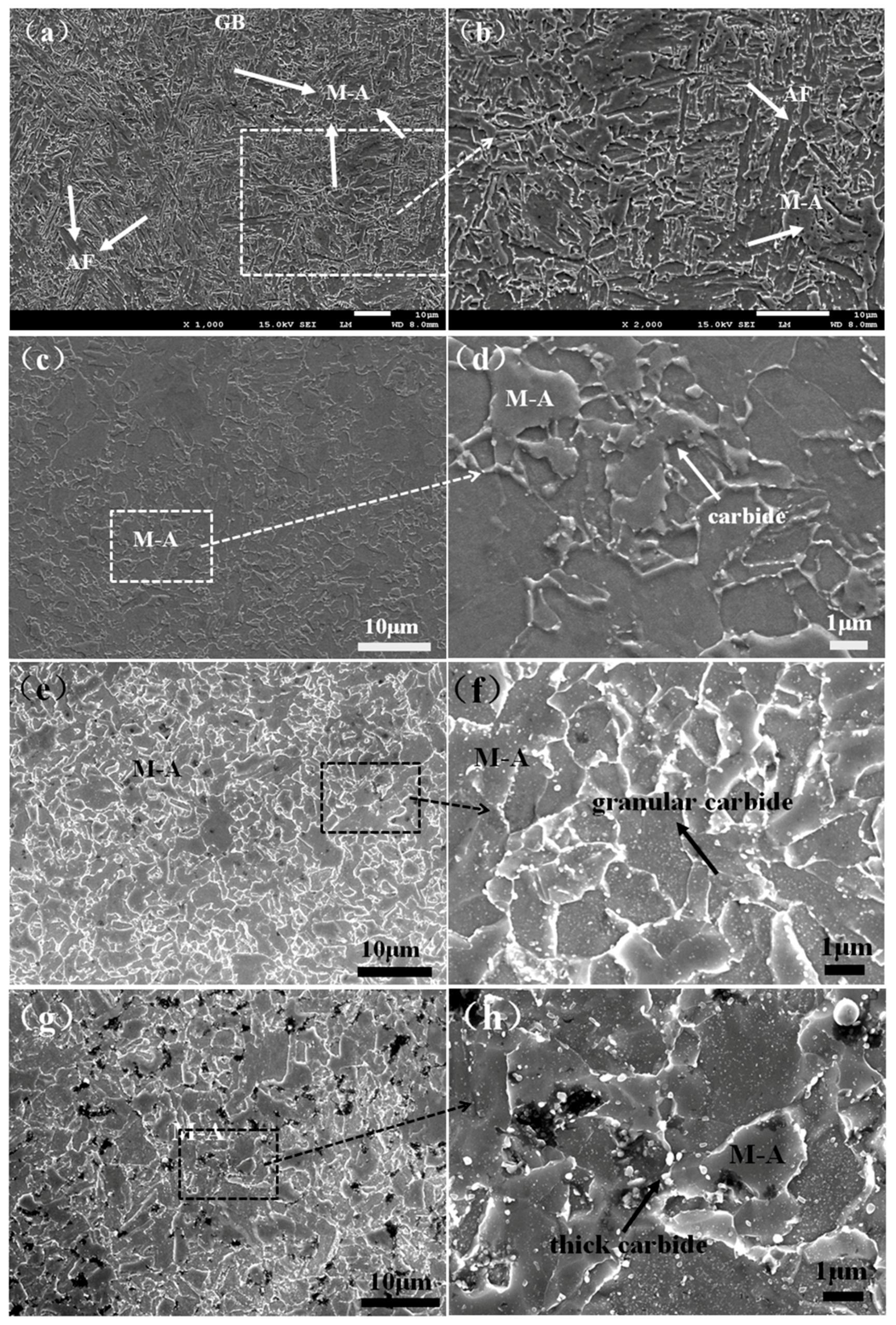

3.1. Microstructure Analysis

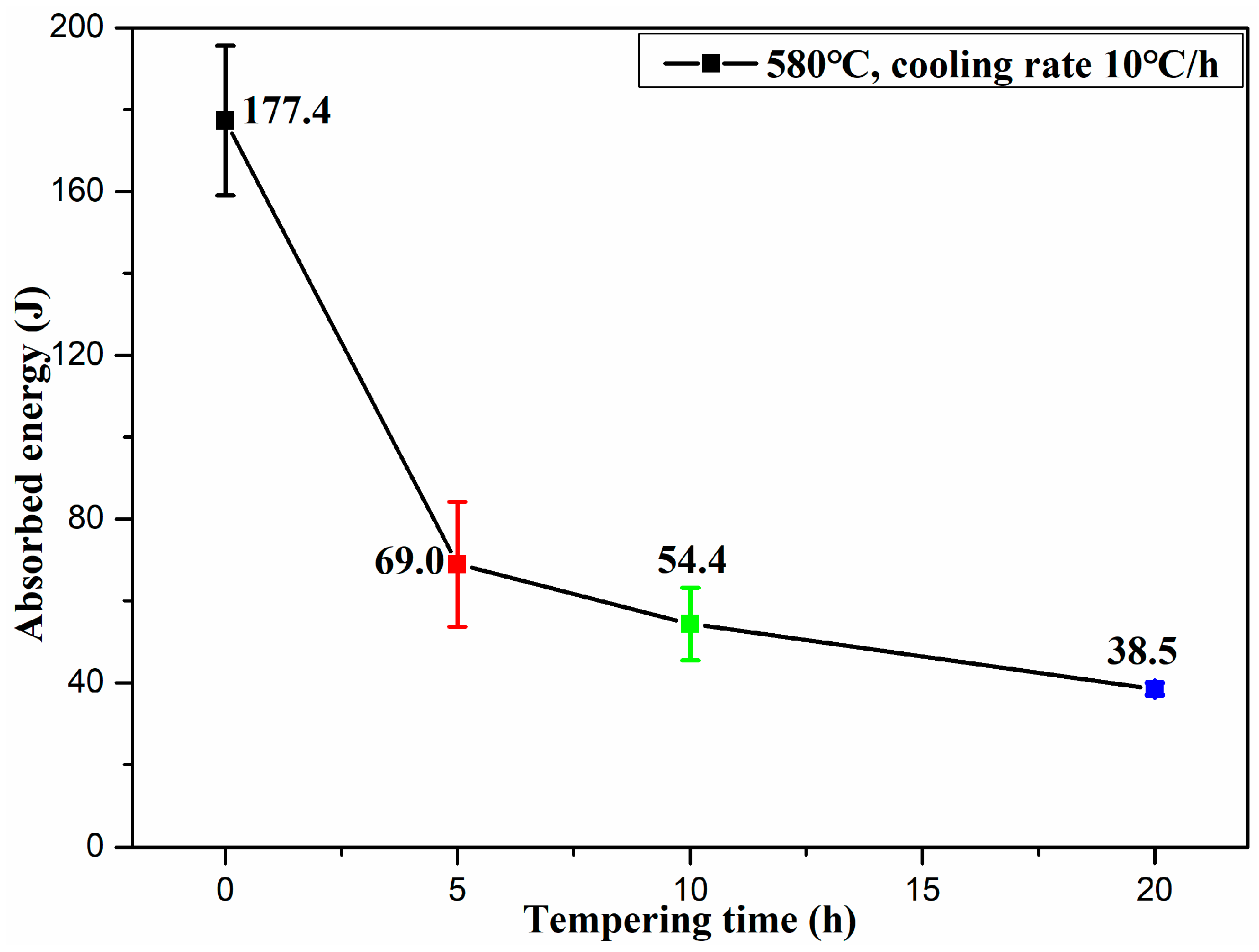

3.2. Charpy Impact Results

3.3. Fractography Characterization

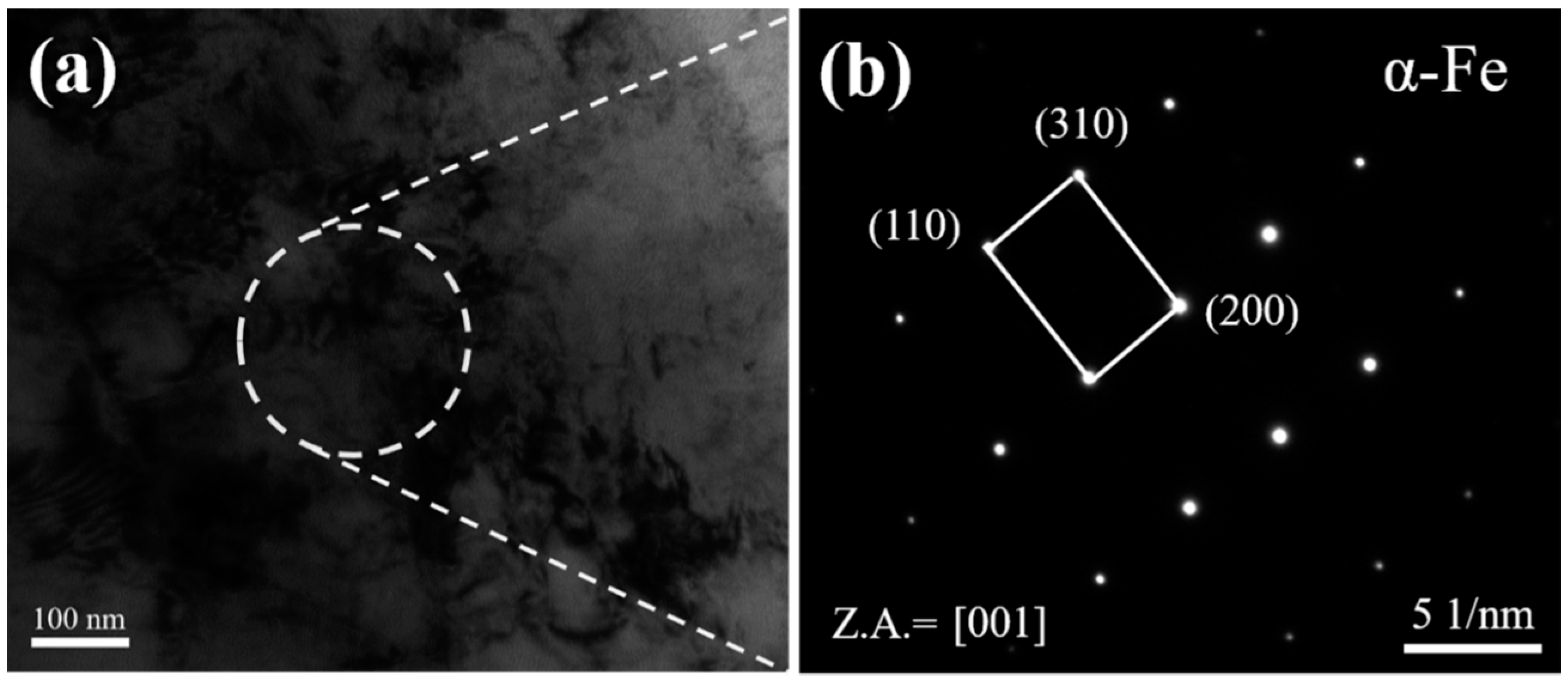

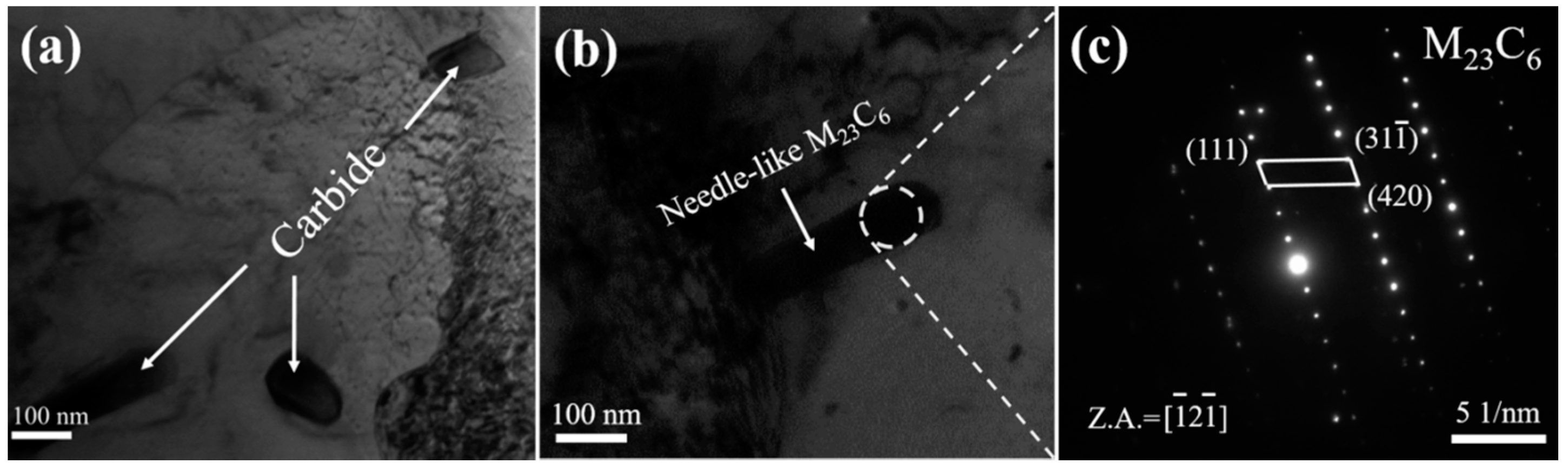

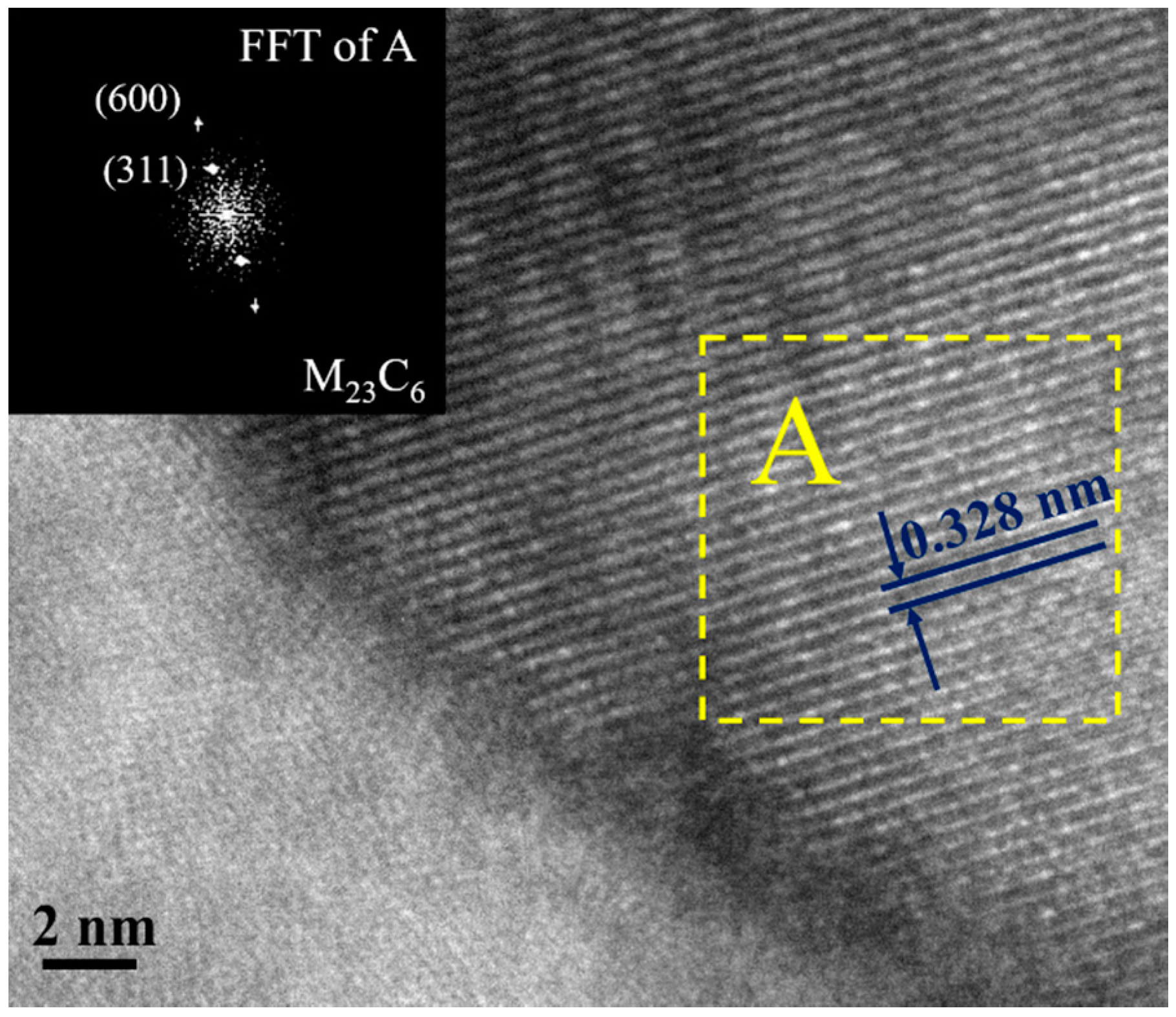

3.4. TEM Characterization

4. Conclusions

- The microstructure of the as-welded sample is composed of granular bainite and acicular ferrite. In addition, a large number of blocky M-A is homogeneously distributed in the bainite and ferrite matrix. The as-welded sample exhibits the highest toughness of 177.4 J.

- After PWHT at 580 °C, the blocky M-A decomposes into ferrite and carbides, and the carbide particles are distributed along the boundary