Mechanical Properties of Stainless-Steel Structures Fabricated by Composite Extrusion Modelling

Abstract

:1. Introduction

2. Materials and Methods

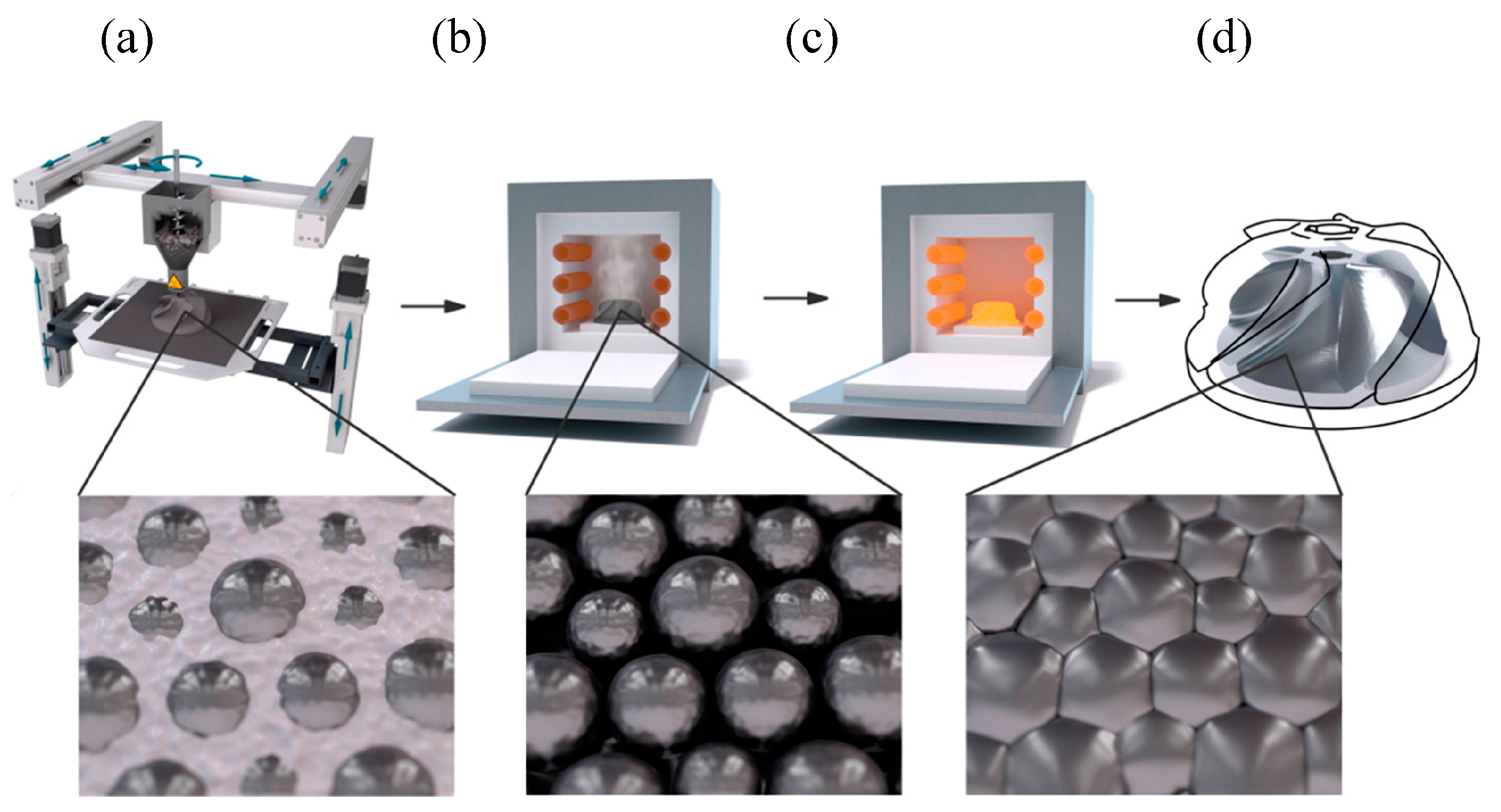

2.1. 3D Printing Device

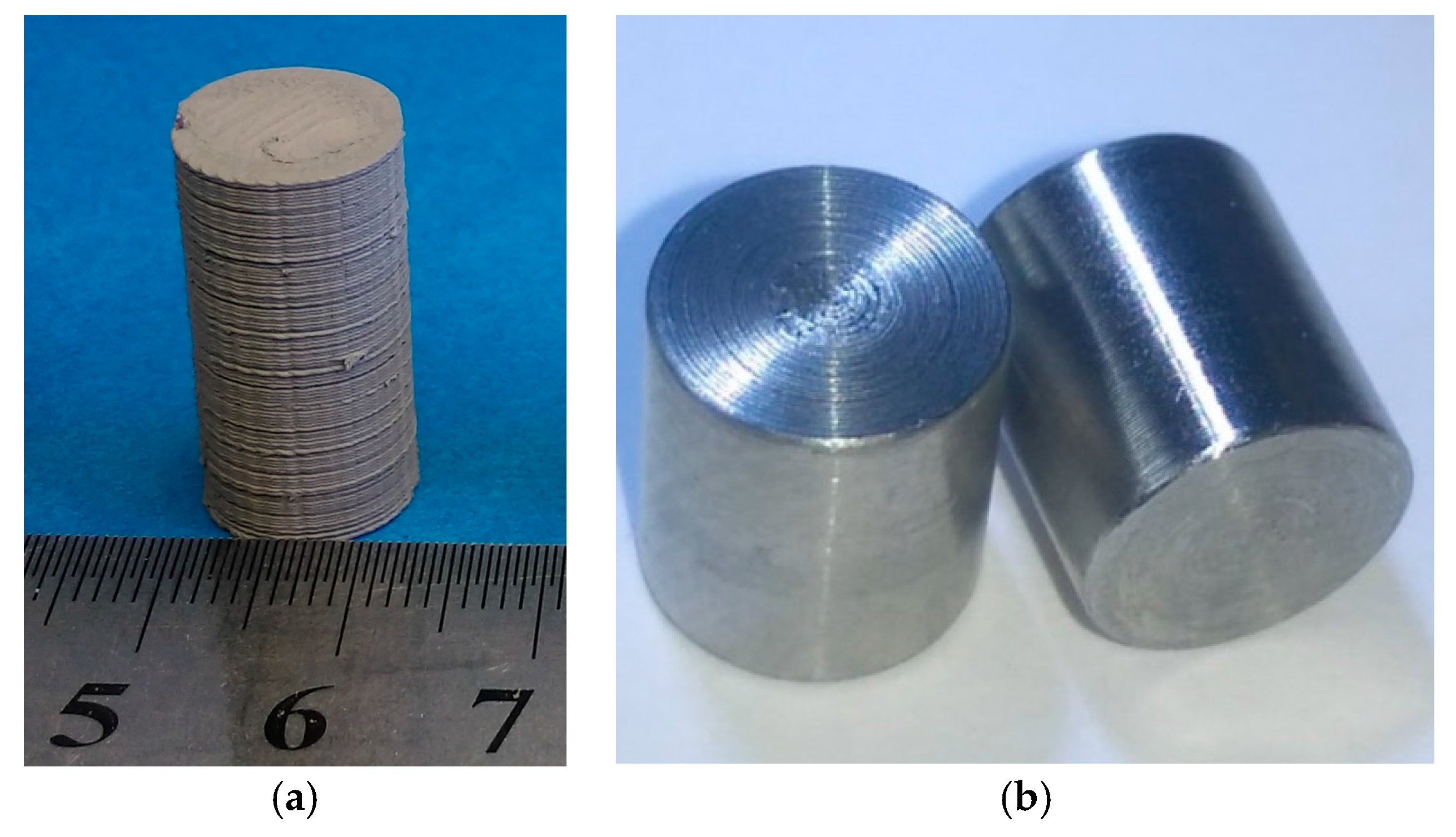

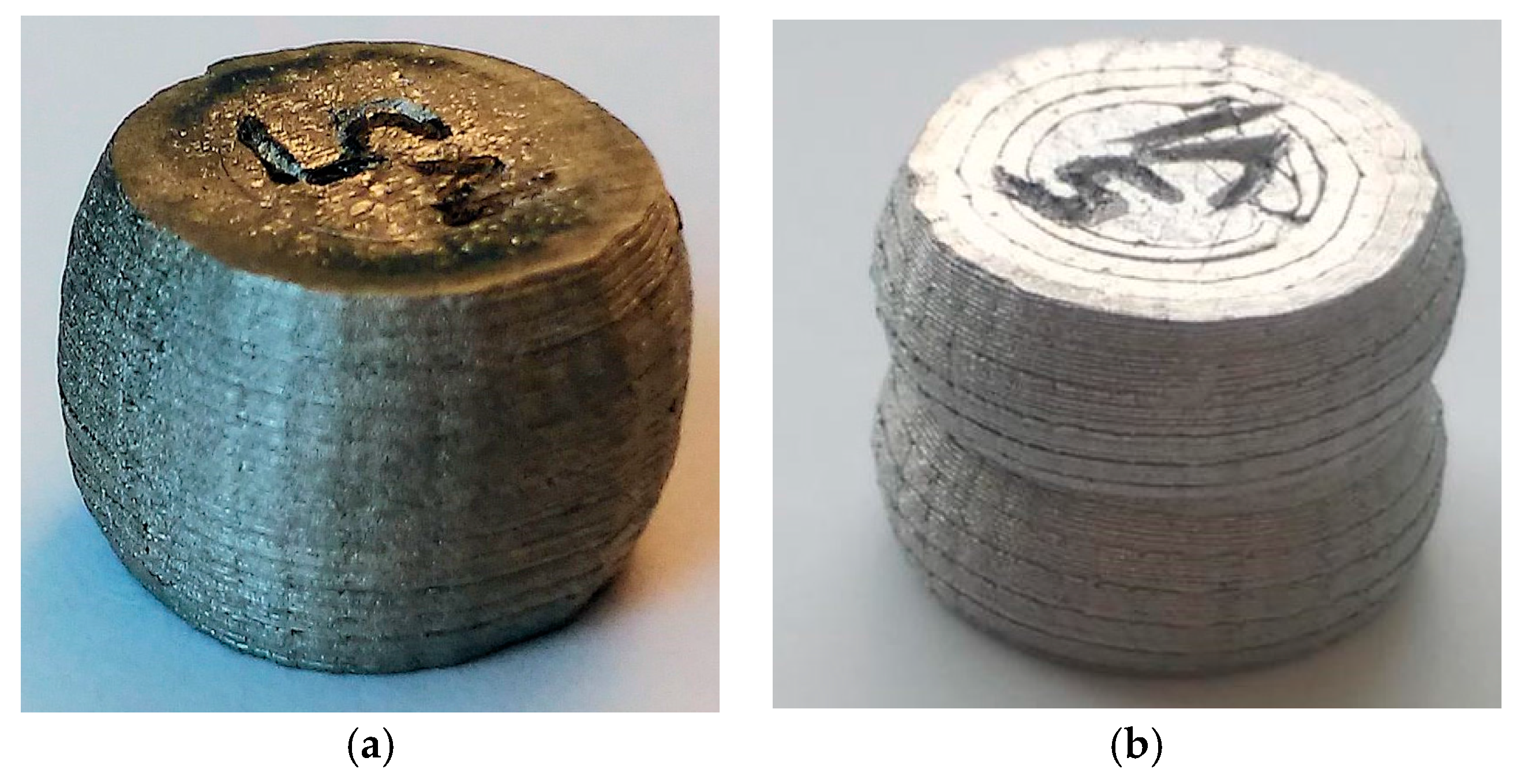

2.2. Test Structures

2.3. Material

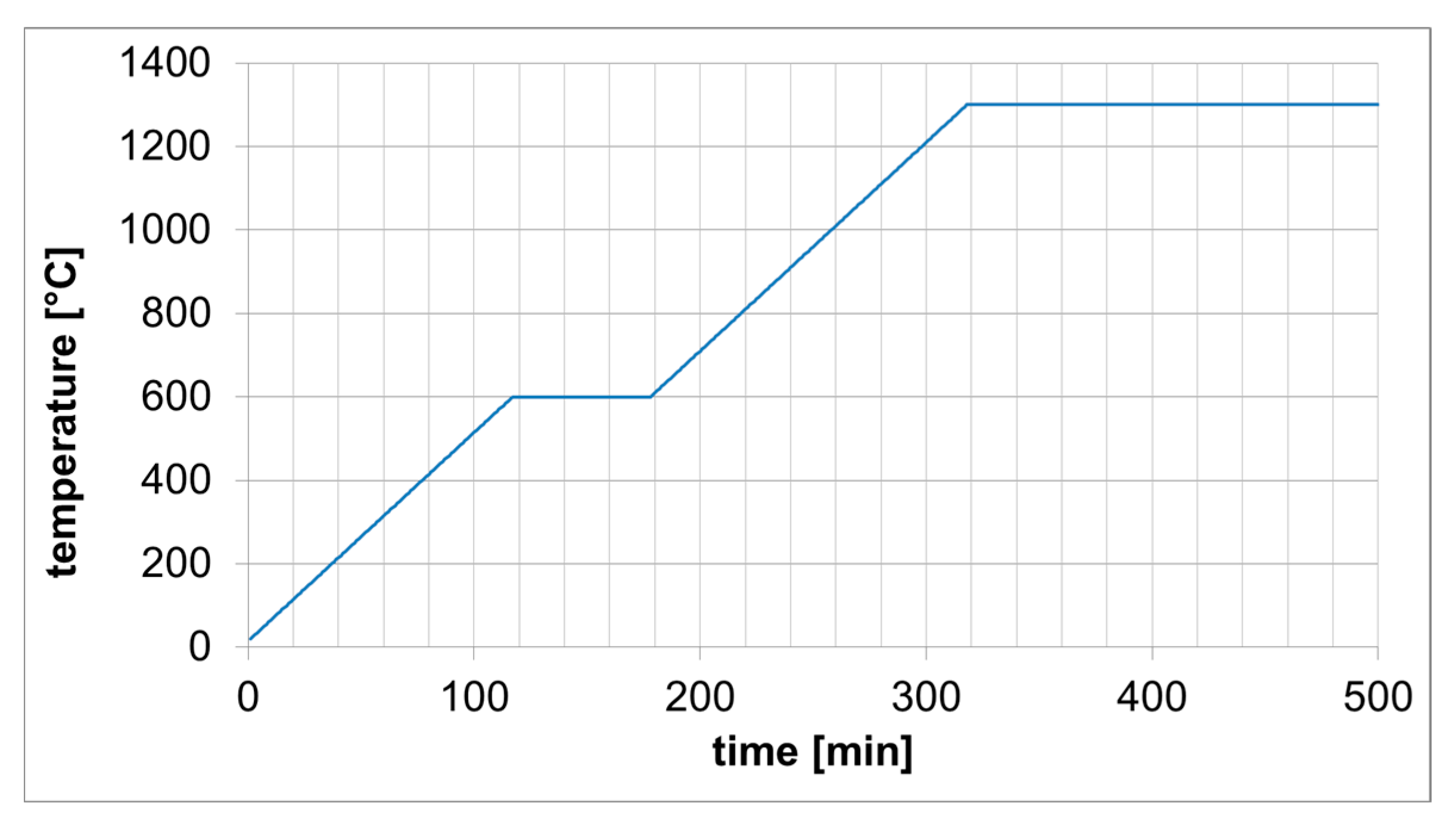

2.4. Debinding and Sintering

2.5. Analysis

3. Results

3.1. Results of Geometrical Investigations and Mass Measurement

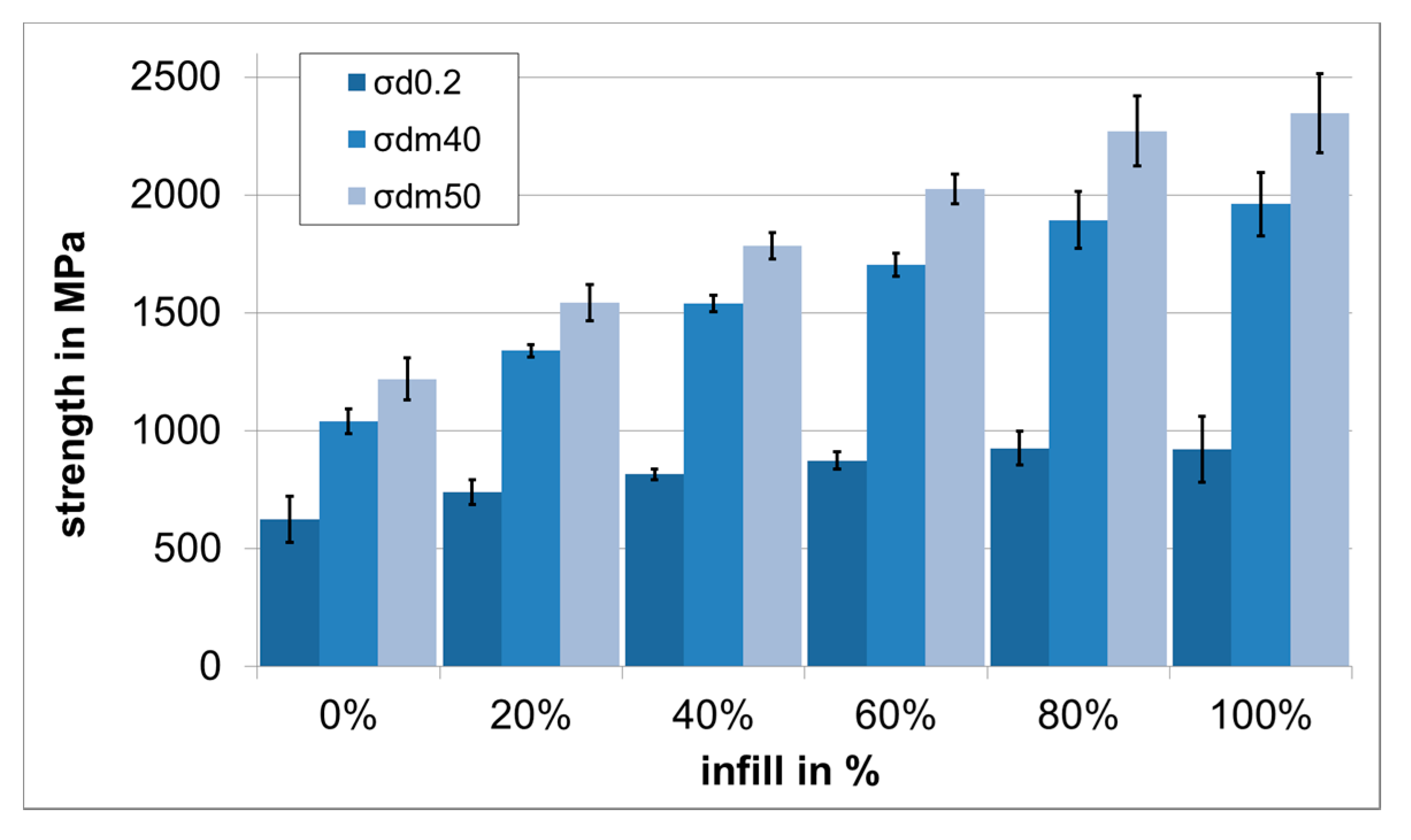

3.2. Results of Mechanical Investigations

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Eyers, D.; Dotchev, K. Technology review for mass customisation using rapid manufacturing. Assem. Autom. 2010, 30, 39–46. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef]

- Wohlers, T. Wohlers Report 2017; Wohlers Associates, Inc.: Fort Collins, CO, USA, 2017; ISBN 978-0-9913332-3-3. [Google Scholar]

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5121329 A, 9 June 1992. [Google Scholar]

- European Powder Metallurgy Association. Metal Injection Moulding: A Manufacturing Process for Precision Engineering Components, 3rd ed.; European Powder Metallurgy Association: Shrewsbury, UK, 2014; pp. 5–8. [Google Scholar]

- Lieberwirth, C.; Harder, A.; Seitz, H. Extrusion based additive manufacturing of metals parts. J. Mech. Eng. Autom. 2017, 7, 79–83. [Google Scholar] [CrossRef]

- Lieberwirth, C.; Seitz, H. Additive manufacturing with metal injection molding granules. In Proceedings of the 13th Rapid.Tech Conference, Erfurt, Germany, 14–16 June 2016; pp. 262–269. [Google Scholar] [CrossRef]