of the blocky M-A. As the holding time in PWHT is increased, more blocky M-A decomposes, and both the number and size of the precipitated carbides grow.

- As the precipitation of carbide particles distributes along the boundary of blocky M-A, the toughness of the weld metal dramatically decreases after PWHT. Both the number and size of precipitated carbide particles grow with the increase in holding time during PWHT. Since the initiation of micro cracks is attributed to the precipitated carbide particles and the crack propagation path is along the boundary of the blocky M-A, the sample with the longer holding time during PWHT has the lower toughness. Therefore, a shorter holding time during PWHT is suggested in order to achieve higher toughness for TIG-welded 25Cr2Ni2MoV steel.

- The precipitated carbide particles are identified as M23C6 carbides by TEM characterization, which is responsible for the dramatic decrease in the toughness of the TIG weld metal of 25Cr2Ni2MoV steel.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, X.J.; Kong, X.B.; Hou, G.L.; Wang, J.H. Modeling of a 1000 MW power plant ultra super-critical boiler system using fuzzy-neural network methods. Energy Convers. Manag. 2013, 65, 518–527. [Google Scholar] [CrossRef]

- Kosman, W. Thermal analysis of cooled supercritical steam turbine components. Energy 2010, 35, 1181–1187. [Google Scholar] [CrossRef]

- Huo, W.; Li, J.; Yan, X. Effects of coolant flow rates on cooling performance of the intermediate pressure stages for an ultra-supercritical steam turbine. Appl. Therm. Eng. 2014, 62, 723–731. [Google Scholar] [CrossRef]

- Chen, C.Y.; Yen, H.W.; Kao, F.H.; Li, W.C.; Huang, C.Y.; Yang, J.R.; Wang, S.H. Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides. Mater. Sci. Eng. A 2009, 499, 162–166. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.Y.; Zhou, X.G.; Wang, G.D.; Misra, R.D.K. Precipitation behavior of nanoscale cementite in hypoeutectoid steels during ultra fast cooling (UFC) and their strengthening effects. Mater. Sci. Eng. A 2013, 575, 189–198. [Google Scholar]

- Liu, P.; Lu, F.; Liu, X.; Ji, H.; Gao, Y. Study on fatigue property and microstructure characteristics of welded nuclear power rotor with heavy section. J. Alloys Compd. 2014, 584, 430–437. [Google Scholar] [CrossRef]

- Hong, S.; Lee, J.; Lee, B.J.; Kim, H.S.; Kim, S.K.; Chin, K.G.; Lee, S. Effects of intergranular carbide precipitation on delayed fracture behavior in three Twinning Induced Plasticity (TWIP) steels. Mater. Sci. Eng. A 2013, 587, 85–99. [Google Scholar] [CrossRef]

- Salemi, A.; Abdollah-zadeh, A. The effect of tempering temperature on the mechanical properties and fracture morphology of a NiCrMoV steel. Mater. Charact. 2008, 59, 484–487. [Google Scholar] [CrossRef]

- Tanaka, Y.; Azuma, T.; Yaegashi, N. Isothermal aging test results (up to 100,000 h) of NiCrMoV steels for low pressure steam turbine. Int. J. Pressure Vessels Pip. 1994, 59, 71–81. [Google Scholar] [CrossRef]