- Lieberwirth, C.; Seitz, H. Extruder for a System for the Additive Manufacture of Metal Parts Using the Composite Extrusion Modeling (CEM) Method. Patent No. WO 2017/202398 A1, 30 November 2017. [Google Scholar]

| Parameter | Value |

|---|---|

| Extruder temperature | 215 °C |

| Bed temperature | 115 °C |

| Nozzle diameter | 0.5 mm |

| Layer height | 0.2 mm |

| First layer height | 0.25 mm |

| Infill type | rectilinear |

| Infill angle | 45° |

| Speed | 20 mm/s |

| Parameter | Typical Value | Test Method |

|---|---|---|

| Mould Flow Index (MFI) | 700 g/10 min | ISO 1133 (190 °C, 21.6 kg) |

| Density (after sintering) | 7.67 g/cm3 | ISO 3369 |

| Oversizing factor | 1.1669 | RC/PQ-SH-1360 |

| Extrusion temperature | <200 °C | - |

| Parameter | Height | Width | Length | Volume | Weight | Density |

|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm3) | (g) | (g/cm3) | |

| Greenpart | 5.70 ± 0.22 | 11.6 ± 0.022 | 136.7 ± 0.12 | 9008 | 41.2 ± 1.24 | 4.57 |

| Sintered part | 4.74 ± 0.18 | 9.87 ± 0.09 | 116.7 ± 0.31 | 5460 | 37.6 ± 1.13 | 6.90 |

| Shrinkage in % | 16.8 | 14.7 | 14.6 | 39.4 | 8.66 | - |

| Oversizing factor | 1.20 | 1.17 | 1.17 | 1.65 | - | - |

| Parameter | Height | Diameter | Volume | Weight | Density |

|---|---|---|---|---|---|

| (mm) | (mm) | (mm3) | (g) | (g/cm3) | |

| Greenpart | 22.7 ± 0.8 | 11.8 ± 0.067 | 2484 | 12.1 ± 0.42 | 4.86 |

| Sintered part | 19.1 ± 0.05 | 10.1 ± 0.12 | 1513 | 11.0 ± 0.39 | 7.28 |

| Shrinkage in % | 15.9 | 14.9 | 39.1 | 8.64 | - |

| Oversizing factor | 1.19 | 1.18 | 1.64 | - | - |

| Height | Diameter | Volume | Weight | Density |

|---|---|---|---|---|

| (mm) | (mm) | (mm3) | (g) | (g/cm3) |

| 10.0 ± 0.02 | 8.95 ± 0.02 | 632.79 | 4.71 ± 0.01 | 7.47 |

| Infill in % | 0% | 20% | 40% | 60% | 80% | 100% |

|---|---|---|---|---|---|---|

| σd0.2 in MPa | 625 ± 97 | 740 ± 52 | 816 ± 22 | 874 ± 36 | 927 ± 72 | 922 ± 138 |

| σdm40 in MPa | 1040 ± 53 | 1339 ± 25 | 1540 ± 36 | 1703 ± 49 | 1893 ± 121 | 1961 ± 134 |

| σdm50 in MPa | 1220 ± 90 | 1543 ± 76 | 1783 ± 56 | 2024 ± 63 | 2271 ± 148 | 2345 ± 168 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lieberwirth, C.; Sarhan, M.; Seitz, H. Mechanical Properties of Stainless-Steel Structures Fabricated by Composite Extrusion Modelling. Metals 2018, 8, 84. https://doi.org/10.3390/met8020084

Lieberwirth C, Sarhan M, Seitz H. Mechanical Properties of Stainless-Steel Structures Fabricated by Composite Extrusion Modelling. Metals. 2018; 8(2):84. https://doi.org/10.3390/met8020084

Chicago/Turabian StyleLieberwirth, Clemens, Mohamed Sarhan, and Hermann Seitz. 2018. "Mechanical Properties of Stainless-Steel Structures Fabricated by Composite Extrusion Modelling" Metals 8, no. 2: 84. https://doi.org/10.3390/met8020084

APA StyleLieberwirth, C., Sarhan, M., & Seitz, H. (2018). Mechanical Properties of Stainless-Steel Structures Fabricated by Composite Extrusion Modelling. Metals, 8(2), 84. https://doi.org/10.3390/met8020084