- Zhu, M.L.; Wang, D.Q.; Xuan, F.Z. Effect of long-term aging on microstructure and local behavior in the heat-affected zone of a Ni-Cr-Mo-V steel welded joint. Mater. Charact. 2014, 87, 45–61. [Google Scholar] [CrossRef]

- Zhu, M.L.; Xuan, F.Z. Correlation between microstructure, hardness and strength in HAZ of dissimilar welds of rotor steels. Mater. Sci. Eng. A 2010, 527, 4035–4042. [Google Scholar] [CrossRef]

- Bhamji, I.; Preuss, M.; Threadgill, P.L.; Moat, R.J.; Addison, A.C.; Peel, M.J. Linear friction welding of AISI 316L stainless steel. Mater. Sci. Eng. A 2010, 528, 680–690. [Google Scholar] [CrossRef]

- Hokamoto, K.; Nakata, K.; Mori, A.; Tsuda, S.; Tsumura, T.; Inoue, A. Dissimilar material welding of rapidly solidified foil and stainless steel plate using underwater explosive welding technique. J. Alloys Compd. 2009, 472, 507–511. [Google Scholar] [CrossRef]

- Torkamany, M.J.; Tahamtan, S.; Sabbaghzadeh, J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser. Mater. Des. 2010, 31, 458–465. [Google Scholar] [CrossRef]

- Beidokhti, B.; Kokabi, A.H.; Dolati, A. A comprehensive study on the microstructure of high strength low alloy pipeline welds. J. Alloys Compd. 2014, 597, 142–147. [Google Scholar] [CrossRef]

- Villaret, V.; Deschaux-Beaume, F.; Bordreuil, C.; Rouquette, S.; Chovet, C. Influence of filler wire composition on weld microstructures of a 444 ferritic stainless steel grade. J. Mater. Process. Technol. 2013, 213, 1538–1547. [Google Scholar] [CrossRef]

- Gunaraj, V.; Murugan, N. Prediction of heat-affected zone characteristics in submerged arc welding of structural steel pipes. Weld. J. 2002, 81, 45–53. [Google Scholar]

- Avazkonandeh-Gharavol, M.H.; Haddad-Sabzevar, M.; Haerian, A. Effect of chromium content on the microstructure and mechanical properties of multipass MMA, low alloy steel weld metal. J. Mater. Sci. 2009, 44, 186–197. [Google Scholar] [CrossRef]

- Shekhter, A.; Kim, S.; Carr, D.G.; Croker, A.B.L.; Ringer, S.P. Assessment of temper embrittlement in an ex-service 1Cr-1Mo-0.25V power generating rotor by Charpy V-Notch testing, KIc fracture toughness and small punch test. Int. J. Pressure Vessels Pip. 2002, 79, 8–10. [Google Scholar] [CrossRef]

- Wu, Q.; Lu, F.; Cui, H.; Liu, X.; Wang, P.; Tang, X. Role of butter layer in low-cycle fatigue behavior of modified 9Cr and CrMoV dissimilar rotor welded joint. Mater. Des. 2014, 59, 165–175. [Google Scholar] [CrossRef]

- Wu, Q.; Lu, F.; Cui, H.; Ding, Y.; liu, X.; Gao, Y. Microstructure characteristics and temperature-dependent high cycle fatigue behavior of advanced 9% Cr/CrMoV dissimilarly welded joint. Mater. Sci. Eng. A 2014, 615, 98–106. [Google Scholar] [CrossRef]

- Farabi, N.; Chen, D.L.; Li, J.; Zhou, Y.; Dong, S.J. Microstructure and mechanical properties of laser welded DP600 steel joints. Mater. Sci. Eng. A 2010, 527, 1215–1222. [Google Scholar] [CrossRef]

- Fattahi, M.; Nabhani, N.; Vaezi, M.R.; Rahimi, E. Improvement of impact toughness of AWS E6010 weld metal by adding TiO2 nanoparticles to the electrode coating. Mater. Sci. Eng. A 2011, 528, 8031–8039. [Google Scholar] [CrossRef]

- Gaffard, V.; Gourgues-Lorenzon, A.F.; Besson, J. High temperature creep flow and damage properties of 9Cr1MoNbV steels: Base metal and weldment. Nucl. Eng. Des. 2005, 235, 2547–2562. [Google Scholar] [CrossRef]

- Karthikeyan, T.; Thomas Paul, V.; Saroja, S.; Moitra, A.; Sasikala, G.; Vijayalakshmi, M. Grain refinement to improve impact toughness in 9Cr-1Mo steel through a double austenitization treatment. J. Nucl. Mater. 2011, 419, 256–262. [Google Scholar] [CrossRef]

- Zhao, M.C.; Huang, X.F.; Atrens, A. Role of second phase cementite and martensite particles on strength and strain hardening in a plain C-Mn steel. Mater. Sci. Eng. A 2012, 549, 222–227. [Google Scholar] [CrossRef]

- Klueh, R.; Hashimoto, N.; Maziasz, P. Development of new nano-particle-strengthened martensitic steels. Scr. Mater. 2005, 53, 275–280. [Google Scholar] [CrossRef]

- Wang, B.; Yi, D.; Liu, H.; Wu, B.; Yuan, J. Effect of tempering temperature on microstructure and mechanical properties of 15Cr2Ni3MoW steel. Trans. Mater. Heat Treat. 2008, 29, 73–77. [Google Scholar]

- Li, Y.; Wang, L.; Wu, J.; Cai, Z.; Pan, J.; Liu, X.; Qiao, S.; Ding, Y.; Shen, H. Determination of toughness weak points of bainite weld metal of NiCrMoV refractory steel. J. Mech. Eng. 2013, 49, 83–88. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Z.; Pan, J.; Liu, X.; Wang, P.; Huo, X.; Shen, H. Research on toughness weak points of joints of NiCrMoV regractory steel for manufacturing steam turbine rotor. Trans. China Weld. Inst. 2014, 35, 73–76. [Google Scholar]

- Zhang, B.; Cai, Z.; Wu, J.; Pan, J.; Liu, X.; Qian, S.; Xu, X.; Huo, X.; Shen, H. Influence of tempering parameter on aged toughness of welding joint of Ni-Cr-Mo-V turbine rotor steel. Electr. Weld. Mach. 2013, 43, 27–32. [Google Scholar]

| Elements | C | Si | Mn | P | S | Cr | Mo | Ni | V | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BM | 0.24 | 0.05 | 0.20 | 0.004 | 0.003 | 2.36 | 0.76 | 2.23 | 0.07 | <0.17 | Balance |

| FM | 0.094 | 0.23 | 1.42 | <0.010 | 0.002 | 0.56 | 0.52 | 2.20 | <0.01 | 0.059 | Balance |

| Parameters | Wire Diameter (mm) | Current (A) | Voltage (V) | Speed (mm/min) | Gas |

|---|---|---|---|---|---|

| - | 1.0 | 270 | 11.2 | 70 | Ar 99.999% 20/30 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Cai, Z.; Yang, S.; Feng, K.; Li, Z. Characterization on the Microstructure Evolution and Toughness of TIG Weld Metal of 25Cr2Ni2MoV Steel after Post Weld Heat Treatment. Metals 2018, 8, 160. https://doi.org/10.3390/met8030160

Liu X, Cai Z, Yang S, Feng K, Li Z. Characterization on the Microstructure Evolution and Toughness of TIG Weld Metal of 25Cr2Ni2MoV Steel after Post Weld Heat Treatment. Metals. 2018; 8(3):160. https://doi.org/10.3390/met8030160

Chicago/Turabian StyleLiu, Xia, Zhipeng Cai, Sida Yang, Kai Feng, and Zhuguo Li. 2018. "Characterization on the Microstructure Evolution and Toughness of TIG Weld Metal of 25Cr2Ni2MoV Steel after Post Weld Heat Treatment" Metals 8, no. 3: 160. https://doi.org/10.3390/met8030160

APA StyleLiu, X., Cai, Z., Yang, S., Feng, K., & Li, Z. (2018). Characterization on the Microstructure Evolution and Toughness of TIG Weld Metal of 25Cr2Ni2MoV Steel after Post Weld Heat Treatment. Metals, 8(3), 160. https://doi.org/10.3390/met8030160